Improvement of the Parallel Compressor Model and Application to Inlet Flow Distortion

Abstract

1. Introduction

2. Local Parallel Compressor Model

- Defining a critical extent for the distorted angular sector [10];

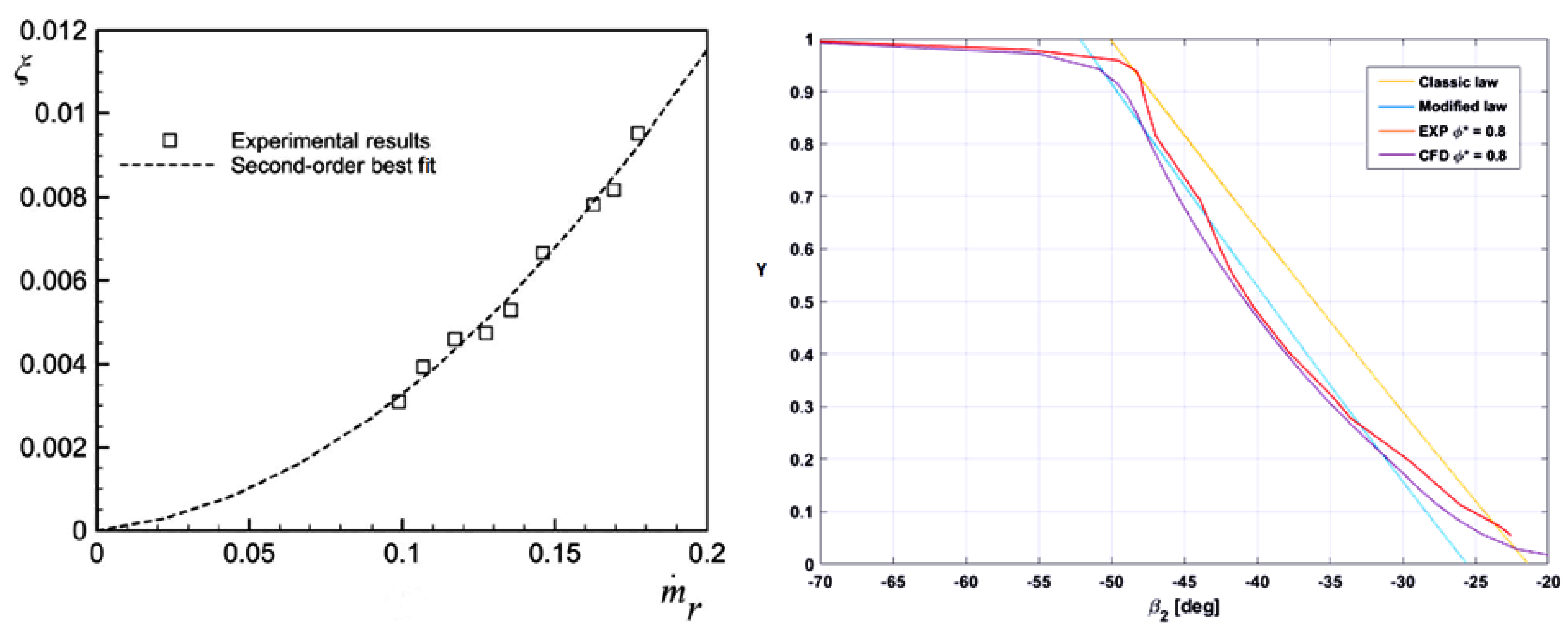

- A loss correlation for the fan stage, expressed as a function of massflow rate with a second-order polynom;

- A modification of McKenzie’s original law (Equation (3)) for flow deviation angle at the rotor outlet [29], based on measured radial profiles (Equation (4)). and refer to the blade camber and solidity, respectively. This correlation is used in the following for both presented operating points, although it should ideally be adapted to the operating conditions.

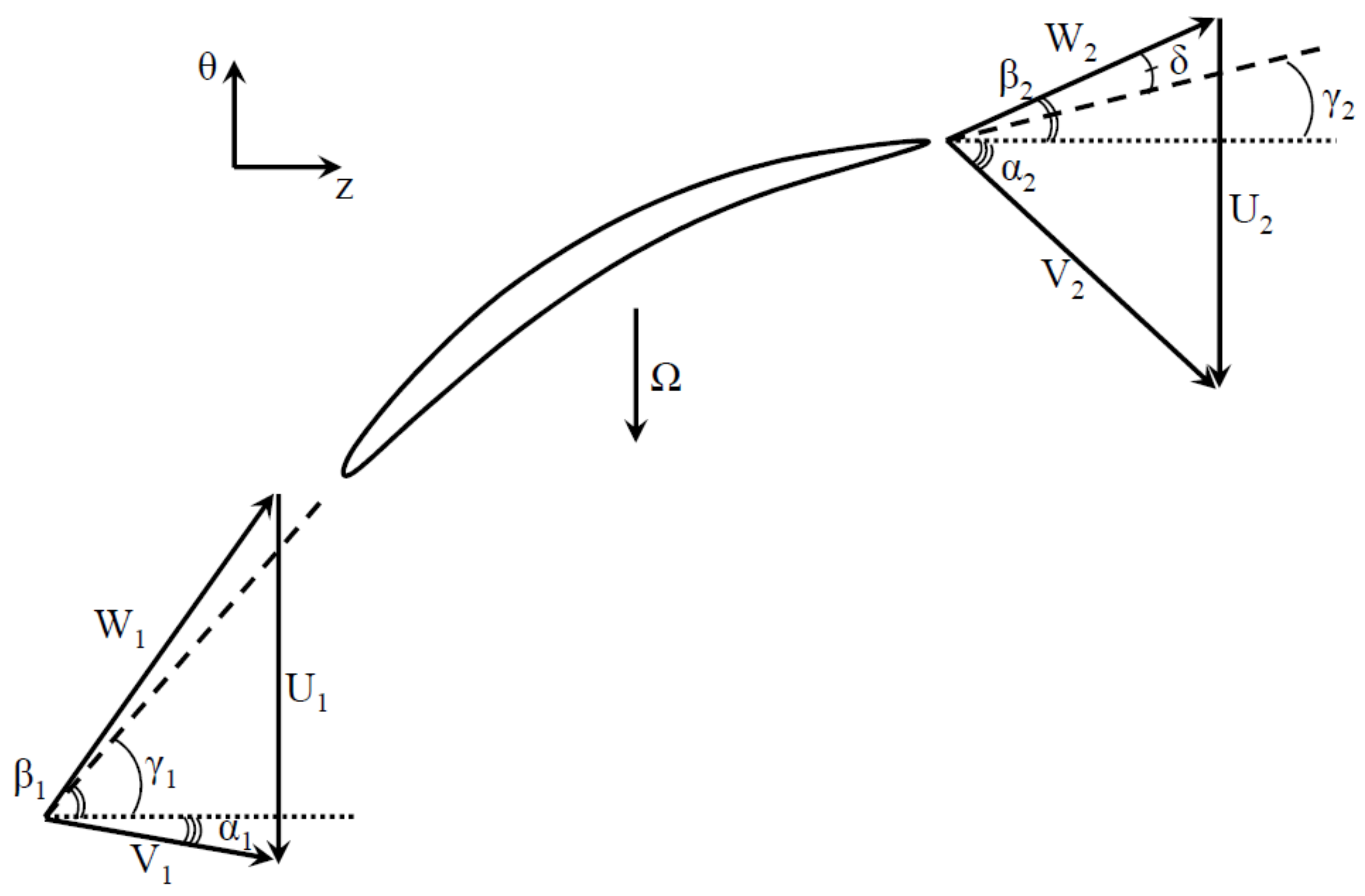

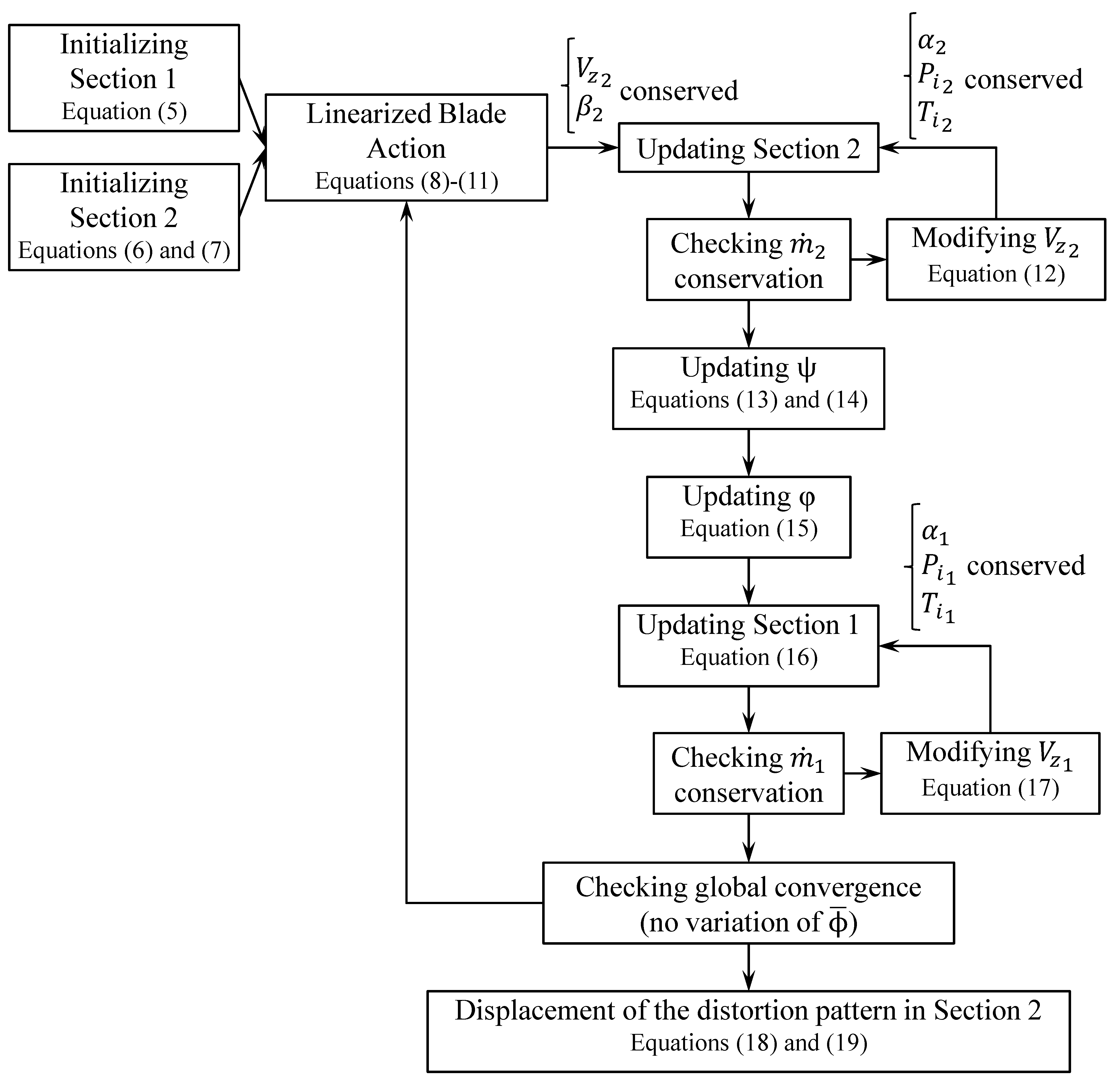

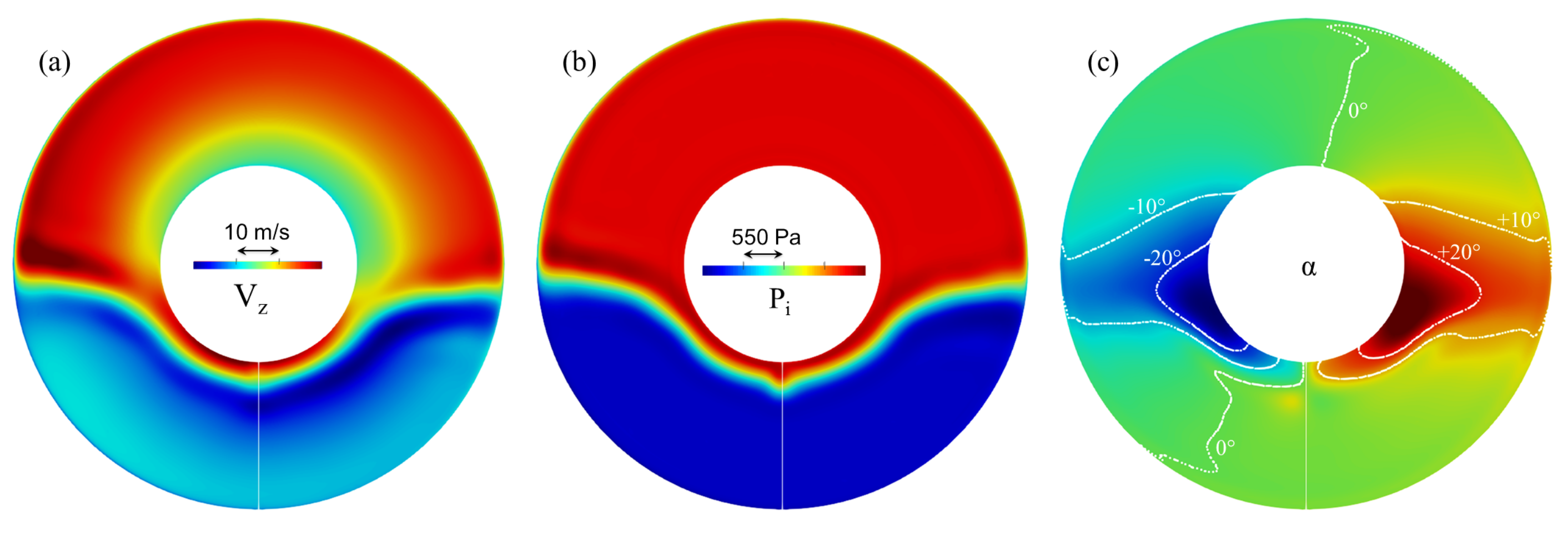

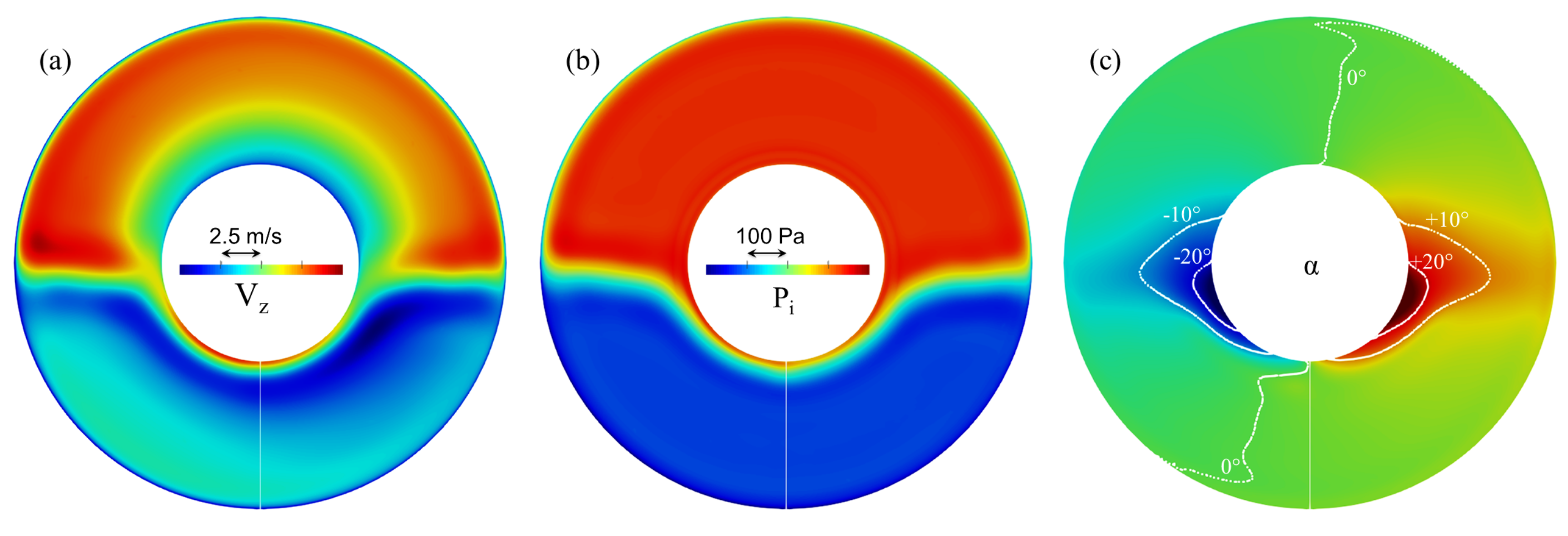

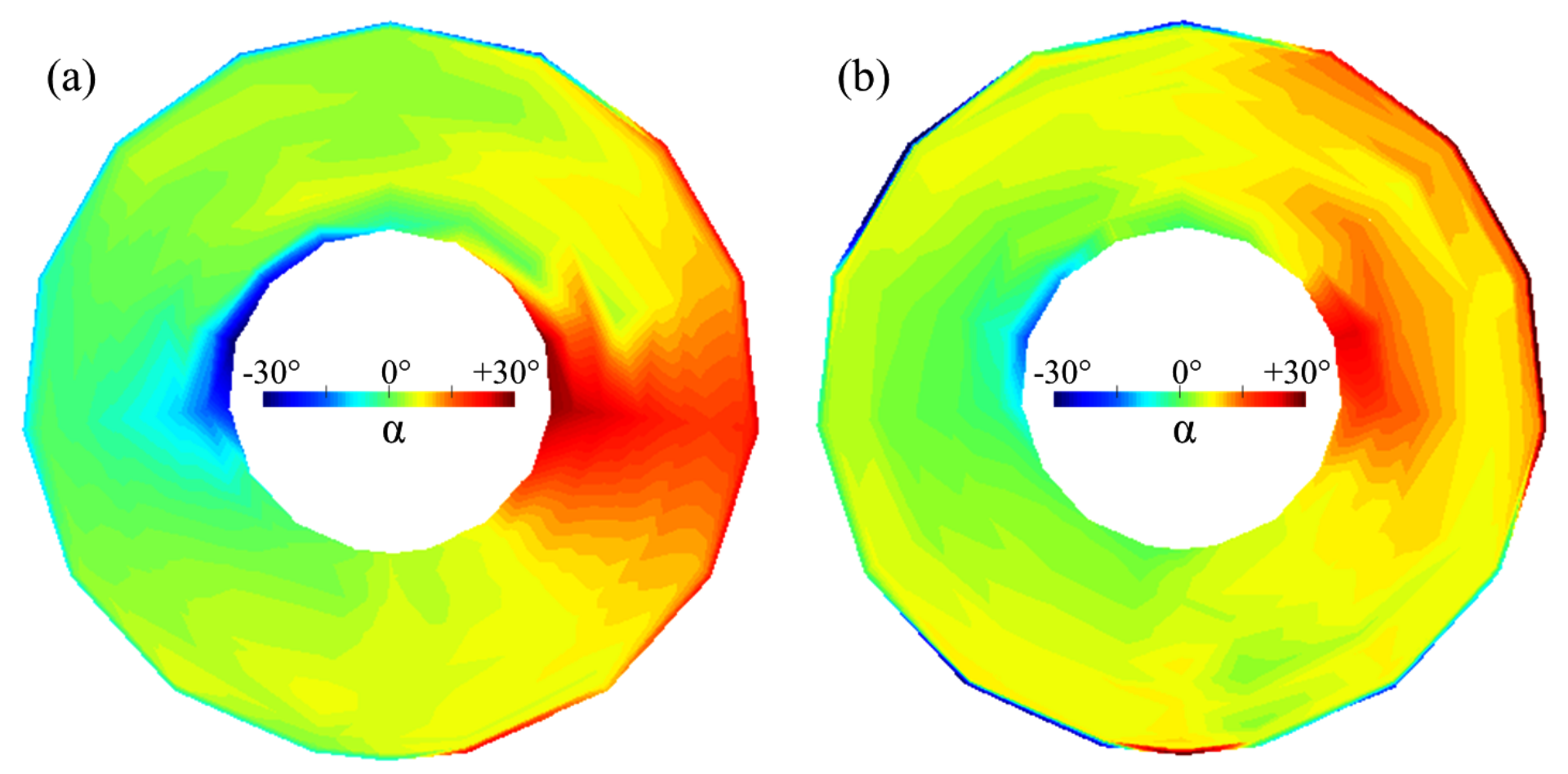

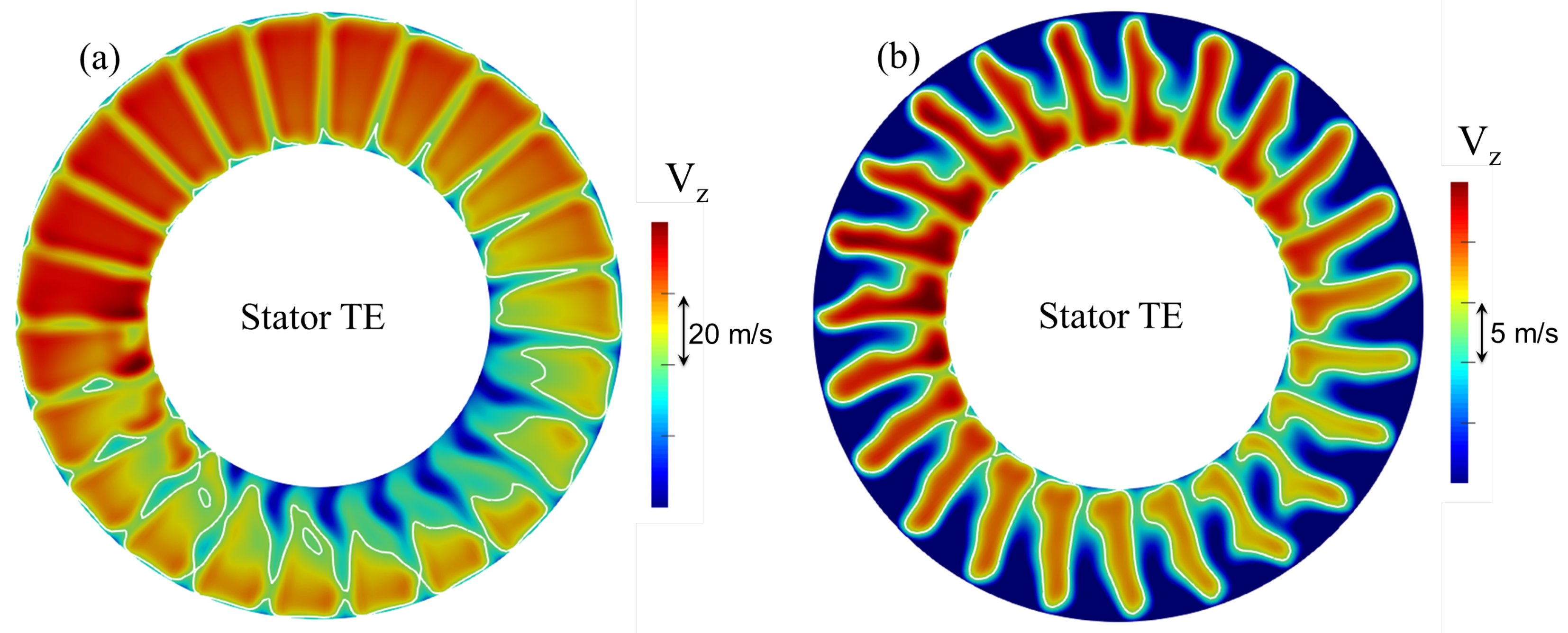

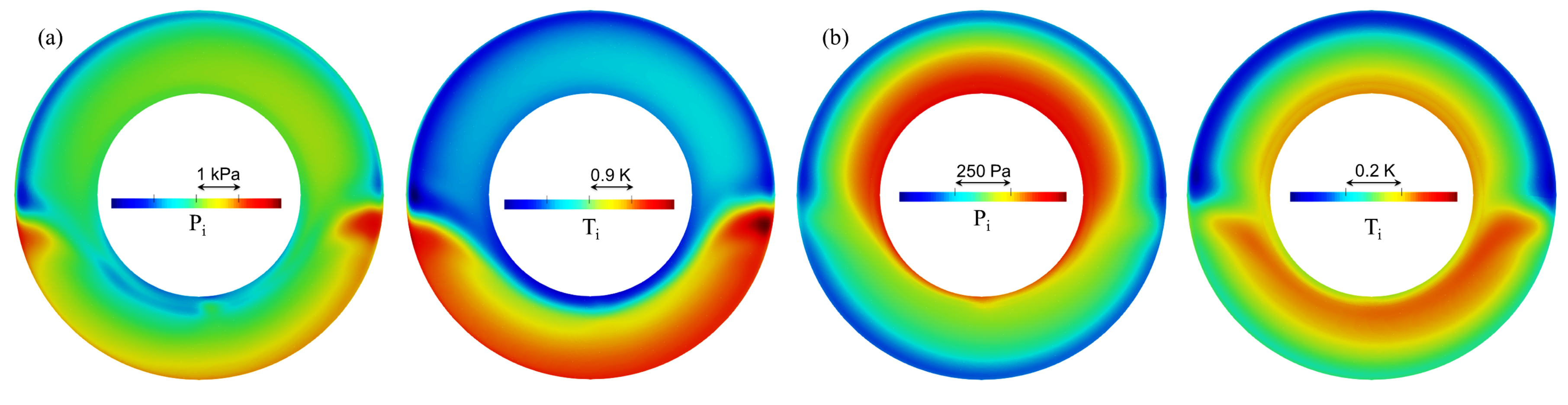

- Section 1 is initialized by sampling URANS results for four quantities: , , , (Figure 8 and 9) and the velocity triangles in Section 1 are calculated. Indeed, URANS maps are coherent with experimental ones (see, for example, Figure 10 for the upstream swirl angle ) and enable the use of an adequate 2D mesh while importing the exact same boundary conditions at the rotor LE for a proper comparison to 3D CFD. Section 2 is initialized by calculating the rotor relative outlet angle thanks to the modified McKenzie’s law for flow deviation (Equation (5)). The axial velocity is initialized using massflow conservation for an incompressible flow (Equation (4)).

- The loading coefficient of the fan is calculated using a simplified analytical model (Equations (6)–(9)), valid under certain assumptions (see [31]);

- is re-evaluated based on Euler’s theorem (Equations (11) and (12)) and is updated using the same value of n as in step 2;

- For each radius, a mean fluid particle passage time and circumferential displacement are calculated (Equations (16)–(18)), which reshapes the resulting field in Section 2.

3. Higher-Fidelity CFD Simulations

- The first one is body force modeling (BFM), which consists of using source terms to reproduce the passage-averaged effect of the blades on the flow. Previous work already evaluated this approach in presence of an upstream flow distortion for a low-speed fan operating as a compressor [33]. This work is extended in this paper to a free windmilling operating point, keeping a simple distortion pattern at the inlet;

- The finest level of fidelity relies on unsteady Reynolds-averaged Navier–Stokes simulations (URANS) performed on the whole annulus of the fan stage. It represents a reference method to capture the aerodynamics of the fan with inflow distortion, but its cost still remains prohibitive for early design phases. It is shown here to complete the experimental results and to evaluate the other approaches.

3.1. Body Force Modeling (BFM)

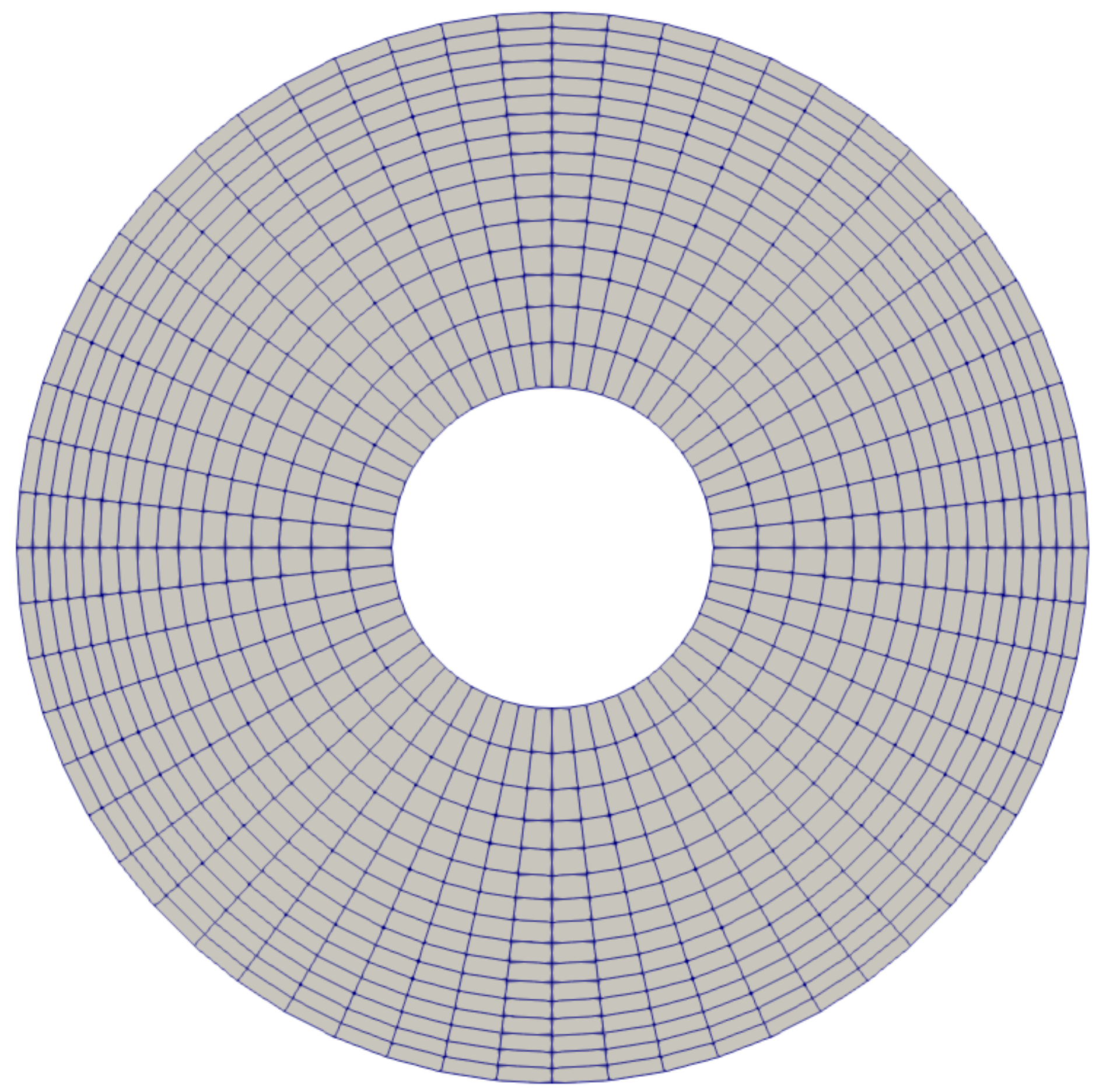

3.2. Unsteady RANS Simulations

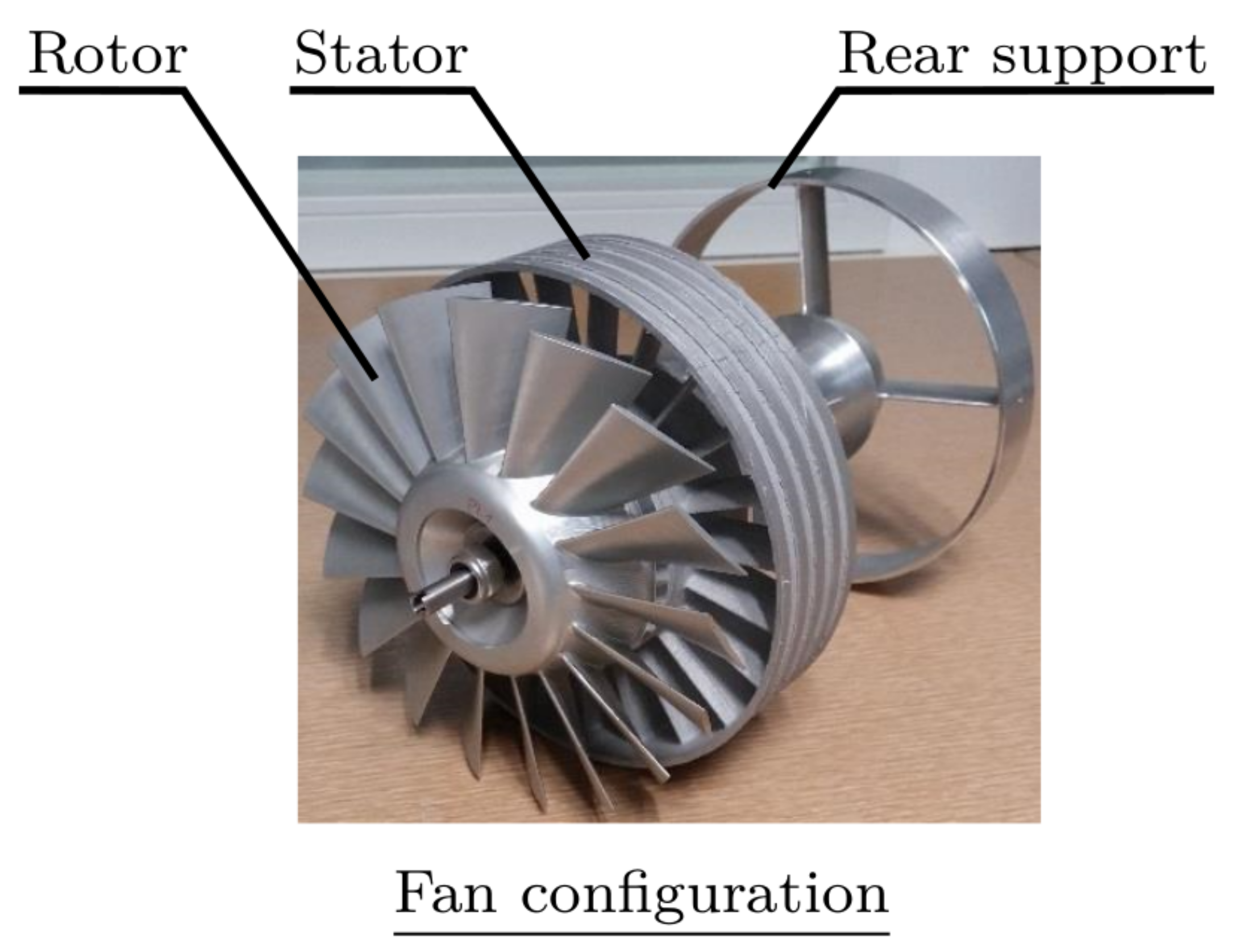

4. Validation Test Case

5. Distortion Patterns and Operating Points

6. Results

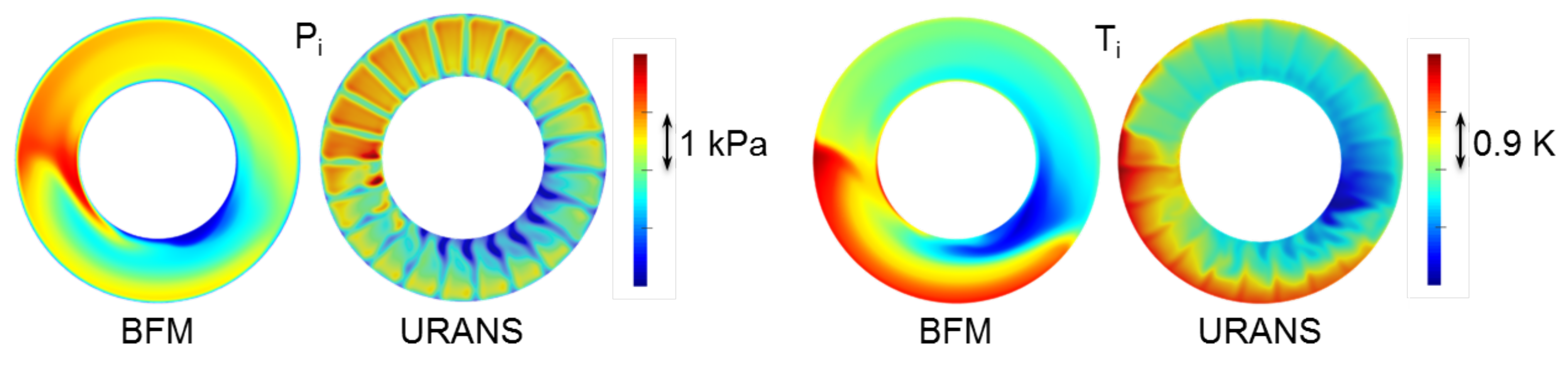

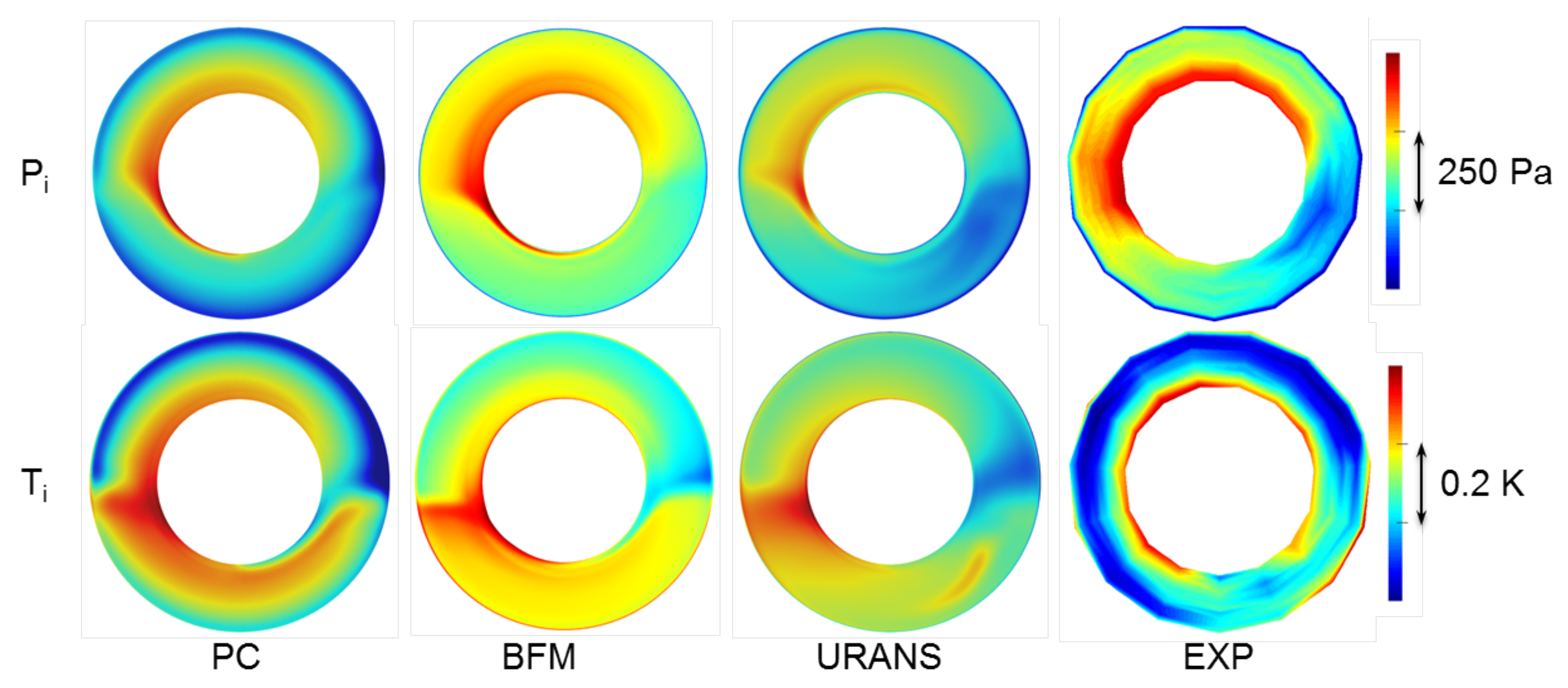

6.1. Compressor-Like Operating Point

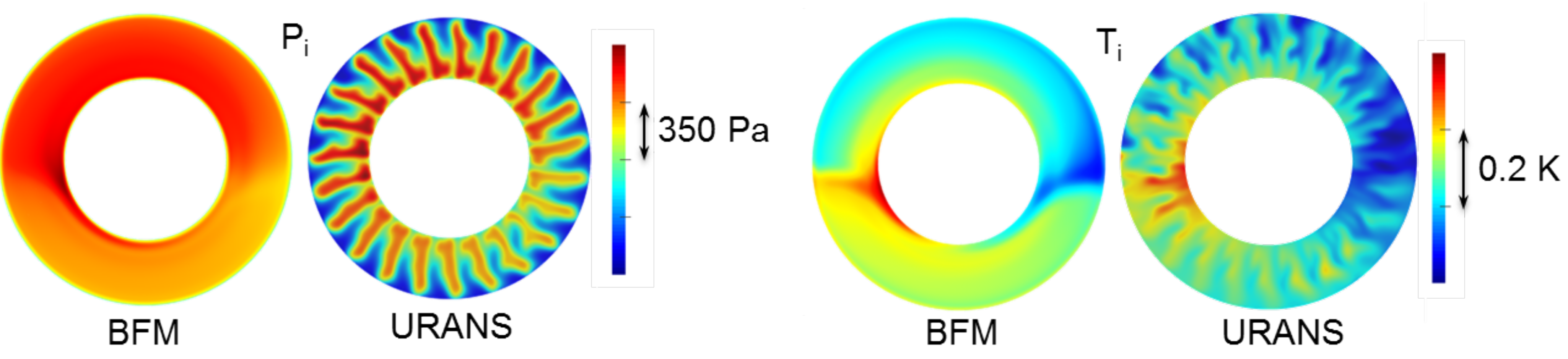

6.2. Free Windmilling Operating Point

6.3. Point of Attention

7. Conclusions

- The idea of the present modeling is very simple since it relies only on the fan blade geometry and on Euler’s theorem;

- Concerning the fan behavior, this tool can be used without additional inputs. However, a finer customization is possible, extracting loss or deviation calibrations from measurements or higher-fidelity CFD, for example. If this approach is to be used during an early design phase, the explored design space must be previously delimited, so that these inputs are reliable enough.

- Although the parallel compressor model can be considered as rather basic, it proves to be sufficient to provide relevant physical insight and to correctly quantify the impact of distortion on the performance near the design operating conditions;

- As could be expected, the most challenging point comes with off-design conditions and this part of the modeling can be improved;

- The use of the new formulation itself comes with a negligible CPU cost, provided that the upstream distortion maps are available.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BLI | Boundary Layer Ingestion |

| CFD | Computational Fluid Dynamics |

| LE | Leading Edge |

| TE | Trailing Edge |

| PC | Parallel Compressors |

| BFM | Body Force Modeling |

| RANS | Reynolds-Averaged Navier–Stokes |

| URANS | Unsteady Reynolds-Averaged Navier–Stokes |

| P | pressure |

| T | temperature |

| W | relative velocity |

| V | absolute velocity |

| U | rotational speed |

| density | |

| flow coefficient | |

| loading coefficient | |

| local deviation angle | |

| pressure ratio | |

| isentropic efficiency | |

| massflow rate | |

| S | section surface |

| absolute flow angle | |

| relative flow angle | |

| axial chord length | |

| blade camber | |

| blade solidity | |

| blade metal angle | |

| V | absolute velocity |

| relative span height | |

| x, y, z | cartesian coordinates |

| z, r, | cylindrical coordinates |

| i | stagnation quantity |

| 1, 2 | relative to the rotor LE, TE sections |

References

- Bijewitz, J.; Seitz, A.; Hornung, M. A review of recent aircraft concepts employing synergistic propulsion-airframe integration. In Proceedings of the 30th Congress of the International Council of the Aeronautical Sciences, Daejeon, Korea, 25–30 September 2016. [Google Scholar]

- Welstead, J.; Felder, J.L. Conceptual design of a single-aisle turboelectric commercial transport with fuselage boundary layer ingestion. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 1027. [Google Scholar]

- Bowman, C.L.; Felder, J.L.; Marien, T.V. Turbo-and Hybrid-electrified aircraft propulsion concepts for commercial transport. In Proceedings of the 2018 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Virtual, 10–12 August 2018; pp. 1–8. [Google Scholar]

- Hall, D.K.; Dowdle, A.; Gonzalez, J.; Trollinger, L.; Thalheimer, W. Assessment of a boundary layer ingesting turboelectric aircraft configuration using signomial programming. In Proceedings of the 2018 Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 25–29 June 2018; p. 3973. [Google Scholar]

- Giannakakis, P.; Maldonado, Y.B.; Tantot, N.; Frantz, C.; Belleville, M. Fuel burn evaluation of a turbo-electric propulsive fuselage aircraft. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Virtual, 19–22 August 2019; p. 4181. [Google Scholar]

- Fernández, A.M.; Smith, H. Effect of a fuselage boundary layer ingesting propulsor on airframe forces and moments. Aerosp. Sci. Technol. 2020, 100, 105808. [Google Scholar] [CrossRef]

- Schmollgruber, P.; Donjat, D.; Ridel, M.; Cafarelli, I.; Atinault, O.; François, C.; Paluch, B. Multidisciplinary design and performance of the ONERA Hybrid Electric Distributed Propulsion concept (DRAGON). In Proceedings of the AIAA Scitech 2020 Forum, Virtual, 11–21 January 2020; p. 0501. [Google Scholar]

- Habermann, A.L.; Gokhale, A.; Hornung, M. Numerical investigation of the effects of fuselage upsweep in a propulsive fuselage concept. CEAS Aeronaut. J. 2021, 12, 173–189. [Google Scholar] [CrossRef]

- Pearson, H.; McKenzie, A. Wakes in axial compressors. Aeronaut. J. 1959, 63, 415–416. [Google Scholar] [CrossRef]

- Reid, C. The Response of Axial Flow Compressors to Intake Flow Distortion; American Society of Mechanical Engineers: New York, NY, USA, 1969; Volume 79832. [Google Scholar]

- Goethert, B.; Reddy, K. Unsteady Aerodynamics of Rotor Blades of a Compressor under Distorted Flow Conditions (Interference Effect between Oscillating and Distorted Inlet Flow on Compressor Stall); Cranfield University: Bedford, UK, 1971. [Google Scholar]

- Melick, H., Jr. Analysis of Inlet Flow Distortion and Turbulence Effects on Compressor Stability; Ames Research Center: Moffett Field, CA, USA, 1973.

- Kimzey, W. An Analysis of the Influence of Some External Disturbances on the Aerodynamic Stability of Turbine Engine Axial Flow Fans and Compressors; Technical Report; Arnold Engineering Development Center: Murfreesboro, TN, USA, 1977. [Google Scholar]

- Mazzawy, R.S. Multiple Segment Parallel Compressor Model for Circumferential Flow Distortion. J. Eng. Power 1977, 99, 288–296. [Google Scholar] [CrossRef]

- Hynes, M. Improvement of the parallel compressor model by consideration of unsteady blade aerodynamics. In Proceedings of the Propulsion and Energetics 68th (A) Specialists’ Meeting, AGARD, Munich, Germany, 10–12 September 1987; Volume 400. [Google Scholar]

- Hynes, T.; Chue, R.; Greitzer, E.; Tan, C. Calculations of inlet distortion induced compressor flowfield instability. In Proceedings of the Propulsion and Energetics 68th (A) Specialists’ Meeting, AGARD, Munich, Germany, 10–12 September 1987; Volume 400. [Google Scholar]

- Hale, A.; Davis, M. DYNamic turbine engine compressor code (DYNTECC)-theory and capabilities. In Proceedings of the 28th Joint Propulsion Conference and Exhibit, Nashville, TN, USA, 6–8 July 1992; p. 3190. [Google Scholar]

- Shahrokhi, K.; Davis, J.M. Application of a modified dynamic compression system model to a low aspect ratio fan-effects of inlet distortion. In Proceedings of the 33rd Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 1995; p. 301. [Google Scholar]

- Davis, R.L.; Yao, J. Computational approach for predicting stall inception in multistage axial compressors. J. Propuls. Power 2007, 23, 257–265. [Google Scholar] [CrossRef]

- Fredrick, N.; Davis, M., Jr. Investigation of the Effects of Inlet Swirl on Compressor Performance and Operability Using a Modified Parallel Compressor Model. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011; Volume 54617. [Google Scholar]

- Davis, M.W., Jr.; Cousins, W.T. Evaluating complex inlet distortion with a parallel compressor model: Part 2—Applications to complex patterns. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2011; Volume 54617, pp. 13–23. [Google Scholar]

- Floyd, R.S., Jr.; Davis, M.W., Jr. Validation of a modified parallel compressor model for prediction of the effects of inlet swirl on compressor performance and operability. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 56628, p. V001T01A024. [Google Scholar]

- Escudero Saiz, A. Investigation of Analytical Models for Evaluating the Impact of Distortion on Compressor Performance and Stability [BR]-Internship. Master’s Thesis, Université de Liège, Liège, Belgium, 2020. [Google Scholar]

- Doulgeris, G.; Khaleghi, H.; Kalfas, A.; Pilidis, P. Development of a method for enhanced fan representation in gas turbine modeling. Int. J. Rotating Mach. 2011, 2011. [Google Scholar] [CrossRef][Green Version]

- Miller, D.; Wasdell, D. Off-Design Prediction of Compressor Blade Losses; C279/87; Japan Science and Technology Agency: Tokyo, Japan, 1987; pp. 249–258.

- Valencia, E.; Hidalgo, V.; Nalianda, D.; Laskaridis, P.; Singh, R. Discretized Miller approach to assess effects on boundary layer ingestion induced distortion. Chin. J. Aeronaut. 2017, 30, 235–248. [Google Scholar] [CrossRef]

- Menegozzo, L.; Benini, E. Meanline calculation of surge margin loss due to inlet flow distortion. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2020. [Google Scholar]

- Budziszewski, N.; Friedrichs, J. Modelling of a boundary layer ingesting propulsor. Energies 2018, 11, 708. [Google Scholar] [CrossRef]

- McKenzie, A.B. Axial flow fans and compressors. In Aerodynamic Design and Performance; Gower Technical: Tokyo, Japan, 1997. [Google Scholar]

- Cousins, W.T.; Davis, M.W., Jr. Evaluating complex inlet distortion with a parallel compressor model: Part 1–Concepts, theory, extensions, and limitations. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2011; Volume 54617, pp. 1–12. [Google Scholar]

- Binder, N. Aéro-Thermodynamique des Turbomachines en Fonctionnement Hors-Adaptation; Université de Toulouse: Toulouse, France, 2016. [Google Scholar]

- Valencia, E.; Nalianda, D.; Laskaridis, P.; Singh, R. Propulsion system analysis using a parametric and the parallel compressor approach to model distortion in Boundary Layer Ingestion systems. Part G J. Aerosp. Eng. 2014. [Google Scholar] [CrossRef]

- Benichou, E.; Dufour, G.; Bousquet, Y.; Binder, N.; Ortolan, A.; Carbonneau, X. Body Force Modeling of the Aerodynamics of a Low-Speed Fan under Distorted Inflow. Int. J. Turbomach. Propuls. Power 2019, 4, 29. [Google Scholar] [CrossRef]

- Hall, D.; Greitzer, E.; Tan, C. Analysis of fan stage conceptual design attributes for boundary layer ingestion. J. Turbomach. 2017, 139, 071012. [Google Scholar] [CrossRef]

- Thollet, W. Body Force Modeling of Fan—Airframe Interactions. Ph.D. Thesis, ISAE-SUPAERO, Toulouse, France, 2017. [Google Scholar]

- Dufour, G.; Thollet, W. Body Force Modeling of the Aerodynamics of the Fan of a Turbofan at Windmill. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2016; Volume 49712, p. V02CT39A045. [Google Scholar]

- Ortolan, A. Aerodynamic Study of Reversible Axial Fans with High Compressor/Turbine Dual Performance. Ph.D. Thesis, ISAE-SUPAERO, Toulouse, France, 2017. [Google Scholar]

- Courty-Audren, S.K.; Ortolan, A.; Carbonneau, X.; Binder, N.; Challas, F. Numerical analysis of secondary flow topologies of low-speed axial fans from compressor to load-controlled windmill. In Proceedings of the 12th European Conference on Turbomachinery Fluid dynamics & Thermodynamics ETC12, Stockholm, Sweden, 3–7 April 2017. [Google Scholar]

- Ferrer-Vidal, L.E.; Schneider, M.; Allegretti, A.; Pachidis, V. A Loss and Deflection Model for Compressor Blading at High Negative Incidence. J. Turbomach. 2019, 141, 121001. [Google Scholar] [CrossRef]

- Righi, M.; Ferrer-Vidal, L.; Pachidis, V. Body-force and mean-line models for the generation of axial compressor sub-idle characteristics. Aeronaut. J. 2020, 124, 1–19. [Google Scholar] [CrossRef]

- Pokhrel, M.; Shi, M.; Ahuja, J.; Gladin, J.; Mavris, D.N. Conceptual Design of a BLI Propulsor Capturing Aero-Propulsive Coupling and Distortion Impacts. In Proceedings of the AIAA SciTech 2019 Forum, San Diego, CA, USA, 7–11 January 2019; p. 1588. [Google Scholar]

- López de Vega, L.; Dufour, G.; García Rosa, N. Fully Coupled Body Force–Engine Performance Methodology for Boundary Layer Ingestion. J. Propuls. Power 2021, 37, 192–201. [Google Scholar] [CrossRef]

- Kolias, I.; Alexiou, A.; Aretakis, N.; Mathioudakis, K. Axial Compressor Mean-Line Analysis: Choking Modelling and Fully-Coupled Integration in Engine Performance Simulations. Int. J. Turbomach. Propuls. Power 2021, 6, 4. [Google Scholar] [CrossRef]

| Diameter | mm |

| Rotor blade count | |

| Stator blade count | |

| Design rotational speed | rpm |

| Axial Mach number | 0.1–0.2 |

| PC | BFM | URANS |

|---|---|---|

| <10 s | 12 h | 1 week |

| BFM—URANS | <0.1% | ||||

| PC—URANS |

| BFM—URANS | |||

| PC—URANS |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Benichou, E.; Binder, N.; Bousquet, Y.; Carbonneau, X. Improvement of the Parallel Compressor Model and Application to Inlet Flow Distortion. Int. J. Turbomach. Propuls. Power 2021, 6, 34. https://doi.org/10.3390/ijtpp6030034

Benichou E, Binder N, Bousquet Y, Carbonneau X. Improvement of the Parallel Compressor Model and Application to Inlet Flow Distortion. International Journal of Turbomachinery, Propulsion and Power. 2021; 6(3):34. https://doi.org/10.3390/ijtpp6030034

Chicago/Turabian StyleBenichou, Emmanuel, Nicolas Binder, Yannick Bousquet, and Xavier Carbonneau. 2021. "Improvement of the Parallel Compressor Model and Application to Inlet Flow Distortion" International Journal of Turbomachinery, Propulsion and Power 6, no. 3: 34. https://doi.org/10.3390/ijtpp6030034

APA StyleBenichou, E., Binder, N., Bousquet, Y., & Carbonneau, X. (2021). Improvement of the Parallel Compressor Model and Application to Inlet Flow Distortion. International Journal of Turbomachinery, Propulsion and Power, 6(3), 34. https://doi.org/10.3390/ijtpp6030034