Tailoring Active Defect Centers During the Growth of Group IV Crystals †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nano-Crystals Experimental Synthesis

2.2. Nano-Crystal Simulated Synthesis

- The code has the possibility to simulate the growth from any surface (polar/non-polar/structured);

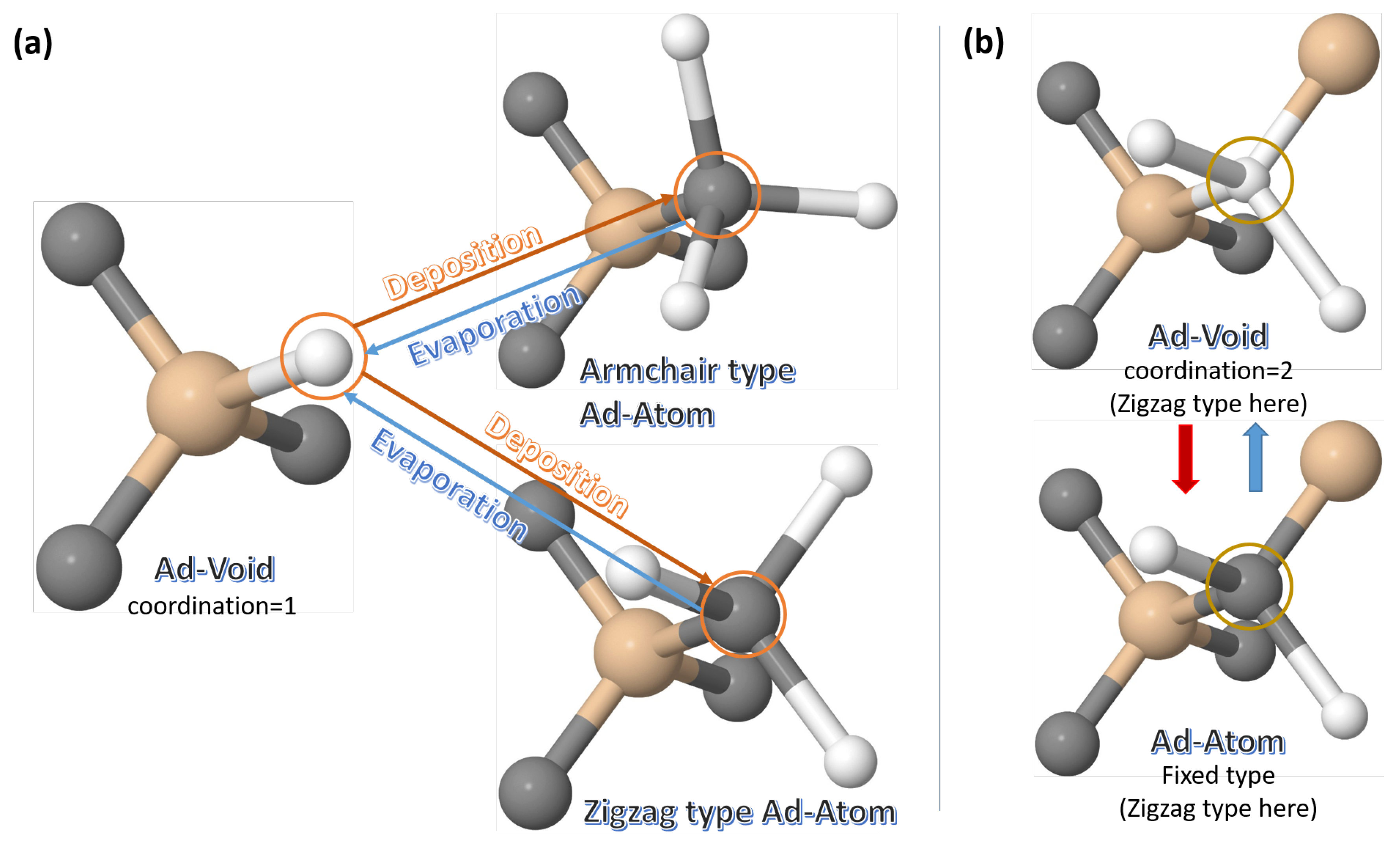

- Kinetics is simulated by a stochastic sequence of evaporation/deposition events whose occurrence probability depends on the local configuration (see Figure 1);

- Switching between cubic and hexagonal symmetry (Figure 1) can be statistically considered during the simulation and, as a consequence, the generation and evolution of extended defects can be predicted;

- The default setting considers a compound material. In this case, atomic species (e.g., Si and C) undergo independent kinetics. An elemental material can be considered by means of symmetric calibrations for the two types of atoms;

- The code allows for the study of point and extended defect generation at an atomic level, considering a non-ideal bonding configuration;

3. Results

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- La Via, F.; Camarda, M.; La Magna, A. Mechanisms of growth and defect properties of epitaxial SiC. Appl. Phys. Rev. 2014, 1, 031301. [Google Scholar] [CrossRef]

- Blase, X.; Bustarret, E.; Chapelier, C.; Klein, T.; Marcenat, C. Superconducting group-IV semiconductors. Nat. Mater. 2009, 8, 375. [Google Scholar] [CrossRef] [PubMed]

- Radulaski, M.; Widmann, M.; Niethammer, M.; Zhang, J.L.; Lee, S.Y.; Rendler, T.; Lagoudakis, K.G.; Son, N.T.; Janzen, E.; Ohshima, T.; et al. Scalable quantum photonics with single color centers in silicon carbide. Nano Lett. 2017, 17, 1782–1786. [Google Scholar] [CrossRef] [PubMed]

- Redman, D.; Brown, S.; Sands, R.; Rand, S. Spin dynamics and electronic states of N-V centers in diamond by EPR and four-wave-mixing spectroscopy. Phys. Rev. Lett. 1991, 1767, 3420–3423. [Google Scholar] [CrossRef] [PubMed]

- Camarda, M.; La Magna, A.; La Via, F. A kinetic Monte Carlo method on super-lattices for the study of the defect formation in the growth of close packed structures. J. Comput. Phys. 2007, 227, 1075–1093. [Google Scholar] [CrossRef]

- Bunea, M.M.; Dunham, S.T. Monte Carlo study of vacancy-mediated impurity diffusion in silicon. Phys. Rev. B 2000, 61, R2397. [Google Scholar] [CrossRef]

- Deretzis, I.; Magna, A.L. Interaction between hydrogen flux and carbon monolayer on SiC (0001): Graphene formation kinetics. Nanoscale 2013, 5, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Deretzis, I.; Magna, A.L. Simulating structural transitions with kinetic Monte Carlo: The case of epitaxial graphene on SiC. Phys. Rev. E 2016, 93, 033304. [Google Scholar] [CrossRef] [PubMed]

- Camarda, M.; La Magna, A.; Fiorenza, P.; Giannazzo, F.; La Via, F. Defect formation and evolution in the step-flow growth of silicon carbide: A Monte Carlo study. J. Cryst. Growth 2008, 310, 971–975. [Google Scholar] [CrossRef]

- La Magna, A.; Alberti, A.; Barbagiovanni, E.; Bongiorno, C.; Cascio, M.; Deretzis, I.; La Via, F.; Smecca, E. Simulation of the Growth Kinetics in Group IV Compound Semiconductors. Phys. Status Solidi A 2018, 1800597. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cascio, M.; Deretzis, I.; Fisicaro, G.; Falci, G.; Mannino, G.; Magna, A.L. Tailoring Active Defect Centers During the Growth of Group IV Crystals. Proceedings 2019, 12, 32. https://doi.org/10.3390/proceedings2019012032

Cascio M, Deretzis I, Fisicaro G, Falci G, Mannino G, Magna AL. Tailoring Active Defect Centers During the Growth of Group IV Crystals. Proceedings. 2019; 12(1):32. https://doi.org/10.3390/proceedings2019012032

Chicago/Turabian StyleCascio, Michele, Ioannis Deretzis, Giuseppe Fisicaro, Giuseppe Falci, Giovanni Mannino, and Antonino La Magna. 2019. "Tailoring Active Defect Centers During the Growth of Group IV Crystals" Proceedings 12, no. 1: 32. https://doi.org/10.3390/proceedings2019012032

APA StyleCascio, M., Deretzis, I., Fisicaro, G., Falci, G., Mannino, G., & Magna, A. L. (2019). Tailoring Active Defect Centers During the Growth of Group IV Crystals. Proceedings, 12(1), 32. https://doi.org/10.3390/proceedings2019012032