Eni Carbon Silicates: Innovative Hybrid Materials for Room-Temperature Gas Sensing †

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

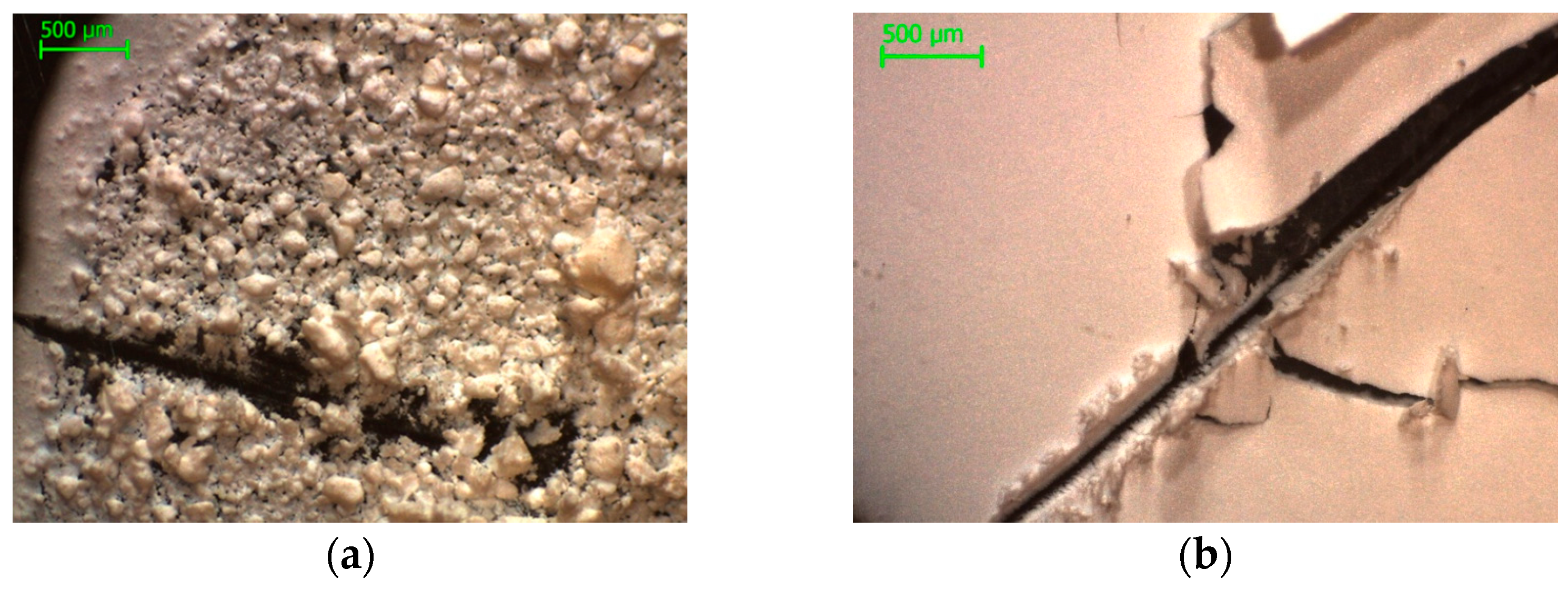

3.1. Solubility Tests and Film Deposition

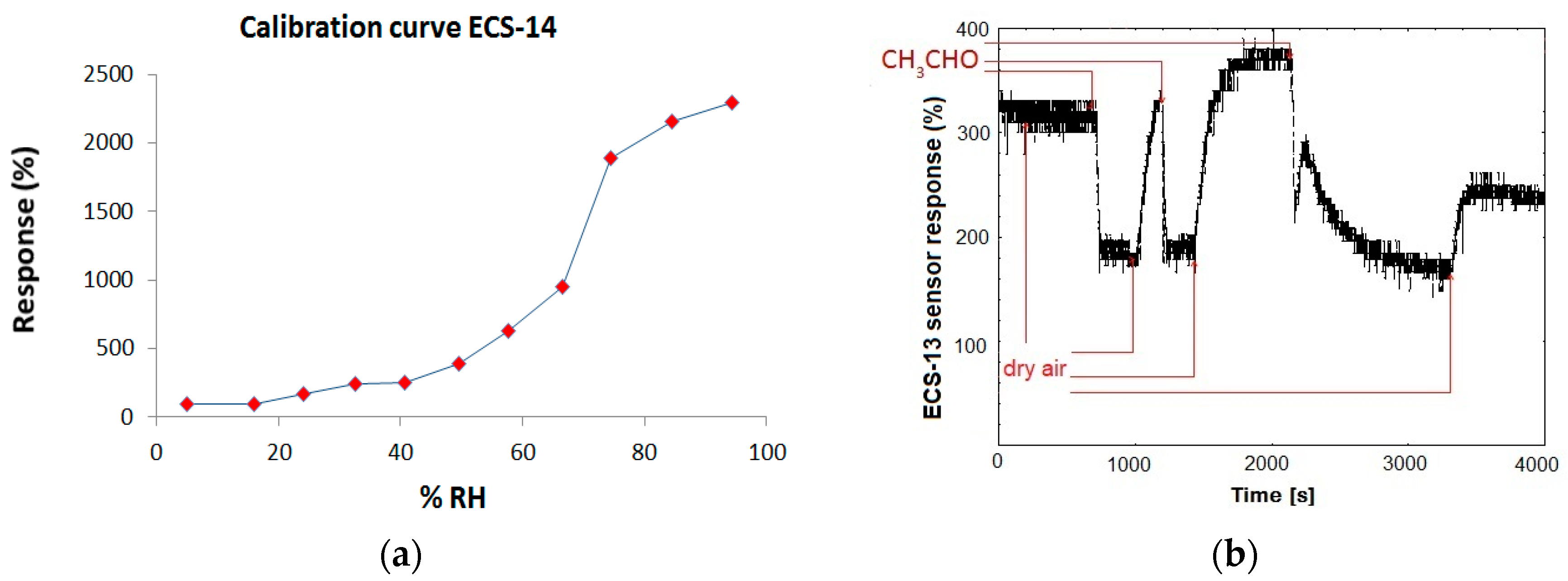

3.2. Study of Gas Sensing Properties

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Yamazoe, N.; Shimanoe, K. Receptor Function and Response of Semiconductor Gas Sensor. J. Sens. 2009, 1–21. [Google Scholar] [CrossRef]

- Yamazoe, N. Toward innovations of gas sensor technology. Sens. Actuators B Chem. 2005, 108, 2–14. [Google Scholar] [CrossRef]

- Wang, S.; Kang, Y.; Wang, L.; Zhang, H.; Wang, Y.; Wang, Y. Organic/inorganic hybrid sensors: A review. Sens. Actuators B Chem. 2013, 182, 467–481. [Google Scholar] [CrossRef]

- Bellussi, G.; Carati, A.; Di Paola, E.; Millini, R.; Parker, W.O., Jr.; Rizzo, C.; Zanardi, S. Crystalline Hybrid Organic-Inorganic Alumino-Silicates. Microporous Mesoporous Mater. 2008, 113, 252–260. [Google Scholar] [CrossRef]

- Zhang, C.; Boudiba, A.; De Marco, P.; Snyders, R.; Olivier, M.-G.; Debliquy, M. Room Temperature Responses of Visible-light Illuminated WO3 Sensors to NO2 in sub-ppm Range. Sens. Actuators B Chem. 2013, 181, 395–401. [Google Scholar] [CrossRef]

- Fabbri, B.; Gaiardo, A.; Giberti, A.; Guidi, V.; Malagù, C.; Martucci, A.; Sturaro, M.; Zonta, G.; Gherardi, S.; Bernardoni, P. Chemoresistive Properties of Photo-activated Thin and Thick ZnO Films. Sens. Actuators B Chem. 2016, 222, 1251–1256. [Google Scholar] [CrossRef]

- Bellussi, G.; Millini, R.; Montanari, E.; Carati, A.; Rizzo, C.; Parker, W.O., Jr.; Cruciani, G.; De Angelis, A.; Bonoldi, L.; Zanardi, S. A Highly Crystalline Microporous Hybrid Organic-Inorganic Aluminosilicate Resembling the AFI-type Zeolite. Chem. Commun. 2012, 48, 7356–7358. [Google Scholar] [CrossRef]

- Zanardi, S.; Bellussi, G.; Parker, W.O., Jr.; Montanari, E.; Bellettato, M.; Cruciani, G.; Carati, A.; Guidetti, S.; Rizzo, C.; Millini, R. The Role of Boric Acid in the Synthesis of Eni Carbon Silicates. Dalton Trans. 2014, 43, 10617–10627. [Google Scholar] [CrossRef] [PubMed]

- Fabbri, B. Eni Carbon Silicates as Crystalline and Mesoporous Hybrids for Gas Sensing. Ph.D. Thesis, University of Ferrara, Ferrara, Italy, 2015. [Google Scholar]

- Fabbri, B.; Bonoldi, L.; Guidi, V.; Cruciani, G.; Casotti, D.; Malagù, C.; Bellussi, G.; Millini, R.; Montanari, L.; Carati, A.; et al. Crystalline Microporous Organo-Silicates with Reversed Functionalities of the Organic and Inorganic Components for Room-Temperature Gas Sensing. ACS Appl. Mater. Interface, 2017; in press. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fabbri, B.; Bonoldi, L.; Guidi, V.; Cruciani, G.; Casotti, D.; Malagù, C.; Bellussi, G.; Millini, R.; Montanari, L.; Carati, A.; et al. Eni Carbon Silicates: Innovative Hybrid Materials for Room-Temperature Gas Sensing. Proceedings 2017, 1, 322. https://doi.org/10.3390/proceedings1040322

Fabbri B, Bonoldi L, Guidi V, Cruciani G, Casotti D, Malagù C, Bellussi G, Millini R, Montanari L, Carati A, et al. Eni Carbon Silicates: Innovative Hybrid Materials for Room-Temperature Gas Sensing. Proceedings. 2017; 1(4):322. https://doi.org/10.3390/proceedings1040322

Chicago/Turabian StyleFabbri, Barbara, Lucia Bonoldi, Vincenzo Guidi, Giuseppe Cruciani, Davide Casotti, Cesare Malagù, Giuseppe Bellussi, Roberto Millini, Luciano Montanari, Angela Carati, and et al. 2017. "Eni Carbon Silicates: Innovative Hybrid Materials for Room-Temperature Gas Sensing" Proceedings 1, no. 4: 322. https://doi.org/10.3390/proceedings1040322

APA StyleFabbri, B., Bonoldi, L., Guidi, V., Cruciani, G., Casotti, D., Malagù, C., Bellussi, G., Millini, R., Montanari, L., Carati, A., Rizzo, C., Montanari, E., & Zanardi, S. (2017). Eni Carbon Silicates: Innovative Hybrid Materials for Room-Temperature Gas Sensing. Proceedings, 1(4), 322. https://doi.org/10.3390/proceedings1040322