Thermoelectric Measurement of a Single, TiO2-Catalyzed Bi2Te3 Nanowire †

Abstract

:1. Introduction and Motivation

2. Bismuth Telluride Nanowires

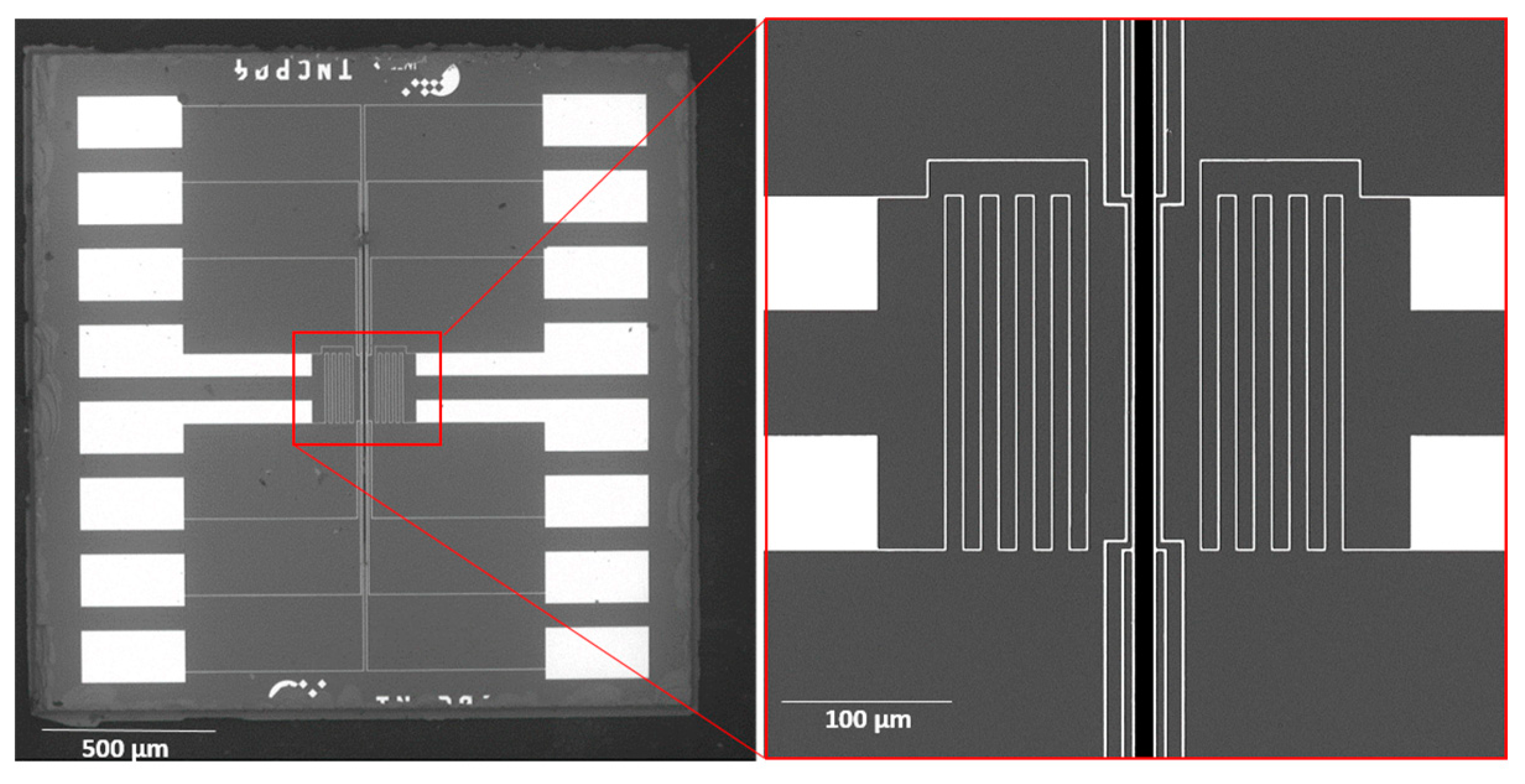

3. Characterization Platform

- Late processed platform: In this case the platform is realized around a selected nanowire that has been deposited onto a suitable substrate [7]. This approach benefits from different aspects, such as a good contact between the nanowire and connecting electrodes. Yet, this concept does not allow for the distribution of measurement chips.

- Early processed platform: Here, the platform is batch-fabricated first and the nanowires are integrated afterwards [8]. This approach provides a true “hand-out” measurement chip which can be used for different nanowire studies. Also the nanowire assembled on this chip will remain intact and unmodified as it does not expose to the platform fabrication process.

4. Experimental Analysis

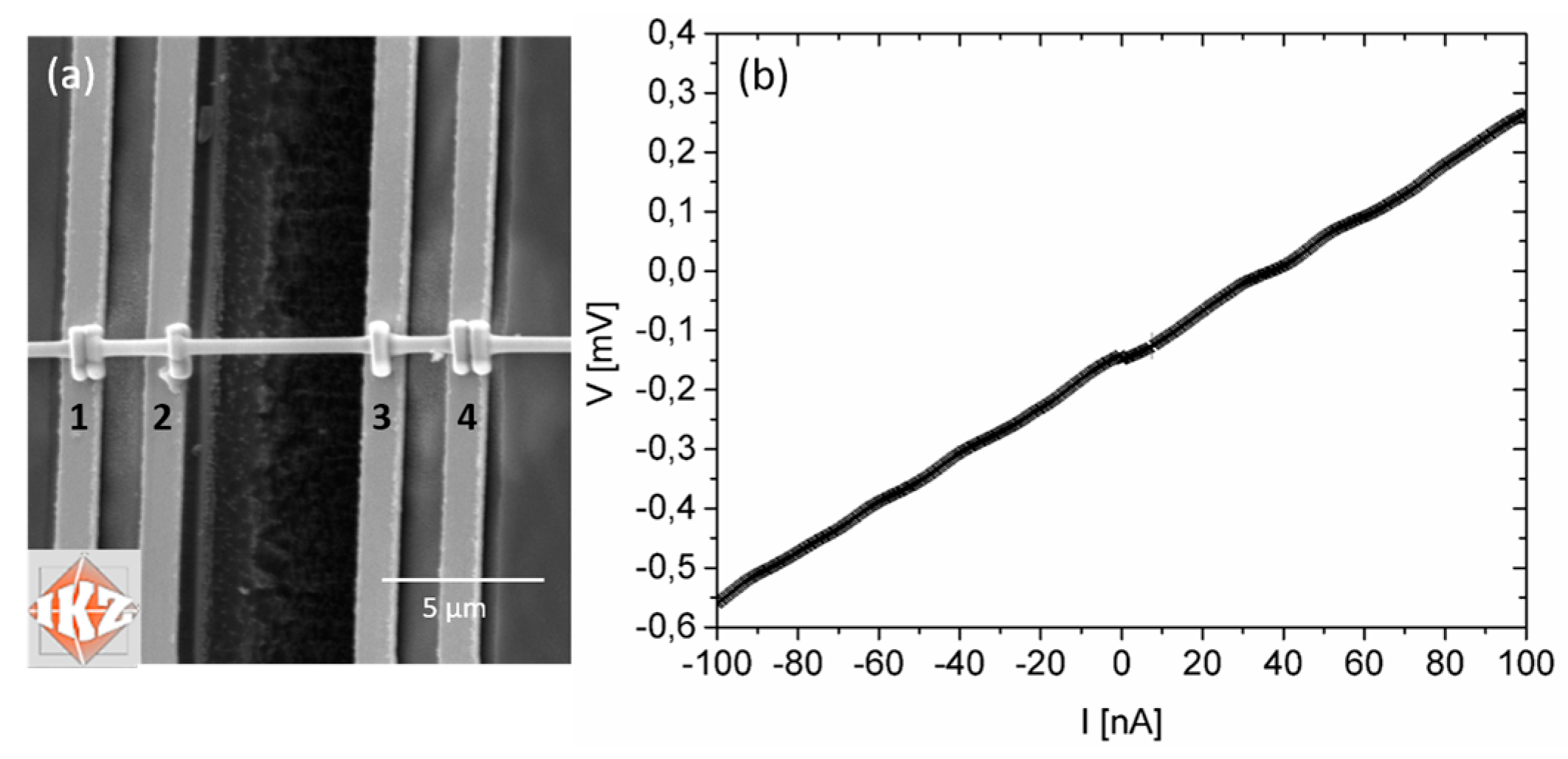

4.1. Nanowire Assembly and Contacting

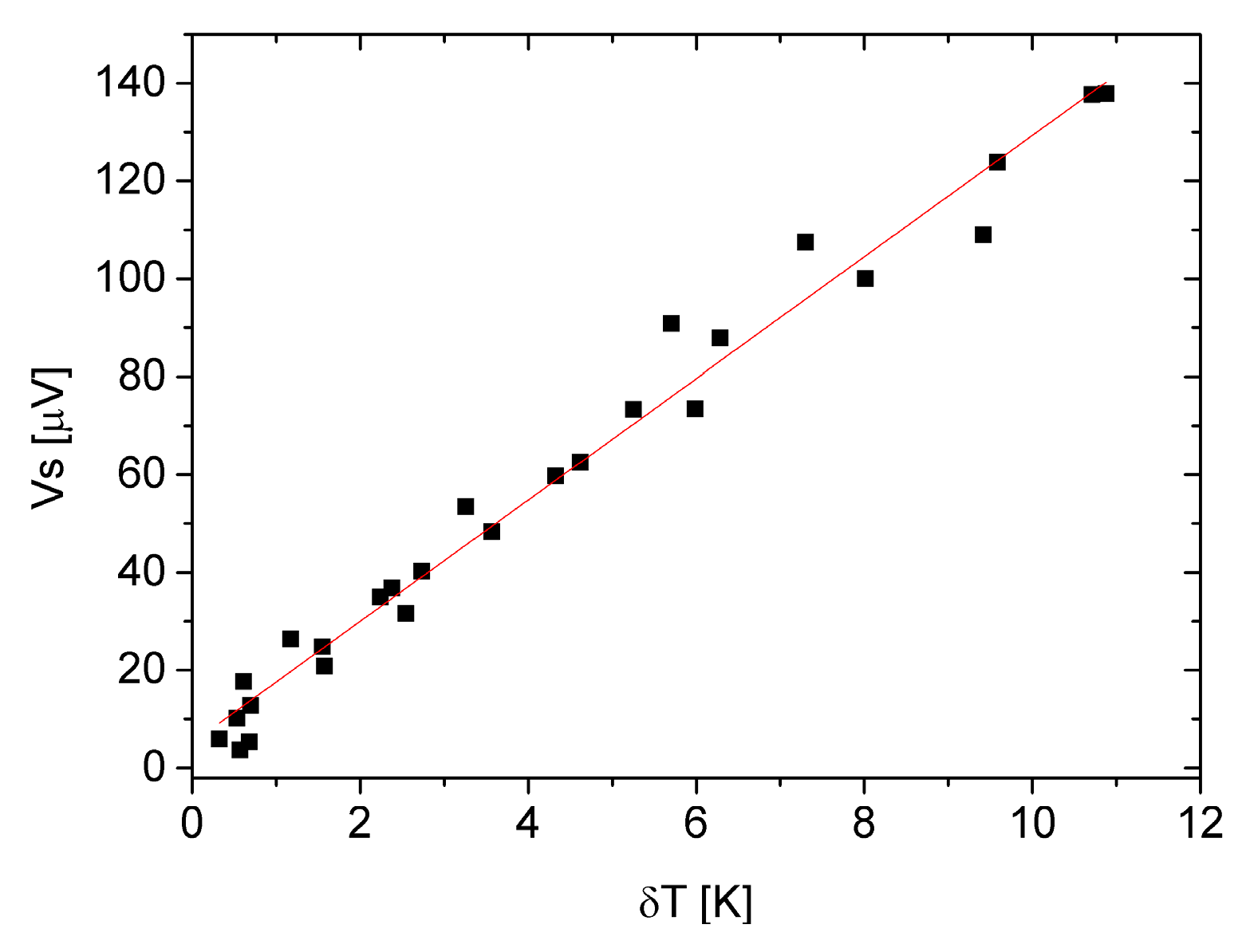

4.2. Seebeck Measurement

5. Discussion and Conclusions

Acknowledgments

Conflicts of Interest

References

- Hicks, L.D.; Dresselhaus, M.S. Thermoelectric figure of merit of a one-dimensional conductor. Phys. Rev. B 1993, 47, 16631–16634. [Google Scholar] [CrossRef] [PubMed]

- Eibl, O.; Nielsch, K.; Peranio, N.; Volklei, F. Thermoelectric Bi2Te3 Nanomaterials; Wiley: Weinheim, Germany, 2015. [Google Scholar]

- Jin, C.; Xiang, X.; Jia, C.; Liu, W.; Cai, W.; Yao, L.; Li, X. Electrochemical fabrication of large-area, ordered Bi2Te3 nanowire arrays. J. Phys. Chem. B 2004, 108, 1844–1847. [Google Scholar] [CrossRef]

- Hamdou, B.; Beckstedt, A.; Kimling, J.; Dorn, A.; Akinsinde, L.; Bäßler, S.; Nielsch, K. The influence of a Te-depleted surface on the thermoelectric transport properties of Bi2Te3 nanowires. Nanotechnology 2014, 25, 365401. [Google Scholar] [CrossRef] [PubMed]

- Schoenherr, P.; Zhang, F.; Kojda, D.; Mitdank, R.; Albrecht, M.; Fischer, S.F.; Hesjedal, T. Free-standing millimetre-long Bi2Te3 sub-micron belts catalyzed by TiO2 nanoparticles. Nanoscale Res. Lett. 2016, 11, 308. [Google Scholar] [CrossRef] [PubMed]

- Kojda, D.; Mitdank, R.; Handwerg, M.; Mogilatenko, A.; Albrecht, M.; Wang, Z.; Ruhhammer, J.; Kroener, M.; Woias, P.; Fischer, S.F. Temperature-dependent thermoelectric properties of individual silver nanowires. Phys. Rev. B 2015, 91, 24302. [Google Scholar] [CrossRef]

- Shapira, E.; Tsukernik, A.; Selzer, Y. Thermopower measurements on individual 30 nm nickel nanowires. Nanotechnology 2007, 18, 485703. [Google Scholar] [CrossRef]

- Wang, Z.; Moosavi, S.H.; Kroener, M.; Woias, P. Development of a Thermoelectric Nanowire Characterization Platform (TNCP) for Structural and Thermoelectric Investigation of Single Nanowires. In Thermoelectric Bi2Te3 Nanomaterials; Eibl, O., Nielsch, K., Peranio, N., Voelklein, F., Eds.; Wiley: Weinheim, Germany, 2015; pp. 253–281. [Google Scholar]

- Moosavi, S.H.; Kroener, M.; Woias, P. Cost effective MEMS fabrication of a nanowire characterization platform with solder coated electrodes. Sens. Actuators A Phys. 2016, 246, 140–147. [Google Scholar] [CrossRef]

- Beckstedt, A. Thermoelektrische Charakterisierung von Einkristallinen BiTe-Nanodrähten Thermoelectric Characterization of Single-Crystalline BiTe Nanowires; Hamburg University: Hamburg, Germany, 2013. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moosavi, S.H.; Kojda, D.; Kockert, M.; Schoenherr, P.; Hesjedal, T.; Fischer, S.F.; Kroener, M.; Woias, P. Thermoelectric Measurement of a Single, TiO2-Catalyzed Bi2Te3 Nanowire. Proceedings 2017, 1, 311. https://doi.org/10.3390/proceedings1040311

Moosavi SH, Kojda D, Kockert M, Schoenherr P, Hesjedal T, Fischer SF, Kroener M, Woias P. Thermoelectric Measurement of a Single, TiO2-Catalyzed Bi2Te3 Nanowire. Proceedings. 2017; 1(4):311. https://doi.org/10.3390/proceedings1040311

Chicago/Turabian StyleMoosavi, S. Hoda, Danny Kojda, Maximilian Kockert, Piet Schoenherr, Thorsten Hesjedal, Saskia F. Fischer, Michael Kroener, and Peter Woias. 2017. "Thermoelectric Measurement of a Single, TiO2-Catalyzed Bi2Te3 Nanowire" Proceedings 1, no. 4: 311. https://doi.org/10.3390/proceedings1040311

APA StyleMoosavi, S. H., Kojda, D., Kockert, M., Schoenherr, P., Hesjedal, T., Fischer, S. F., Kroener, M., & Woias, P. (2017). Thermoelectric Measurement of a Single, TiO2-Catalyzed Bi2Te3 Nanowire. Proceedings, 1(4), 311. https://doi.org/10.3390/proceedings1040311