Flow-Ratio Monitoring in a Microchannel by Liquid-Liquid Interface Interferometry †

Abstract

:1. Introduction

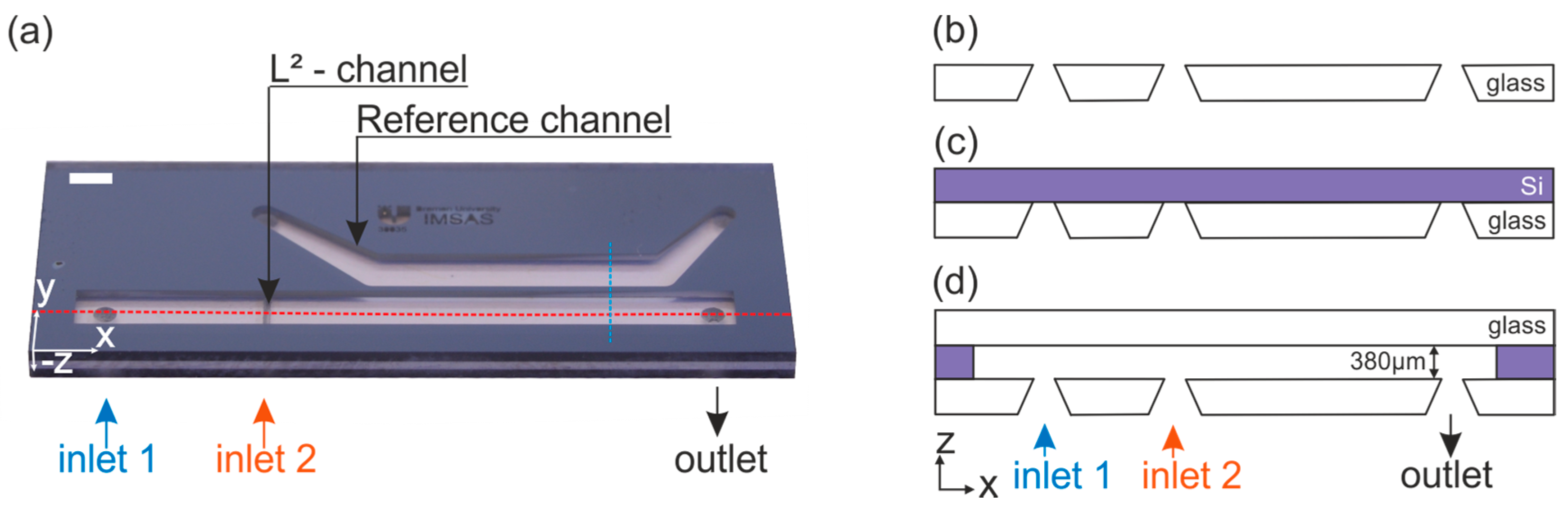

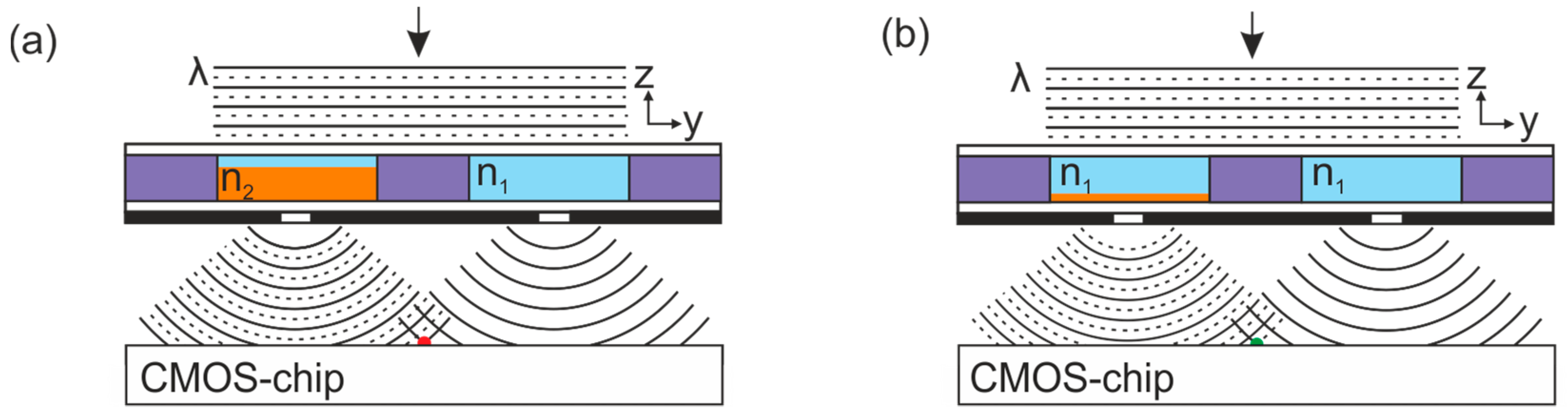

2. Materials and Methods

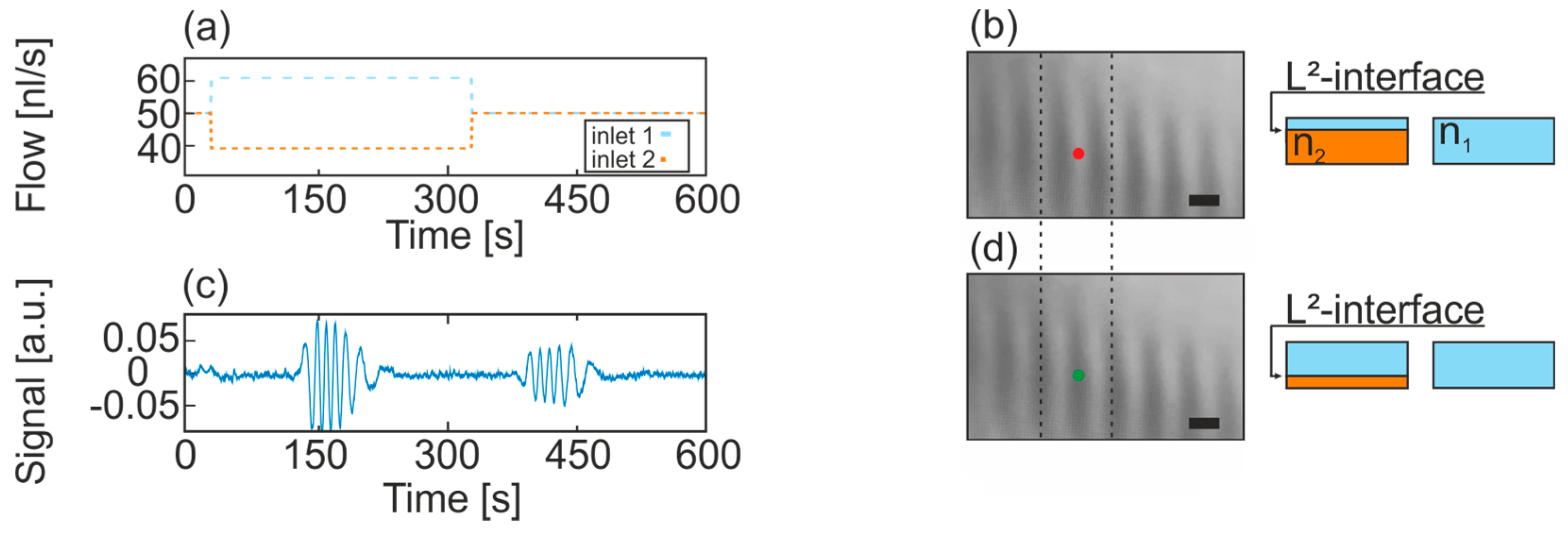

3. Results

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Rosenauer, M.; Vellekoop, M.J. Characterization of an on-chip reconfigurable 3D optofluidic microlens by confocal laser scanning microscopy. Procedia Eng. 2010, 5, 440–443. [Google Scholar] [CrossRef]

- Wolfe, D.; Conroy, R.; Garstecki, P.; Mayers, B.; Fischbach, M.; Paul, K.; Prentiss, M.; Whitesides, G. Dynamic control of liquid-core/liquid-cladding optical waveguides. Proc. Natl. Acad. Sci. USA 2004, 101, 12434–12438. [Google Scholar] [CrossRef] [PubMed]

- Brandhoff, L.; Vellekoop, M.J. Optofluidic out-of-plane interferometer. In Proceedings of the IEEE Sensor, Baltimore, MD, USA, 3–6 November 2013. [Google Scholar]

- Lapsley, M.; Chiang, I.; Zheng, Y.; Ding, X.; Mao, X.; Huang, T. A single-layer, planar, optofluidic Mach-Zehnder interferometer for label-free detection. LOC 2011, 11, 1795–1800. [Google Scholar] [CrossRef] [PubMed]

- Sumriddetchkajorn, S.; Chaitavon, K.; Nukeaw, J. A free-space interferometric refractometer structure with simple microfluidic chips. IEEE Sens. J. 2012, 12, 404–409. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oellers, M.; Bunge, F.; Vinayaka, P.; Driesche, S.v.d.; Vellekoop, M.J. Flow-Ratio Monitoring in a Microchannel by Liquid-Liquid Interface Interferometry. Proceedings 2017, 1, 498. https://doi.org/10.3390/proceedings1040498

Oellers M, Bunge F, Vinayaka P, Driesche Svd, Vellekoop MJ. Flow-Ratio Monitoring in a Microchannel by Liquid-Liquid Interface Interferometry. Proceedings. 2017; 1(4):498. https://doi.org/10.3390/proceedings1040498

Chicago/Turabian StyleOellers, Martin, Frank Bunge, Poornanchandra Vinayaka, Sander van den Driesche, and Michael J. Vellekoop. 2017. "Flow-Ratio Monitoring in a Microchannel by Liquid-Liquid Interface Interferometry" Proceedings 1, no. 4: 498. https://doi.org/10.3390/proceedings1040498

APA StyleOellers, M., Bunge, F., Vinayaka, P., Driesche, S. v. d., & Vellekoop, M. J. (2017). Flow-Ratio Monitoring in a Microchannel by Liquid-Liquid Interface Interferometry. Proceedings, 1(4), 498. https://doi.org/10.3390/proceedings1040498