The Evaluation of a Novel Denitrifying Woodchip Bioreactor: Fairmont, MN, USA

Abstract

1. Introduction

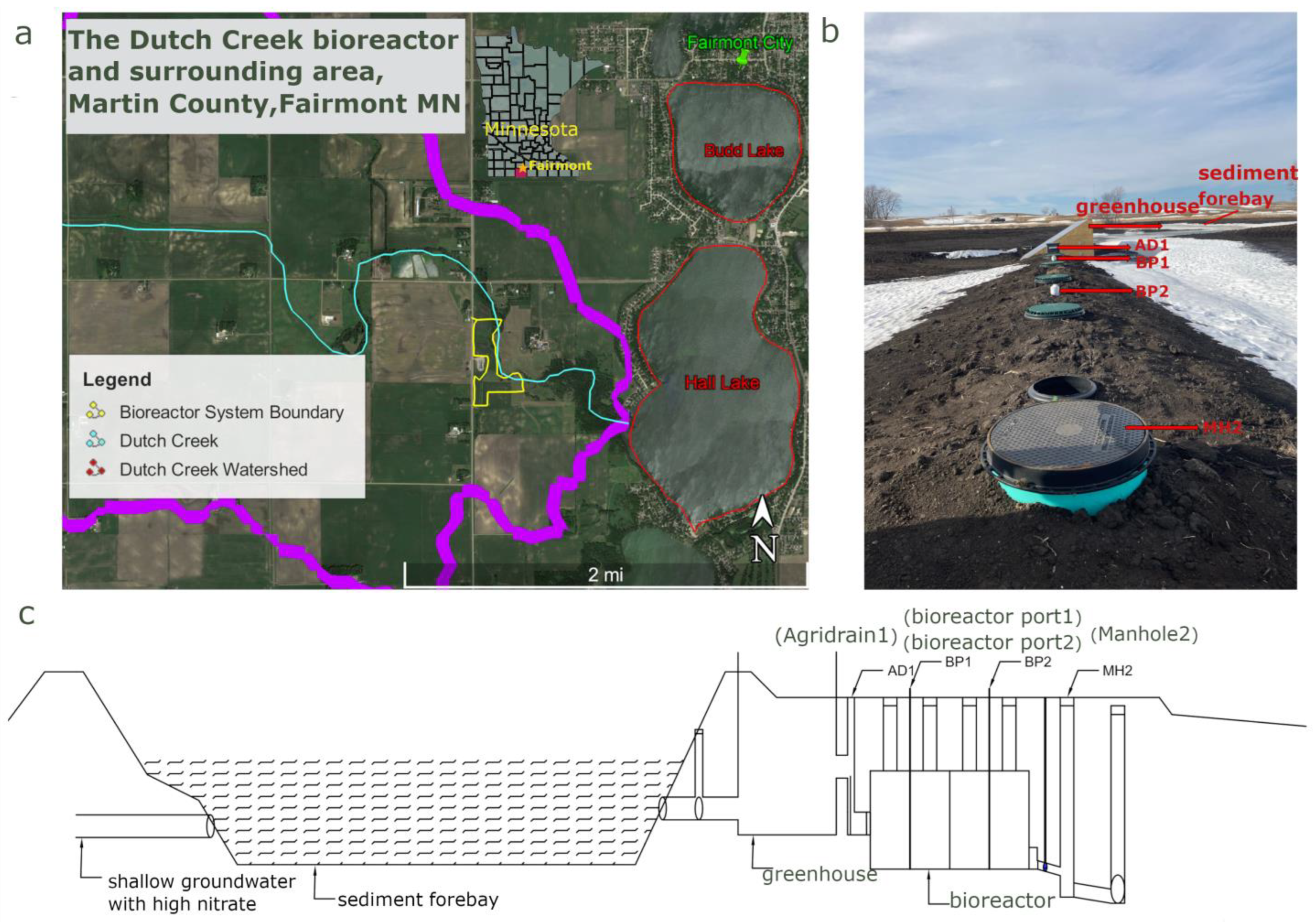

2. Materials and Methods

2.1. Temperature

2.2. Water Depth

2.3. Flow Rates

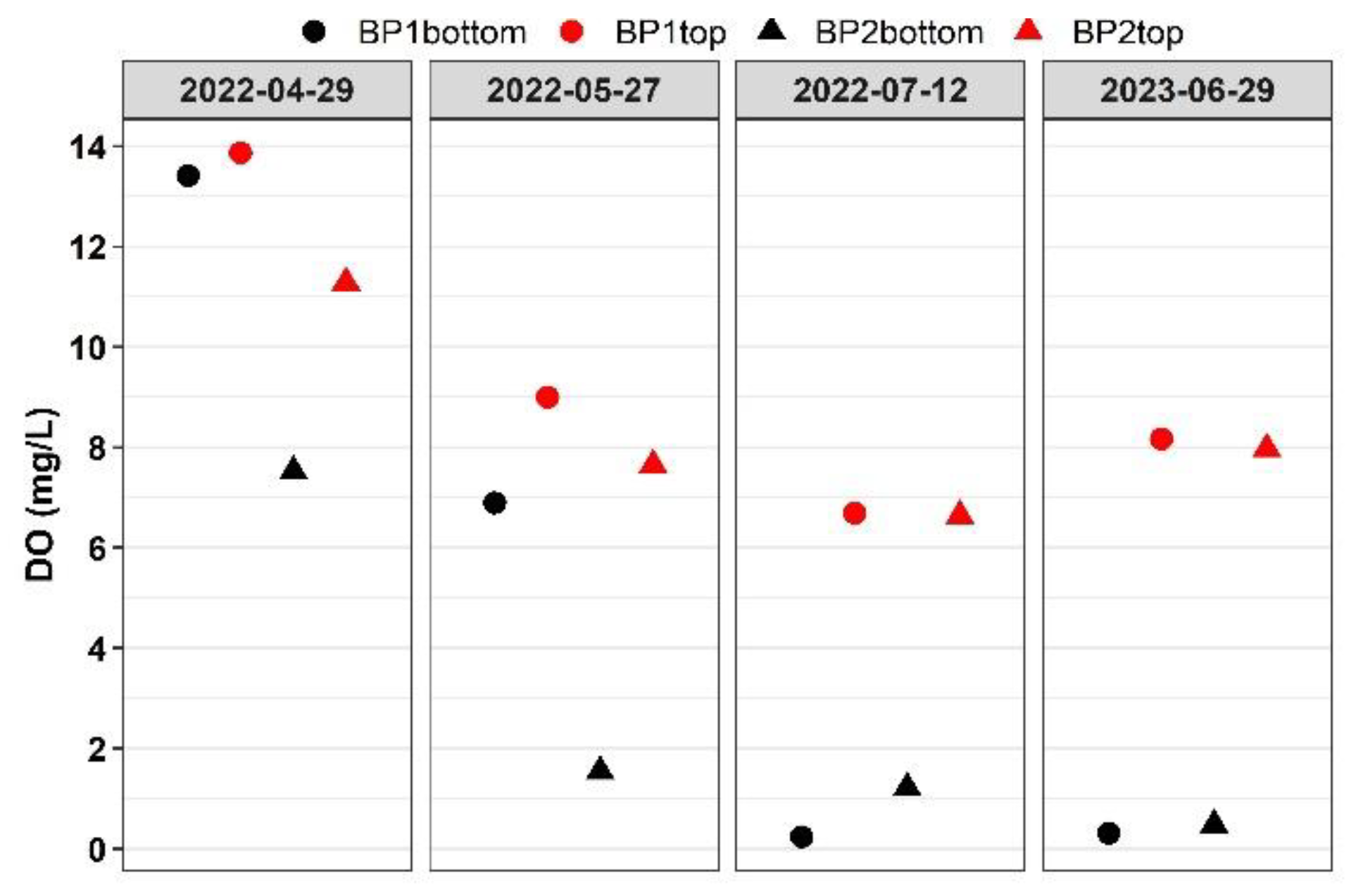

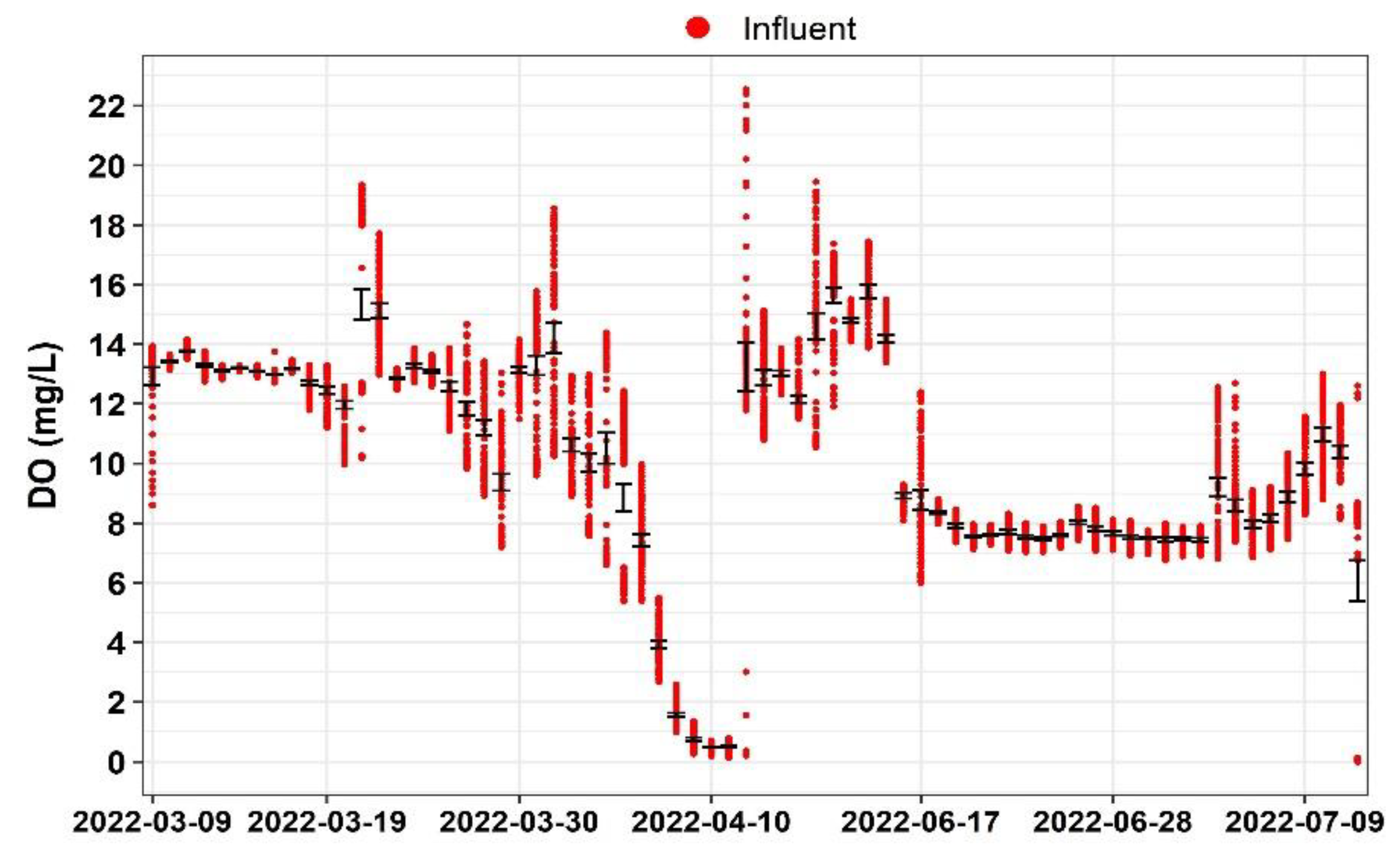

2.4. Water Quality

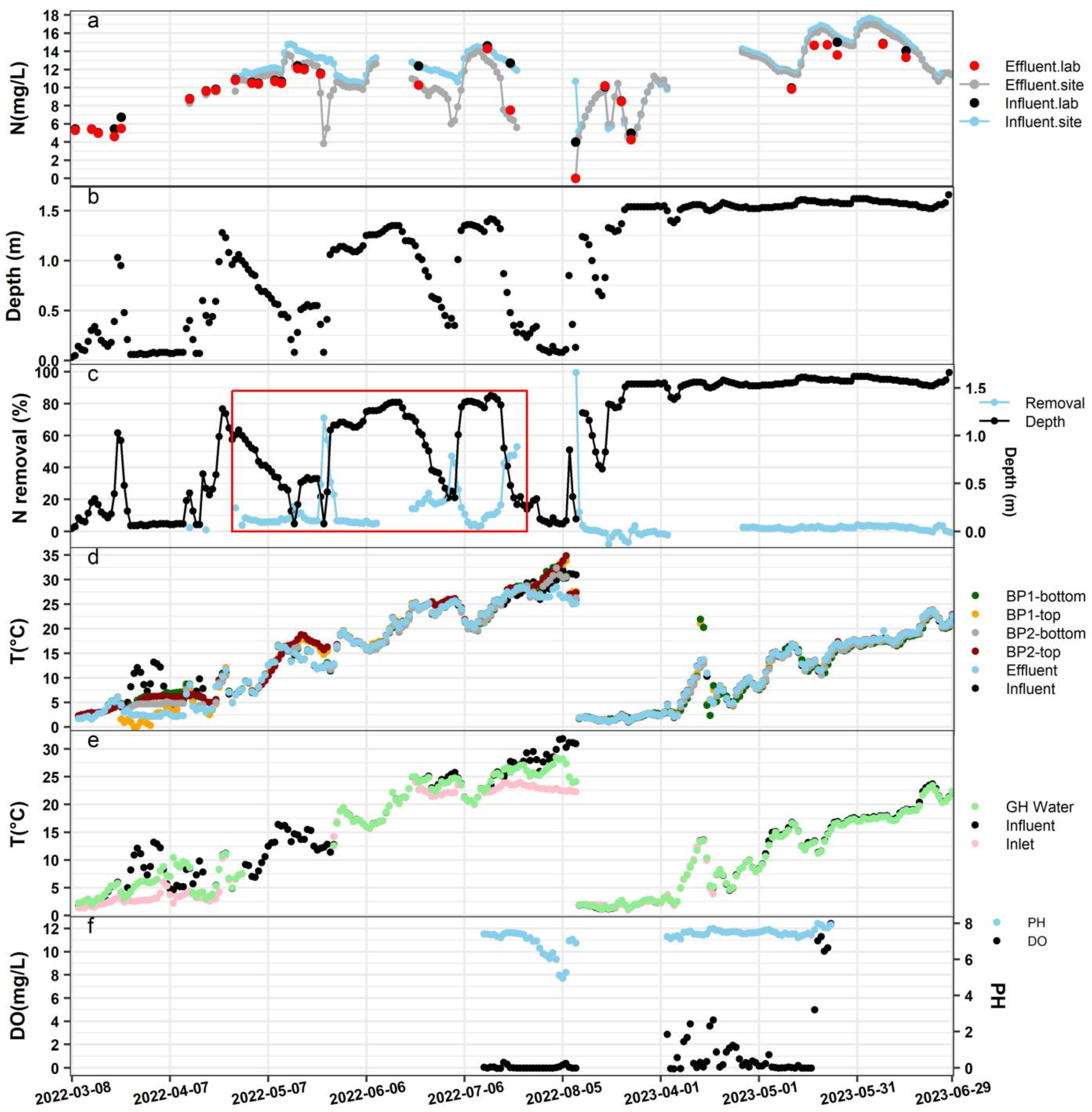

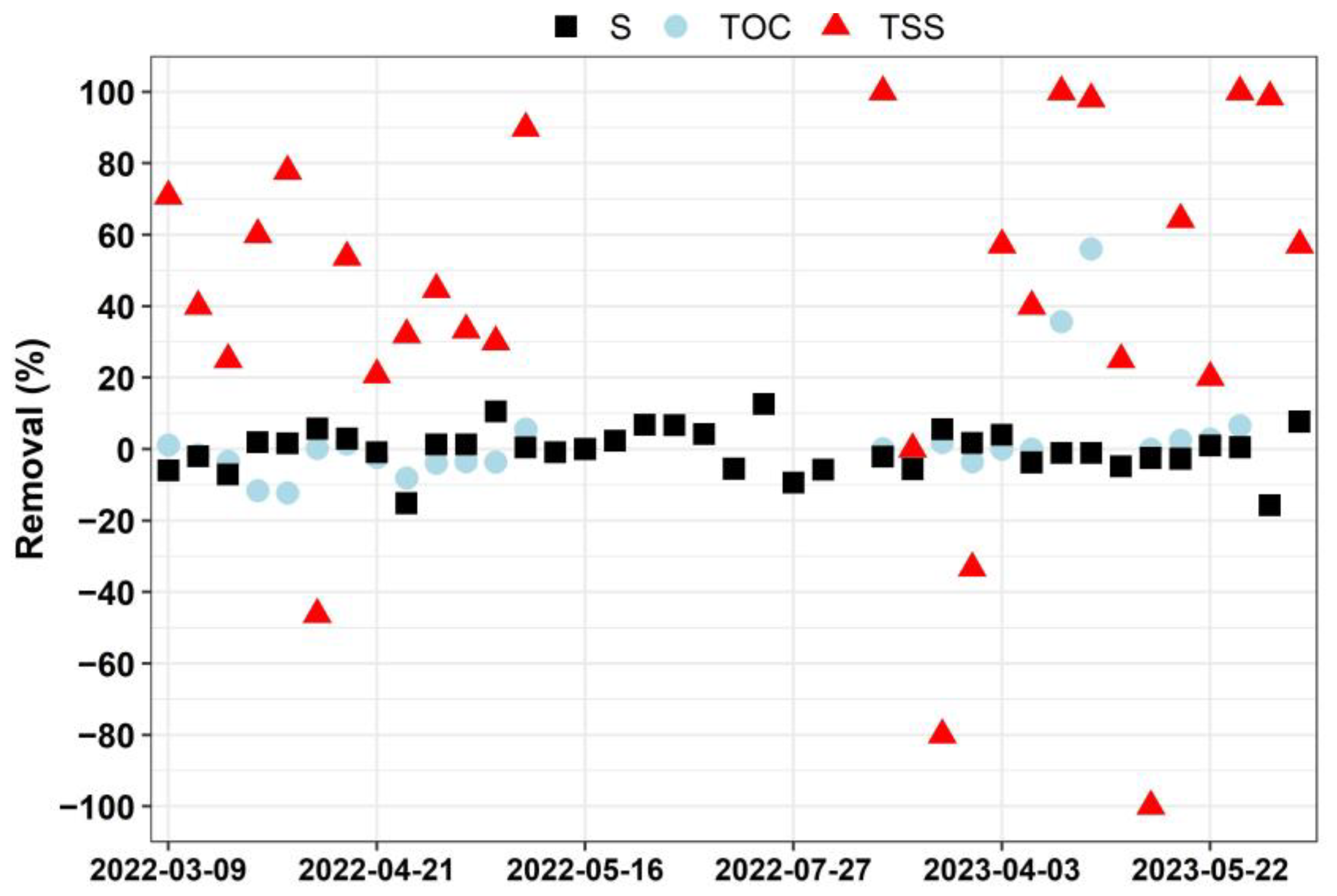

3. Results

4. Conclusions and Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nemmers, T.; Spring Biological Nitrate Removal to Protect Drinking Water. City of Fairmont. 2019. Available online: https://www.lccmr.mn.gov/projects/2019/work_plans_june/2019_04r.pdf (accessed on 20 October 2023).

- Addy, K.; Gold, A.J.; Christianson, L.E.; David, M.B.; Schipper, L.A.; Ratigan, N.A. Denitrifying Bioreactors for Nitrate Removal: A Meta-Analysis. J. Environ. Qual. 2016, 45, 873–881. [Google Scholar] [CrossRef] [PubMed]

- Investigate Midwest. Fertilizer Runoff Disproportionately Harms Low-Income Communities’ Drinking Water. Treatment is Expensive—Investigate Midwest (26 August 2021). Available online: https://investigatemidwest.org/2021/08/26/fertilizer-runoff-disproportionately-harms-low-income-communities-drinking-water-treatment-is-expensive/ (accessed on 20 October 2023).

- White, S.A.; Conrad, S.R.; Woodrow, R.L.; Tucker, J.P.; Wong, W.W.; Cook, P.M.; Santos, I.R. Natural attenuation of large anthropogenic nitrate loads in a subtropical stream revealed by δ15N and δ18O. J. Hydrol. 2021, 598, 126077. [Google Scholar] [CrossRef]

- Schipper, L.A.; Cameron, S.C.; Warneke, S. Nitrate removal from three different effluents using large-scale denitrification beds. Ecol. Eng. 2010, 36, 1552–1557. [Google Scholar] [CrossRef]

- Martin County. Available online: https://martinswcd.net/wp-content/uploads/2022/03/2021-Grant-Update-Fairmont-Watershed.pdf (accessed on 23 October 2023).

- Minnesota Legislature 2019 Projects. Available online: https://www.lccmr.mn.gov/projects/2019-index.html#201904r (accessed on 23 October 2023).

- Christianson, L.E.; Cooke, R.A.; Hay, C.H.; Helmers, M.J.; Feyereisen, G.W.; Ranaivoson, A.Z.; Ian, A. Effectiveness of denitrifying bioreactors on water pollutant reduction from agricultural areas. Trans. ASABE 2021, 64, 641–658. [Google Scholar] [CrossRef]

- Illinois Nutrient Loss Reduction Strategy. Available online: https://epa.illinois.gov/content/dam/soi/en/web/epa/documents/water-quality/watershed-management/nlrs/nlrs-final-revised-083115.pdf (accessed on 23 October 2023).

- Iowa Nutrient Reduction Strategy: A Science and Technology Based Framework to Assess and Reduce Nutrients to Iowa Waters and the Gulf of Mexico. (December 2017). Available online: https://www.nutrientstrategy.iastate.edu/sites/default/files/documents/2017%20INRS%20Complete_Revised%202017_12_11.pdf (accessed on 25 October 2023).

- Anderson, W.P.; Wall, D.; Olson, J.L. Minnesota nutrient reduction strategy. In Proceedings of the 2016 10th International Drainage Symposium Conference, Minneapolis, MN, USA, 6–9 September 2016. [Google Scholar]

- Gulf Hypoxia Action Plan 2008y. US EPA (16 June 2008). Available online: https://www.epa.gov/sites/default/files/2015-03/documents/2008_8_28_msbasin_ghap2008_update082608.pdf (accessed on 25 October 2023).

- Schipper, L.A.; Robertson, W.D.; Gold, A.J.; Jaynes, D.B.; Cameron, S.C. Denitrifying bioreactors—An approach for re-ducing nitrate loads to receiving waters. Ecol. Eng. 2010, 36, 1532–1543. [Google Scholar] [CrossRef]

- Warneke, S.; Schipper, L.A.; Bruesewitz, D.A.; McDonald, I.; Cameron, S. Rates, controls and potential adverse effects of nitrate removal in a denitrification bed. Ecol. Eng. 2011, 37, 511–522. [Google Scholar] [CrossRef]

- Christianson, L.E. Design and Performance of Denitrification Bioreactors for Agricultural Drainage. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2011. [Google Scholar]

- Hoover, N.L.; Bhandari, A.; Soupir, M.L.; Moorman, T.B. Woodchip denitrification bioreactors: Impact of temperature and hydraulic retention time on nitrate removal. J. Environ. Qual. 2016, 45, 803–812. [Google Scholar] [CrossRef]

- Barr Engineering. Habitat Restoration and Nitrate Bioreactor. City of Fairmont. 2021. Available online: https://documentcloud.adobe.com/link/track?uri=urn:aaid:scds:US:46f795ba-5fe7-44ee-986d-8003cdd7645f#pageNum=1 (accessed on 30 October 2023).

- Fan, Y.; Essington, M.; Jagadamma, S.; Zhuang, J.; Schwartz, J.; Lee, J. The global significance of abiotic factors affecting nitrate removal in woodchip bioreactors. Sci. Total Environ. 2022, 848, 157739. [Google Scholar] [CrossRef]

- Rendall, T.J. Effect of Passive and Active Heating on the Performance of Denitrifying Bioreactors. Master’s Thesis, University of Illinois in Urbana-Champaign, Urbana, IL, USA, 2015. [Google Scholar]

- Nordström, A.; Herbert, R.B. Determination of major biogeochemical processes in a denitrifying woodchip bioreactor for treating mine drainage. Ecol. Eng. 2018, 110, 54–66. [Google Scholar] [CrossRef]

- Wrightwood, O.M.; Hattaway, M.E.; Young, T.M.; Bischel, H.N. Assessment of woodchip bioreactor characteristics and their influences on joint nitrate and pesticide removal. ACS ES&T Water 2021, 2, 106–116. [Google Scholar]

- Davis, M.P.; Martin, E.A.; Moorman, T.B.; Isenhart, T.M.; Soupir, M.L. Nitrous oxide and methane production from denitrifying woodchip bioreactors at three hydraulic residence times. J. Environ. Manag. 2019, 242, 290–297. [Google Scholar] [CrossRef]

- Zhu, L.; Shi, W.; Van Dam, B.; Kong, L.; Yu, J.; Qin, B. Algal accumulation decreases sediment nitrogen removal by uncoupling nitrification-denitrification in shallow eutrophic lakes. Environ. Sci. Technol. 2020, 54, 6194–6201. [Google Scholar] [CrossRef]

- Hathaway, S.K.; Bartolerio, N.A.; Rodríguez, L.F.; Kent, A.D.; Zilles, J.L. Denitrifying bioreactors resist disturbance from fluctuating water levels. Front. Environ. Sci. 2017, 5, 35. [Google Scholar] [CrossRef]

- Rivas, A.; Barkle, G.; Maxwell, B.; Moorhead, B.; Stenger, R.; Schipper, L.; Birgand, F.; Clague, J. Determining the spatial variability of nitrate removal in a woodchip bioreactor through high frequency monitoring at multiple locations. In Nutrient Management in Farmed Landscapes: 33rd Annual FLRC Workshop; Farmed Landscapes Research Centre, Massey University: Palmerston North, New Zealand, 2020; Volume 33, pp. 1–11. [Google Scholar]

- Christianson, L.E.; Lepine, C.; Sharrer, K.L.; Summerfelt, S.T. Denitrifying bioreactor clogging potential during wastewater treatment. Water Res. 2016, 105, 147–156. [Google Scholar] [CrossRef]

- Gosch, L.; Liu, H.; Lennartz, B. Performance of a woodchip bioreactor for the treatment of nitrate-laden agricultural drainage water in northeastern Germany. Environments 2020, 7, 71. [Google Scholar] [CrossRef]

- Pluer, W.T.; Hoffman, R.; and Walter, M.T. Reducing stormwater nitrogen with denitrifying bioreactors: Florida case study. J. Sustain. Water Built Environ. 2018, 4, 06018002. [Google Scholar] [CrossRef]

- Christianson, L.E.; Bhandari, A.; Helmers, M.J. A practice-oriented review of woodchip bioreactors for subsurface agricul-tural drainage. Appl. Eng. Agric. 2012, 28, 861–874. [Google Scholar] [CrossRef]

- Christianson, R.; Christianson, L.; Wong, C.; Helmers, M.; McIsaac, G.; Mulla, D.; McDonald, M. Beyond the nutrient strategies: Common ground to accelerate agricultural water quality improvement in the upper Midwest. J. Environ. Manag. Ment 2018, 206, 1072–1080. [Google Scholar] [CrossRef]

- Greenan, C.M.; Moorman, T.B.; Parkin, T.B.; Kaspar, T.C.; Jaynes, D.B. Denitrification in wood chip bioreactors at different water flows. J. Environ. Qual. 2009, 38, 1664–1671. [Google Scholar] [CrossRef] [PubMed]

- Hassanpour, B.; Giri, S.; Pluer, W.T.; Steenhuis, T.S.; Geohring, L.D. Seasonal performance of denitrifying bioreactors in the Northeastern United States: Field trials. J. Environ. Manag. 2017, 202, 242–253. [Google Scholar] [CrossRef] [PubMed]

- Ghane, E.; Feyereisen, G.W.; Rosen, C.J.; Sadowsky, M.J.; Christianson, L.E. Performance of denitrification beds for removing nitrate from drainage water at cold temperatures. In Proceedings of the 2016 10th International Drainage Symposium Conference, Minneapolis, MN, USA, 6–9 September 2016. [Google Scholar]

- Feyereisen, G.W.; Wang, H.; Wang, P.; Anderson, E.L.; Jang, J.; Ghane, E.; Coulter, J.A.; Rosen, C.J.; Sadowsky, M.J.; Ishii, S. Carbon supplementation and bioaugmentation to improve denitrifying woodchip bioreactor performance under cold conditions. Ecol. Eng. 2023, 191, 106920. [Google Scholar] [CrossRef]

- Moghaddam, R.; Barkle, G.; Rivas, A.; Schipper, L. Flow analysis and hydraulic performance of denitrifying bioreactors under different carbon dosing treatments. J. Environ. Manag. 2023, 328, 116926. [Google Scholar] [CrossRef] [PubMed]

- Hartfiel, L.M.; Díaz-García, C.; Christianson, L.E.; Soupir, M.L. Scenario-based techno-economic analysis of pumped denitrification bioreactors. Water Resour. Econ. 2024, 46, 100238. [Google Scholar] [CrossRef]

- Kramer, G.; Peterson, J.; Han, J.; Hansen, B.; Magner, J.; Wilson, B.; Nieber, J. Design and construction of an alternative drainage ditch system. Int. J. Hydrol. 2019, 3, 259–268. [Google Scholar]

- Krider, L.; Kramer, G.; Wilson, B.; Magner, J.; Lazarus, W.; Hansen, B.; Nieber, J. Alternative Agricultural Ditch Designs, NO3-N Treatment, Construction Costs, and Benefits—Mower County, Minnesota, USA. J. Environ. Sci. Eng. 2022, B11, 229–240. [Google Scholar] [CrossRef]

| Parameters | Used Tool | Location of Measurements | ||||

|---|---|---|---|---|---|---|

| Water depth | Pressure transducers | AD1 | BP1 | MH2 | ||

| Total nitrogen (N) | N probe | AD1 | MH2 | |||

| Temperature (T) | Sonde | AD1 | BP1 | BP2 | AD2 | MH2 |

| Dissolved oxygen (DO) | Sonde | AD1 | BP1 | BP2 | ||

| pH | Sonde | AD1 | BP1 | BP2 | ||

| Sulfate (S) | Lab equipment | AD1 | MH2 | |||

| Total organic carbon (TOC) | Lab equipment | AD1 | MH2 | |||

| Total suspended solids (TSS) | Lab equipment | AD1 | MH2 | |||

| Total nitrogen (N) | Lab equipment | AD1 | MH2 | |||

| Mean of N (mg/L) | p-Value | ||

|---|---|---|---|

| Influent | Effluent | ||

| 2022 (April–August) | 12.4 (1.34) | 10.4 (2.47) | 0 |

| 2023 (March–June) | 12.6 (3.63) | 12.4 (3.44) | 0.68 |

| T (°C) | |||||

|---|---|---|---|---|---|

| Influent–Effluent | BP1top–BP1bottom | BP2top–BP2bottom | BP1top–BP2top | BP1bottom–BP2bottom | |

| Difference in mean | 0.53 (1.95) | 0.13 (1.46) | 0.70 (1.07) | −0.39 (1.30) | 0.17 (1.08) |

| p-value | 0.47 | 0.86 | 0.35 | 0.61 | 0.81 |

| Bioreactor DO (mg/L) | |||

|---|---|---|---|

| 25 Percentiles | Average | 75 Percentiles | |

| 2022 (July–August) | −0.026 | 0.048 (0.14) | 0.049 |

| 2023 (April–May) | 0.027 | 1.85 (3.29) | 1.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Holmberg, K.; Magner, J. The Evaluation of a Novel Denitrifying Woodchip Bioreactor: Fairmont, MN, USA. Nitrogen 2024, 5, 152-162. https://doi.org/10.3390/nitrogen5010010

Xu L, Holmberg K, Magner J. The Evaluation of a Novel Denitrifying Woodchip Bioreactor: Fairmont, MN, USA. Nitrogen. 2024; 5(1):152-162. https://doi.org/10.3390/nitrogen5010010

Chicago/Turabian StyleXu, Limeimei, Kerry Holmberg, and Joe Magner. 2024. "The Evaluation of a Novel Denitrifying Woodchip Bioreactor: Fairmont, MN, USA" Nitrogen 5, no. 1: 152-162. https://doi.org/10.3390/nitrogen5010010

APA StyleXu, L., Holmberg, K., & Magner, J. (2024). The Evaluation of a Novel Denitrifying Woodchip Bioreactor: Fairmont, MN, USA. Nitrogen, 5(1), 152-162. https://doi.org/10.3390/nitrogen5010010