Abstract

The coffee supply chain generates over 10 million tons of waste annually, with 70% comprising the fruit pulp and skin. This study investigates using coffee cherry flour from fresh coffee husk as an alternative ingredient in pastries with baking powder and baker’s yeast. We characterized the nutritional and physicochemical properties of this flour, developed high-fiber recipes, and evaluated the effects of substituting wheat flour with varying proportions of coffee cherry flour in plain cakes and sweet yeast breads. We found that coffee cherry flour reduced yeast dough volume increase and pastry specific volume in the coffee cherry flour pastries but enriched them with higher mineral and dietary fiber content compared to the wheat flour pastries.

1. Introduction

Every year, the coffee supply chain generates over 10 million tons of waste [1]. Approximately 70% of this waste consists of the pulp and skin of the coffee cherry [2]. These by-products, which are produced during post-harvest processing in coffee-growing regions, are primarily composed of carbohydrates, dietary fiber, protein, and ash [3,4]. In addition to these components, coffee cherry pulp and skin contain bioactive compounds, such as chlorogenic acids, carotenoids, and anthocyanins, which have antioxidant properties [5,6,7]. However, these by-products also contain caffeine and tannins, which can be considered antinutritional factors [3,4,8].

To mitigate the environmental impact of coffee waste and provide a new income source for smallholder farmers, valorizing coffee cherry husk is a promising solution. Several studies have explored the valorization of coffee by-products by producing coffee flour and enriching food products with it [9,10,11,12]. To produce coffee flour, coffee cherries are separated from the bean, dried, ground, and added to conventional recipes as a food ingredient [13].

This study investigates the use of coffee cherry flour as an alternative baking ingredient in pastries made with two different leavening agents. The goals were to characterize the nutritional and physicochemical properties of the coffee cherry flour, develop high-fiber recipes, and evaluate the effects of replacing wheat flour with varying proportions of coffee cherry flour in plain cakes and sweet yeast bread.

2. Materials and Methods

2.1. Coffee Cherry Flour

The Coffea arabica cherries used to produce the coffee cherry flour were grown at Bella Vista farm in Cartago, Costa Rica (9°54′54″ N 83°59′03″ W). After harvesting, cleaning, and depulping, the fresh husk was stored at −18 °C until further processing. After thawing, impurities such as kernels, leaves, and other residues were sorted out. The thawed husk was then dried for 5 h at 55 °C in the tray dryer (TY2 48397 The National Drying Machinery Co., Philadelphia, PA, USA). The grinding process consisted of three steps: First, the dried material was ground in a hammer mill (AP00.18 1009 NA046 Tainea S.A., San José, Costa Rica) using a 3.18 mm sieve. Then, it was re-ground using a 1.60 mm sieve. Finally, it was ground in a centrifugal mill (ZM 200 Retsch GmbH, Haan, Germany) at a rotational speed of 8000 rpm using a 1.00 mm sieve suitable for thermosensitive products.

2.2. Pastries

Two pastries with different leavening agents, a plain cake (with baking powder) and a sweet yeast bread (with baker’s yeast), were produced following the German guidelines for fine baked goods [14,15]. In both pastries, three different proportions of wheat flour were replaced with coffee cherry flour. The recipes without coffee cherry flour were designated as reference (REF), and the recipes containing 4.49%, 8.99%, and 15.73% as LOW, MED, and HIGH, respectively. Table 1 shows the ingredients for all eight recipes used in this study.

Table 1.

Ingredient quantities for the plain cake and the sweet yeast bread with different proportions of coffee cherry flour. REF = no coffee cherry flour, LOW = 4.49% coffee cherry flour, MED = 8.99% coffee cherry flour, and HIGH = 15.73% coffee cherry flour.

Each of the formulations was prepared in triplicate. Doughs for the plain cakes were mixed for 3 min with a K-hook at stirring stage 5 in a Kenwood Chef Titanium food processor KM001 (Kenwood Ltd., Havant, UK), while doughs for the sweet yeast breads were mixed for 5 min with a dough hook at stirring stage 1 and then left to ferment for one hour. Both doughs were baked in silicone pans in a preheated oven at 160 °C until the desired dough consistency (chopstick method for the plain cake) or crust firmness (manual check for the sweet yeast bread) was reached. After baking, the pastries were cooled, frozen, and later prepared for analysis. This involved defrosting, cutting, drying in a conventional dryer (Heraeus Holding GmbH, Hanau, Germany) initially at 45 °C for 24 h and then at 65 °C for 24 h. The dried pastries were ground using a knife mill (Grindomix GM 200 Retsch GmbH, Haan, Germany) and finally vacuum packed and stored at 4 °C until further analyses.

2.3. Laboratory Analyses

Yeast dough rise, which is the volume increase of the yeast dough during fermentation, was determined using a 500 mL measuring cylinder (Labsolute, a brand of Th. Geyer GmbH & Co. KG, Renningen, Germany). The volume increase of the dough after 1 h of resting time was recorded. The specific volume of the pastries was calculated according to Asamoah et al. [16] by relating the volume to the mass. The volume of the pastries was determined on their reconstructed digital three-dimensional (3D) mesh. Therefore, the pastries were placed on a cardboard sheet containing six control points and 50 RGB images of each pastry were captured from different perspectives using the Samsung Galaxy S20+ smartphone (Samsung Electronics GmbH., Eschborn, Germany) equipped with a 12-megapixel camera. The software 3DF Zephyr version 7.505 (3Dflow, Verona, Italy) was used to generate the triangular mesh. The dimensions of the 3D mesh were calibrated using the x- and y-coordinates of the six control points. The reliability of the 3D model was determined by comparing the manually measured lengths of the pastry and the lengths of the 3D mesh pastry, leading to a mean absolute percentage error of 1.02%.

The total carbohydrates in the coffee flour were determined by difference, involving quantification of moisture, ash, crude fat, and crude protein contents. These constituents’ sum was subtracted from the sample’s total weight to calculate the carbohydrate content. The monosaccharides fructose, glucose, and sucrose were quantified using HPLC-RID, following the methods described by Pirisino [17] and Sullivan and Carpenter [18] with slight modifications. The total dietary fiber content of the coffee flour was determined using the enzymatic–gravimetric assay procedure from C. Gerhardt GmbH & Co. KG [19]. The pastries’ total dietary fiber content was calculated using the results of the coffee cherry flour and a total dietary fiber content of 3.90 g/100 g for wheat flour [20].

The protein content of the coffee cherry flour was determined using the Kjeldahl method, as specified by the AOAC method 979.09 [21]. The same Kjeldahl principle was applied to quantify the protein content in the pastries, following the procedure outlined by C. Gerhardt GmbH & Co. KG [22]. Dry matter and ash content were determined gravimetrically. Samples were dried in an oven at 103 ± 2 °C until reaching a constant mass. The dried samples were then calcined in a muffle furnace at 550 °C for a minimum of 5 h. The fat content of the coffee flour was analyzed according to the AOAC method 920.97 [23].

The caffeine content was quantified using a HPLC coupled with a UV detector (detection at 272 nm), following methods adapted from the International Organization for Standardization [24], Nour et al. [25], and Srdjenovic et al. [26]. Caffeine was extracted from 0.5–1 g of the sample by adding 2–5 g of magnesium oxide and 50 mL of Millipore water. The mixture was heated in a water bath at 90 °C for 20 min with vortexing every 5 min. After centrifugation at 10,000 rpm for 10 min, the supernatant was filtered through a 0.45 µm polytetrafluoroethylene (PTFE) syringe filter into a vial. Tannins were determined using a UV–VIS spectrophotometer (DR 6000 Hach-Lange GmbH, Berlin, Germany) according to the method 16.4.3 described by the VDLUFA (Verband Deutscher Landwirtschaftlicher Untersuchungs- und Forschungsanstalten) [27].

2.4. Statistical Analysis

The statistical analysis was conducted using the software Origin 2023 version 10.0 (Originlab Corporation, Northampton, MA, USA). The mean values of the nutritional and physicochemical analysis of plain cake and sweet yeast bread were subjected to a one-way analysis of variance (ANOVA) using the post-hoc Tukey test at a significance level of α = 0.05. Graphs were generated using R version 4.2.2 [28] with the ggplot2 package [29].

3. Results

Table 2 presents the nutritional profile of the coffee cherry flour. It contains approximately 75 g of total carbohydrates per 100 g of dry matter, comprising 30.10 g of sugars, including 16.20 ± 2.30 g of fructose and 13.90 ± 2.20 g of glucose. Additionally, it contains 49.95 g of total dietary fiber and 8.13 ± 0.11 g of crude protein.

Table 2.

Coffee cherry flour nutritional values in g per 100 g dry basis (db). Values are presented as mean value with standard deviation, except for the total dietary fiber content, as the sample was analyzed only once, (n = 3).

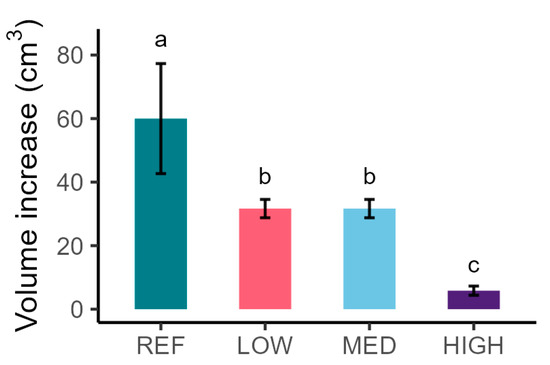

The dough rising of the sweet yeast bread was significantly affected by the proportion of coffee cherry flour in the recipes. Figure 1 illustrates the dough volume increase measured after a 1 h resting period. The recipe with the highest coffee cherry flour content (HIGH) shows the least rise in dough volume at 5.83 ± 1.44 cm3, whereas the reference recipe (REF) showed a volume increase of 60.00 ± 17.32 cm3.

Figure 1.

Increase in dough volume measured after one hour of resting time. REF = no coffee cherry flour, LOW = 4.49% coffee cherry flour, MED = 8.99% coffee cherry flour, and HIGH = 15.73% coffee cherry flour. Different letters in a graph indicate significant differences at p < 0.05, (n = 3).

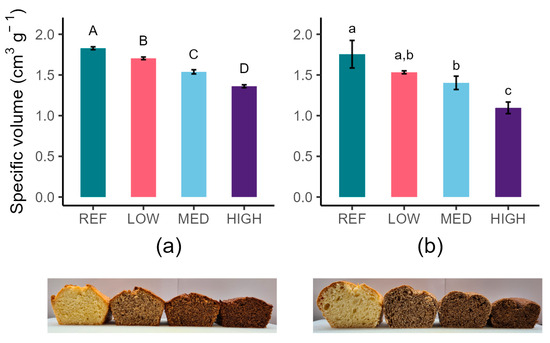

These results are consistent with the specific volume of the baked pastries shown in Figure 2. The specific volume of the plain cakes leavened with baking powder exhibited significant differences across all proportions of coffee cherry flour, with the reference recipe achieving the highest specific volume. The recipe HIGH for the sweet yeast bread achieved a specific volume of 1.20 ± 0.07 cm3/g, while the reference recipe reached 1.75 ± 0.17 cm3/g.

Figure 2.

Specific Volume measurements and pictures of the cross-section of the plain cakes (a) and the sweet yeast breads (b), each with their four different proportions of coffee cherry flour enrichment. REF = no coffee cherry flour, LOW = 4.49% coffee cherry flour, MED = 8.99% coffee cherry flour, and HIGH = 15.73% coffee cherry flour. Results are presented as mean values with standard deviation. Different letters indicate significant differences for plain cake (upper case letters) and sweet yeast bread (lower case letters) at p ≤ 0.05 (n = 3).

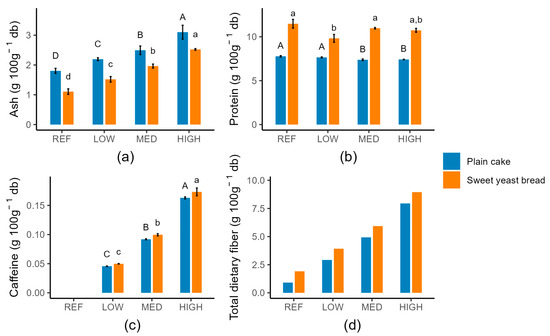

Figure 3 shows the results of the pastries for the following nutritional parameters: ash, protein, caffeine, and total dietary fiber content. In both the plain cake and the sweet yeast bread, the reference recipes exhibited the lowest ash content: 1.80 ± 0.09 g/100 g db and 1.11 ± 0.09 g/100 g db, respectively. Ash content increased significantly with higher proportions of coffee cherry flour in both pastries. The protein content of the plain cakes in the REF and LOW recipes was significantly higher than in the MED and HIGH recipes. Sweet yeast breads showed less pronounced differences, with only the LOW recipe showing significantly lower protein content compared to the REF and MED recipes. Increasing the coffee cherry flour content led to a significant increase in caffeine content, reaching 0.16 ± 1.7 × 10−3 g/100 g db and 0.17 ± 6.8 × 10−3 g/100 g db for the plain cake and the sweet yeast bread, respectively. Furthermore, total dietary fiber content increased with higher coffee flour content in both plain cake and sweet yeast bread. The highest total dietary fiber contents were calculated for the plain cake recipe HIGH (8.15 g/100 g db) and the sweet yeast bread recipe HIGH (9.16 g/100 g db).

Figure 3.

Ash content (a), protein content (b), caffeine content (c), and total dietary fiber content (d) of the plain cakes and the sweet yeast breads, each with their four different proportions of coffee cherry flour enrichment. REF = no coffee cherry flour, LOW = 4.49% coffee cherry flour, MED = 8.99% coffee cherry flour, and HIGH = 15.73% coffee cherry flour. Results are presented as mean values with standard deviation, except for the total dietary fiber content, as this was calculated based on the recipes. Different letters indicate significant differences for plain cake (upper case letters) and sweet yeast bread (lower case letters) at p ≤ 0.05 (n = 3).

4. Conclusions

This study has demonstrated the effect of coffee cherry flour on yeast dough and baked pastries. The experiments revealed that incorporating coffee cherry flour negatively influences the volume increase of yeast dough and reduces the specific volume of the resulting pastries. Moreover, pastries enriched with coffee cherry flour exhibited higher levels of minerals and dietary fiber compared to those made exclusively with wheat flour. These findings suggest that future formulations should be carefully adjusted to take full advantage of the nutritional benefits and structural properties offered by coffee cherry flour.

Author Contributions

Conceptualization, A.-J.R., C.A.-G., K.S., V.M.J., and J.M.; methodology, A.-J.R., C.A.-G., and K.S.; validation, A.-J.R., C.A.-G., and K.S.; formal analysis, A.-J.R., C.A.-G., and K.S.; investigation, K.S. and T.C.-O.; resources, O.A., V.M.J., and J.M.; data curation, A.-J.R. and K.S.; writing—original draft preparation, A.-J.R. and K.S.; writing—review and editing, C.A.-G., T.C.-O., O.A., V.M.J., and J.M.; visualization, A.-J.R. and K.S.; supervision, O.A., V.M.J., and J.M.; project administration, V.M.J. and J.M.; funding acquisition, K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the Fiat Panis foundation, grant number 202302.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets presented in this article are not readily available because the data are part of an ongoing study. Requests to access the datasets should be directed to the corresponding author.

Acknowledgments

The authors would like to thank the laboratory teams of the Institute of Agricultural Engineering (440e), Tropics and Subtropics Group from the University of Hohenheim, the National Center for Food Science and Technology (CITA), and the Grain and Seed Research Center (CIGRAS) from the University of Costa Rica for their technical support. During the preparation of this work the authors used ChatGPT to improve the readability. After using this tool, the authors reviewed and edited the content as needed and take full responsibility for the content of the publication.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Echeverria, M.C.; Nuti, M. Valorisation of the residues of coffee agro-industry: Perspectives and limitations. Open Waste Manag. J. 2017, 10, 13–22. [Google Scholar] [CrossRef]

- Bressani, R. The by-products of coffee berries. In Coffee Pulp: Composition, Technology and Utilization; Braham, J.E., Bressani, R., Eds.; IDRC: Ottawa, ON, Canada, 1979; pp. 5–10. ISBN 0-88936-190-8. [Google Scholar]

- Del Castillo, M.D.; Fernandez-Gomez, B.; Martinez-Saez, N.; Iriondo-DeHond, A.; Mesa, M.D. Chapter 12. Coffee by-products. In Coffee: Production, Quality and Chemistry; Farah, A., Ed.; Royal Society of Chemistry: London, UK, 2019; pp. 309–334. ISBN 978-1-78262-004-4. [Google Scholar]

- European Food Safety Authority. Technical Report on the Notification of Dried Cherry Pulp from Coffea arabica L. and Coffea canephora Pierre ex A. Froehner As a Traditional Food from a Third Country Pursuant to Article 14 of Regulation (EU) 2015/2283. EFSA Supporting Publication 2021:EN-6808. 2021. Available online: https://efsa.onlinelibrary.wiley.com/doi/abs/10.2903/sp.efsa.2021.EN-6808 (accessed on 3 July 2024).

- Alves, R.C.; Rodrigues, F.; Antónia Nunes, M.; Vinha, A.F.; Oliveira, M.B.P. Chapter 1—State of the art in coffee processing by-products. In Handbook of Coffee Processing by-products: Sustainable applications; Galanakis, C.M., Ed.; Academic Press: London, England, 2017; pp. 1–26. ISBN 9780128112915. [Google Scholar]

- Gawlik-Dziki, U.; Bryda, J.; Dziki, D.; Świeca, M.; Habza-Kowalska, E.; Złotek, U. Impact of interactions between ferulic and chlorogenic acids on enzymatic and non-enzymatic lipids oxidation: An example of bread enriched with green coffee flour. Appl. Sci. 2019, 9, 568. [Google Scholar] [CrossRef]

- Esquivel, P.; Viñas, M.; Steingass, C.B.; Gruschwitz, M.; Guevara, E.; Carle, R.; Schweiggert, R.M.; Jiménez, V.M. Coffee (Coffea arabica L.) by-products as a source of carotenoids and phenolic compounds—Evaluation of varieties with different peel color. Front. Sustain. Food Syst. 2020, 4, 590597. [Google Scholar] [CrossRef]

- Esquivel, P.; Jiménez, V.M. Functional properties of coffee and coffee by-products. Food Res. Int. 2012, 46, 488–495. [Google Scholar] [CrossRef]

- Wiliana, A.; Sherly, A.; Kumalaputri, A.J.; Abduh, M.Y. Production and characterization of cascara powder from coffee pulp. Chem. Nat. Res. Eng. J. 2022, 6, 1–15. [Google Scholar] [CrossRef]

- Ramirez Velez, A.; Jaramillo Lopez, J.C. Process for Obtaining Honey and/or Flour or Coffee from the Pulp or Husk and the Mucilage of the Coffee Bean. U.S. Patent No. 10,010,092, 3 July 2018. [Google Scholar]

- Jiamjariyatam, R.; Krajangsang, S.; Lorliam, W. Development of biscuit products from coffee cherry pulp. J. Culin. Sci. Technol. 2023, 1–21. [Google Scholar] [CrossRef]

- Rosas-Sánchez, G.A.; Hernández-Estrada, Z.J.; Suárez-Quiroz, M.L.; González-Ríos, O.; Rayas-Duarte, P. Coffee cherry pulp by-product as a potential fiber source for bread production: A fundamental and empirical rheological approach. Foods 2021, 10, 742. [Google Scholar] [CrossRef] [PubMed]

- Arya, S.S.; Venkatram, R.; More, P.R.; Vijayan, P. The wastes of coffee bean processing for utilization in food: A review. J. Food Sci. Technol. 2022, 59, 429–444. [Google Scholar] [CrossRef] [PubMed]

- Bundesministerium Für Ernährung Und Landwirtschaft. Leitsätze Für Feine Backwaren. 2010. Available online: https://www.bmel.de/SharedDocs/Downloads/DE/_Ernaehrung/Lebensmittel-Kennzeichnung/LeitsaetzeFeineBackwaren.pdf?__blob=publicationFile&v=4 (accessed on 18 June 2024).

- Hamatschek, J. Lebensmitteltechnologie: Die Industrielle Herstellung Von Lebensmitteln Aus Landwirtschaftlichen Rohstoffen; 2. überarb. u. erw. Aufl.; utb GmbH: Stuttgart, Germany, 2021; ISBN 9783838555058. [Google Scholar]

- Asamoah, E.A.; Le-Bail, A.; Oge, A.; Queveau, D.; Rouaud, O.; Le-Bail, P. Impact of baking powder and leavening acids on batter and pound cake properties. Foods 2023, 12, 946. [Google Scholar] [CrossRef]

- Pirisino, J.F. High performance liquid chromatographic determination of lactose, glucose, and galactose in lactose-reduced milk. J. Food Sci. 1983, 48, 742–744. [Google Scholar] [CrossRef]

- Sullivan, D.M.; Carpenter, D.E. Methods of Analysis for Nutrition Labeling; Association of Official Analytical Chemists: Arlington, VA, USA, 1993; ISBN 0935584528. [Google Scholar]

- C. Gerhardt GmbH & Co. KG. Applikation Faserbestimmung: G.0.FibreBag Gesamtballaststoffe in Lebensmitteln; C. Gerhardt GmbH & Co. KG: Königswinter, Germany, 2021. [Google Scholar]

- Kalnina, S.; Rakcejeva, T.; Gramatina, I.; Kunkulberga, D. Investigation of total dietary fiber, B1 and B2 vitamin content of flour blend for pasta production. In Proceedings of the 9th Baltic Conference on Food Science and Technology, “Food for Consumer Well-Being” Foodbalt 2014 Conference Proceedings, Jelgava, Latvia, 8–9 May 2014; pp. 133–137. [Google Scholar]

- Horwitz, W.; Association of Official Analytical Chemists. Official Methods of Analysis of AOAC International, 17th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- C. Gerhardt GmbH & Co. KG. Handbuch Stickstoffbestimmung: Kjeldahlanalytik; C. Gerhardt GmbH & Co. KG: Königswinter, Germany, 2012. [Google Scholar]

- Horwitz, W.; Latimer, G.W. Official Methods of Analysis of AOAC International, 18th ed.; AOAC International: Gaithersburg, MD, USA, 2005; ISBN 0935584757. [Google Scholar]

- ISO 20481:2008; Coffee and Coffee Products—Determination of the Caffeine Content Using High Performance Liquid Chromatography (HPLC): Reference Method. ISO (International Organization for Standardization): Geneva, Switzerland, 2008.

- Nour, V.; Trandafir, I.; Ionica, M. Chromatographic determination of caffeine contents in soft and energy drinks available on the Romanian market. Sci. Study Res.-Chem. C 2010, 11, 351–358. [Google Scholar]

- Srdjenovic, B.; Djordjevic-Milic, V.; Grujic, N.; Injac, R.; Lepojevic, Z. Simultaneous HPLC determination of caffeine, theobromine, and theophylline in food, drinks, and herbal products. J. Chromatogr. Sci. 2008, 46, 144–149. [Google Scholar] [CrossRef]

- Naumann, C.; Bassler, R. Methodenbuch: Die Chemische Untersuchung von Futtermitteln: Grundwerk Einschl. 1.–8. Ergänzungslieferung, 3rd ed.; VDLUFA—Verlag: Darmstadt, Germany, 2012; ISBN 978-3-941273-14-6. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical; R Foundation for Statistical Computing: Vienna, Austria, 2022. [Google Scholar]

- Wickham, H. ggplot2: Elegant Graphics for Data Analysis; Springer: New York, NY, USA, 2016. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).