Fractional-Order Creep Hysteresis Modeling of Dielectric Elastomer Actuator and Its Implicit Inverse Adaptive Control

Abstract

1. Introduction

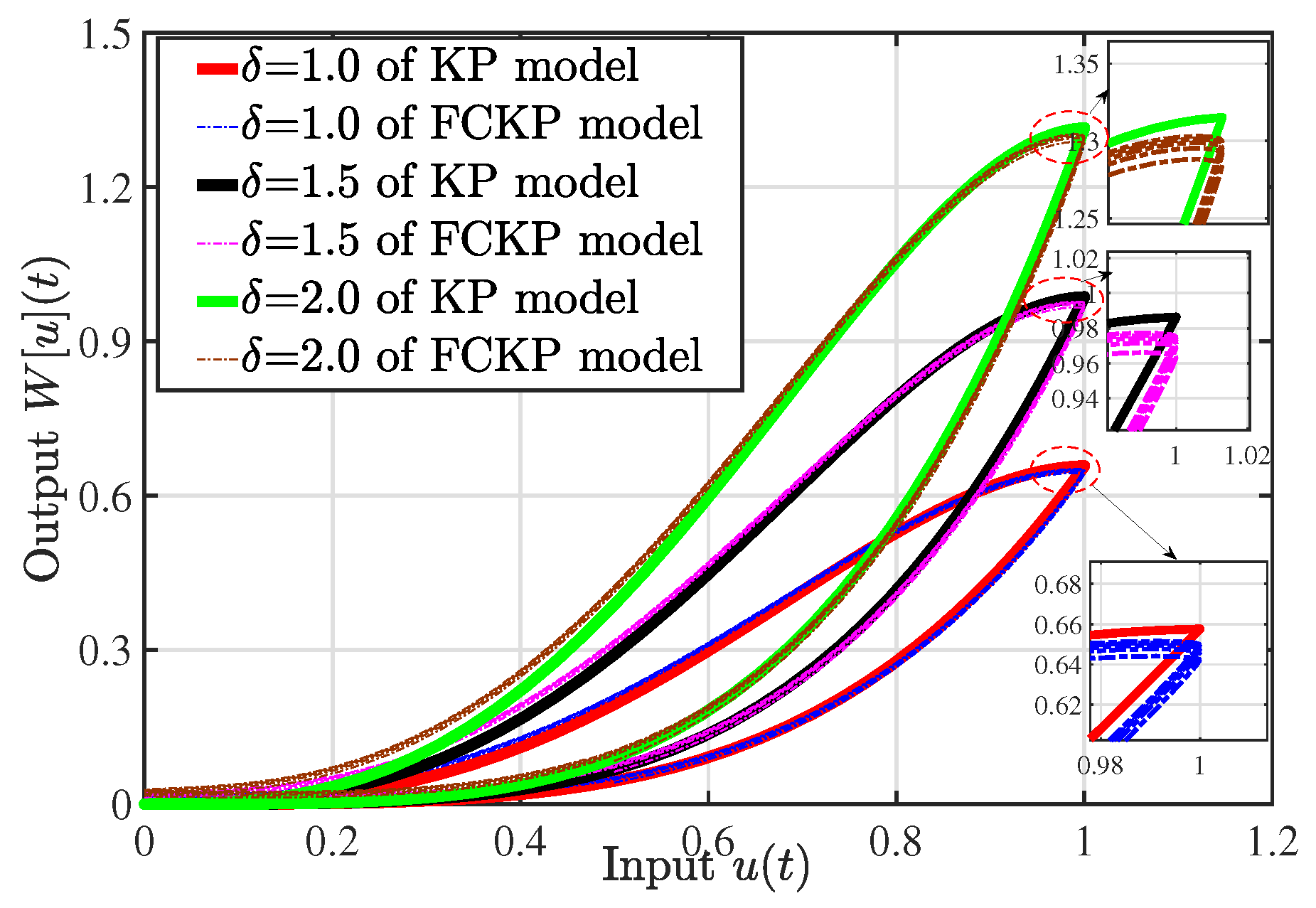

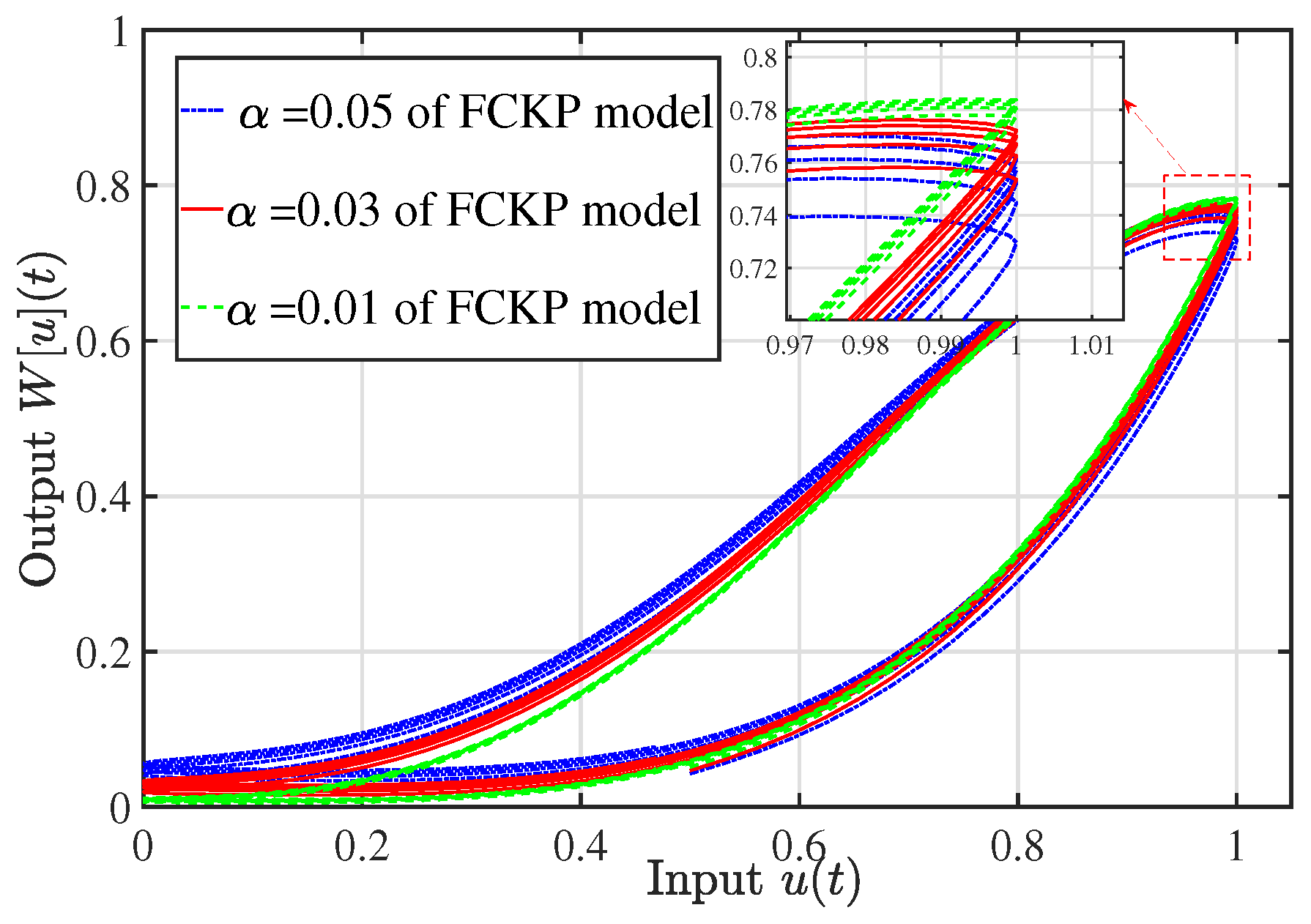

- Innovatively integrates the fractional-order creep characteristics into the classical KP model, and the FCKP hysteresis model that can describe creep is first proposed. Compared with traditional description, this model enhances creep representation and simplifies parameter identification. To our best knowledge, no prior research has coupled fractional-order creep characteristics with the KP model to describe hysteresis phenomena, particularly in the modeling of dielectric elastomer actuators.

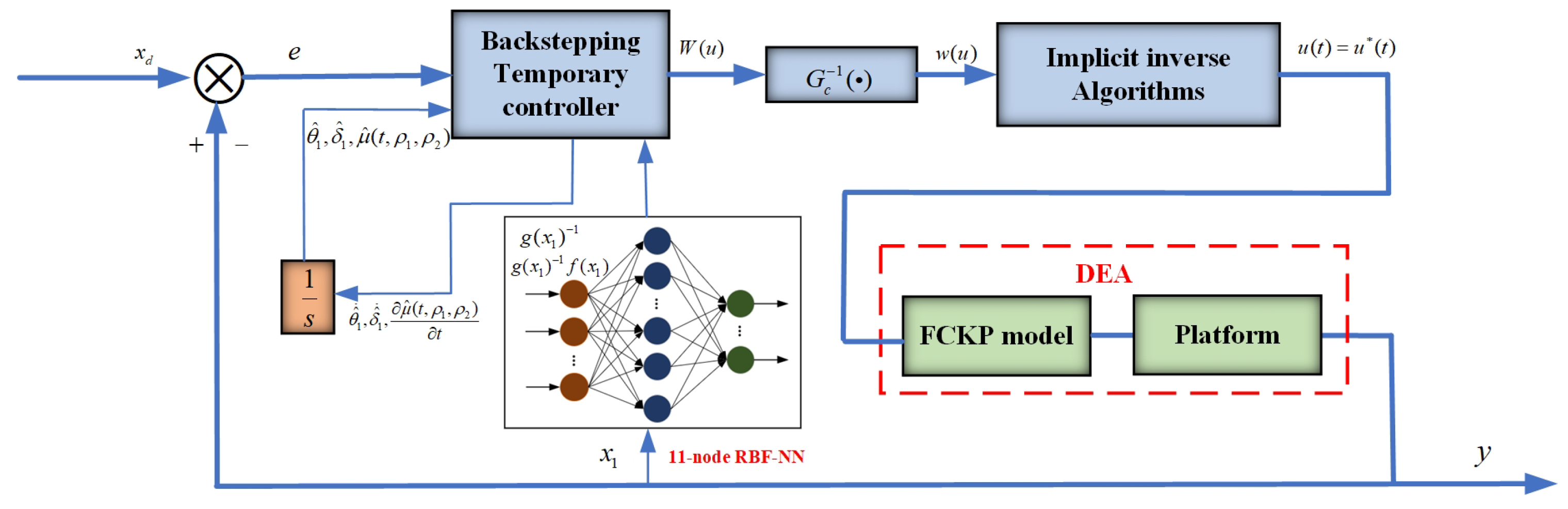

- A novel method combining direct creep inverse compensation and implicit inverse compensation is designed to eliminate the impact of creep-characteristic hysteresis on the control system. It is also found that the FCKP hysteresis model developed in this paper is more conducive to feed-forward compensation, thereby facilitating control scheme design.

- An implicit inverse adaptive controller based on backstepping and direct creep inverse compensation is designed to control the DEA. Using a Radial Basis Function Neural Network (RBFNN) to estimate unknown nonlinear functions in a system, the control accuracy of the system is improved. The adaptive backstepping methods incorporating neural network approximation in [34,35,36] have achieved mature results. However, their control systems assume known gains for the control signals, unlike this study, where the gain is an unknown nonlinear function. Ref. [37] addresses unknown nonlinear gains but uses adaptive fuzzy control, which is less model-dependent. Since DEA requires high precision, a model-independent approach may degrade control performance. Finally, the effectiveness of this approach is validated on a self-built experimental platform.

2. System Descriptions and Preliminaries

2.1. Dielectric Elastomer Driven Dynamic Model

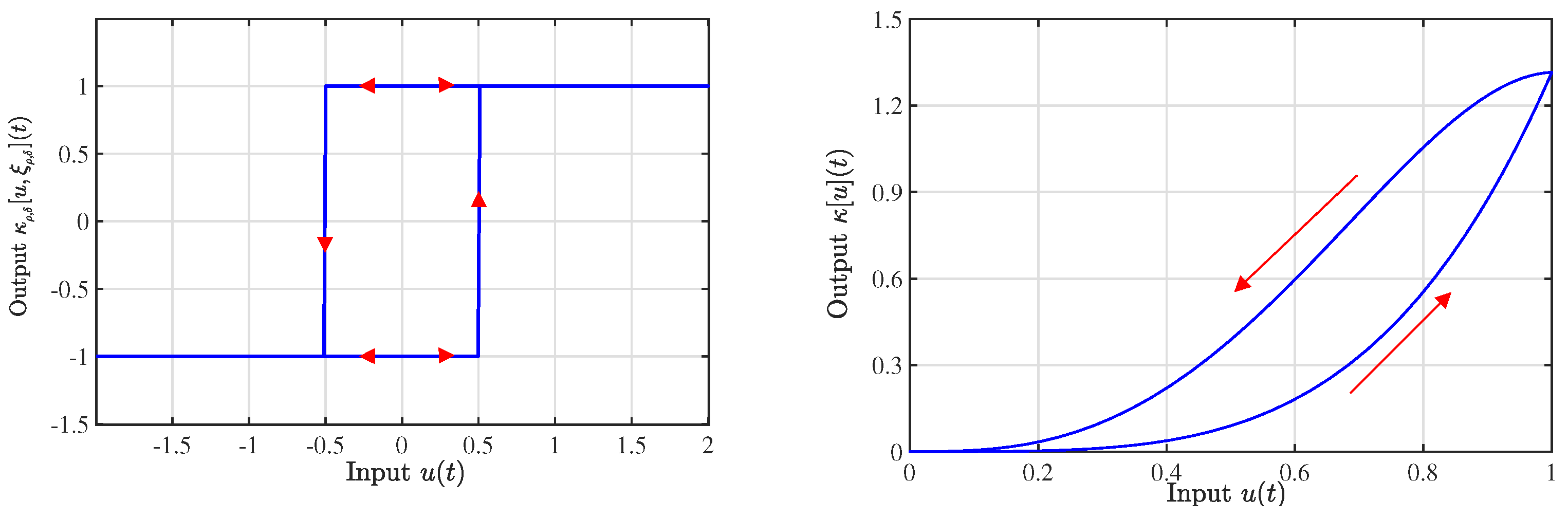

2.2. Modeling of Hysteresis with Creep

2.3. Creep Inverse Compensation

2.4. Function Approximation Using RBFNN

3. Design of Control Scheme

3.1. Design of Hysteretic Temporary Controller

3.2. Design of Implicit Inverse Algorithm for Hysteresis

4. Stability Analysis

5. Experimental Verification

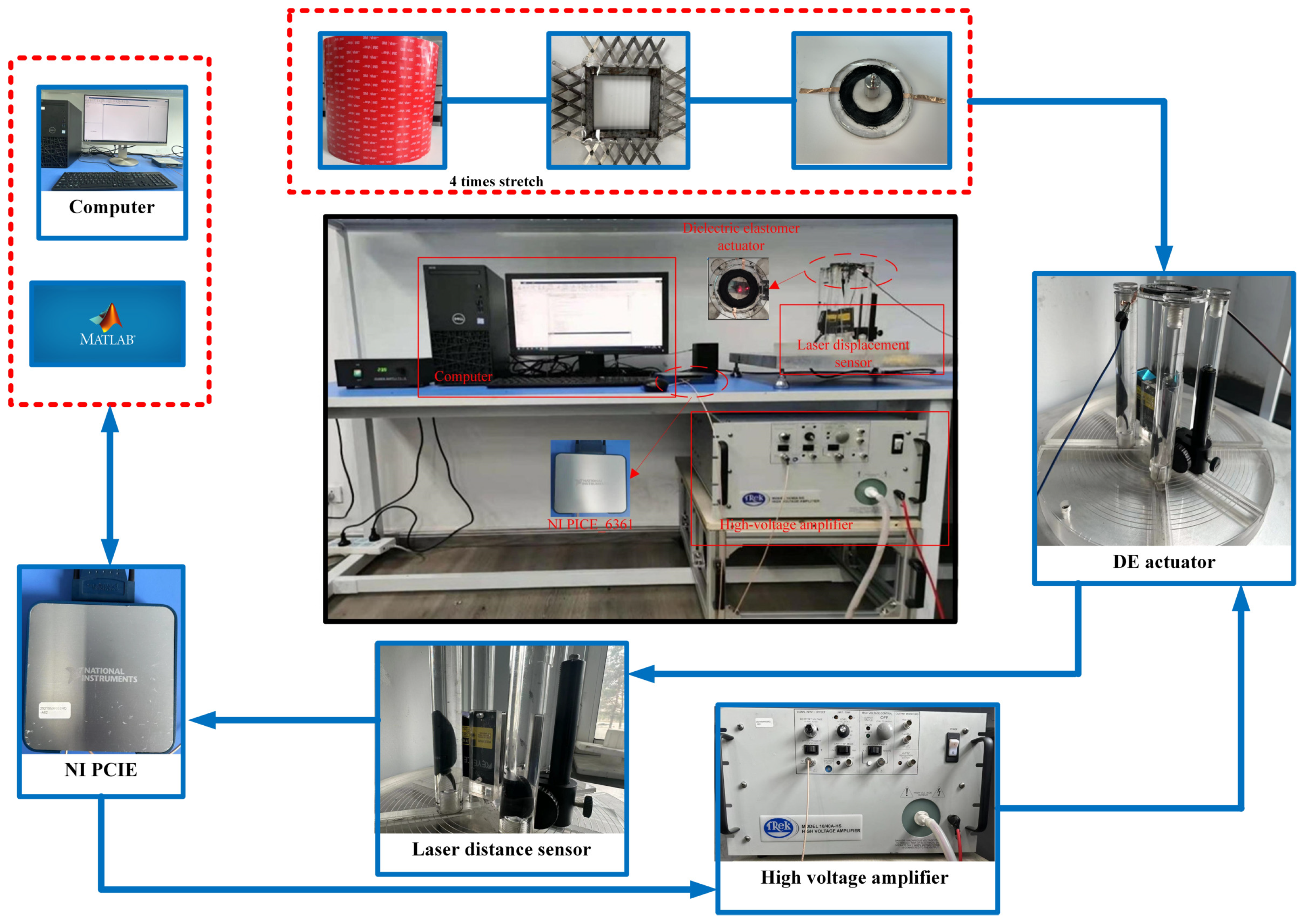

- Preparation of DEA: Select a dielectric elastomer membrane based on VHB-4910 (Minnesota Mining and Manufacturing, St. Paul, MN, USA) material; fix the pre-stretched film on a polymethylmethacrylate ring; the DEA has an inner diameter of 40 mm and an outer diameter of 60 mm. Carbon conductive grease 864-80G (M.G. Chemicals, Burlington, ON, Canada) is uniformly applied to the annular areas on both sides of the DEA. Then, 20 g load mass is positioned at the center of the DEA membrane.

- The LK-H152 laser displacement sensor (Keyence, Osaka, Japan) measures the loaded weight’s displacement in the DEA experiment with a ±40 mm range and a 10 µs sampling period.

- The PCIe-6361 (National Instruments, Austin, TX, USA) multi-functional I/O device handles data transmission and analog-to-digital conversion in the DEA experiment. It supports various I/O channels, sampling rates, and output rates with a maximum single-channel sampling rate of 2.00 M/s and an input/output range of ±10 V.

- The TERK10/40A-HS voltage amplifier (TREK, Inc., Lockport, NY, USA) amplifies the PCIe-6361 voltage signal with a fixed gain of 1000 V/V.

- The computer (Dell, Round Rock, TX, USA) with Intel i7-9700 CPU (3.00 GHz) is used to generate control signals by executing the control algorithm to drive the DEA to achieve tracking control and perform experimental data processing.

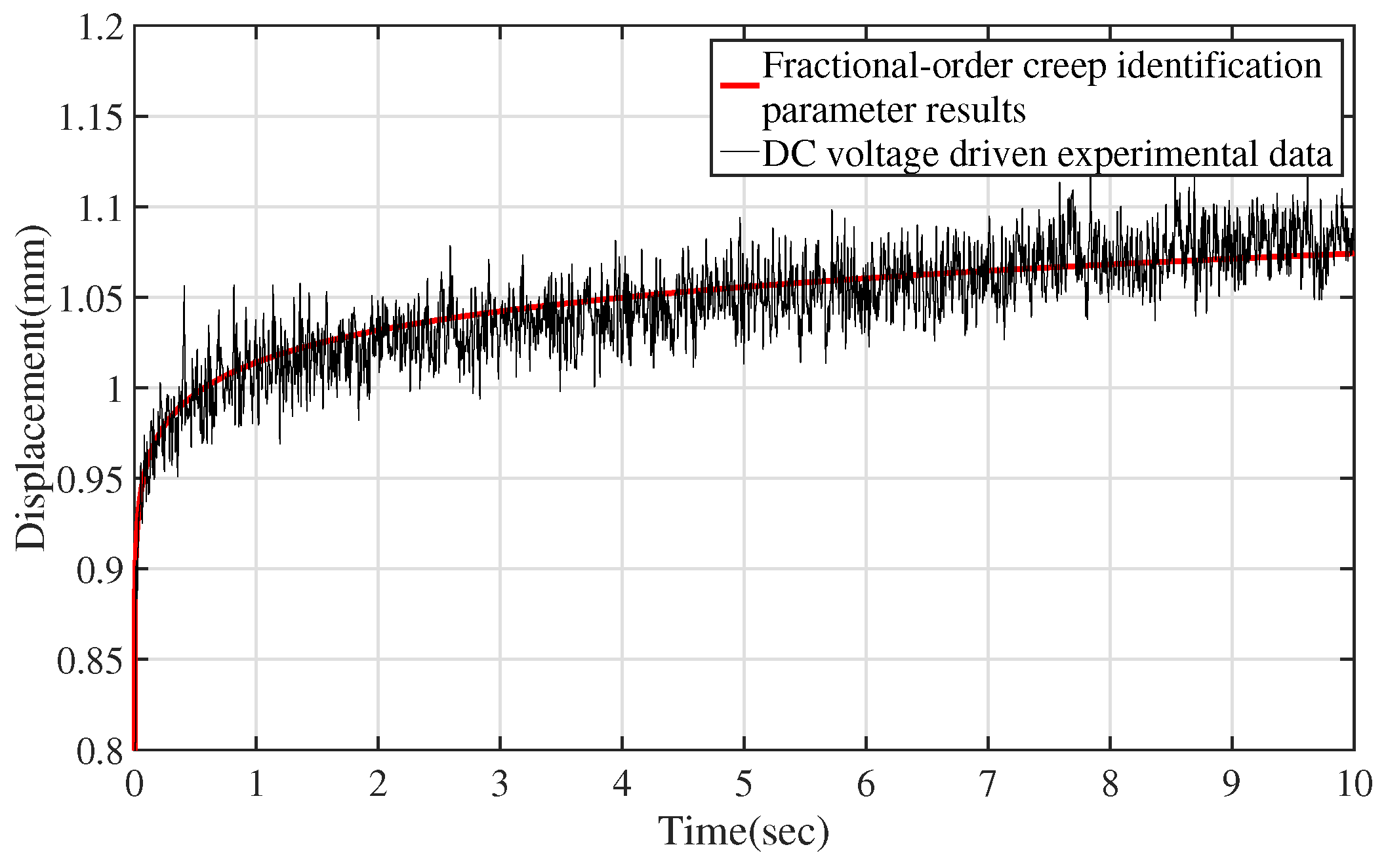

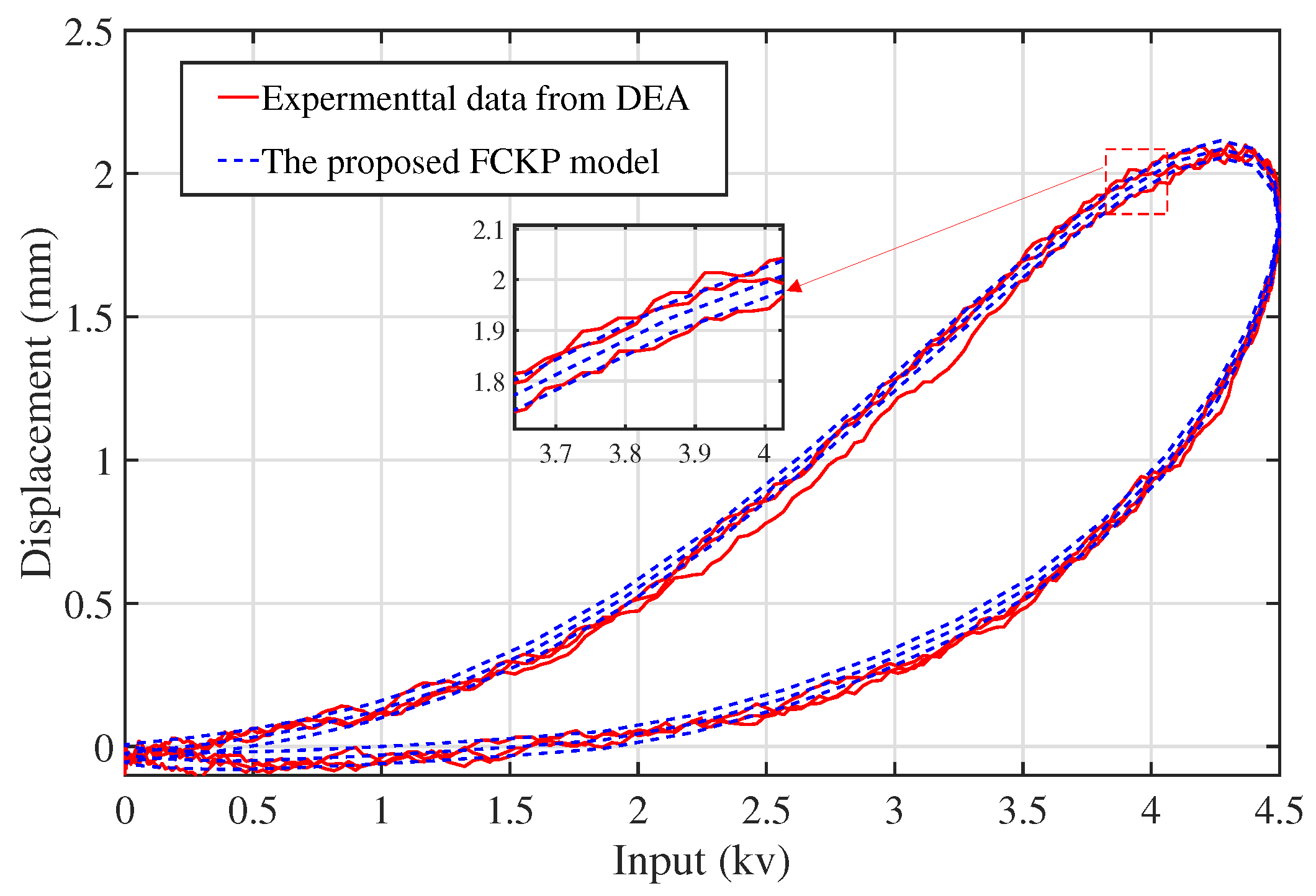

5.1. Experimental Validation of FCKP Model

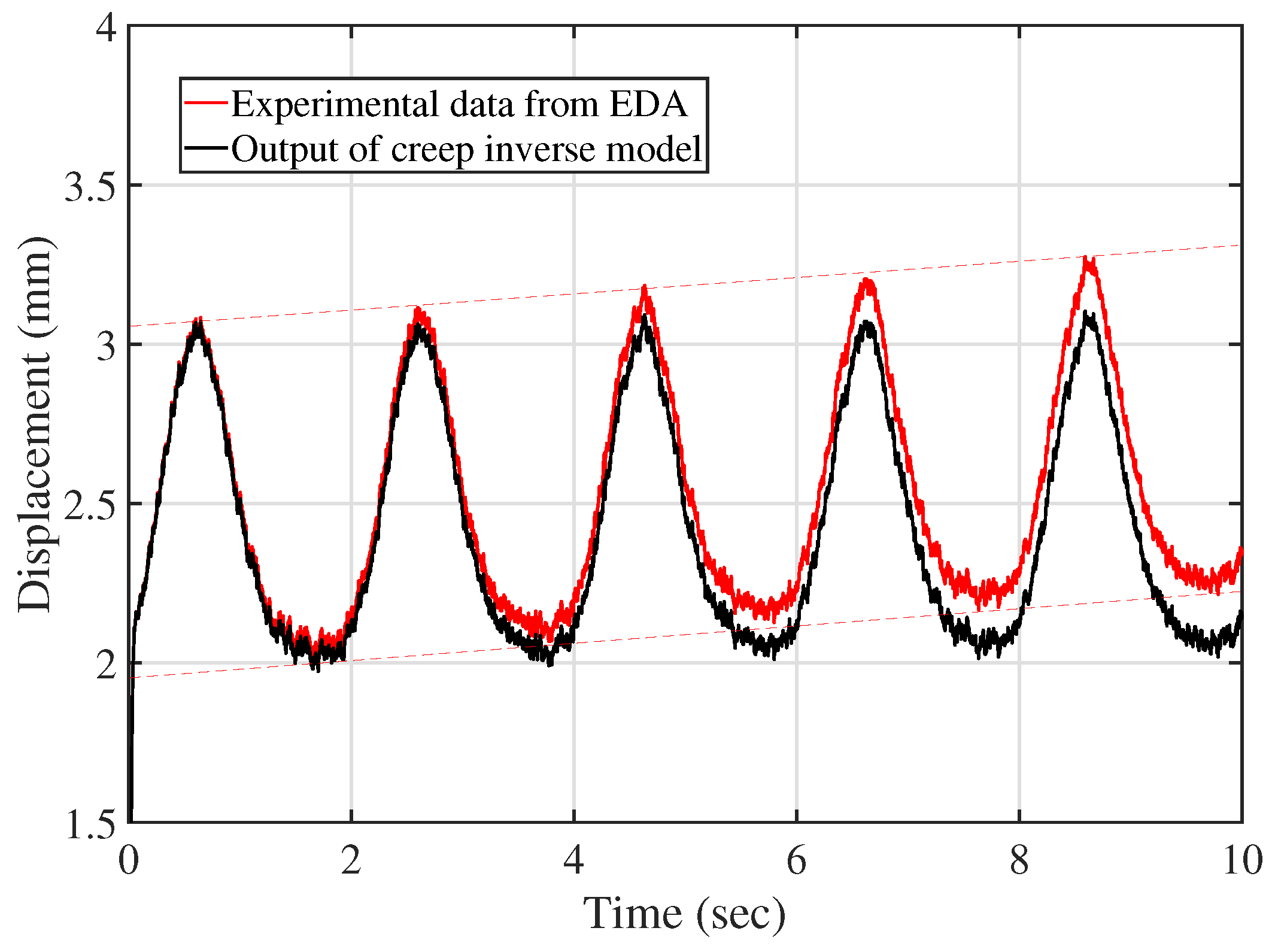

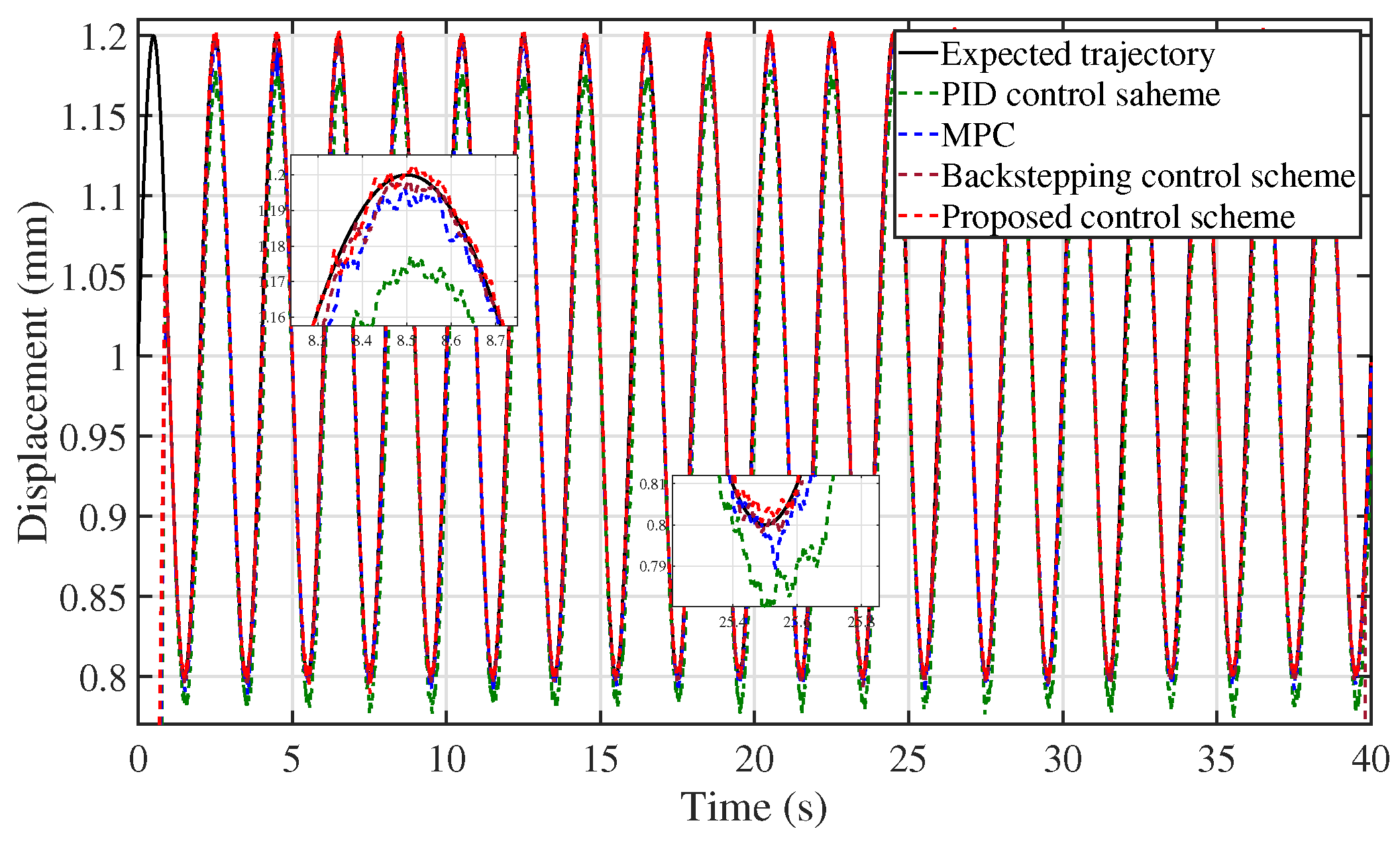

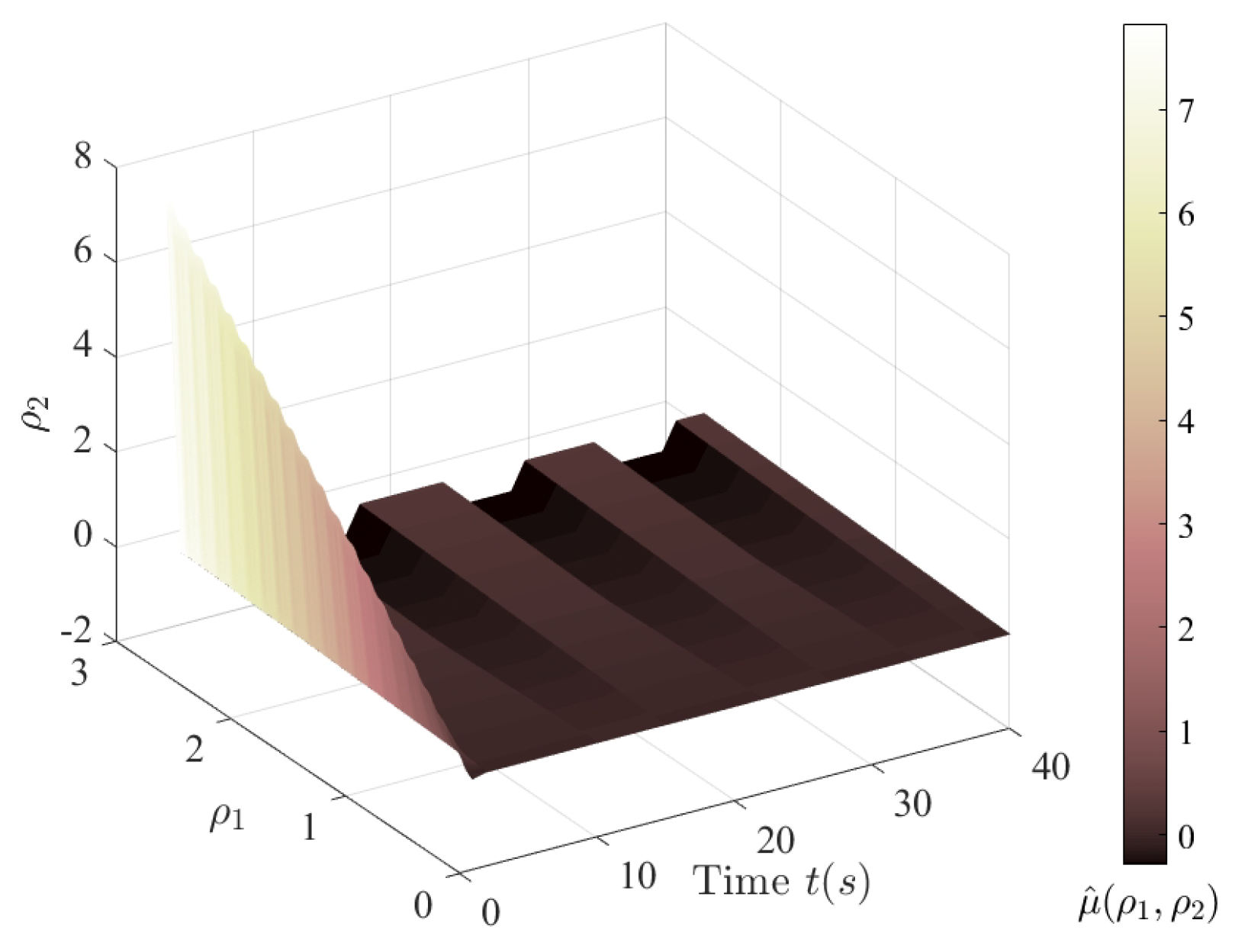

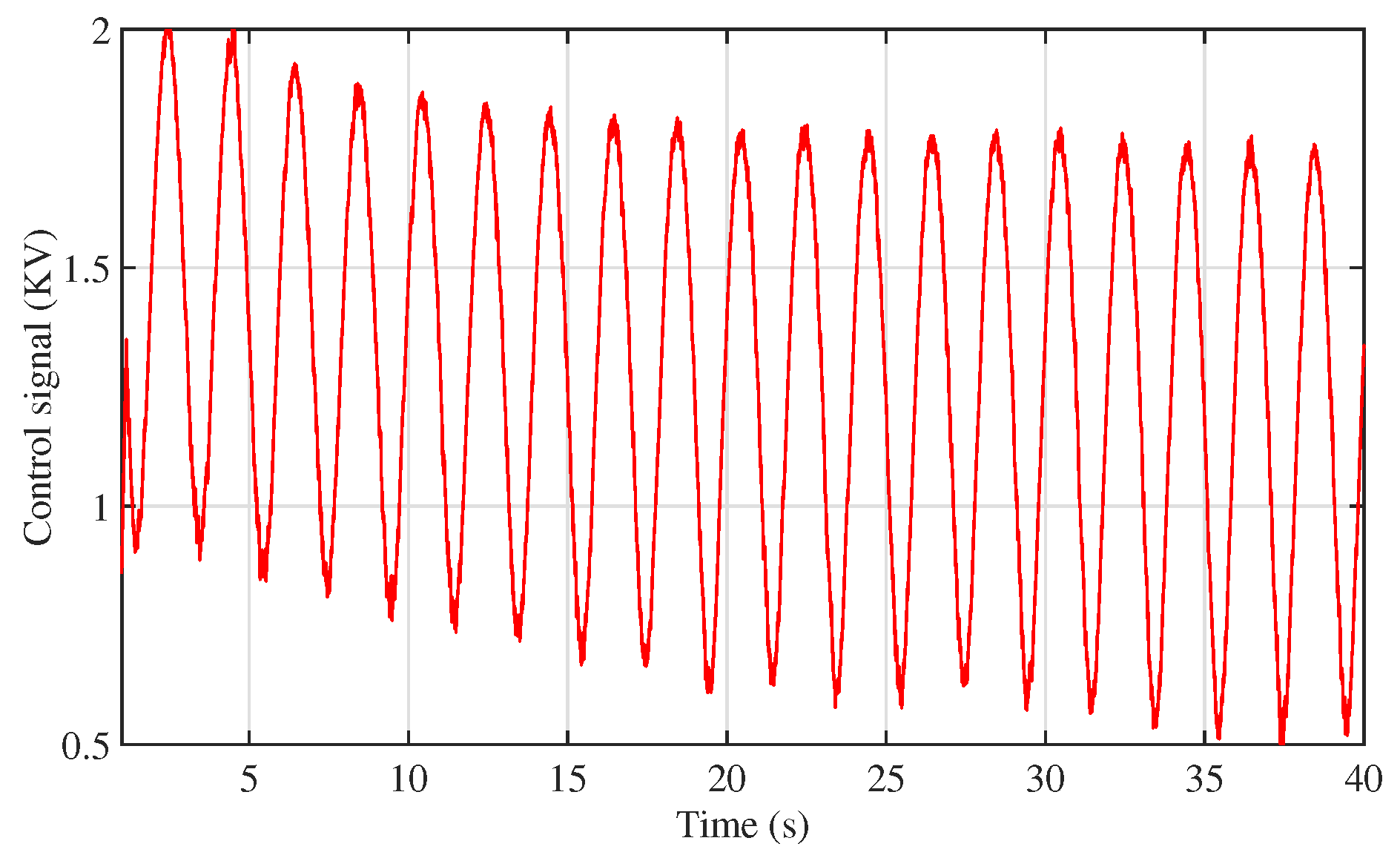

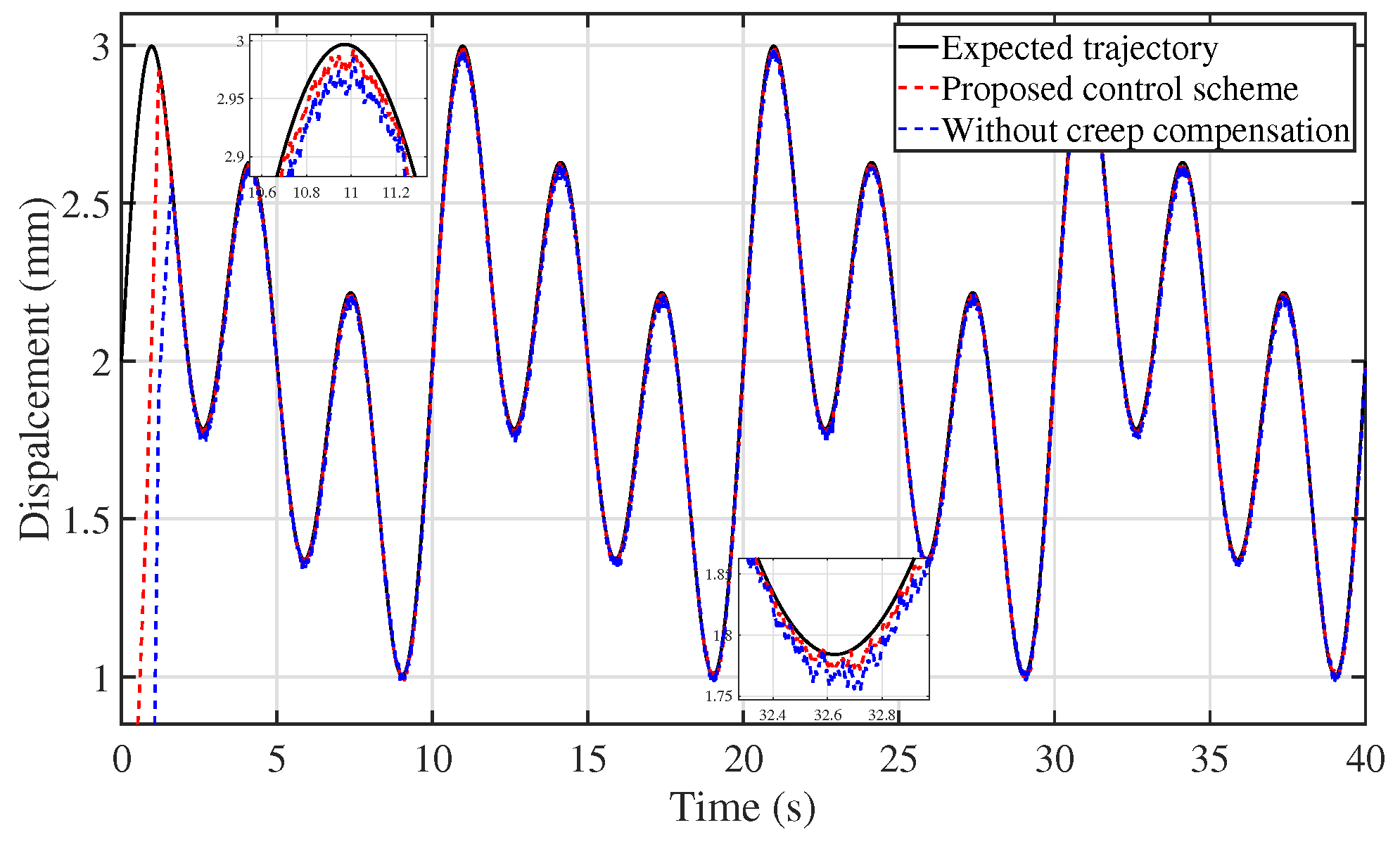

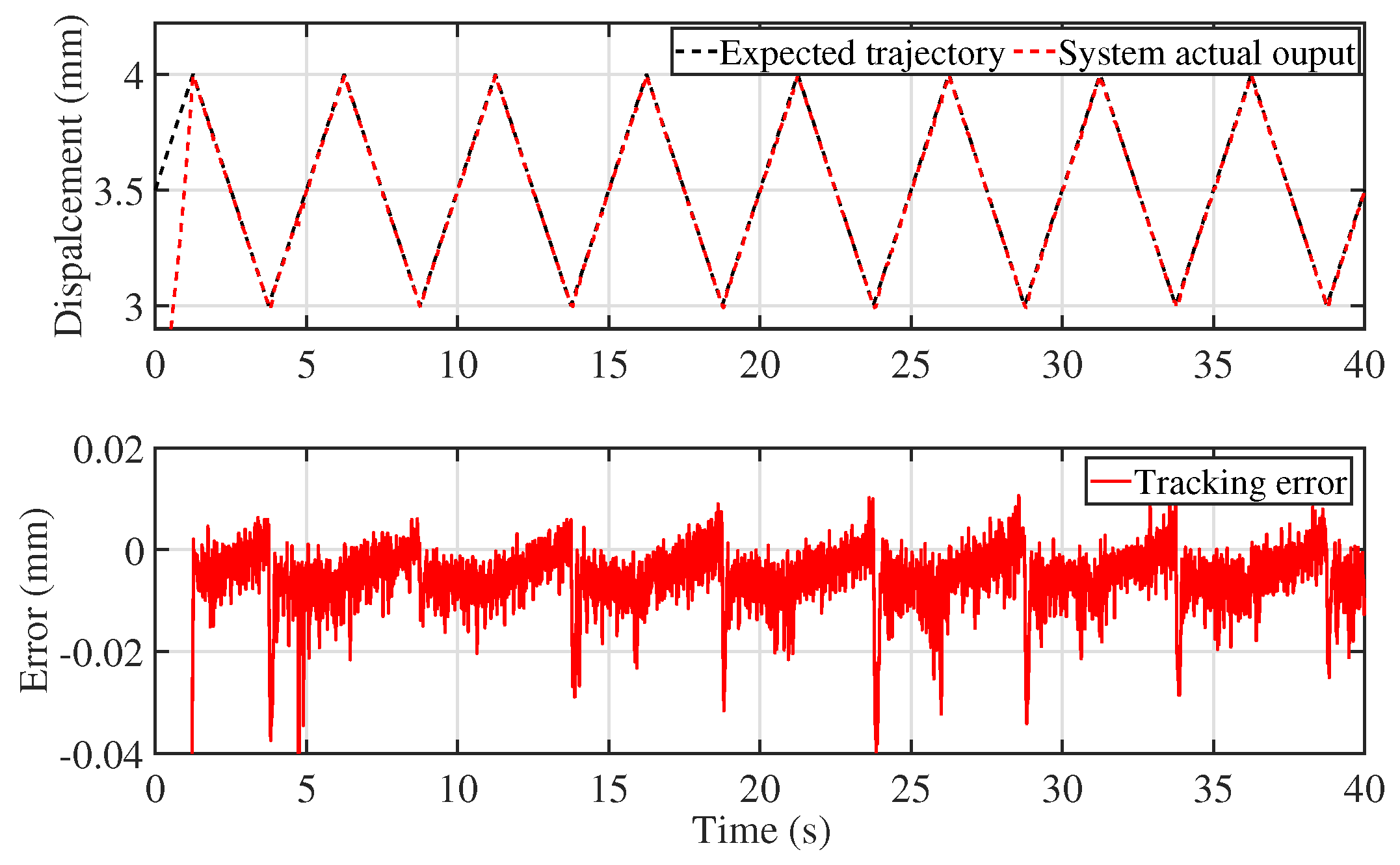

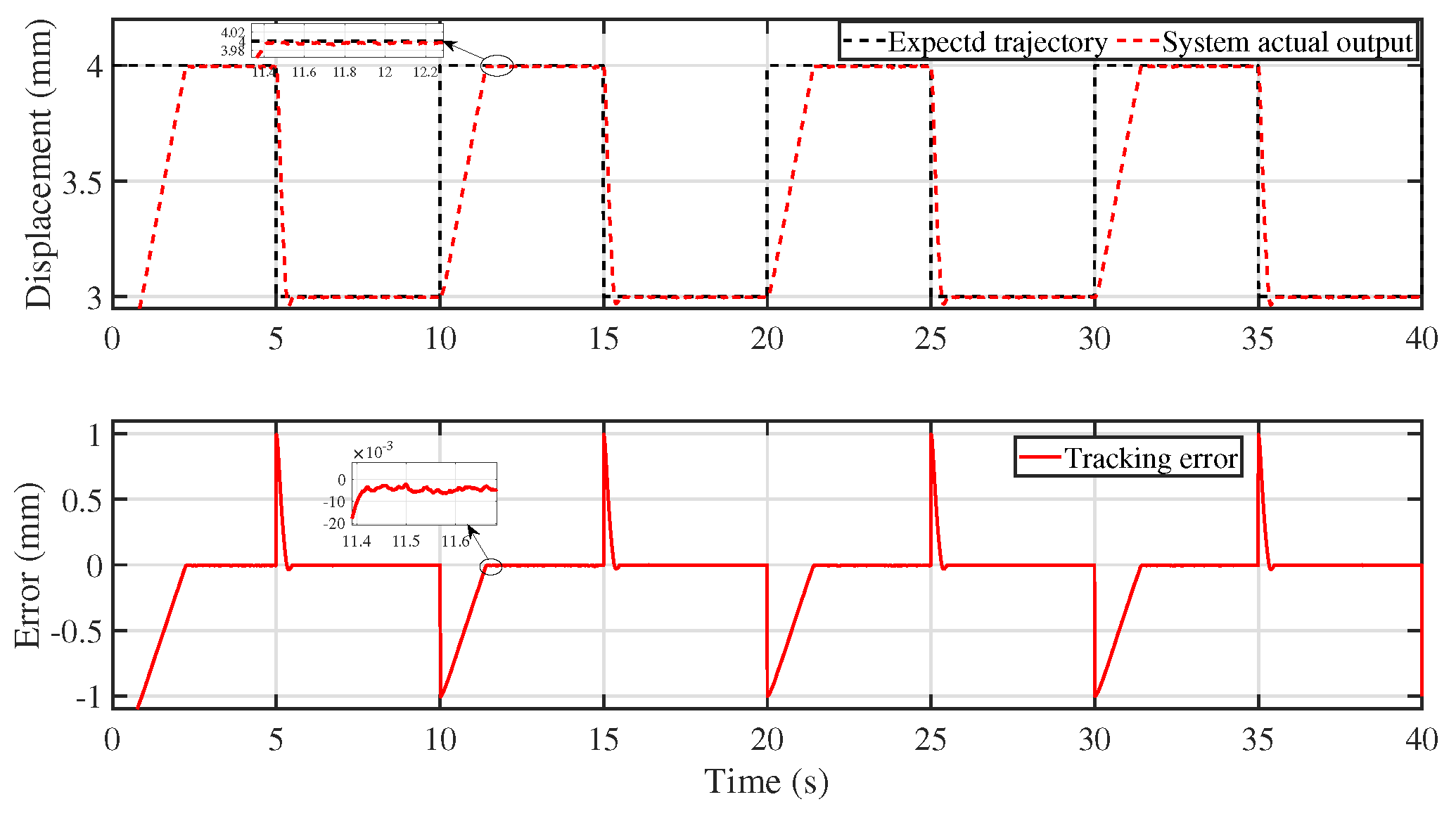

5.2. Experimental Validation of Control Performance

6. Practical Implications

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karner, T.; Belšak, R.; Gotlih, J. Using a fully fractional generalised Maxwell model for describing the time dependent sinusoidal creep of a dielectric elastomer actuator. Fractal Fract. 2022, 6, 720. [Google Scholar] [CrossRef]

- Li, Q.; Sun, Z. Dynamic modeling and response analysis of dielectric elastomer incorporating fractional viscoelasticity and gent function. Fractal Fract. 2023, 7, 786. [Google Scholar] [CrossRef]

- Hwang, G.; Park, J.; Cortes, D.S.D.; Hyeon, K.; Kyung, K.U. Electroadhesion-based high-payload soft gripper with mechanically strengthened structure. IEEE Trans. Ind. Electron. 2021, 69, 642–651. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, C.; Wang, Y.; Zhou, M. Neural-network-based iterative learning control for hysteresis in a magnetic shape memory alloy actuator. IEEE/ASME Trans. Mechatron. 2021, 27, 928–939. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, C.; Han, Z.; Zhou, M. Hysteresis modeling of magnetic shape memory alloy actuator based on volterra series. IEEE Trans. Magn. 2021, 57, 4001604. [Google Scholar] [CrossRef]

- Xie, D.; Yang, Y.; Zhang, Y.; Yang, B. Precision positioning based on temperature dependence self-sensing magnetostrictive actuation mechanism. Int. J. Mech. Sci. 2024, 272, 109174. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, T. An active disturbance rejection control for hysteresis compensation based on neural networks adaptive control. ISA Trans. 2021, 109, 81–88. [Google Scholar] [CrossRef]

- Jian, Y.; Huang, D.; Liu, J.; Min, D. High-precision tracking of piezoelectric actuator using iterative learning control and direct inverse compensation of hysteresis. IEEE Trans. Ind. Electron. 2018, 66, 368–377. [Google Scholar] [CrossRef]

- Zhou, M.; Yang, X.; Zhang, C.; Pan, W.; Yu, Y.; Song, M.; He, Y.; Gao, W. Duhem model and inverse compensation controller for trajectory tracking in piezo-actuated micropositioning stage based on neural network. Sens. Actuators A Phys. 2024, 377, 115685. [Google Scholar] [CrossRef]

- Wang, J.; Ni, Y.; Zhang, X.; Li, Z.; Wang, C.; Su, C.Y. Adaptive neural indirect inverse control for a class of fractional-order hysteretic nonlinear time-delay systems and its application. IEEE Trans. Ind. Electron. 2024, 71, 16357–16367. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Wu, J.; Meng, Q.; Su, C.Y. Model Reference Adaptive Control Method for Dielectric Elastomer Material-Based Intelligent Actuator. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 2181–2191. [Google Scholar] [CrossRef]

- Li, Z.; Shan, J.; Gabbert, U. Inverse compensation of hysteresis using Krasnoselskii-Pokrovskii model. IEEE/ASME Trans. Mechatron. 2018, 23, 966–971. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Xu, H.; Zhang, X.; Su, C.Y. Development of a butterfly fractional-order backlash-like hysteresis model for dielectric elastomer actuators. IEEE Trans. Ind. Electron. 2022, 70, 1794–1801. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, X.; Zhu, G.; Su, C.Y. Output feedback adaptive motion control and its experimental verification for time-delay nonlinear systems with asymmetric hysteresis. IEEE Trans. Ind. Electron. 2019, 67, 6824–6834. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Wang, C.; Su, C.Y.; Li, Z.; Chen, X. Adaptive estimated inverse output-feedback quantized control for piezoelectric positioning stage. IEEE Trans. Cybern. 2018, 49, 2106–2118. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, Q.; Chen, W.; Xiao, J.; Hao, L.; Li, Z. Dynamic modelling and inverse compensation for coupled hysteresis in pneumatic artificial muscle-actuated soft manipulator with variable stiffness. ISA Trans. 2024, 145, 468–478. [Google Scholar] [CrossRef]

- Chen, X.; Su, C.Y.; Fukuda, T. Adaptive control for the systems preceded by hysteresis. IEEE Trans. Autom. Control 2008, 53, 1019–1025. [Google Scholar] [CrossRef]

- Zhang, B.; Gupta, B.; Ducharne, B.; Sebald, G.; Uchimoto, T. Dynamic magnetic scalar hysteresis lump model based on Jiles–Atherton quasi-static hysteresis model extended with dynamic fractional derivative contribution. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Padilha, J.; Kuo-Peng, P.; Sadowski, N.; Leite, J.; Batistela, N. Restriction in the determination of the Jiles-Atherton hysteresis model parameters. J. Magn. Magn. Mater. 2017, 442, 8–14. [Google Scholar] [CrossRef]

- Alatawneh, N.; Al Janaideh, M. A frequency-dependent Prandtl–Ishlinskii model of hysteresis loop under rotating magnetic fields. IEEE Trans. Power Deliv. 2019, 34, 2263–2265. [Google Scholar] [CrossRef]

- Dargahi, A.; Rakheja, S.; Sedaghati, R. Development of a field dependent Prandtl-Ishlinskii model for magnetorheological elastomers. Mater. Des. 2019, 166, 107608. [Google Scholar] [CrossRef]

- Huang, K.; Lai, G.; Zhang, Y.; Liu, Z.; Wu, Y.; Chen, C.P. Prescribed fixed-time adaptive fuzzy control for uncertain MIMO nonlinear systems with Preisach operators. Nonlinear Dyn. 2024, 112, 471–489. [Google Scholar] [CrossRef]

- Lai, G.; Deng, G.; Yang, W.; Wang, X.; Su, X. Tracking Control of Uncertain Neural Network Systems with Preisach Hysteresis Inputs: A New Iteration-Based Adaptive Inversion Approach. Actuators 2023, 12, 341. [Google Scholar] [CrossRef]

- Jung, H.; Shim, J.Y.; Gweon, D. New open-loop actuating method of piezoelectric actuators for removing hysteresis and creep. Rev. Sci. Instruments 2000, 71, 3436–3440. [Google Scholar] [CrossRef]

- Changhai, R.; Lining, S. Hysteresis and creep compensation for piezoelectric actuator in open-loop operation. Sens. Actuators A Phys. 2005, 122, 124–130. [Google Scholar] [CrossRef]

- Liu, Y.; Shan, J.; Qi, N. Creep modeling and identification for piezoelectric actuators based on fractional-order system. Mechatronics 2013, 23, 840–847. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, H.; Chen, X.; Li, Z.; Su, C.Y. Modeling and adaptive output feedback control of butterfly-like hysteretic nonlinear systems with creep and their applications. IEEE Trans. Ind. Electron. 2022, 70, 5182–5191. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Meng, Q.; Wang, Y.; Su, C.Y. Robust control of dielectric elastomer smart actuator for tracking high-frequency trajectory. IEEE Trans. Ind. Inform. 2023, 20, 224–234. [Google Scholar] [CrossRef]

- Soleti, G.; Massenio, P.R.; Kunze, J.; Rizzello, G. Model-Based Robust Position Control of an Underactuated Dielectric Elastomer Soft Robot. IEEE Trans. Robot. 2025, 41, 1693–1710. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, Y.; Wang, Q. Dynamic compensation of load-dependent creep in dielectric electro-active polymer actuators. IEEE Sensors J. 2021, 22, 1948–1955. [Google Scholar] [CrossRef]

- Chen, X.; Ren, J.; Gu, G.; Zou, J. Dynamic Model Based Neural Implicit Embedded Tracking Control Approach for Dielectric Elastomer Actuators With Rate-Dependent Viscoelasticity. IEEE Robot. Autom. Lett. 2024, 9, 9031–9038. [Google Scholar] [CrossRef]

- Xu, Y.; Luo, Y.; Luo, X.; Chen, Y.; Liu, W. Fractional-order modeling of piezoelectric actuators with coupled hysteresis and creep effects. Fractal Fract. 2023, 8, 3. [Google Scholar] [CrossRef]

- Xu, Z.; Wu, J.; Wang, Y. Fractional order modeling and internal model control method for dielectric elastomer actuator. Asian J. Control 2025, 27, 117–127. [Google Scholar] [CrossRef]

- Phan, V.D.; Ahn, K.K. Fault-tolerant control for an electro-hydraulic servo system with sensor fault compensation and disturbance rejection. Nonlinear Dyn. 2023, 111, 10131–10146. [Google Scholar] [CrossRef]

- Truong, H.V.A.; Phan, V.D.; Tran, D.T.; Ahn, K.K. A novel observer-based neural-network finite-time output control for high-order uncertain nonlinear systems. Appl. Math. Comput. 2024, 475, 128699. [Google Scholar] [CrossRef]

- Phan, V.D.; Vo, C.P.; Ahn, K.K. Adaptive neural tracking control for flexible joint robot including hydraulic actuator dynamics with disturbance observer. Int. J. Robust Nonlinear Control 2024, 34, 8744–8767. [Google Scholar] [CrossRef]

- Phan, V.D.; Phan, Q.C.; Ahn, K.K. Observer-Based Adaptive Fuzzy Tracking Control for a Valve-Controlled Electro-Hydraulic System in Presence of Input Dead Zone and Internal Leakage Fault. Int. J. Fuzzy Syst. 2025, 1–14. [Google Scholar] [CrossRef]

- Lu, X.; Lin, Y.; Hu, T. Physic-based and control-oriented modeling based robust control for soft dielectric elastomer actuator. Smart Mater. Struct. 2020, 29, 035026. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Li, Z.; Chen, X.; Su, C.Y. Adaptive implicit inverse control for a class of butterfly-like hysteretic nonlinear systems and its application to dielectric elastomer actuators. IEEE Trans. Ind. Electron. 2022, 70, 731–740. [Google Scholar] [CrossRef]

- Liu, L.; Yun, H.; Li, Q.; Ma, X.; Chen, S.L.; Shen, J. Fractional order based modeling and identification of coupled creep and hysteresis effects in piezoelectric actuators. IEEE/ASME Trans. Mechatron. 2020, 25, 1036–1044. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X. Model order reduction for the Krasnoselskii–Pokrovskii (KP) model. Smart Mater. Struct. 2019, 28, 095001. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, Y.; Ji, K.; Zhu, D. Model reference adaptive control based on KP model for magnetically controlled shape memory alloy actuators. J. Appl. Biomater. Funct. Mater. 2017, 15, 31–37. [Google Scholar] [CrossRef]

- Xu, R.; Tian, D.; Zhou, M. A rate-dependent KP modeling and direct compensation control technique for hysteresis in piezo-nanopositioning stages. J. Intell. Mater. Syst. Struct. 2022, 33, 629–640. [Google Scholar] [CrossRef]

- Hoffstadt, T.; Maas, J. Adaptive sliding-mode position control for dielectric elastomer actuators. IEEE/ASME Trans. Mechatron. 2017, 22, 2241–2251. [Google Scholar] [CrossRef]

- Suo, Z. Theory of dielectric elastomers. Acta Mech. Solida Sin. 2010, 23, 549–578. [Google Scholar] [CrossRef]

| Symbol | Unit | Meaning |

|---|---|---|

| y | mm | The driving displacement of DEA |

| g | m/s2 | The gravitational acceleration |

| N | The viscoelastic stress of DEA | |

| N | The electrical stress of DEA | |

| N | The elastic stress of DEA | |

| H | mm | The initial thickness of the membrane |

| / | The total stretching degree | |

| / | The pre-stretching degree | |

| ° | The deflection angle | |

| MPa | The strain shear modulus | |

| F/m | The dielectric constant of the film | |

| N/m | The spring stiffness coefficient | |

| N · s/m | The damper damping coefficient | |

| R | mm | The horizontal distance from a point to the center |

| mm | The hysteresis output displacement of the DEA with creep effect | |

| / | The fractional-order integral operator | |

| / | The historical function value | |

| / | The generalized binomial coefficient | |

| / | The Gamma function | |

| / | The fractional order | |

| / | The output of the KP hysteresis model | |

| / | The Gamma function | |

| / | The two-dimensional integration region | |

| / | KP kernel | |

| / | The KP kernel thresholds | |

| / | The ridge function | |

| / | The slope parameter of the KP kernel |

| Kind of Tracking Error | MAE | RMSE |

|---|---|---|

| Proposed control scheme | 0.35 × 10−2 | 0.44 × 10−2 |

| Backstepping control | 0.46 × 10−2 | 0.71 × 10−2 |

| PID control | 2.55 × 10−2 | 3.04 × 10−2 |

| MPC | 0.58 × 10−2 | 0.8 × 10−2 |

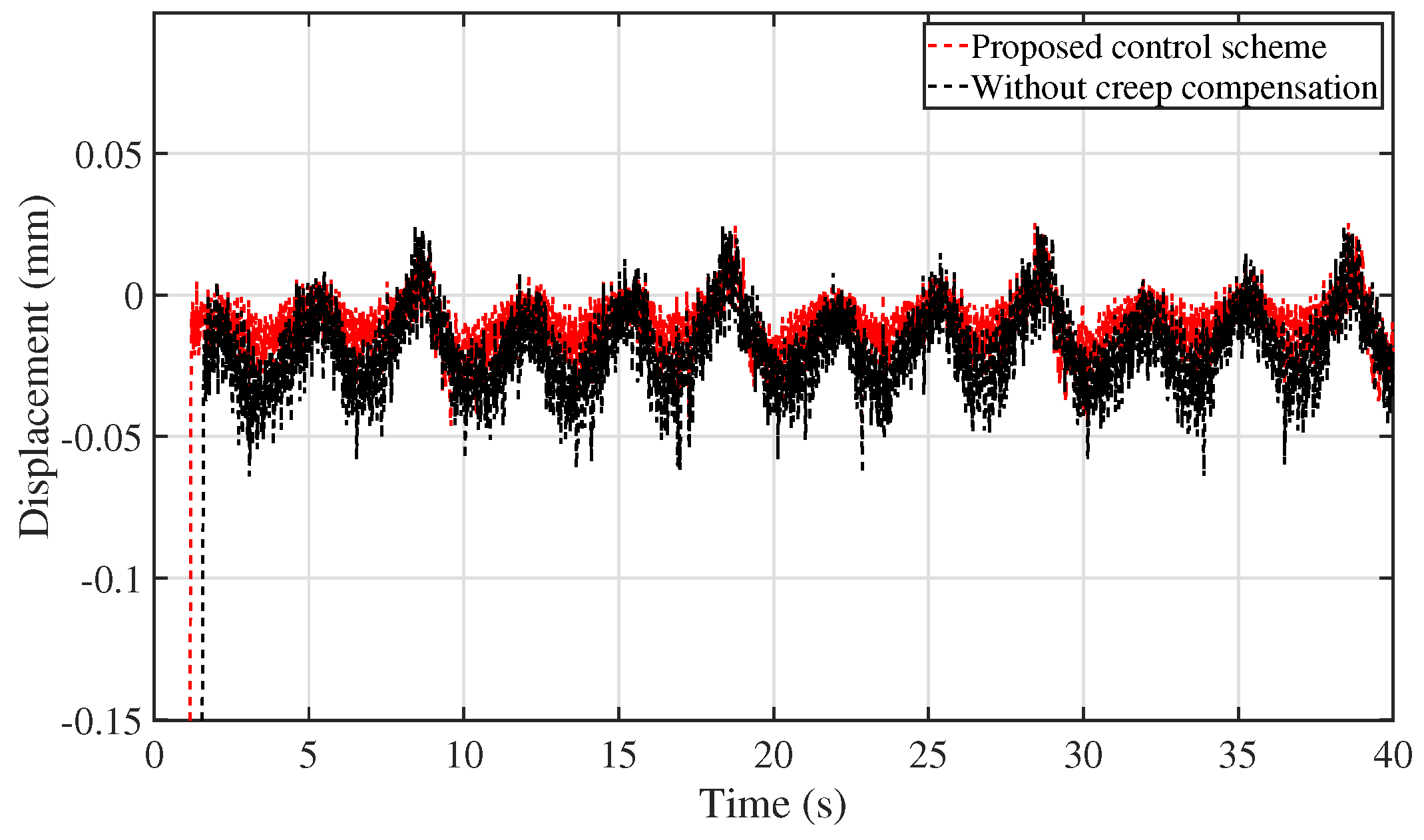

| Kind of Tracking Error | MAE | RMSE |

|---|---|---|

| Proposed control scheme | 0.0111 | 0.0133 |

| Without creep compensation | 0.0202 | 0.0235 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liu, Y.; Zhang, X.; Zhang, X.; Han, L.; Li, Z. Fractional-Order Creep Hysteresis Modeling of Dielectric Elastomer Actuator and Its Implicit Inverse Adaptive Control. Fractal Fract. 2025, 9, 479. https://doi.org/10.3390/fractalfract9080479

Wang Y, Liu Y, Zhang X, Zhang X, Han L, Li Z. Fractional-Order Creep Hysteresis Modeling of Dielectric Elastomer Actuator and Its Implicit Inverse Adaptive Control. Fractal and Fractional. 2025; 9(8):479. https://doi.org/10.3390/fractalfract9080479

Chicago/Turabian StyleWang, Yue, Yuan Liu, Xiuyu Zhang, Xuefei Zhang, Lincheng Han, and Zhiwei Li. 2025. "Fractional-Order Creep Hysteresis Modeling of Dielectric Elastomer Actuator and Its Implicit Inverse Adaptive Control" Fractal and Fractional 9, no. 8: 479. https://doi.org/10.3390/fractalfract9080479

APA StyleWang, Y., Liu, Y., Zhang, X., Zhang, X., Han, L., & Li, Z. (2025). Fractional-Order Creep Hysteresis Modeling of Dielectric Elastomer Actuator and Its Implicit Inverse Adaptive Control. Fractal and Fractional, 9(8), 479. https://doi.org/10.3390/fractalfract9080479