Nanogap Pirani Sensor Operating in Constant Temperature Mode for Near Atmospheric Pressure Measurements †

Abstract

:1. Introduction

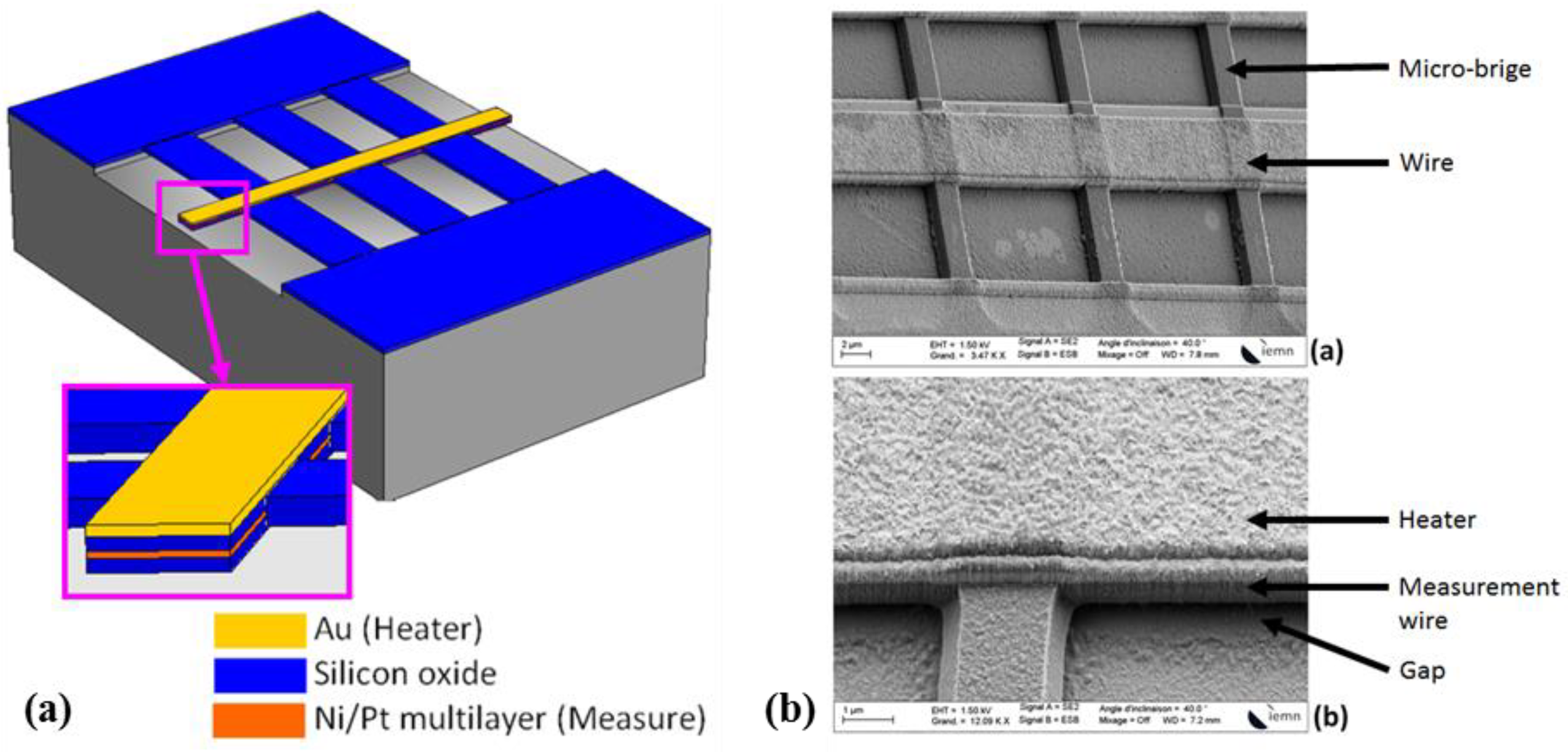

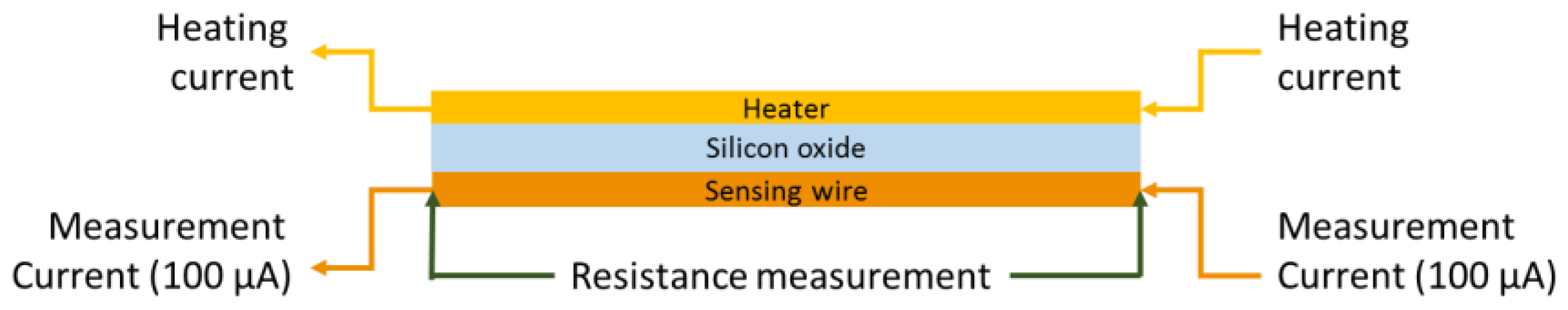

2. Sensor Design

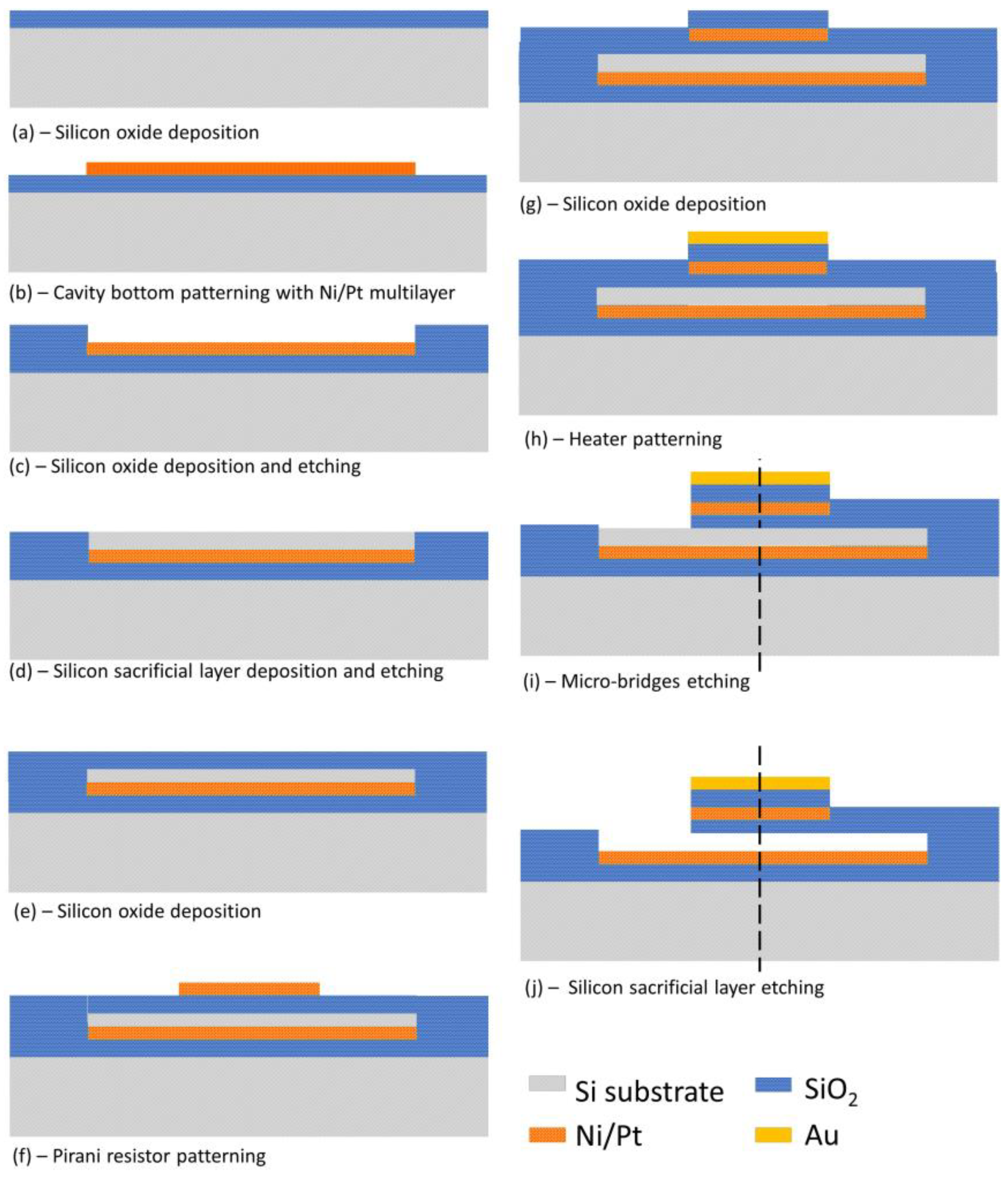

3. Fabrication Process

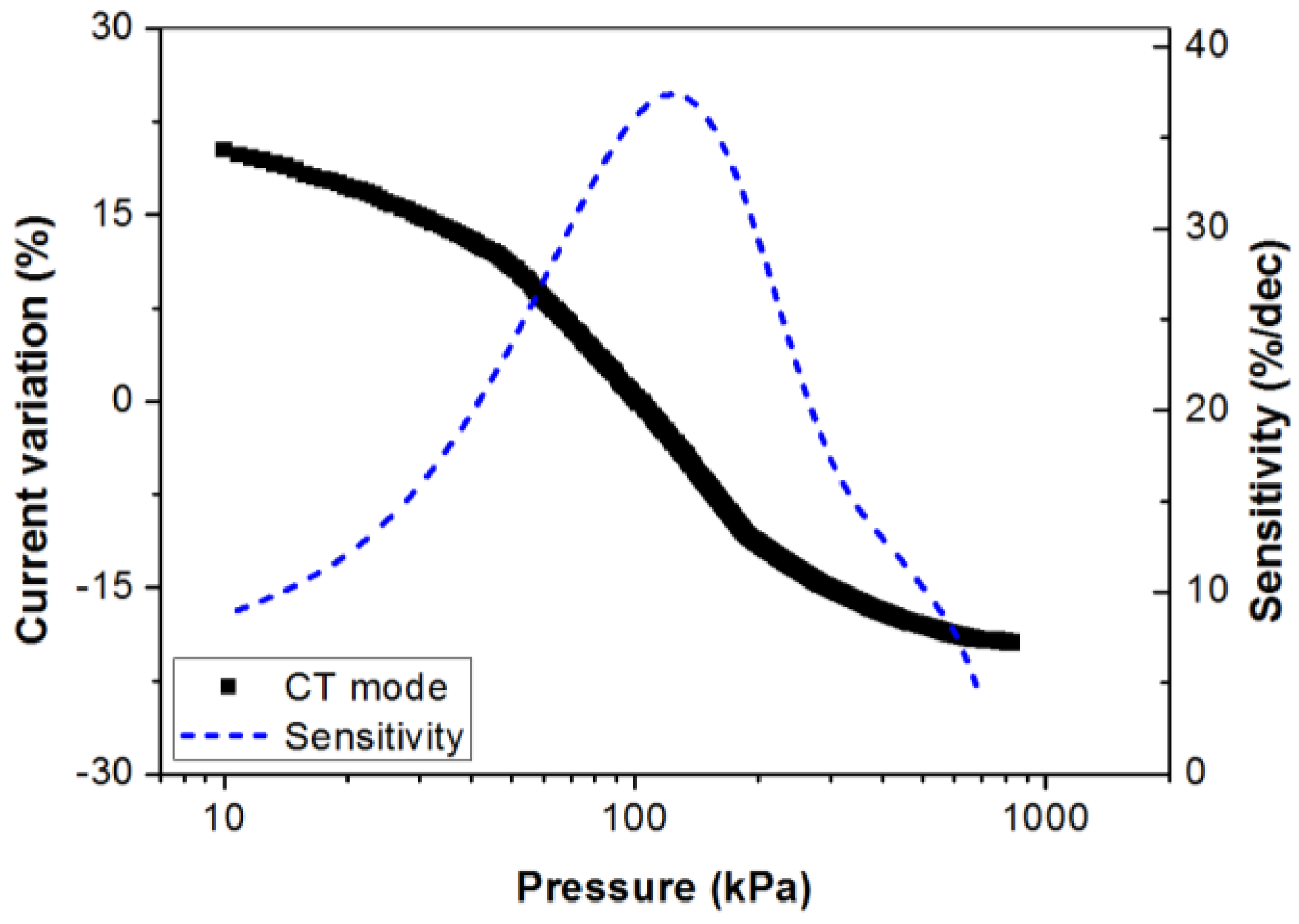

4. Characterizations in Pressurized Environment

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Zhang, F.T.; Tang, Z.; Yu, J.; Jin, R.C. A micro-Pirani vacuum gauge based on micro-hotplate technology. Sens. Actuators Phys. 2006, 126, 300–305. [Google Scholar] [CrossRef]

- Khosraviani, K.; Leung, A.M. The nanogap Pirani—A pressure sensor with superior linearity in an atmospheric pressure range. J. Micromech. Microeng. 2009, 19, 045007. [Google Scholar] [CrossRef]

- Brun, T.; Mercier, D.; Koumela, A.; Marcoux, C.; Duraffourg, L. Silicon nanowire based Pirani sensor for vacuum measurements. Appl. Phys. Lett. 2012, 101, 183506. [Google Scholar] [CrossRef]

- Claudel, J.; Ghouila-Houri, C.; Gerbedoen, J.C.; Gallas, Q.; Garnier, E.; Merlen, A.; Elmazria, O.; Viard, R.; Talbi, A.; Pernod, P. High Resolution Nano-gap Pirani Sensor for Pressure Measurement in Wide Dynamic Range Operation Around Atmospheric Pressure. Procedia Eng. 2016, 168, 798–801. [Google Scholar] [CrossRef]

- Puers, R.; Reyntjens, S.; De Bruyker, D. The NanoPirani—An extremely miniaturized pressure sensor fabricated by focused ion beam rapid prototyping. Sens. Actuators Phys. 2002, 97, 208–214. [Google Scholar] [CrossRef]

- Viard, R.; Talbi, A.; Merlen, A.; Pernod, P.; Frankiewicz, C.; Gerbedoen, J.C.; Preobrazhensky, V. A robust thermal microstructure for mass flow rate measurement in steady and unsteady flows. J. Micromech. Microeng. 2013, 23, 65016. [Google Scholar] [CrossRef]

- Ghouila-Houri, C.; Claudel, J.; Gerbedoen, J.C.; Gallas, Q.; Garnier, E.; Merlen, A.; Viard, R.; Talbi, A.; Pernod, P. Wall Shear Stress and Flow Direction Thermal MEMS Sensor for Separation Detection and Flow Control Applications. Procedia Eng. 2016, 168, 774–777. [Google Scholar] [CrossRef]

- Ghouila-Houri, C.; Claudel, J.; Gerbedoen, J.C.; Gallas, Q.; Garnier, E.; Merlen, A.; Viard, R.; Talbi, A.; Pernod, P. High temperature gradient micro-sensor for wall shear stress and flow direction measurements. Appl. Phys. Lett. 2016, 109, 241905. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghouila-Houri, C.; Sindjui, R.; Moutaouekkil, M.; Elmazria, O.; Gallas, Q.; Garnier, E.; Merlen, A.; Viard, R.; Talbi, A.; Pernod, P. Nanogap Pirani Sensor Operating in Constant Temperature Mode for Near Atmospheric Pressure Measurements. Proceedings 2017, 1, 377. https://doi.org/10.3390/proceedings1040377

Ghouila-Houri C, Sindjui R, Moutaouekkil M, Elmazria O, Gallas Q, Garnier E, Merlen A, Viard R, Talbi A, Pernod P. Nanogap Pirani Sensor Operating in Constant Temperature Mode for Near Atmospheric Pressure Measurements. Proceedings. 2017; 1(4):377. https://doi.org/10.3390/proceedings1040377

Chicago/Turabian StyleGhouila-Houri, Cécile, Ralph Sindjui, Mohammed Moutaouekkil, Omar Elmazria, Quentin Gallas, Eric Garnier, Alain Merlen, Romain Viard, Abdelkrim Talbi, and Philippe Pernod. 2017. "Nanogap Pirani Sensor Operating in Constant Temperature Mode for Near Atmospheric Pressure Measurements" Proceedings 1, no. 4: 377. https://doi.org/10.3390/proceedings1040377

APA StyleGhouila-Houri, C., Sindjui, R., Moutaouekkil, M., Elmazria, O., Gallas, Q., Garnier, E., Merlen, A., Viard, R., Talbi, A., & Pernod, P. (2017). Nanogap Pirani Sensor Operating in Constant Temperature Mode for Near Atmospheric Pressure Measurements. Proceedings, 1(4), 377. https://doi.org/10.3390/proceedings1040377