Fractal Characteristics of Deep Shales in Southern China by Small-Angle Neutron Scattering and Low-Pressure Nitrogen Adsorption

Abstract

:1. Introduction

2. Materials and Methods

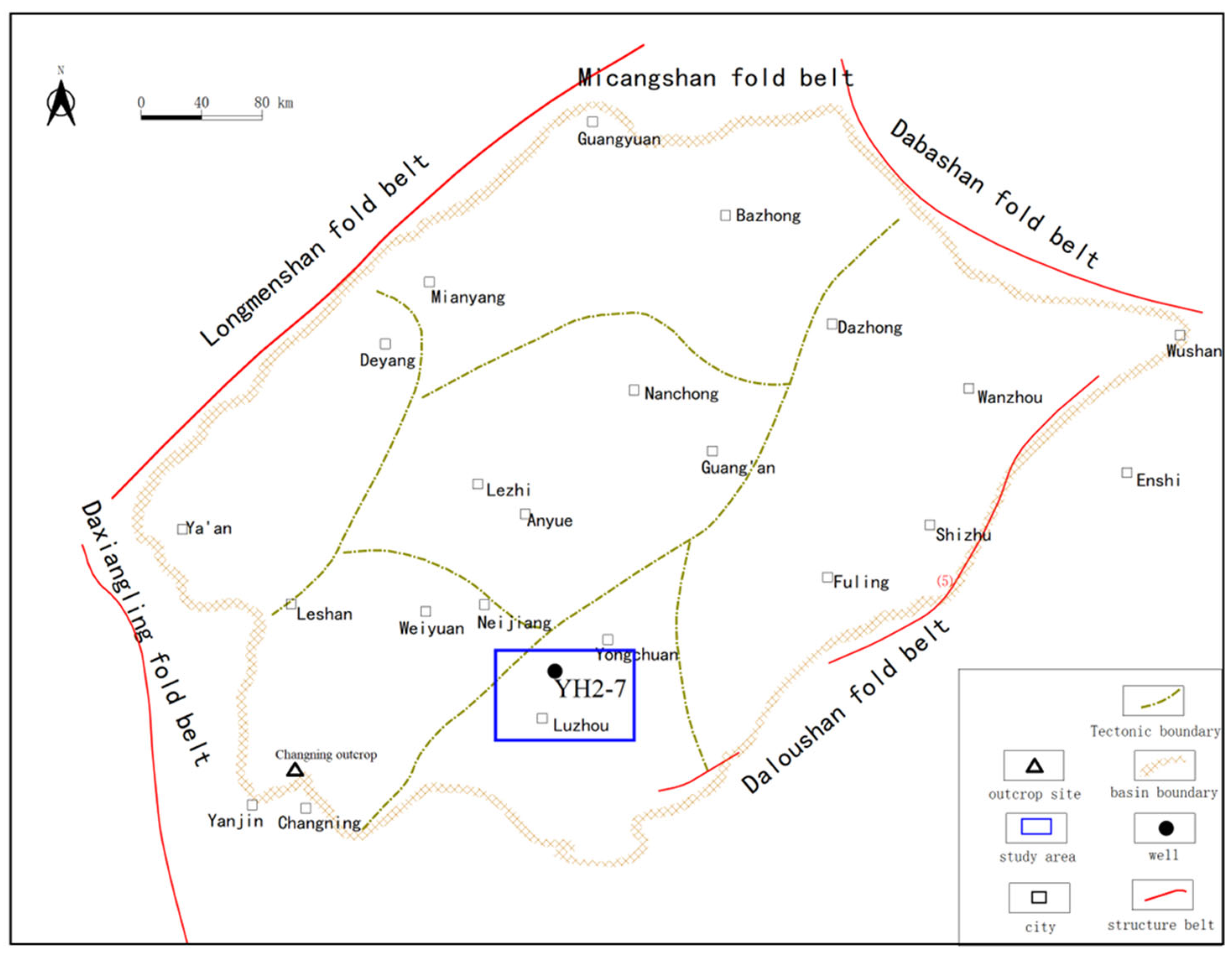

2.1. Samples

2.2. Methods

2.2.1. Small-Angle Neutron Scattering

2.2.2. Low-Pressure Nitrogen Adsorption

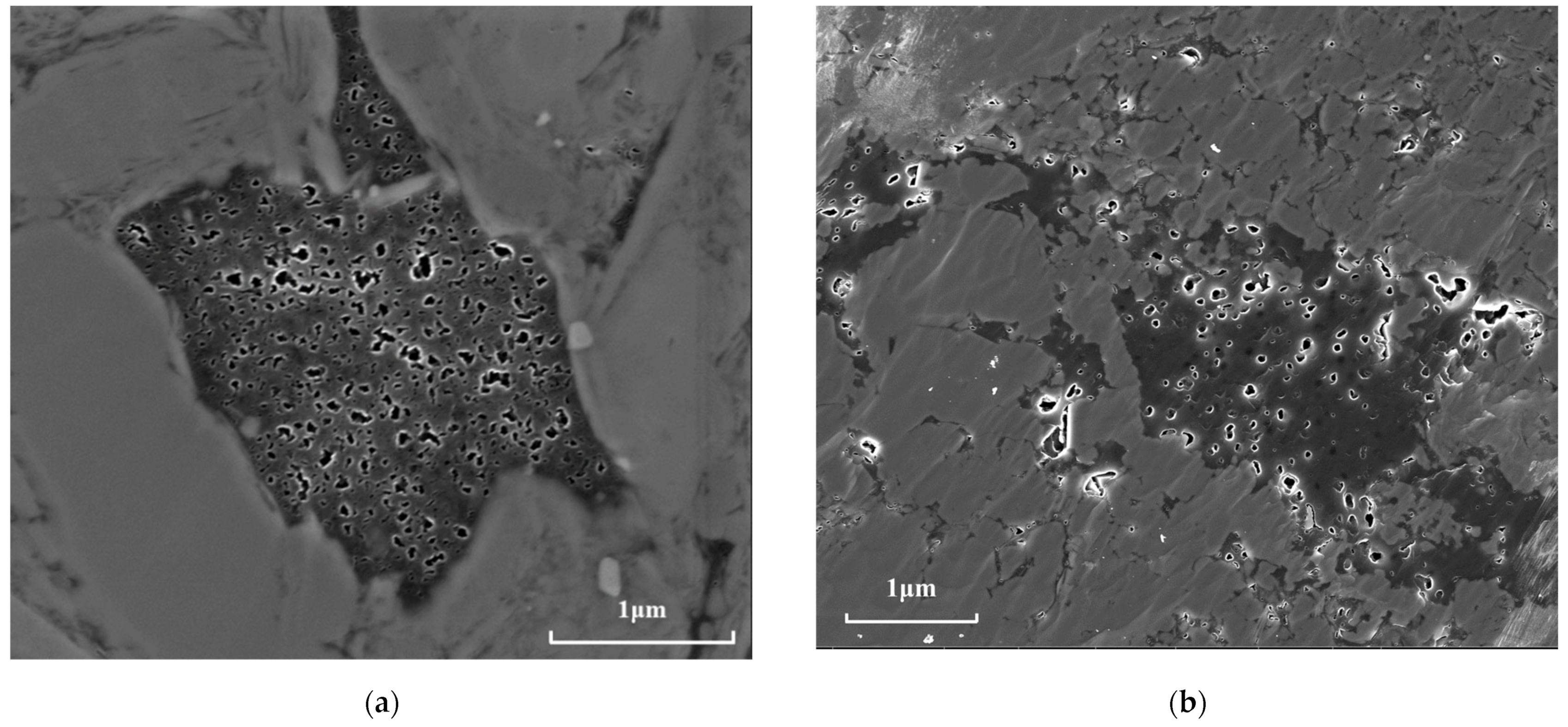

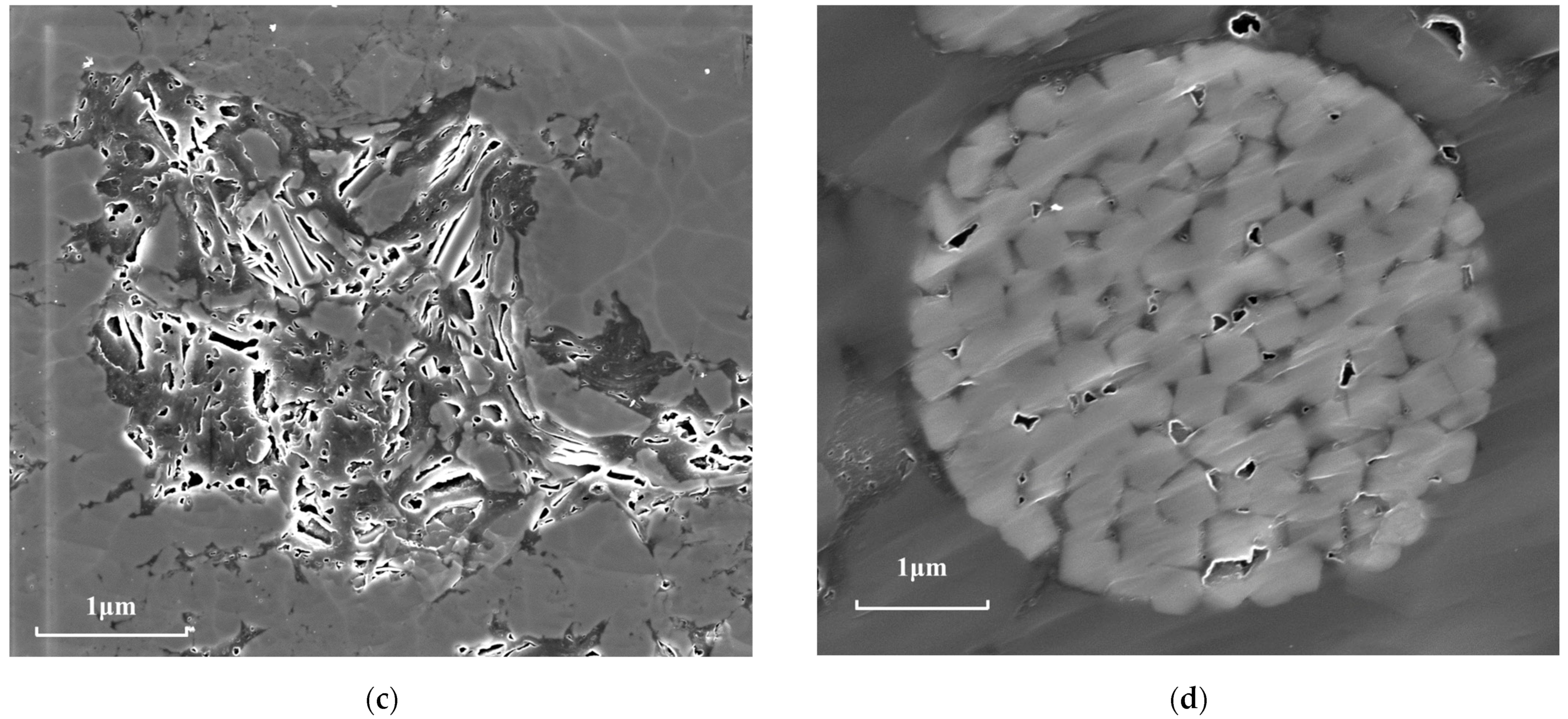

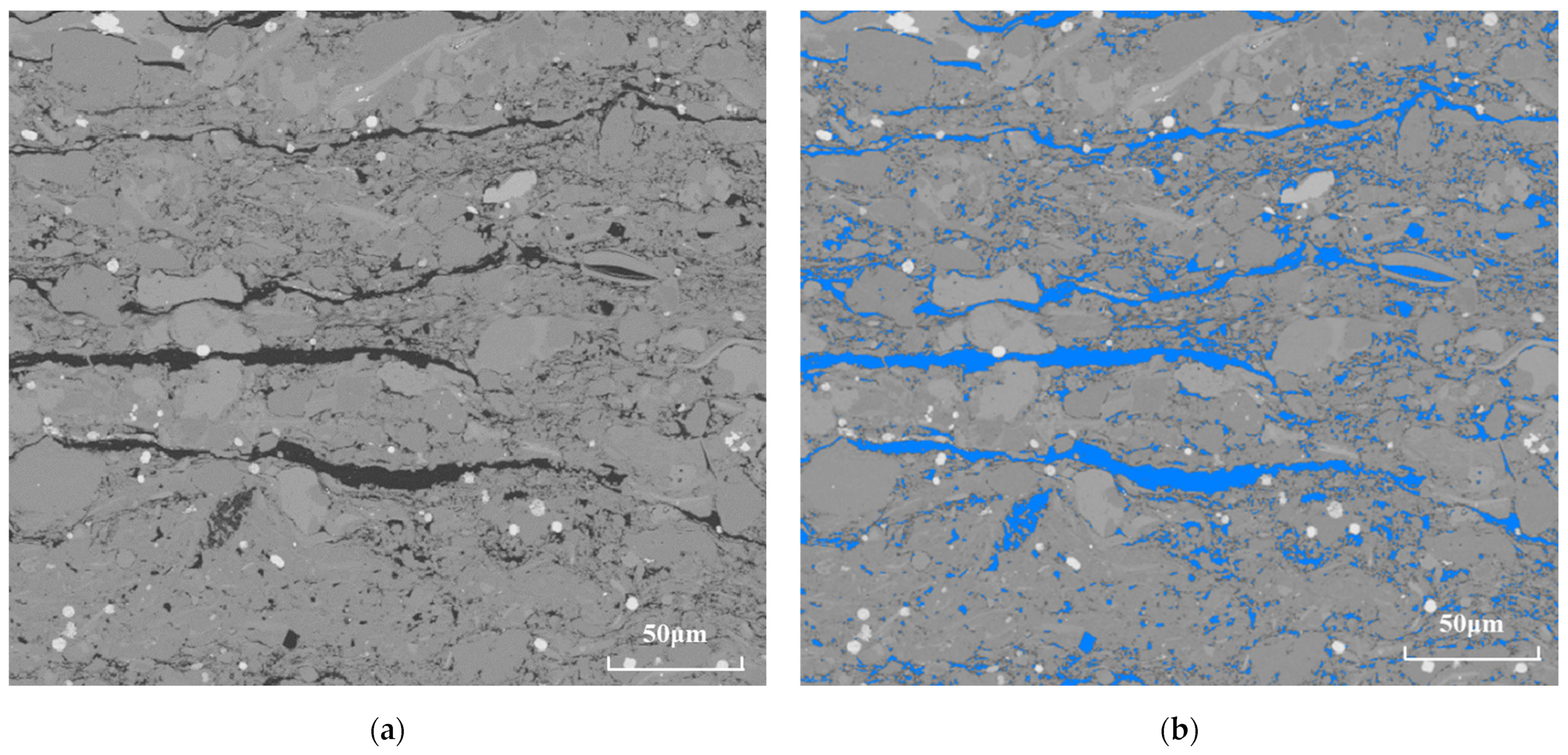

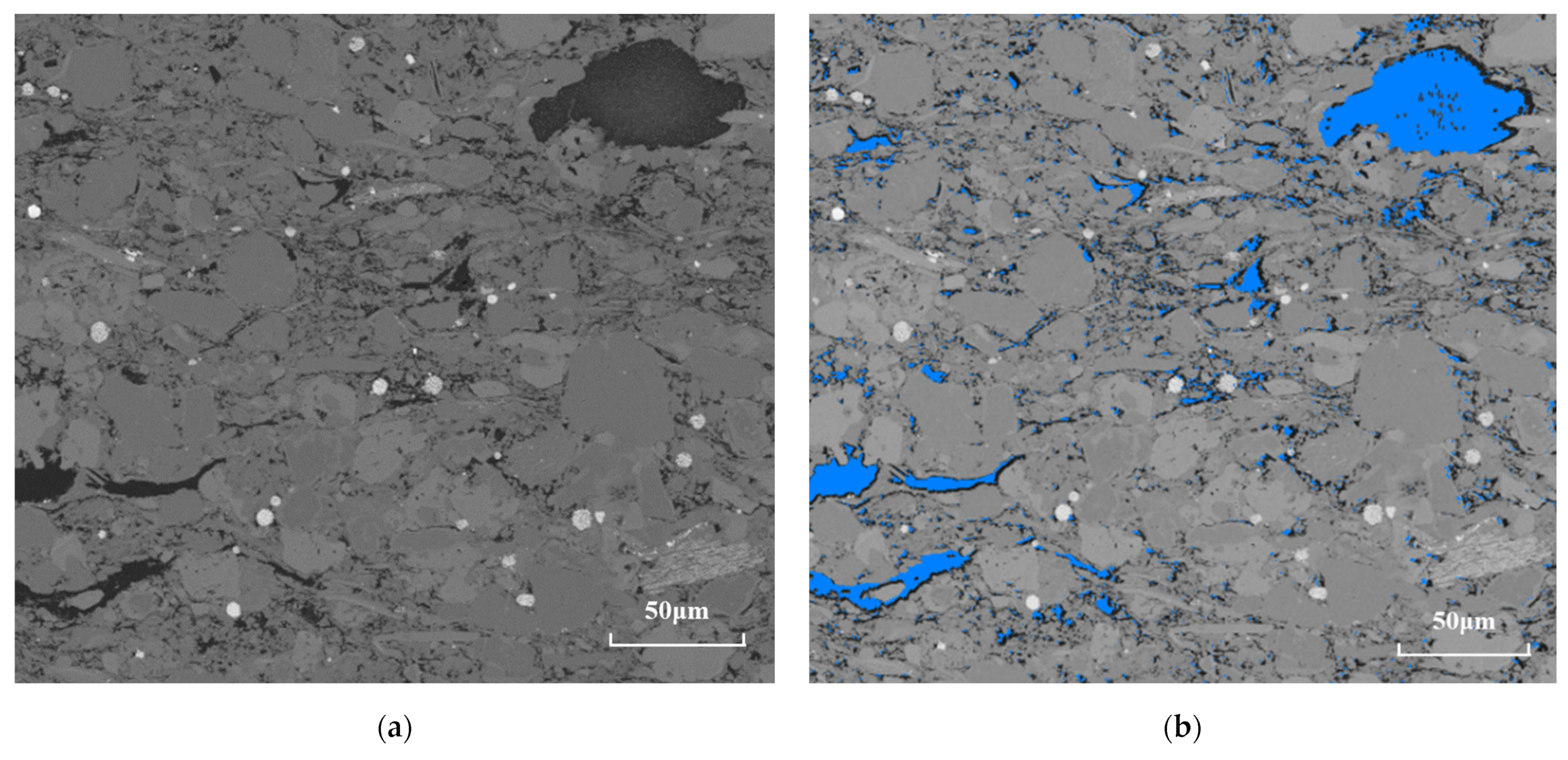

2.2.3. Large Field of View Mosaic Scanning Electron Microscope

3. Results

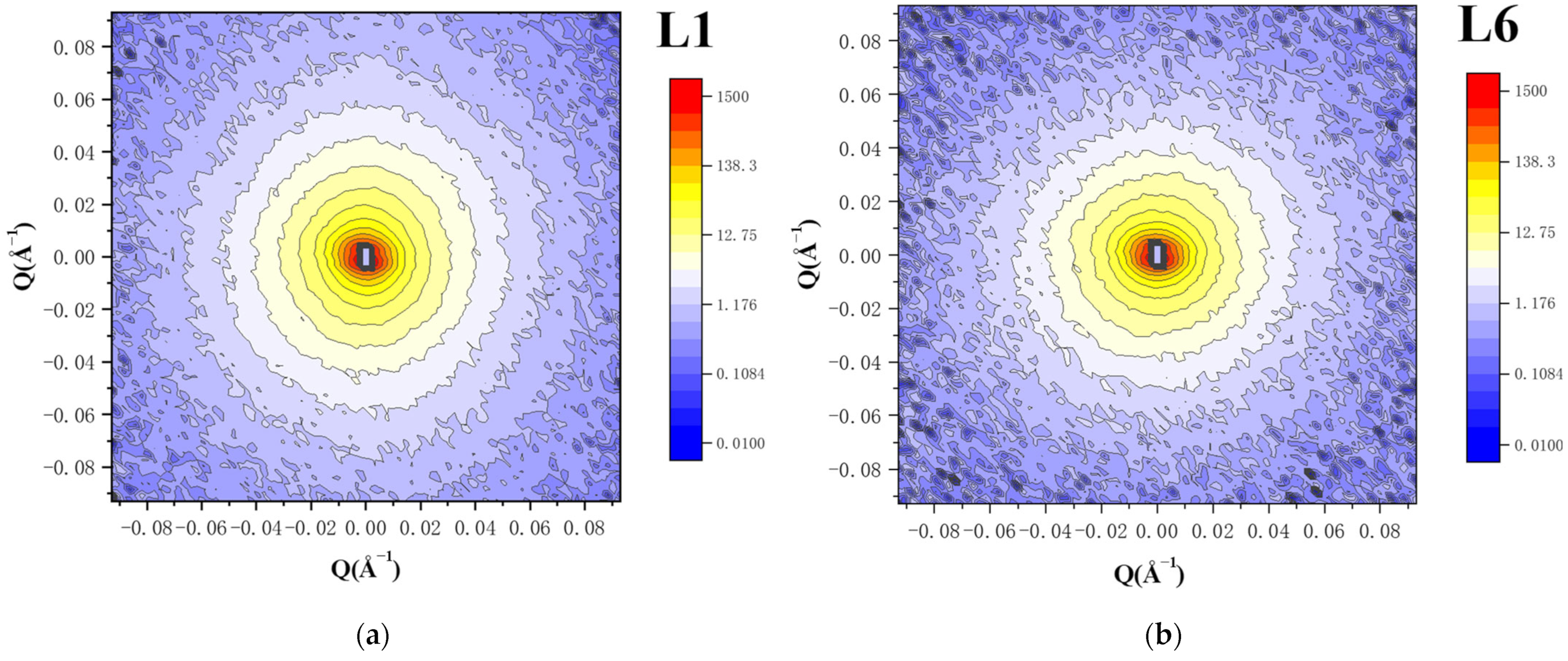

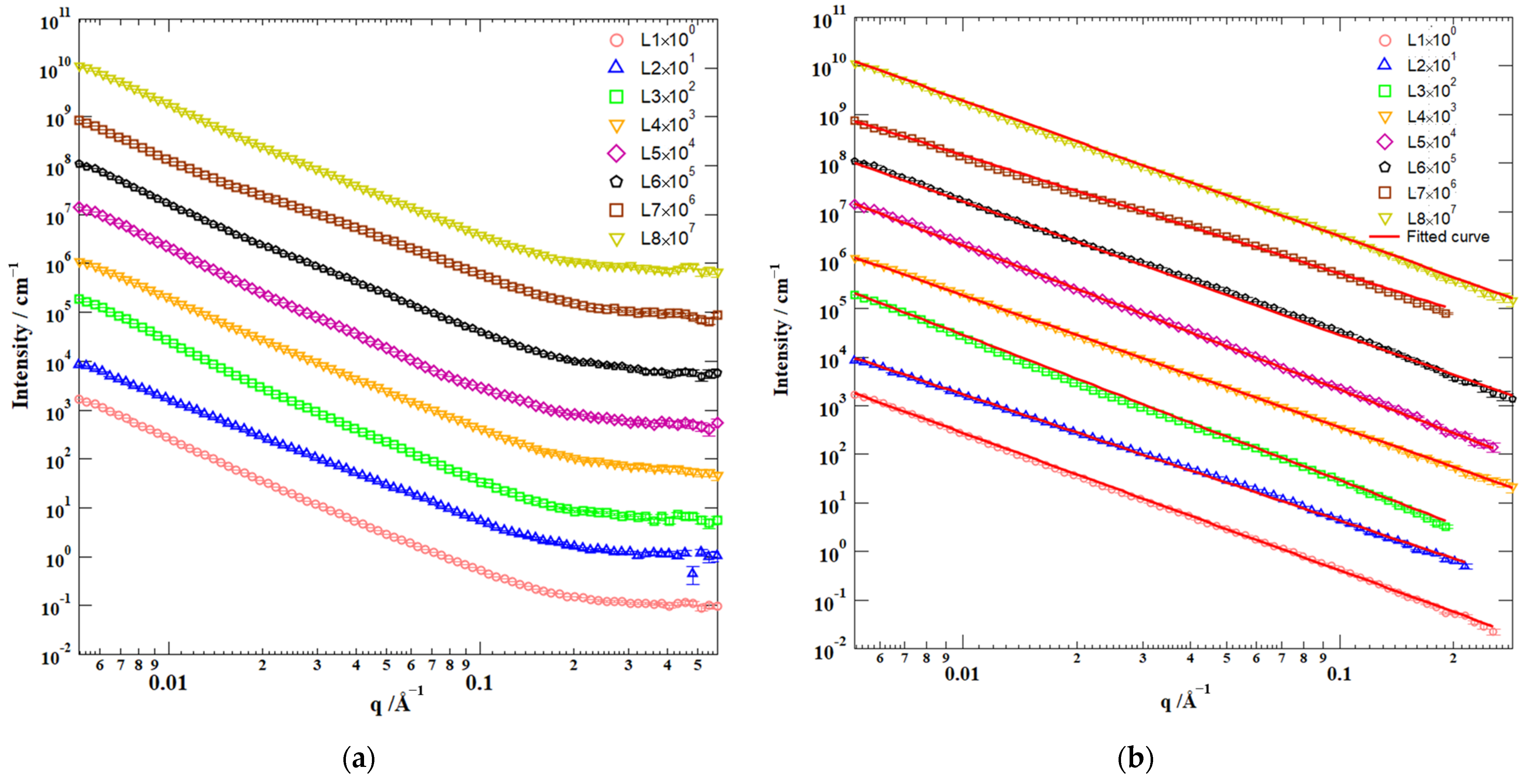

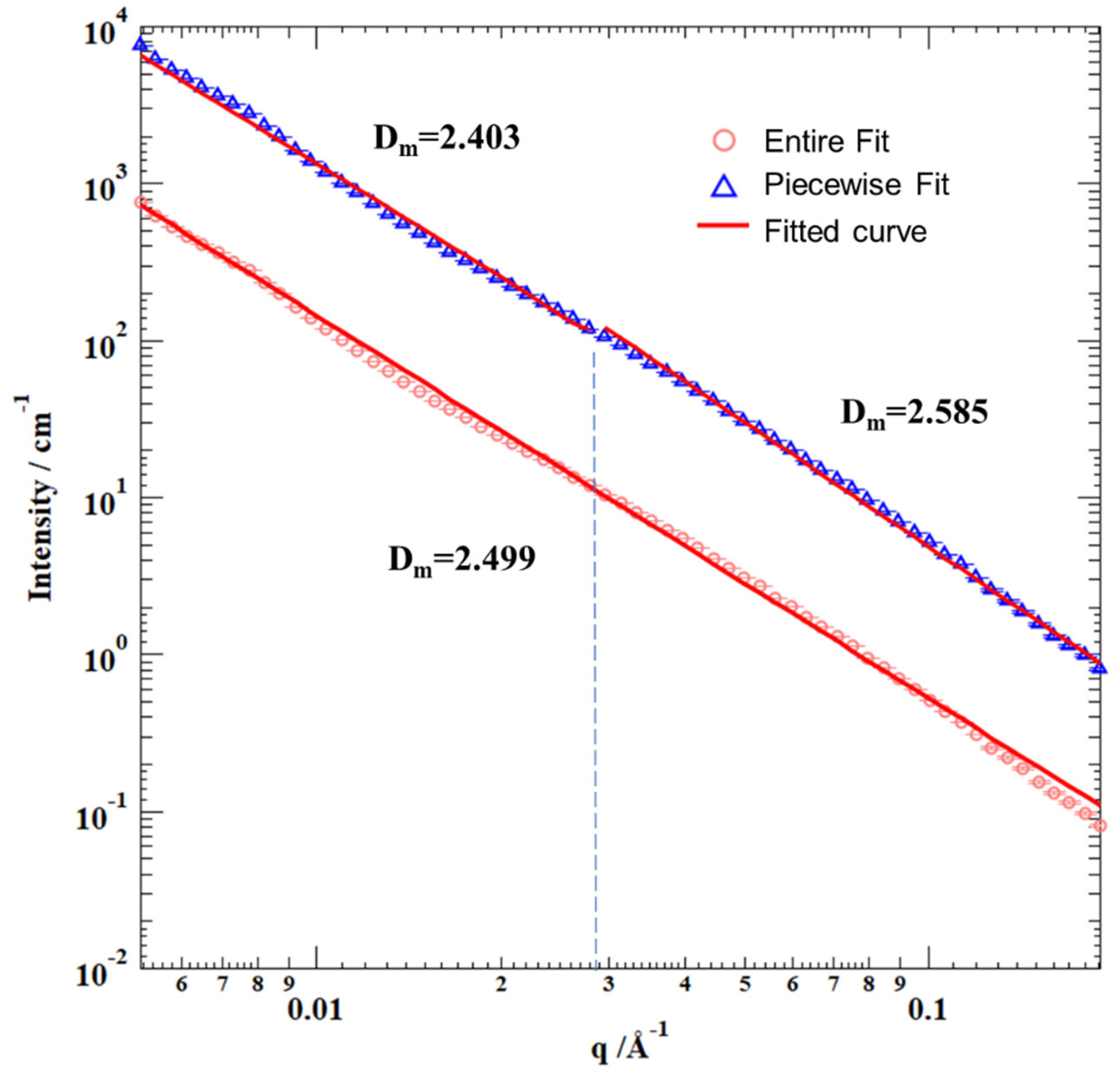

3.1. SANS Experimental Results

3.1.1. Calculation of Scattering Length Density (SLD)

3.1.2. Calculation of SANS Experimental Results

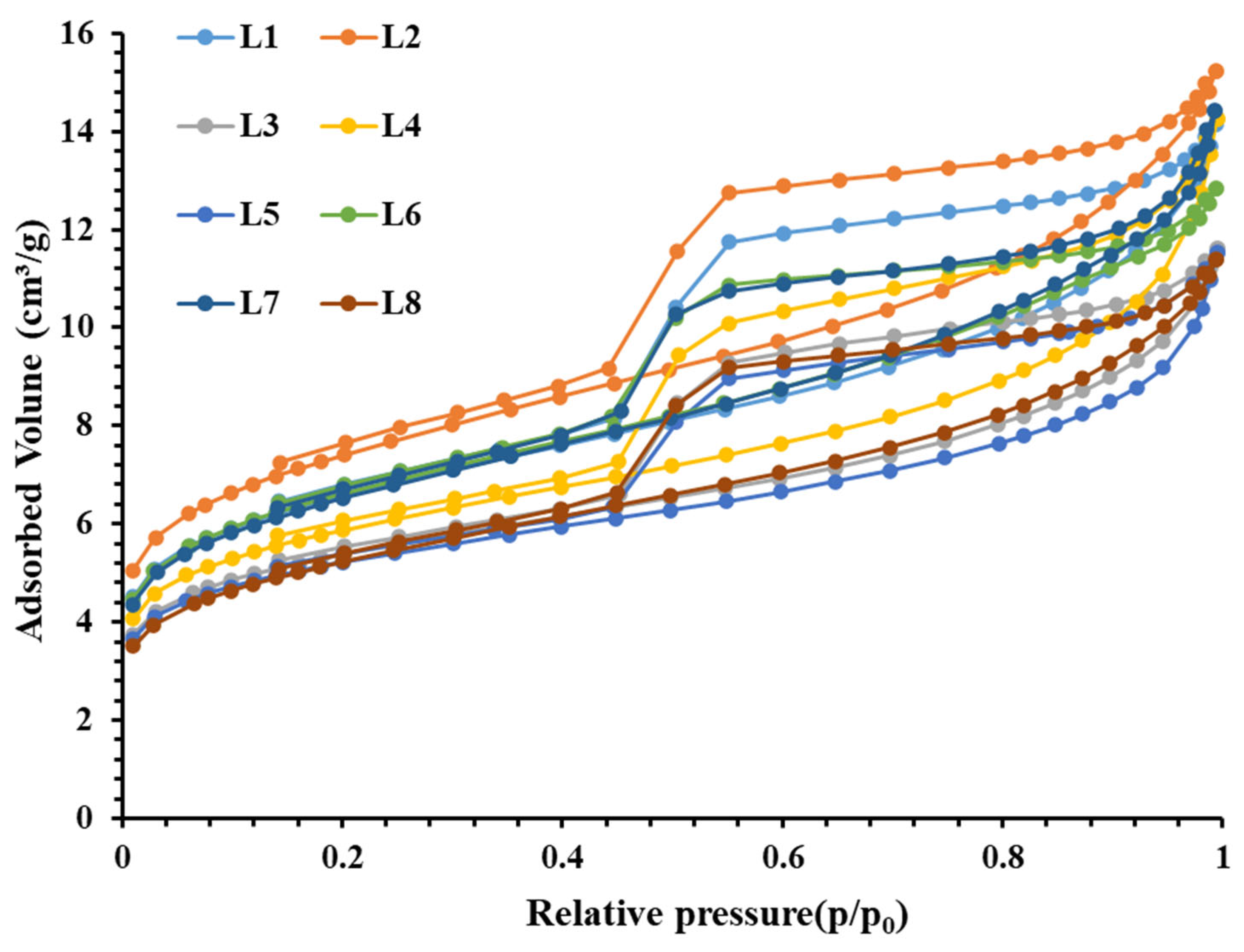

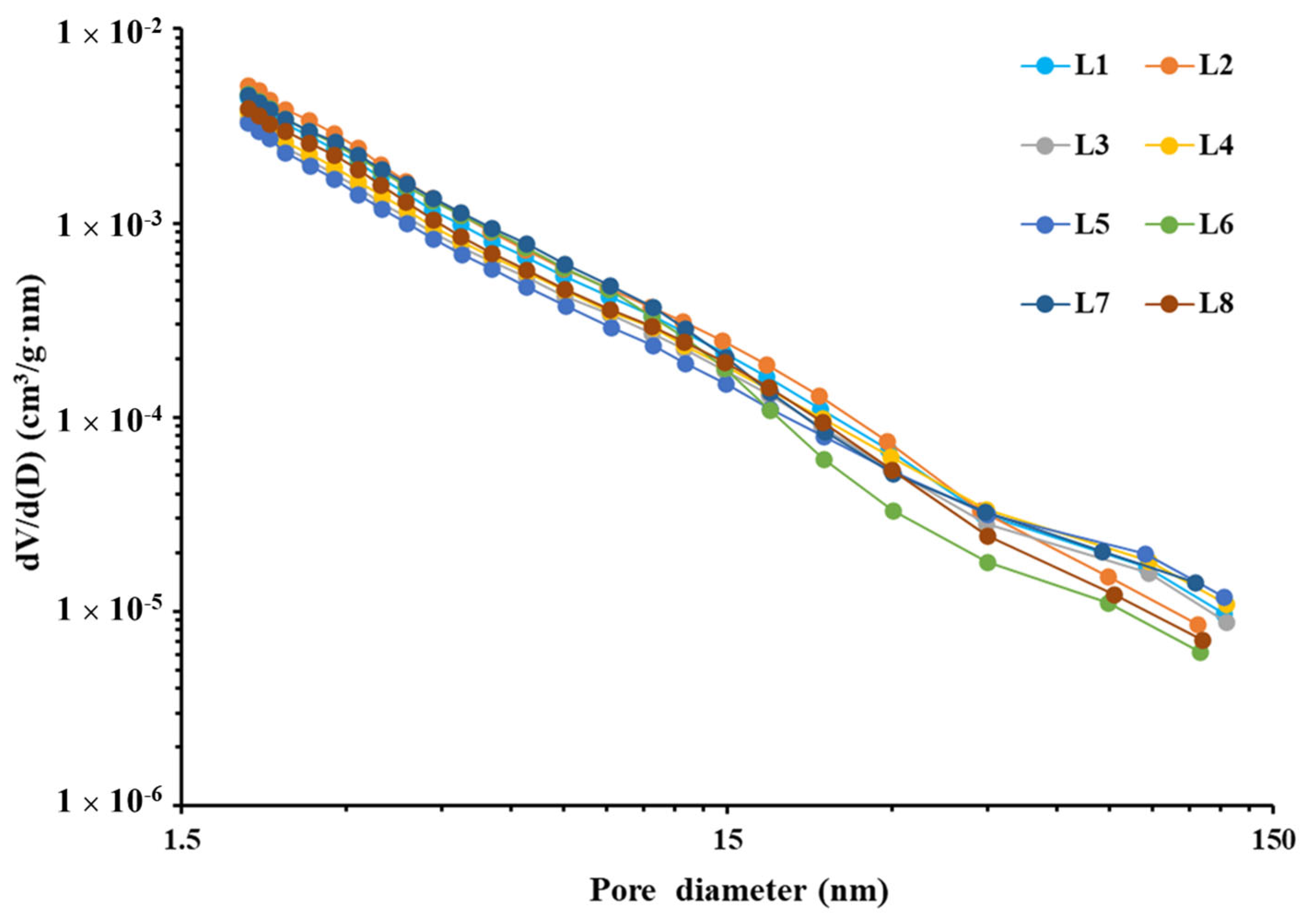

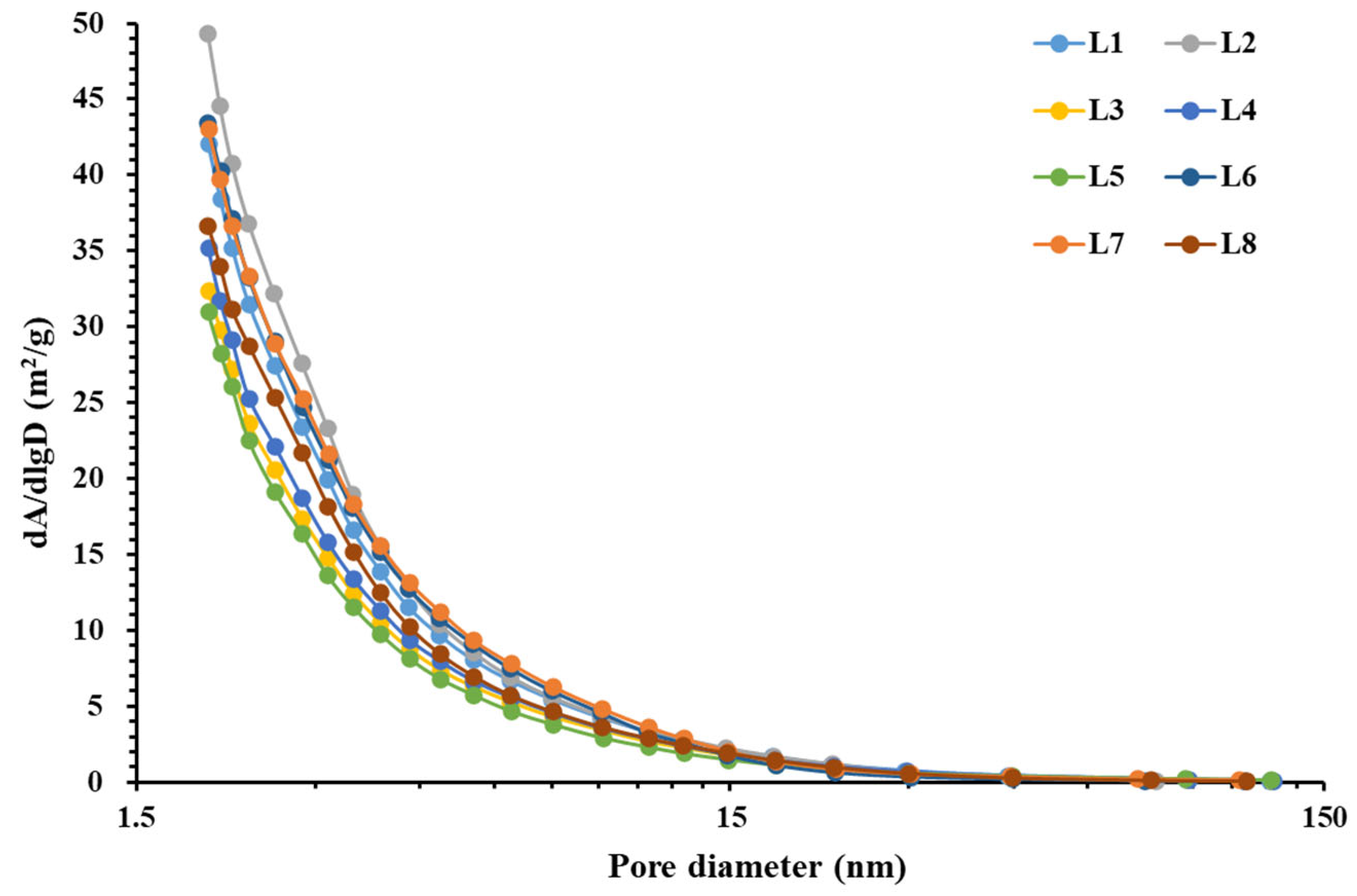

3.2. Low-Pressure Nitrogen Adsorption Experiment Results

4. Discussion

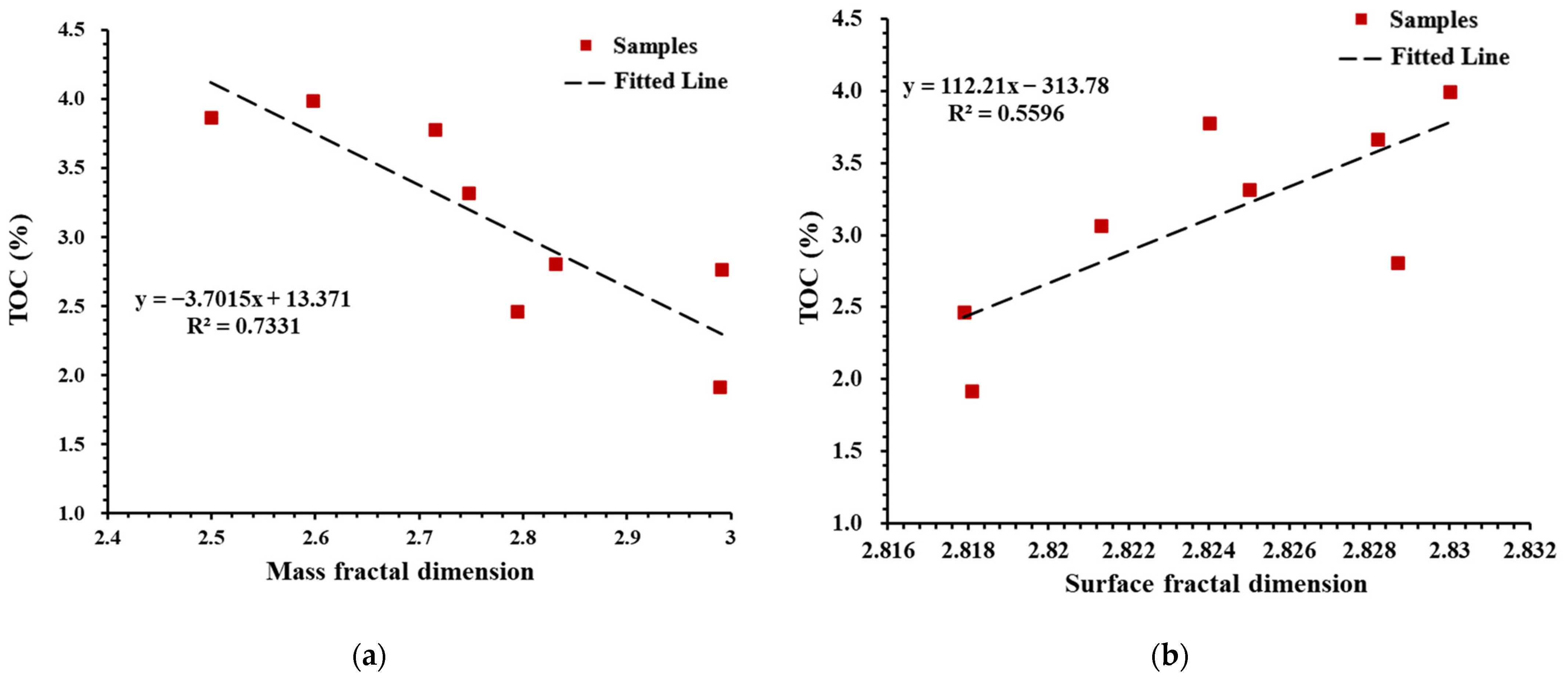

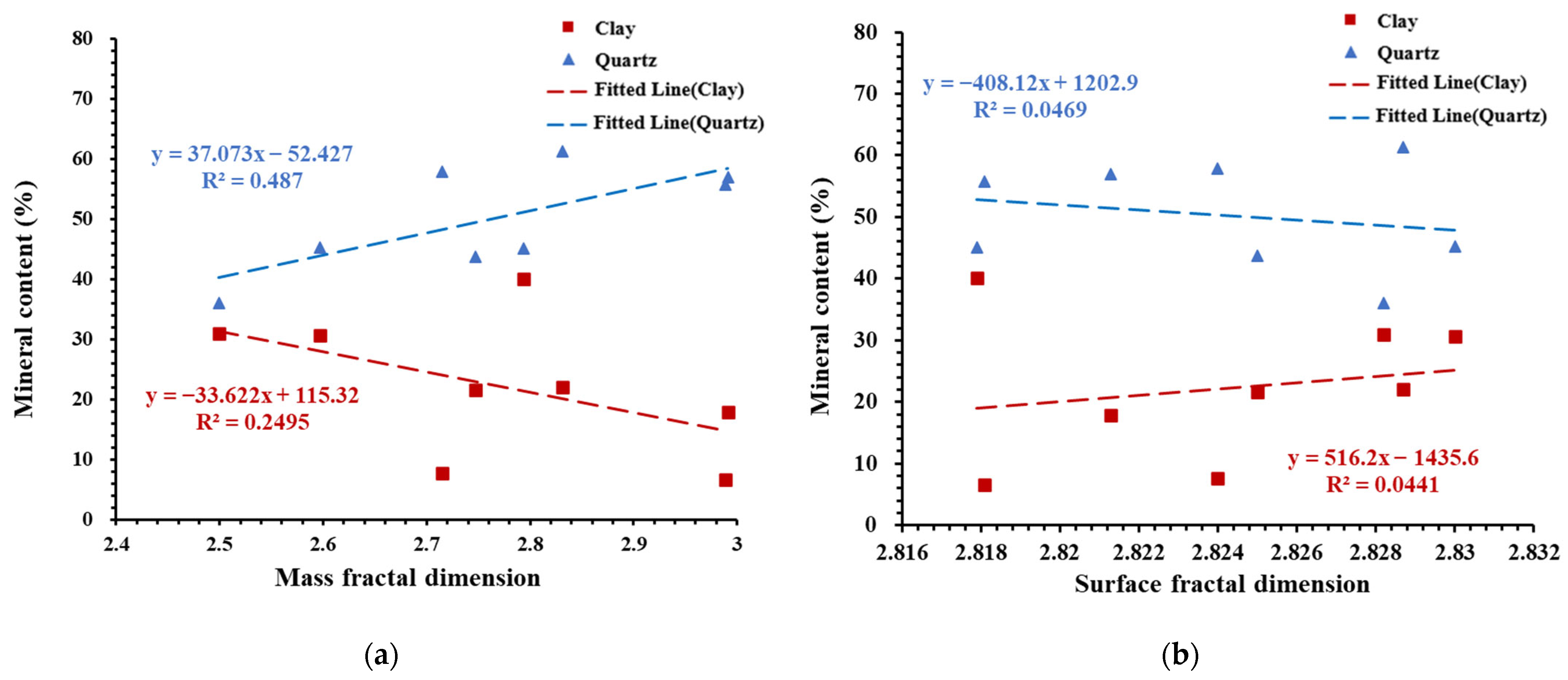

4.1. The Relationship between Fractal Dimensions and the Composition and TOC Content of Deep Shales

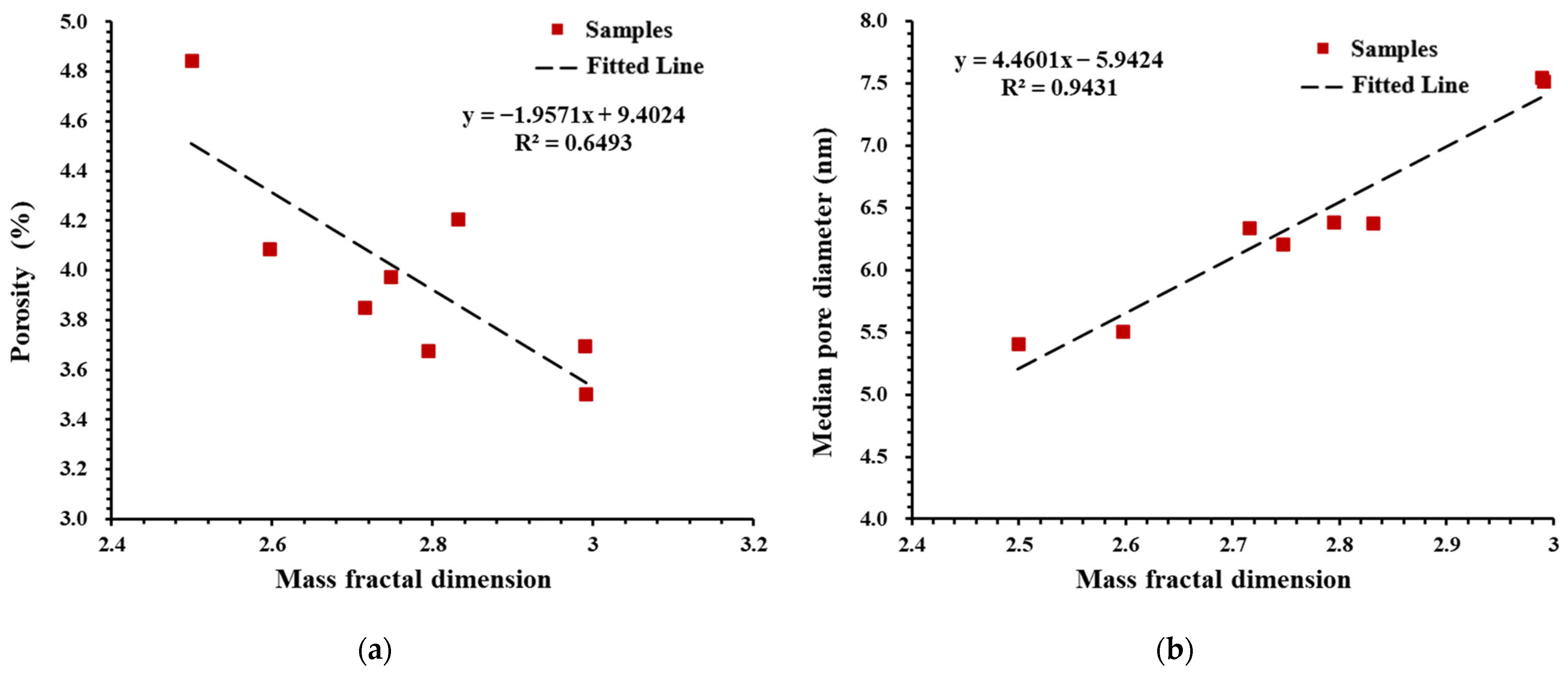

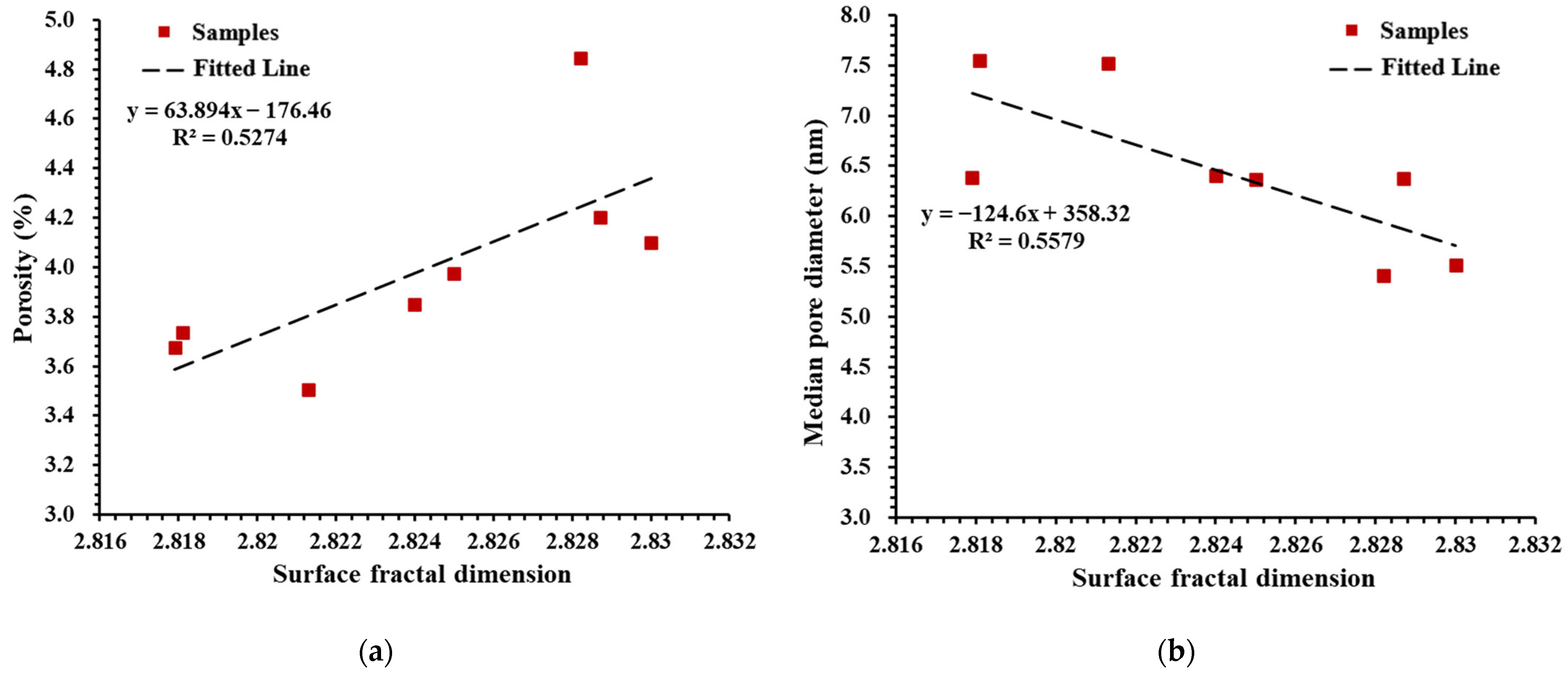

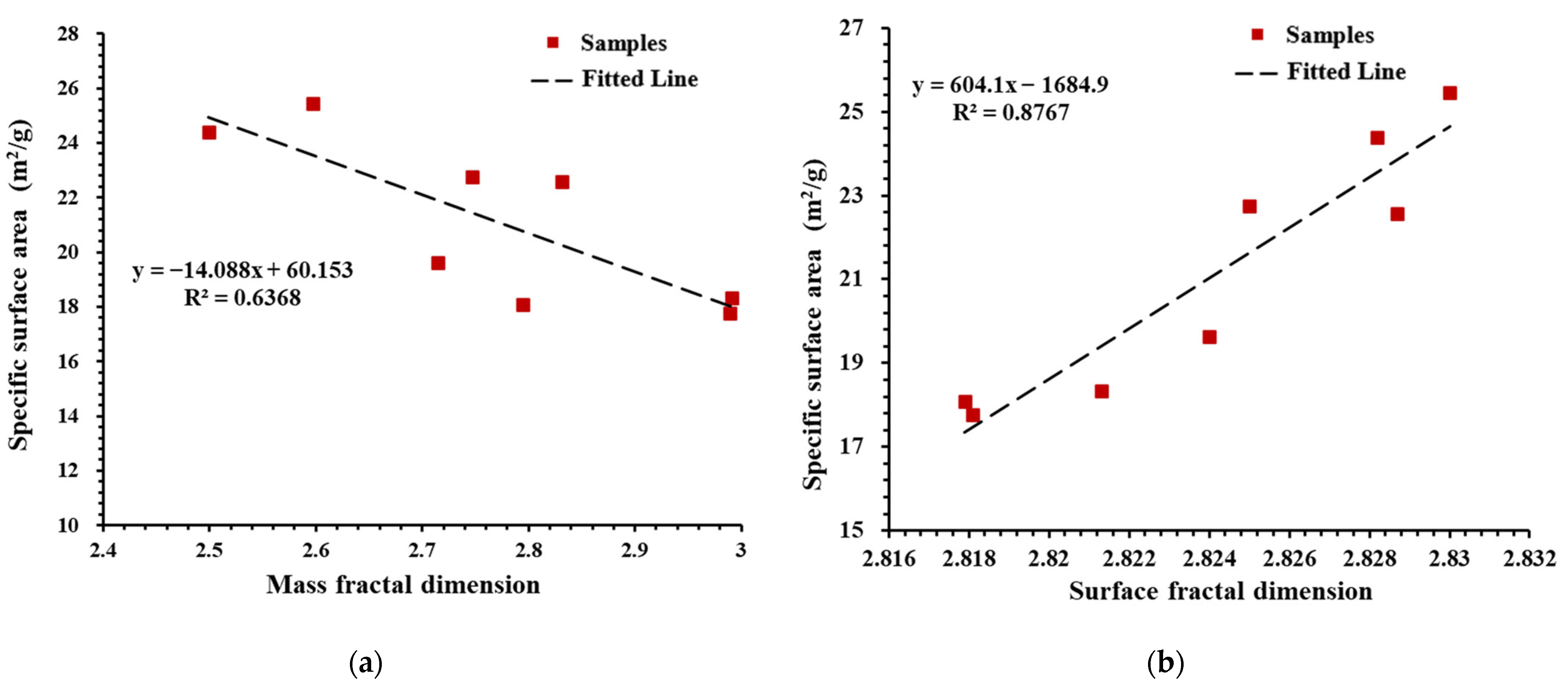

4.2. The Relationship between Fractal Dimension and Pore Structure of Deep Shale

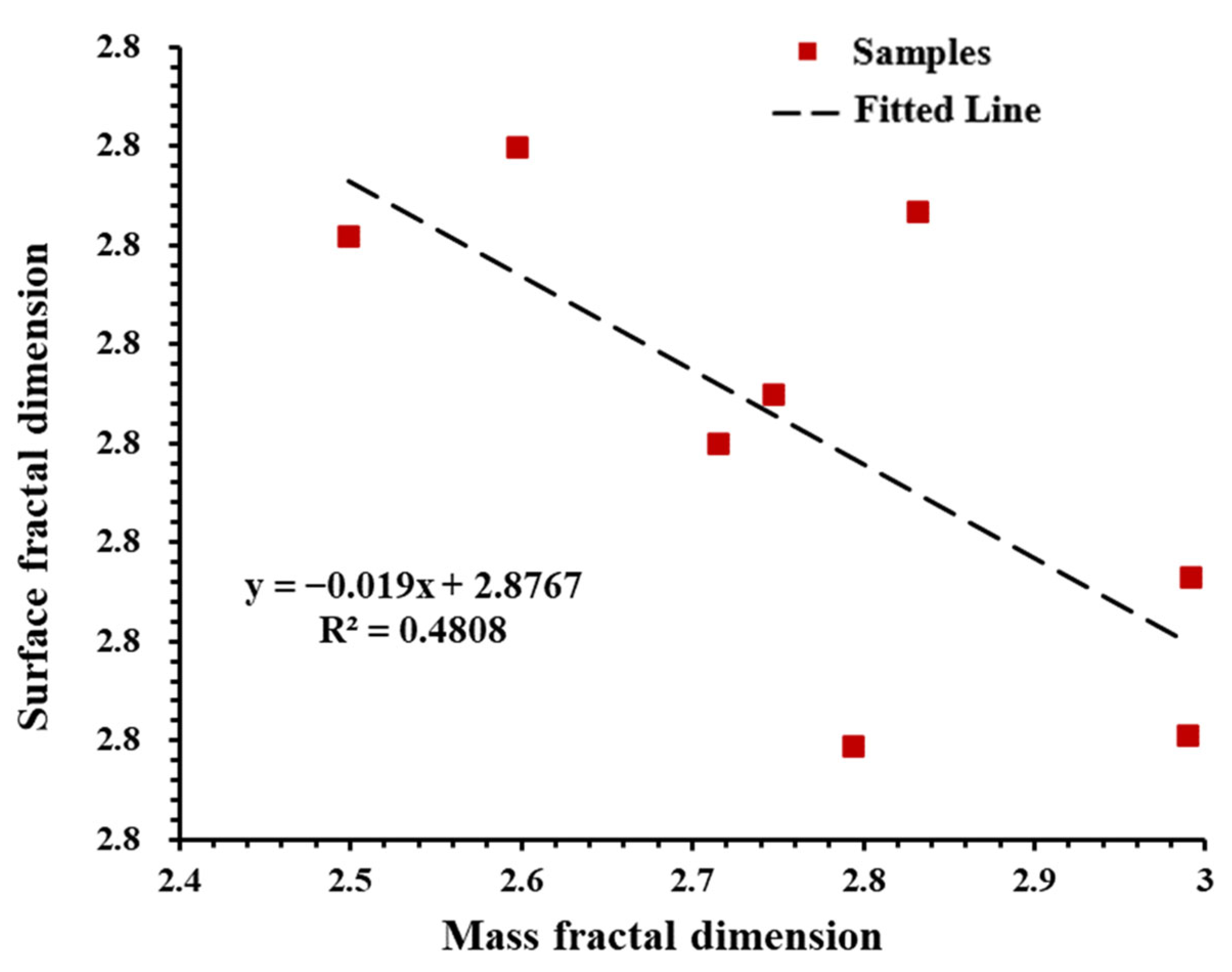

4.3. The Relationship between Mass Fractal Dimension and Surface Fractal Dimension

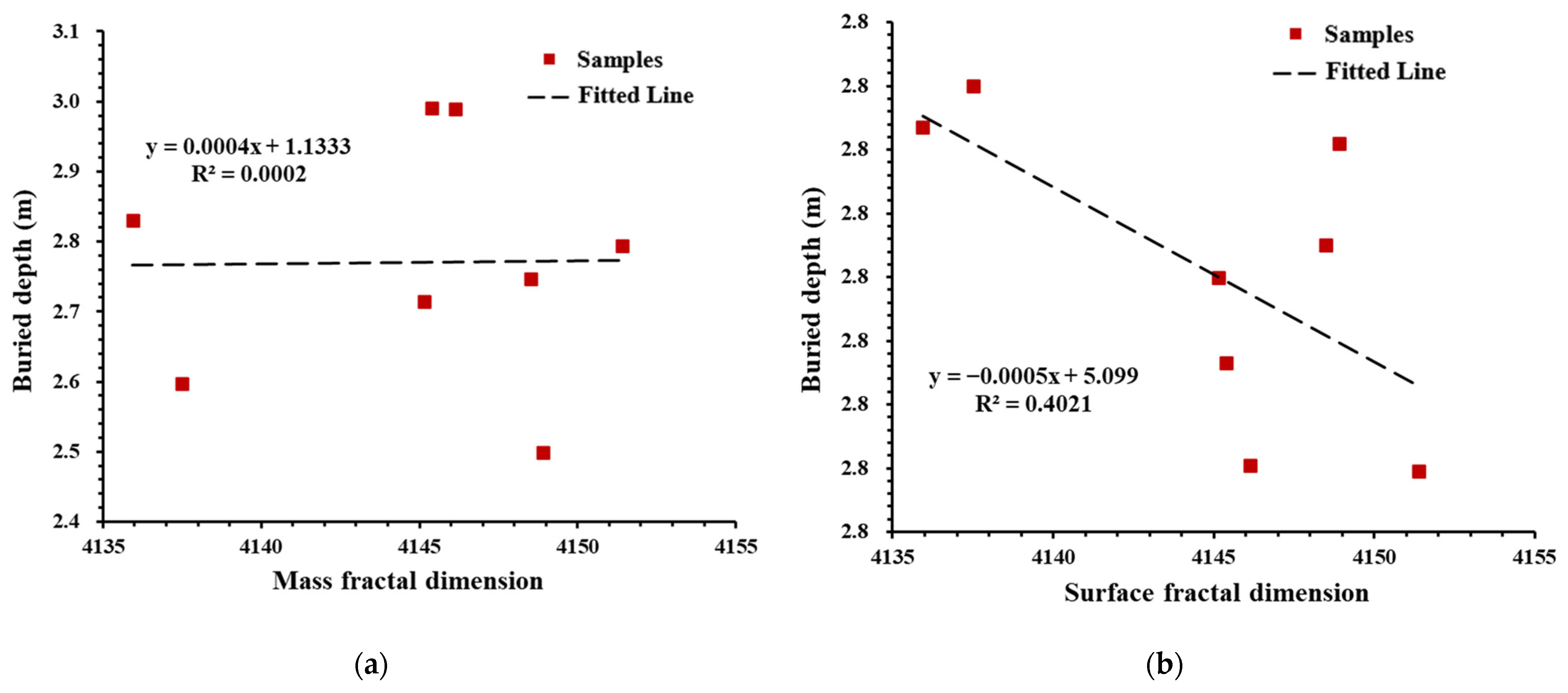

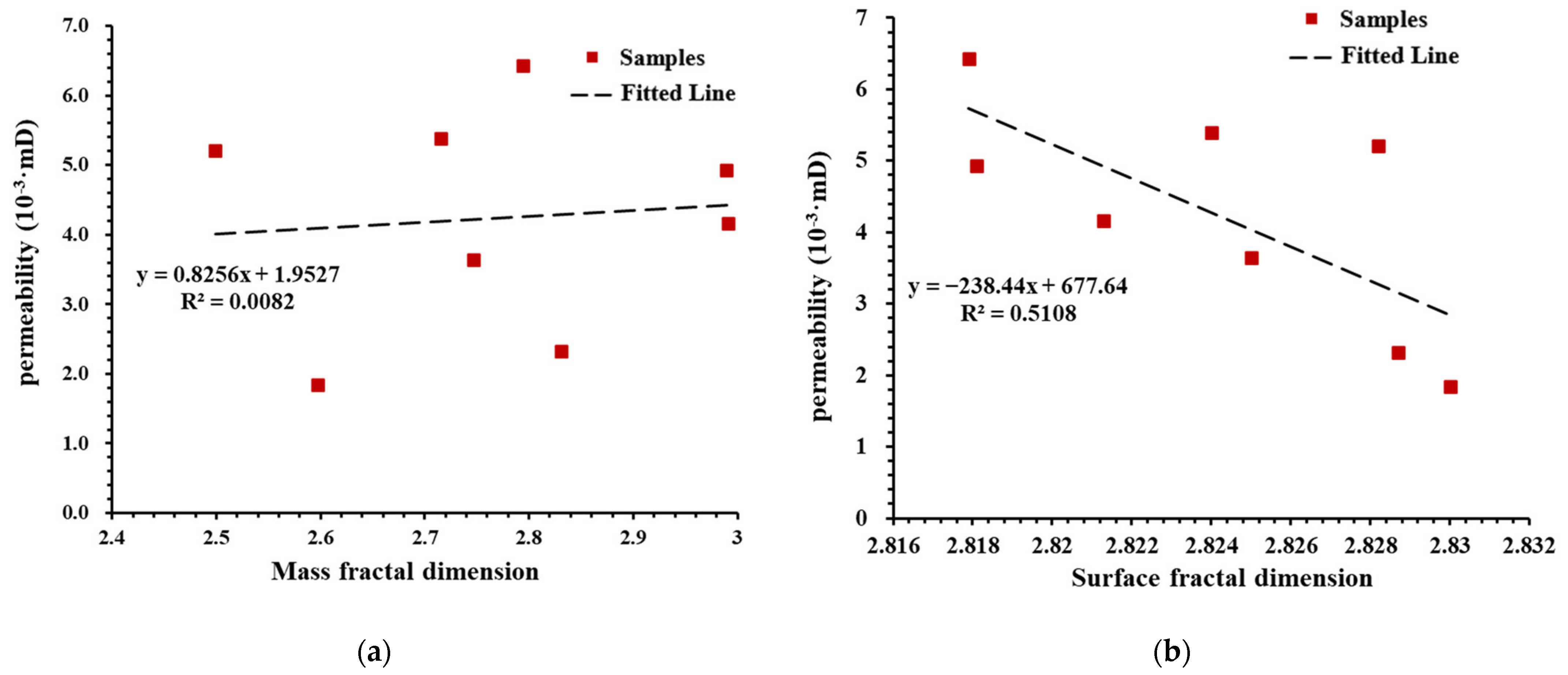

4.4. The Relationship between the Fractal Dimension and Deep Shale Connectivity

4.5. Experimental Error Analysis

5. Conclusions

- Deep shale has double the fractal characteristics, meaning that its pore distribution has mass fractal characteristics, and its pore surface has surface fractal characteristics. The deep shale’s mass distribution dimension ranges from 2.499 to 2.991, while the surface fractal dimension ranges from 2.814 to 2.831, indicating that both the pore distribution and the pore surface of the shale are heterogeneous. Moreover, the mass fractal dimension of deep shale is negatively related to the surface fractal dimension. Therefore, the characteristics of the shale reservoirs can be more comprehensively characterised by studying shale reservoirs in terms of mass fractal dimension and surface fractal dimension.

- The organic matter content is the controlling factor of the fractal dimension of deep shale, and the small-diameter organic pores generated in the organic matter will control the fractal characteristics of the shale. Among them, the TOC content is negatively correlated with the mass fractal dimension; however, it is positively related to the surface fractal dimension. There is no evident correlation between the fractal dimension and inorganic mineral content.

- The mass fractal dimension displays a highly negative correlation with the median pore size (R2 = 0.94) and has a moderate correlation with the porosity and specific surface. This suggests that the mass fractal dimension is directly influenced by the distribution of the shale pore volume. Similarly, the specific surface area is the direct influencing factor of the surface fractal dimension. This points out that the direct influencing factors of various fractal dimensions are different, necessitating the distinction and discussion of the fractal characteristics of shale.

- The permeability and the surface fractal dimension are negatively correlated. The larger the surface fractal dimension, the more complex the shale surface, and the greater the gas flow resistance. No significant correlation exists between the mass fractal dimension and permeability. The distribution of organic matter substantially impacts the shale connectivity, which is enhanced when the organic matter is distributed along the bedding, thereby resulting in some samples of low-mass fractal dimensions with high permeability.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vidic, R.D.; Brantley, S.L.; Vandenbossche, J.M.; Yoxtheimer, D.; Abad, J.D. Impact of shale gas development on regional water quality. Science 2013, 340, 1235009. [Google Scholar] [CrossRef]

- Zou, C.; Zhao, Q.; Cong, L.; Wang, H.; Shi, Z.; Wu, J.; Pan, S. Development progress, potential and prospect of shale gas in China. Nat. Gas Ind. 2021, 41, 1–14. [Google Scholar]

- Li, X.; Guo, Z.; Hu, Y.; Liu, X.; Wan, Y.; Luo, R.; Sun, Y.; Che, M. High-quality development of ultra-deep large gas fields in China: Challenges, strategies and proposals. Nat. Gas Ind. B 2020, 7, 505–513. [Google Scholar] [CrossRef]

- Shen, W.; Ma, T.; Li, X.; Sun, B.; Hu, Y.; Xu, J. Fully coupled modeling of two-phase fluid flow and geomechanics in ultra-deep natural gas reservoirs. Phys. Fluids 2022, 34, 043101. [Google Scholar] [CrossRef]

- Nie, H.K.; Bian, R.K.; Zhang, P.X.; Gao, B. Micro-types and characteristics of shale reservoir of the lower paleozoic in southeast Sichuan basin, and their effects on the gas content. Earth Sci. Front. 2014, 21, 331–343. [Google Scholar]

- Ma, X.H.; Li, X.Z.; Liang, F.; Wan, Y.J.; Shi, Q.; Wang, Y.H.; Zhang, X.W.; Che, M.G.; Guo, W. Dominating factors on well productivity and development strategies optimization in Weiyuan shale gas play, Sichuan Basin, SW China. Pet. Explor. Dev. 2020, 47, 594–602. [Google Scholar] [CrossRef]

- Liu, S.; Jiao, K.; Zhang, J.; Ye, Y.; Xie, G.; Deng, B.; Ran, B.; Li, Z.; Wu, J.; Li, J.; et al. Research progress on the pore characteristics of deep shale gas reservoirs: An example from the lower paleozoic marine shale in the Sichuan Basin. Nat. Gas Ind. 2021, 41, 29–41. [Google Scholar]

- Han, L.; Li, X.; Guo, W.; Ju, W.; Cui, Y.; Liu, Z.; Qian, C.; Shen, W. Characteristics and dominant factors for natural fractures in deep shale gas reservoirs: A case study of the wufeng-longmaxi formations in Luzhou Block, Southern China. Lithosphere 2022, 2022, 9662175. [Google Scholar] [CrossRef]

- Yang, R.; He, S.; Yi, J.; Hu, Q. Nano-scale pore structure and fractal dimension of organic-rich Wufeng-Longmaxi shale from Jiaoshiba area, Sichuan Basin: Investigations using FE-SEM, gas adsorption and helium pycnometry. Mar. Pet. Geol. 2016, 70, 27–45. [Google Scholar] [CrossRef]

- Lin, W.; Li, X.; Yang, Z.; Lin, L.; Xiong, S.; Wang, Z.; Wang, X.; Xiao, Q. A new improved threshold segmentation method for scanning images of reservoir rocks considering pore fractal characteristics. Fractals 2018, 26, 1840003. [Google Scholar] [CrossRef]

- Lin, W.; Wu, Z.; Li, X.; Yang, Z.; Hu, M.; Han, D.; Wang, C.; Zhang, J. Digital characterization and fractal quantification of the pore structures of tight sandstone at multiple scales. J. Pet. Explor. Prod. Technol. 2022, 12, 2565–2575. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Aizenman, M. Fractals: Form, chance, and dimension. Phys. Today 1979, 32, 65–66. [Google Scholar] [CrossRef]

- Pfeifer, P.; Avnir, D. Chemistry in noninteger dimensions between two and three. I. Fractal theory of heterogeneous surfaces. J. Chem. Phys. 1983, 79, 3558–3565. [Google Scholar] [CrossRef]

- Katz, A.J.; Thompson, A.H. Fractal sandstone pores: Implications for conductivity and pore formation. Phys. Rev. Lett. 1985, 54, 1325–1328. [Google Scholar] [CrossRef] [PubMed]

- Krohn, C.E. Sandstone fractal and Euclidean pore volume distributions. J. Geophys. Res. Solid Earth 1988, 93, 3286–3296. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Huang, W. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Shao, X.; Pang, X.; Li, Q.; Wang, P.; Chen, D.; Shen, W.; Zhao, Z. Pore structure and fractal characteristics of organic-rich shales: A case study of the lower Silurian Longmaxi shales in the Sichuan Basin, SW China. Mar. Pet. Geol. 2017, 80, 192–202. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, J.; Ding, J.; Liu, T.; Shi, G.; Li, X.; Dang, W.; Cheng, Y.; Guo, R. Pore structure and fractal characteristics of different shale lithofacies in the dalong formation in the western area of the Lower Yangtze Platform. Minerals 2020, 10, 72. [Google Scholar] [CrossRef]

- Martin, J.E. Scattering exponents for polydisperse surface and mass fractals. J. Appl. Crystallogr. 1986, 19, 25–27. [Google Scholar] [CrossRef]

- Yang, R.; He, S.; Hu, Q.; Sun, M.; Hu, D.; Yi, J. Applying SANS technique to characterize nano-scale pore structure of Longmaxi shale, Sichuan Basin (China). Fuel 2017, 197, 91–99. [Google Scholar]

- Liu, K.; Ostadhassan, M.; Sun, L.; Zou, J.; Yuan, Y.; Gentzis, T.; Zhang, Y.; Carvajal-Ortiz, H.; Rezaee, R. A comprehensive pore structure study of the Bakken Shale with SANS, N2 adsorption and mercury intrusion. Fuel 2019, 245, 274–285. [Google Scholar] [CrossRef]

- Neil, C.W.; Hjelm, R.P.; Hawley, M.E.; Watkins, E.B.; Cockreham, C.; Wu, D.; Mao, Y.; Fischer, T.B.; Stokes, M.R.; Xu, H. Small-angle neutron scattering (SANS) characterization of clay- and carbonate-rich shale at elevated pressures. Energy Fuels 2020, 34, 8178–8185. [Google Scholar] [CrossRef]

- Mastalerz, M.; He, L.; Melnichenko, Y.B.; Rupp, J.A. Porosity of coal and shale: Insights from gas adsorption and SANS/USANS techniques. Energy Fuels 2012, 26, 5109–5120. [Google Scholar] [CrossRef]

- Gu, X.; Cole, D.R.; Rother, G.; Mildner, D.F.R.; Brantley, S.L. Pores in Marcellus shale: A neutron scattering and FIB-SEM study. Energy Fuels 2015, 29, 1295–1308. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, G. Technical aspects of the pore structure in shale measured by small-angle and ultrasmall-angle neutron scattering: A mini review. Energy Fuels 2021, 35, 1957–1965. [Google Scholar] [CrossRef]

- Jubb, A.M.; Ruppert, L.F.; Youngs, T.G.A.; Headen, T.F. Exploring methane behavior in Marcellus shale micropores via contrast matching neutron scattering. Energy Fuels 2020, 34, 10926–10932. [Google Scholar] [CrossRef]

- Ruppert, L.F.; Sakurovs, R.; Blach, T.P.; He, L.; Melnichenko, Y.B.; Mildner, D.F.R.; Alcantar-Lopez, L. A USANS/SANS study of the accessibility of pores in the barnett shale to methane and water. Energy Fuels 2013, 27, 772–779. [Google Scholar] [CrossRef]

- Radliński, A.P.; Boreham, C.J.; Lindner, P.; Randl, O.; Wignall, G.D.; Hinde, A.; Hope, J.M. Small angle neutron scattering signature of oil generation in artificially and naturally matured hydrocarbon source rocks. Org. Geochem. 2000, 31, 1–14. [Google Scholar] [CrossRef]

- Sun, M.; Yu, B.; Hu, Q.; Yang, R.; Zhang, Y.; Li, B.; Melnichenko, Y.B.; Cheng, G. Pore structure characterization of organic-rich niutitang shale from China: Small angle neutron scattering (SANS) study. Int. J. Coal Geol. 2018, 186, 115–125. [Google Scholar] [CrossRef]

- Zhan, H.; Li, X.; Hu, Z.; Duan, X.; Guo, W.; Li, Y. Influence of particle size on the low-temperature nitrogen adsorption of deep shale in southern Sichuan, China. Minerals 2022, 12, 302. [Google Scholar] [CrossRef]

- Hu, X.; Chen, S.; Zeng, Z.; Zhu, D.; Wu, M. Neutron scattering and spallation neutron source in China. J. Dongguan Univ. Technol. 2007, 14, 43–46. [Google Scholar]

- Zuo, T.; Ma, C.; Han, Z.; Li, Y.; Li, M.; Cheng, H. The basic principle of small angle neutron scattering and its application in macromolecules. Acta Polym. Sin. 2021, 52, 1192–1205. [Google Scholar]

- Yang, F.; Xie, C.; Ning, Z.; Krooss, B.M. High-pressure methane sorption on dry and moisture-equilibrated shales. Energy Fuels 2017, 31, 482–492. [Google Scholar] [CrossRef]

- Sun, M.; Yu, B.; Hu, Q.; Zhang, Y.; Li, B.; Yang, R.; Melnichenko, Y.B.; Cheng, G. Pore characteristics of Longmaxi shale gas reservoir in the Northwest of Guizhou, China: Investigations using small-angle neutron scattering (SANS), helium pycnometry, and gas sorption isotherm. Int. J. Coal Geol. 2017, 171, 61–68. [Google Scholar] [CrossRef]

- Tomchuk, O.V.; Avdeev, M.V.; Aleksenskii, A.E.; Vul, A.Y.; Ivankov, O.I.; Ryukhtin, V.V.; Füzi, J.; Garamus, V.M.; Bulavin, L.A. Sol–gel transition in nanodiamond aqueous dispersions by small-angle scattering. J. Phys. Chem. C 2019, 123, 18028–18036. [Google Scholar] [CrossRef]

- Radlinski, A.P.; Mastalerz, M. Neutron scattering study of vitrinite: Insights into sub-micrometer inclusions in North American Carboniferous coals of bituminous rank. Int. J. Coal Geol. 2018, 186, 145–154. [Google Scholar] [CrossRef]

- Bahadur, J.; Radlinski, A.P.; Melnichenko, Y.B.; Mastalerz, M.; Schimmelmann, A. Small-angle and ultrasmall-angle neutron scattering (SANS/USANS) study of New Albany Shale: A treatise on microporosity. Energy Fuels 2015, 29, 567–576. [Google Scholar] [CrossRef]

- Lee, S.; Fischer, T.B.; Stokes, M.R.; Klingler, R.J.; Ilavsky, J.; McCarty, D.K.; Wigand, M.O.; Derkowski, A.; Winans, R.E. Dehydration effect on the pore size, porosity, and fractal parameters of shale rocks: Ultrasmall-angle X-ray scattering study. Energy Fuels 2014, 28, 6772–6779. [Google Scholar] [CrossRef]

- Jin, L.; Mathur, R.; Rother, G.; Cole, D.; Bazilevskaya, E.; Williams, J.; Carone, A.; Brantley, S. Evolution of porosity and geochemistry in Marcellus formation black shale during weathering. Chem. Geol. 2013, 356, 50–63. [Google Scholar] [CrossRef]

- Sun, M.; Zhao, J.; Pan, Z.; Hu, Q.; Yu, B.; Tan, Y.; Sun, L.; Bai, L.; Wu, C.; Blach, T.P.; et al. Pore characterization of shales: A review of small angle scattering technique. J. Nat. Gas Sci. Eng. 2020, 78, 103294. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Thommes, M. Physical adsorption characterization of nanoporous materials. Chem. Ing. Tech. 2010, 82, 1059–1073. [Google Scholar] [CrossRef]

- Li, B.; Chen, F.; Xiao, D.; Lu, S.; Zhang, L.; Zhang, Y.; Gong, C. Effect of particle size on the experiment of low temperature nitrogen adsorption: A case study of marine gas shale in Wufeng-Longmaxi formation. J. China Univ. Min. Technol. 2019, 48, 395–404. [Google Scholar]

- Sun, M.; Zhang, L.; Hu, Q.; Pan, Z.; Yu, B.; Sun, L.; Bai, L.; Fu, H.; Zhang, Y.; Zhang, C.; et al. Multiscale connectivity characterization of marine shales in southern China by fluid intrusion, small-angle neutron scattering (SANS), and FIB-SEM. Mar. Pet. Geol. 2020, 112, 104101. [Google Scholar] [CrossRef]

- Wang, Y.; Qin, Y.; Zhang, R.; He, L.; Anovitz, L.; Bleue, M.; Mildner, D.; Liu, S.; Zhu, Y. Evaluation of nanoscale accessible pore structures for improved prediction of gas production potential in chinese marine shales. Energy Fuels 2018, 32, 12447–12461. [Google Scholar] [CrossRef]

| Sample | TOC | Quartz (%) | Calcite (%) | Dolomite (%) | Plagioclase (%) | Pyrite (%) | Illite (%) | Montmorillonite (%) | Chlorite (%) | SLD (1010·cm−2) |

|---|---|---|---|---|---|---|---|---|---|---|

| L1 | 2.81 | 61.34 | 2.52 | 3.69 | 6.34 | 4.11 | 16.04 | 2.82 | 3.14 | 4.11 |

| L2 | 3.99 | 45.30 | 5.60 | 6.80 | 4.80 | 6.90 | 23.10 | 4.13 | 3.37 | 4.12 |

| L3 | 3.07 | 56.98 | 7.57 | 12.10 | 2.52 | 3.02 | 14.72 | 2.50 | 0.59 | 4.26 |

| L4 | 3.78 | 57.86 | 8.96 | 18.41 | 3.11 | 3.97 | 5.85 | 1.00 | 0.83 | 4.37 |

| L5 | 1.92 | 55.84 | 9.91 | 20.86 | 4.19 | 2.60 | 4.69 | 0.87 | 1.05 | 4.43 |

| L6 | 3.32 | 43.81 | 8.87 | 20.46 | 2.73 | 2.57 | 17.65 | 2.09 | 1.82 | 4.36 |

| L7 | 3.67 | 36.12 | 1.41 | 9.41 | 11.21 | 10.85 | 24.70 | 3.50 | 2.80 | 4.10 |

| L8 | 2.47 | 45.10 | 6.93 | 5.24 | 1.95 | 0.68 | 29.57 | 4.83 | 5.71 | 4.11 |

| Sample | Mass Fractal Dimension | R2 | Porod Porosity (%) | Qmin (Å−1) | Qmax (Å−1) |

|---|---|---|---|---|---|

| L1 | 2.831 | 0.9988 | 5.81 | 0.00515 | 0.254 |

| L2 | 2.597 | 0.9977 | 5.69 | 0.00515 | 0.214 |

| L3 | 2.991 | 0.9981 | 4.82 | 0.00515 | 0.191 |

| L4 | 2.715 | 0.9982 | 4.83 | 0.00515 | 0.287 |

| L5 | 2.989 | 0.9977 | 4.25 | 0.00515 | 0.255 |

| L6 | 2.747 | 0.9976 | 4.25 | 0.00515 | 0.287 |

| L7 | 2.499 | 0.9968 | 5.70 | 0.00515 | 0.191 |

| L8 | 2.794 | 0.9985 | 4.39 | 0.00515 | 0.287 |

| Sample | Fractal Fitting Equation | R2 | Surface Fractal Dimension | N2 Porosity (%) | Median Pore size (nm) | Specific Surface Area (m2/g) |

|---|---|---|---|---|---|---|

| L1 | Y = −0.1822X + 1.9676 | 0.945 | 2.828 | 4.21 | 6.38 | 22.57 |

| L2 | Y = −0.1700X + 2.0869 | 0.927 | 2.830 | 4.09 | 5.51 | 25.45 |

| L3 | Y = −0.1787X + 1.7620 | 0.955 | 2.821 | 3.50 | 7.52 | 18.33 |

| L4 | Y = −0.1761X + 1.8918 | 0.962 | 2.824 | 3.85 | 6.34 | 19.63 |

| L5 | Y = −0.1819X + 1.7262 | 0.965 | 2.818 | 3.70 | 7.55 | 17.76 |

| L6 | Y = −0.1750X + 1.9730 | 0.907 | 2.825 | 3.98 | 6.21 | 22.76 |

| L7 | Y = −0.1818X + 1.9674 | 0.926 | 2.828 | 4.85 | 5.41 | 24.40 |

| L8 | Y = −0.1821X + 1.7481 | 0.922 | 2.818 | 3.68 | 6.39 | 18.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, H.; Li, X.; Hu, Z.; Duan, X.; Wu, W.; Guo, W.; Lin, W. Fractal Characteristics of Deep Shales in Southern China by Small-Angle Neutron Scattering and Low-Pressure Nitrogen Adsorption. Fractal Fract. 2022, 6, 484. https://doi.org/10.3390/fractalfract6090484

Zhan H, Li X, Hu Z, Duan X, Wu W, Guo W, Lin W. Fractal Characteristics of Deep Shales in Southern China by Small-Angle Neutron Scattering and Low-Pressure Nitrogen Adsorption. Fractal and Fractional. 2022; 6(9):484. https://doi.org/10.3390/fractalfract6090484

Chicago/Turabian StyleZhan, Hongming, Xizhe Li, Zhiming Hu, Xianggang Duan, Wei Wu, Wei Guo, and Wei Lin. 2022. "Fractal Characteristics of Deep Shales in Southern China by Small-Angle Neutron Scattering and Low-Pressure Nitrogen Adsorption" Fractal and Fractional 6, no. 9: 484. https://doi.org/10.3390/fractalfract6090484

APA StyleZhan, H., Li, X., Hu, Z., Duan, X., Wu, W., Guo, W., & Lin, W. (2022). Fractal Characteristics of Deep Shales in Southern China by Small-Angle Neutron Scattering and Low-Pressure Nitrogen Adsorption. Fractal and Fractional, 6(9), 484. https://doi.org/10.3390/fractalfract6090484