The Counterbalance of the Adverse Effect of Abrasion on the Properties of Concrete Incorporating Nano-SiO2 and Polypropylene Fiber Based on Pore Structure Fractal Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials, Casting, and Curing

2.2. Experiment Methods

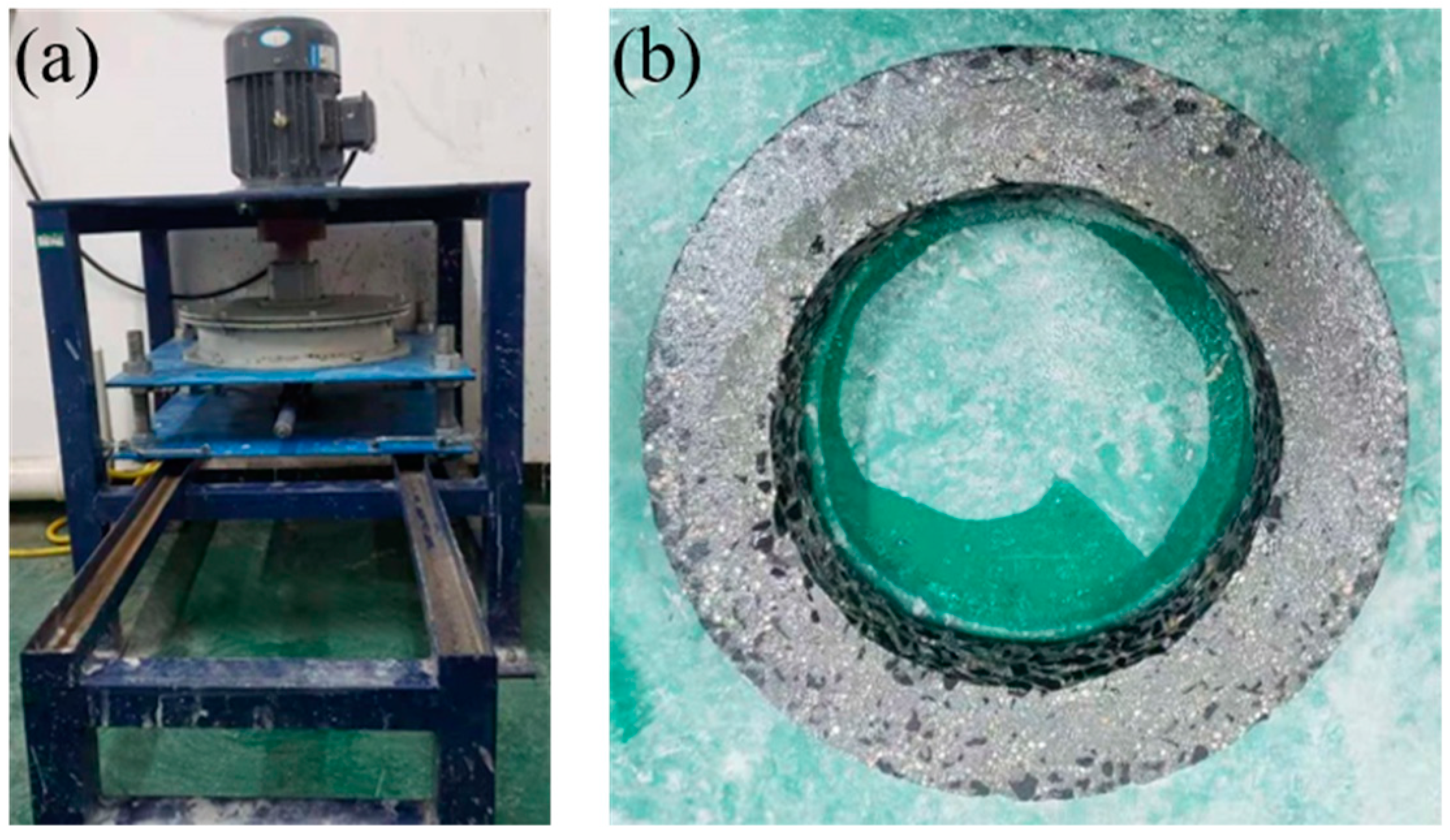

2.2.1. Abrasion Resistance Strength

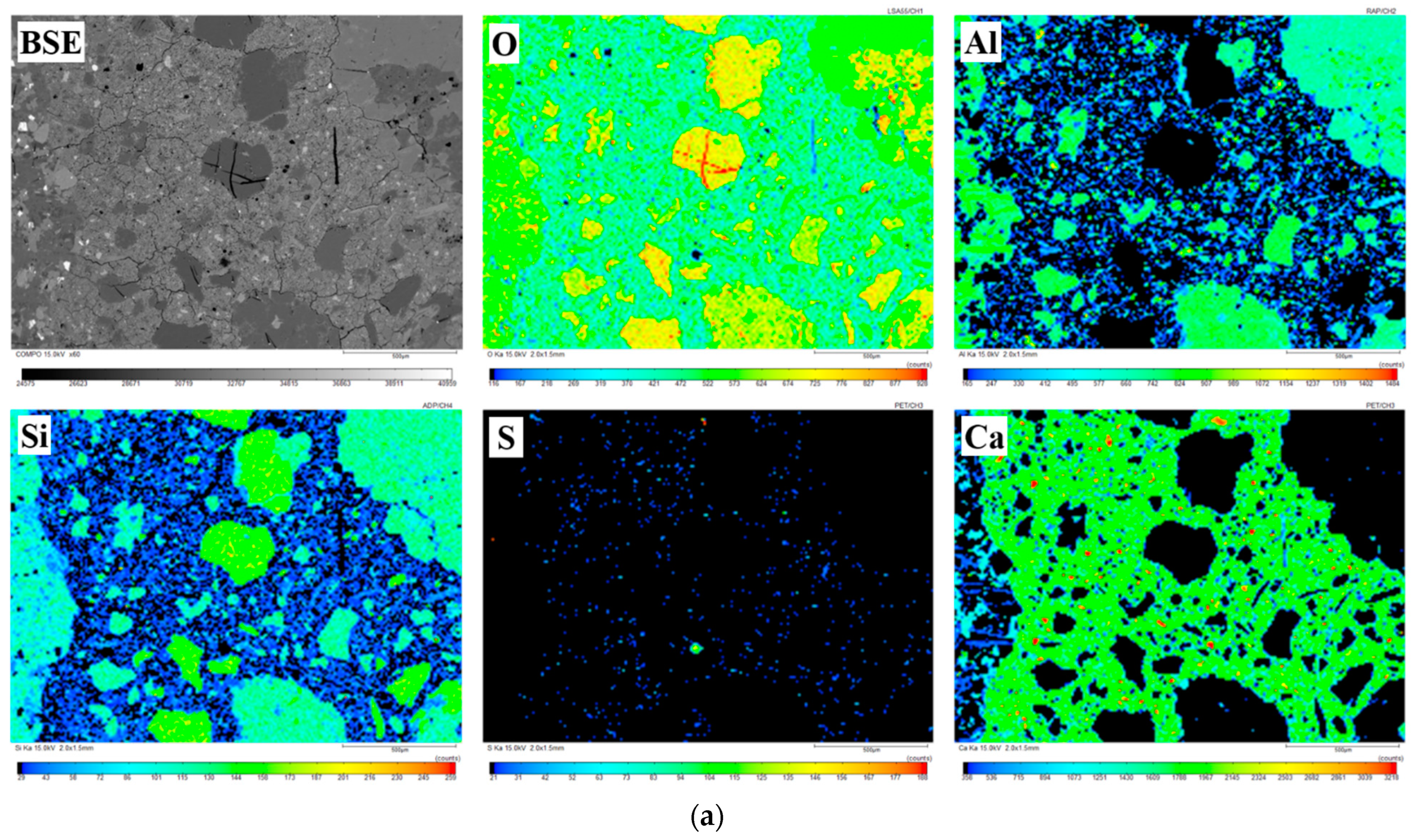

2.2.2. Microstructural Monitoring

2.2.3. Fractal Dimension

3. Results and Discussion

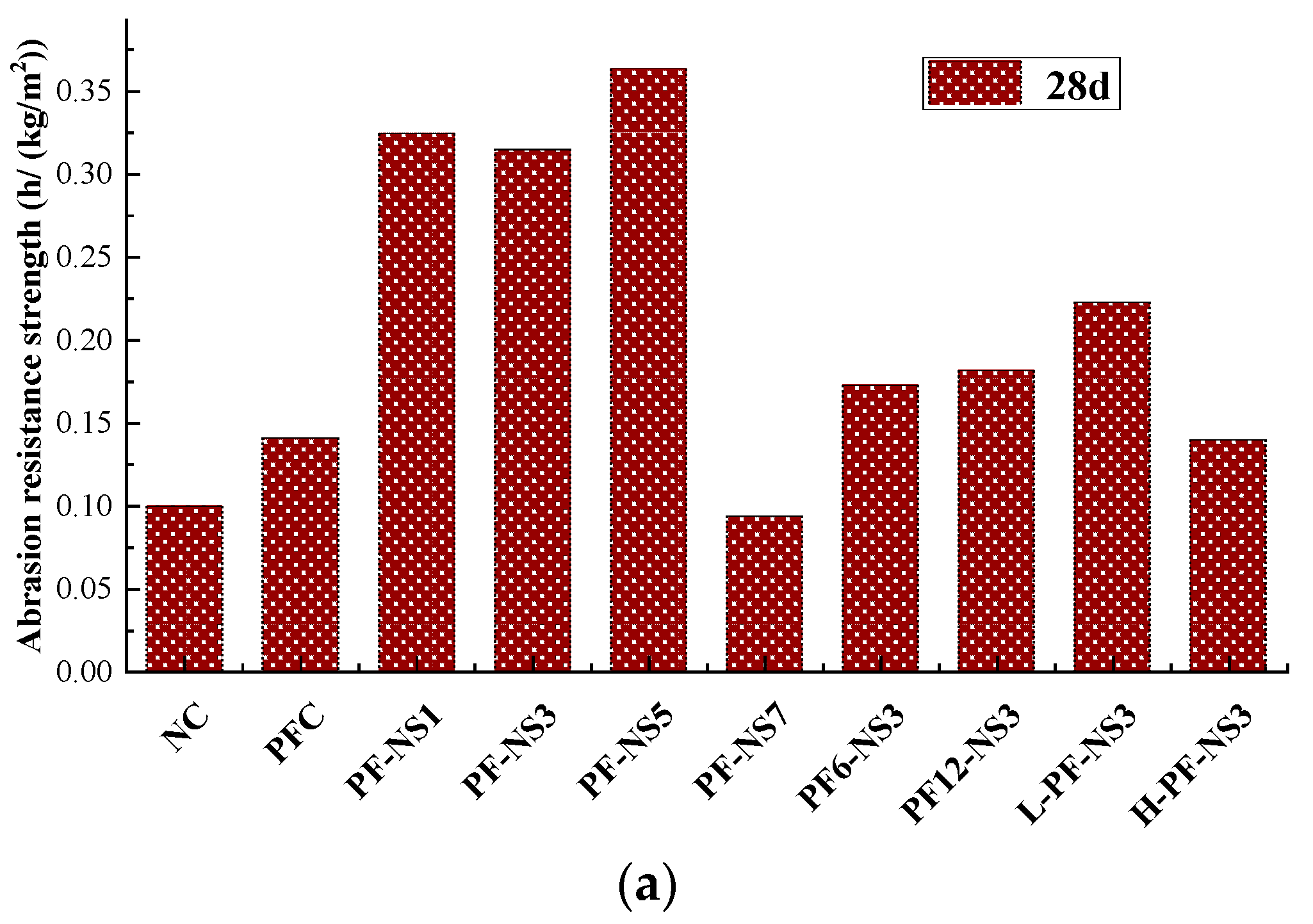

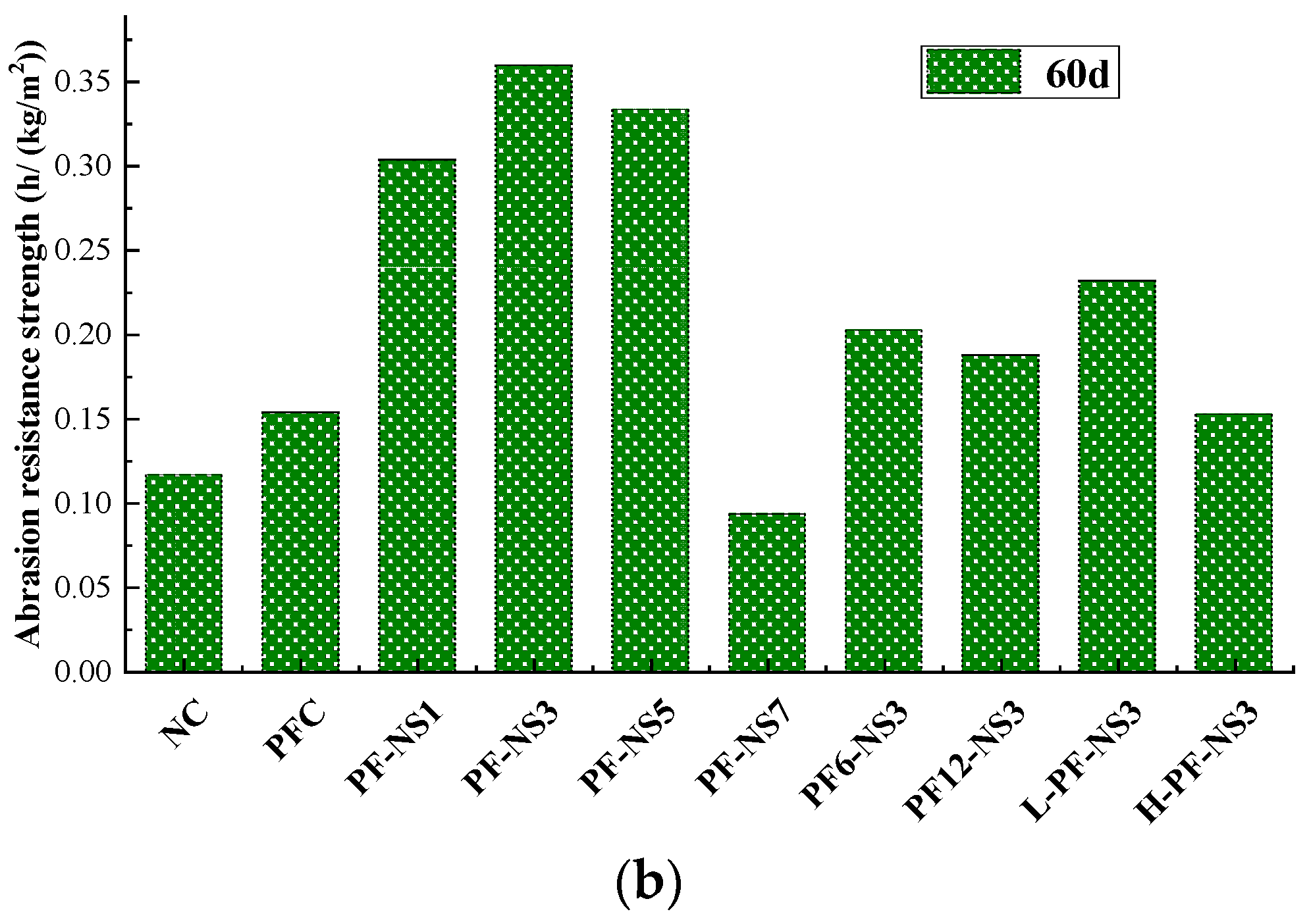

3.1. Abrasion Resistance Strength

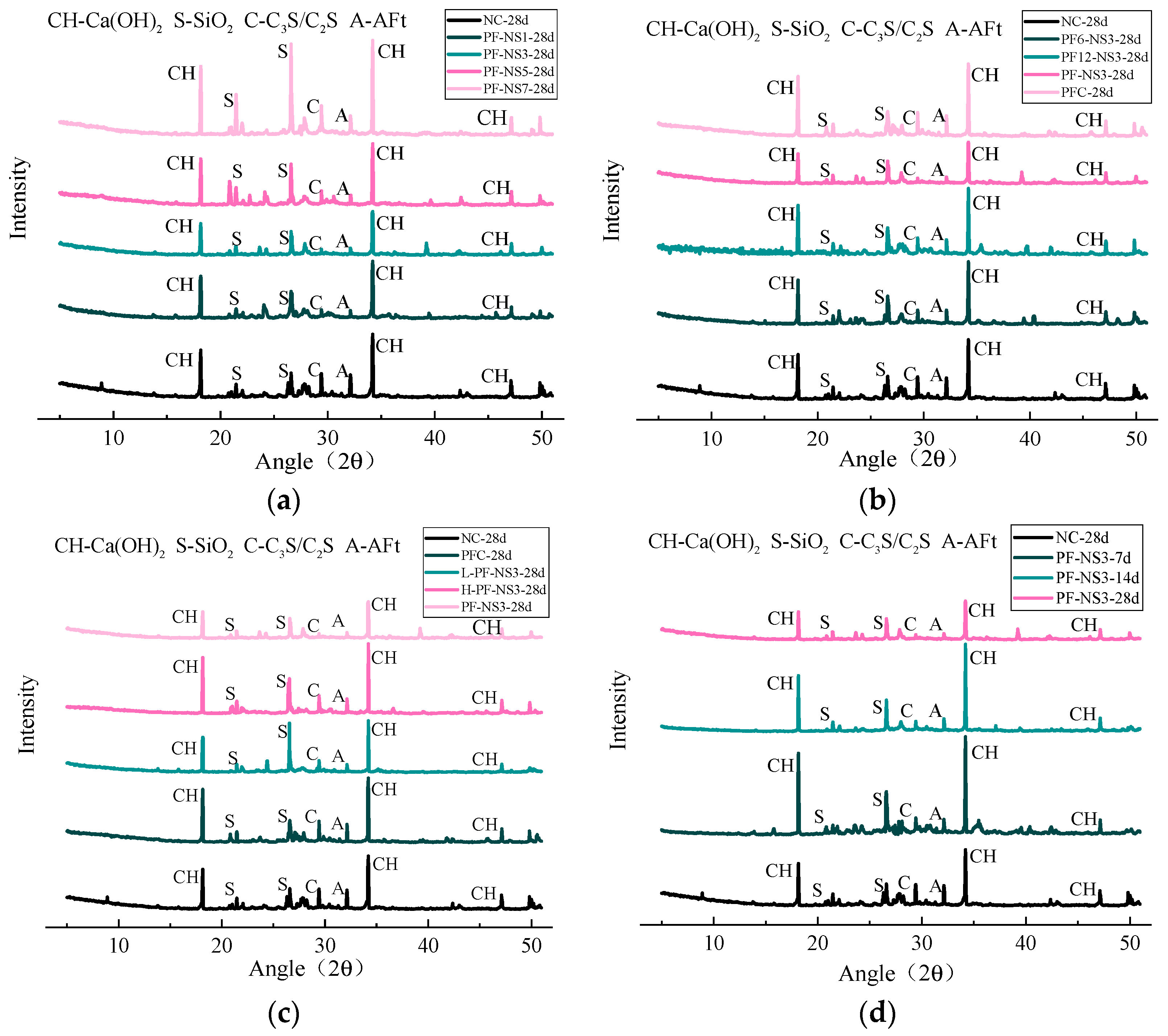

3.2. Mineral Phases by XRD

3.3. Pore Structure Fractal Characteristic by SEM and EPMA

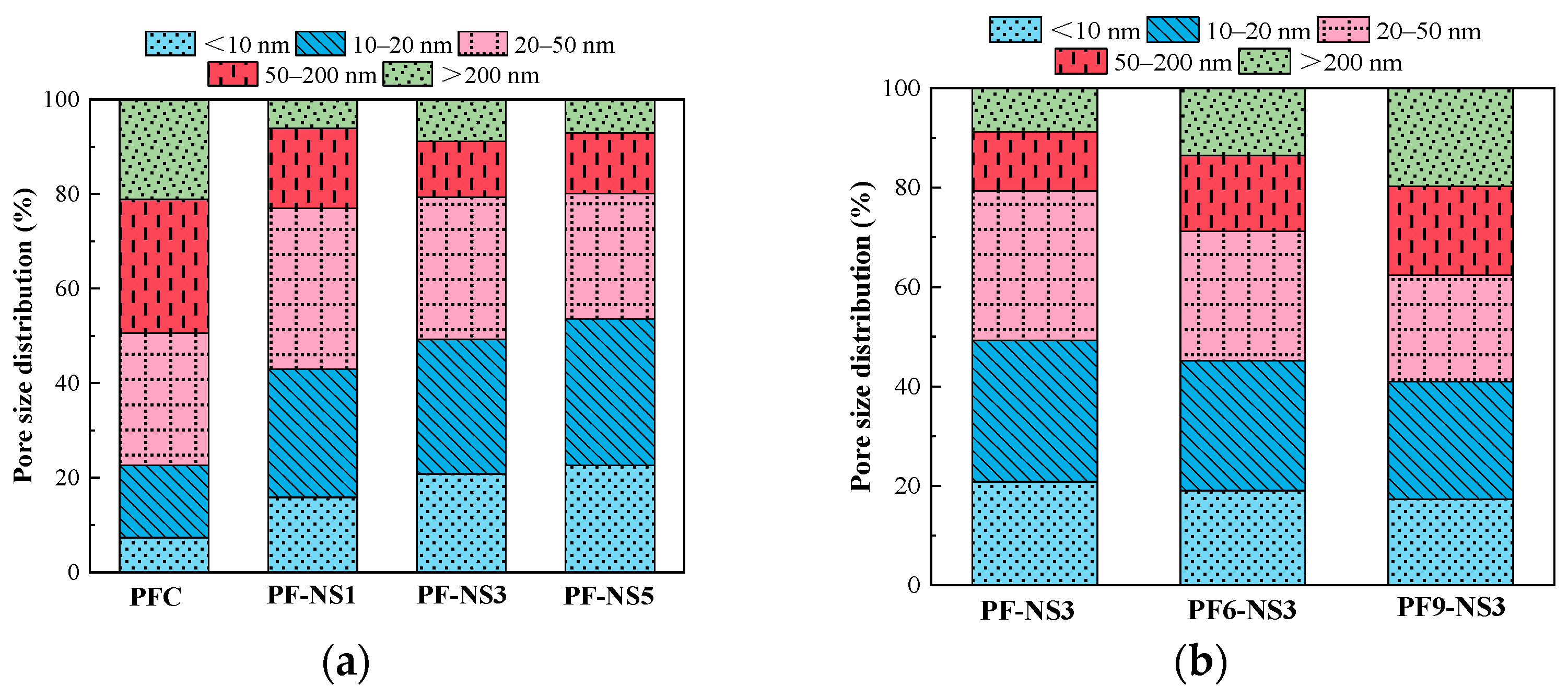

3.4. Pore Size Distribution by MIP

3.5. Fractal Analysis

4. Conclusions

- (1)

- When the dosage is between 1% and 5%, nano-SiO2 can compact the microstructure of concrete and promote the hydration of cement to generate more Ca(OH)2 and AFt crystals in the early stage of curing. Due to its small specific surface area and high chemical activity, nano-SiO2 can continue to play the role of control and refinement during the hydration process, reducing the proportion of macro-pores inside concrete and increasing the formation of C-S-H gel. When the dosage of nano-SiO2 is 3%, the internal structure of concrete is the optimum. However, excessive dosage will increase the content of harmful pores and inhibit the hydration process of cement.

- (2)

- When the content of polypropylene fibers is 0.9kg/m3, the fibers form a stable structure, overlapping each other inside the concrete, which promotes a smoother and flatter microstructure of the matrix. At the same time, under this dosage, the fibers can restrain the separation of the broken cement blocks during the process of abrasion damage, thereby improving the abrasion resistance of concrete. However, a too-high fiber dosage, such as 1.2 kg/m3, will produce a vulnerable pore structure due to the unfavorable dispersibility of fibers, resulting in an increase in pore volume and a decrease in concrete performance.

- (3)

- The internal pore structure of concrete with nano-SiO2 and polypropylene fiber shows obvious fractal characteristics. At the same time, the fractal dimension has a close positive correlation with the concrete abrasion resistance strength. The larger the fractal dimension, the higher the abrasion resistance strength and toughness of concrete.

- (4)

- In general, the incorporation of nano-SiO2 and polypropylene fibers in concrete improves the abrasion resistance of concrete. Nano-SiO2 can promote cement hydration, compact the microstructure of concrete, and enhance the bond between the cement matrix and the fibers so that the fibers can fully exert the restraint effect on the broken cement blocks. Moreover, the polypropylene fiber in the concrete will also play a role in controlling the cracks that are easily generated in the early stage after the incorporation of nano-SiO2. The results derived show that when the contents of nano-SiO2 and polypropylene fiber are 3% and 0.9 kg/m3, the effect of improving the abrasion resistance of concrete is the best. In practical engineering, it is recommended to use the mix proportion of the PF-NS3 specimen to improve guidance on the mixture design of concrete when exposure to abrasion is expected in the field.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, X.; Li, C.; Gao, Q.; Duan, X.; Liu, H. Comparison of Microstructure, Microhardness, Fracture Toughness, and Abrasive Wear of WC-17Co Coatings Formed in Various Spraying Ways. Coatings 2022, 12, 814. [Google Scholar] [CrossRef]

- Guo, J.-J.; Wang, K.; Qi, C.-G. Determining the Mineral Admixture and Fiber on Mechanics and Fracture Properties of Concrete under Sulfate Attack. J. Mar. Sci. Eng. 2021, 9, 251. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Li, M.; Gao, F.; Taheri, A.; Huo, B.; Jin, L. Expansion Properties of Cemented Foam Backfill Utilizing Coal Gangue and Fly Ash. Minerals 2022, 12, 763. [Google Scholar] [CrossRef]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and Durability Properties of Self Consolidating High Performance Concrete Incorporating Natural Zeolite, Silica Fume and Fly Ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- An, Q.; Ming, W.; Chen, M. Experimental Investigation on Cutting Characteristics in Nanometric Plunge-Cutting of BK7 and Fused Silica Glasses. Materials 2015, 8, 1428–1441. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, H.M.; Zhang, S.M.; Chen, P.; Shao, D.K.; Tang, S.W.; Li, J.Z. High-ferrite Portland cement with slag: Hydration, microstructure, and resistance to sulfate attack at elevated temperature. Cem. Concr. Compos. 2022, 130, 104560. [Google Scholar] [CrossRef]

- Warda, M.A.; Ahmad, S.S.E.; Mahdi, I.M.; Sallam, H.E.-D.M.; Khalil, H.S. The Applicability of TOPSIS- and Fuzzy TOPSIS-Based Taguchi Optimization Approaches in Obtaining Optimal Fiber-Reinforced Concrete Mix Proportions. Buildings 2022, 12, 796. [Google Scholar] [CrossRef]

- Suparp, S.; Ali, N.; Al Zand, A.W.; Chaiyasarn, K.; Rashid, M.U.; Yooprasertchai, E.; Hussain, Q.; Joyklad, P. Axial Load Enhancement of Lightweight Aggregate Concrete (LAC) Using Environmentally Sustainable Composites. Buildings 2022, 12, 851. [Google Scholar] [CrossRef]

- Sangirardi, M.; Altomare, V.; De Santis, S.; de Felice, G. Detecting Damage Evolution of Masonry Structures through Computer-Vision-Based Monitoring Methods. Buildings 2022, 12, 831. [Google Scholar] [CrossRef]

- Taengua, E.J.G.; Sonebi, M.; Hossain, K.; Lachemi, M.; Khatib, J.M. Effects of the addition of nanosilica on the rheology, hydrationand development of the compressive strength of cement mortars. Compos. Part B Eng. 2015, 81, 120–129. [Google Scholar] [CrossRef]

- Wang, K.; Guo, J.-J.; Yang, L. Effect of dry–wet ratio on sulfate transport-reaction mechanism in concrete. Constr. Build. Mater. 2021, 302, 124418. [Google Scholar] [CrossRef]

- Yue, J.; Sheng, J.; Wang, H.; Hu, Y.; Zhang, K.; Luo, Y.; Zhou, Q.; Zhan, M. Investigation on Pore Structure and Permeability of Concrete–Rock Interfacial Transition Zones Based on Fractal Theory. Fractal Fract. 2022, 6, 329. [Google Scholar] [CrossRef]

- Arena, M.; Viscardi, M.; Barra, G.; Vertuccio, L.; Guadagno, L. Multifunctional Performance of a Nano-Modified Fiber Reinforced Composite Aeronautical Panel. Materials 2019, 12, 869. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, X.-M.; Zhang, P.; Wang, T.-Y.; Zheng, Y.; Qiu, L.-H.; Sun, S.-W. Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network. Nanotechnol. Rev. 2022, 11, 1181–1192. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.-J.; Wang, T.-Y. Influencing factors analysis and optimized prediction model for rheology and flowability of nano-SiO2 and PVA fiber reinforced alkali-activated composites. J. Clean. Prod. 2022, 366, 132988. [Google Scholar] [CrossRef]

- Wang, W.; Liu, X.; Guo, L.; Duan, P. Evaluation of Properties and Microstructure of Cement Paste Blended with Metakaolin Subjected to High Temperatures. Materials 2019, 12, 941. [Google Scholar] [CrossRef] [Green Version]

- Han, Q.-Y.; Zhang, P.; Wu, J.-J.; Jing, Y.-T.; Zhang, D.; Zhang, T.-H. Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2. Nanotechnol. Rev. 2022, 11, 1478–1498. [Google Scholar] [CrossRef]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. China Building Industry Press: Beijing, China, 2011.

- DLT 5332-2005; Norm for Fracture Test of Hydraulic Concrete. Chinese Standard Institution Press: Beijing, China, 2006.

- Peng, Y.; Tang, S.; Huang, J.; Tang, C.; Wang, L.; Liu, Y. Fractal Analysis on Pore Structure and Modeling of Hydration of Magnesium Phosphate Cement Paste. Fractal Fract. 2022, 6, 337. [Google Scholar] [CrossRef]

- Ma, G.; Li, J.; Zhou, X.; Zhang, L.; Qiu, P.; Yu, Y. Application of Asymmetric Notched Semi-Circular Bending Specimen to Evaluate Mixed-Mode I-II Fracture Behaviors of Sandstone. Fractal Fract. 2022, 6, 336. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N. Self-Healing in Cementitious Materials—A Review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [Green Version]

- Vodinchar, G.; Feshchenko, L. Fractal Properties of the Magnetic Polarity Scale in the Stochastic Hereditary αω-Dynamo Model. Fractal Fract. 2022, 6, 328. [Google Scholar] [CrossRef]

- Babič, M.; Marinković, D.; Kovačič, M.; Šter, B.; Calì, M. A New Method of Quantifying the Complexity of Fractal Networks. Fractal Fract. 2022, 6, 282. [Google Scholar] [CrossRef]

| Binder | Oxide Composition (%) | Loss on Ignition (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Na2O | K2O | Cl− | ||

| Cement | 41.27 | 31.34 | 12.34 | 3.33 | 3.34 | 3.22 | 0.43 | 0.80 | - | 1.09 |

| Fly ash | 1.5 | 58 | 30 | 4.3 | 2.8 | 1.22 | - | 1.36 | - | 0.82 |

| Fiber Content (%) | Diameter (μm) | Length (mm) | Tensile Strength (MPa) | Elongation Ultimate (%) | Elasticity Modulus (MPa) | Melting Point (℃) | Specific Gravity (g/cm3) |

|---|---|---|---|---|---|---|---|

| 100 | 20 | 9 | 579 | 27.6 | 5274 | 161 | 1.36 |

| Code | Water | Cement | Sand | Aggregate | Fly Ash | Nano SiO2 | Polypropylene Fiber | Superplasticizer |

|---|---|---|---|---|---|---|---|---|

| NC | 165 | 330 | 674.1 | 1198.4 | 82.5 | 0 | 0 | 0.8% |

| PFC | 165 | 330 | 674.1 | 1198.4 | 82.5 | 0 | 0.9 | 0.85% |

| PF-NS1 | 165 | 325.875 | 674.1 | 1198.4 | 82.5 | 4.125 | 0.9 | 0.95% |

| PF-NS3 | 165 | 317.625 | 674.1 | 1198.4 | 82.5 | 12.375 | 0.9 | 1.25% |

| PF-NS5 | 165 | 309.375 | 674.1 | 1198.4 | 82.5 | 20.625 | 0.9 | 1.65% |

| PF-NS7 | 165 | 301.125 | 674.1 | 1198.4 | 82.5 | 28.875 | 0.9 | 1.9% |

| PF6-NS3 | 165 | 317.625 | 674.1 | 1198.4 | 82.5 | 12.375 | 0.6 | 1.25% |

| PF12-NS3 | 165 | 317.625 | 674.1 | 1198.4 | 82.5 | 12.375 | 1.2 | 1.25% |

| L-PF-NS3 | 150 | 317.625 | 674.1 | 1198.4 | 82.5 | 12.375 | 0.9 | 1.35% |

| H-PF-NS3 | 180 | 317.625 | 674.1 | 1198.4 | 82.5 | 12.375 | 0.9 | 1% |

| Code | Curing for 28 Days | Curing for 60 Days |

|---|---|---|

| NC | 0.1 | 0.117 |

| PFC | 0.141 | 0.154 |

| PF-NS1 | 0.325 | 0.304 |

| PF-NS3 | 0.315 | 0.36 |

| PF-NS5 | 0.364 | 0.334 |

| PF-NS7 | 0.094 | 0.094 |

| PF6-NS3 | 0.173 | 0.203 |

| PF12-NS3 | 0.182 | 0.188 |

| L-PF-NS3 | 0.223 | 0.232 |

| H-PF-NS3 | 0.14 | 0.153 |

| Code | Nano-SiO2 Content (%) | Polypropylene Fiber (kg/m3) | Ds | R2 |

|---|---|---|---|---|

| NC | 0 | 0 | 2.6 | 0.997 |

| PFC | 0 | 0.9 | 2.83 | 0.998 |

| PF-NS1 | 1 | 0.9 | 2.920 | 0.996 |

| PF-NS3 | 3 | 0.9 | 2.813 | 0.997 |

| PF-NS5 | 5 | 0.9 | 2.965 | 0.997 |

| PF-NS7 | 7 | 0.9 | 2.73 | 0.994 |

| PF6-NS3 | 3 | 0.6 | 2.88 | 0.998 |

| PF12-NS3 | 3 | 1.2 | 2.86 | 0.996 |

| L-PF-NS3 | 3 | 0.9 | 2.91 | 0.997 |

| H-PF-NS3 | 3 | 0.9 | 2.80 | 0.998 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Guo, J.; Zhang, P.; Meng, Q. The Counterbalance of the Adverse Effect of Abrasion on the Properties of Concrete Incorporating Nano-SiO2 and Polypropylene Fiber Based on Pore Structure Fractal Characteristics. Fractal Fract. 2022, 6, 392. https://doi.org/10.3390/fractalfract6070392

Wang K, Guo J, Zhang P, Meng Q. The Counterbalance of the Adverse Effect of Abrasion on the Properties of Concrete Incorporating Nano-SiO2 and Polypropylene Fiber Based on Pore Structure Fractal Characteristics. Fractal and Fractional. 2022; 6(7):392. https://doi.org/10.3390/fractalfract6070392

Chicago/Turabian StyleWang, Kun, Jinjun Guo, Peng Zhang, and Qingxin Meng. 2022. "The Counterbalance of the Adverse Effect of Abrasion on the Properties of Concrete Incorporating Nano-SiO2 and Polypropylene Fiber Based on Pore Structure Fractal Characteristics" Fractal and Fractional 6, no. 7: 392. https://doi.org/10.3390/fractalfract6070392

APA StyleWang, K., Guo, J., Zhang, P., & Meng, Q. (2022). The Counterbalance of the Adverse Effect of Abrasion on the Properties of Concrete Incorporating Nano-SiO2 and Polypropylene Fiber Based on Pore Structure Fractal Characteristics. Fractal and Fractional, 6(7), 392. https://doi.org/10.3390/fractalfract6070392