Experimental Investigation of the Compaction-Crushing Characteristics of Graded Fractured Coal Gangue Based on Infill Mining

Abstract

1. Introduction

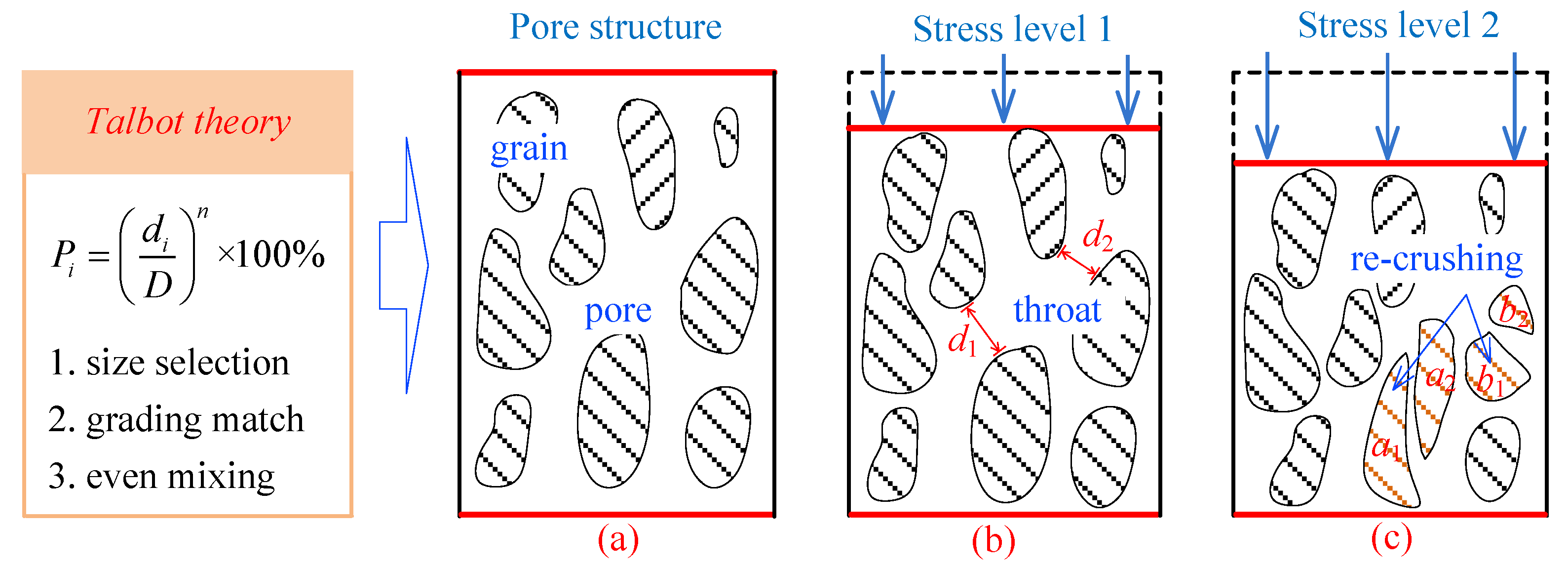

2. Compaction and Re-Crushing Process of Crushed Coal Gangue

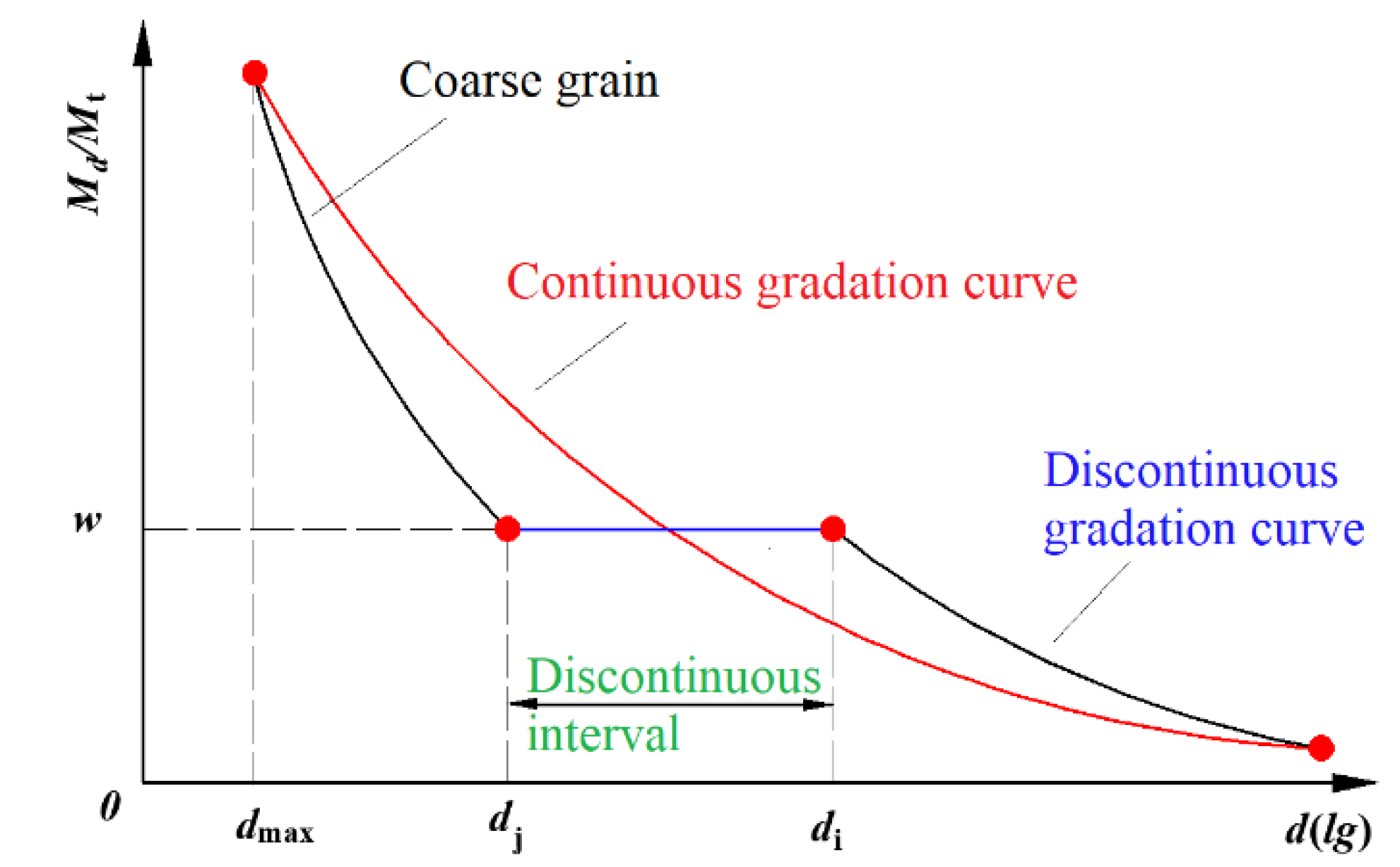

2.1. Re-Crushing of Crushed Gangue

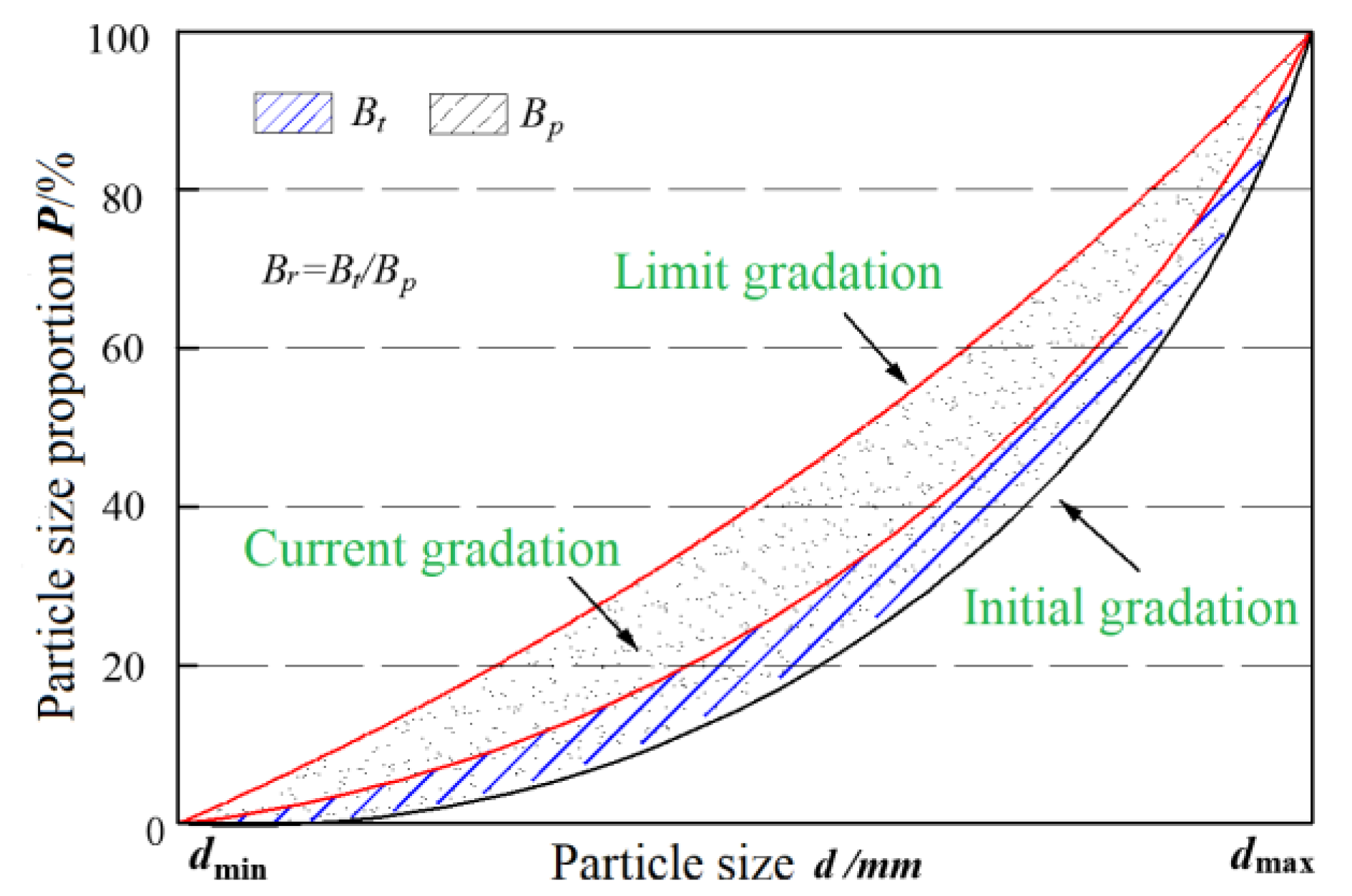

2.2. Particle Size Distribution Characteristics of Crushed Coal Gangue

3. Materials and Methods

3.1. Materials

3.1.1. Research Background

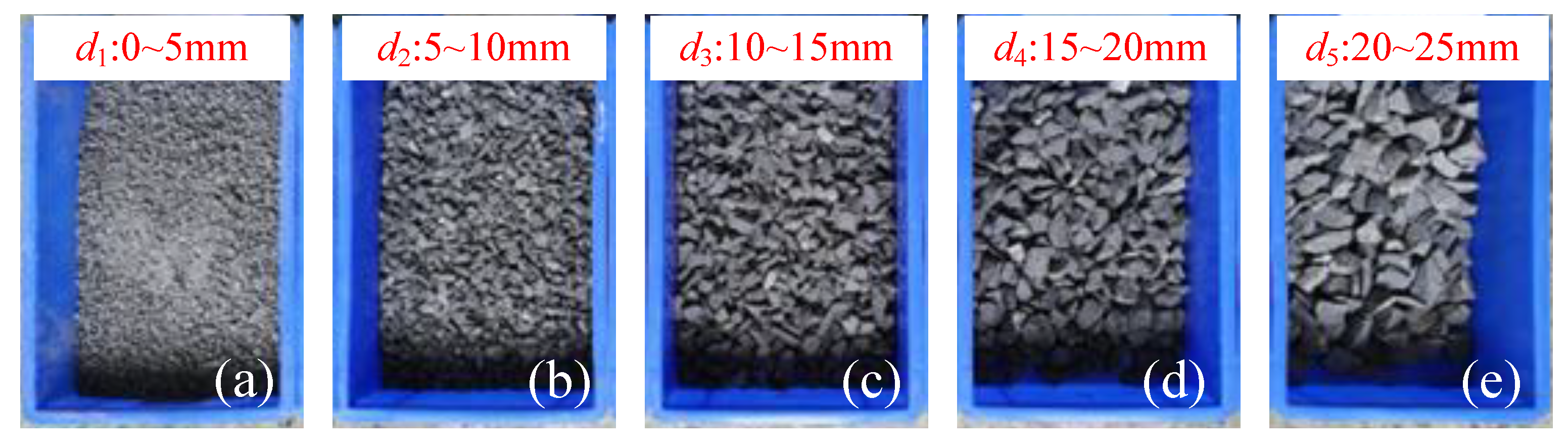

3.1.2. Material Preparation

3.2. Methodologies

3.2.1. Experiment Design

- The samples with intermittent grading structure are based on the samples with continuous grading structure, and the same quality of the control crushed samples and two grading structures are set under each power index n, intermittent 0~5 mm particle size, and intermittent 15~20 mm particle size, according to the principle of isometric scaling. The particles with sizes ranging from 0 to 5 mm are fine particles, and the particles with sizes greater than 5 mm are coarse particles. We let the mass of fine material be Ms, the mass of coarse material be Ml, and we use ω to express the fine material content:

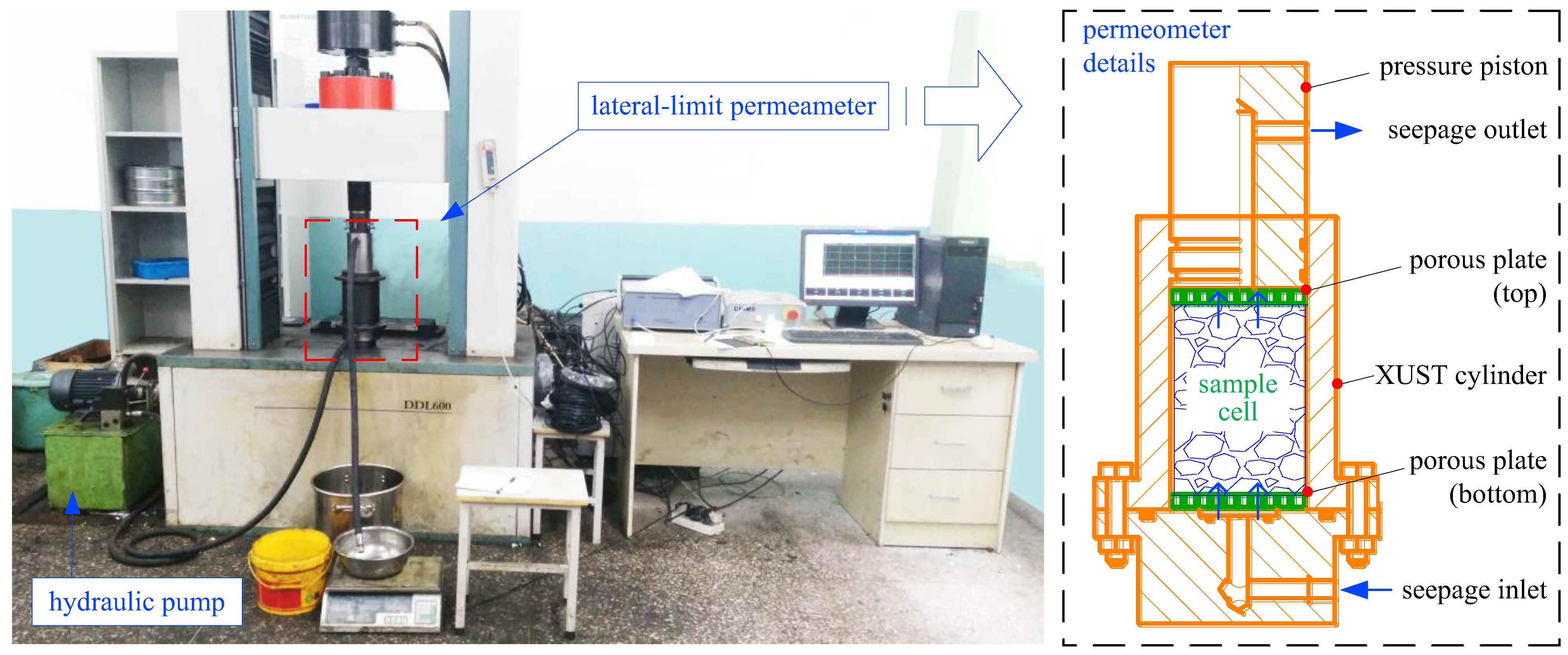

3.2.2. Experimental Equipment

3.2.3. Experimental Procedure

- Obtaining the raw material and specimen preparation. The laboratory crusher was used to crush the gangue particles, and then sieving gave five particle size intervals (0~5 mm, 5~10 mm, 10~15 mm, 15~20 mm, and 20~25 mm);

- According to Table 1 and Table 2 of the gradation test protocol, the gradation configuration of the different particle masses was conducted using an electronic scale and mixed well, and the configured samples were numbered in turn. The continuous grading power index of n = 0.2 was used as a benchmark for the intermittently-graded samples in the present work;

- Following the continuous and intermittent test programs, a graded loading program was established and saved in the axial pressure control system before specimen I was loaded into the cylinder, and the felt was placed on the upper surface of the specimen, followed by the displacement of the piston and its levelling using the piston to avoid errors caused by the loading process on the initial porosity;

- The prepared specimen was placed on the test bench so that the piston was facing the indenter. After the first level of the axial stress loading test was completed, the loaded gangue specimen was fully sieved using the automatic sieving device for crushed rock, the particle mass was weighed, and data were recorded using an electronic scale for each particle size interval;

- For the loading of the crushed specimen into the cylinder, the next level of stress loading was applied, and the above steps were repeated until all four levels of stress loading were completed; after the end of Group I grading, a Group II grading test and a complete grading test for each group were conducted in turn according to the test protocol; the above steps were repeated and the relevant test parameters were recorded.

4. Results and Discussion

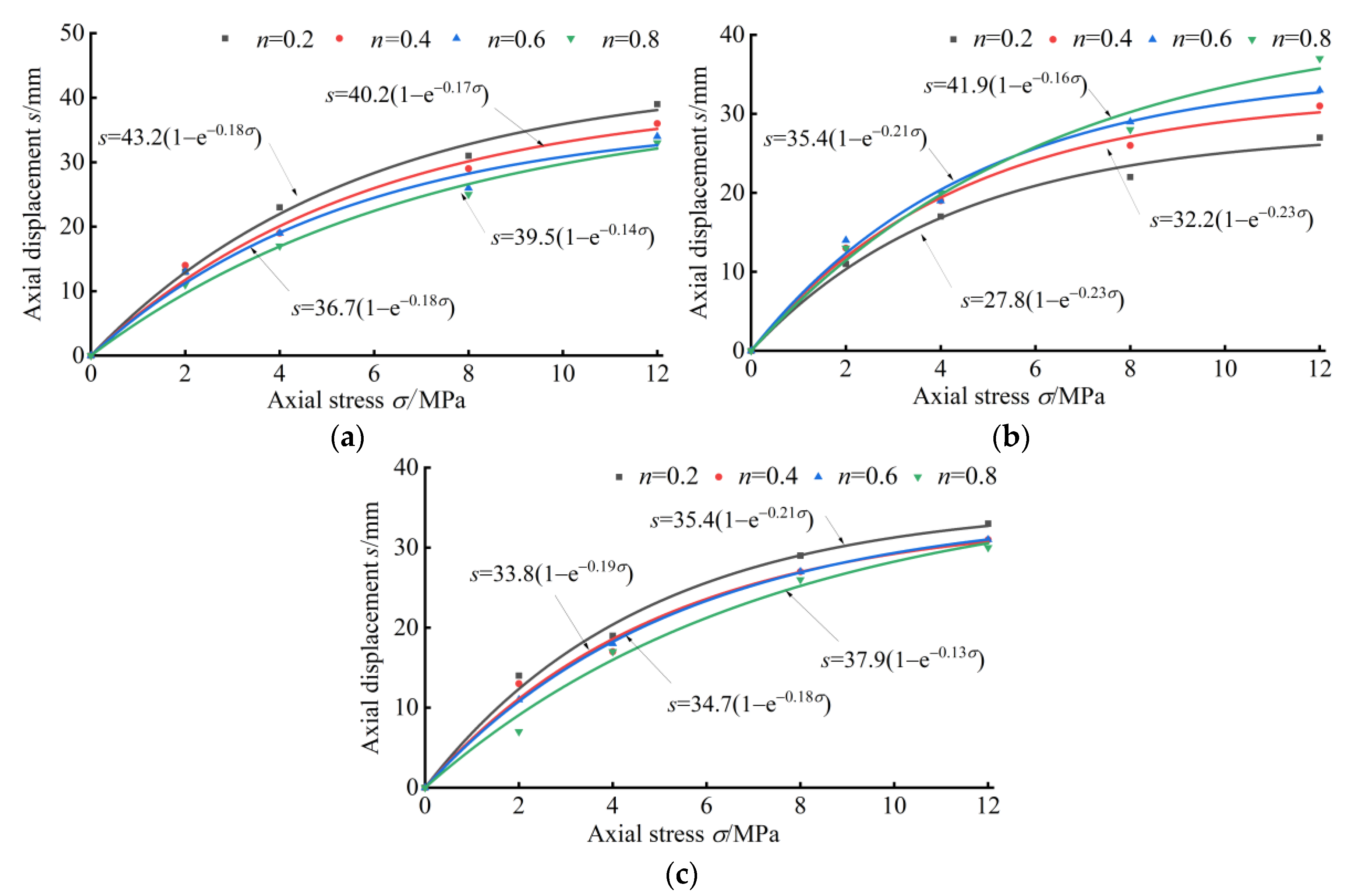

4.1. The Relationship between Deformation and Damage of Crushed Coal Gangue

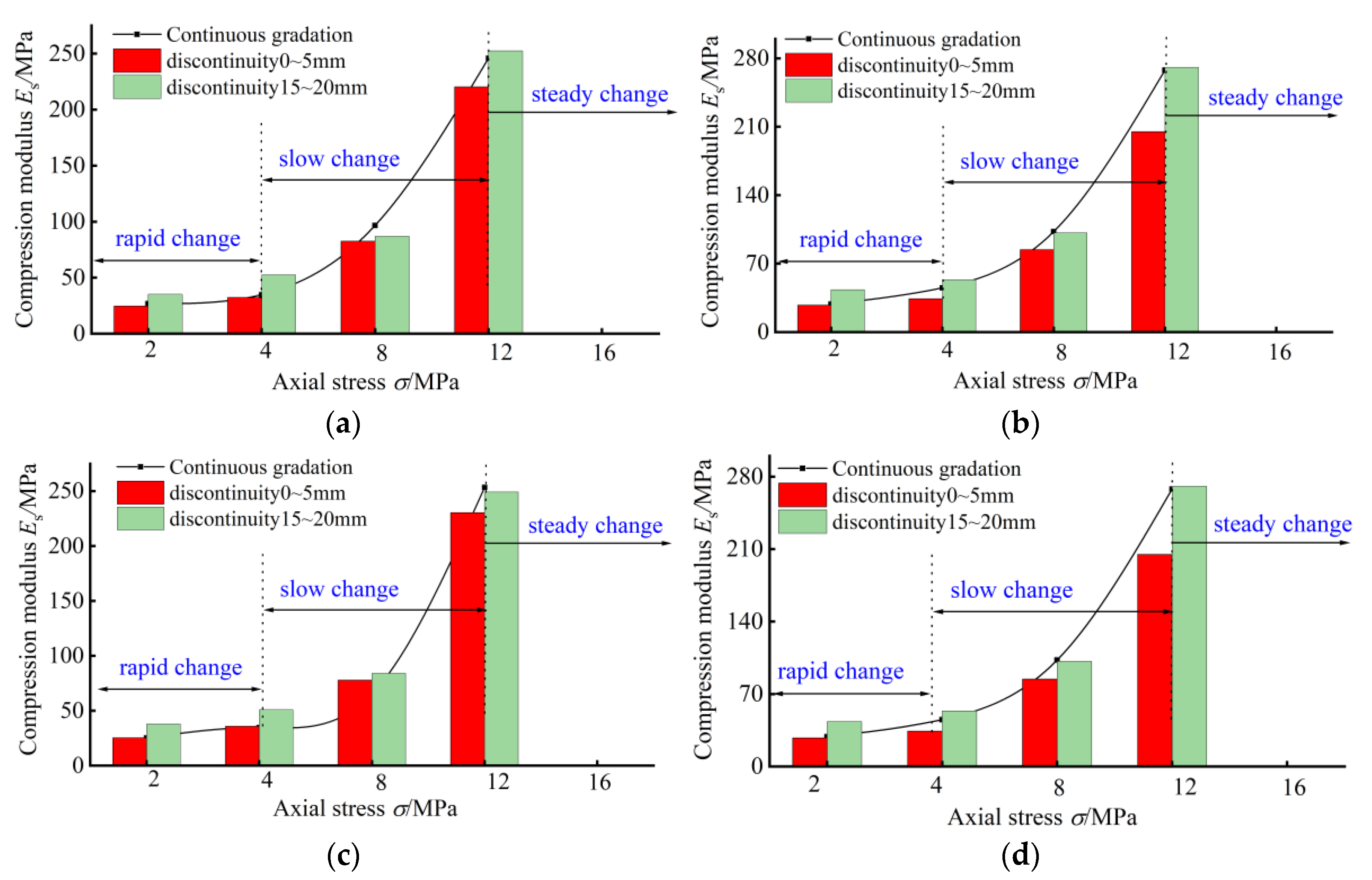

4.2. Analysis of Compaction and Re-Crushing Characteristics of Crushed Coal Gangue

4.2.1. Compaction and Re-Crushing Properties

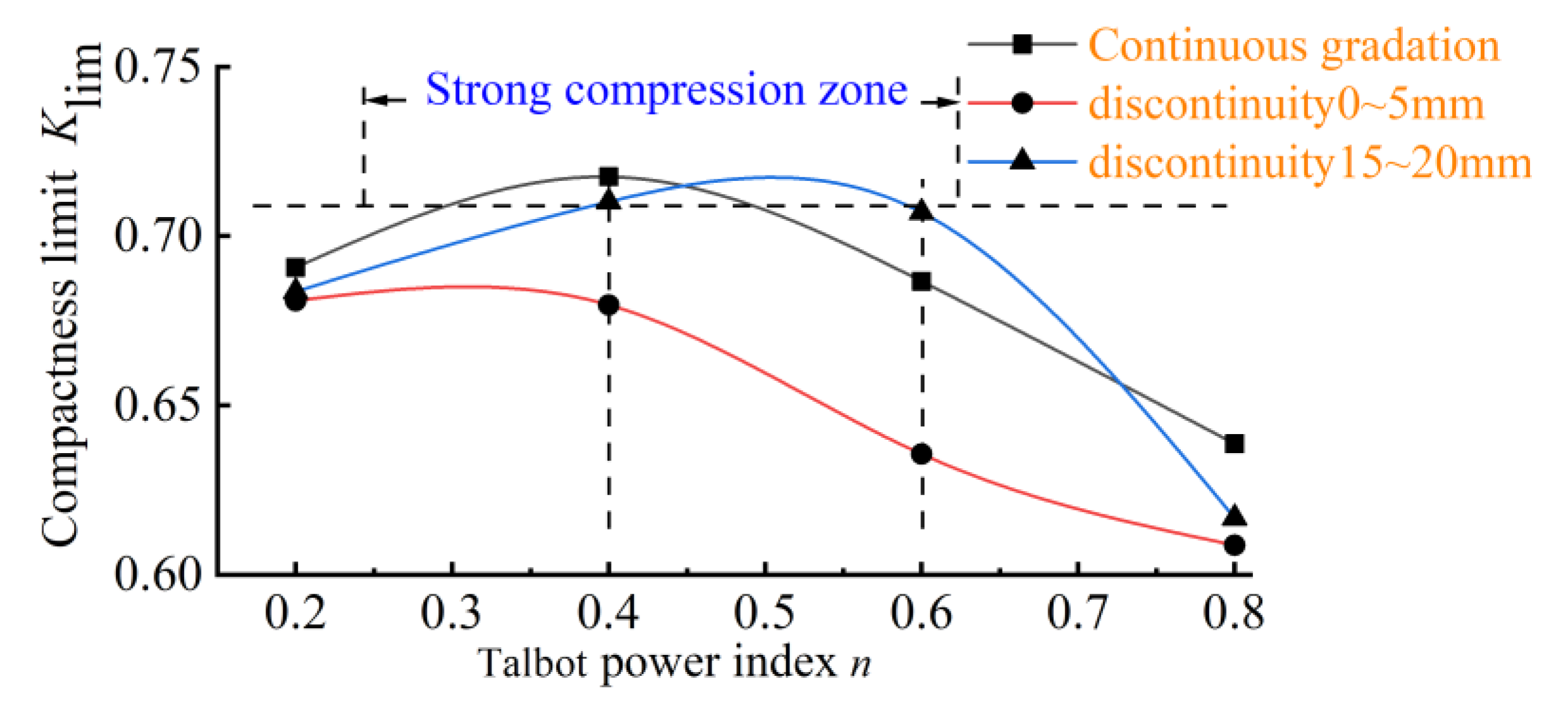

4.2.2. Compaction Limit Values

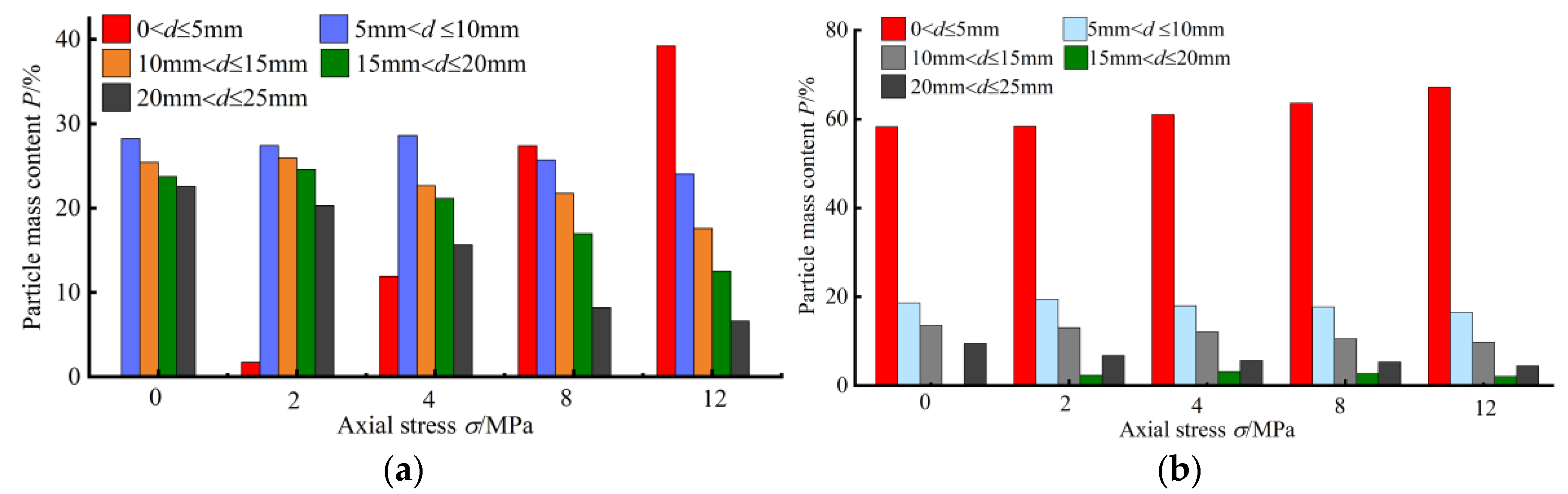

4.3. Particle Size Distribution Characteristics of Crushed Coal Gangue

4.3.1. Particle Size Interval Distribution

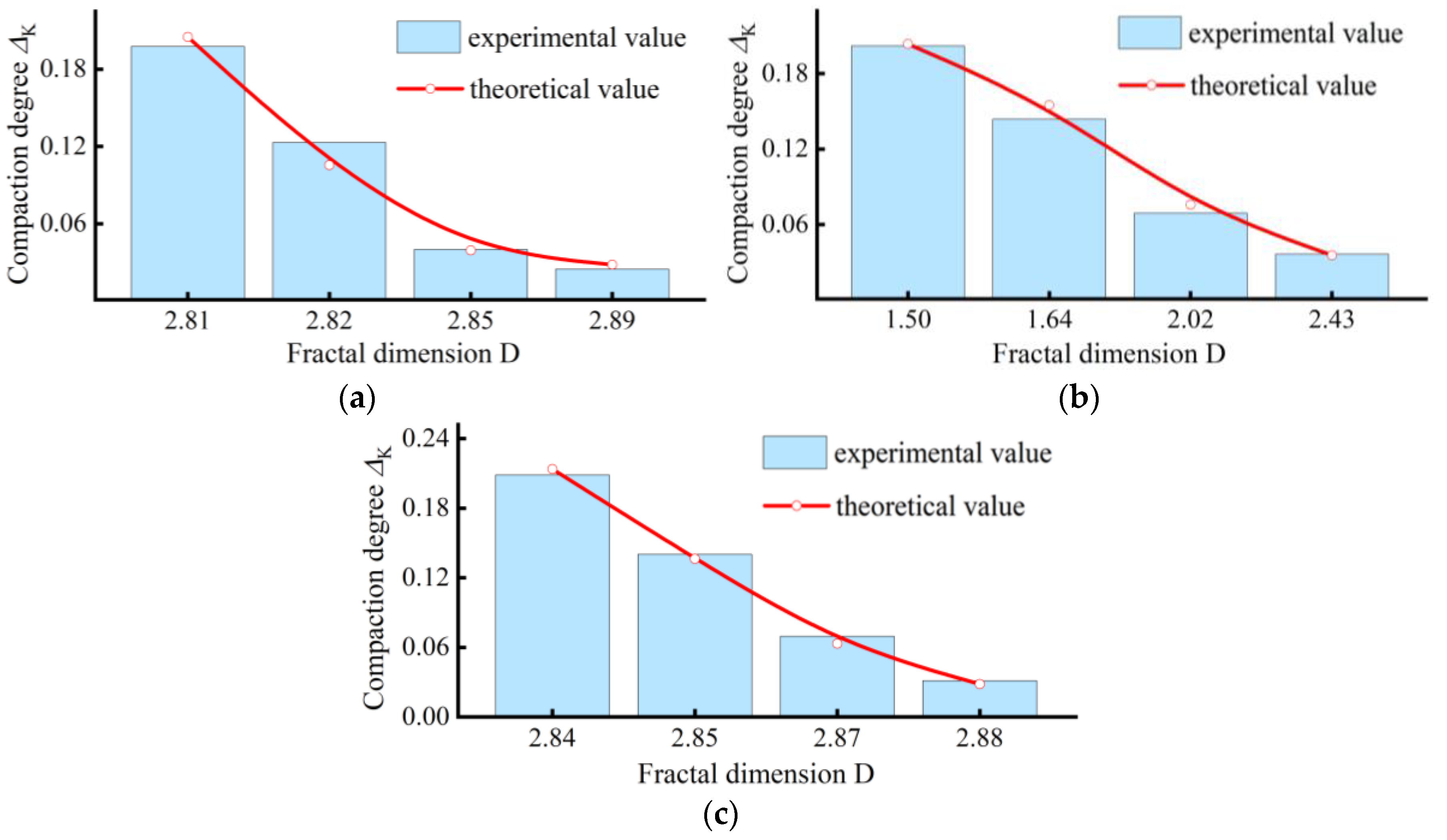

4.3.2. Changes in Fractal Dimension

4.4. Compaction-Crushing Modelling of Crushed Coal Gangue

4.4.1. Size Distribution of Gangue Crushing

4.4.2. Compaction-Crushing Modelling

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, D.; Duan, H.; Liu, J.; Li, X.; Zhou, Z. The role of gangue on the mitigation of mining-induced hazards and environmental pollution: An experimental investigation. Sci. Total Environ. 2019, 664, 436–448. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Tu, S.; Zhao, Y. Compaction characteristics of the caving zone in a longwall goaf: A review. Environ. Earth Sci. 2019, 78, 27–42. [Google Scholar] [CrossRef]

- Meng, Q.; Zhang, M.; Han, L.; Pu, H.; Chen, Y. Acoustic emission characteristics of red sandstone specimens under uniaxial cyclic loading and unloading compression. Rock Mech. Rock Eng. 2018, 51, 969–988. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, J.; Duan, H.; Huang, Y.; Li, M.; Sun, Q.; Zhou, N. Reutilization of gangue wastes in underground backfilling mining: Overburden aquifer protection. Chemosphere 2021, 264, 128400. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.M.; Yang, B.B.; Yuan, S.C.; Shen, Z.Z.; Feng, D. Seepage-Fractal Model of Embankment Soil and Its Application. Fractal Fract. 2022, 6, 277. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Q. Seepage failure mechanism of the Gouhou rockfill dam during reservoir water infiltration. Soils Found. 2011, 46, 557–568. [Google Scholar] [CrossRef]

- Gfa, C.; Jza, C.; Hw, D.; Zhen, L.; Zfa, C.; Wfa, C. Study of the internal re-breaking characteristics of broken limestone during compression. Powder Technol. 2022, 396, 449–455. [Google Scholar]

- Pang, M.K.; Zhang, T.J.; Ji, X.; Wu, J.Y.; Song, S. Measurement of the coefficient of seepage characteristics in pore-crushed coal bodies around gas extraction boreholes. Energy 2022, 254, 124276. [Google Scholar] [CrossRef]

- Wan, F.; Li, X.; Zhang, X.; Tian, S. Mechanical characteristics of karst tunnel lining structure under the action of groundwater from rainfall seepage. IOP Conf. Ser. Earth Environ. Sci. 2021, 769, 032056. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, F.; Li, X. Experimental Investigation on Mass Loss Characteristics of Broken Rocks with Discontinuous Gradation. Int. J. Geomech. 2021, 21, 04021168. [Google Scholar] [CrossRef]

- Yu, B.; Chen, Z.; Ding, Q.; Wang, L. Non-Darcy flow seepage characteristics of saturated broken rocks under compression with lateral constraint. Int. J. Min. Sci. Technol. 2016, 26, 1145–1151. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, F. A damage constitutive model for intermittent jointed rocks under cyclic uniaxial compression. Int. J. Rock Mech. Min. Sci. 2018, 103, 289–301. [Google Scholar] [CrossRef]

- Yang, X.; Liu, E.; Han, X.; Han, X.; Da, W. Experimental Study on Energy Evolution of Sandstone under Uniaxial Cyclic Loading. Coal Technol. 2018, 37, 21–24. [Google Scholar]

- Zhou, Z.; Cai, X.; Li, X.; Cao, W.; Du, X. Dynamic Response and Energy Evolution of Sandstone Under Coupled Static–Dynamic Compression: Insights from Experimental Study into Deep Rock Engineering Applications. Rock Mech. Rock Eng. 2020, 53, 1305–1331. [Google Scholar] [CrossRef]

- Zhang, T.J.; Zhang, L.; Li, S.G.; Liu, J.L.; Pan, H.Y.; Ji, X. Wave Velocity and Power Spectral Density of Hole-Containing Specimens with Different Moisture Content under Uniaxial Compression. Energies 2018, 11, 3166. [Google Scholar] [CrossRef]

- Gatumu, N.; Ndiritu, H.; Gathitu, B. Experimental study of the performance and emission characteristics of a compression ignition (ci) engine using syngas-diesel blend. J. Ene. Tec. Policy 2020, 10, 1. [Google Scholar]

- Slangen, P.; Fannin, R.J. The role of particle type on suffusion and suffosion. Géotechnique Lett. 2017, 7, 6–10. [Google Scholar] [CrossRef]

- Le, V.T.; Marot, D.; Rochim, A.; Bendahmane, F.; Nguyen, H.H. Suffusion susceptibility investigation by energy based method and statistical analysis. Can. Geotech. J. 2018, 55, 57–68. [Google Scholar] [CrossRef]

- Wang, H.; Bu, Y.; Wang, Y.; Yang, X.; You, Z. The Effect of Morphological Characteristic of Coarse Aggregates Measured with Fractal Dimension on Asphalt Mixture’s High-Temperature Performance. Adv. Mater. Sci. Eng. 2016, 2016, 6264317. [Google Scholar] [CrossRef]

- Caquot, A. The role of materials in concrete. In Memories of the French Society of Civil Engineers; French Society of Civil Engineers: Paris, France, 1937; pp. 562–582. [Google Scholar]

- Francois, O. GB5 mix design: High-performance and cost-effective asphalt concretes by use of gap-graded curves and SBS modified bitumens. Road Mater. Pavement Des. 2012, 13 (Suppl. S1), 234–259. [Google Scholar]

- Liu, Z.; Li, J.; Zhao, Q.; Wang, J.; Liu, T.; Zhang, Q. Gradation Design of Phosphorus Tailing–Graded Waste Rock Subgrade Filling Using Discrete Element Method. Minerals 2022, 12, 573. [Google Scholar] [CrossRef]

- Cai, X.; Wu, K.H.; Huang, W.K.; Wan, C. Study on the correlation between aggregate skeleton characteristics and rutting performance of asphalt mixture. Constr. Build. Mater. 2018, 179, 294–301. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M. Estimation of the Permeability of Rock Samples Obtained from the Mercury Intrusion Method Using the New Fractal Method. Fractal Fract. 2022, 9, 463. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, J.; Ranjith, P.G.; Gao, F.; Xie, H.; Wang, J. Changes in microstructure and mechanical properties of low-permeability coal induced by pulsating nitrogen fatigue fracturing tests. Rock Mech. Rock Eng. 2022, 55, 7469–7488. [Google Scholar] [CrossRef]

- Lv, R.; Zhu, Y.; Ma, X.; Ni, X.; Ren, J. Coupled Seepage Mechanics Model of Coal Containing Methane Based on Pore Structure Fractal Features. Fractal Fract. 2022, 6, 391. [Google Scholar] [CrossRef]

- Wong, P.; Howard, J.; Lin, J. Surface roughening and the fractal nature of rocks. Phys. Rev. Lett. 1986, 57, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.M.; Wang, S.; Li, X.L. Research on theory and technology of floor heave control in semicoal rock roadway: Taking longhu coal mine in Qitaihe mining area as an Example. Lithosphere 2022, 2022, 3810988. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Zhang, J.; Liu, X.; Li, Z. Numerical simulation of water-silt inrush hazard of fault rock: A three-phase flow model. Rock Mech. Rock Eng. 2022, 55, 5163–5182. [Google Scholar] [CrossRef]

- Pang, M.; Zhang, T.; Gao, L.; Qin, B. Investigating the effects of effective stress on pore-dependent permeability measurements of crushed coal. PLoS ONE 2021, 16, e0261678. [Google Scholar] [CrossRef]

- Wang, K.; Pan, H.; Zhang, T.; Wang, H. Experimental study on the radial vibration characteristics of a coal briquette in each stage of its life cycle under the action of CO2 gas explosion. Fuel 2022, 320, 123922. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Liu, D.; Cai, Y.; Liu, Y. Characterizations of full-scale pore size distribution, porosity and permeability of coals: A novel methodology by nuclear magnetic resonance and fractal analysis theory. Int. J. Coal Geol. 2018, 196, 148–158. [Google Scholar] [CrossRef]

- Wang, C.; Shen, B.; Chen, J.; Tong, W.; Jiang, Z.; Liu, Y.; Li, Y. Compression characteristics of filling gangue and simulation of mining with gangue backfilling: An experimental investigation. Geomech. Eng. 2020, 20, 485–495. [Google Scholar]

- Liu, H.Y.; Zhang, B.Y.; Li, X.L. Research on roof damage mechanism and control technology of gob-side entry retaining under close distance gob. Eng. Fail. Anal. 2022, 138, 106331. [Google Scholar] [CrossRef]

- Sui, L.; Wang, H.; Wu, J.; Zhang, J.; Yu, J.; Ma, X.; Sun, Q. Fractal Description of Rock Fracture Networks Based on the Space Syntax Metric. Fractal Fract. 2022, 6, 353. [Google Scholar] [CrossRef]

- Fu, X.; Ding, H.; Sheng, Q.; Zhang, Z.; Yin, D.; Chen, F. Fractal Analysis of Particle Distribution and Scale Effect in a Soil-Rock Mixture. Fractal Fract. 2022, 6, 120. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Zhang, J. Solid grain migration on hydraulic properties of fault rocks in underground mining tunnel: Radial seepage experiments and verification of permeability prediction. Tunn. Undergr. Space Technol. 2022, 126, 104525. [Google Scholar] [CrossRef]

- Gong, F.Q.; Si, X.F.; Li, X.B.; Wang, S.Y. Dynamic triaxial compression tests on sandstone at high strain rates and low confining pressures with split Hopkinson pressure bar. Int. J. Rock Mech. Min. Sci. 2019, 113, 211–219. [Google Scholar] [CrossRef]

- Mansouri, H.; Ajalloeian, R. Mechanical behavior of salt rock under uniaxial compression and creep tests. Int. J. Rock Mech. Min. Sci. 2018, 110, 19–27. [Google Scholar] [CrossRef]

- Li, B.; Liang, Y.; Zhang, L.; Zou, Q. Breakage law and fractal characteristics of broken coal and rock masses with different mixing ratios during compaction. Energy Sci. Eng. 2019, 7, 1000–1015. [Google Scholar] [CrossRef]

- Hardin, B.O. Crushing of soil particles. J. Geotech. Eng. 1985, 111, 1177–1192. [Google Scholar] [CrossRef]

| Talbot Power Index n | Particle Size Interval Mass at Each Level/g | ||||

|---|---|---|---|---|---|

| 0~5 mm | 5~10 mm | 10~15 mm | 15~20 mm | 20~25 mm | |

| 0.2 | 724.7 | 107.8 | 70.4 | 53.4 | 43.7 |

| 0.4 | 525.3 | 167.8 | 122.1 | 99.4 | 85.4 |

| 0.6 | 380.7 | 196.4 | 158.9 | 138.7 | 125.3 |

| 0.8 | 275.9 | 204.5 | 184.1 | 172.0 | 163.5 |

| Baseline Grading Power Index n | Particle Size Interval Mass at Each Level/g | ||||

|---|---|---|---|---|---|

| 0~5 mm | 5~10 mm | 10~15 mm | 15~20 mm | 20~25 mm | |

| 0.2 | 0 | 391.6 | 257.0 | 194.0 | 158.7 |

| 0.2 | 765.6 | 113.9 | 74.4 | 0 | 46.1 |

| 0.4 | 0 | 353.5 | 257.2 | 209.3 | 180.0 |

| 0.4 | 583.3 | 186.3 | 135.6 | 0 | 94.8 |

| 0.6 | 0 | 317.1 | 256.6 | 224.0 | 202.3 |

| 0.6 | 442.0 | 228.0 | 184.5 | 0 | 145.5 |

| 0.8 | 0 | 282.4 | 254.2 | 237.5 | 225.9 |

| 0.8 | 333.2 | 247.0 | 222.3 | 0 | 197.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, M.; Pan, H.; Yang, S.; Zhu, S.; Zhang, T. Experimental Investigation of the Compaction-Crushing Characteristics of Graded Fractured Coal Gangue Based on Infill Mining. Fractal Fract. 2023, 7, 33. https://doi.org/10.3390/fractalfract7010033

Pang M, Pan H, Yang S, Zhu S, Zhang T. Experimental Investigation of the Compaction-Crushing Characteristics of Graded Fractured Coal Gangue Based on Infill Mining. Fractal and Fractional. 2023; 7(1):33. https://doi.org/10.3390/fractalfract7010033

Chicago/Turabian StylePang, Mingkun, Hongyu Pan, Shihua Yang, Shipeng Zhu, and Tianjun Zhang. 2023. "Experimental Investigation of the Compaction-Crushing Characteristics of Graded Fractured Coal Gangue Based on Infill Mining" Fractal and Fractional 7, no. 1: 33. https://doi.org/10.3390/fractalfract7010033

APA StylePang, M., Pan, H., Yang, S., Zhu, S., & Zhang, T. (2023). Experimental Investigation of the Compaction-Crushing Characteristics of Graded Fractured Coal Gangue Based on Infill Mining. Fractal and Fractional, 7(1), 33. https://doi.org/10.3390/fractalfract7010033