The Effect of Monolayer Graphene on the UV Assisted NO2 Sensing and Recovery at Room Temperature †

Abstract

:1. Introduction

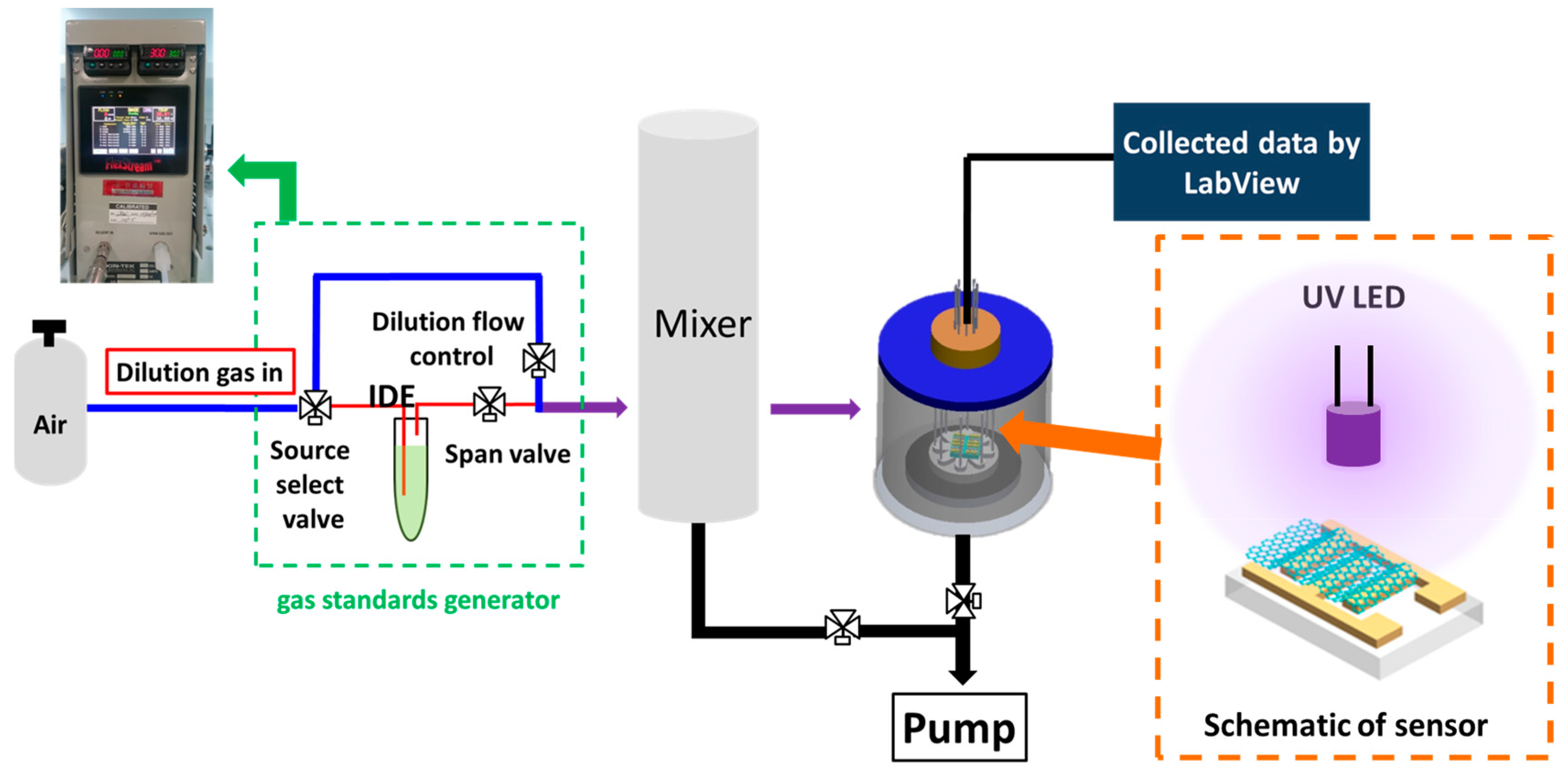

2. Experimental

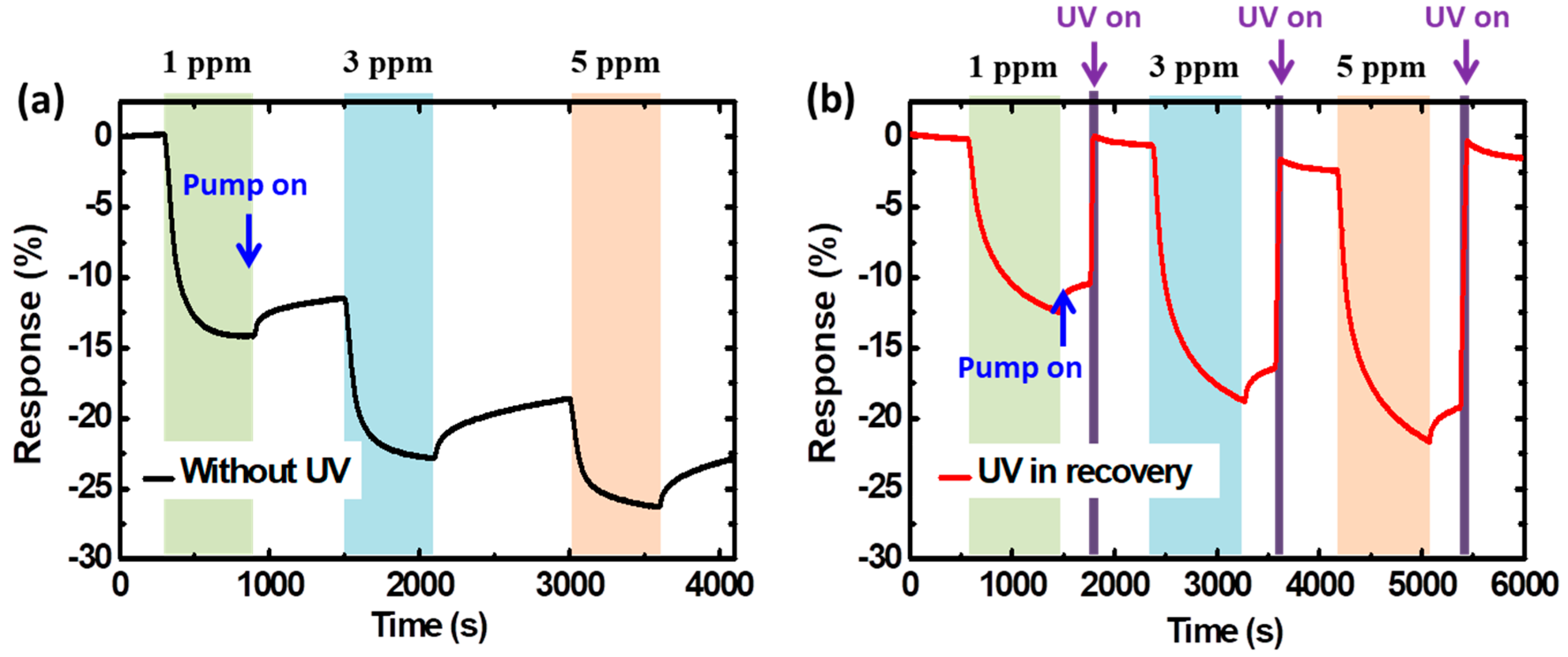

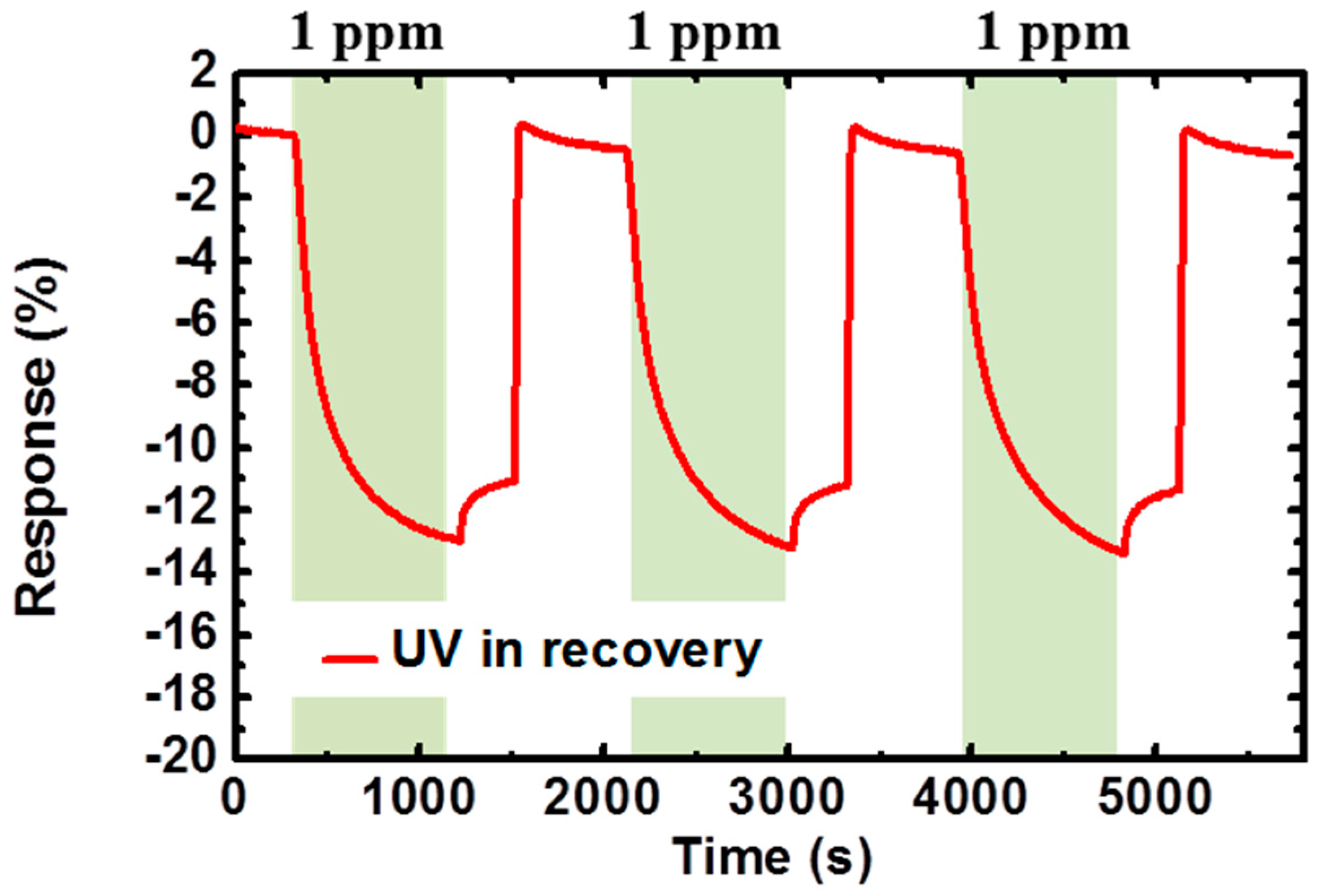

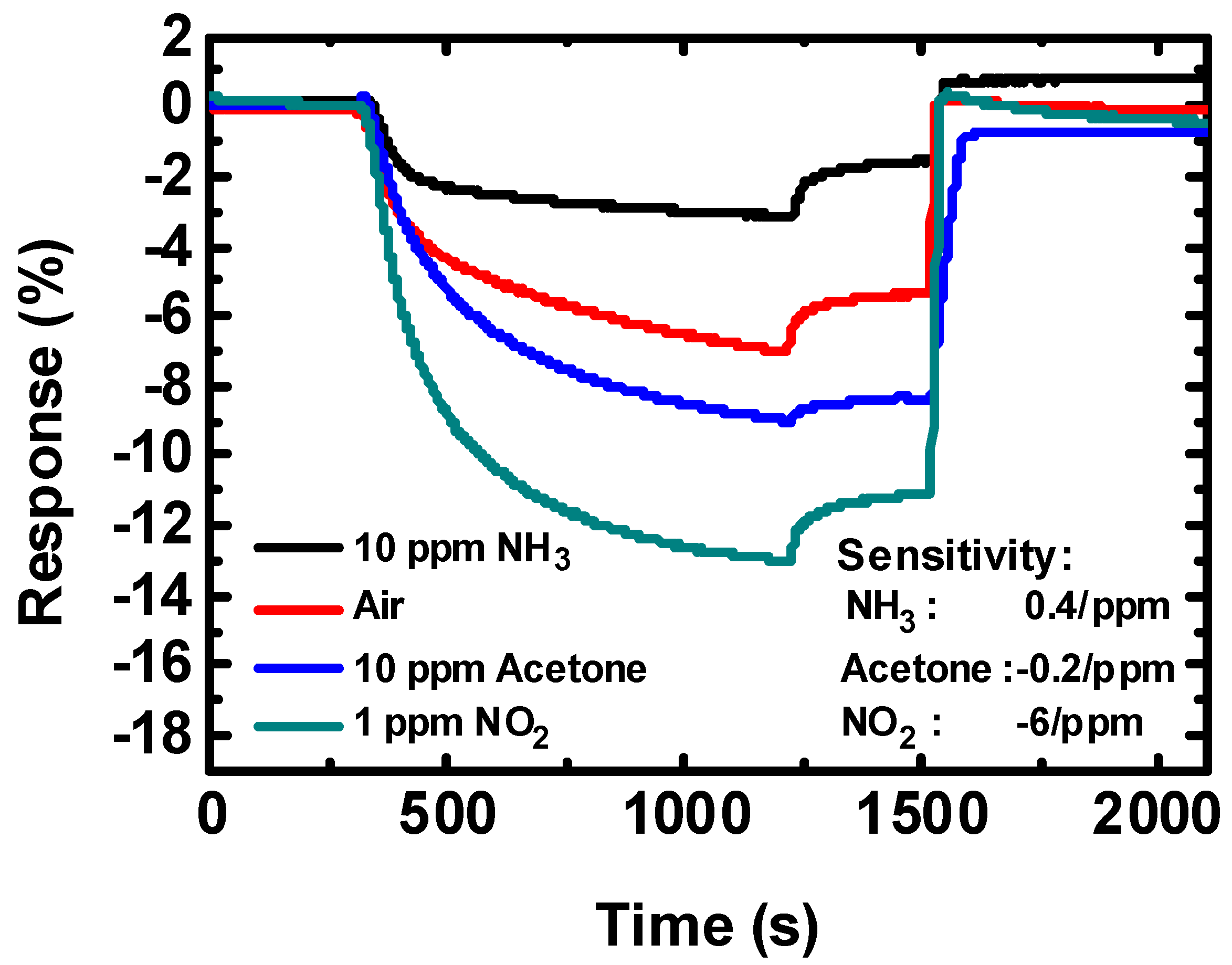

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Li, J.; Lu, Y.; Ye, Q.; Delzeit, L.; Meyyappan, M. A gas sensor array using carbon nanotubes and microfabrication technology. Electrochem. Solid State Lett. 2005, 8, H100–H102. [Google Scholar] [CrossRef]

- Gu, D.; Li, X.; Zhao, Y.; Wang, J. Enhanced NO2 sensing of SnO2/SnS2 heterojunction based sensor. Sens. Actuators B Chem. 2017, 244, 67–76. [Google Scholar] [CrossRef]

- Long, H.; Harley-Trochimczyk, A.; Pham, T.; Tang, Z.; Shi, T.; Zettl, A.; Carraro, C.; Worsley, M.A.; Maboudian, R. High Surface Area MoS2 / Graphene Hybrid Aerogel for Ultrasensitive NO2 Detection. Adv. Funct. Mater. 2016, 26, 5158–5165. [Google Scholar] [CrossRef]

| Without UV Light | With UV Light | |||

|---|---|---|---|---|

| NO2 (ppm) | Response (%) | Recovery (%) | Response (%) | Recovery (%) |

| 1 | −14.35 | 21 | −12.33 | 100 |

| 3 | −11.57 | 38 | −18.25 | 100 |

| 5 | −7.7 | 51 | −21.8 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.-C.; Yang, Y.-C.; Liu, H.-L.; Yang, C.-M.; Meyyappan, M.; Lai, C.-S. The Effect of Monolayer Graphene on the UV Assisted NO2 Sensing and Recovery at Room Temperature. Proceedings 2017, 1, 461. https://doi.org/10.3390/proceedings1040461

Chen T-C, Yang Y-C, Liu H-L, Yang C-M, Meyyappan M, Lai C-S. The Effect of Monolayer Graphene on the UV Assisted NO2 Sensing and Recovery at Room Temperature. Proceedings. 2017; 1(4):461. https://doi.org/10.3390/proceedings1040461

Chicago/Turabian StyleChen, Tsung-Cheng, Yu-Cheng Yang, Hui-Ling Liu, Chia-Ming Yang, M. Meyyappan, and Chao-Sung Lai. 2017. "The Effect of Monolayer Graphene on the UV Assisted NO2 Sensing and Recovery at Room Temperature" Proceedings 1, no. 4: 461. https://doi.org/10.3390/proceedings1040461

APA StyleChen, T.-C., Yang, Y.-C., Liu, H.-L., Yang, C.-M., Meyyappan, M., & Lai, C.-S. (2017). The Effect of Monolayer Graphene on the UV Assisted NO2 Sensing and Recovery at Room Temperature. Proceedings, 1(4), 461. https://doi.org/10.3390/proceedings1040461