Microstructure for Thermal Impedance Spectroscopy for Biofuel Composition Measurement †

Abstract

:1. Introduction

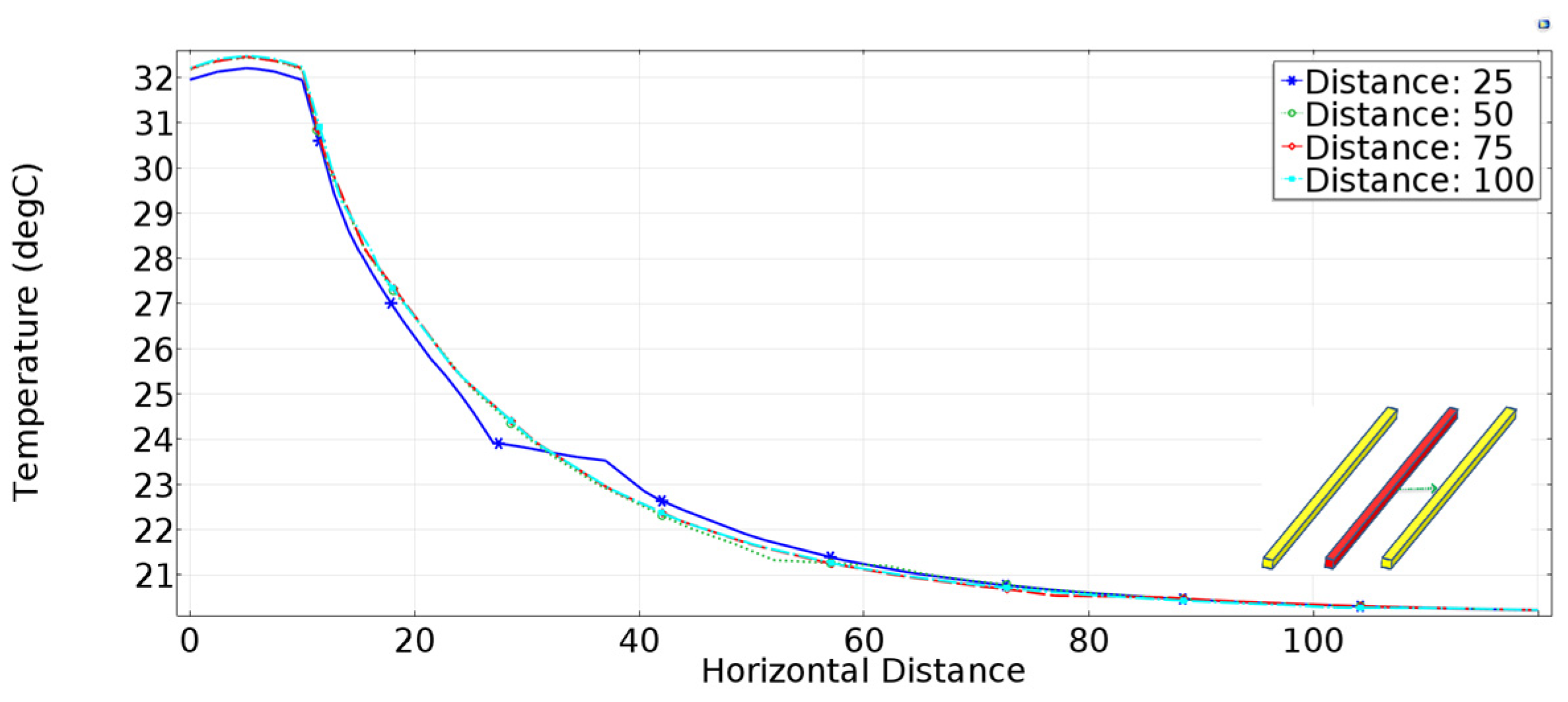

2. Structure Design Process

2.1. Heat Flux Efficiency

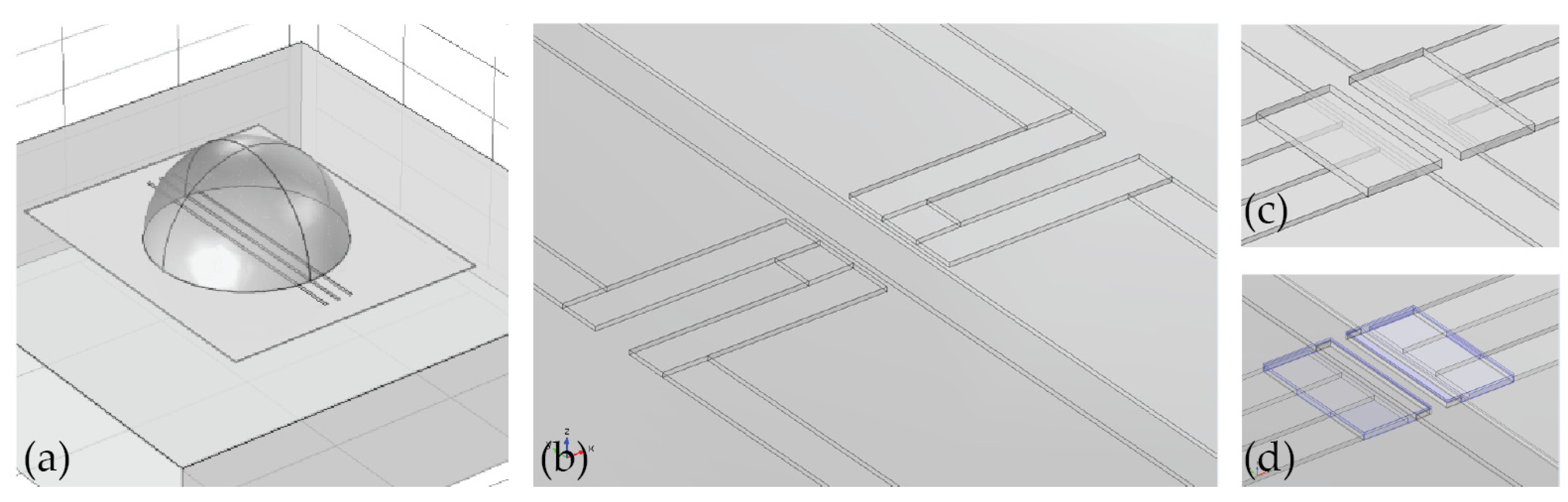

2.2. Design Structures

3. Simulation Results

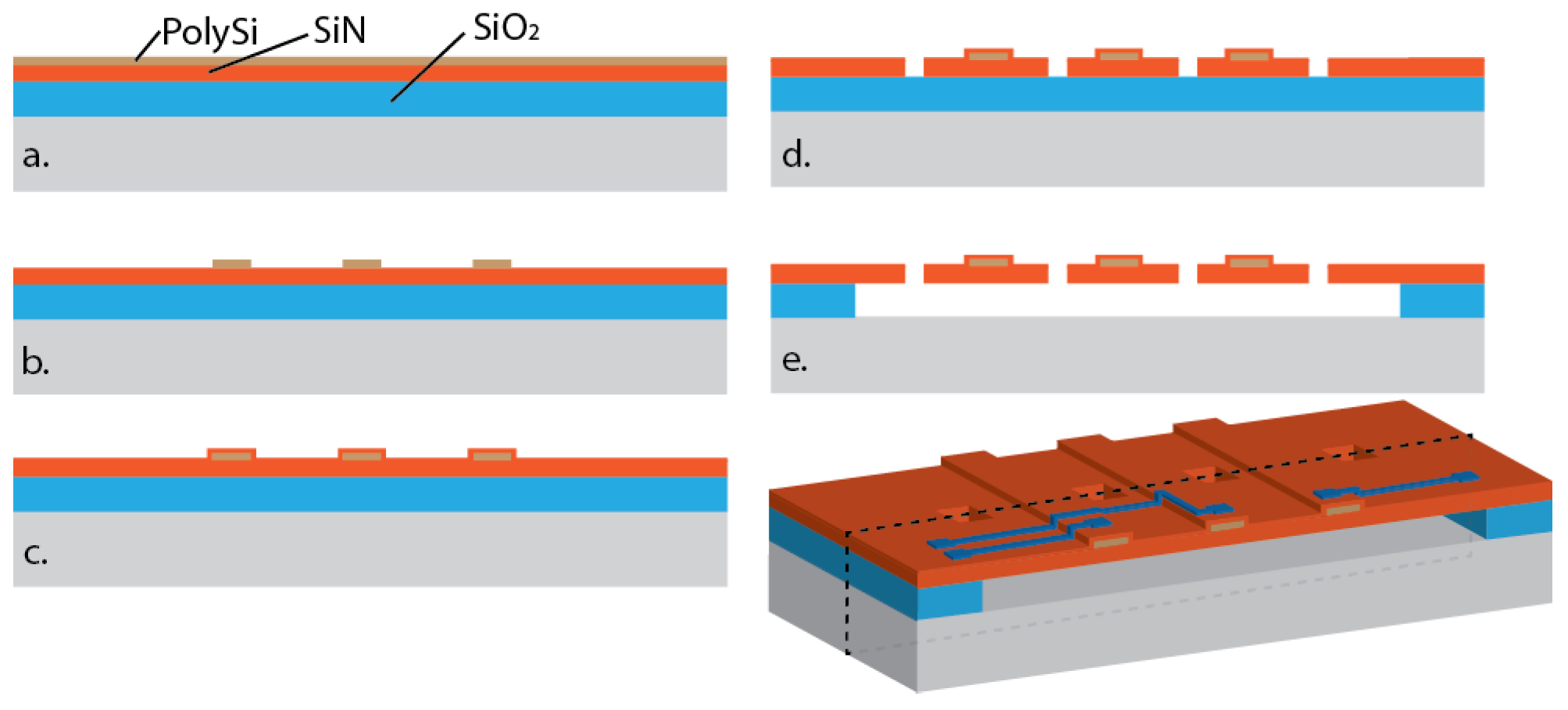

4. Fabrication Process

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Middelburg, L.M.; de Graaf, G.; Ghaderi, M.; Bossche, A.; Bastemeijer, J.; Visser, J.H.; Soltis, R.E.; Wolffenbuttel, R.F. Optical spectroscopy for biofuel composition sensing. Procedia Eng. 2016, 168, 55–58. [Google Scholar] [CrossRef]

- Park, B.K.; Yi, N.; Park, J.; Kim, D. Note: Development of a microfabricated sensor to measure thermal conductivity of picoliter scale liquid samples. Rev. Sci. Instrum. 2012, 83, 106102. [Google Scholar] [CrossRef] [PubMed]

- Yoshimitsu, Z.; Nakajima, A.; Watanabe, T.; Hashimoto, K. Effects of surface structure on the hydrophobicity and sliding behavior of water droplets. Langmuir 2002, 18, 5818–5822. [Google Scholar] [CrossRef]

- Gao, J.; Zhao, J.; Liu, L.; Xue, W. Dimensional effects of polymer pillar arrays on hydrophobicity. Surf. Eng. 2016, 32, 125–131. [Google Scholar] [CrossRef]

| Liquid | Thermal Cond. [W/(mK)] | Specific Heat Capacity [kJ/(kgK)] |

|---|---|---|

| Ethanol | 0.179 | 2.443 |

| Gasoline | 0.15 | 2.22 |

| Water | 0.58 | 4.182 |

| E85 | 0.175 | 2.41 |

| Air | 0.026 | 1.005 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, B.; Ghaderi, M.; Bossche, A.; Visser, J.H.; Wolffenbuttel, R.F. Microstructure for Thermal Impedance Spectroscopy for Biofuel Composition Measurement. Proceedings 2017, 1, 396. https://doi.org/10.3390/proceedings1040396

Jiang B, Ghaderi M, Bossche A, Visser JH, Wolffenbuttel RF. Microstructure for Thermal Impedance Spectroscopy for Biofuel Composition Measurement. Proceedings. 2017; 1(4):396. https://doi.org/10.3390/proceedings1040396

Chicago/Turabian StyleJiang, Bo, Mohammadamir Ghaderi, Andre Bossche, Jaco H. Visser, and Reinoud F. Wolffenbuttel. 2017. "Microstructure for Thermal Impedance Spectroscopy for Biofuel Composition Measurement" Proceedings 1, no. 4: 396. https://doi.org/10.3390/proceedings1040396

APA StyleJiang, B., Ghaderi, M., Bossche, A., Visser, J. H., & Wolffenbuttel, R. F. (2017). Microstructure for Thermal Impedance Spectroscopy for Biofuel Composition Measurement. Proceedings, 1(4), 396. https://doi.org/10.3390/proceedings1040396