Abstract

The quality of firewood combustion processes can be considerably improved by automated control of the combustion air streams. For this purpose, continuous flue gas analysis using in-situ sensors is essential. In order to monitor the unburned exhaust gas components like carbon monoxide (CO) and hydrocarbons (CxHy), for the first time a novel thermoelectric gas sensor was applied directly in the exhaust gas. The sensor is made of high temperature stable materials and promises the needed robustness. Here, the sensor signal is compared to flue gas analysis data from FTIR measurements during a wood-log batch firing experiment. An impressive correlation between both data was found.

Published: 8 August 2017

1. Introduction

Low-power wood-log fueled furnaces operated at domestic households are well known to contribute considerably to air pollution by toxic emissions of unburned exhaust gas components (CO/HC) and particulate matter (PM). Automatic control of the combustion air streams based on combustion temperature and exhaust gas analysis by determining the residual oxygen concentration (ROC) and the CO/HC content allows tremendous reduction of toxic gas emissions by about 80% compared to the emissions of fireplaces operated manually [1]. However, a CO/HC-sensor providing enough sensitivity, robustness, and long-term stability in those harsh flue gas environments is still not available. In the past, several sensing principles and devices have been investigated for that purpose [2,3]. Here, the sensing behavior of a novel thermoelectric device when operated in real exhaust is reported.

2. Experimental

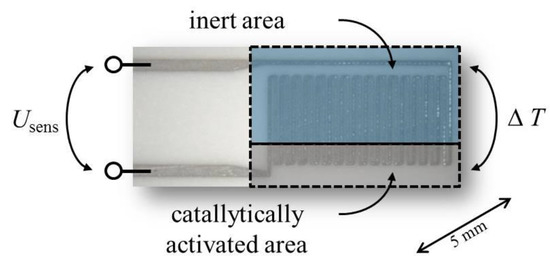

The sensor principle is explicitly described in [4]. In our application, it consists of a screen-printed Pt/PtRh-thermopile structure (for details see [5]) on the front side of an alumina substrate. One junction is catalytically activated by a Pt-loaded alumina thick-film; one is covered inertly (see Figure 1). Gas combustion processes on the sensors front side in presence of the catalyst lead to exothermic heat and therefore to a temperature gradient (ΔT) between both areas that is measured as a thermovoltage (Usens). An integrated heating element on the reverse side adjusts a certain absolute sensor temperature (Tabs = 600 °C) to keep the catalyst active. The sensor shows a linear characteristic curve. Its sensitivity dependence is well understood and the whole sensor behavior can even be described by modelling [6]. By operation at different temperatures Tabs, different gas components can be distinguished from each other due to their individual activation energies of combustion [7].

Figure 1.

Part of the sensors front side: A screen-printed Pt/PtRh thermopile structure measures the temperature gradient between an inert and a catalytically activated area by a thermovoltage. Gas reactions on the catalyst affect the signal.

The here-presented data represent measurements in the exhaust gas of a wood-log fueled fireplace. The firing system was automatically operated as described in [1] and the exhaust gas was continuously analyzed using a high-temperature FTIR-system.

3. Results

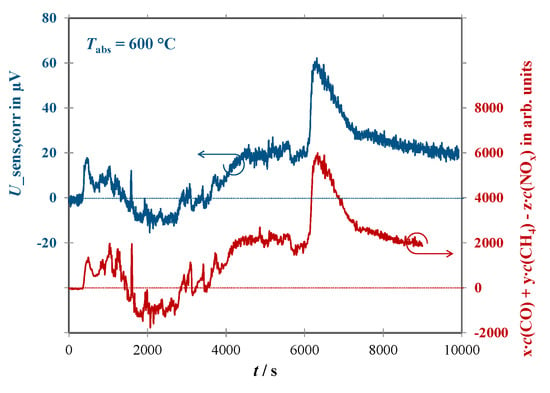

To relate the sensor signal to the exhaust composition and to determine the quality of the sensor performance, the measured thermovoltage is compared to FTIR data during the whole batch firing process. We found CO and CH4 to be the main reducing components in the exhaust, but also NO arises in certain phases of the combustion process. The other components were determined to occur only in low concentrations (<100 ppm) and therefore, they should not considerably influence the course of the signal representing various exhaust compositions during the batch process.

As a matter of principle, the sensor voltage is also affected by any temperature inhomogeneity resulting from the integrated heater or the sensor housing. So, the raw data (Usens) have to be corrected by an offset voltage. This signal is now compared to those gas analytic data that contribute to the heat of combustion (Figure 2). Therefore, the concentrations of the main components (measured by FTIR) were multiplied by an individual factor and summed up to meet a value related to the combustion heat over time. NO was handled as a negative value, assuming endothermic reaction. The resulting curve cohere extremely well with the corrected sensor signal (Usens,corr) during the whole batch firing process.

Figure 2.

Comparison of the corrected sensor signal (details see text) and evaluated FTIR-data for a 2.5 h wood-log fueled firing experiment.

4. Conclusions and Outlook

As a result of continuous operation of a thermoelectric CO/HC-sensor device in the exhaust gas of a wood-log batch firing process, an impressive correlation between real gas analytic data and the sensor signal was found. It is assumed that thereby a more exact control of the firing process will be achieved, which will lead to further emission reductions. Future work will focus on investigations concerning the sensors long-term stability and the correlation of the sensor signals to various gas species arising in those exhausts.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ojha, B.; Illyaskutty, N.; Knoblauch, J.; Balachandran, M.R.; Kohler, H. High-temperature CO/HC gas sensors to optimize firewood combustion in low-power fireplaces. J. Sens. Sens. Syst. 2017, 6, 237–246. [Google Scholar] [CrossRef]

- Butschbach, P.; Hammer, F.; Kohler, H.; Potreck, A.; Trautmann, T. Extensive reduction of toxic gas emissions of firewood-fueled low power fireplaces by improved in situ gas sensorics and catalytic treatment of the exhaust gas. Sens. Actuators B Chem. 2009, 137, 32–41. [Google Scholar] [CrossRef]

- Andersson, M.; Pearce, R.; Spetz, A.L. New generation SiC based field effect transistor gas sensors. Sens. Actuators B Chem. 2013, 179, 95–106. [Google Scholar] [CrossRef]

- Wiegärtner, S.; Hagen, G.; Kita, J.; Reitmeier, W.; Hien, M.; Grass, P.; Moos, R. Thermoelectric hydrocarbon sensor in thick-film technology for on-board-diagnostics of a diesel oxidation catalyst. Sens. Actuators B Chem. 2015, 21, 234–240. [Google Scholar] [CrossRef]

- Kita, J.; Wiegärtner, S.; Moos, R.; Weigand, P.; Pliscott, A.; LaBranche, M.H.; Glicksman, H.D. Screen-printable type S thermocouple for thick-film technology. Procedia Eng. 2015, 120, 828–831. [Google Scholar] [CrossRef]

- Ritter, T.; Wiegärtner, S.; Hagen, G.; Moos, R. Simulation of a thermoelectric gas sensor to determine hydrocarbons in exhaust gases and to characterize catalyst materials. In Proceedings of the AMA Conferences 2017, Nürnberg, Germany, 30 May–1 June 2017. [Google Scholar] [CrossRef]

- Hagen, G.; Leupold, N.; Wiegärtner, S.; Moos, R. Sensor Tool for Fast Catalyst Material Characterization. Top. Catal. 2017, 60, 312–317. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).