Diamond Coated LW-SAW Sensors-Study of Diamond Thickness Effect †

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

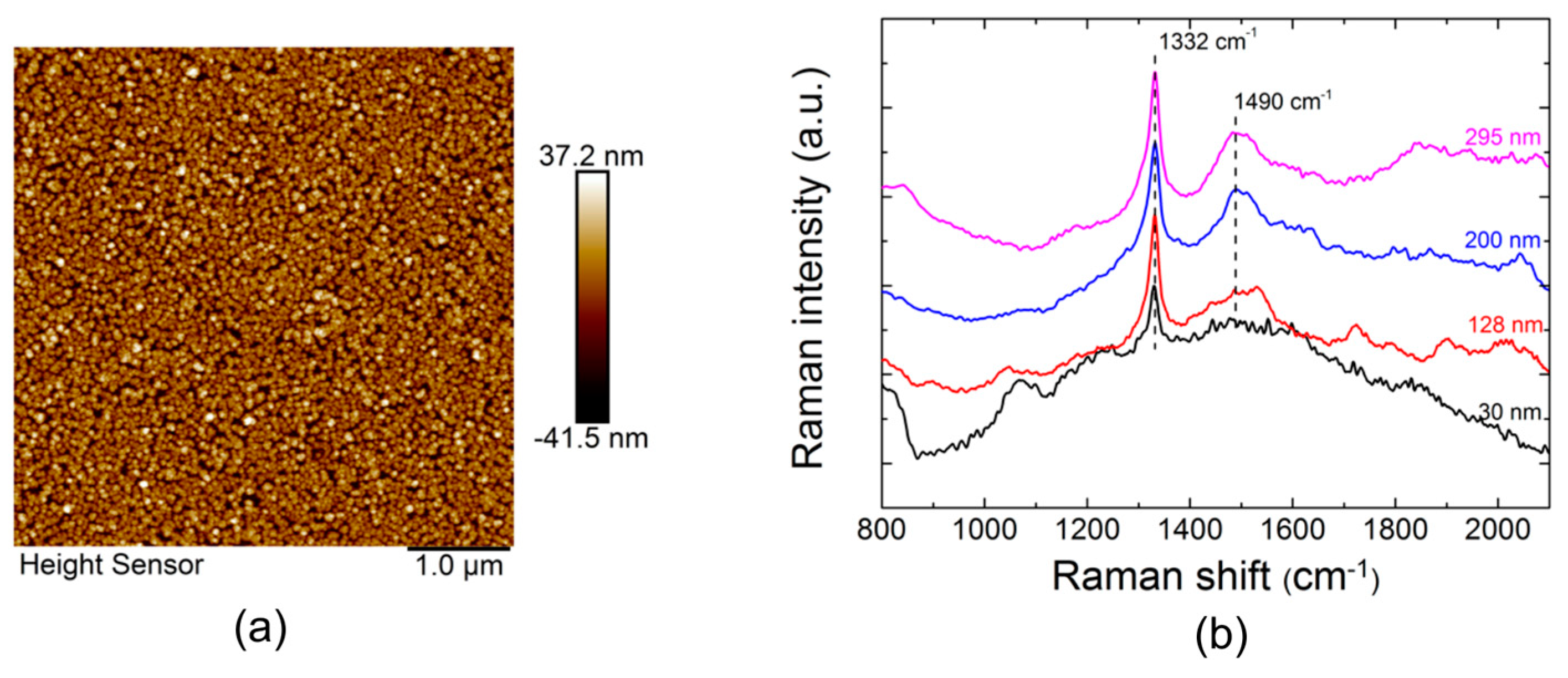

3.1. Effect of NCD Layer Thickness

3.2. Sensitivity

3.3. Sensor Operation in Liquids

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Singh, A.; Glass, N.; Tolba, M.; Brovko, L.; Griffiths, M.; Evoy, S. Immobilization of bacteriophages on gold surfaces for the specific capture of pathogens. Biosens. Bioelectron. 2009, 24, 3645–3651. [Google Scholar] [CrossRef] [PubMed]

- Du, J.; Harding, G.; Collings, A.; Dencher, P. An experimental study of Love-wave acoustic sensors operating in liquids. Sens. Actuators A Phys. 1997, 60, 54–61. [Google Scholar] [CrossRef]

- Herrmann, F.; Weihnacht, M.; Büttgenbach, S. Properties of shear-horizontal surface acoustic waves in different layered quartz–SiO2 structures. Ultrasonics 1999, 37, 335–341. [Google Scholar] [CrossRef]

- Krueger, A.; Lang, D. Functionality is Key: Recent Progress in the Surface Modification of Nanodiamond. Adv Funct Mater. 2012, 22, 890–906. [Google Scholar] [CrossRef]

- Mochaling, V.N.; Shenderova, O.; Ho, D.; Gogotsi, Y. The properties and applications of nanodiamonds. Nat. Nanotechnol. 2012, 7, 11–23. [Google Scholar] [CrossRef] [PubMed]

- Vaijayanthimala, V.; Cheng, P.-Y.; Yeh, S.-H.; Liu, K.-K.; Hsiao, C.-H.; Chao, J.-I.; Chang, H.-C. The long-term stability and biocompatibility of fluorescent nanodiamond as an in vivo contrast agent. Biomaterials 2012, 33, 7794–7802. [Google Scholar] [CrossRef] [PubMed]

- Azevedo, A.F.; Baldan, M.R.; Ferreira, N.G. Nanodiamond Films for Applications in Electrochemical Systems. Int. J. Electrochem. 2012, 2012, 1–16. [Google Scholar] [CrossRef]

- Talbi, A.; Soltani, A.; Rumeau, A.; Taylor, A.; Drbohlavová, L.; Klimša, L.; Kopeček, J.; Fekete, L.; Krečmarová, M.; Mortet, V. Simulations, fabrication, and characterization of diamond-coated Love wave-type surface acoustic wave sensors. Phys. Status Solidi A. 2015, 212, 2606–2610. [Google Scholar] [CrossRef]

- Turton, A.C.; Bhattacharyya, D.; Wood, D. High sensitivity Love-mode liquid density sensors. Sens. Actuators A Phys. 2005, 123–124, 267–273. [Google Scholar] [CrossRef]

| Liquid | Dielectric Constant (-) | Viscosity (mPa·s) |

|---|---|---|

| Water | 80.1 | 1.002 |

| PBS buffer | - | |

| MeOH | 0.58 | |

| IPA | 2.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drbohlavová, L.; Gerbedoen, J.C.; Taylor, A.; Talbi, A.; Fekete, L.; Ashcheulov, P.; Soltani, A.; Bovtun, V.; Kempa, M.; Bartoň, J.; et al. Diamond Coated LW-SAW Sensors-Study of Diamond Thickness Effect. Proceedings 2017, 1, 540. https://doi.org/10.3390/proceedings1040540

Drbohlavová L, Gerbedoen JC, Taylor A, Talbi A, Fekete L, Ashcheulov P, Soltani A, Bovtun V, Kempa M, Bartoň J, et al. Diamond Coated LW-SAW Sensors-Study of Diamond Thickness Effect. Proceedings. 2017; 1(4):540. https://doi.org/10.3390/proceedings1040540

Chicago/Turabian StyleDrbohlavová, L., J. C. Gerbedoen, A. Taylor, A. Talbi, L. Fekete, P. Ashcheulov, A. Soltani, V. Bovtun, M. Kempa, J. Bartoň, and et al. 2017. "Diamond Coated LW-SAW Sensors-Study of Diamond Thickness Effect" Proceedings 1, no. 4: 540. https://doi.org/10.3390/proceedings1040540

APA StyleDrbohlavová, L., Gerbedoen, J. C., Taylor, A., Talbi, A., Fekete, L., Ashcheulov, P., Soltani, A., Bovtun, V., Kempa, M., Bartoň, J., Cígler, P., & Mortet, V. (2017). Diamond Coated LW-SAW Sensors-Study of Diamond Thickness Effect. Proceedings, 1(4), 540. https://doi.org/10.3390/proceedings1040540