High Gauge Factor Piezoresistors Using Aluminium Induced Crystallisation of Silicon at Low Thermal Budget †

Abstract

:1. Introduction

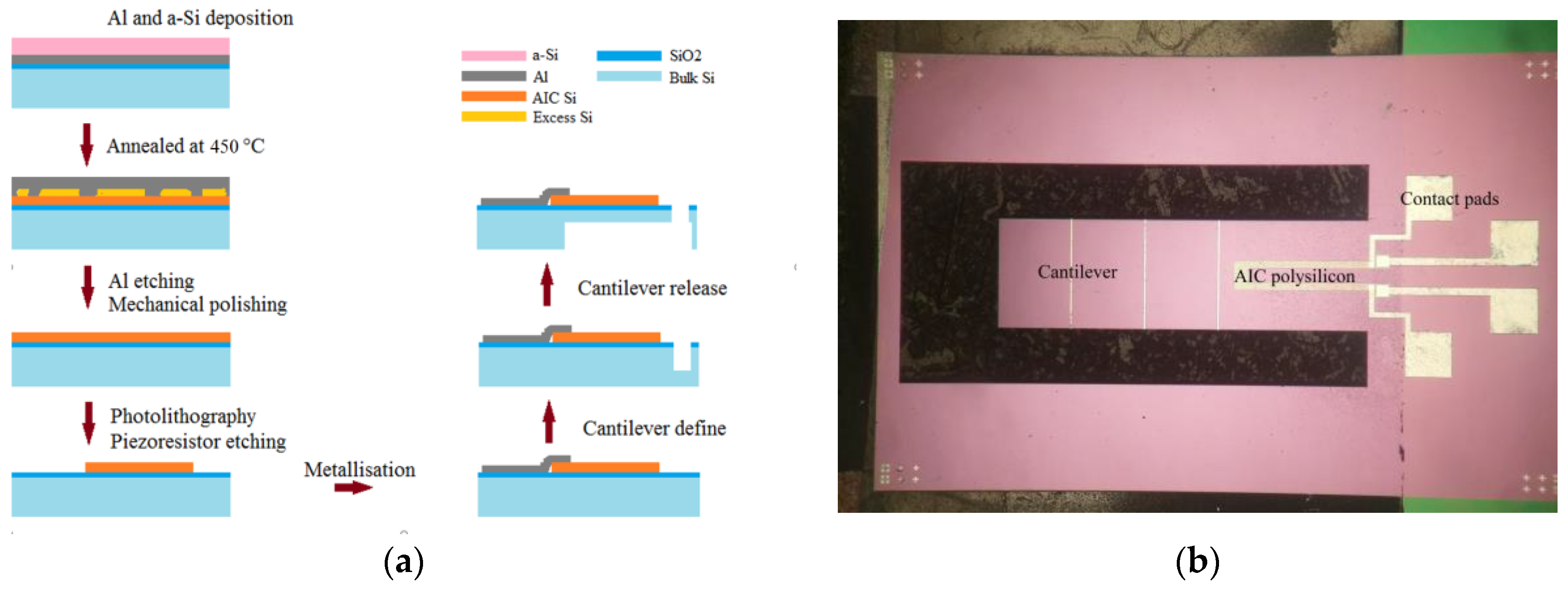

2. Experiment

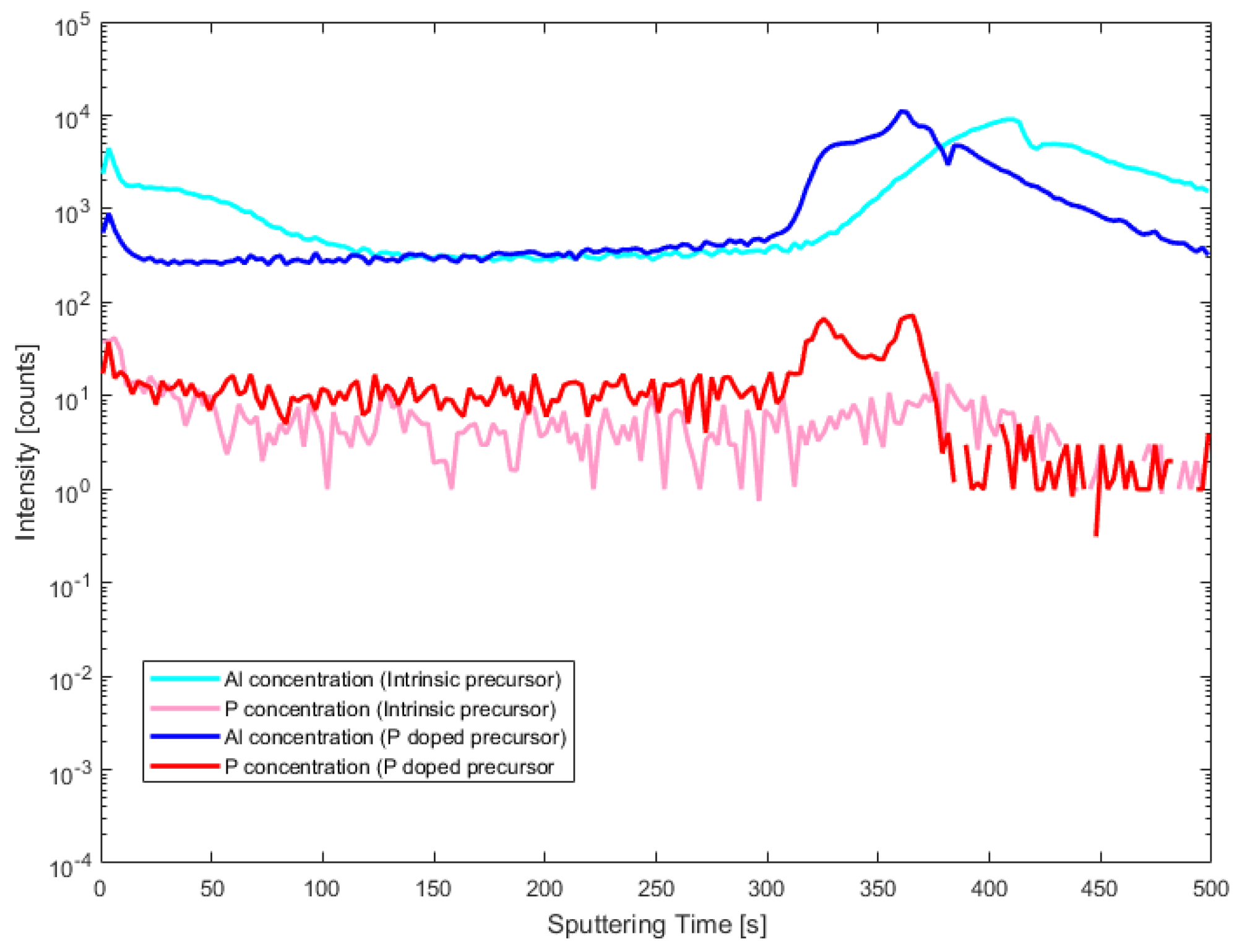

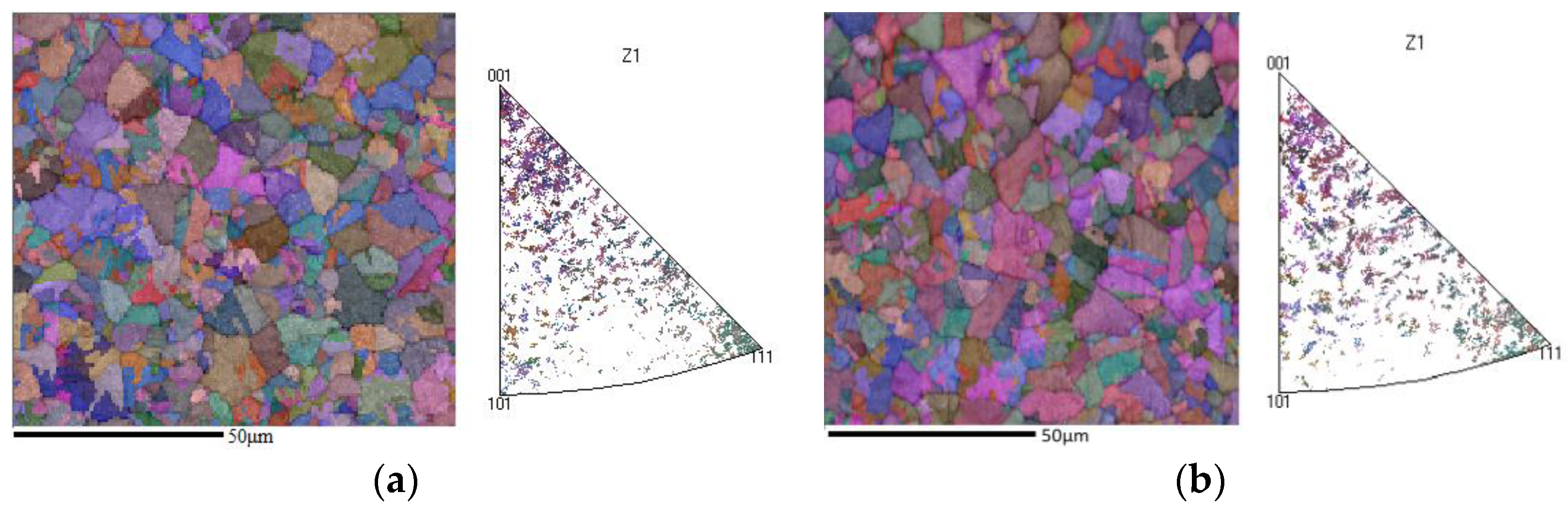

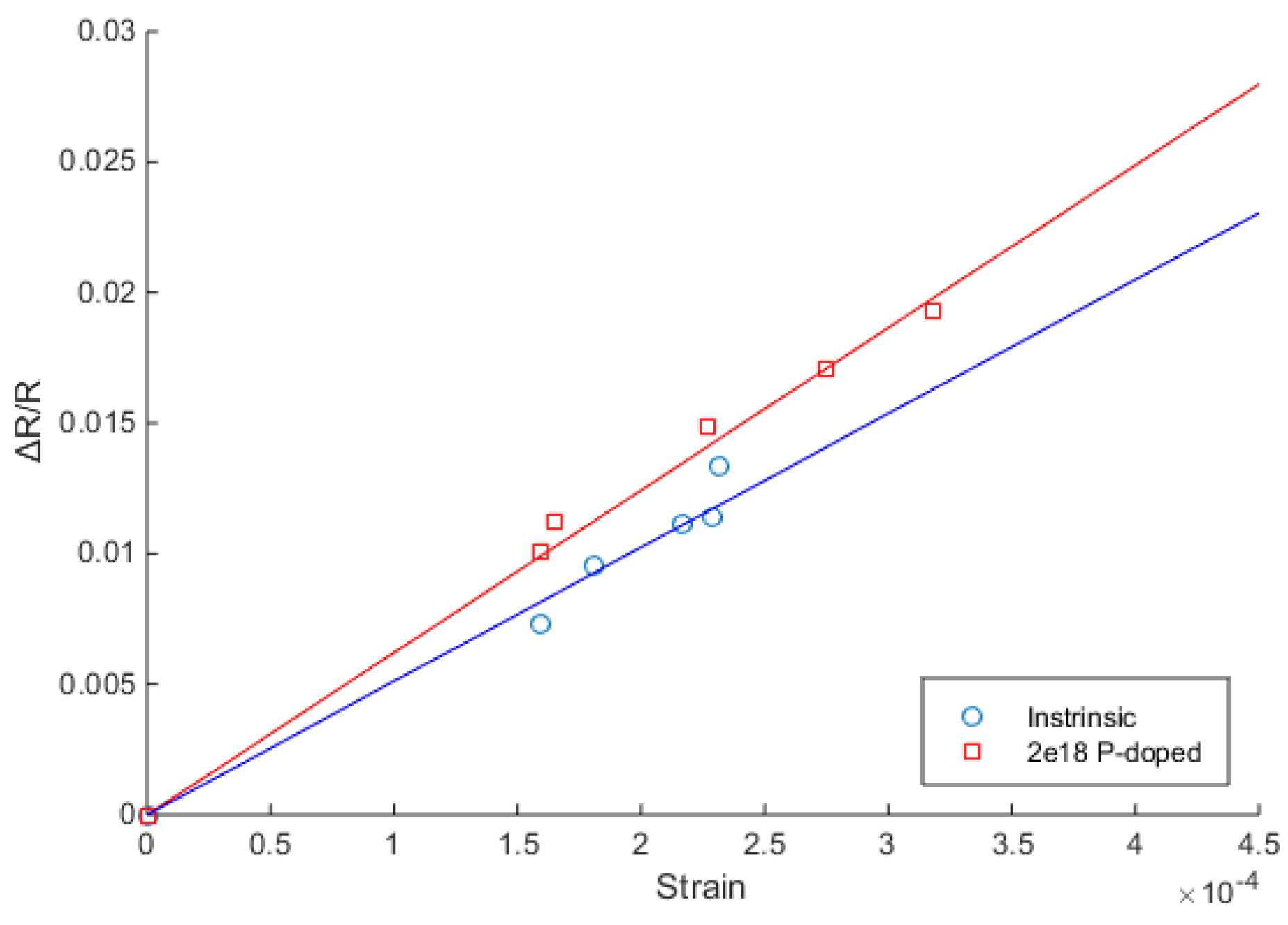

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Nast, O.; Wenham, S.R. Elucidation of the layer exchange mechanism in the formation of polycrystalline silicon by aluminum-induced crystallization. J. Appl. Phys. 2000, 88, 124–132. [Google Scholar] [CrossRef]

- Uhlig, S.; Rau, S.; Schultes, G. Piezoresistivity of polycrystalline silicon applying the AIC process-route. Sens. Actuators A Phys. 2011, 172, 447–454. [Google Scholar] [CrossRef]

- Patil, S.K.; Çelik-Butler, Z.; Butler, D.P. Piezoresistive polysilicon film obtained by low-temperature aluminum-induced crystallization. Thin Solid Films 2010, 519, 479–486. [Google Scholar] [CrossRef]

- French, P.J.; Evans, A.G.R. Piezoresistance in polysilicon and its applications to strain gauges. Solid State Electron. 1989, 32, 1–10. [Google Scholar] [CrossRef]

| Doping | Intrinsic | 2 × 1018/cm3 |

|---|---|---|

| Sheet Resistance [Ω/sq] | 686 | 840 |

| Doping | Intrinsic | 2 × 1018/cm3 |

|---|---|---|

| Gauge Factor | 52 | 62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chuang, I.; Michael, A.; Kwok, C.Y. High Gauge Factor Piezoresistors Using Aluminium Induced Crystallisation of Silicon at Low Thermal Budget. Proceedings 2017, 1, 354. https://doi.org/10.3390/proceedings1040354

Chuang I, Michael A, Kwok CY. High Gauge Factor Piezoresistors Using Aluminium Induced Crystallisation of Silicon at Low Thermal Budget. Proceedings. 2017; 1(4):354. https://doi.org/10.3390/proceedings1040354

Chicago/Turabian StyleChuang, Ian, Aron Michael, and Chee Yee Kwok. 2017. "High Gauge Factor Piezoresistors Using Aluminium Induced Crystallisation of Silicon at Low Thermal Budget" Proceedings 1, no. 4: 354. https://doi.org/10.3390/proceedings1040354

APA StyleChuang, I., Michael, A., & Kwok, C. Y. (2017). High Gauge Factor Piezoresistors Using Aluminium Induced Crystallisation of Silicon at Low Thermal Budget. Proceedings, 1(4), 354. https://doi.org/10.3390/proceedings1040354