1. Introduction

Organic materials take up importance in a wide range of electronic applications. It is possible to utilize them as conductive, semiconductive and also insulating layers. In past years, the attractiveness of polymers and organic-inorganic composites increased also in the field of sensing applications.

Piezoresistivity is a physical phenomenon defined as a change of the electrical resistivity of a material when subjected to mechanical strain. Piezoresistive behavior can be observed on pure metals and their alloys (Pt, Au, Ag, NiCr, CuNi) [

1], crystalline material and their poly-, nano-crystalline form (Si, Ge, GaAs, GaN, diamond) [

2], polymers (PEDOT:PSS, PVDF:TrFe [

3,

4]), and composites of conductive or semiconductive micro- and nano-particles in polymer matrixes (polymeric silver or carbon black pastes [

5], CNT-PDMS composites [

6] and other poly-amide, -imide, PMMA composites [

7]).

In contrast to the majority of work in the field of organic strain sensitive elements, which has laid the focus mainly on flexible or wearable electronics, this work addresses the embedding of functional polymers into organic coatings deposited on mostly rigid substrates such as sheet metals. That way an organic coating, initially intended just for protective or optical purposes, can turn into something smart and intelligent.

2. Materials and Methods

2.1. Fabrication of Strain-Gauges

Screen printing was recently demonstrated to be a most suitable technology for embedding strain gauges and heaters in the organic coatings [

5]. Substrates were provided in the pre-coated state as steel sheet substrates with organic primer coatings. Sensor structures were printed using the semi-automatic screen print machine RokuPrint SD05. The printed strain gauges were then thermally cured at the recommended temperatures for each ink. Carbon black (EDAG PR 406B E&C, Henkel, Düsseldorf, Germany) is cured at 150 °C for 30 min, silver (EDAG PF050 E&C, Henkel, Düsseldorf, Germany) is cured at 140 °C for 4 min. Thermal curing was done convection oven. Afterwards, the strain gauges can optionally be top coated. If applied, it is spin coated at a speed of 2000 rpm for 120 s followed by a curing at 250 °C for 90 s to cure the top coat.

2.2. Piezoresistivity Testing

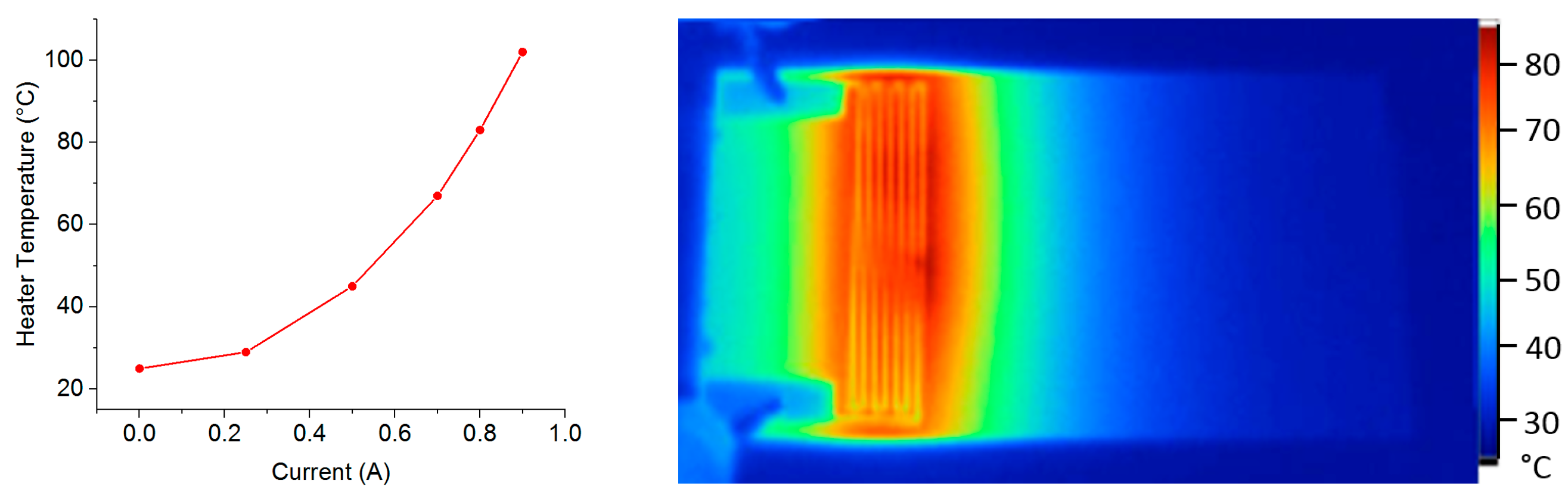

A strain gauge array was printed on top of a coated steel substrate. The heater, which is used for temperature characterization is printed underneath on the bottom side of the substrate. The heater covers the area of the sensor array to achieve a uniform temperature distribution along the sensor array (see

Figure 1). The screen printed heater is capable of heating the substrate (130 × 70 × 0.6 mm

3) up to 100 °C at a power of 25 W. The stability of the surface temperature (on the sensor side) was measured using a PT1000 temperature sensor in an SMT0603 package.

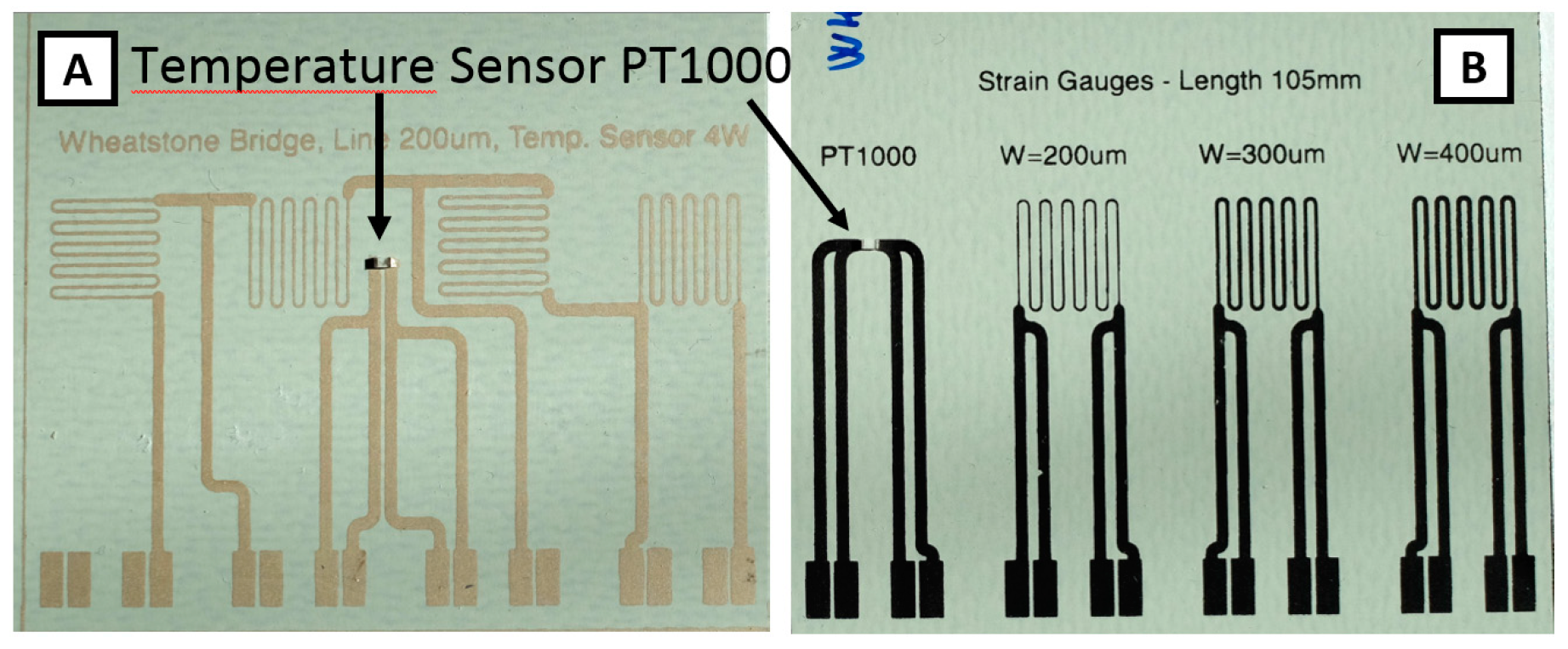

The structure of sensor array is depicted in

Figure 2. Resistors in a Wheatstone bridge configuration which are oriented perpendicularly to the applied strain are insensitive to the mechanical load applied to the free end of the single clamped steel beam and facilitate a basic temperature compensation of the bridge output voltage. Changes in the bridge voltage according to the applied tensile and compressive strain were measured at different operating temperatures. Conductive carbon black (PR-406B) and silver (PF-050) pastes were printed to create meander–like resistors with a linewidth of 100 μm, 200 μm, 300 μm, and 400 μm respectively.

The fabricated samples were tested on a test bench where the strain is produced using a linear motorized stage to deflect the free end of single side fixed steel. The test bench provides automated control of the linear stage, of the heater, and of the acquisition of the measured data.

3. Results

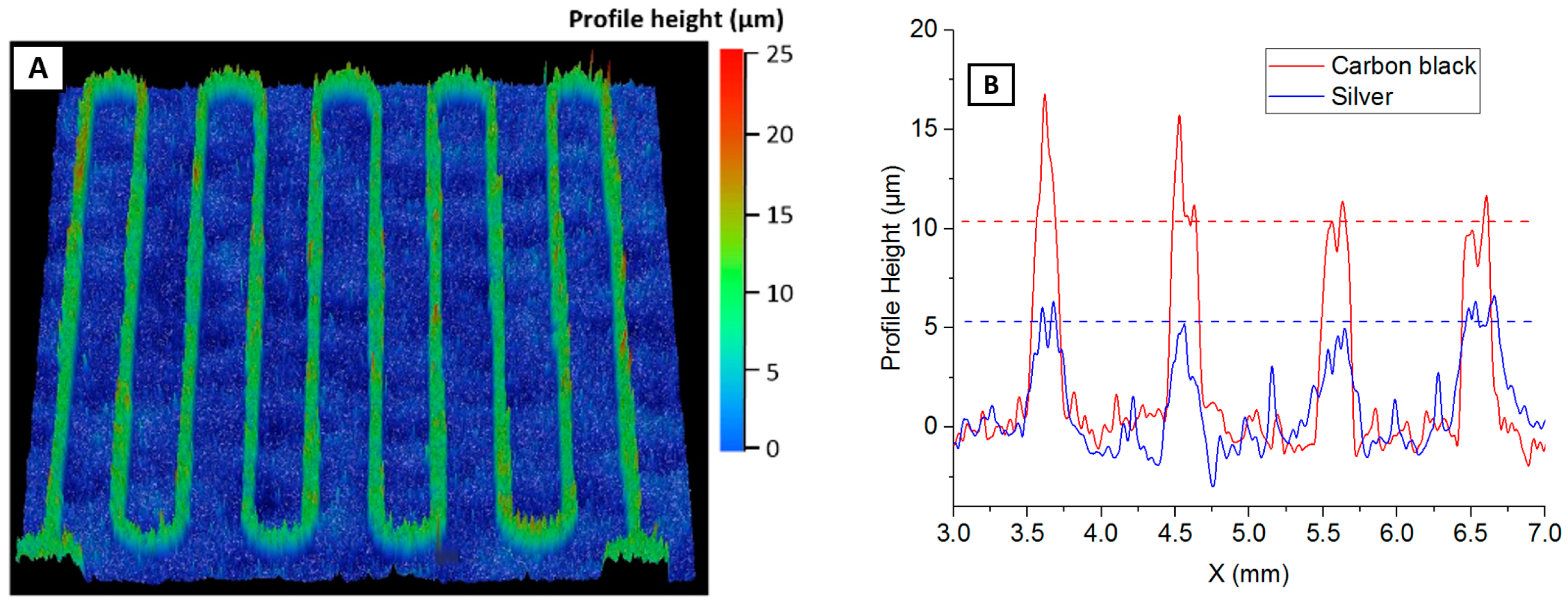

Realized structures were scanned with a Bruker Dektak XT profilometer. The measured profiles depicted in

Figure 3 show that final thicknesses of the sensitive layers are ~5 μm and ~10 μm for silver and carbon black respectively (a 120/34 threads/inch screen printing mesh was used).

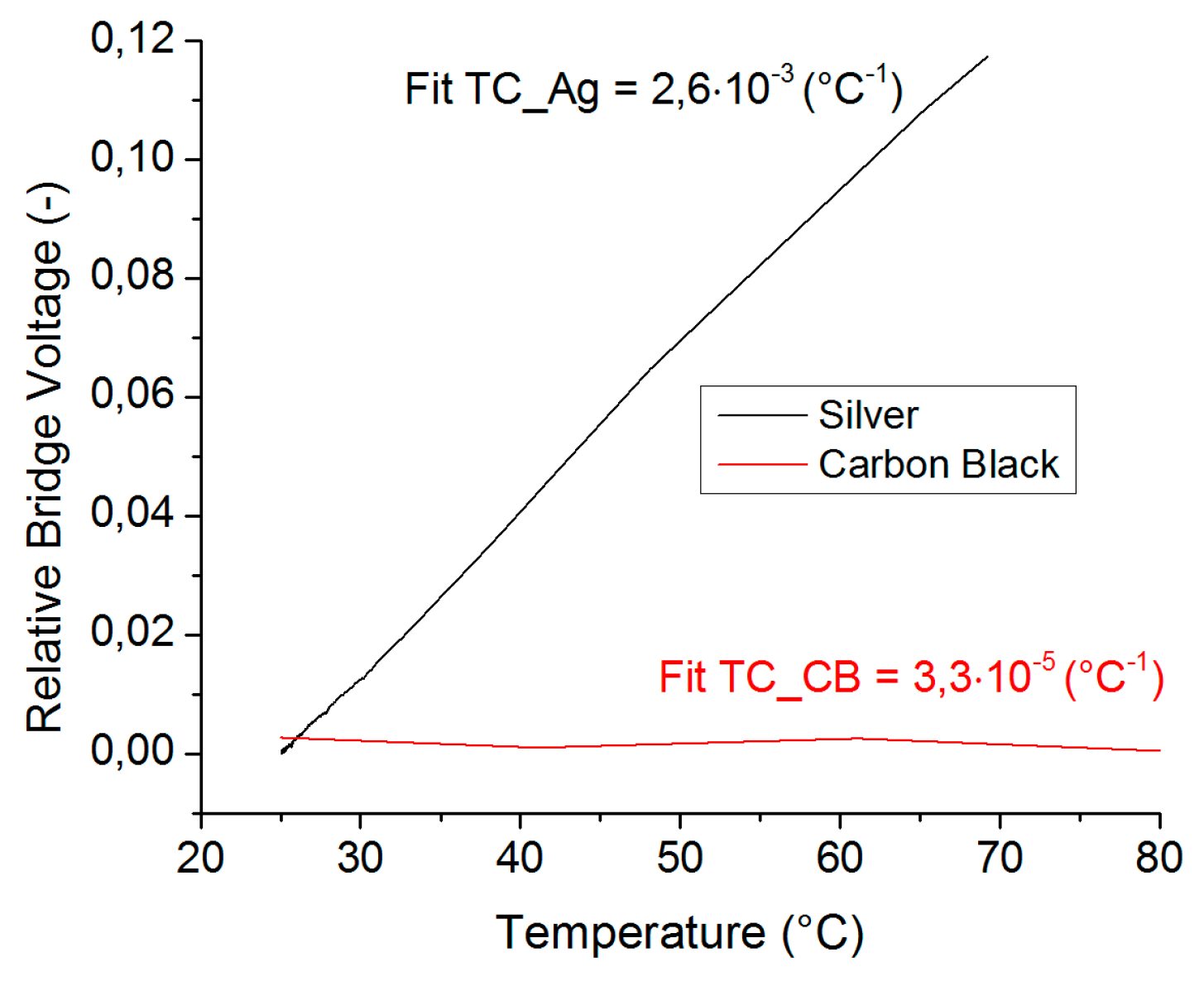

The result from the characterization of the gauge factor and its temperature dependence are depicted in

Figure 4. Ten loading cycles (leading to a compressive and tensile strain of ±4.5 × 10

−4 (-)) were performed for each temperature step. The resistance of individual resistors or bridge output voltage was measured using a precision multimeter (Keithley DMM7510). The strain sensitivity (GF) of the silver piezoresistors remains constant at the level of GF = 1.75 (-) over the measured temperature range, while the sensitivity of the carbon-black piezoresistors increased by 40% up to the level of GF = 5.81 (-). A similar behavior can be observed for bridge based samples. The low absolute resistance (50 ÷ 150 Ω) of the silver resistors shows that the paste is fully cured. The silver particles create a good conductive path which is stable even at elevated temperatures. However, the GF of the silver paste provides a lower strain sensitivity, which is mainly caused by a change in dimensions due to applied strain. In the case of carbon black, lower particle conductivity and lower percolation levels lead to higher absolute resistances (6 ÷ 15 kΩ) and stronger intra- and inter-particle effects under applied strain and thus higher GF, which shows a stronger temperature dependence.

Figure 5 depicts significant difference in the temperature dependence of the bridge output voltage of the silver and carbon black samples.

In contrast to deformation sensitivity, the carbon black piezoresistors connected to Wheatstone bridge exhibit lower temperature coefficient of the bridge output voltage.

4. Conclusions

The results show that, while the strain sensitivity of silver paste is constant over the measured temperature range (gauge factor GF ~1.8), the sensitivity of carbon black has increased in the measured temperature range from 0 to 80 °C (GF 4.1 ÷ 5.8).

In both cases, the electrical conductivity originates from conductive paths within the polymer matrix, and the piezoresistive behavior is influenced by both intra- and inter-particle effects. The resulting strain sensitivity depends on factors like particle conductivity, percolation level and process parameters (e.g., curing temperature). Silver strain gauges exhibits excellent linearity, repeatability and constant temperature coefficient of resistance over wide range of temperatures. Carbon black exhibits a higher deformation sensitivity (GF is 2 ÷ 3× higher, compared to silver), but its temperature dependence of deformation sensitivity is also higher and disadvantageous in the practical utilization and design of conditioning circuits.