Full-Scale Pore Structure Characterization and Its Impact on Methane Adsorption Capacity and Seepage Capability: Differences between Shallow and Deep Coal from the Tiefa Basin in Northeastern China

Abstract

1. Introduction

2. Materials and Methods

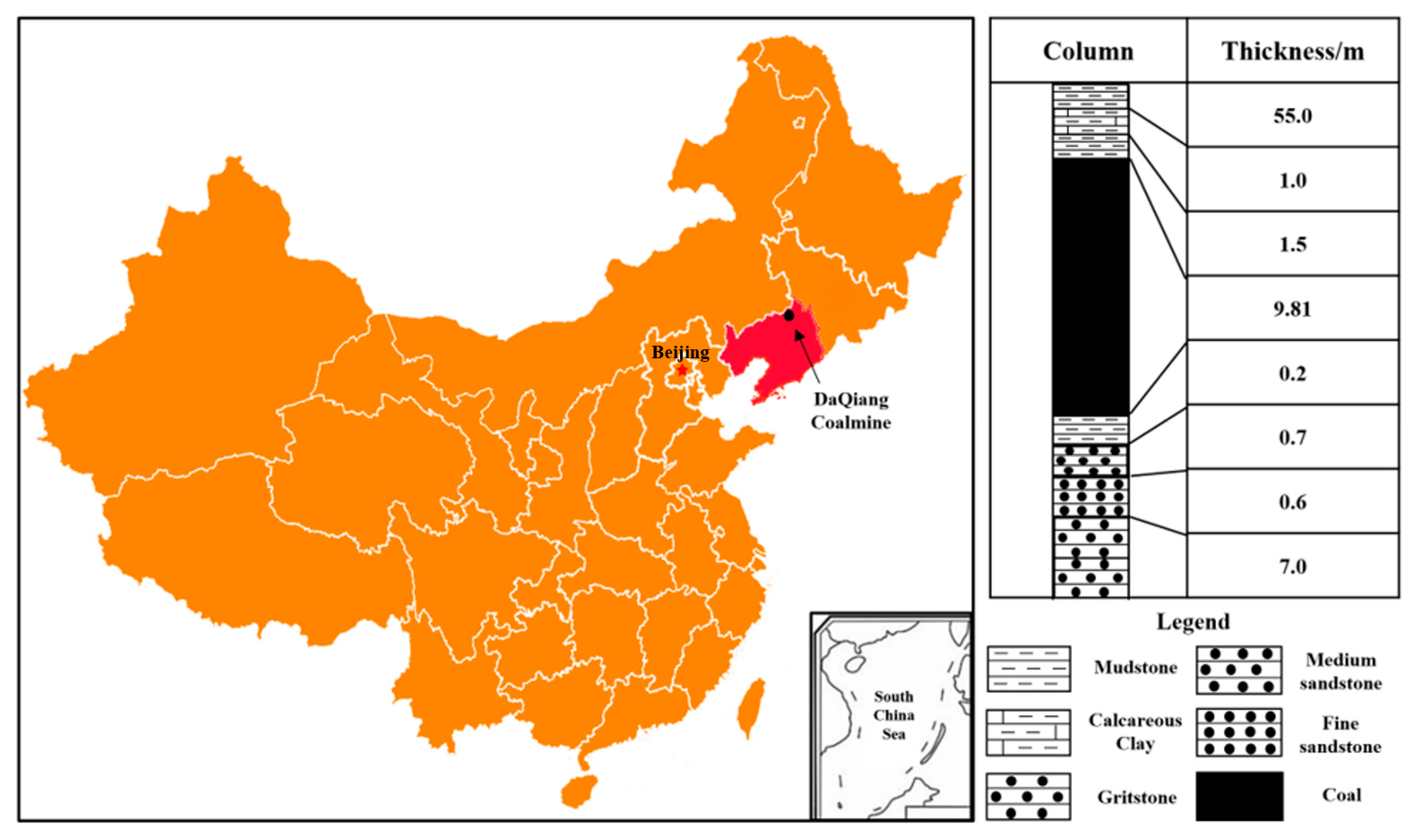

2.1. Sampling

2.2. N2 Adsorption/Desorption, CO2 Adsorption, and CH4 Isotherm Adsorption Analysis

2.3. MIP Measurements and CT Measurements

2.4. Fractal Theory

3. Results

3.1. Coal Characteristics

3.2. The Pore Structure Features of Daqiang Coal

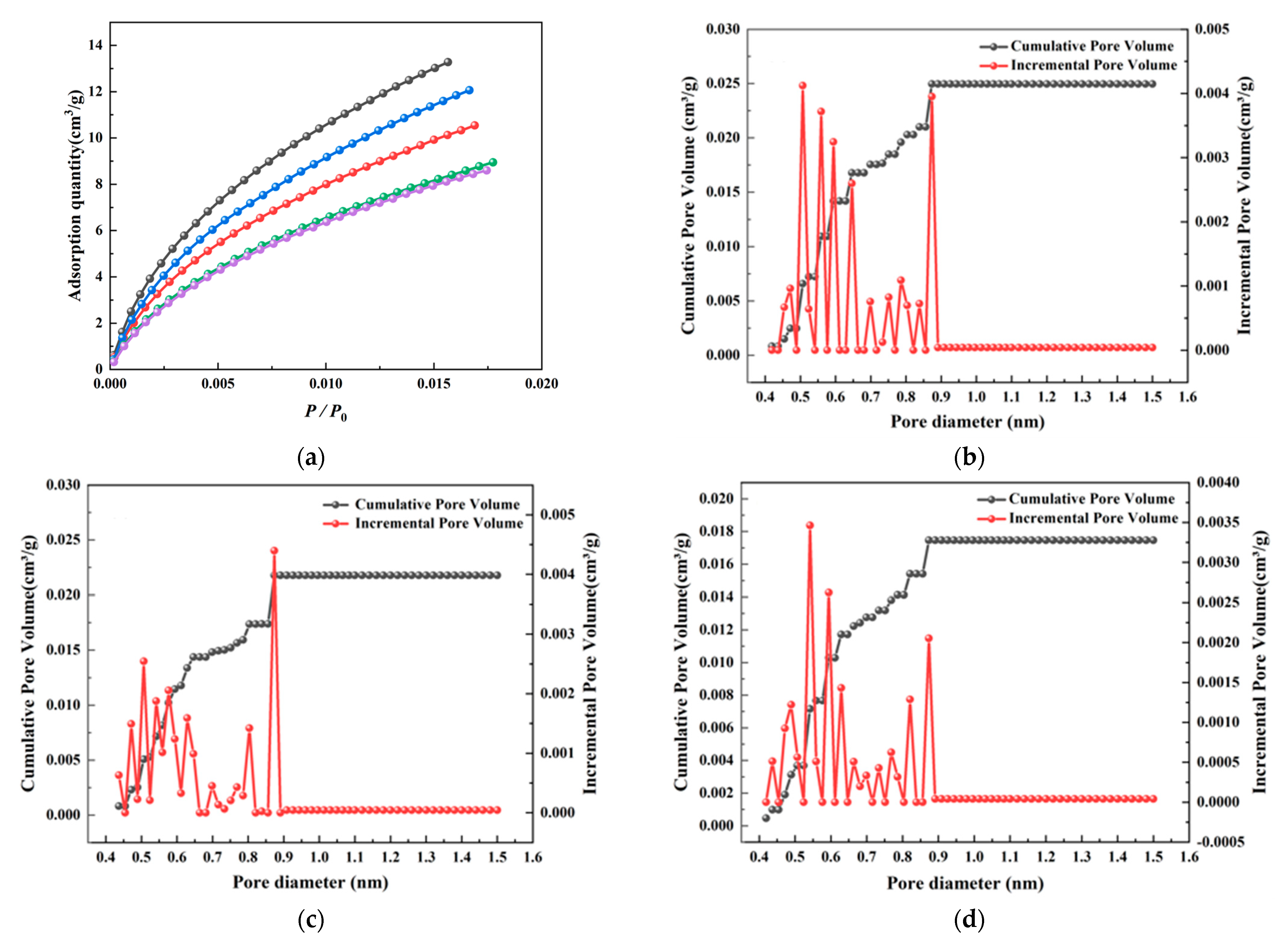

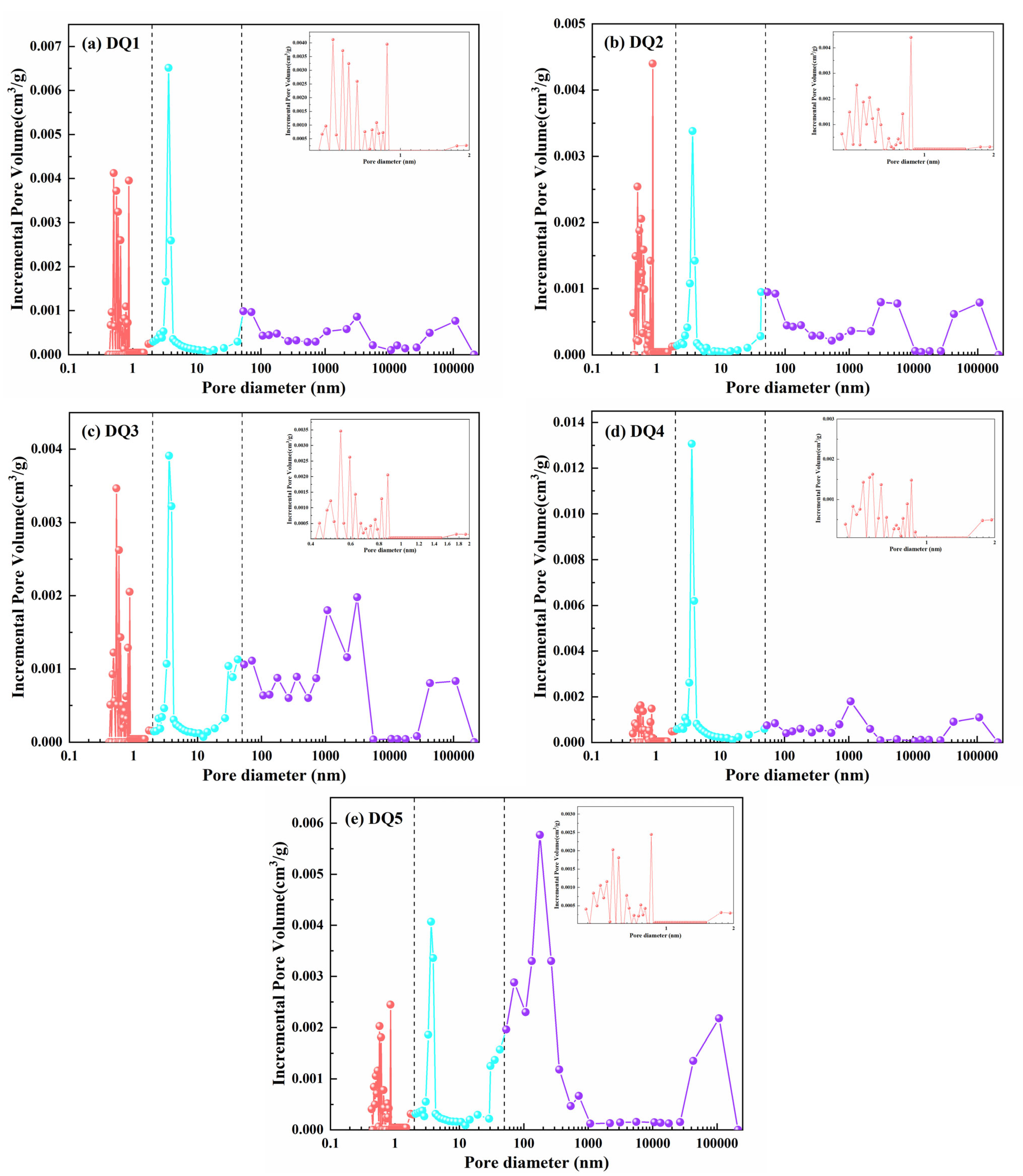

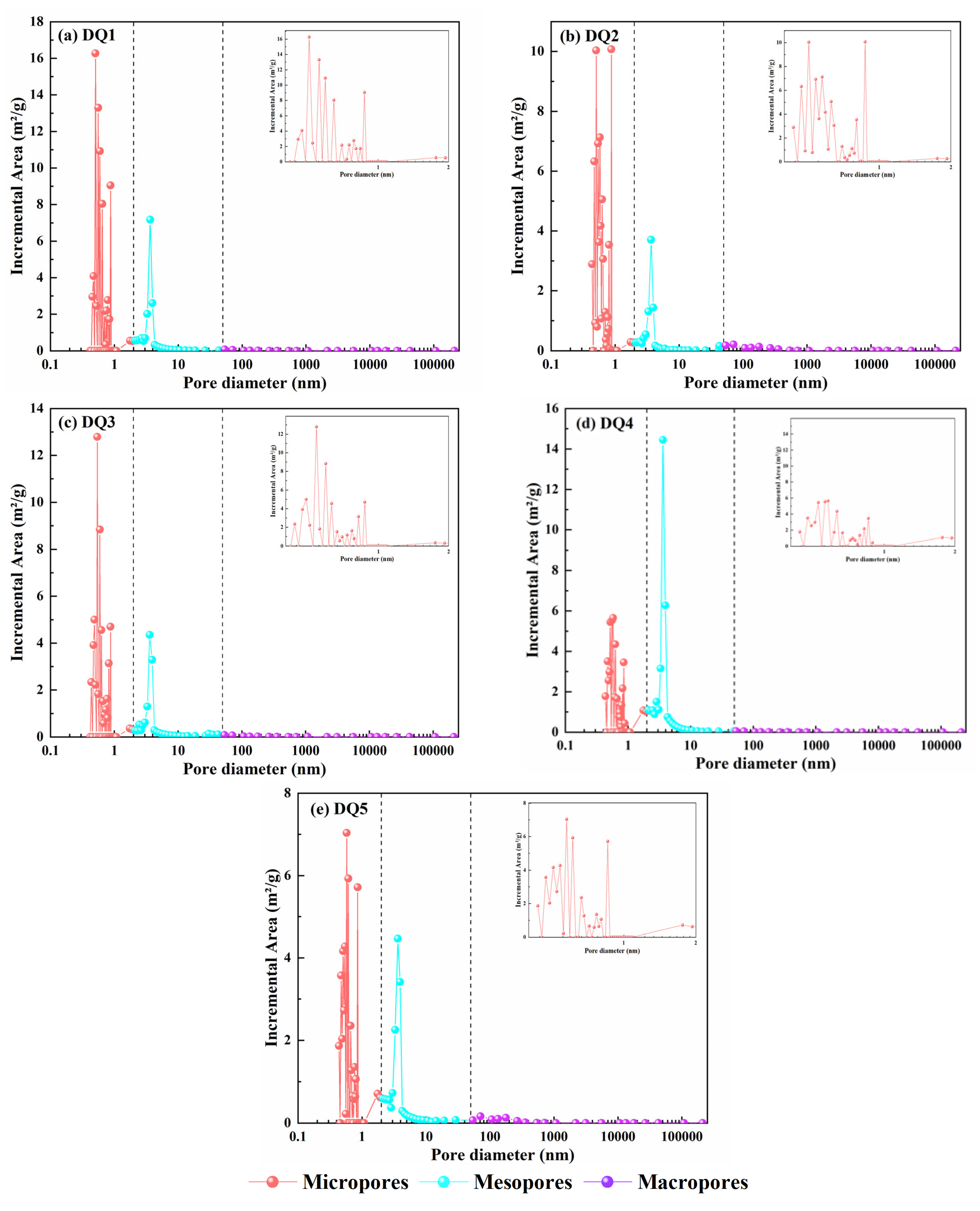

3.2.1. Micropore Structure Characteristic Determined by CO2 Adsorption

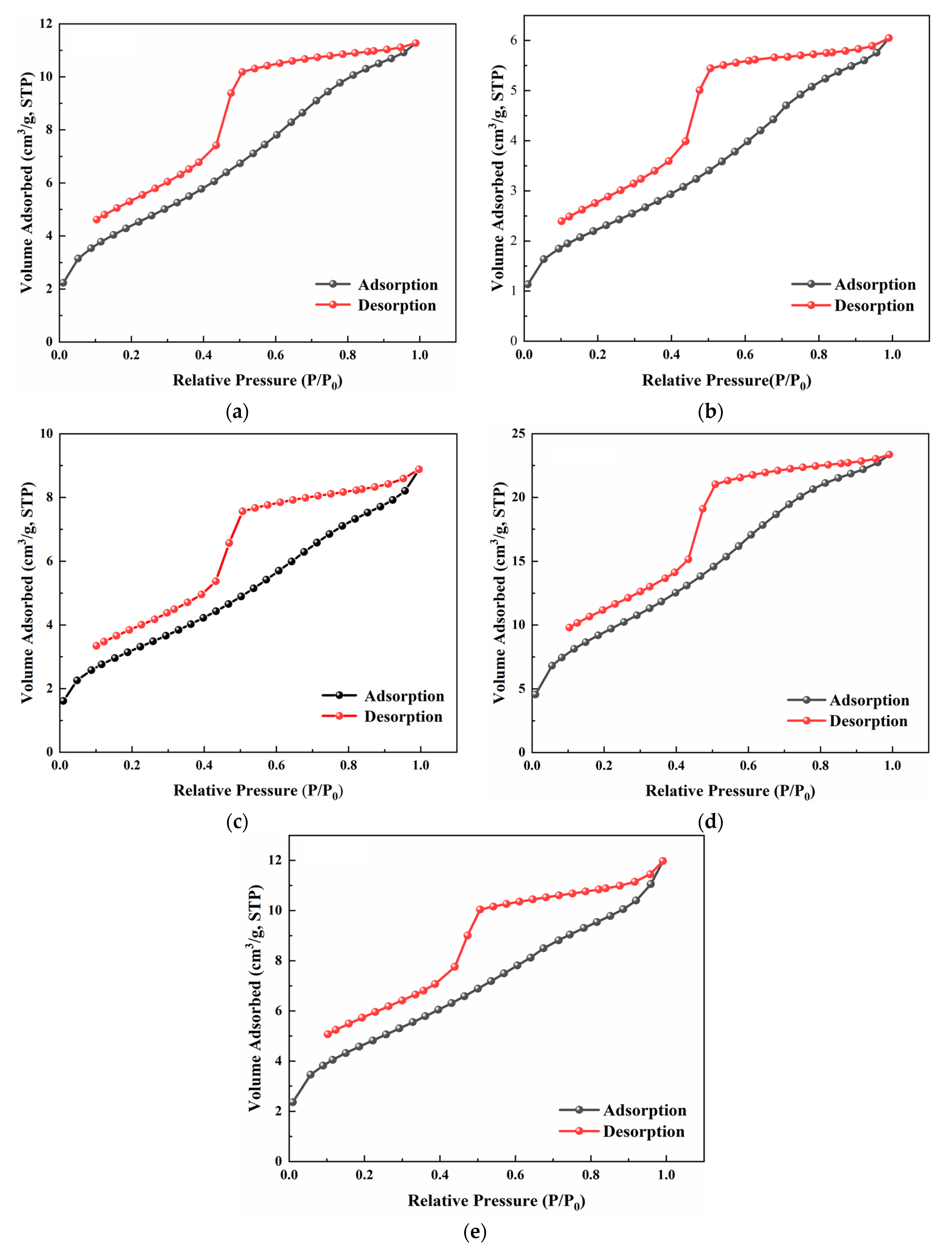

3.2.2. Mesopore Structure Characteristic Determined by N2 Adsorption

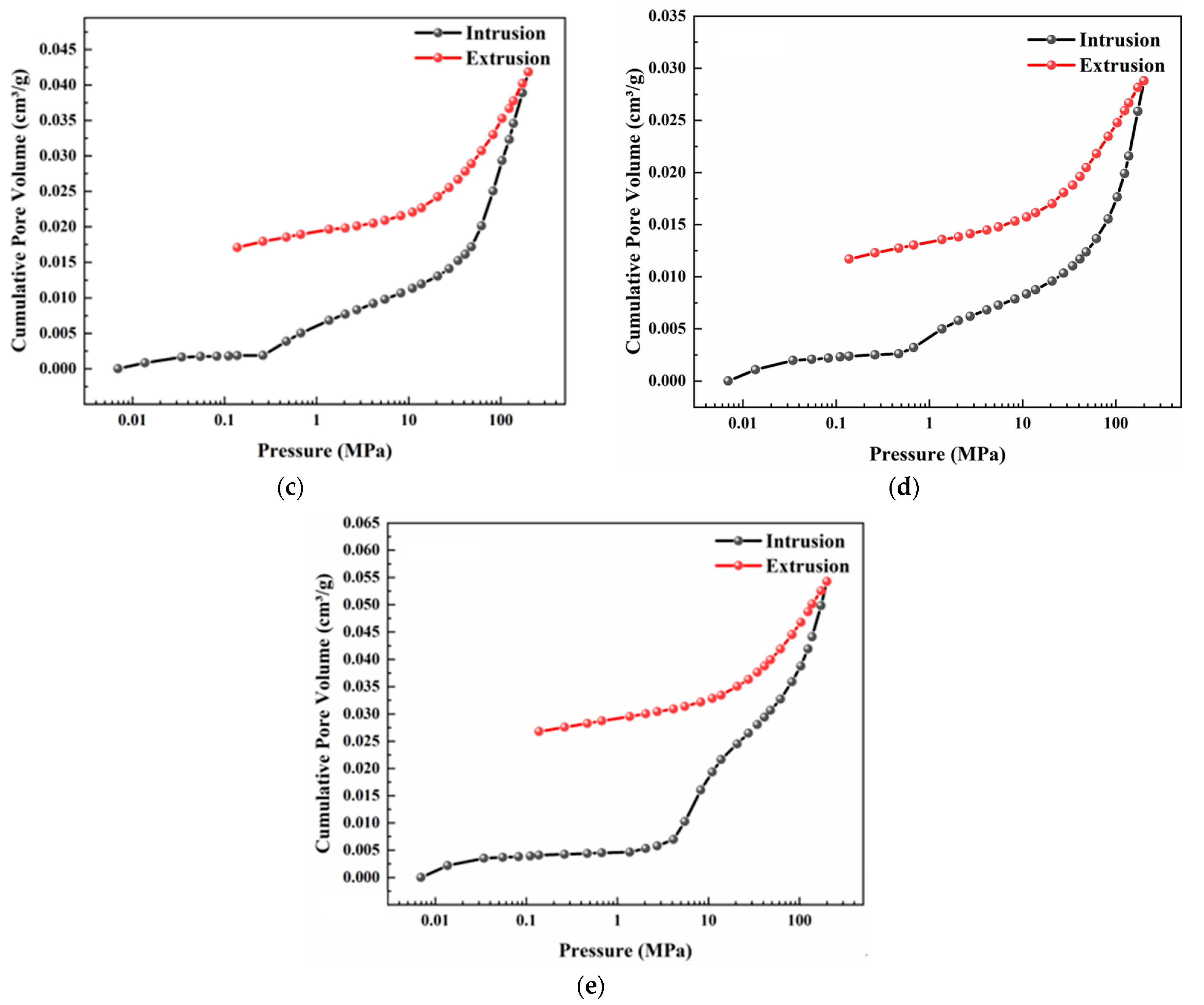

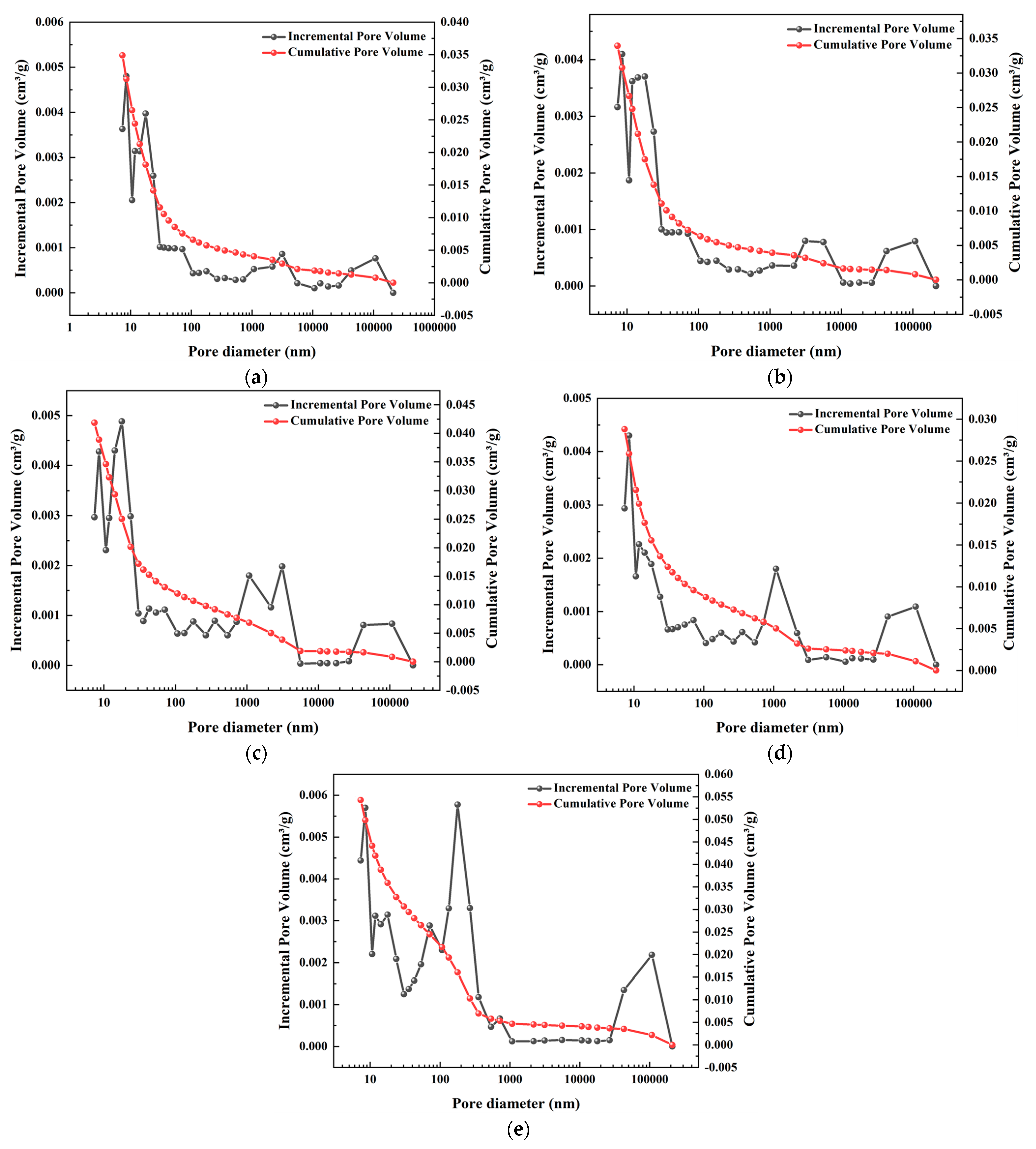

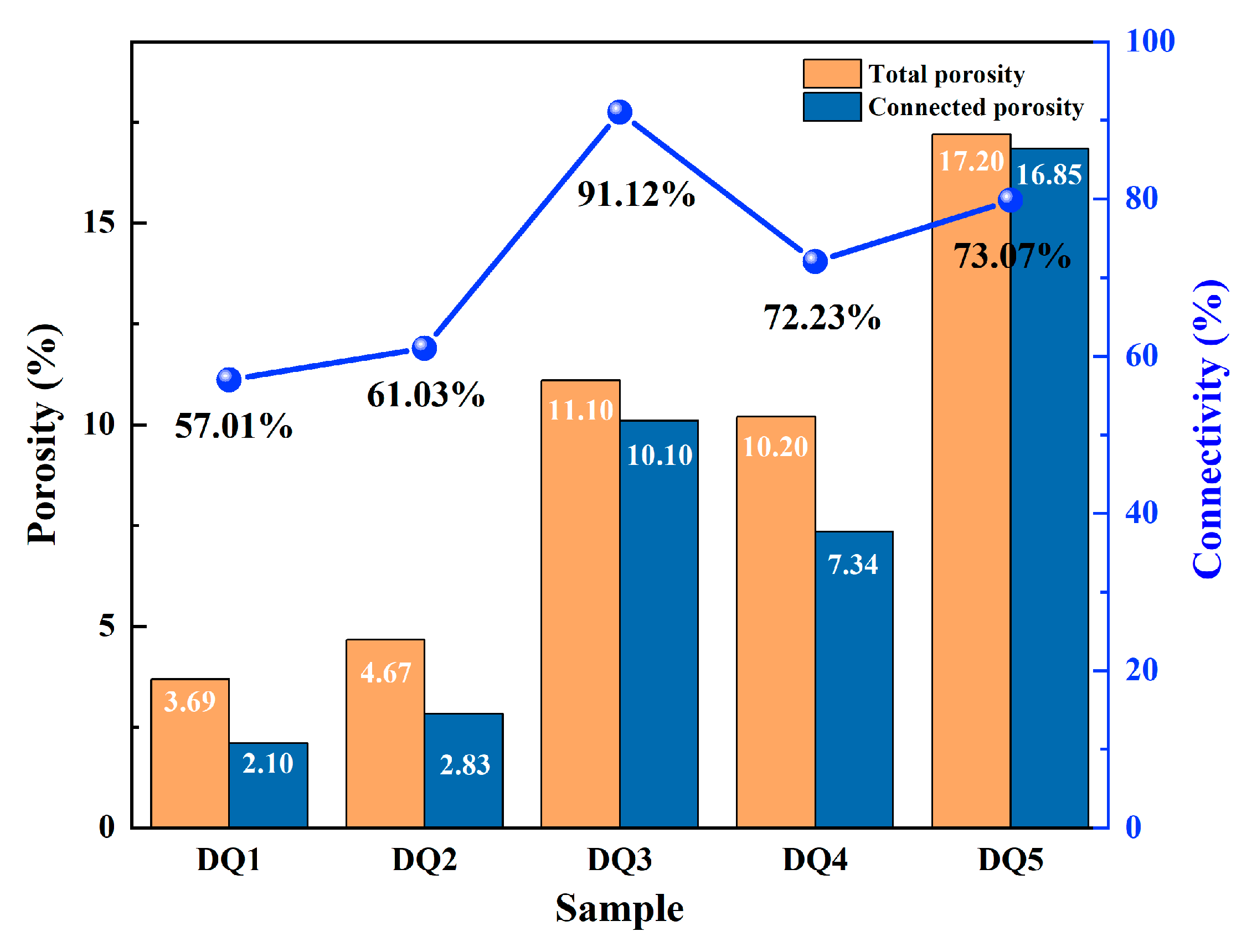

3.2.3. Macropore Structure Characteristic Determined with MIP

3.2.4. Spatial Distribution of Pore Structure Determined with CT

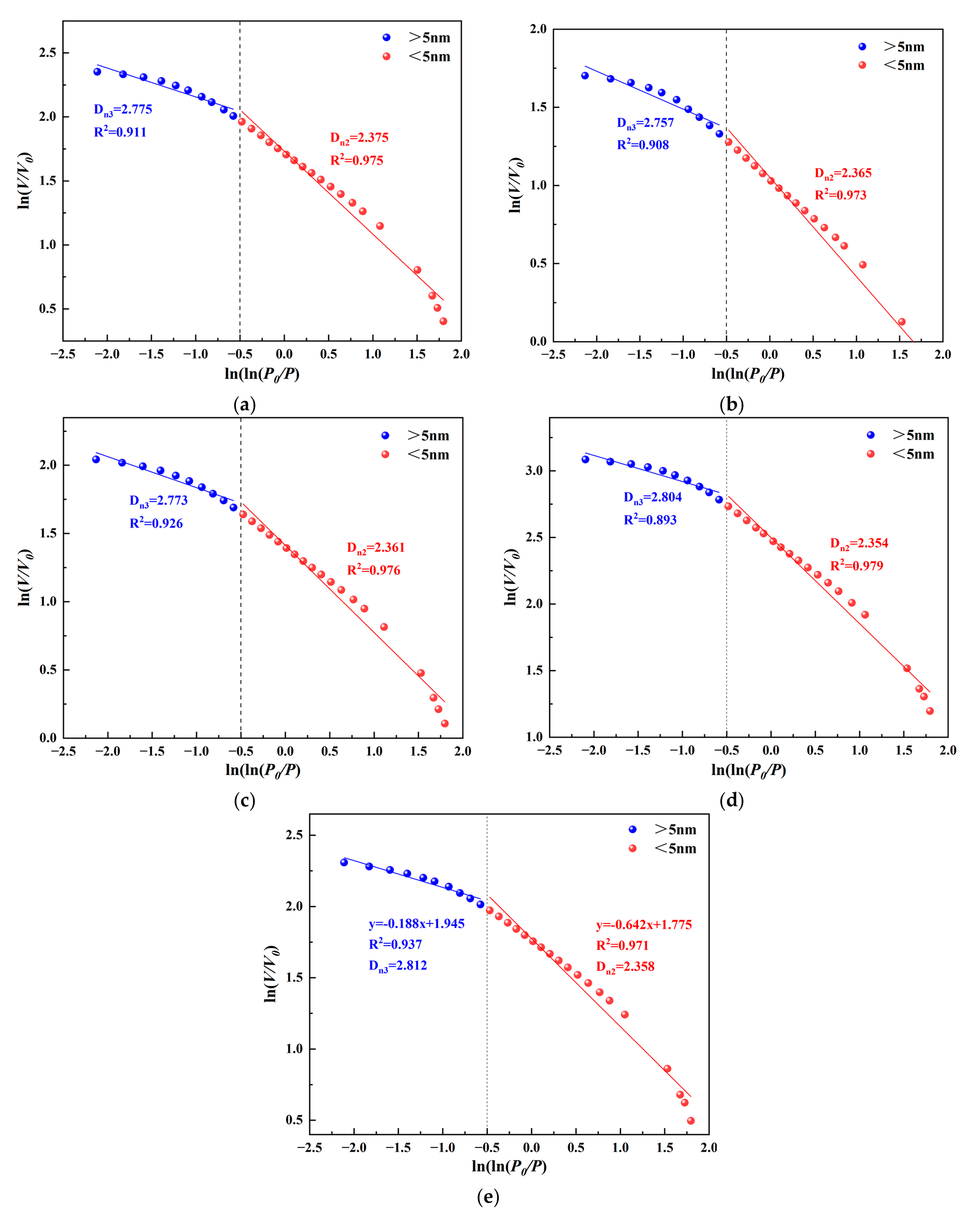

3.3. Pore Fractal Analysis

4. Discussion

4.1. Full-Size Pore Structure Characterization

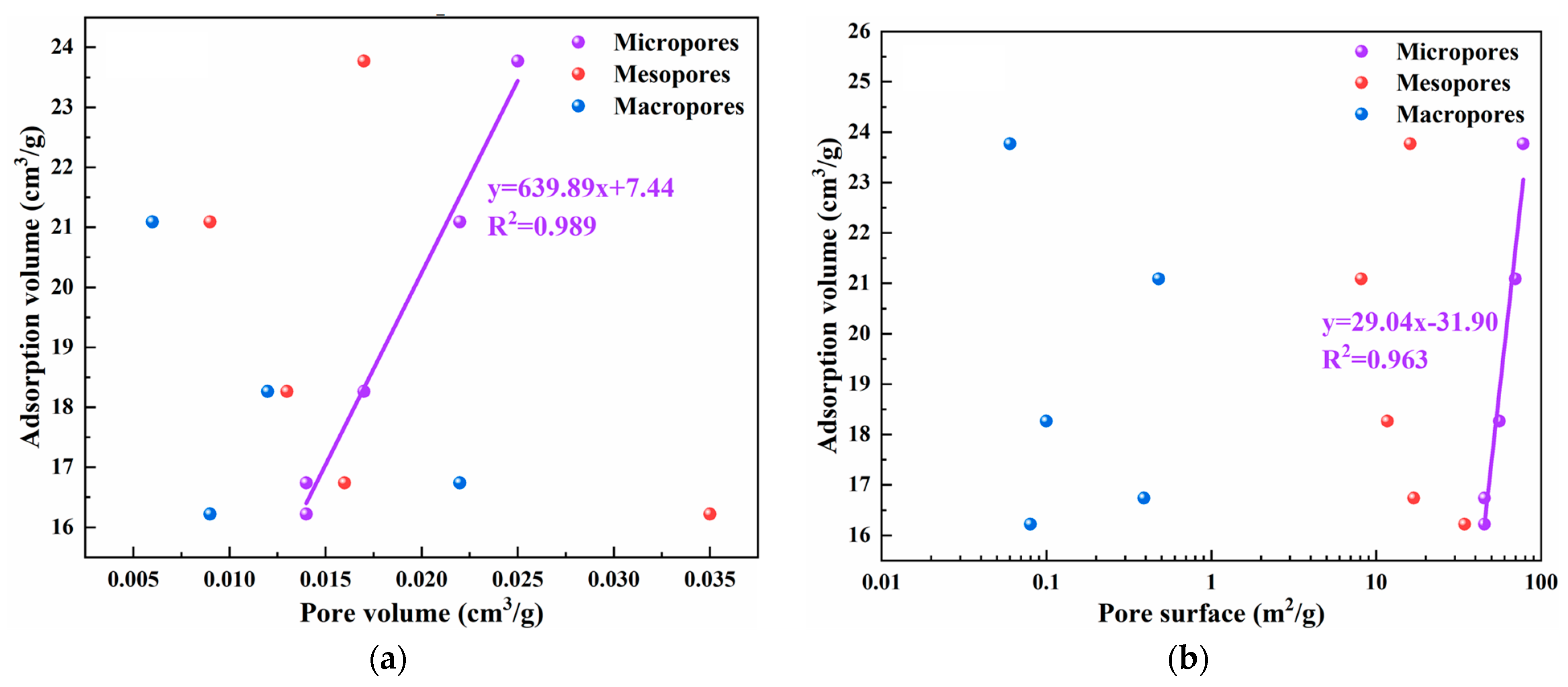

4.2. Influences of Pore Structure on the Capacity of Methane Adsorption

4.3. Influences of Fractal Dimension on the Capacity of Methane Adsorption

4.4. Influences of Pore Structure and Fractal Dimension on the Capacity of Methane Seepage

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, H.; Tang, D.; Xu, T.; Xu, H.; Tao, S.; Li, S.; Yin, Z.; Chen, B.; Zhang, C.; Wang, L. Characteristics of pore structure and fractal dimension of low-rank coal: A case study of Lower Jurassic Xishanyao coal in the southern Junggar Basin, NW China. Fuel 2017, 193, 254–264. [Google Scholar] [CrossRef]

- Xin, F.; Xu, H.; Tang, D.; Yang, J.; Chen, Y.; Cao, L.; Qu, H. Pore structure evolution of low-rank coal in China. Int. J. Coal. Geol. 2019, 205, 126–139. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Gan, H.; Nandi, S.P.; Walker, P.L. Nature of the porosity in American coals. Fuel 1972, 51, 272–277. [Google Scholar] [CrossRef]

- Li, X.; Kang, Y.; Haghighi, M. Investigation of pore size distributions of coals with different structures by nuclear magnetic resonance (NMR) and mercury intrusion porosimetry (MIP). Measurement 2018, 116, 122–128. [Google Scholar] [CrossRef]

- Liu, W.; Wang, G.; Han, D.; Xu, H.; Chu, X. Accurate characterization of coal pore and fissure structure based on CT 3D reconstruction and NMR. J. Nat. Gas Sci. Eng. 2021, 96, 104242. [Google Scholar] [CrossRef]

- Wang, G.; Han, D.; Qin, X.; Liu, Z.; Liu, J. A comprehensive method for studying pore structure and seepage characteristics of coal mass based on 3D CT reconstruction and NMR. Fuel 2020, 281, 118735. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.M.M.; Chalmers, G.R.L.; He, L.; Melnichenko, Y.B.; Radliński, A.P.; Blach, T.P. Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Okolo, G.N.; Everson, R.C.; Neomagus, H.W.J.P.; Roberts, M.J.; Sakurovs, R. Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques. Fuel 2015, 141, 293–304. [Google Scholar] [CrossRef]

- Guo, X.; Huang, Z.; Zhao, L.; Han, W.; Ding, C.; Sun, X.; Yan, R.; Zhang, T.; Yang, X.; Wang, R. Pore structure and multi-fractal analysis of tight sandstone using MIP, NMR and NMRC methods: A case study from the Kuqa depression, China. J. Pet. Sci. Eng. 2019, 178, 544–558. [Google Scholar] [CrossRef]

- Wang, F.; Yang, K.; You, J.; Lei, X. Analysis of pore size distribution and fractal dimension in tight sandstone with mercury intrusion porosimetry. Results. Phys. 2019, 13, 102283. [Google Scholar] [CrossRef]

- Wang, F.; Yang, K.; Cai, J. Fractal characterization of tight oil reservoir pore structure using nuclear magnetic resonance and mercury intrusion porosimetry. Fractals 2018, 26, 1840017. [Google Scholar] [CrossRef]

- Song, Z.; Liu, G.; Yang, W.; Zou, H.; Sun, M.; Wang, X. Multi-fractal distribution analysis for pore structure characterization of tight sandstone—A case study of the Upper Paleozoic tight formations in the Longdong District, Ordos Basin. Mar. Pet. Geol. 2018, 92, 842–854. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, S.; Wang, J.; Hu, Q.; Wang, M.; Chao, J. Applying Fractal Theory to Characterize the Pore Structure of Lacustrine Shale from the Zhanhua Depression in Bohai Bay Basin, Eastern China. Energ. Fuel. 2018, 32, 7539–7556. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G. Fractal analysis of tight gas sandstones using high-pressure mercury intrusion techniques. J. Nat. Gas Sci. Eng. 2015, 24, 185–196. [Google Scholar] [CrossRef]

- Turlapati, V.Y.; Prusty, B.K.; Bakshi, T. Detailed Pore Structure Study of Damodar Valley and Upper Assam Basin Shales Using Fractal Analysis. Energ. Fuel. 2020, 34, 14001–14011. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Wei, Q.; Sun, K.; Zhang, G.; Wang, F. Characterization of Full-Sized Pore Structure and Fractal Characteristics of Marine–Continental Transitional Longtan Formation Shale of Sichuan Basin, South China. Energ. Fuel. 2017, 31, 10490–10504. [Google Scholar] [CrossRef]

- Zhou, L.; Kang, Z. Fractal characterization of pores in shales using NMR: A case study from the Lower Cambrian Niutitang Formation in the Middle Yangtze Platform, Southwest China. J. Nat. Gas Sci. Eng. 2016, 35, 860–872. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Che, Y.; Tang, D.; Tang, S.; Huang, W. Petrophysical characterization of coals by low-field nuclear magnetic resonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Wei, Q.; Li, X.; Zhang, J.; Hu, B.; Zhu, W.; Liang, W.; Sun, K. Full-size pore structure characterization of deep-buried coals and its impact on methane adsorption capacity: A case study of the Shihezi Formation coals from the Panji Deep Area in Huainan Coalfield, Southern North China. J. Pet. Sci. Eng. 2019, 173, 975–989. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Y.; Zhang, R.; Zhang, B.; Tang, J.; He, F. Surface fractal dimensions as a characterization parameter for methane adsorption–induced coal strains. Arab. J. Geosci. 2020, 13, 997. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Pan, Z.; Yao, Y.; Li, J.; Qiu, Y. Pore structure and its impact on CH4 adsorption capacity and flow capability of bituminous and subbituminous coals from Northeast China. Fuel 2013, 103, 258–268. [Google Scholar] [CrossRef]

- Yu, S.; Bo, J.; Fengli, L.; Jiegang, L. Structure and fractal characteristic of micro- and meso-pores in low, middle-rank tectonic deformed coals by CO2 and N2 adsorption. Micropor. Mesopor. Mat. 2017, 253, 191–202. [Google Scholar] [CrossRef]

- Jiang, J.; Yang, W.; Cheng, Y.; Zhao, K.; Zheng, S. Pore structure characterization of coal particles via MIP, N2 and CO2 adsorption: Effect of coalification on nanopores evolution. Powder Technol. 2019, 354, 136–148. [Google Scholar] [CrossRef]

- Nie, B.; Liu, X.; Yang, L.; Meng, J.; Li, X. Pore structure characterization of different rank coals using gas adsorption and scanning electron microscopy. Fuel 2015, 158, 908–917. [Google Scholar] [CrossRef]

- GB/T 6948-2008; Method of Determining Microscopically the Reflectance of Vitrinite in Coal. Standardization administration: Beijing, China, 2008.

- GB/T 8899-2013; Determination of Maceral Group Composition and Minerals in Coal. Standardization administration: Beijing, China, 2013.

- ISO 17246:2010; Coal Proximate Analysis. International Organization for Standardization: Geneva, Switzerland, 2010.

- GB/T 19143-2017; Analytical Method of Element for Carbon, Hydrogen, Oxygen and Nitrogen in Rock Organics. Standardization administration: Beijing, China, 2017.

- GB/T 29172-2012; Practices For core Analysis. Standardization administration: Beijing, China, 2012.

- GB/T 21650.3-2011; Pore Size Distribution and Porosity of Solid Materials Bymercury Porosimetry and Gas Adsorption—Part 3 Analysis of Micropores by Gas Adsorption. Standardization administration: Beijing, China, 2011.

- Qi, L.; Tang, X.; Wang, Z.; Peng, X. Pore characterization of different types of coal from coal and gas outburst disaster sites using low temperature nitrogen adsorption approach. Int. J. Min. SCI. Technol. 2017, 27, 371–377. [Google Scholar] [CrossRef]

- GB/T 19560-2008; Experimental Method of High-Pressure Isothermal Adsorption to Coal. Standardization administration: Beijing, China, 2008.

- Qi, H.; Ma, J.; Wong, P.-z. Adsorption isotherms of fractal surfaces. Colloids Surfaces A 2002, 206, 401–407. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Huang, W. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal. Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Rouquerol, J.; Avnir, D.; Fairbridge, C.W.; Everett, D.H.; Haynes, J.M.; Pernicone, N.; Ramsay, J.D.F.; Sing, K.S.W.; Unger, K.K. Recommendations for the characterization of porous solids. Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

- Liu, X.; Kong, X.; Nie, B.; Song, D.; He, X.; Wang, L. Pore Fractal Dimensions of Bituminous Coal Reservoirs in North China and Their Impact on Gas Adsorption Capacity. Nat. Resour. Res. 2021, 30, 4585–4596. [Google Scholar] [CrossRef]

- Li, Z.; Lin, B.; Gao, Y.; Cao, Z.; Cheng, Y.; Yu, J. Fractal analysis of pore characteristics and their impacts on methane adsorption of coals from Northern China. Int. J. Oil. Gas. Coal. T. 2015, 10, 306–324. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Huang, W.; Liu, Z.; Che, Y. Fractal characterization of seepage-pores of coals from China: An investigation on permeability of coals. Comput. Geocsi-UK 2009, 35, 1159–1166. [Google Scholar] [CrossRef]

- Mahamud, M.; López, Ó.; Pis, J.J.; Pajares, J.A. Textural characterization of coals using fractal analysis. Fuel Process. Technol. 2003, 81, 127–142. [Google Scholar] [CrossRef]

- Zhang, S.; Tang, S.; Tang, D.; Pan, Z.; Yang, F. The characteristics of coal reservoir pores and coal facies in Liulin district, Hedong coal field of China. Int. J. Coal. Geol. 2010, 81, 117–127. [Google Scholar] [CrossRef]

- Wu, S.; Tang, D.; Li, S.; Meng, Y.; Lin, W. Evaluation of pore development in different coal reservoirs based on centrifugation experiment. J. Pet. Sci. Eng. 2017, 157, 1095–1105. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Cai, Y.; Li, J. Advanced characterization of pores and fractures in coals by nuclear magnetic resonance and X-ray computed tomography. Sci. China. Earth. SCI. 2010, 53, 854–862. [Google Scholar] [CrossRef]

| No. | Ro,max (%) | Porosity φ (%) | Permeability K (mD) | Proximate Analysis (%) | Coal Composition (%) | Methane Isothermal Adsorption | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Moisture Content | Ash Yield | Volatile Matter | Fixed Carbon | Vitrinite/ Huminite | Inertinite | Exinite | VL (cm3/g) | PL (MPa) | ||||

| DQ1 | 0.62 | 4.14 | 0.020 | 6.23 | 3.46 | 38.15 | 51.92 | 84.17 | 11.61 | 4.22 | 23.92 | 2.02 |

| DQ2 | 0.58 | 2.87 | 0.024 | 6.28 | 4.31 | 38.39 | 50.32 | 89.84 | 6.80 | 3.36 | 21.22 | 2.03 |

| DQ3 | 0.60 | 10.98 | 0.274 | 6.61 | 27.11 | 31.31 | 34.57 | 83.52 | 8.64 | 7.84 | 18.47 | 2.06 |

| DQ4 | 0.63 | 11.70 | 0.543 | 6.98 | 21.78 | 35.58 | 36.13 | 91.91 | 5.62 | 2.47 | 16.34 | 1.92 |

| DQ5 | 0.64 | 16.15 | 0.948 | 7.21 | 23.28 | 31.99 | 38.77 | 83.45 | 14.57 | 1.98 | 16.74 | 1.89 |

| W-1 | 0.81 | 4.54 | / | 1.49 | 19.73 | 37.39 | / | 80.04 | 10.78 | 7.10 | 11.66 | 2.39 |

| W-2 | 0.73 | 4.48 | / | 1.25 | 8.86 | 42.62 | / | 68.73 | 21.32 | 7.64 | 13.51 | 2.72 |

| W-3 | 0.75 | 3.07 | / | 1.41 | 10.68 | 41.15 | / | 83.15 | 13.43 | 1.65 | 12.98 | 1.16 |

| W-4 | 0.72 | 24.24 | / | 1.40 | 32.10 | 43.67 | / | 38.41 | 29.78 | 5.56 | 15.42 | 2.50 |

| W-5 | 0.74 | 11.12 | / | 1.43 | 20.73 | 42.07 | / | 71.00 | 12.58 | 6.65 | 23.44 | 1.08 |

| W-6 | 0.80 | 17.33 | / | 1.08 | 15.20 | 38.22 | / | 75.46 | 46.54 | 7.65 | 17.74 | 3.11 |

| Sample No. | Vtotal/ (cm3·g−1) | Volume/ (cm3·g−1) | Volume ratio/ (%) | Stotal/ (m2·g−1) | Specific Surface Area/ (m2·g−1) | Specific Surface Area ratio/(%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V1 | V2 | V3 | V1 | V2 | V3 | S1 | S2 | S3 | S1 | S2 | S3 | |||

| DQ1 | 0.048 | 0.025 | 0.017 | 0.007 | 51.55 | 34.69 | 13.76 | 94.15 | 78.03 | 16.06 | 0.06 | 82.88 | 17.06 | 0.06 |

| DQ2 | 0.037 | 0.022 | 0.009 | 0.006 | 59.09 | 23.93 | 16.98 | 78.54 | 69.94 | 8.12 | 0.48 | 89.05 | 10.34 | 0.61 |

| DQ3 | 0.042 | 0.017 | 0.013 | 0.012 | 41.74 | 29.90 | 28.36 | 67.79 | 55.98 | 11.71 | 0.10 | 87.57 | 17.28 | 0.15 |

| DQ4 | 0.058 | 0.014 | 0.035 | 0.009 | 24.25 | 60.55 | 15.20 | 79.89 | 45.36 | 34.45 | 0.08 | 56.78 | 43.13 | 0.09 |

| DQ5 | 0.052 | 0.014 | 0.016 | 0.022 | 26.78 | 31.96 | 41.26 | 62.71 | 45.46 | 16.96 | 0.39 | 72.38 | 27.01 | 0.61 |

| Sample No. | Equivalent Diameter/μm | Equivalent Diameter Interval/μm | Statistical Frequency | Porosity Ratio /% |

|---|---|---|---|---|

| DQ1 | 3.44 | 1 < dep ≤ 10 | 7902 | 0.97 |

| 10 < dep ≤ 50 | 214 | 6.52 | ||

| 50 < dep ≤ 100 | 17 | 73.22 | ||

| dep > 100 | 4 | 19.29 | ||

| DQ2 | 3.76 | 1 < dep ≤ 10 | 8109 | 0.95 |

| 10 < dep ≤ 50 | 216 | 5.23 | ||

| 50 < dep ≤ 100 | 22 | 75.22 | ||

| dep > 100 | 3 | 18.61 | ||

| DQ3 | 4.31 | 1 < dep ≤ 10 | 7016 | 0.94 |

| 10 < dep ≤ 50 | 172 | 3.21 | ||

| 50 < dep ≤ 100 | 25 | 16.12 | ||

| dep > 100 | 11 | 79.73 | ||

| DQ4 | 4.02 | 1 < dep ≤ 10 | 6563 | 1.19 |

| 10 < dep ≤ 50 | 161 | 2.52 | ||

| 50 < dep ≤ 100 | 22 | 20.73 | ||

| dep > 100 | 10 | 75.56 | ||

| DQ5 | 5.08 | 1 < dep ≤ 10 | 7965 | 0.83 |

| 10 < dep ≤ 50 | 194 | 3.21 | ||

| 50 < dep ≤ 100 | 25 | 10.23 | ||

| dep>100 | 17 | 85.73 |

| Sample No. | D1 (0.4–2 nm) | D2 (2–5 nm) | D3 (5–50 nm) | D4 (>50 nm) |

|---|---|---|---|---|

| DQ1 | 2.337 | 2.375 | 2.775 | 2.980 |

| DQ2 | 2.335 | 2.365 | 2.757 | 2.971 |

| DQ3 | 2.330 | 2.361 | 2.773 | 2.951 |

| DQ4 | 2.324 | 2.354 | 2.804 | 2.957 |

| DQ5 | 2.321 | 2.358 | 2.812 | 2.946 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, N.; Wang, S.; Wu, J.; Li, Z.; Wang, X. Full-Scale Pore Structure Characterization and Its Impact on Methane Adsorption Capacity and Seepage Capability: Differences between Shallow and Deep Coal from the Tiefa Basin in Northeastern China. Fractal Fract. 2024, 8, 48. https://doi.org/10.3390/fractalfract8010048

Zhang N, Wang S, Wu J, Li Z, Wang X. Full-Scale Pore Structure Characterization and Its Impact on Methane Adsorption Capacity and Seepage Capability: Differences between Shallow and Deep Coal from the Tiefa Basin in Northeastern China. Fractal and Fractional. 2024; 8(1):48. https://doi.org/10.3390/fractalfract8010048

Chicago/Turabian StyleZhang, Na, Shuaidong Wang, Jiaqi Wu, Zheng Li, and Xinyue Wang. 2024. "Full-Scale Pore Structure Characterization and Its Impact on Methane Adsorption Capacity and Seepage Capability: Differences between Shallow and Deep Coal from the Tiefa Basin in Northeastern China" Fractal and Fractional 8, no. 1: 48. https://doi.org/10.3390/fractalfract8010048

APA StyleZhang, N., Wang, S., Wu, J., Li, Z., & Wang, X. (2024). Full-Scale Pore Structure Characterization and Its Impact on Methane Adsorption Capacity and Seepage Capability: Differences between Shallow and Deep Coal from the Tiefa Basin in Northeastern China. Fractal and Fractional, 8(1), 48. https://doi.org/10.3390/fractalfract8010048