2.1. Theory of Fractional-Order Models

FOMs provide more accurate physical system descriptions than their integer-order counterparts. Among existing fractional-order definitions, including Riemann–Liouville (R-L), Caputo, and Oustaloup’s approximation, each suited to different applications, the Grünwald–Letnikov (G-L) definition [

33] is adopted herein. As a direct extension of classical integer-order calculus, the inherent simplicity and ease of use of the G-L method are highly effective for establishing FOMs of batteries and implementing their numerical calculations. The formula can be presented as follows:

where

, the term

denotes the fractional-order integral if

, and it signifies the fractional-order differential if

. The constant

serves as the lower integration boundary, physically corresponding to the starting time. Within the scope of this research, the system’s initial time is established as zero, meaning

.

In addition, for any given function

, its G-L definition for a fractional order

is given by the following [

34]:

In this equation,

denotes the sampling interval; the term

represents the integral component of the ratio

. Furthermore, it should be noted that

, representing the Newtonian binomial coefficient, is defined as follows:

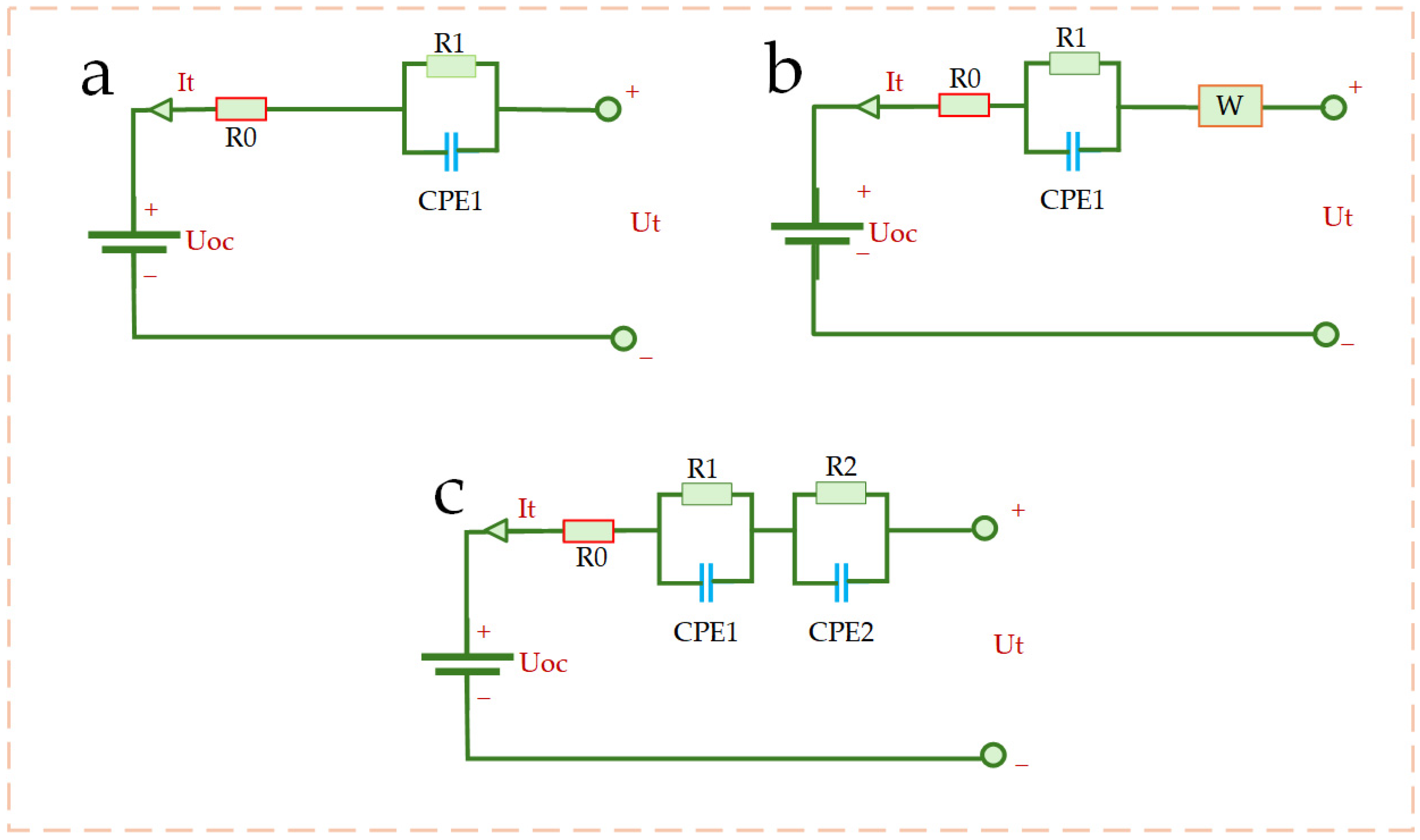

2.2. Fractional-Order Model of the Battery

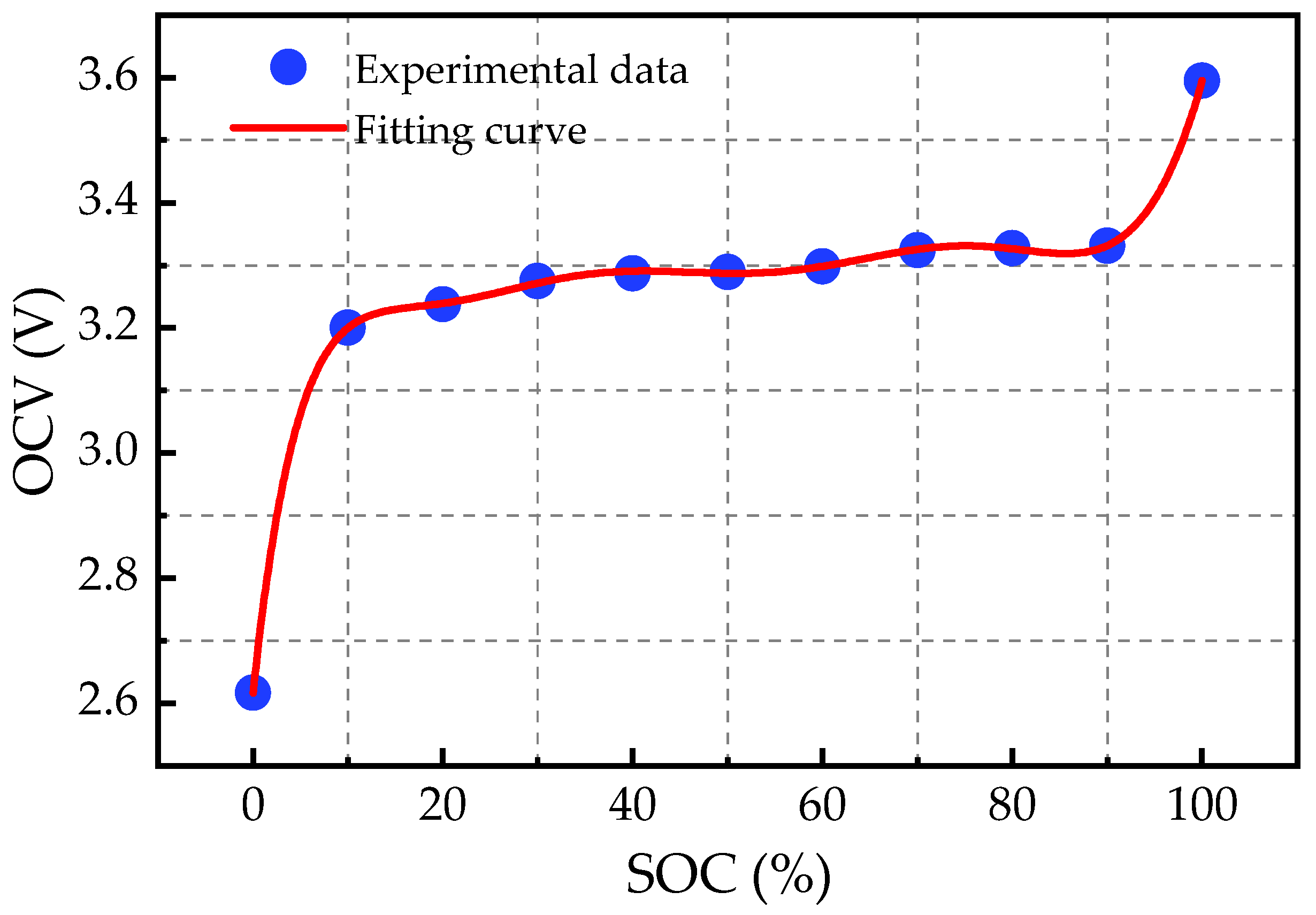

In order to further use fractional-order theory for model construction, the electrochemical impedance technology (EIS) is briefly discussed here. It is reported that EIS can been utilized for characterizing the impedance behavior of a battery across different frequency bands. And the prerequisite for realizing this function requires applying a small-amplitude sinusoidal current perturbation over a wide frequency range. A typical impedance spectrum for LIB is illustrated in

Figure 1, which exhibits distinct frequency regions. These regions are often interpreted and modeled using equivalent circuits composed of resistors, capacitors, and CPE [

35]

According to descriptions in the Ref. [

36], the high-frequency domain primarily indicates the resistive behavior of the electrolyte and diaphragm, a characteristic linked to the transport of lithium-ions and electrons; this behavior is typically represented by a single resistive component. The mid-frequency semicircle shown in

Figure 1 is linked to the charge transfer taking place at the boundary between the electrode and electrolyte and is typically represented using a resistor and a CPE in a parallel arrangement. Moreover, the inclined line observed at lower frequencies stems from the diffusion processes of lithium ions within the solid phase of the active material; an appropriate impedance model for this section is chosen based on particular requirements. For instance, to enhance computational speed, Tian J et al. disregarded the effects from the low-frequency domain [

33]. To characterize the low-frequency behavior, Umar A et al. incorporated a Warburg impedance into their model [

37]. For an improved representation of the mid-frequency impedance response, Chen L et al. introduced an additional R-CPE parallel circuit to an existing fractional first-order model [

23].

Based on the electrochemical principle, the impedance of a CPE is given by the following:

where

is the impedance and

is the fractional order. When

, CPE is equivalent to a capacitive element, and when

, CPE can be viewed as a Warburg element.

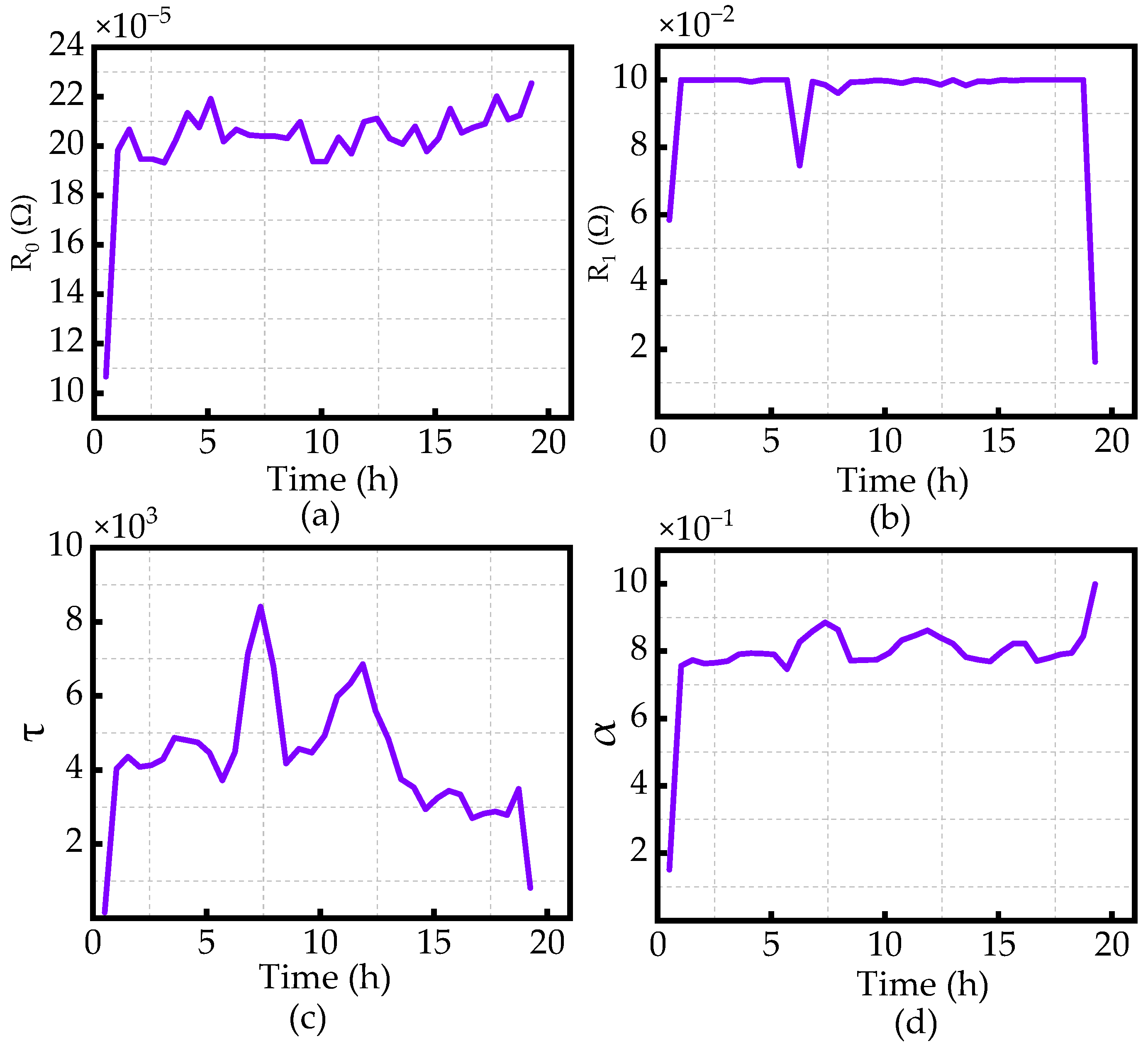

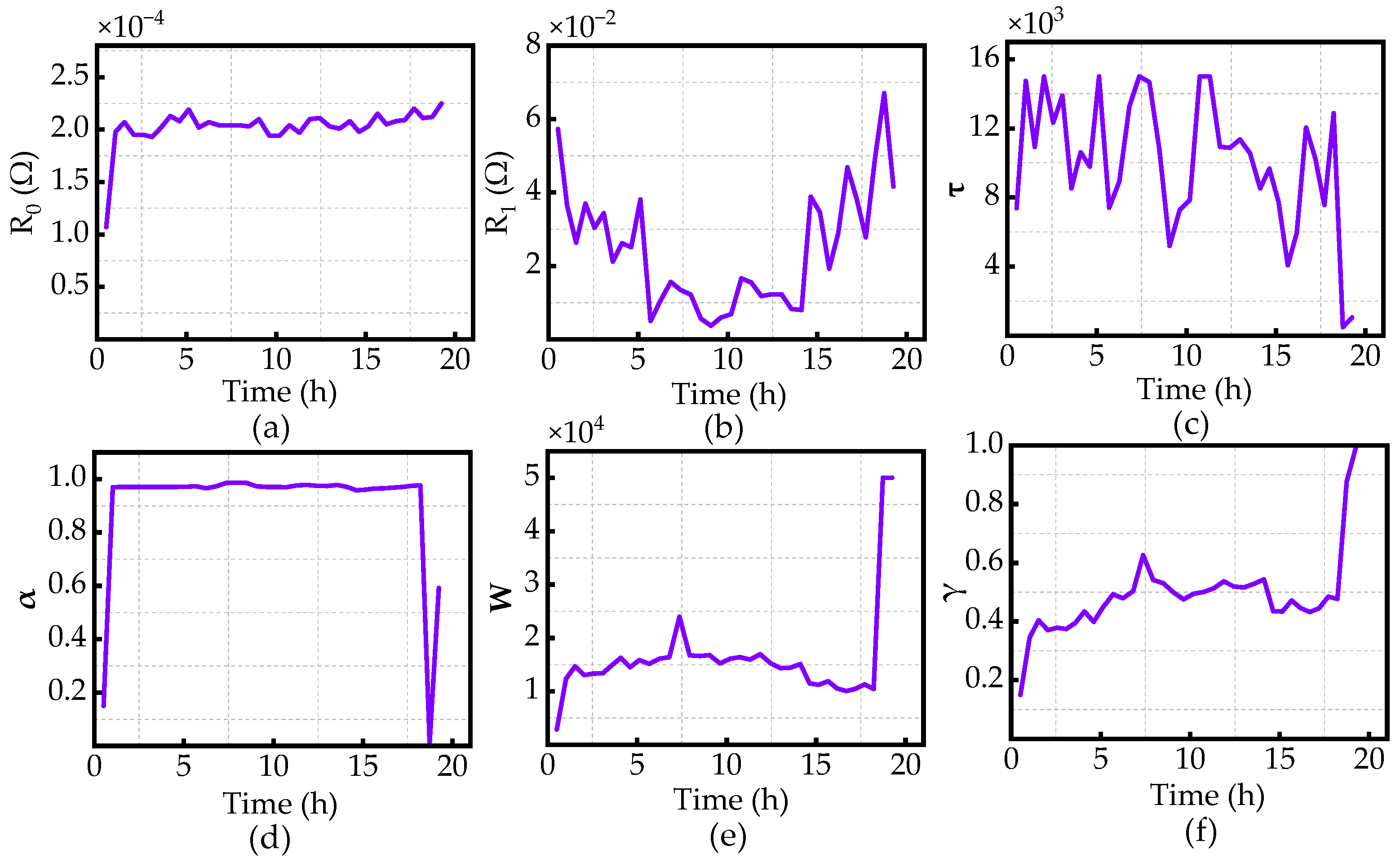

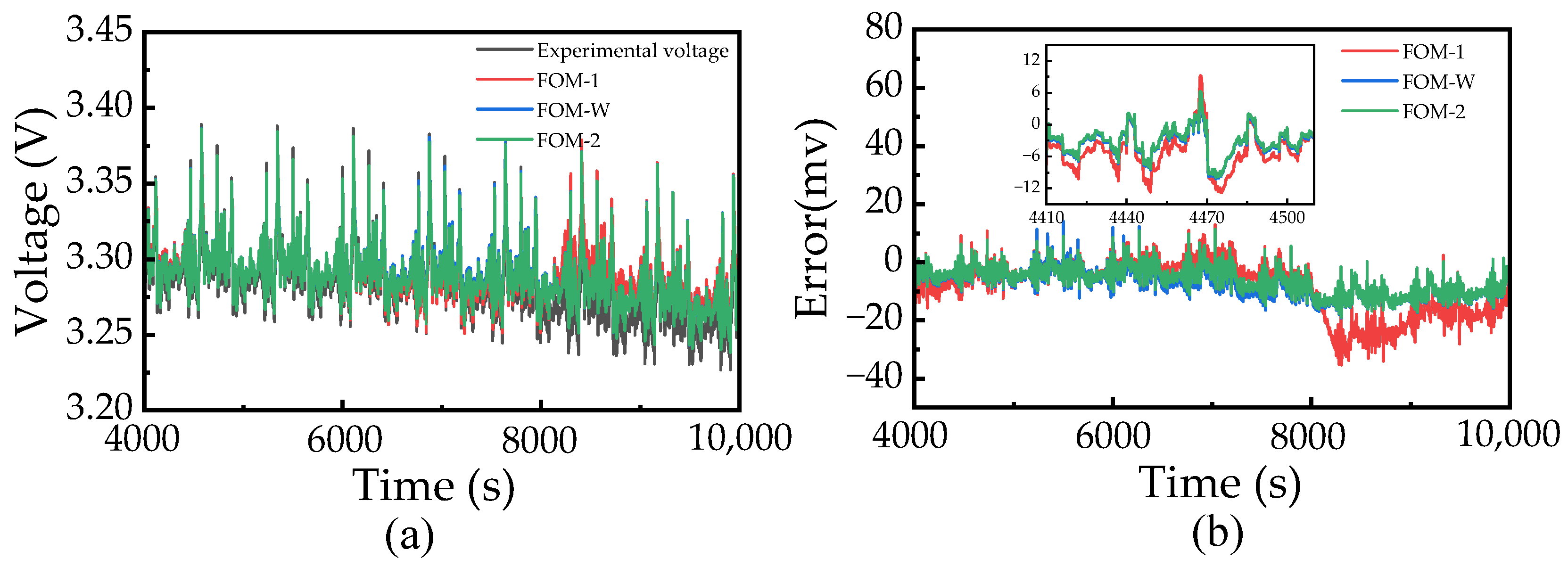

Considering this advantage and the importance of model selection to accurately predict battery performance, this study selects three representative FOMs that differ in complexity and their representation of electrochemical dynamics: a fractional first-order model (called FOM-1) [

27], fractional first-order model with Warburg impedance (called FOM-W) [

38], and fractional second-order model (called FOM-2) [

39]. And the detailed structure of these models can be found in

Figure 2. The specific mathematical derivation and structure of these FOMs will be further described in

Section 2.2.1, prior to their comparative evaluation under a novel driving cycle dataset which aims to provide a practical reference for LIB model selection.

2.2.1. FOM-1

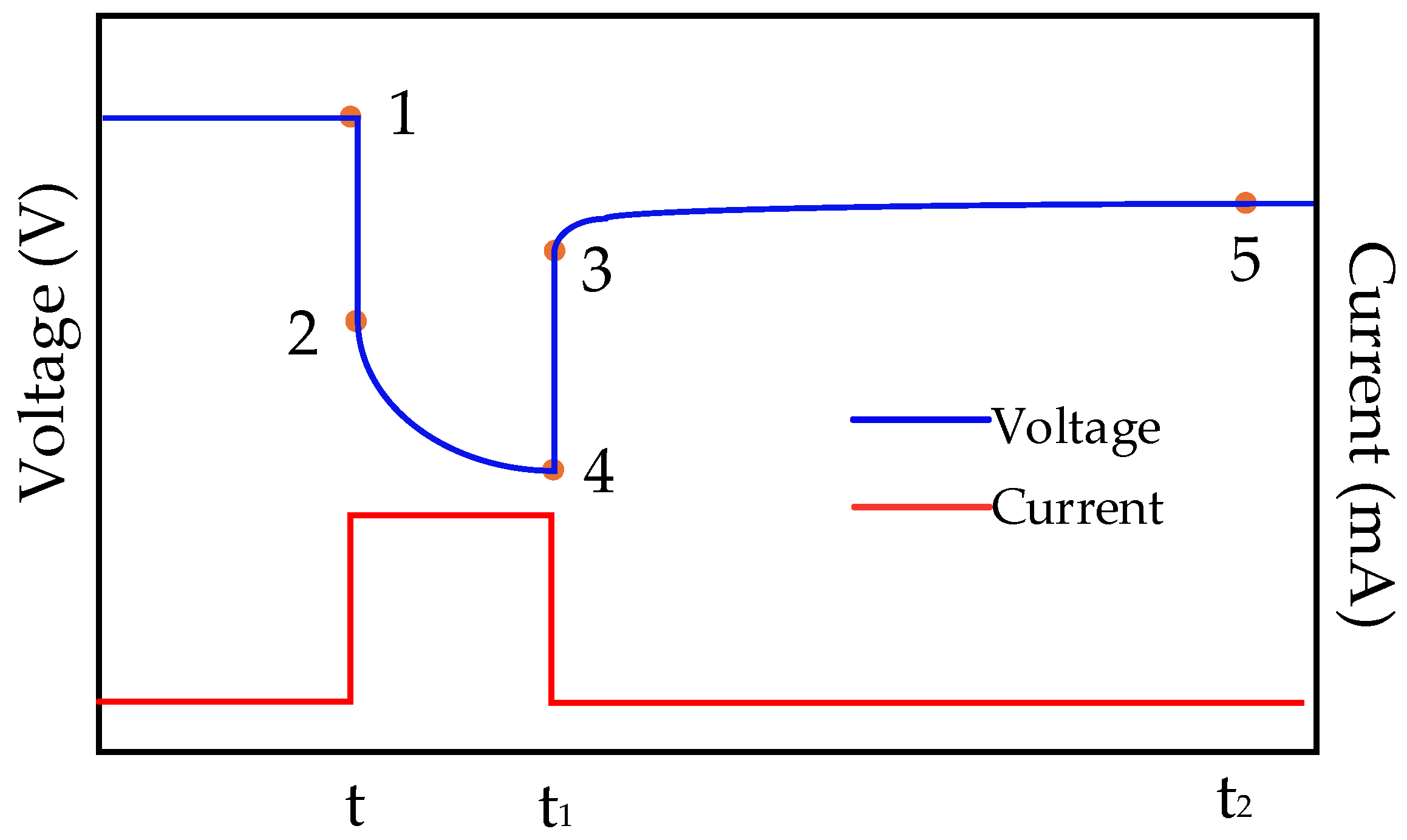

As shown in

Figure 2a, the FOM-1 architecture comprises an open-circuit voltage (OCV) source, an ohmic resistor R0, and an R-CPE network [

6]. To elaborate on its components, within FOM-1, the OCV element primarily serves to model the open-circuit voltage. The resistor R0 is employed to represent the cell’s static behavior, while the R-CPE network is included to better capture the cell’s performance during dynamic operations. A discussion of more structural parameters can be found in Ref. [

33].

Applying Kirchhoff’s current and voltage laws, the equations for this single fractional-order RC model are derived as follows:

The expression for the terminal voltage is as follows:

The voltage behavior of the R-CPE network is given by the following:

The updated formula after G-L discretization can be expressed as follows:

where

denotes the sampling interval,

represents the weighting coefficient,

signifies the memory length, and

is the discrete time step.

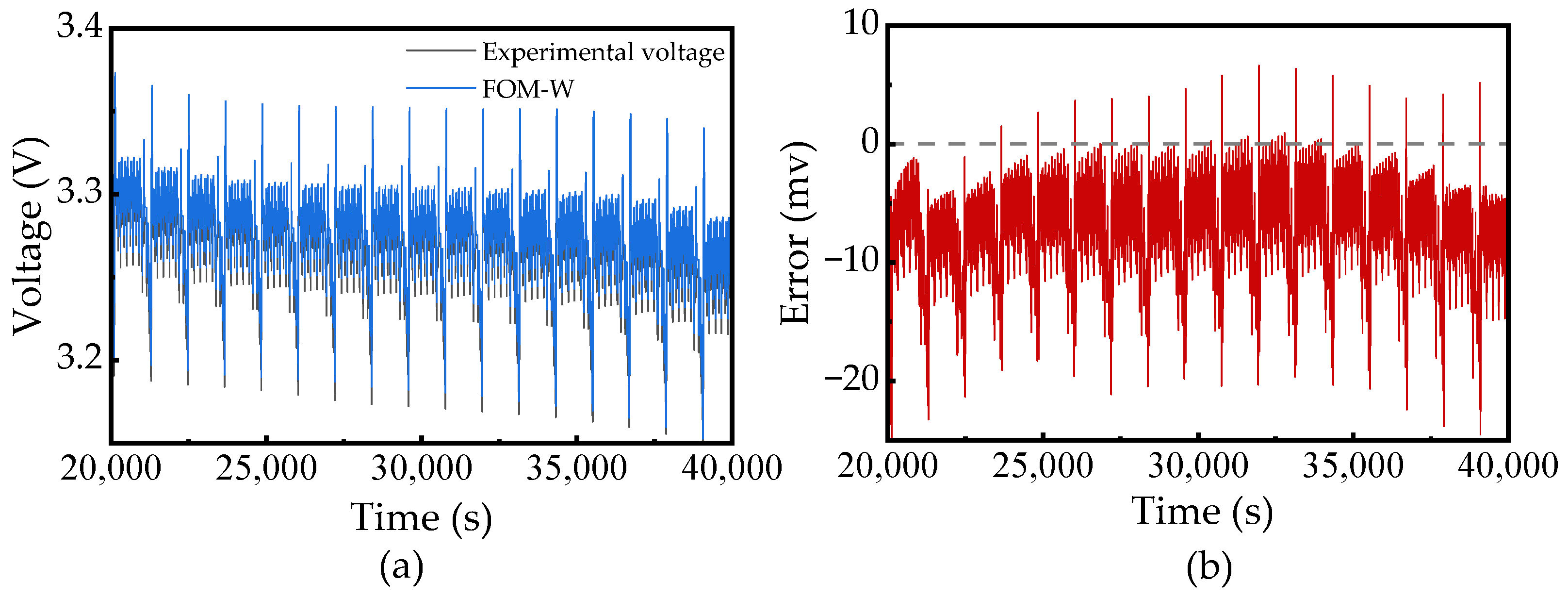

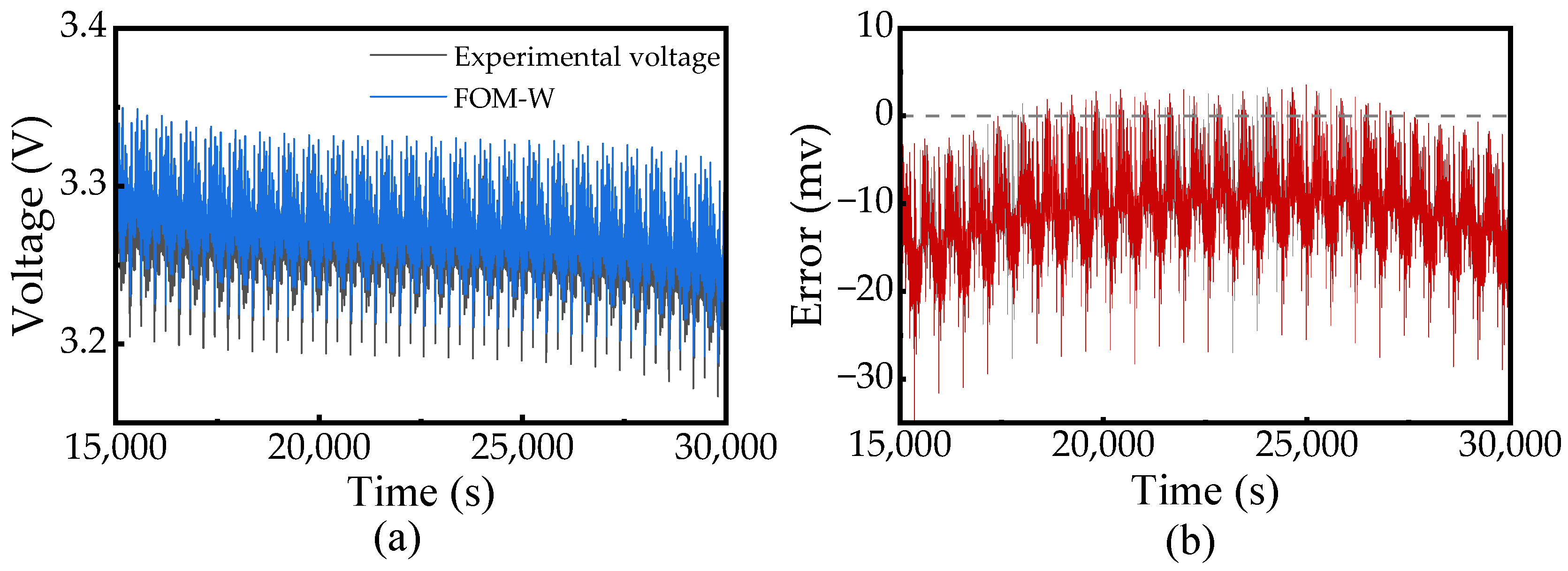

2.2.2. FOM-W

To explain the FOM-W model, its structure can be found in

Figure 2b. Specifically, a Warburg element is incorporated in series with FOM-1, traditionally employing a fixed order of 0.5 to represent the model’s diffusion-driven low-frequency behavior [

38]. However, in the present work, the Warburg element’s order is treated as an identifiable variable during parameter estimation, granting it a flexibility comparable to that of a CPE. The element’s coefficient and order are denoted by W and γ, respectively.

The voltage behavior of the combined R-W-CPE network is given by the following:

The voltage characteristics of Warburg components can be expressed as follows:

The update equation for the Warburg component is given by the following:

where

is the voltage of the Warburg element at a discrete moment k,

represents the Warburg coefficient, and

indicates its fractional order.

The formulation for the weighting factors is as follows:

2.2.3. FOM-2

To potentially capture more complex battery dynamics than FOM-1, the second-order fractional model (FOM-2) is introduced, as depicted in

Figure 2c. This model enhances the FOM-1 structure by incorporating an additional R-CPE network [

39].

The equations defining the terminal voltage are formulated as follows:

The characteristics of the additionally incorporated R-CPE network are described by the following:

The updated formula of the fractional-order R2-CPE2 network after the G-L discretization form is as follows:

The weighting factors can be expressed as the following:

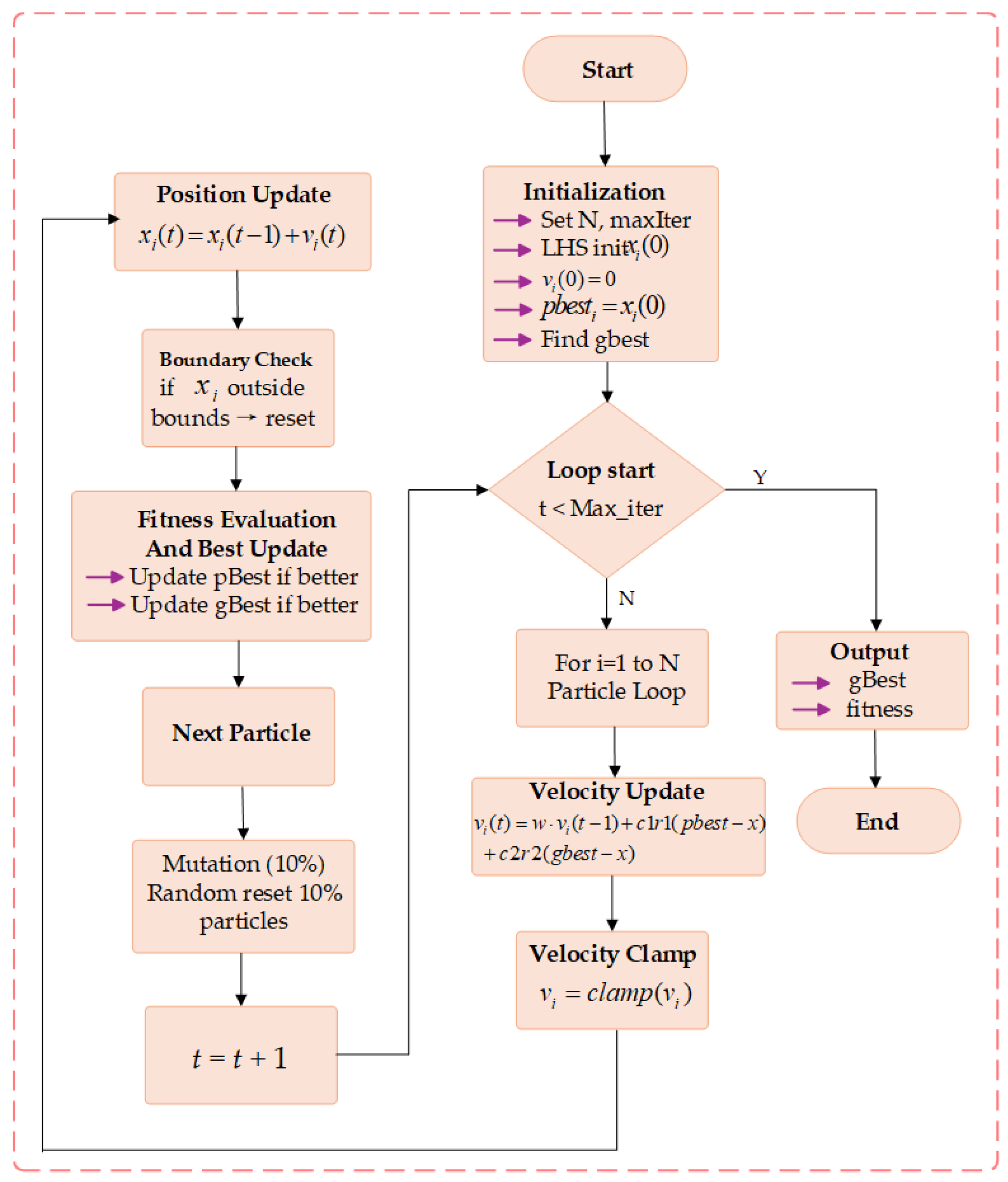

2.3. Parameter Identification of FOMs Based on the PSO Algorithm

Within the domain of parameter identification, numerous methodologies have been investigated by researchers, such as the genetic algorithm (GA) and recursive least squares (RLS). Nevertheless, the GA is susceptible to converging at local optima, and the RLS often lacks precision for the highly non-linear characteristics inherent in these FOMs, and the extended Kalman filter (EKF) [

30] is often constrained by the high computational cost stemming from the large number of state variables in such FOMs. In contrast, the PSO algorithm, leveraging its robust global search ability [

40], is particularly effective for finding optimal parameter solutions in complex and nonlinear fitting problems, proving highly suitable for the FOMs in this study. Furthermore,

Figure 3 illustrates the detailed procedure of its application for determining the FOM parameters.

To facilitate a clearer comprehension of this procedure and the fundamental principles of the selected algorithm for identifying the parameters of the FOMs, a concise overview of PSO is firstly introduced. In general, the PSO functions as a probabilistic optimization method inspired by the collective behavior observed in natural swarms. Although the PSO has certain general limitations, it is more suitable for parameter identification and analysis of different fractional-order models compared with other optimization algorithms. It needs to be emphasized that the algorithm strives to find the optimal FOM parameters by iteratively adjusting particle positions and velocities within a high-dimensional search space corresponding to the FOM parameter domain. The following outlines its primary process steps:

This involves defining the swarm (population) size

, establishing the upper limit for iterations

, specifying the permissible range for parameters

(which correspond to the bounds for each parameter of the FOMs, such as

,

,

, etc.), and formulating the objective function as indicated below:

Here, n represents the aggregate quantity of values, with being the experimentally recorded voltage and the voltage predicted by the FOMs using a candidate set of parameters.

Latin Hypercube Sampling (LHS) is used to initialize the positions of particles in space , where is the parameter dimension of the FOMs. The initial velocity is set to zero.

Then, calculate the initial fitness of each particle in parallel, and determine the initial individual optimal fitness ; next, select the particle with optimal , and assign its position and fitness to the global optimal position and global optimal fitness .

Update for each population particle .

The velocity update is as follows: The new speed is calculated according to Equation (17).

In Equation (17), represents the inertia weight factor; and are termed the acceleration constants; and signify randomly generated values within the range [0, 1]; and denotes dimension index.

The velocity limit is as follows: limit the updated velocity to , where .

The position update is as follows: the particle’s new position is then computed using the subsequent formula:

The fitness evaluation is as follows: compute the fitness of the new location .

The individual and global optimal updates are as follows: If is better than , then update and . If is better than , then update and ;

The mutation mechanism is as follows: In each iteration, about 10% of particles are randomly selected with a probability of 10%, and their positions are randomly initialized into the search space to enhance population diversity and avoid premature convergence.

When reaching Max_iter or satisfying the set iterative optimal value, the algorithm terminates. The final global optimal position is output as the identification result for the FOM parameters, and the evolution history, of , of the optimization process is recorded.