In-Hole Measurements of Flow Inside Fan-Shaped Film Cooling Holes and Downstream Effects

Abstract

1. Introduction

2. Materials and Methods

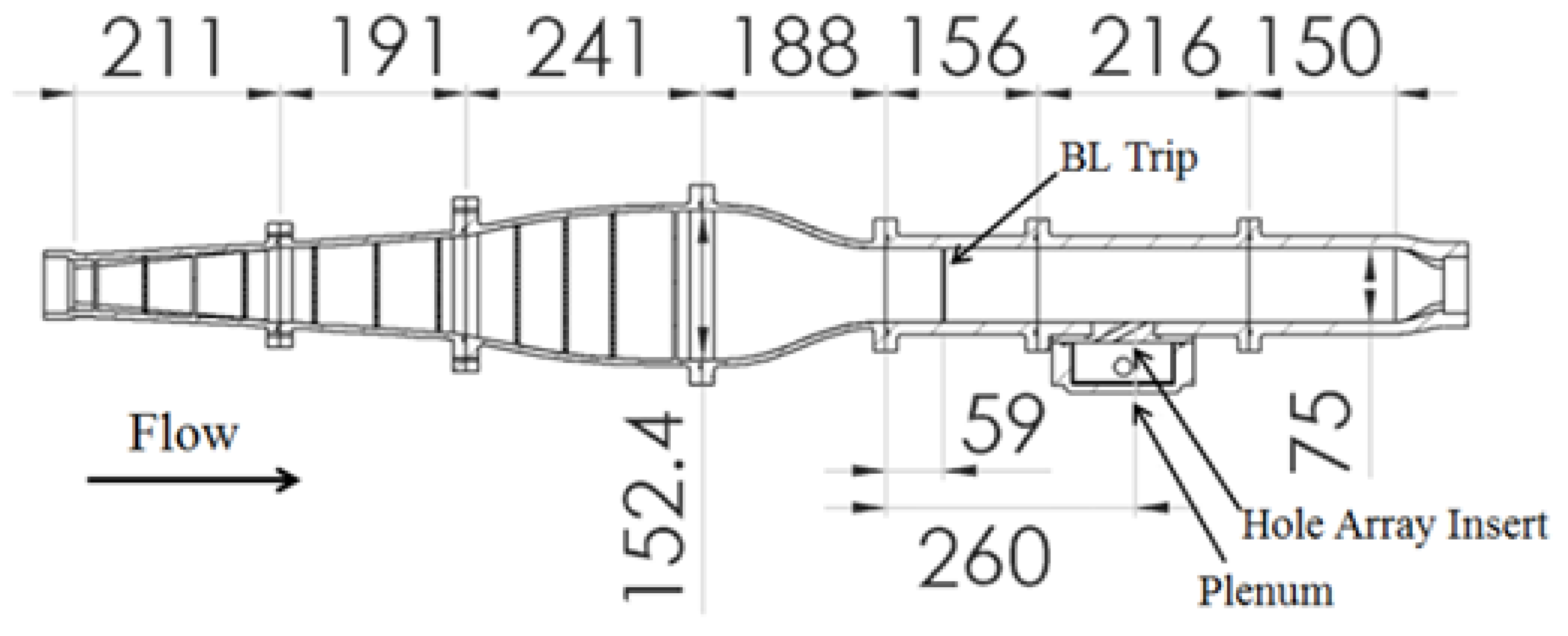

2.1. Experimental Setup

2.2. Uncertainty Analysis

3. Results

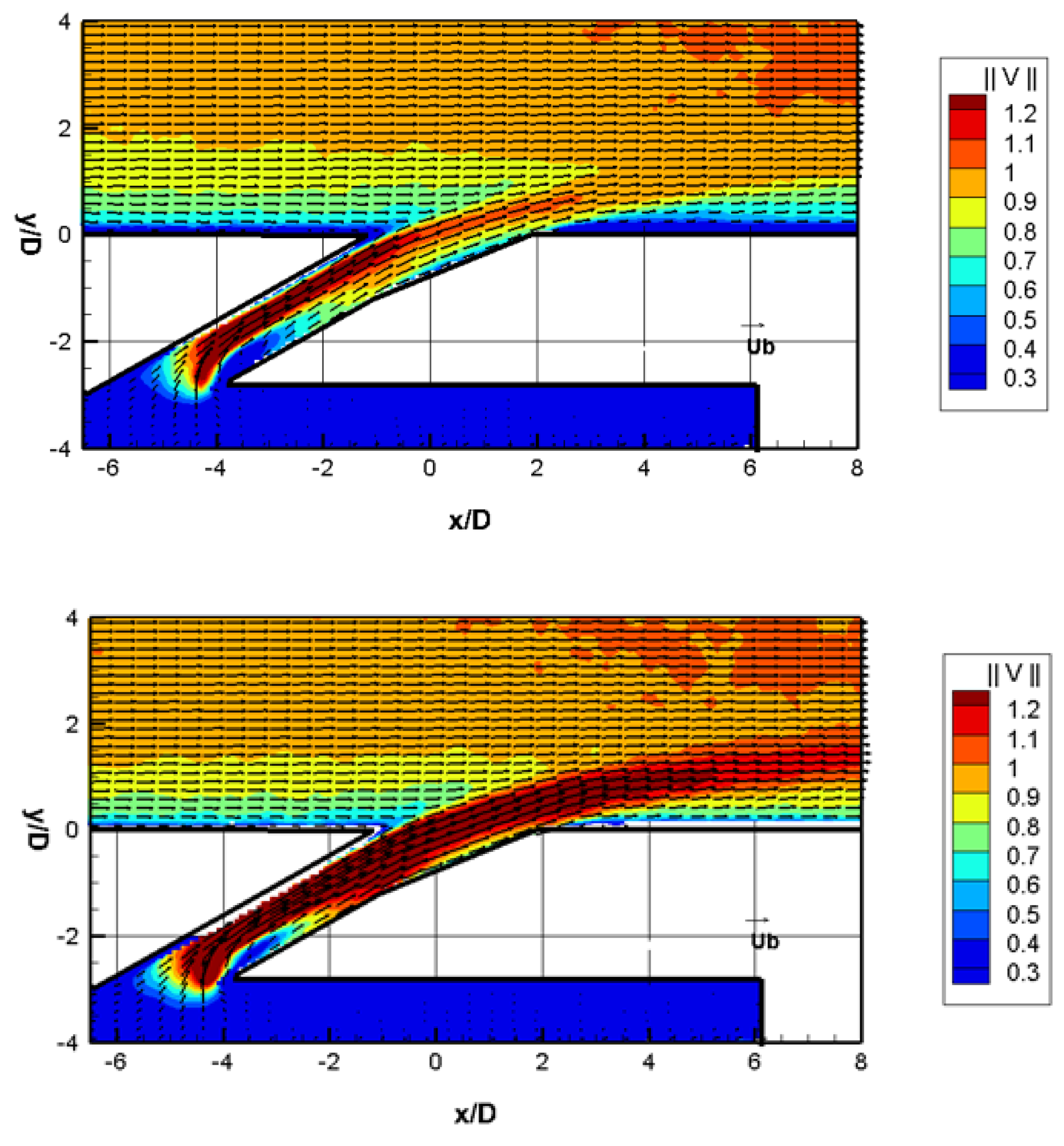

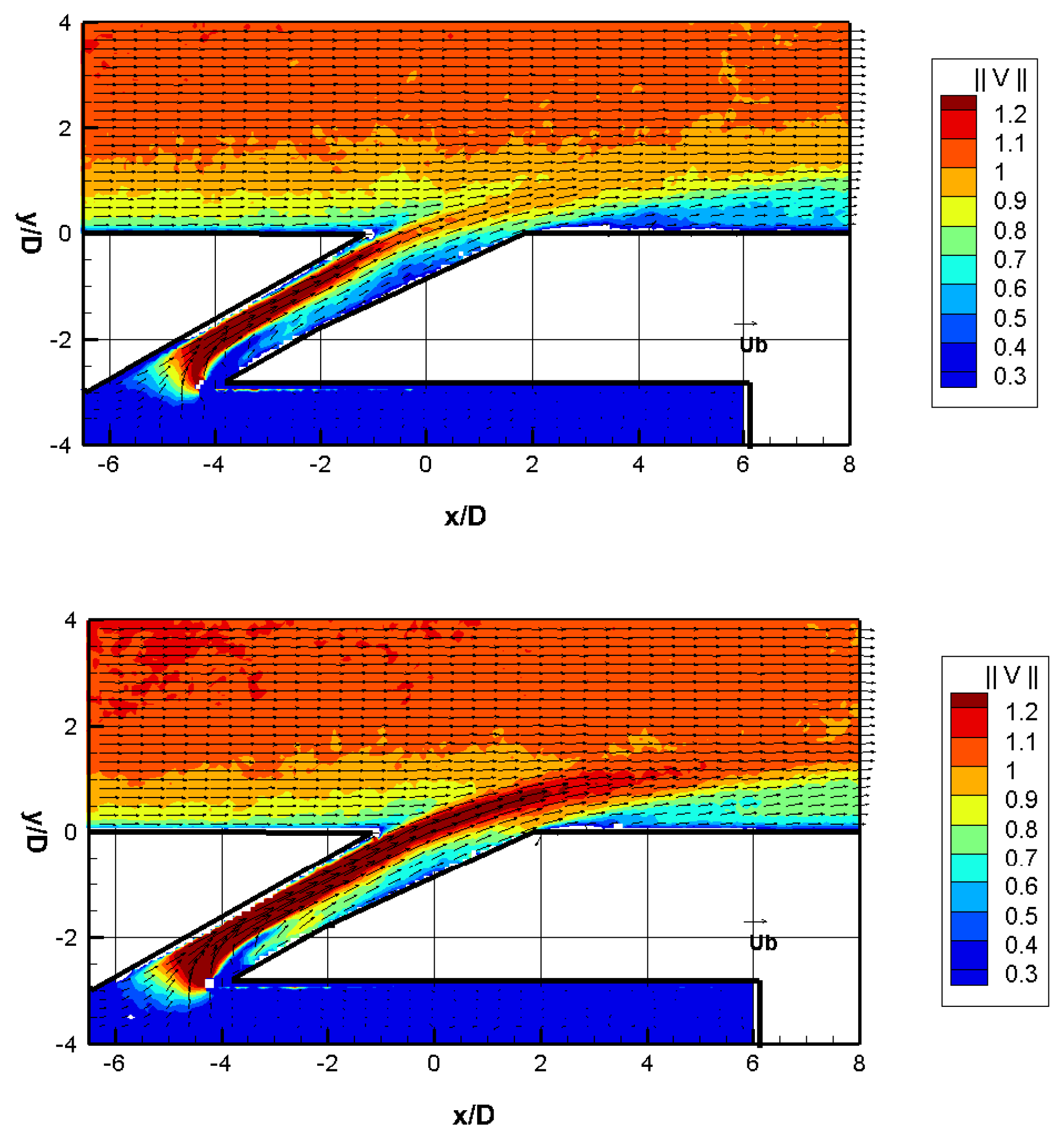

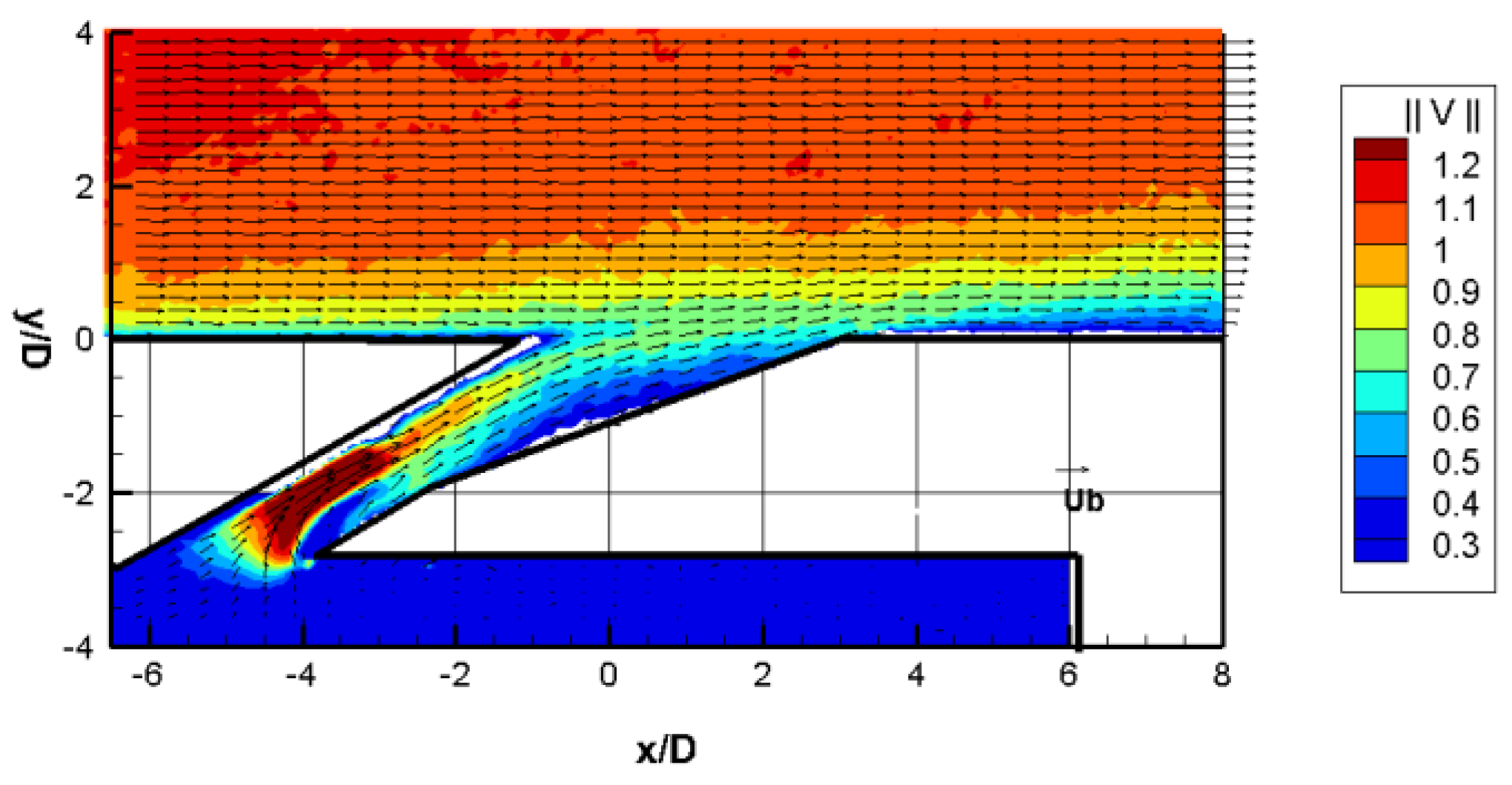

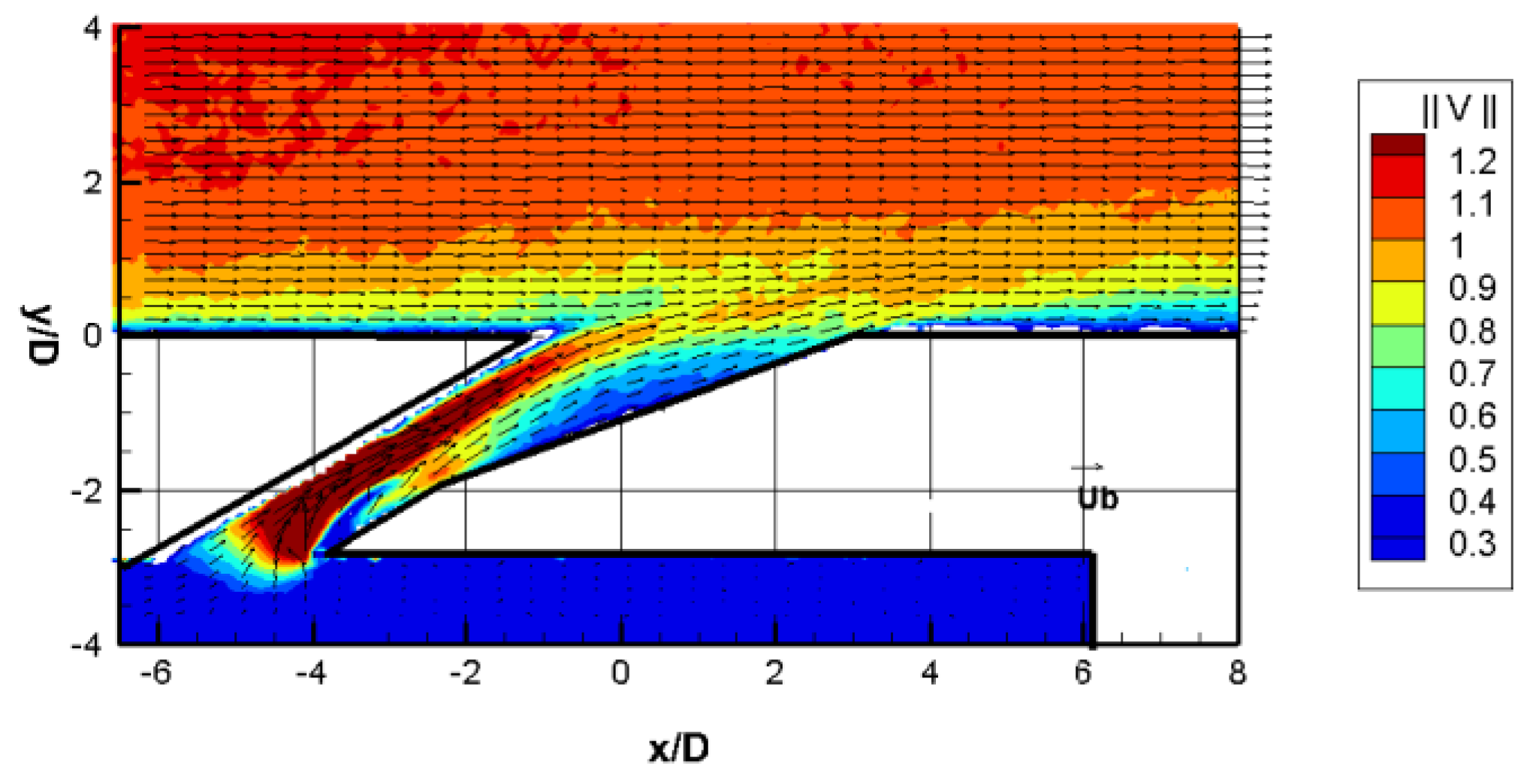

3.1. In-Hole Separation

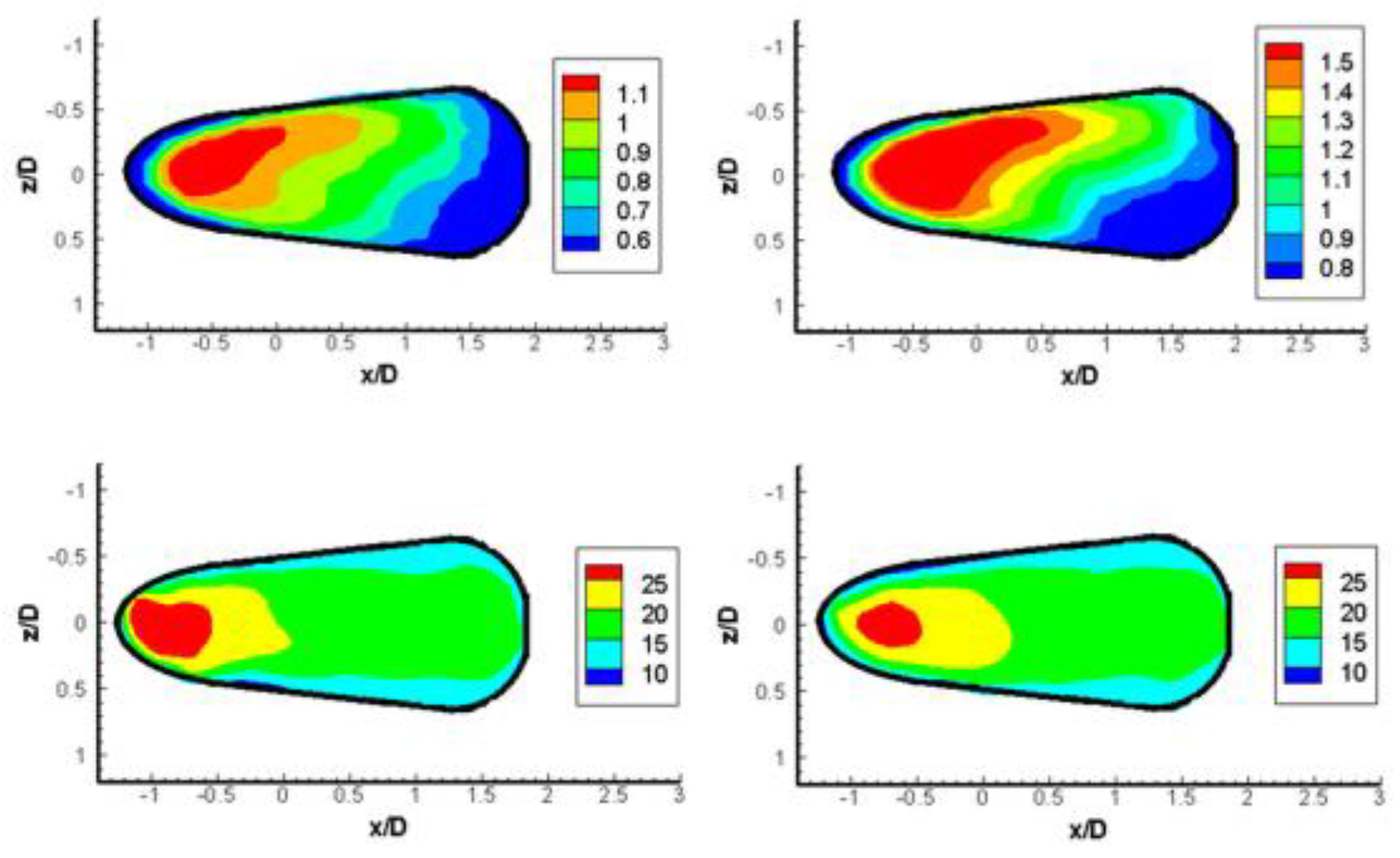

3.2. Exit Velocities

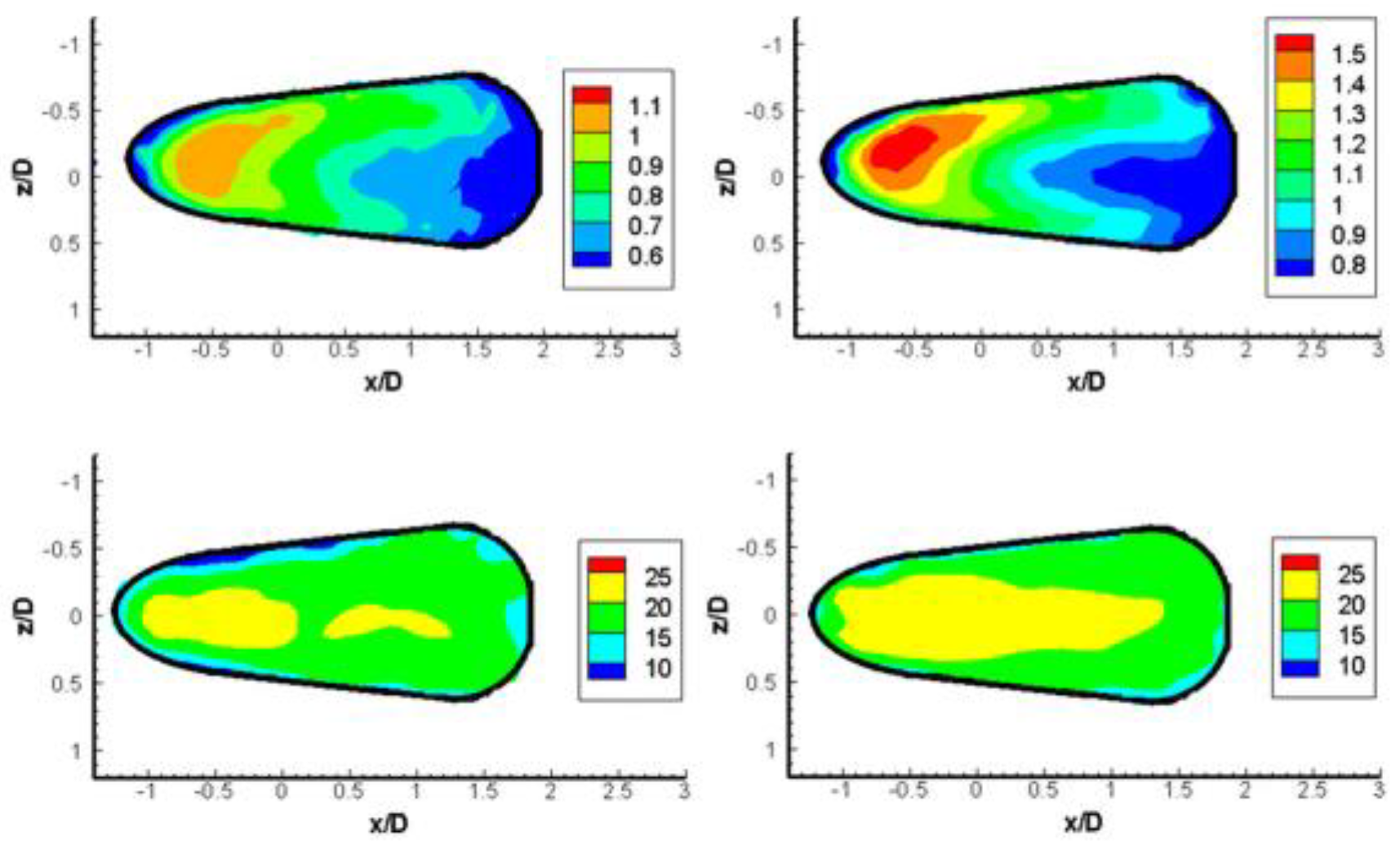

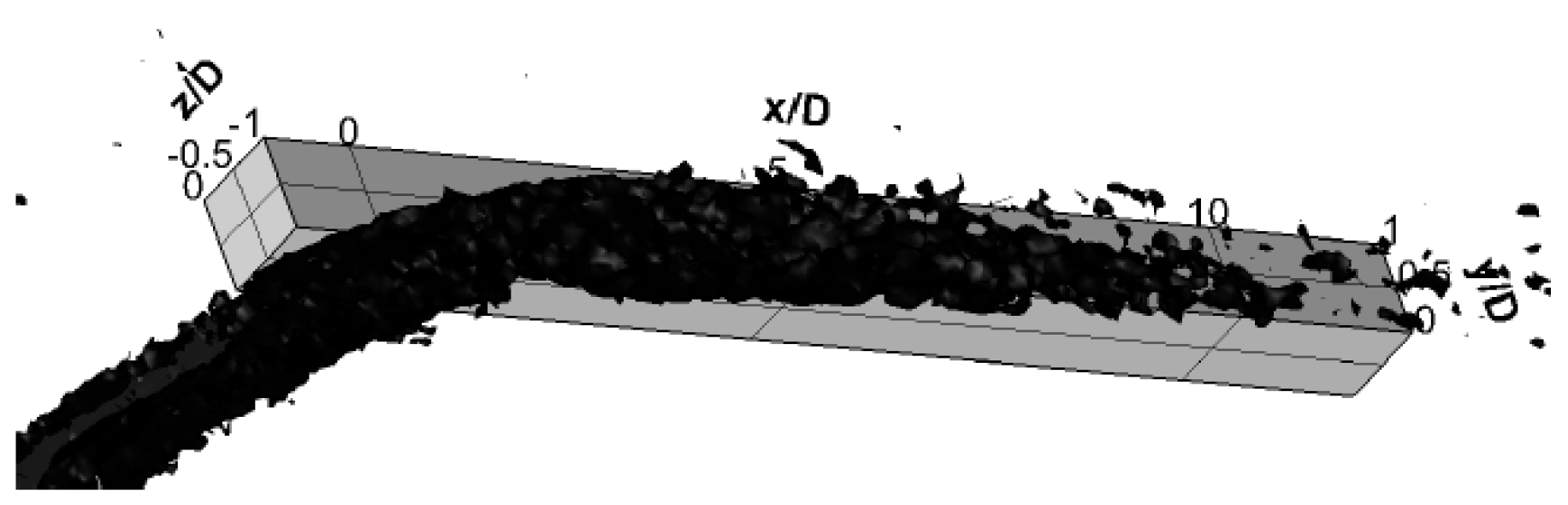

3.3. Counter-Rotating Vortex Pair

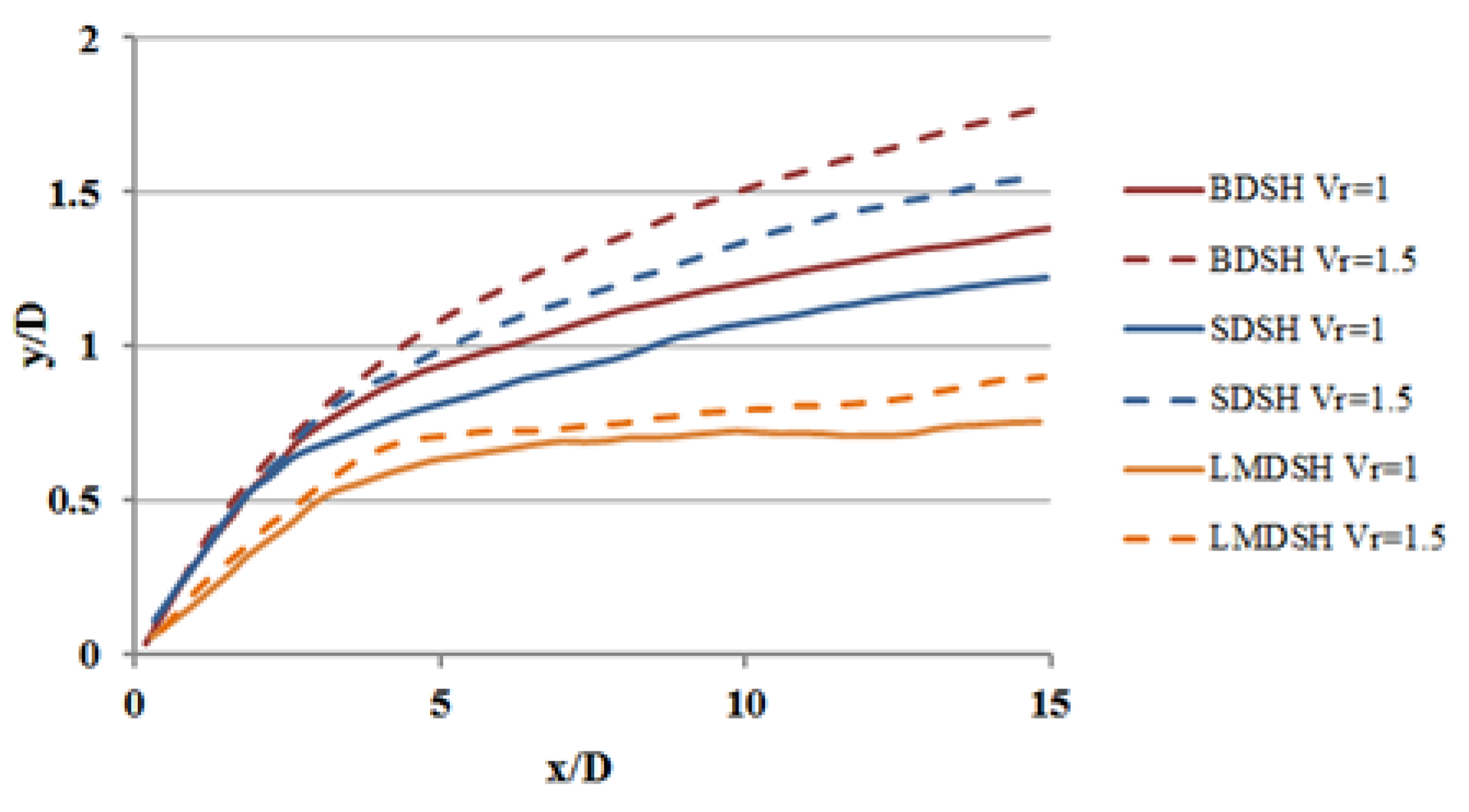

3.4. Center Streamlines

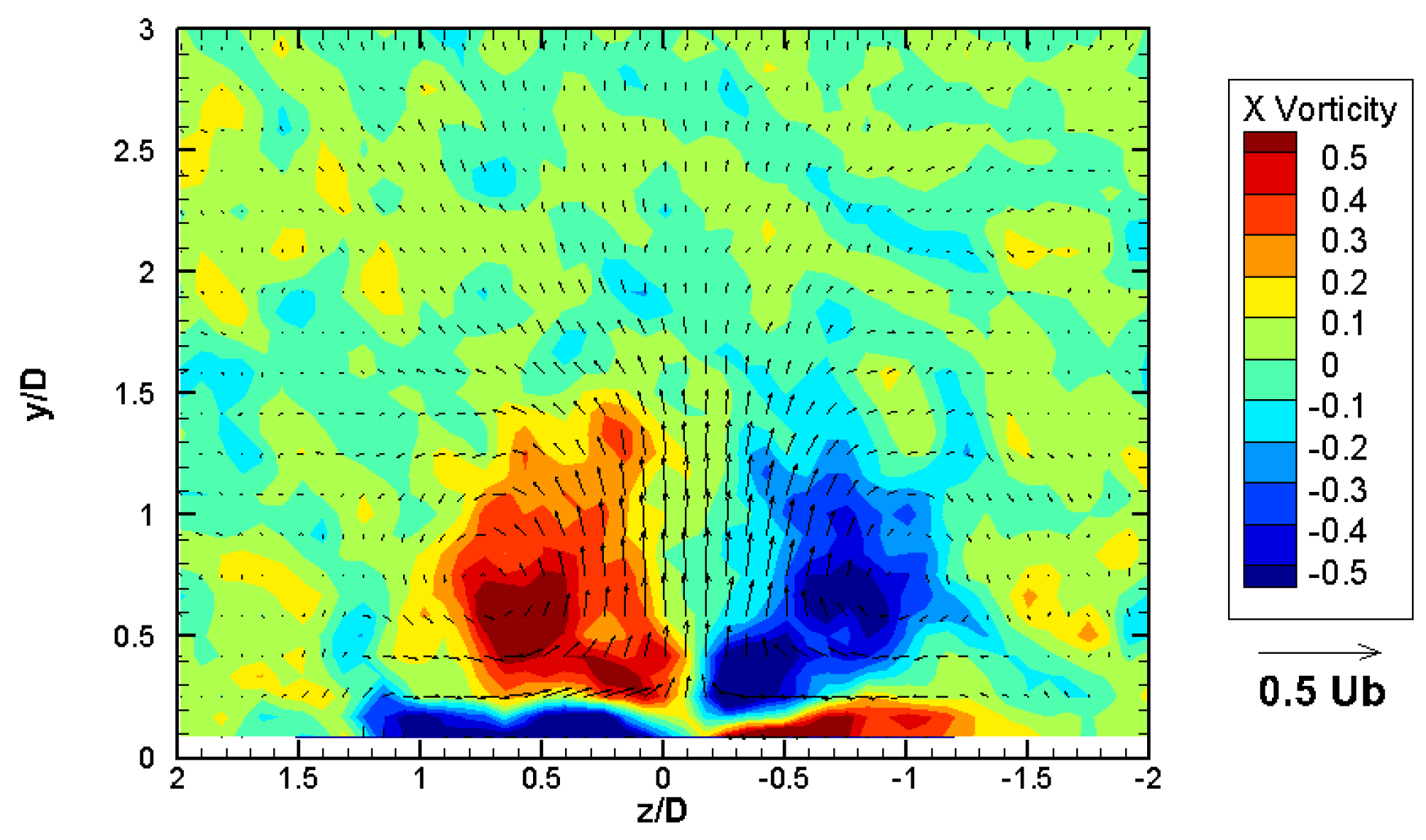

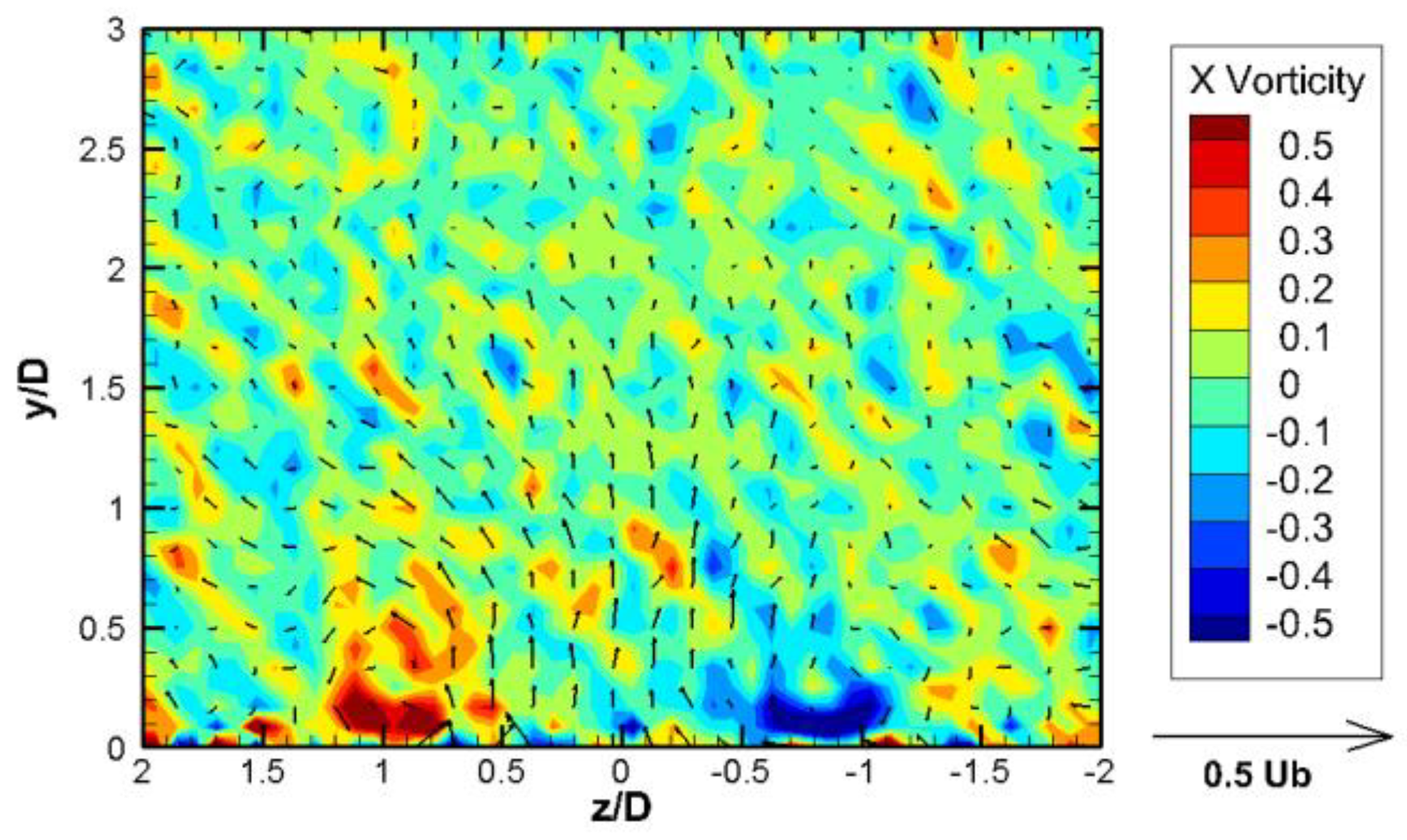

3.5. Vorticity

4. Discussion

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| D | Cooling Hole Diameter |

| L | Length of Hole |

| MRV | Magnetic Resonance Velocimetry |

| Re | Reynolds Number |

| S | Hole Spanwise Spacing |

| Ub | Bulk Mainflow Velocity |

| Uv | Velocity Uncertainty |

| Vr | Velocity Ratio |

| α | Ejection Angle |

References

- Goldstein, R.J.; Eckert, E.R.G.; Burggraf, F. Effects of Hole Geometry and Density on Three-Dimensional Film Cooling. Int. J. Heat Mass Transf. 1974, 17, 595–607. [Google Scholar] [CrossRef]

- Heidmann, J.D.; Ekkad, S.V. A Novel Antivortex Turbine Film Cooling Hole Concept. J. Turbomach. 2008, 130, 031020. [Google Scholar] [CrossRef]

- Okita, Y.; Nishiura, M. Film Effectiveness Performance of an Arrowhead-shaped Film-cooling Hole Geometry. ASME J. Turbomach. 2007, 129, 331–339. [Google Scholar] [CrossRef]

- Kusterer, K.; Elyas, A.; Bohn, D.; Sugimoto, T.; Tanaka, R.; Kazari, M. The NEKOMIMI Cooling Technology: Cooling Holes with Ears for High-Efficient Film Cooling. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011; Paper GT2011-45524. pp. 303–313. [Google Scholar]

- Thole, K.; Gritsch, M.; Schulz, A.; Wittig, S. Flowfield Measurements for Film Cooling Holes With Expanded Exits. In Proceedings of the ASME 1996 International Gas Turbine and Aeroengine Congress and Exhibition, Birmingham, UK, 10–13 June 1996. Paper 96-GT-174. [Google Scholar]

- Ganzert, W.; Hildebrandt, T.; Fottner, L. Systematic Experimental and Numerical Investigations on the Aerothermodynamics of a Film Cooled Turbine Cascade with Variation of the Cooling Hole Shape, Part 1, Experimental Approach. In Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, Munich, Germany, 8–11 May 2000. Paper 2000-GT-295. [Google Scholar]

- Issakhanian, E.; Elkins, C.J.; Eaton, J.K. Film Cooling Effectiveness Improvements Using a Nondiffusing Oval Hole. J. Turbomach. 2016, 138, 2016. [Google Scholar] [CrossRef]

- Issakhanian, E.; Elkins, C.J.; Eaton, J.K. In-hole and mainflow velocity measurements of low-momentum jets in crossflow emanating from short holes. Exp. Fluids 2012, 53, 1765–1778. [Google Scholar] [CrossRef]

- Elkins, C.; Alley, M. Magnetic resonance velocimetry: Applications of magnetic resonance imaging in the measurement of fluid motion. Exp. Fluids 2007, 43, 823–858. [Google Scholar] [CrossRef]

- Schroeder, R.P.; Thole, K. Adiabatic Effectiveness Measurements for a Baseline Shaped Film Cooling Hole. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. Paper GT-2014-25992. [Google Scholar]

- Saumweber, C.; Schulz, A.; Wittig, S. Free-Stream Turbulence Effects on Film Cooling with Shaped Holes. J. Turbomach. 2003, 125, 65–73. [Google Scholar] [CrossRef]

| Shape | Vr | SNR | UV (mm/s) |

|---|---|---|---|

| Base | 1 | 80 | (5, 5, 4) |

| Base | 1.5 | 80 | (7, 7, 5) |

| Shallow | 1 | 74 | (6, 6, 4) |

| Shallow | 1.5 | 90 | (6, 6, 4) |

| Large-Mouth | 1 | 88 | (5, 5, 4) |

| Large-Mouth | 1.5 | 76 | (7, 7, 5) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Published by MDPI on behalf of the EUROTURBO. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Issakhanian, E. In-Hole Measurements of Flow Inside Fan-Shaped Film Cooling Holes and Downstream Effects. Int. J. Turbomach. Propuls. Power 2024, 9, 36. https://doi.org/10.3390/ijtpp9040036

Issakhanian E. In-Hole Measurements of Flow Inside Fan-Shaped Film Cooling Holes and Downstream Effects. International Journal of Turbomachinery, Propulsion and Power. 2024; 9(4):36. https://doi.org/10.3390/ijtpp9040036

Chicago/Turabian StyleIssakhanian, Emin. 2024. "In-Hole Measurements of Flow Inside Fan-Shaped Film Cooling Holes and Downstream Effects" International Journal of Turbomachinery, Propulsion and Power 9, no. 4: 36. https://doi.org/10.3390/ijtpp9040036

APA StyleIssakhanian, E. (2024). In-Hole Measurements of Flow Inside Fan-Shaped Film Cooling Holes and Downstream Effects. International Journal of Turbomachinery, Propulsion and Power, 9(4), 36. https://doi.org/10.3390/ijtpp9040036