Abstract

The energy consumption of buildings lies often far above the performance objectives of the design phase. This is due to several factors among other serious deficits in the energy operation of building services. TOPAs adopts the principle of continuous performance auditing by not only considering energy use but also knowledge and understanding of the buildings use and their climatic state. Thus it provides a holistic performance auditing process through supporting tools and methodologies that try to minimise the gap between predicted and actual energy use. TOPAs offers an open BMS (Building Management System) IoT driven framework. This framework is composed of core services to connect to any BMS and aggregate all the information in an open platform. Add-on services are also available to improve the understanding of buildings and reduce further the gap.

1. Introduction

Buildings consume 40% of the total energy use across Europe and do not reach their designed energy performance in many cases. This is due to many factors among other a lack of continuous supervision and transparency on the energy behaviour of buildings. Better supervising the energy operation of buildings on the basis of data is a non-trivial task due to the heterogeneity of Building Automation and Management Systems (BAS/BMS). In addition, with the advent of the Internet-of-Things (IoT) building systems are beginning to evolve more towards an open and rich source of data for detailed analysis of building performance. The first step to reduce the gap is to have a detailed baseline of performance for the building. Then, a continuous auditing process can be put in place to improve the building’s performances, reduce the gap and thus save energy. This paper presents how, through a core platform and add-on services, TOPAs tackles these challenges.

2. TOPAS Platform

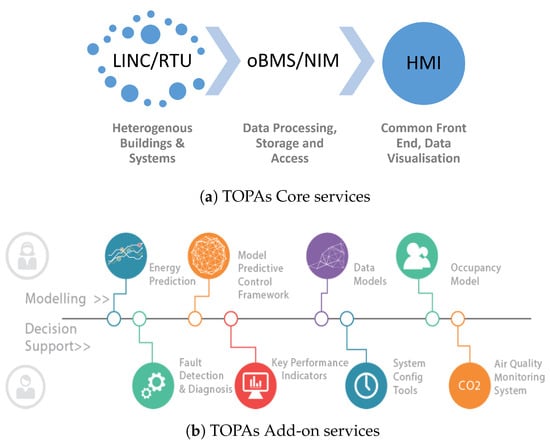

A significant challenge facing the Facility Managers (FM) is the high amount of tools they have to use. Furthermore, with the IoT devices available today, more and more information can be gathered on building but yet again with another tool or communication technology. The next challenge is to know what information is important and how to extract this data from the building. Finally buildings contains large quantities of raw data, hence it is required to integrate, interrogate and convert this data to useful knowledge for the FM. To answer these challenges, TOPAs contains a core platform (Figure 1a) to connect to heterogeneous building systems and provide a simple and unified representation. In addition to the core tools, add-on services provide site-specific services covering modeling and decision support (Figure 1b).

Figure 1.

TOPAs core and add-on services.

LINC/RTU: At the lowest level, the building and data heterogeneity is hidden by LINC [1] and the RTU (ACE1000 Remote Terminal Unit) (https://www.motorolasolutions.com/en_us/products/industrial-internet-of-things/scada/ace1000-rtu.html). LINC provides a universal abstraction layer based on tuple spaces. A prerequisite is the availability of a driver code to extract the information from the BMS protocol (e.g., BacNet, Modbus or OPC) or the IoT devices (e.g., ZigBee, Bluetooth or a web server). However once the driver is available, LINC provides a unified interface to the building data. The RTU provides a secure physical connection to the building network and hosts the LINC abstraction layer. Note that it is also possible to run LINC on a Linux or Windows PC or an android tablet or phone. With this, it is possible to extract the data of any building. The next step is to know what to read, i.e., configure the TOPAs core platform, and to make the buildings data available.

oBMS / NIM: Building Automation System data can come in many different forms from time series data from sensors, to their meta-information such as the sensor type and location; to event streams for alarms, or binary images. oBMS supports data exchange and storage of these various data types. It differentiates the data into structured, unstructured and semantic data and stores it on a cloud platform. The Neighbored Information Model (NIM, extension of [2]) provides a centralized meta-data store capturing all building, systems and devices. We assume that event streams are unstructured data such as text entries in logs. They are stored in a No-SQL database (Cloudant). A homogeneous open API hides the various technologies such that the user does not need to deal with the various storage technologies underneath. The TOPAs platform takes an IoT architectural approach by specifying a set of modular and interchangeable components with a data-centric view and open interfaces to support easy integration and extensibility [3].

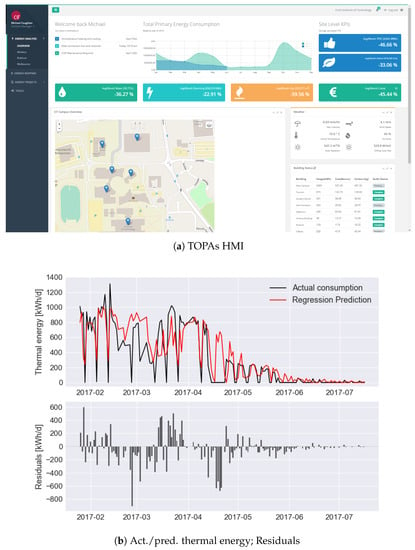

HMI: When managing multiple buildings, it can be challenging to achieve a holistic view on where the potential for energy savings can be. The TOPAs HMI provides a common entry point that allows users to assess and drill down to specific issues occurring on their site, such as identifying primary energy users, assessing the success of interventions that have been put in place (Figure 2a). Current BMS are typically standalone applications running on computers located in a basement with restricted interfaces and are either overly complex representation of building systems or overly simplistic controls. The TOPAs HMI is a web based application that aggregates and presents the raw building data sets extracting from buildings (via oBMS). The interface is configurable to the needs of various stakeholders (Facilities & Building Managers, ESCOs, and Occupants) via reusable visual components or widgets to ensure the user is only presented with the most pertinent information required to understand their building performance.

Figure 2.

TOPAs HMI and Add-on models results.

Currently energy audits are typically carried out on a once off basis, e.g., yearly for reporting, however this approach can result in missed opportunities to make changes that can have a positive impact on energy usage (gas, electricity, water). Therefore the TOPAs core platform facilitates a shift in mind-set towards a continuous audit methodology where the building or facility manager can react quickly to the dynamics in buildings (usage, occupants and system failures). This is further bolstered by amalgamating models such as energy (thermal & electrical) and occupancy prediction with raw operational data (e.g., energy meters) enabling a better representation of building performance and ultimately an improved decision making process.

3. TOPAs Add-on Services

TOPAs provides energy consumption prediction models for thermal (heating and cooling) and electrical (plug loads, lighting, etc.) energy of buildings. They generate a one-day-ahead forecast of the energy consumption and can thus help facility managers to better understand the performance of their buildings as well as to support the supervision and the optimization of the building services operation. Furthermore, the energy predictions can be used in advanced control algorithms for example for load shifting or schedule planning of energy supply systems.

TOPAs currently investigates two modeling methods, with different internal model structures. White box models use analytical relations described by physical equations such as energy or mass balances while black box models have no physical meaning and rest upon statistical relations between input and output data. Black box models generate a prediction of the energy consumption on a daily basis as output by the mean of functions fitted solely with measurement data and forecasts of weather and occupancy. Due to their underlying principle, the prediction accuracy of the black box models relies in a large extent on the quality and amount of the available measurement data. White box models in contrast can achieve a higher accuracy and still provide exploitable results if measurement data is missing or insufficient. Nevertheless, they require typically higher modeling efforts and a higher level on information on the building physics (e.g., U-values of facades and windows, geometrical information) which has first to be gathered and is sometimes hardly accessible in existing buildings. In TOPAs, NIM provides this information in a persistent way to the prediction models.

Using model based predictions in daily energy management of buildings requires accurate and reliable models. With TOPAs core system, a continuous and automatic process for the adaptation of the models has been developed to consider seasonal and operational changes in buildings. The models are iteratively re-calibrated with new data with a weekly or a monthly pattern. For the black box models this is done by re-fitting the underlying functions to the new available data samples. For the white box models simulation-based optimization methods are used to calibrate free and uncertain building physics or usage related parameters.

In addition, TOPAs provides a Fault Detection and Diagnosis (FDD) module that aims at detecting automatically faults, malfunctions and operational deviations in building systems like e.g., HVAC systems. FDD can identify sources of unplanned energy demands during the operation of buildings, reducing their impact and thus contributing to lower the gap between anticipated and actual energy demand. The FDD method [4] applied in TOPAs is based on qualitative models that are generated by stochastic qualitative identification from time-series data fetched from the core platform. If a fault is detected, results along possible diagnoses are pushed to the HMI.

4. Demonstration and First Results

Energy savings: The Cork Institute of Technology (CIT) is a college campus located in the south of Ireland. It consists of multiple buildings with various usage (e.g., class rooms, offices, laboratories and restaurants), age (from early 70s to new developments and retrofitted buildings) and as such different energy management requirements and performance. As a public body the college have to achieve a very ambitious energy efficiency targets as defined by EU and national directives, an energy reduction of 33% by 2020 across the campus. To achieve this the buildings and estates offices are implementing a continuous auditing process through ISO 50001 certification. A major challenge for the campus manager is that there are currently several different BMS deployed across the site making it very difficult to extract, interrogate, interpret and assess energy performance data. TOPAs has been deployed in CIT to reduce this complexity. The campus manager is now able to have a site level and building specific view of performance with visualization of relevant energy performance indicators and aggregated data sets. Through the use of TOPAs, initial energy saving potentials in the heat supply of a campus building due to a malfunction of a combined heat and power plant and boilers could be identified. Savings amounting to around 12%, corresponding to 7.6 MWh and 1.9 tons of CO and can be achieved with low-cost measures by enhancing the control strategy of the plant. Further analysis is currently being carried out at the CIT campus as well as on two additional demonstration sites in France and Ireland.

Predictions Models: A white box model of a CIT building has been developed and calibrated with measurement data. Simultaneously, black box models based on five different regression approaches (multiple linear regression, support vector machine regression, Gaussian process regression, k-Nearest neighbors regression, random forest regression) have been trained and tested on measurement data fetched from the oBMS and their results have been compared with each other. Random Forest Regression (RFR) was found to achieve the highest accuracy in terms of coefficient of determination and normalized mean absolute error among the analyzed methods. The features used in the RFR are the outdoor air temperature, the total occupancy and the day type. Resulting coefficients of determination for the test and the training periods are and . Nevertheless, due to the limited amount of data available, preliminary results are available at this stage of the project. Figure 2b shows the applied model reaches both good prediction accuracy (February, May 2017) and larger deviations (March–April 2017).

5. Conclusions

This paper presented the TOPAs approach to reduce the gap between actual and predicted buildings’ energy consumption. A core platform abstracts buildings heterogeneity and provides continuous auditing and monitoring. Add-on services have been developed to contribute to the energy performance gap reduction.

Acknowledgments

This work is partially funded by the H2020 TOPAs project (grant 676760).

Author Contributions

The work described in this paper is a joint work of the authors in the scope of the H2020 TOPAs project (grant 676760). Authors contributions are all important and valuable, hence the authors are listed in alphabetical order. In more details, contributions are as follows. Suzanne Lesecq and Susan Rea worked on the general structure and writing of the paper. Maxime Louvel worked on LINC and wrote the section about LINC/RTU. Joern Ploennigs wrote the oBMS/NIM section and implemented core elements of the oBMS. Alan McGibney worked on the HMI and wrote the corresponding sections. Nicolas Rehault and Dominik Wystrcil worked on the prediction models as well as FDD and wrote the corresponding sections in the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Louvel, M.; Pacull, F. LINC: A Compact Yet Powerful Coordination Environment. In Proceedings of the International Conference on Coordination Models and Languages, Berlin, Germany, 3–5 June 2014; Springer: Berlin, Germany, 2014; pp. 83–98. [Google Scholar]

- Ploennigs, J.; Hensel, B.; Dibowski, H.; Kabitzsch, K. BASont—A modular, adaptive building automation system ontology. In Proceedings of the 38th Annual Conference on IEEE Industrial Electronics Society (IECON 2012), Montreal, QC, Canada, 25–28 October 2012; pp. 4827–4833. [Google Scholar]

- McGibney, A.; Rea, S.; Ploennigs, J. Open BMS-IoT driven architecture for the internet of buildings. In Proceedings of the 42nd Annual Conference of the IEEE Industrial Electronics Society (IECON 2016), Florence, Italy, 23–26 October 2016; pp. 7071–7076. [Google Scholar]

- Müller, T.; Kruppa, K.; Lichtenberg, G.; Réhault, N. Fault detection with qualitative models reduced by tensor decomposition methods. IFAC-PapersOnLine 2015, 48, 416–421. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).