Angle Measurement and 3D Magnetic Field Sensing Using Circular Hall Microsensor †

Abstract

:1. Introduction

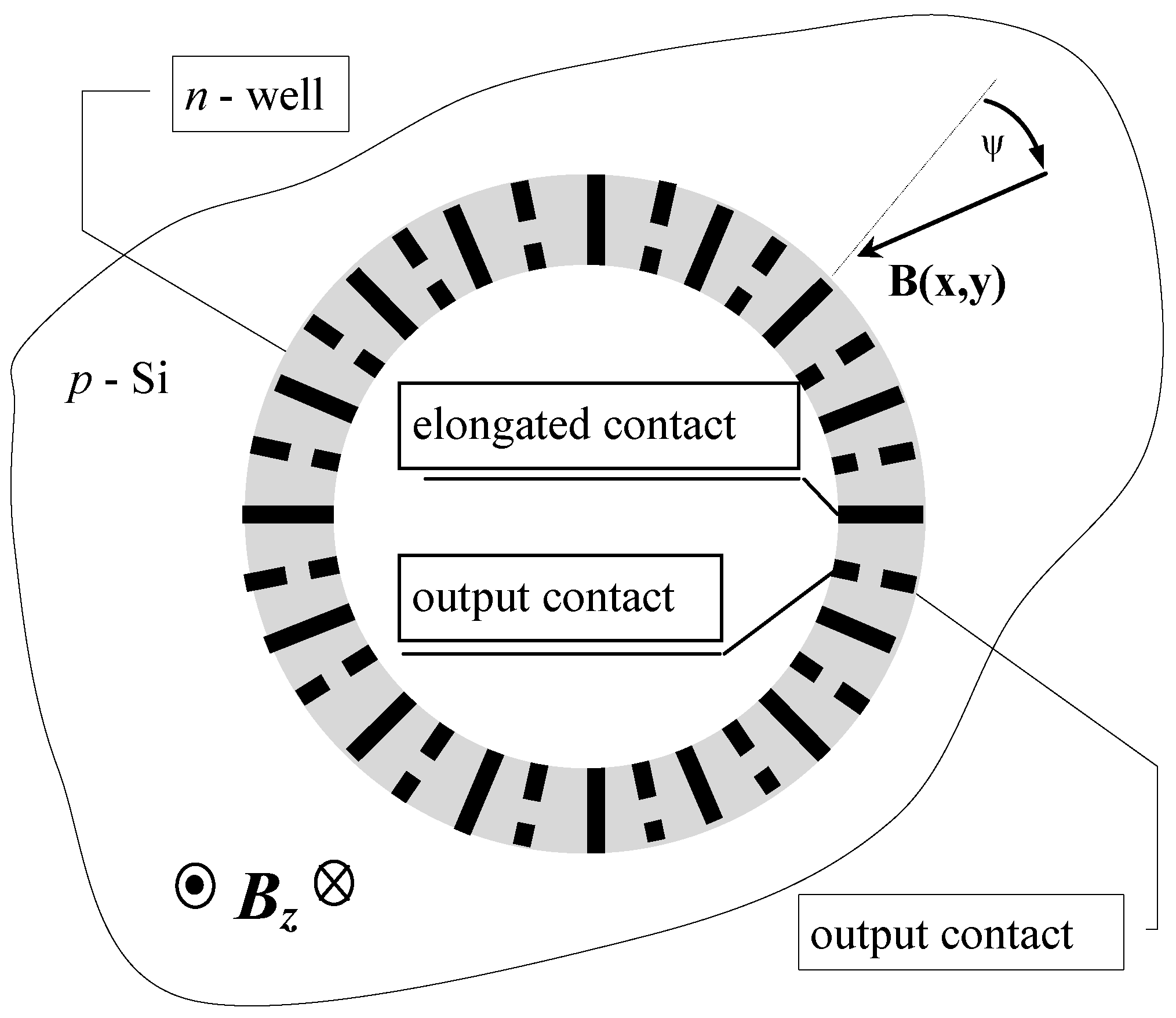

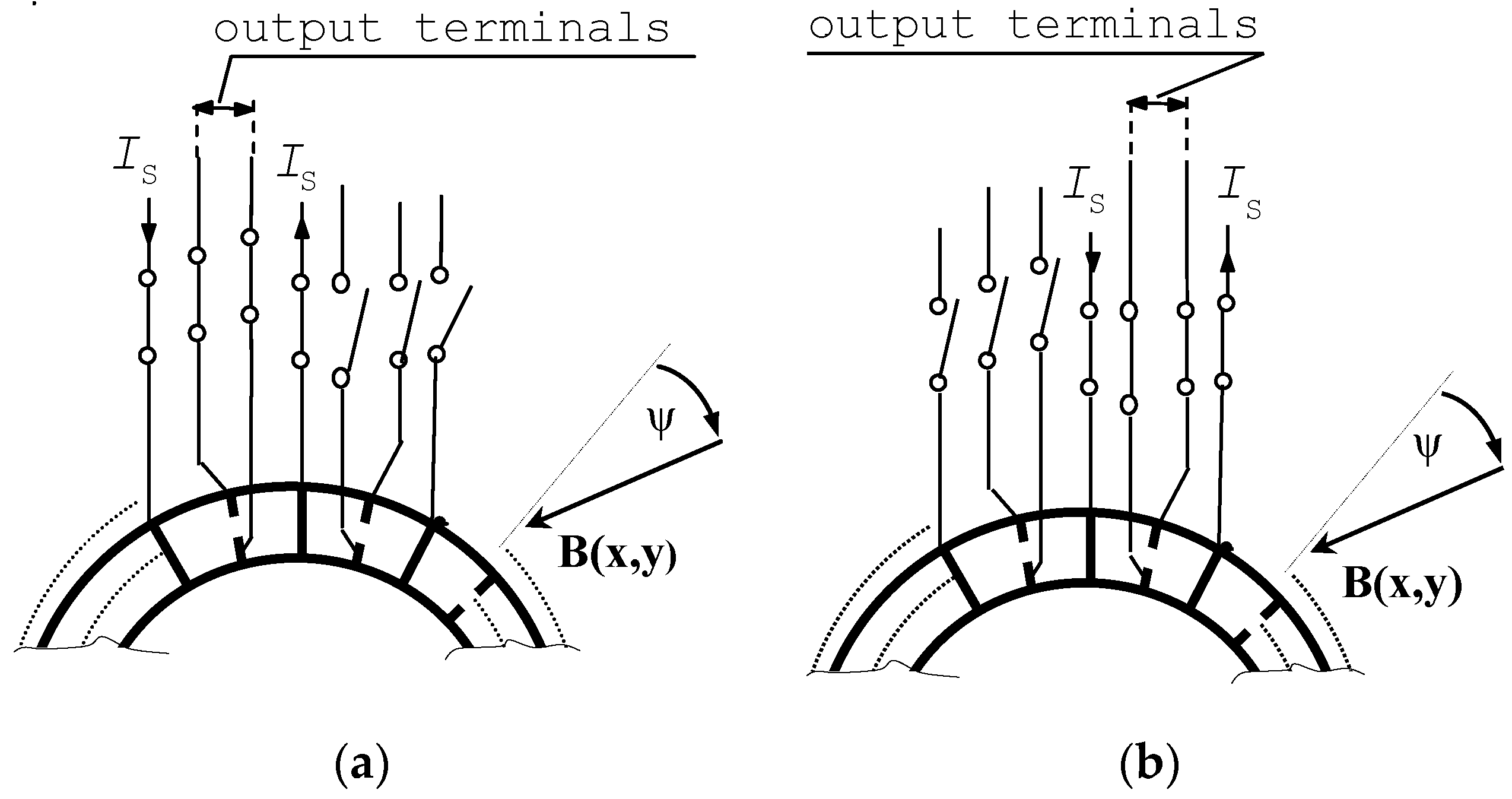

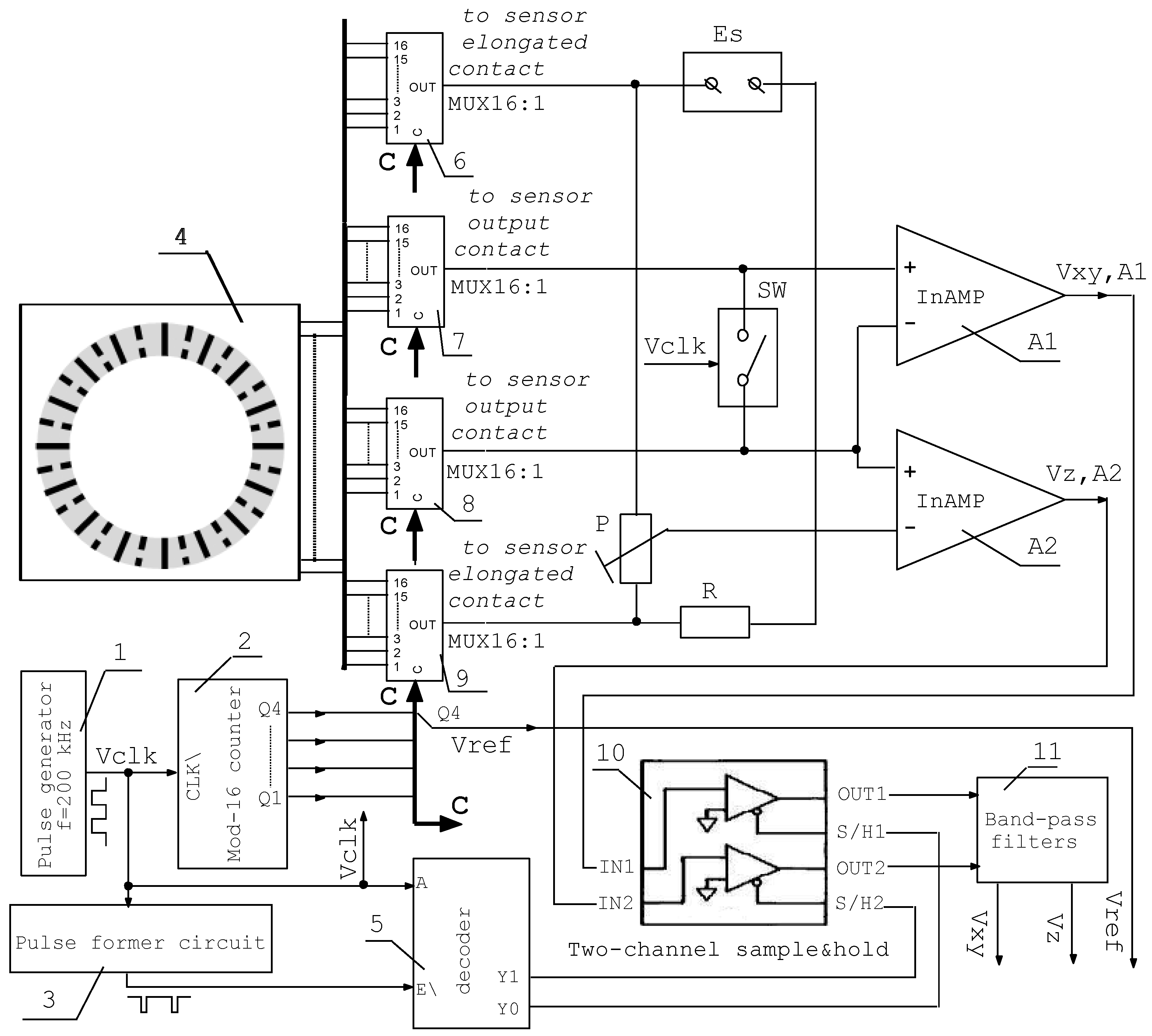

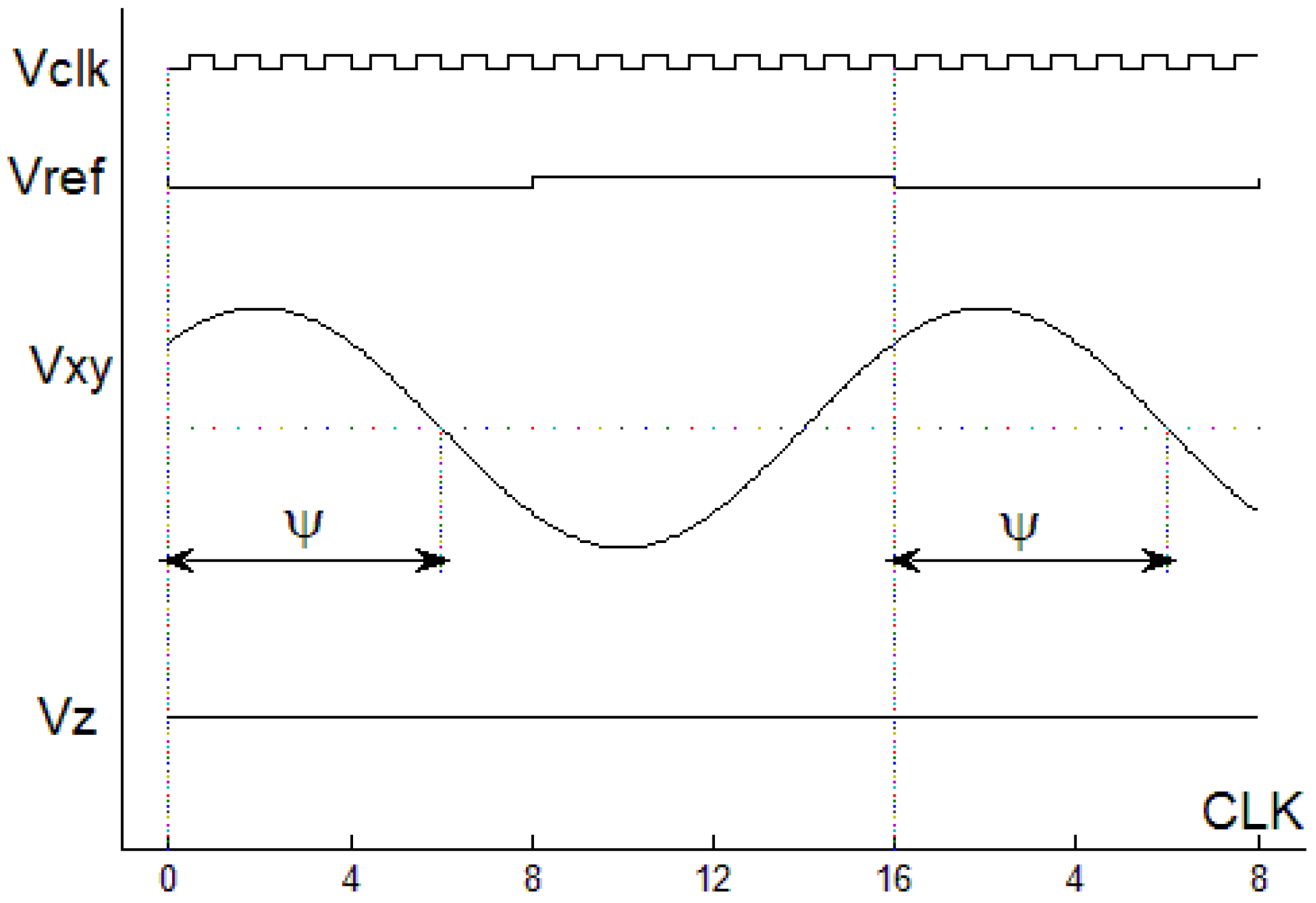

2. Realization and Working Principle of the Magnitometer

3. Experimental Results and Conclusions

Acknowledgments

Conflicts of Interest

References

- Paranjape, M.; Ristic, L.; Allegretto, W. Simulation, design and fabrication of a vertical Hall device for two-dimensional magnetic field sensing. Sens. Mater. 1993, 42, 91–101. [Google Scholar]

- Roumenin, C. Microsensors for magnetic field (Chapter 9). In MEMS—A Practical Guide to Design, Analysis and Applications; Korvink, J., Paul, O., Eds.; William Andrew Publishing: Norwich, NY, USA, 2006; pp. 453–523. ISBN 0-8155-1497-2. [Google Scholar]

- Banjevic, M.; Furrer, B.; Popovic, R. 2D CMOS integrated magnetometer based on the miniaturized circular vertical hall device. In Proceedings of the Transducers 2009, Denver, CO, USA, 21–25 June 2009; pp. 877–880. [Google Scholar]

- Kejik, P.; Reymond, S.; Popovic, R. Circular Hall transducer for angular position sensing. In Proceedings of the Transducers ′07 & Eurosensors XXI: The 14th International Conference on Solid-State Sensors, Actuators, and Microsystems, Cité I Centre des Congrès, Lyon, France, 10–14 June 2007; Digest of Technical Paper. Volume 2, pp. 2593–2596. [Google Scholar]

- Noykov, S.; Lozanova, S.; Roumenin, C. Two-axis magnetometer using a circular parallel-field Hall microsensor for contactless angle measurement. Electron. Lett. 2010, 46, 1130–1132. [Google Scholar] [CrossRef]

- Lozanova, S.; Noykov, S.; Roumenin, C. 2-D semiconductor magnitometer. Regist. Bulg. Pat. Appl. N 112109/07.10.2015.

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lozanova, S.; Noykov, S.; Ivanov, A.; Roumenin, C. Angle Measurement and 3D Magnetic Field Sensing Using Circular Hall Microsensor. Proceedings 2017, 1, 330. https://doi.org/10.3390/proceedings1040330

Lozanova S, Noykov S, Ivanov A, Roumenin C. Angle Measurement and 3D Magnetic Field Sensing Using Circular Hall Microsensor. Proceedings. 2017; 1(4):330. https://doi.org/10.3390/proceedings1040330

Chicago/Turabian StyleLozanova, S., S. Noykov, A. Ivanov, and C. Roumenin. 2017. "Angle Measurement and 3D Magnetic Field Sensing Using Circular Hall Microsensor" Proceedings 1, no. 4: 330. https://doi.org/10.3390/proceedings1040330

APA StyleLozanova, S., Noykov, S., Ivanov, A., & Roumenin, C. (2017). Angle Measurement and 3D Magnetic Field Sensing Using Circular Hall Microsensor. Proceedings, 1(4), 330. https://doi.org/10.3390/proceedings1040330