Multiresonator-Based Printable Chipless RFID for Relative Humidity Sensing †

Abstract

:1. Introduction

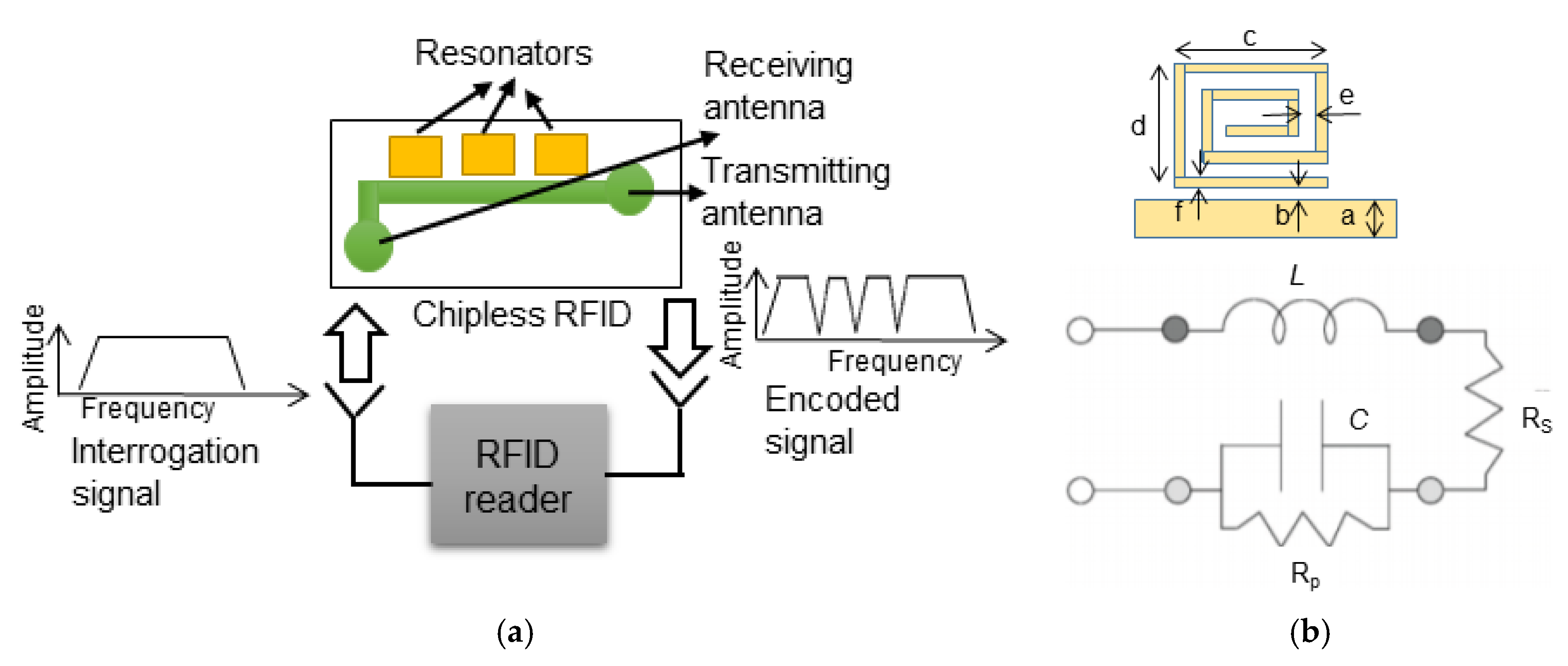

2. Operation

2.1. Multiresonator Based Chipless RFID System

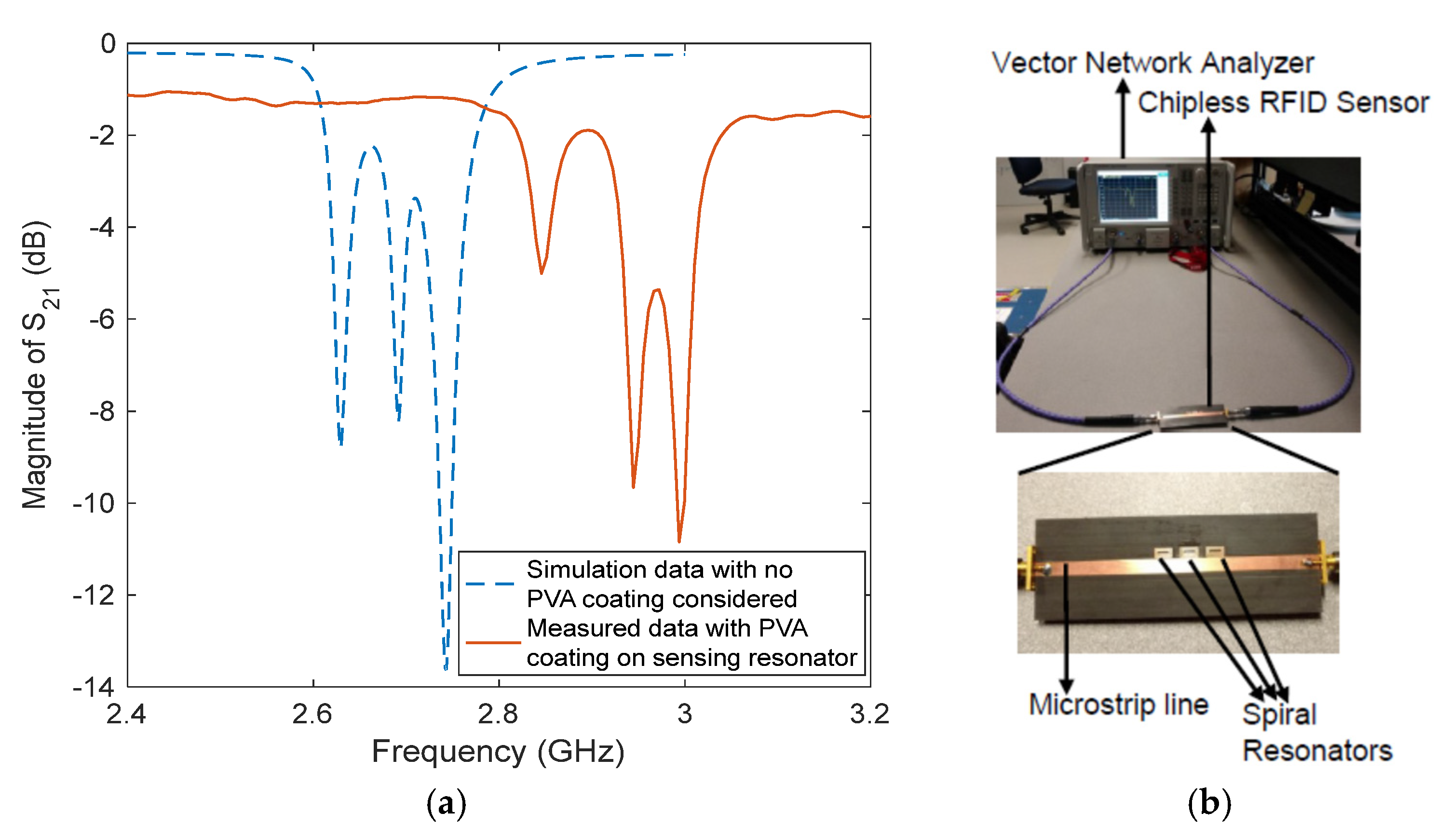

2.2. Multiresonator Humidity Sensing

3. Simulation and Results

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Shibata, H.; Ito, M.; Asakursa, M.; Watanabe, K. A digital hygrometer using a polyimide film relative humidity sensor. IEEE Trans. Instrum. Meas. 1996, 45, 564–569. [Google Scholar] [CrossRef]

- Amin, E.M.; Karmakar, N. Development of a chipless RFID temperature sensor using cascaded spiral resonators. IEEE Sens. Proc. 2001, 554–557. [Google Scholar] [CrossRef]

- Buff, W.; Klett, S.; Rusko, M.; Ehrenpfordt, J.; Goroli, M. Passive remote sensing for temperature and pressure using SAW resonator devices. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1998, 45, 1388–1392. [Google Scholar] [CrossRef]

- Schueler, M.; Mandel, C.; Puentes, M.; Jakoby, R. Metamaterial inspired microwave sensors. IEEE Microw. Mag. 2012, 13, 57–68. [Google Scholar] [CrossRef]

| Parameters (mm) | Resonator 1 | Resonator 2 | Resonator 3 |

|---|---|---|---|

| a | 4.86 | 4.86 | 4.86 |

| b | 0.28 | 0.28 | 0.28 |

| c | 6 | 6.1 | 6.2 |

| d | 3.4 | 3.4 | 3.4 |

| e | 0.3 | 0.3 | 0.3 |

| f | 0.3 | 0.3 | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dominic, D.; Krafft, S.; Safdari, N.; Bhadra, S. Multiresonator-Based Printable Chipless RFID for Relative Humidity Sensing. Proceedings 2017, 1, 367. https://doi.org/10.3390/proceedings1040367

Dominic D, Krafft S, Safdari N, Bhadra S. Multiresonator-Based Printable Chipless RFID for Relative Humidity Sensing. Proceedings. 2017; 1(4):367. https://doi.org/10.3390/proceedings1040367

Chicago/Turabian StyleDominic, Daniel, Simon Krafft, Naeem Safdari, and Sharmistha Bhadra. 2017. "Multiresonator-Based Printable Chipless RFID for Relative Humidity Sensing" Proceedings 1, no. 4: 367. https://doi.org/10.3390/proceedings1040367

APA StyleDominic, D., Krafft, S., Safdari, N., & Bhadra, S. (2017). Multiresonator-Based Printable Chipless RFID for Relative Humidity Sensing. Proceedings, 1(4), 367. https://doi.org/10.3390/proceedings1040367