Continuum Damage Dynamic Model Combined with Transient Elastic Equation and Heat Conduction Equation to Solve RPV Stress

Abstract

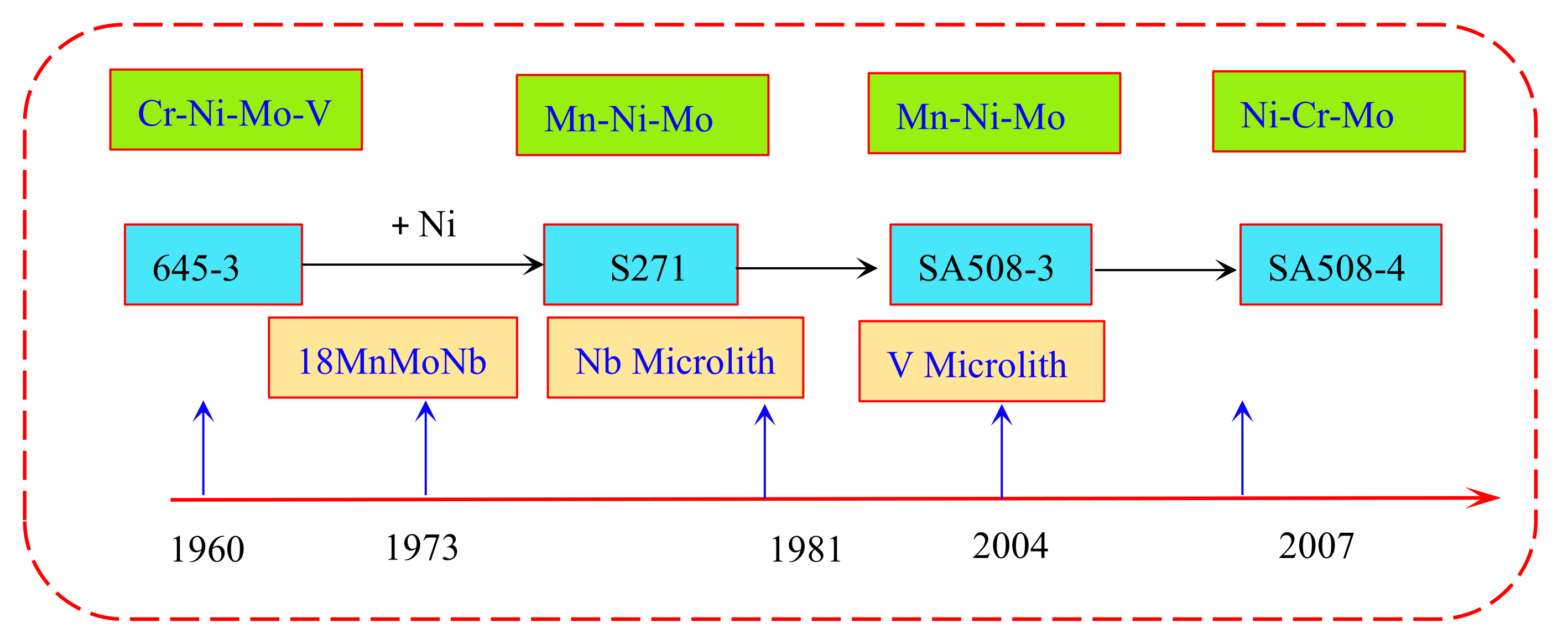

1. Introduction

1.1. Research Motivation and Significance

1.2. Related Work

1.3. Contributions

1.4. Structure and Framework of This Paper

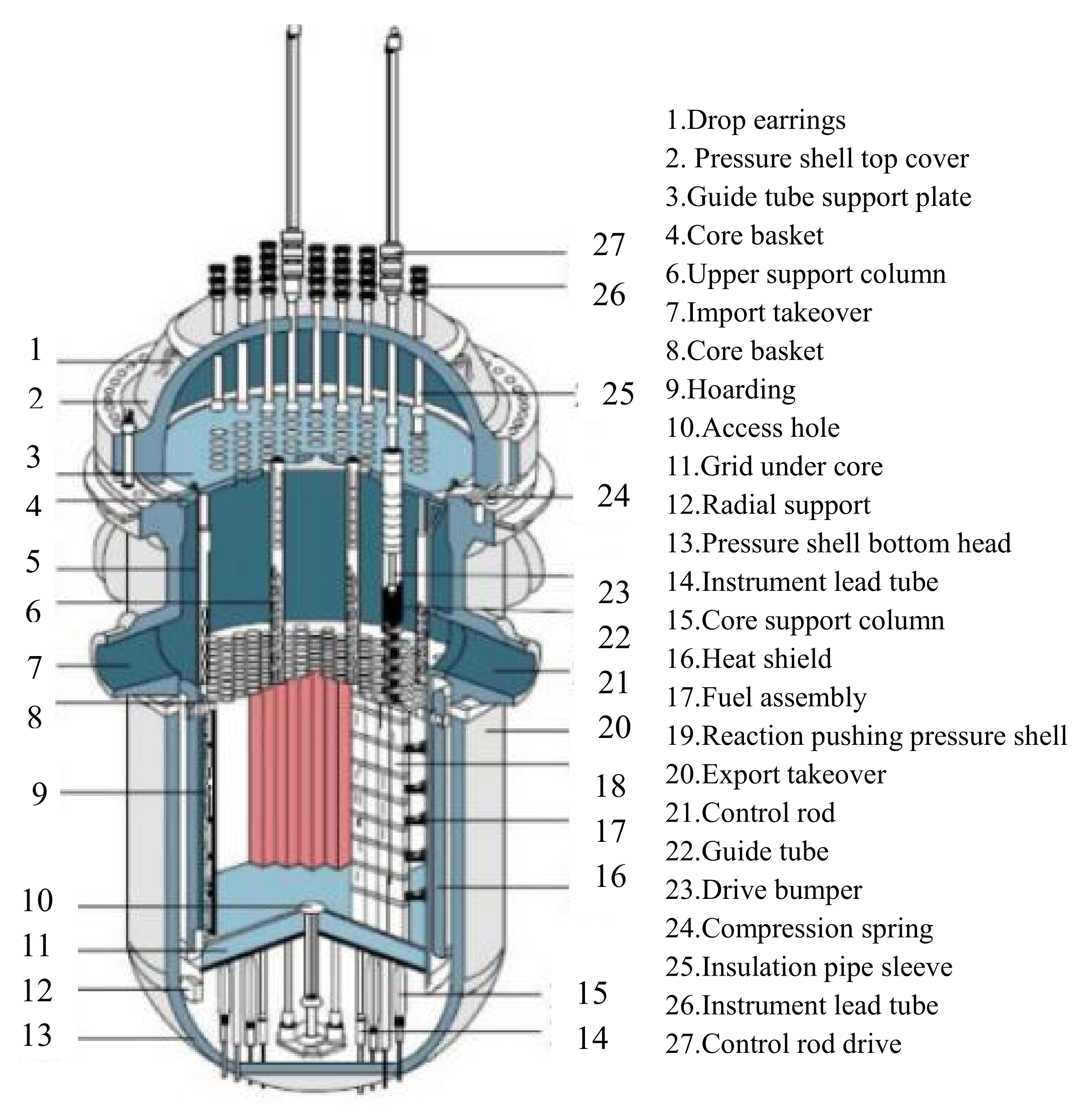

2. RPV Working Principle and Internal Structure of Nuclear Power

2.1. RPV Working Principle of Nuclear Power

- (a)

- Reactor—converting nuclear energy into water heat.

- (b)

- Steam generator—transferring the heat from the high-temperature and high-pressure water in the first loop to the water in the second loop, so that it becomes saturated steam.

- (c)

- Steam turbine—converting the heat energy of saturated steam into the mechanical energy of high-speed rotation of a steam turbine rotor.

- (d)

- Generator—converting mechanical energy from the steam turbine into electrical energy. To use power generation, they need to go through multiple complex processes. The working principle diagram of the pressurized water reactor nuclear power plant is shown in Figure 2.

2.2. RPV Classification and Internal Structure

2.3. Four Model Assumptions of RPV

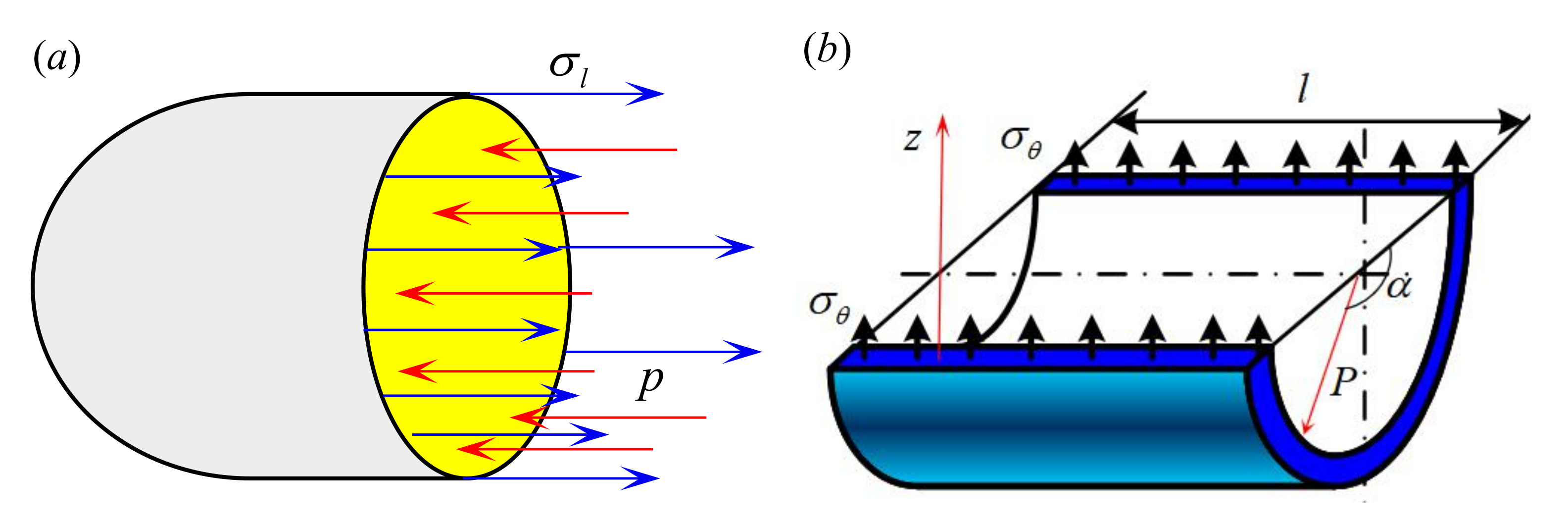

3. RPV Stress by the Simple Mechnical Balance

4. Continuum Damage Dynamics Model with Transient Cross-Section FEM

4.1. Continuum Damage Dynamics Model

4.2. Transient Cross-Section FEM Method

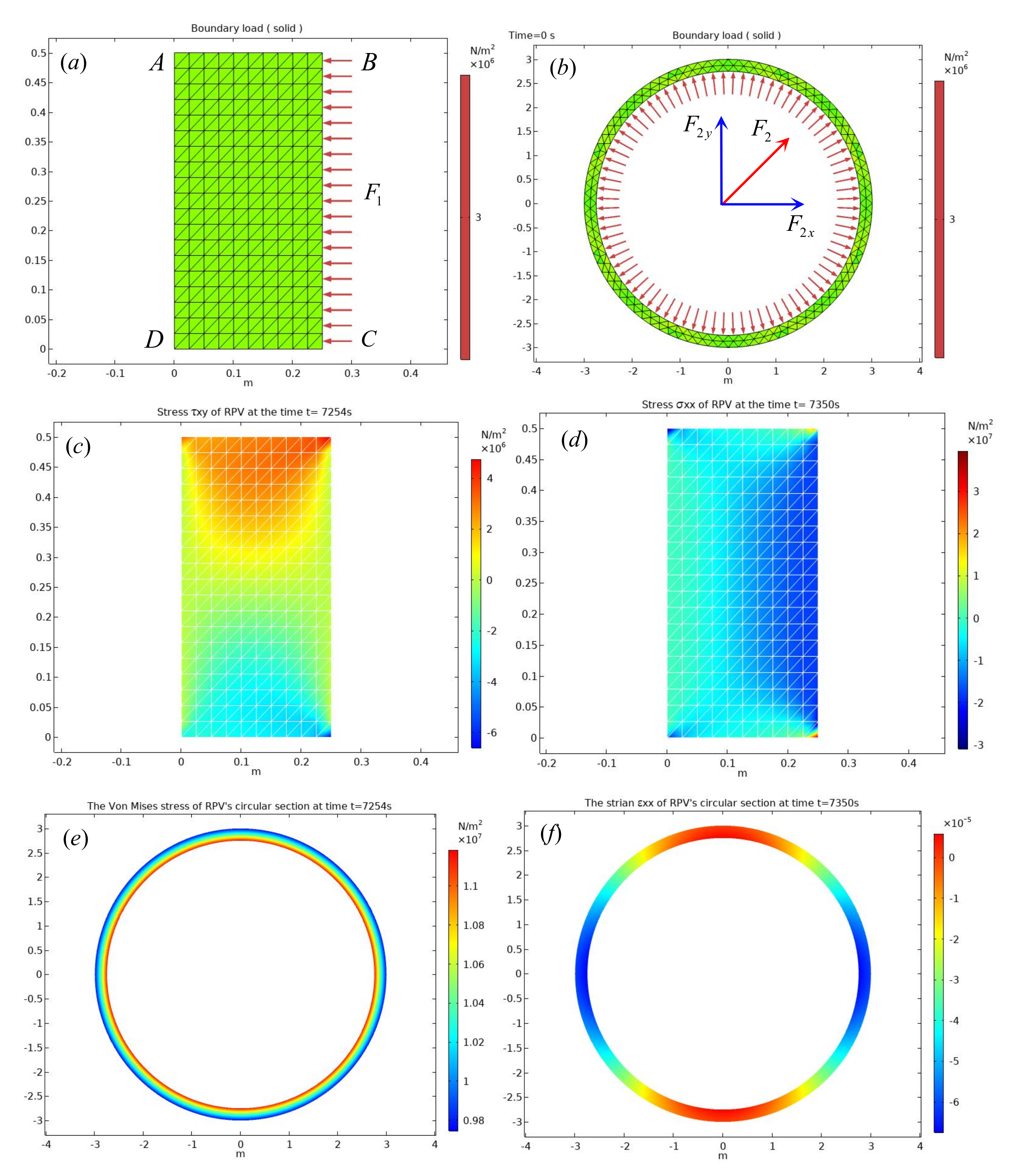

4.3. Numerical Simulation with CDDM-TCFEM Method

4.3.1. RPV Axial Section Solved by CDDM-TCFEM Method

- (1)

- The displacement boundary conditions.

- (2)

- The force boundary conditions.

4.3.2. Radial Section Solved by CDDM-TCFEM Method

- (1)

- The displacement boundary conditions.

- (2)

- The force boundary condition.

4.4. Numerical Example 1 Result Display

5. Axisymmetric FEM Method to Solve RPV Stress

5.1. The Theories Axisymmetric FEM Method of RPV

5.2. Axisymmetric Numerical Simulation Example

6. Three-Dimensional (3D) Multi-Physics Field Model of RPV

6.1. Three-Dimensional Transient Elastic Equation

6.2. Three-Dimensional Stress Analysis Model of RPV

6.3. Three-Dimensional Transient Heat Conduction Equation

- (1)

- Class I boundary conditions: The solid surface temperature is a known function of the time t.

- (2)

- Class II boundary conditions: The thermal flow density of the solid surface is equal to the change value of the temperature T in the direction of each component.

- (3)

- Class III boundary conditions: The difference between the heat flow density of the solid surface is proportional to the surface temperature T and the fluid surface temperature .is the direction cosine of the normal line outside the boundary, is a given temperature, is the heat flow density vector on the boundary , h is the thermal conductivity coefficient on the boundary, is the insulating temperature of the boundary layer under natural convection conditions, and the combination of all boundaries can be expressed as .

6.4. h-p Method Error Estimate

- (1)

- p-type adaptive error analysis

- (2)

- h-type adaptive error.

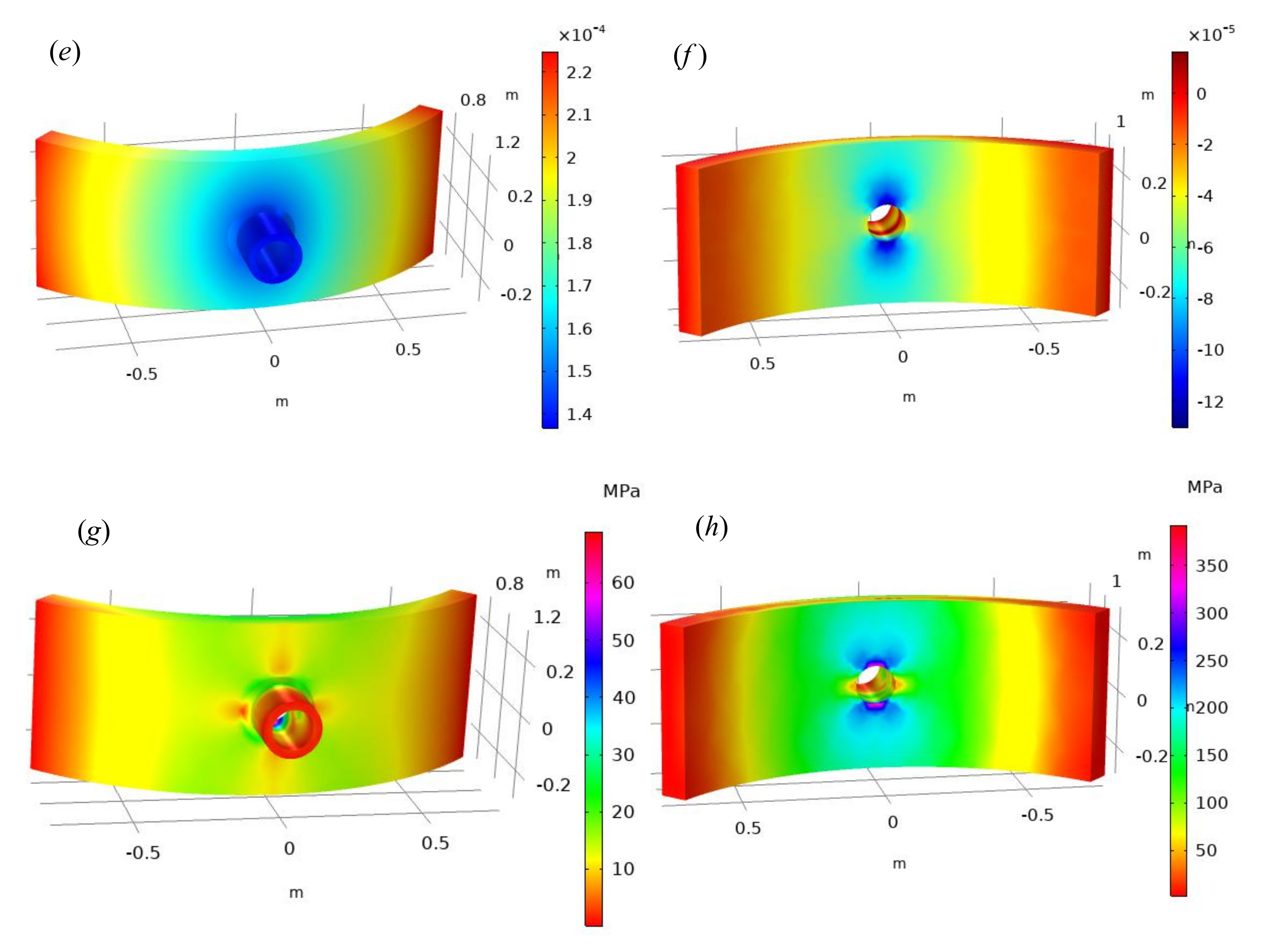

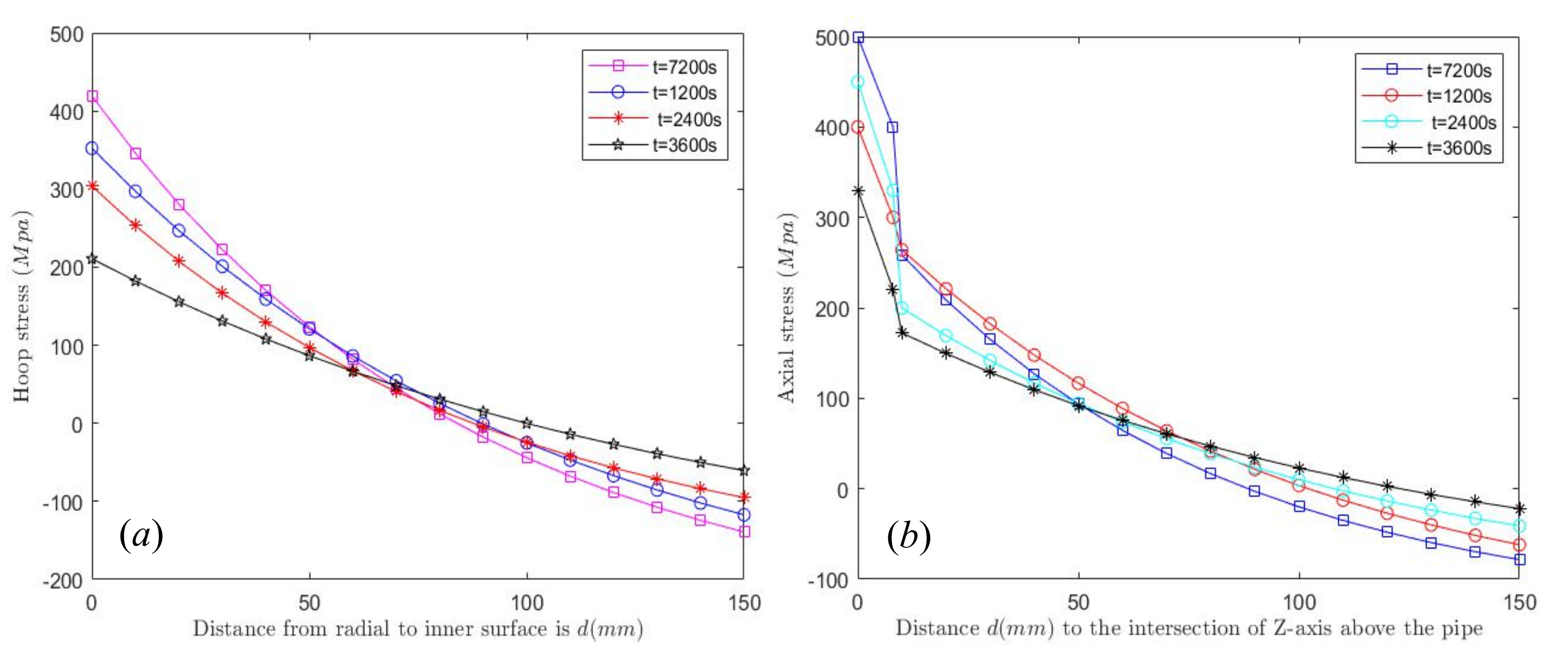

6.5. Numerical Result Display

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z. Hybridized Heuristic Heterogeneous Mathematical modeling for sustainable International comparison of the economic efficiency in nuclear energy. Sustain. Energy Technol. Assess. 2022, 50, 101578. [Google Scholar] [CrossRef]

- Niu, X.; Zhu, S.; He, J.; Ai, Y.; Shi, K.; Zhang, L. Fatigue reliability design and assessment of reactor pressure vessel structures: Concepts and validation. Int. J. Fatigue 2021, 153, 106524. [Google Scholar] [CrossRef]

- Solazzi, L.; Vaccari, M. Reliability design of a pressure vessel made of composite materials. Compos. Struct. 2022, 279, 114726. [Google Scholar] [CrossRef]

- Onizawa, K.; Nishikawa, H.; Itoh, H. Development of probabilistic fracture mechanics analysis codes for reactor pressure vessels and piping considering welding residual stress. Int. J. Press. Vessel. Pip. 2010, 87, 2–10. [Google Scholar] [CrossRef]

- Kanto, Y.; Onizawa, K.; Machida, H.; Isobe, Y.; Yoshimura, S. Recent Japanese research activities on probabilistic fracture mechanics for pressure vessel and piping of nuclear power plant. Int. J. Press. Vessel. Pip. 2010, 87, 11–16. [Google Scholar] [CrossRef]

- Chou, H.; Chang, C. Probabilistic fracture analysis for boiling water reactor vessels considering seismic loads during decommissioning transition period. Ann. Nucl. Energy 2022, 167, 108827. [Google Scholar] [CrossRef]

- Huang, C.; Chou, H.; Chen, B.; Liu, R.; Lin, H. Probabilistic fracture analysis for boiling water reactor pressure vessels subjected to low temperature over-pressure event. Ann. Nucl. Energy 2012, 43, 61–67. [Google Scholar] [CrossRef]

- Li, C.; Shu, G.; Liu, W.; Duan, Y. The unified model for irradiation embrittlement prediction of reactor pressure vessel. Ann. Nucl. Energy 2020, 139, 107246. [Google Scholar] [CrossRef]

- Bhattacharyya, M.; Fau, A.; Desmorat, R.; Alameddin, S.; Néron, D.; Ladevèze, P.; Nackenhorst, U. A kinetic two-scale damage model for high-cycle fatigue simulation using multi-temporal Latin framework. Eur. J. Mech. Solids 2019, 77, 103808. [Google Scholar] [CrossRef]

- Naumenko, K.; Gariboldi, E. Experimental analysis and constitutive modeling of anisotropic creep damage in a wrought age-hardenable Alalloy. Eng. Fract. Mech. 2022, 259, 108119. [Google Scholar] [CrossRef]

- Yvonnet, J.; He, Q.; Li, P. A data-driven harmonic approach to constructing anisotropic damage models with a minimum number of internal variables. J. Mech. Phys. Solids 2022, 162, 104828. [Google Scholar] [CrossRef]

- Murtaza, U.T.; Hyder, M.J. Optimization of the size and shape of the set-in nozzle for a PWR reactor pressure vessel. Nucl. Eng. Des. 2015, 284, 219–227. [Google Scholar] [CrossRef]

- Lu, B.T.; Song, F.; Gao, M.; Elboujdaini, M. Crack growth prediction for underground high pressure gas lines exposed to concentrated carbonate–bicarbonate solution with high pH. Eng. Fract. Mech. 2011, 78, 1452–1465. [Google Scholar] [CrossRef]

- Singh, R.; Singh, V.; Arora, A.; Mahajan, D.K. In-situ investigations of hydrogen influenced crack initiation and propagation under tensile and low cycle fatigue loadings in RPV steel. J. Nucl. Mater. 2020, 529, 151912. [Google Scholar] [CrossRef]

- Vukojević, N.; Gubeljak, N.; Terzic, M.; Hadžikadunić, F. Analysis of the impact of position in fatigue cracks on the fracture toughness of thick-walled pressure vessel material. Procedia Struct. Integr. 2016, 2, 2982–2988. [Google Scholar] [CrossRef][Green Version]

- Czapski, P. Influence of laminate code and curing process on the stability of square cross-section, composite columns—Experimental and FEM studies. Compos. Struct. 2020, 250, 112564. [Google Scholar] [CrossRef]

- Kundrák, J.; Karpuschewski, B.; Pálmai, Z.; Felhő, C.; Makkai, T.; Borysenko, D. The energetic characteristics of milling with changing cross-section in the definition of specific cutting force by FEM method. CIRP J. Manuf. Sci. Technol. 2021, 32, 61–69. [Google Scholar] [CrossRef]

- Dodig, H. A boundary integral method for numerical computation of radar cross section of 3D targets using hybrid BEM/FEM with edge elements. J. Comput. Phys. 2017, 348, 790–802. [Google Scholar] [CrossRef]

- Oh, C.; Lee, S.; Jhung, M.J. Analytical method to estimate cross-section stress profiles for reactor vessel nozzle corners under internal pressure. Nucl. Eng. Technol. 2022, 54, 401–413. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Z.; Fan, H.; Liu, P. Investigation on theoretical solution of geometric deformation of pressure vessel and pipe subjected to thermo-mechanical loadings. Int. J. Press. Vessel. Pip. 2021, 194, 104564. [Google Scholar] [CrossRef]

- Moskovka, A.; Valdman, J. Fast MATLAB evaluation of nonlinear energies using FEM in 2D and 3D: Nodal elements. Appl. Math. Comput. 2022, 424, 127048. [Google Scholar] [CrossRef]

- Hwang, J.; Kim, Y.; Kim, J. Energy-based damage model incorporating failure cycle and load ratio effects for very low cycle fatigue crack growth simulation. Int. J. Mech. Sci. 2022, 221, 107223. [Google Scholar] [CrossRef]

- González-Albuixech, V.F.; Qian, G.; Sharabi, M.; Niffenegger, M.; Niceno, B.; Lafferty, N. Coupled RELAP5, 3D CFD and FEM analysis of postulated cracks in RPVs subjected to PTS loading. Nucl. Eng. Des. 2016, 297, 111–122. [Google Scholar] [CrossRef]

- González-Albuixech, V.F.; Qian, G.; Sharabi, M.; Niffenegger, M.; Niceno, B.; Lafferty, N. Comparison of PTS analyses of RPVs based on 3D-CFD and RELAP5. Nucl. Eng. Des. 2015, 291, 168–178. [Google Scholar] [CrossRef]

- Chouhan, R.; Kansal, A.K.; Maheshwari, N.K.; Sharma, A. Computational studies on pressurized thermal shock in reactor pressure vessel. Ann. Nucl. Energy 2021, 152, 107987. [Google Scholar] [CrossRef]

- Chen, M.; Yu, W.; Qian, G.; Shi, J.; Cao, Y.; Yu, Y. Crack initiation, arrest and tearing assessments of a RPV subjected to PTS events. Ann. Nucl. Energy 2018, 116, 143–151. [Google Scholar] [CrossRef]

- Huang, P.; Chou, H.; Ferng, Y.; Kang, C. Large thermal gradients on structural integrity of a reactor pressure vessel subjected to pressurized thermal shocks. Int. J. Press. Vessel. Pip. 2020, 179, 103942. [Google Scholar] [CrossRef]

- Sun, X.; Lu, W.; Chai, G.; Bao, Y. Effect of cladding thickness on brittle fracture prevention of the base wall of reactor pressure vessel. Thin-Walled Struct. 2021, 158, 107163. [Google Scholar] [CrossRef]

- Christian, R.; Lee, Y.; Kang, H.G. Emergency core cooling system performance criteria for Multi-Layered Silicon Carbide nuclear fuel cladding. Nucl. Eng. Des. 2019, 353, 110280. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, L.; Qu, J.; Tong, J.; Wu, G. Rapid accident source term estimation (RASTE) for nuclear emergency response in high temperature gas cooled reactor. Ann. Nucl. Energy 2020, 147, 107654. [Google Scholar] [CrossRef]

- Oliver, S.; Simpson, C.; Collins, D.M.; Reinhard, C.; Pavier, M.; Mostafavi, M. In-situ measurements of stress during thermal shock in clad pressure vessel steel using synchrotron X-ray diffraction. Int. J. Mech. Sci. 2021, 192, 106136. [Google Scholar] [CrossRef]

- Zhao, P.; Ji, K.; Zhang, J.; Chen, Y.; Dong, Z.; Zheng, J.; Fu, J. In-situ ultrasonic measurement of molten polymers during injection molding. J. Mater. Process. Technol. 2021, 293, 117081. [Google Scholar] [CrossRef]

- Tasavori, M.; Maleki, A.T.; Ahmadi, I. Composite coating effect on stress intensity factors of aluminum pressure vessels with inner circumferential crack by X-FEM. Int. J. Press. Vessel. Pip. 2021, 194, 104445. [Google Scholar] [CrossRef]

- Zhang, K.; Sanchez-Espinoza, V.H. The Dynamic-Implicit-Additional-Source (DIAS) method for multi-scale coupling of thermal-hydraulic codes to enhance the prediction of mass and heat transfer in the nuclear reactor pressure VESSEL. Int. J. Heat Mass Transf. 2020, 147, 118987. [Google Scholar] [CrossRef]

- Huo, Y.; Yu, H.; Wang, M.; Tian, W.; Qiu, S.; Su, G.H. Development and application of TaSNAM 2.0 for advanced pressurized water reactor. Ann. Nucl. Energy 2022, 166, 108801. [Google Scholar] [CrossRef]

- Mackerle, J. Finite elements in the analysis of pressure vessels and piping—A bibliography (1976–1996). Int. J. Press. Vessel. Pip. 1996, 69, 279–339. [Google Scholar] [CrossRef]

- Mohanavel, V.; Prasath, S.; Arunkumar, M.; Pradeep, G.M.; Babu, S.S. Modeling and stress analysis of aluminium alloy based composite pressure vessel through ANSYS software. Mater. Today Proc. 2021, 37, 1911–1916. [Google Scholar] [CrossRef]

- You, Q.; Mo, N.; Liu, X.; Luo, H.; Shi, Z. Experiments on helium breakdown at high pressure and temperature in uniform field and its simulation using COMSOL Multiphysics and FD-FCT. Ann. Nucl. Energy 2020, 141, 107351. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, H. A continuum fatigue damage model for the cyclic thermal shocked ceramic-matrix composites. Int. J. Fatigue 2020, 134, 105507. [Google Scholar] [CrossRef]

- Damhof, F.; Brekelmans, W.A.M.; Geers, M.G.D. Non-local modeling of thermal shock damage in refractory materials. Eng. Fract. Mech. 2008, 75, 4706–4720. [Google Scholar] [CrossRef]

- Zhu, C.; Li, Y.; Tan, H.; Shi, J.; Nie, Y.; Qiu, Q. Multi-field coupled effect of thermal disturbance on quench and recovery characteristic along the hybrid energy pipe. Energy 2022, 246, 123362. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.L.; Maji, A.K. Mechanics of Solid Materials. J. Eng. Mech. 1992, 119, 642–643. [Google Scholar] [CrossRef]

- Almasi, A.; Baghani, M.; Moallemi, A. Thermomechanical analysis of hyperelastic thick-walled cylindrical pressure vessels, analytical solutions and FEM. Int. J. Mech. Sci. 2017, 130, 426–436. [Google Scholar] [CrossRef]

- Yang, Z.; Lui, H. A continuum damage mechanics model for 2-D woven oxide/oxide ceramic matrix composites under cyclic thermal shocks. Ceram. Int. 2020, 46, 6029–6037. [Google Scholar] [CrossRef]

- Yang, Y.; Schiavone, P.; Li, X. Effect of surface elasticity on transient elastic field around a mode-III crack-tip under impact loads. Eng. Fract. Mech. 2021, 258, 108062. [Google Scholar] [CrossRef]

- Chen, W.; Dai, S.; Zheng, B. ARIMA-FEM Method with Prediction Function to Solve the Stress-Strain of Perforated Elastic Metal Plates. Metals 2022, 12, 179. [Google Scholar] [CrossRef]

- Demirbas, M.D. Thermal stress analysis of functionally graded plates with temperature-dependent material properties using theory of elasticity. Engineering 2017, 131, 100–124. [Google Scholar] [CrossRef]

- Li, C.; Guo, H.; Tian, X.; He, T. Time-domain finite element method to generalized diffusion-elasticity problems with the concentration-dependent elastic constants and the diffusivity. Appl. Math. Model. 2020, 87, 55–76. [Google Scholar] [CrossRef]

- Si, H.M.; Cho, C.; Kwahk, S.Y. A hybrid method for casting process simulation by combining FDM and FEM with an efficient data conversion algorithm. J. Mater. Process. Technol. 2003, 133, 311–321. [Google Scholar] [CrossRef]

- Zhang, H.; Tong, L.; Addo, M.A.; Liang, J.; Wang, L. Research on contact algorithm of unbonded flexible riser under axisymmetric load. Int. J. Press. Vessel. Pip. 2020, 188, 104248. [Google Scholar] [CrossRef]

- Que, Z.; Seifert, H.P.; Spätig, P.; Zhang, A.; Holzer, J.; Rao, G.S.; Ritter, S. Effect of dynamic strain ageing on environmental degradation of fracture resistance of low-alloy RPV steels in high-temperature water environments. Corros. Sci. 2019, 152, 172–189. [Google Scholar] [CrossRef]

- Li, Y.; Jin, T.; Wang, Z.; Wang, D. Engineering critical assessment of RPV with nozzle corner cracks under pressurized thermal shocks. Nucl. Eng. Technol. 2020, 52, 2638–2651. [Google Scholar] [CrossRef]

- Sun, X.; Chai, G.; Bao, Y. Ultimate bearing capacity analysis of a reactor pressure vessel subjected to pressurized thermal shock with XFEM. Eng. Fail. Anal. 2017, 80, 102–111. [Google Scholar] [CrossRef]

- Bao, W.; Garcke, H.; Nürnberg, R.; Zhao, Q. Volume-preserving parametric finite element methods for axisymmetric geometric evolution equations. J. Comput. Phys. 2022, 460, 111180. [Google Scholar] [CrossRef]

- Li, Q.; Hou, P.; Shang, S. Accurate 3D thermal stress analysis of thermal barrier coatings. Int. J. Mech. Sci. 2022, 217, 107024. [Google Scholar] [CrossRef]

- Upadhyay, K.; Subhash, G.; Spearot, D. Hyperelastic constitutive modeling of hydrogels based on primary deformation modes and validation under 3D stress states. Int. J. Eng. Sci. 2020, 154, 103314. [Google Scholar] [CrossRef]

- Zhou, F.; You, Y.; Li, G.; Xie, G.; Li, G. The precise integration method for semi-discretized equation in the dual reciprocity method to solve three-dimensional transient heat conduction problems. Eng. Anal. Bound. Elem. 2018, 95, 160–166. [Google Scholar] [CrossRef]

- Wu, Q.; Peng, M.J.; Fu, Y.D.; Cheng, Y.M. The dimension splitting interpolating element-free Galerkin method for solving three-dimensional transient heat conduction problems. Eng. Anal. Bound. Elem. 2021, 128, 326–341. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Huang, W. Influence of the thermal insulation layer on radial stress and collapse resistance of subsea wet insulation pipe. Ocean Eng. 2021, 235, 109374. [Google Scholar] [CrossRef]

- Chen, W.; Dai, S.; Zheng, B.; Lin, H. An Efficient Evaluation Method for Automobile Shells Design Based on Semi-supervised Machine Learning Strategy. J. Phys. Conf. Ser. ICCBD2021 2022, 2171, 012026. [Google Scholar] [CrossRef]

- Duru, K.L.; Rannabauer, L.; Gabriel, A.; Ling, O.K.A.; Igel, H.; Bader, M. A stable discontinuous Galerkin method for linear elastodynamics in 3D geometrically complex elastic solids using physics based numerical fluxes. Comput. Methods Appl. Mech. Eng. 2022, 389, 114386. [Google Scholar] [CrossRef]

- Yalameha, S.; Nourbakhsh, Z.; Vashaee, D. ElATools: A tool for analyzing anisotropic elastic properties of the 2D and 3D materials. Comput. Phys. Commun. 2022, 271, 108195. [Google Scholar] [CrossRef]

- Xu, F.; Liu, Q.; Shibahara, M. Transient and steady-state heat transfer for forced convection of helium gas in minichannels with various inner diameters. Int. J. Heat Mass Transf. 2022, 191, 122813. [Google Scholar] [CrossRef]

- Solin, P.; Dubcova, L.; Kruis, J. Adaptive hp-FEM with dynamical meshes for transient heat and moisture transfer problems. J. Comput. Appl. Math. 2010, 12, 3103–3112. [Google Scholar] [CrossRef][Green Version]

- Erath, C.; Gantner, G.; Praetorius, D. Optimal convergence behavior of adaptive FEM driven by simple-type error estimators. Comput. Math. Appl. 2020, 79, 623–642. [Google Scholar] [CrossRef]

- Bériot, H.; Gabard, G. Anisotropic adaptivity of the p-FEM for time-harmonic acoustic wave propagation. J. Comput. Phys. 2019, 378, 234–256. [Google Scholar] [CrossRef]

- Giani, S.; Solin, P. Solving elliptic eigenproblems with adaptive multimesh hp-FEM. J. Comput. Appl. Math. 2021, 394, 113528. [Google Scholar] [CrossRef]

| Pressure Classification | Pressure Range | Temperature Classification | Temperature Range |

|---|---|---|---|

| Low-pressure vessel (L) | Cryogenic container | C | |

| Medium-pressure vessel (M) | Normal-temperature vessel | −20 C 150 C | |

| High-pressure vessel (H) | Medium-temperature vessel | 150 C 450 C | |

| Super-high-pressure vessels (U) | High-temperature vessels | 450 C |

| Temperature T (C) | Specific Heat Capacity C (J/kg/C) | Heat Conduction K (J/kg/C) | Thermal Expansion | Density |

|---|---|---|---|---|

| 20 | 63.5 | 454 | 13.1 | 7846 |

| 100 | 68.6 | 485 | 13.4 | 7817 |

| 200 | 52.7 | 528 | 13.8 | 7788 |

| 300 | 46.7 | 592 | 14.0 | 7753 |

| 400 | 40.8 | 680 | 14.5 | 7717 |

| 500 | 37.4 | 703 | 14.8 | 7681 |

| 600 | 34.0 | 880 | 11.9 | 7643 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Dai, S.; Zheng, B. Continuum Damage Dynamic Model Combined with Transient Elastic Equation and Heat Conduction Equation to Solve RPV Stress. Fractal Fract. 2022, 6, 215. https://doi.org/10.3390/fractalfract6040215

Chen W, Dai S, Zheng B. Continuum Damage Dynamic Model Combined with Transient Elastic Equation and Heat Conduction Equation to Solve RPV Stress. Fractal and Fractional. 2022; 6(4):215. https://doi.org/10.3390/fractalfract6040215

Chicago/Turabian StyleChen, Wenxing, Shuyang Dai, and Baojuan Zheng. 2022. "Continuum Damage Dynamic Model Combined with Transient Elastic Equation and Heat Conduction Equation to Solve RPV Stress" Fractal and Fractional 6, no. 4: 215. https://doi.org/10.3390/fractalfract6040215

APA StyleChen, W., Dai, S., & Zheng, B. (2022). Continuum Damage Dynamic Model Combined with Transient Elastic Equation and Heat Conduction Equation to Solve RPV Stress. Fractal and Fractional, 6(4), 215. https://doi.org/10.3390/fractalfract6040215