1. Introduction

The development of sustainable composite materials is gaining increasing attention across multiple sectors, particularly in applications where thermal regulation and environmental impact are critical. Among emerging solutions, flexible polyurethane (PU) foams incorporating microencapsulated phase change materials (PCMs) have shown significant potential. These foams are synthesized using polyols derived from renewable waste sources, such as waste cooking oil (WCO), and partially bio-based isocyanates, aligning with the principles of the circular economy and sustainable manufacturing [

1].

A key aspect of qualifying such materials lies in the accurate characterization of their thermophysical properties, in particular thermal diffusivity, which governs the rate of heat propagation. Conventional techniques, such as flash thermography and the Parker method, although widely adopted, often prove to be less effective for materials that are heterogeneous, porous, or semi-transparent, like foams. In these systems, the combined effects of conduction and radiative transfer, as well as morphological variability, introduce complexities that require alternative approaches [

2,

3,

4].

To address these challenges, this study introduces a procedure of data analysis based on the application of active thermography in lock-in transmission mode [

5].

Different foam panels were fabricated by varying the PCM content, in order to assess the effect of PCM loading on the structural and thermal properties of the composites. The PCM microcapsules were uniformly dispersed within the PU matrix, leading to a slight reduction in average cell size and an increase in foam density, thereby influencing both the mechanical and thermal properties of the material.

Active thermographic tests were carried out by adopting three thermal cycles to capture the cyclic thermal behavior of the materials. The analysis of the time-delay profiles revealed a different temperature response behavior when comparing the virgin PU foams with those containing microencapsulated PCMs. An initial correlation between the measured time delays and the thermophysical properties suggested the feasibility of obtaining a preliminary quantitative correlation between the foams based on their thermal performance by means of lock-in thermography.

2. Materials and Methods

The experimental setup used for the thermographic investigation is shown in

Figure 1. After preliminary tests carried out to assess the transmissivity by standards of the foams, considering two infrared sensors operating in different wavelength ranges, the tests revealed no substantial differences in transmissivity (variations within 0.02–0.03). As a result, the cooled MWIR detector (FLIR X6981HS, Teledyne FLIR LLC, Wilsonville, OR, USA) with a lens of 50 mm was selected for the measurements in transmission configuration to have a spatial resolution of 0.2 mm/pixel. The adopted temperature range was of −20 °C to 55 °C (integration time 0.42 µs) with a frame rate of 50 Hz. A 650 W halogen lamp, controlled by the MultiDES

® system (Diagnostic Engineering Solutions, Bari, Italy)was placed in front of the specimen to ensure uniform heating. Following preliminary evaluations, tests were carried out on two foam samples—a virgin PU foam and a PU-PCM foam containing 15 phr of PCM—each one with a nominal thickness of 5 mm. After preliminary tests at different excitation periods, a total of five measurements for each specimen were performed over three thermal cycles, modulating the heating source with a square wave having a period of 60 s. The lamp and IR detector were synchronized during the acquisitions, with a start delay of 1 s. The evolution of the thermal excitation on the front side was monitored through a small hole in the mask, allowing for real-time control of the heating process.

As measures of reference, the density of the flexible panels was measured by standard using rectangular samples (50 mm × 50 mm × 30 mm) cut from the panels. The reported density corresponds to the average of five replicate measurements.

Thermal conductivity k (W/m∙k) was measured using (a) in bulk mode, based on the standard, using rectangular samples of the same dimensions and a 10 mm sensor. Measurements were conducted at ambient temperature (20 ± 1 °C), and the mean and standard deviation values were assessed from five repeated measurements per sample.

3. Results and Discussion

An experimental protocol using lock-in thermography was developed to assess the thermal behavior of polyurethane foams under cyclic excitation. The goal was to establish a simple, fast, and reproducible method for both comparing different formulations and mapping spatial variations in thermal response via full-field imaging.

By monitoring time-resolved thermal signals on the rear surface, key indicators such as temporal delay were extracted, which relate to through-thickness thermal diffusivity. While no direct calculation of diffusivity was performed, the time delay correlates with it according to 1D unsteady heat conduction theory, where phase delay scales with the inverse square root of diffusivity (α).

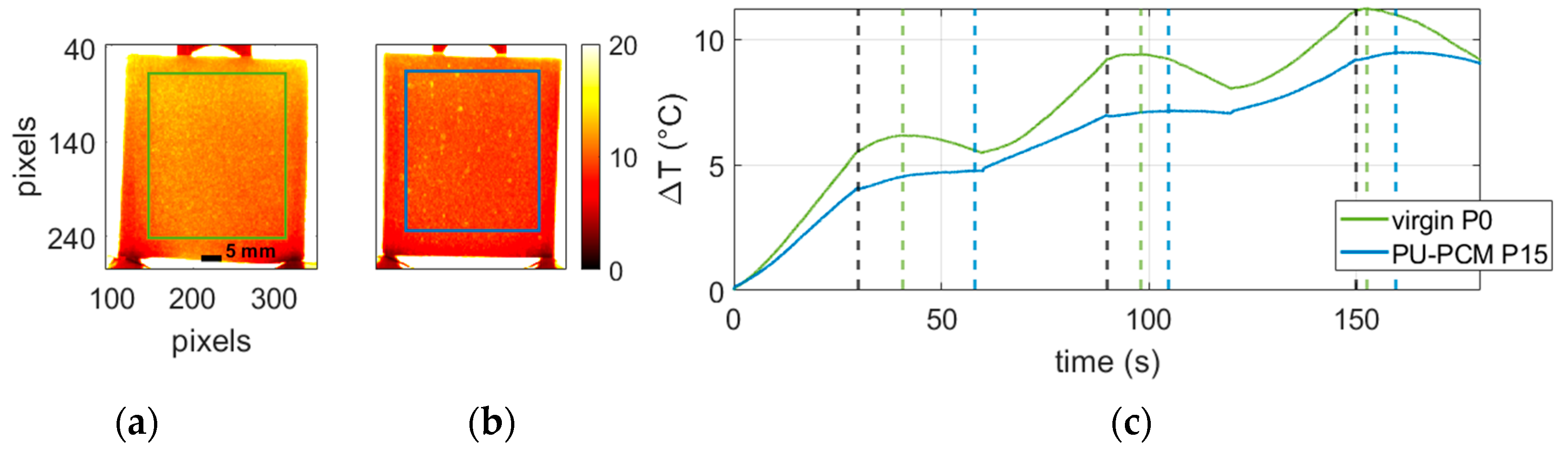

Figure 2 shows the results obtained with the proposed experimental procedure, focusing on the temperature evolution at the rear surface of the two foam specimens, starting when the halogen lamp is switched on (time 0). In particular,

Figure 2c presents the trend of the maximum temperature variation (ΔT) in the central heated area (20.000 pixels, mean of 3 repetitions), calculated by subtracting the initial cold image from the subsequent thermal frames during the excitation cycles. Black dotted lines indicate the time the lamp was switched off for each thermal cycle (theoretical maximum value for the 3 cycles of a period of 60 s, slightly visible even in transmission due to the material’s semitransparency). In contrast, the green and blue dotted lines represent the time-delay observed for the two foam samples, defined as the time the maximum temperature on the rear surface was reached, respectively. The results reveal that, during the thermal transient, the time difference between the peaks of the two foams decreases over successive cycles, with the largest delay observed in the first cycle. Moreover, the PCM-containing foam reaches a lower maximum temperature and exhibits a slower cooling rate, as indicated by the nearly flat temperature slope after the lamp is switched off. These findings suggest the possibility of identifying multiple thermal features that characterize the different thermophysical behaviors of the two foams, offering a promising basis for comparative and quantitative thermal analysis.

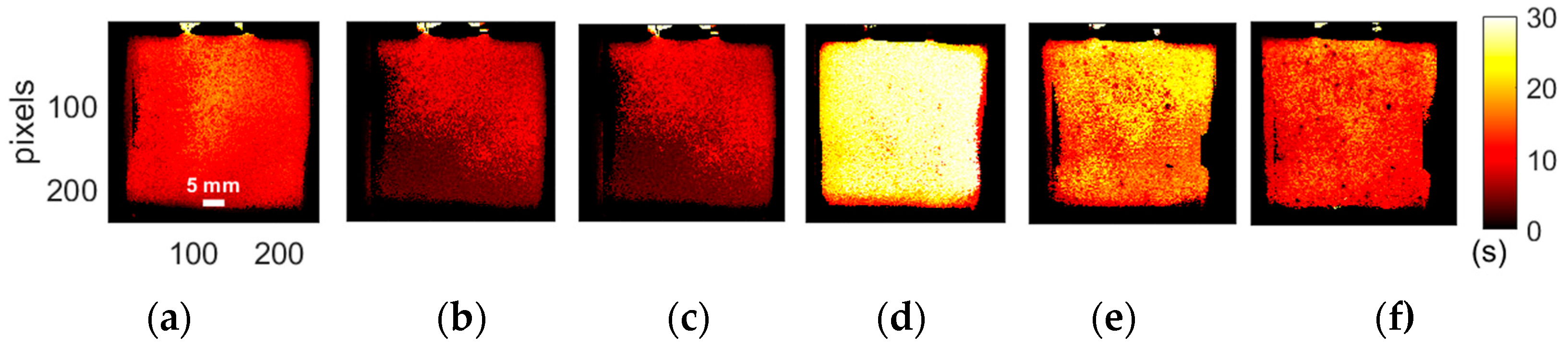

Pixel-wise time delay analysis produced full-field maps for each thermal cycle (

Figure 3), revealing consistent differences between P0 and P15 foams. Delays decreased over cycles but remained distinguishable, confirming repeatable thermal behavior.

Spatial variations within the same foam, likely due to local porosity or uneven PCM distribution, were detected thanks to high-resolution IR imaging (0.2 mm/pixel). Slight forward scattering from material semitransparency may affect peak accuracy; future improvements will include wavelet filtering and phase-based processing to enhance signal quality and robustness.

Table 1 presents the thermographic time delays (with standard deviations), thickness measurements, density, and thermal conductivity for the virgin (P0) and PCM-loaded (P15) PU foams. Bulk density ranges from 128 to 157 kg/m

3, typical for flexible PU foams used in insulation and packaging.

The P0 foam has a thermal conductivity of 46.55 mW/m·K at 20 °C, consistent with standard open-cell foams [

1]. The P15 foam shows a slightly higher conductivity (48.44 mW/m·K), due to the silica-based PCM shell, which improves heat transfer by increasing the overall thermal conductivity of the composite. Given the statistically similar thicknesses (

p = 0.22), the observed increases in thermal delay (∆t) for P15 (

p < 0.01) reflect the influence of PCM on bulk density and thermal conductivity.

4. Conclusions and Outlook

The proposed lock-in transmission thermography protocol effectively distinguished the thermal responses of PU foams with and without PCM under cyclic excitation. Time-delay differences were significant, repeatable, and spatially resolved, demonstrating their value for comparative thermal analysis.

Despite foam variability in porosity and thickness, the method proved robust for preliminary screening. However, thickness variations can influence delay measurements and should be considered in quantitative analysis.

Future work will include thickness correction using profilometry or 3D scanning, and numerical simulations to separate geometric effects from intrinsic thermal behavior, aiming to establish a reliable, contactless method for lab and industrial use.

Author Contributions

Conceptualization, G.D. and D.P.; methodology, G.D., D.P., E.D. and U.G.; validation, G.D., E.D. and D.P.; formal analysis, E.D., D.R. and I.A.; investigation, E.D. and D.P.; resources, M.S., D.P. and U.G.; data curation, E.D.; writing—original draft preparation, G.D. and E.D.; writing—review and editing, D.P.; project administration, M.S. and D.P.; funding acquisition, M.S. and D.P. All authors have read and agreed to the published version of the manuscript.

Funding

Financed by the European Union-NextGenerationEU (National Sustainable Mobility Center CN00000023, Italian Ministry of University and Research Decree n. 1033-17/06/2022, Spoke 11-Innovative Materials & Lightweighting). The opinions expressed are those of the authors only and should not be considered as representative of the European Union or the European Commission’s official position. Neither the European Union nor the European Commission can be held responsible for them.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Available after request to the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Anguillesi, I.; Rossi, D.; Cappello, M.; Dell’Anna, M.M.; Seggiani, M. Novel Flexible Polyurethane Foams with High Bio-Based Content Derived from Waste Cooking Oil: Synthesis and Characterization. Sci. Rep. 2025, in press. [Google Scholar]

- Cernuschi, F.; Bison, P. Thirty Years of Thermal Barrier Coatings (TBC), Photothermal and thermographic techniques: Best practices and lessons learned. J. Therm. Spray Technol. 2022, 31, 716–744. [Google Scholar] [CrossRef]

- Bernegger, R.; Altenburg, S.J.; Roellig, M.; Maierhofer, C. Applicability of a 1D analytical model for pulse thermography of laterally heterogeneous semitransparent materials. Int. J. Thermophys. 2018, 39, 39. [Google Scholar] [CrossRef]

- Dell’Avvocato, G.; Palumbo, D.; Galietti, U. A non-destructive thermographic procedure for the evaluation of heat treatment in Usibor® 1500 through the thermal diffusivity measurement. NDT E Int. 2023, 133, 102748. [Google Scholar] [CrossRef]

- Aversa, P.; Palumbo, D.; Donatelli, A.; Tamborrino, R.; Ancona, F.; Galietti, U.; Luprano, V.A.M. Infrared thermography for the investigation of dynamic thermal behaviour of opaque building elements: Comparison between empty and filled with hemp fibres prototype walls. Energy Build. 2017, 152, 264–272. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).