Abstract

This paper presents a new improved approach to calculation of polytropic performance of centrifugal compressors. This rapid solution technique is based upon a constant efficiency, temperature-entropy polytropic path represented by cubic polynomials. New thermodynamic path slope constraints have been developed that yield highly accurate results while requiring fewer computing resources and reducing computing elapsed time. Applying this thermodynamically sound cubic polynomial model would improve accuracy and shorten compressor performance test duration at a vendor’s shop. A broad range of example case results verify the accuracy and ease of use of the method. The example cases confirm the cubic polynomial methods result in lower calculation uncertainty than other methods.

1. Introduction

A highly accurate centrifugal compressor polytropic performance approximation method has been developed that is easy to employ. This real gas method is based upon a constant efficiency, temperature-entropy polytropic path. The elegance of this method is its exceedingly simple way of calculating polytropic efficiency with sufficiently high precision as required for compressor performance testing, while providing the polytropic compression path on T-s and h-s diagrams to a high degree of accuracy. A constant efficiency polytropic path can be modeled as either a single or several sequential piecewise cubic polynomial segments affording solutions that allow for determining thermodynamic state variables along a continuous path [1,2]. New analytic terms have been developed for slope and curvature of temperature versus entropy along the constant efficiency polytropic path [1]. Furthermore, a new screening method has been developed to assist in determining how many cubic polynomial segments are required to provide sufficient accuracy for a given application. Example cases are reported that demonstrate accuracy and comparisons to other polytropic performance calculation methods as well as a review of results documented by Evans [3]. Cubic polynomial endpoint path methods are demonstrated to achieve better accuracy than any other endpoint polytropic efficiency calculation method. Cubic polynomial sequential segment path methods are shown to be superior to other multi-point numerical methods described in available literature.

The Taher–Evans Cubic Polynomial method (TE-CP) provides not only overall polytropic compression performance results but has the ability to predict fluid state parameters at any arbitrary point along the polytropic compression path. The analysis is based upon an inlet flange to discharge flange constant efficiency polytropic path for a single, uncooled, compressor section that may contain multiple impellers. Thermodynamic state parameters used in the calculations are based upon total conditions at inlet and discharge measurement locations. Typically, these are pressure and temperature measurements. An Equation of State (EOS) provides all other necessary thermodynamic state parameters based upon known fluid composition, total pressures and total temperatures. These guiding principles align the TE-CP calculation method with requirements of the ASME PTC-10 [4].

1.1. Polytropic History

A compressor polytropic performance calculation method was first documented in the 1860′s by Zeuner as discussed in the 1906 English version of his thermodynamics book [5]. In the 1960’s, Schultz [6] documented an expanded version of Zeuner’s work and added a correction factor to acknowledge that fluids were neither perfect nor ideal. These polytropic analysis methods were included in the ASME PTC 10 version published in 1965 [7], resulting in the industry accepted vernacular label of “Schultz Methods”. The 1997 version of ASME PTC 10 [4], retained the basic Schultz methods but changed the path definition model from constant efficiency dictated by [6,8], to constant polytropic exponent, which is an incorrect definition for the polytropic process of real gas compression. While useful for some applications, Schultz’s methods have been shown to provide results that are less accurate than required, especially near a fluid’s critical point and in the dense phase region [9].

Since Schultz’s methods were first codified by ASME, analysts have published suggested refinements, improvements and alternatives. Some notable references are, Kent [10]; Mallen and Saville [9]; Nathoo and Gottenberg [11,12]; Huntington [13,14]; Hunseid, et al. [15]; Oldrich [16]; Sandberg and Colby [17]; Taher [18]; Wettstein [19]; Plano [20]; Evans and Huble [21,22]; Sandberg [23]; Taher [1]. The variations included the use of several different polytropic path equations as well as a plethora of numerical integration techniques. Evans and Huble [21] provided concise reviews of several of these methods while a tutorial by Evans and Huble [22] provided implementation details for some of them.

It is important for the reader to keep in mind that any calculated polytropic path is an approximation based upon an assumed model of the actual thermodynamic process rather than an absolute knowledge of the exact path. However, in much of the currently available technical literature on the subject, Schultz’s methods have been described as an almost universal default definition for “polytropic performance”. Evans and Huble [22], pointed out the error of assuming that Schultz’s formulas represent “a fundamental truth instead of a model used for convenience”. George Box, a statistician, said “Remember that all models are wrong; the practical question is how wrong do they have to be to not be useful” [24]. While Schultz’s methods are acceptable for introducing polytropic concepts in a classroom, their limitations must also be taught. When using any mathematical model of a constant efficiency polytropic path, an analyst must understand the limitations of the model and take care not to apply it outside of its useful boundaries. This paper thoroughly documents the thermodynamic soundness and superior features of the Taher–Evans Cubic Polynomial methods for calculation of polytropic efficiency to satisfy the requirements of ASME PTC-10 [4].

In the quest to provide improved calculation methods for the PTC-10 code, the reality of how OEMs operate compressor test stands was taken into account. Real time performance analyses and results can be provided by existing, dedicated, data acquisitions systems, which can significantly shorten testing duration and thus, lower costs. This imposes two competing requirements on polytropic efficiency calculations within the computing systems; namely: (1) high accuracy and (2) rapid solutions.

Many publications have documented that numerical methods satisfy the first requirement. However, numerical solutions typically involve significant resources and computing elapsed time. The Taher–Evans Cubic Polynomial methods described in this paper have been shown to uniquely satisfy both requirements stated above as well as provide a thermodynamically sound documentation of the theory behind the solutions.

1.2. Polytropic Process

Unlike an isentropic process, the polytropic process accounts for degradation of energy. Converting mechanical work to gas energy in a compressor results in the useful compression work, , which is always less than the gas enthalpy change, , by the amount of as shown in Equation (1).

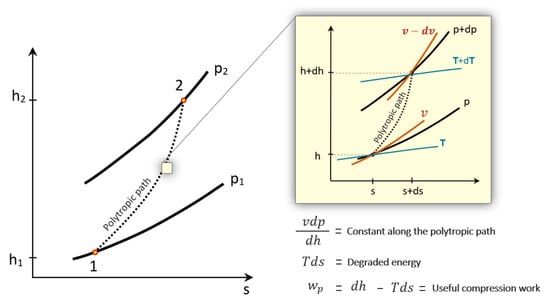

The polytropic compression process is defined as a reversible and non-adiabatic process, in which the ratio of useful compression work, to the change of enthalpy, , remains constant along the polytropic compression path as defined by Equation (2) and illustrated in Figure 1.

Figure 1.

Polytropic compression path on the h-s Diagram.

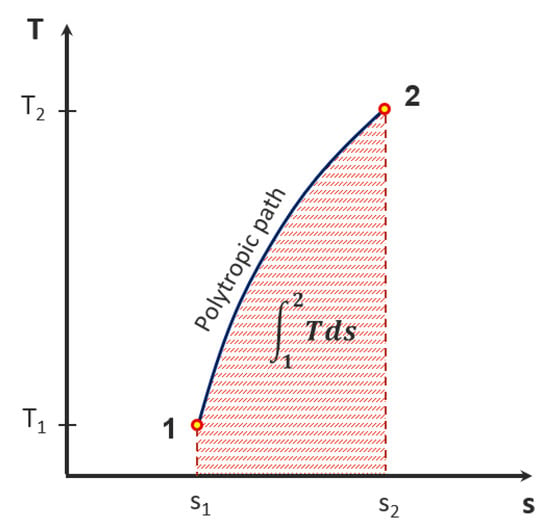

Since the polytropic process is defined as a reversible process, the degraded energy can be represented by heat, which is equal to . The polytropic work as the measure of useful compression work, is the difference between the total enthalpy change and the area under the polytropic path on the T-s diagram between inlet and discharge, as illustrated in Figure 2. Substituting Equation (1) into Equation (2) yields a convenient form for compressor polytropic efficiency shown in Equation (3).

Figure 2.

Area under the polytropic path on the T-s diagram represents degradation of energy in a polytropic compression process. Additionally, see Figure 10 for different possible curve shapes of the polytropic path between endpoints.

The compressor polytropic efficiency always deviates from unity () for an uncooled compressor section ().

The shape of the polytropic path on the T-s diagram, which illustrates the gas behavior as temperature and entropy increase during the compression process, can significantly influence the value of degraded energy, . Additionally, the use of different equations of state to predict thermodynamic conditions along the polytropic compression path can greatly influence the results, as illustrated by example cases in Appendix D.

2. Polytropic Path: Polynomial Approximation Methods

The constant efficiency polytropic path on the T-s diagram is a continuous real-valued function of entropy defined on a bounded interval . This actual polytropic path can be approximated to a high degree of accuracy using a single polynomial or a series of sequential piecewise segment polynomials. The concept is to accurately estimate the actual unknown temperature function, T(s), by an approximating function that is simple but accurate enough (i.e., within acceptably small error tolerances) to calculate , which is the degraded part of energy transfer in the polytropic compression process. Taher [1], documented the mathematics of applying sequential piecewise cubic polynomials to approximate a constant efficiency temperature-entropy polytropic path.

The temperature-entropy relationship along the polytropic path can be approximated using a single polynomial for the entire range from inlet to discharge. This is referred to as an “Endpoint” method since the thermodynamic state variables at both compressor inlet and discharge are required inputs and are known from testing. For some applications, when a single polynomial cannot provide sufficient accuracy, a series of sequential steps or segments of polynomials can be employed. The following sections will discuss and compare first- and third-degree polynomial approximants as used to calculate . First degree polynomials are described as using “steps” while third degree polynomials are described as using “segments”. This distinction is due to the discontinuity of path slope change for linear steps whereas sequential piecewise cubic segments possess a continuous slope change. It will be shown that this continuity of slope at the knots gives rise to increased accuracy while using fewer segments to achieve the desired accuracy.

2.1. Temperature-Entropy Polytropic Path Approximation: Linear Polynomial Endpoint Method

A linear straight-line approximation between inlet and discharge conditions has been used by Kent [10] and Sandberg [23] to approximate the actual polytopic path on the T-s diagram. Neither Kent nor Sandberg explicitly mentioned employing a linear approximation for the polytropic path on the T-s diagram, but in fact a straight-line approximation of temperature, T, as a function of entropy, s, is used in their linear approximation method. Since pressure and temperature are known at both endpoints, all other thermodynamic properties at inlet and discharge can be determined by an equation of state.

Equation (4) represents temperature as a function of entropy connecting compressor section inlet and discharge points on a T-s diagram. The form of the function is a classic straight line.

The constraints applied to Equation (4) are shown in Equations (5) and (6).

Equations (7) and (8) show the analytically derived values for the slope and intercept of the straight-line approximant. These values are constant and only dependent upon the thermodynamic parameters at the compression endpoints.

Substituting Equations (7) and (8) into Equation (4) yields Equation (9), , which is a first-degree polynomial that approximates the actual polytropic path .

The deviation of the approximated temperature from the actual temperature value using a linear approximant is represented by the error function in Equation (10).

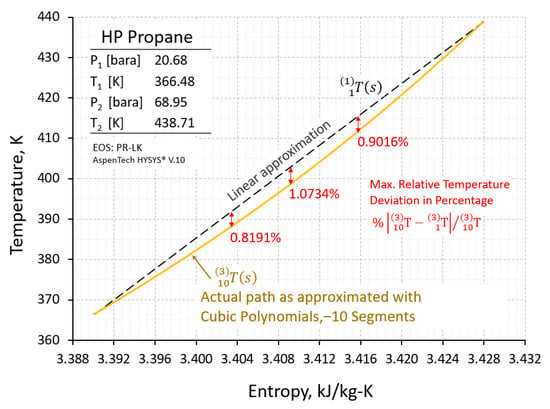

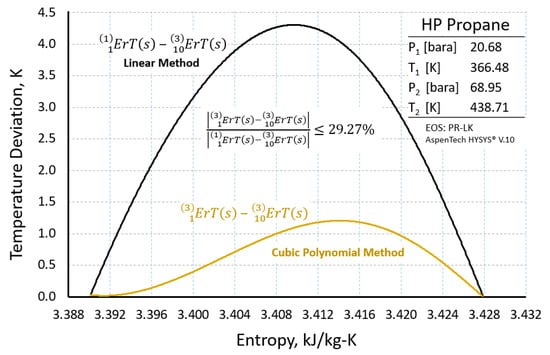

As shown in Figure 3, temperature deviation varies along the polytropic path in the interval from the compressor section inlet to discharge. The actual polytropic path may largely deviate from a straight line connecting the endpoints.

Figure 3.

Temperature deviation of the linear approximant from the actual polytropic path as approximated with 10-segment piecewise cubic polynomials is shown. The highest temperature deviation is 4.276 K (1.0734% relative deviation), in the middle of the interval range (s = 3.409 kJ/kg-K). The error in estimating the degraded energy is (0.698% relative deviation), which is represented by the area bounded between the two curves of .

The term in Equation (11) shows the error in calculating using a linear approximation for the temperature-entropy relationship between endpoints of the polytropic compression path.

The error can only be estimated by comparing the result against a more accurate approximation for the polytropic path. In this paper, a 10-segment cubic polynomial method (i.e., using approximants) is used as the basis of evaluation. (See Appendix B for confirmation of the accuracy of the multi-segment cubic polynomial method as applied with 10 segments).

Employing a straight line as the approximant to model the actual polytropic path on the T-s diagram overly simplifies the actual compression path resulting in reduced accuracy of the calculation for the and thus the resulting polytopic efficiency rendering the polytropic work values less accurate. For example, as illustrated in Figure 3, a linear approximation for the polytropic path on T-s diagram overestimates the degraded energy (i.e.,) by the bounded area between the linear approximant and the actual path as estimated with the cubic polynomial method. A linear approximant is inherently limited to a fixed constant slope along the entire polytropic path. This is a major factor in estimating the with large errors using a linear endpoint approximant.

2.2. Temperature-Entropy Polytropic Path Approximation: Cubic Polynomial Endpoint Method

The desire to improve the accuracy of approximating the actual polytropic path on the T-s diagram has led to employing the approximant function as a cubic polynomial. Polynomials of the first degree and second degree are limited since they cannot account for path slope changes and concavity of the actual polytropic path respectively. A polynomial of the third degree is the simplest form of a polynomial approximant, which allows the model to account for these two important features. As explained later in this paper (see Section 4), the slope and concavity of the polytropic path on the T-s diagram reveal significant thermodynamic insight about the behavior of fluids during the compression process and must be carefully studied.

Using Equation (12), the actual temperature that increases with entropy, along the polytropic path of a compressor section can be approximated using the third-degree polynomial .

Since thermodynamic conditions at endpoints are known, the constraints applied to Equation (12) are shown in Equations (13)–(16).

Relationships (15) and (16) determine values of the slope of the temperature-entropy curve at endpoints of the polytropic path. For details on how these equations are derived from thermodynamic relationships, see Appendix A.

Coefficients A, B, C and D of the third order polynomial in Equation (12) are “analytically” derived from the known conditions above. The results are shown in Equations (17)–(20).

Coefficient A accounts for the deviation of the average value of the slope at the endpoints, , from that of the straight line, which connects the endpoints, (. Coefficient B accounts for the change of slope along the polytropic path. When the polytopic path on the T-s diagram approaches to a straight line that connects the endpoints, (e.g., in the case of compressing an ideal gas) coefficients A and B approach zero and coefficients C and D represent the slope and the intercept of the straight line as shown in relationships (7) and (8).

The deviation of the temperature approximated using a cubic polynomial approximant from the actual temperature value is shown by the error function in Equation (21). The temperature deviation varies along the polytropic path in the interval from the compressor inlet to discharge.

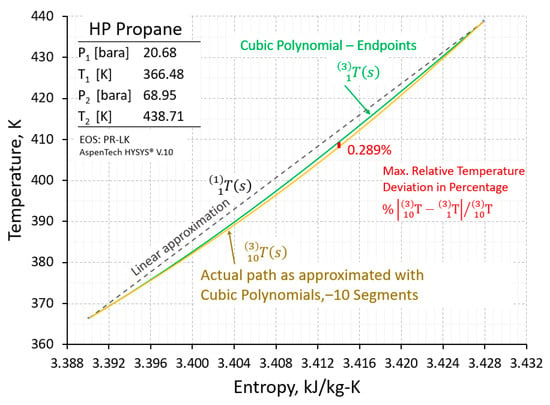

As illustrated in Figure 4, the deviation of approximated temperature from the actual temperature shows significant improvement for the cubic polynomial approximation over the linear version, which is expected since .

Figure 4.

Temperature deviation of the cubic polynomial endpoint method from the actual polytropic path as approximated with 10-segment piecewise cubic polynomial approximants is shown. The highest temperature deviation is 1.185 K (0.289% relative deviation), at s = 3.414 kJ/kg-K. The error in estimating the degraded energy is (0.157% relative deviation), which is represented by the area bounded between the two curves of .

Figure 5 compares the temperature deviation of the linear, and cubic polynomial, endpoint approximants from the highly accurate polytropic path as approximated with a 10-segment piecewise cubic polynomials, for the high pressure propane case with the endpoint conditions shown on the figure. The cubic polynomial endpoint approximant provides a maximum temperature deviation that is less than a third of that of the linear endpoint approximant.

Figure 5.

Distribution of temperature deviation shows the maximum error of cubic polynomial endpoint approximant is less than one third of the linear endpoint approximation.

The term in Equation (22) shows the error in calculating using the cubic polynomial endpoint approximation.

The improved accuracy of calculating using the cubic polynomial endpoint approximant, , as compared to the linear approximant, , can be calculated using Equation (23).

Equation (23) shows that the accuracy of the cubic polynomial approximant as compared to a linear approximant increases for compression applications with a large difference between the slopes at the endpoints. As explained in the next section of this paper, this analytical relationship conveniently provides a means to evaluate accuracy of the linear endpoint method.

3. Polytropic Efficiency Calculation

Since the late 19th century, various calculation methods have been proposed to estimate polytropic efficiency. The polytropic efficiency can only be estimated. The accuracy of the estimation depends upon the calculation method and the accuracy of thermodynamic properties used in the calculation. As shown in this paper, different equations of state for a fixed method can result in variation of polytropic efficiency values, which may be even larger than the effect of measurement uncertainties. It is important to ensure that the same equation of state as used for calculating expected performance is used when calculating polytropic efficiency based on equipment test results.

Regardless of which calculation method is used, usually five significant digits can well serve the purpose for any compressor performance evaluation. Accuracy of measured inlet and discharge conditions as well as of the equation of state and test data used to obtain thermodynamic properties for the calculation method may impose to reduce the number of significant digits. The identification of significant digits is only possible through knowledge of the circumstances [25]. However, in this paper, the intended precision of polytropic efficiency is chosen as five significant digits in order to evaluate different polytropic efficiency calculation methods.

A novel approach is used in this paper to differentiate between the actual polytropic efficiency (for a fixed calculation method and EOS) from the calculated polytropic efficiency by using an error function, . This is believed to help clarify that regardless of the calculation method, the actual polytropic efficiency, , can only be estimated with some acceptable error, , as compared to a more accurate reference method. In this paper, the Taher–Evans Cubic Polynomial 10-segment method is used as the basis to compare the accuracy of other methods.

3.1. Polytropic Efficiency Calculation: Linear Polynomial Endpoint Method

In the simplest case, the polytropic path can be approximated using a linear approximant, which connects the endpoints (i.e., one step) as follows:

The degraded energy in the polytropic compression process, , is approximated using the linear endpoint approximant :

By replacing from (24) and analytically performing the integral using the relationship (9), the relationship (26) emerges:

Using the relationships (2) and (26), the polytopic efficiency, , as approximated with the linear endpoint approximation method is developed as follows:

The deviation of the approximated endpoint polytropic efficiency, , from the actual polytropic efficiency, , using the linear endpoint approximant, , is represented by the error function in Equation (28).

A similar relationship to (27) for calculating the polytropic efficiency was suggested by Stepanoff [26] in 1955.

3.2. Polytropic Efficiency Calculation: Taher–Evans Cubic Polynomial Endpoint Method

In a more accurate case, the polytropic path can be approximated using a cubic polynomial, which connects the endpoints (i.e., one segment) as follows:

The degraded energy in the polytropic compression process, , can be approximated using the cubic polynomial endpoint approximant, :

By replacing from (29) and analytically performing the integral, using relationships (17)–(20), the relationship (31) emerges:

Using the relationships (2) and (31), the polytopic efficiency, , as approximated with the cubic polynomial endpoint approximation method is developed as follows:

Equation (32) can be solved recursively by assuming an initial value for the efficiency to calculate endpoint slopes and , calculating the resulting efficiency from (32), and minimizing the difference between assumed and calculated efficiency.

The deviation of the approximated endpoint polytropic efficiency, , from the actual polytropic efficiency, , using Taher–Evans cubic polynomial endpoint approximant , is represented by the error function in Equation (33).

By comparing relationships (27) and (32) the efficiency deviation between the linear and cubic polynomial endpoint methods can be developed as follows:

As shown by the relationship (34), the deviation linearly increases with the change of slopes, , at endpoints. This analytical relationship conveniently provides a means to evaluate accuracy of the linear methods as applied to endpoints.

Once the polytropic efficiency, is determined, coefficients A, B, C, and D are calculated, and the polytopic path model on T-s and h-s diagrams can be graphically represented using relationships (29) and (51).

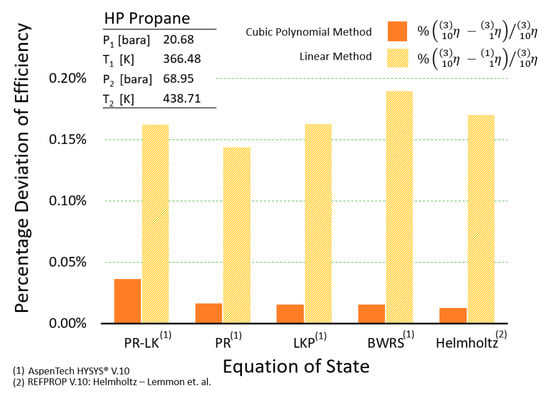

Figure 6 compares the efficiency deviation of the linear endpoint and cubic polynomial endpoint methods from the highly accurate 10-segment cubic polytropic efficiency, using different equations of state for the high pressure propane case with the conditions shown on the figure. Evidently, the linear endpoint method involves significantly larger deviations for the polytropic efficiency as compared with the cubic polynomial endpoint method.

Figure 6.

Percentage deviation of polytropic efficiency of the linear, and cubic polynomial, endpoint methods from the highly accurate 10-segment cubic polynomials polytropic efficiency,, as calculated using different equation of states.

Using illustrative examples in Appendix B, it is shown that Taher–Evans cubic polynomial endpoint method provides the highest accuracy among all other endpoint methods.

3.3. Polytropic Efficiency Calculation: Linear Multistep Method

As illustrated in Figure 3 and Figure 6, the linear approximant, , when applied to endpoints may introduce large deviations from the actual T-s polytropic path resulting in reduced accuracy for the calculated polytropic efficiency, . By applying the composite trapezoidal rule, the integral is approximated by employing piecewise linear polynomial approximants that cover the entire path in multiple steps with smaller subintervals .

In the linear multi-step method, temperature deviation along the polytropic path reduces as the number of steps, , which approximate the entropy interval increases.

where for the th step, is defined in the sub-interval .

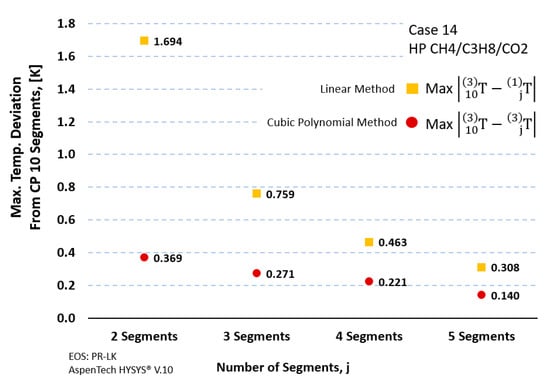

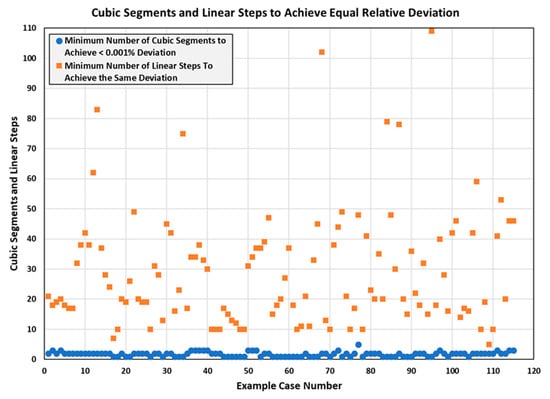

As shown in Figure 7, maximum temperature deviation along the polytropic path reduces as the number of steps increases. As expected, linear approximation involves larger deviation as compared with cubic polynomial approximation for the same number of steps or segments. As reviewed in Appendix C, a maximum of five cubic polynomial segments has been documented to provide sufficient accuracy for a broad range of example cases by Evans [3].

Figure 7.

Maximum temperature deviation along the polytropic path for the example case 14. See Table A1 in Appendix B for gas compositions and compressor inlet and discharge conditions.

The degraded energy in the polytropic compression process, , is approximated by dividing the path into j-steps and using a linear approximant for each step.

where shows the error in approximating the integral, , by using the linear approximant in the subinterval . By summing up errors of all j-steps, the total error for approximating the integral , with linear approximants using j-steps is developed:

By applying the relationship (26) for each step, and using the composite trapezoidal rule, the integral, , is approximated as follows:

Using the relationships (2) and (38), the polytopic efficiency, , is developed as follows:

The deviation of the approximated polytropic efficiency, , from the actual polytropic efficiency, using linear approximants, , at each step is represented by the error function, in Equation (40).

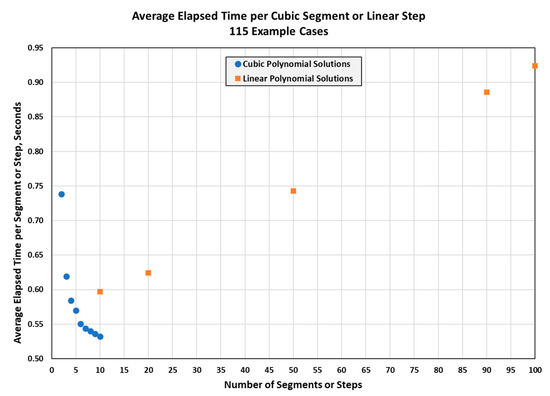

Because the linear method ignores the change in slope and concavity along the compression path, a large number of steps are needed to achieve the desired accuracy. Sandberg [23] provided no criteria to determine the required number of linear steps to approximate . The uncertainty about the required number of steps in the linear multi-step method could possibly be overcome by applying a large number of linear steps (50 to 100+ steps) to ensure sufficient accuracy. However, pre-selecting 50 or 100+ linear polynomial steps has been shown to be inefficient, (see Figure 11). Utilizing a large number of linear steps significantly increases the calculation time due to the required nested iteration loops. Figure A3b documents a comparison of elapsed time measurements for the supercritical propane example case.

3.4. Polytropic Efficiency Calculation: Taher–Evans Cubic Polynomial Multi-Segment Method

The T-s polytropic path can be accurately approximated with a set of piecewise thermodynamically coupled cubic polynomials. The T-s polytropic path is divided into “j” segments over the entropy range, [], from compressor section inlet to discharge. Each subinterval of the actual path, is approximated by a cubic polynomial approximant, , which allows the temperature as well as T-s polytropic path slope, to be matched at endpoints of adjacent segments, thus increasing accuracy while smoothing the overall path. The key factor in the accuracy of cubic polynomial multi-segment method as compared with the linear multistep method is taking advantage of applying the thermodynamic constraint, at each intermediate point (knot) to enable smooth transition from one to the following segment.

The relationship (41) shows the actual temperature-entropy path, as approximated with a set of “” cubic polynomial approximants, , and the temperature deviation at each segment,

where at each segment is determined by:

The coefficients , of each cubic polynomial approximant are calculated using the relationships (17) to (20), where subscripts 1 and 2 are replaced with endpoint conditions of the th segment.

Similar to relationships (30) and (31), the degraded energy is calculated, and its related error, , at each segment are defined. The total error for approximating the integral , using cubic polynomial approximants is determined by summing up errors of each segment.

By applying the relationship (32) for each segment, the integral, , is approximated as follows:

Using the relationships (2) and (44), the polytopic efficiency is developed as follows:

The deviation of the approximated polytropic efficiency from the actual polytropic efficiency, using cubic polynomial approximants at each step is represented by the error function in Equation (46).

3.4.1. Polytropic Efficiency Calculation Procedure: Taher–Evans Cubic Polynomial Multi-Segment Method

The solution requires an initial estimate of efficiency and then recursive solutions for segment discharge temperature. Equation (45) is solved recursively by assuming an initial value for the efficiency, to calculate endpoint slopes and , calculating the resulting efficiency from (45), and minimizing the difference between assumed and calculated efficiency. The step-by-step procedure is explained as follows:

Note: inlet and discharge pressures and temperatures discussed below are assumed to be for total conditions at a given compressor section.

- (1)

- Determine an initial estimate of polytropic efficiency by assuming in the relationship (45) for the cubic polynomial endpoint method.Note: for the purpose of compressor performance testing, the initial value of the efficiency is the expected efficiency provided by the compressor manufacturer.

- (2)

- Select the number of segments ().There are different ways to select intermediate knots. In this paper, the overall pressure ratio is divided across the number of segments () to determine equal pressure ratio steps as shown in the next step.

- (3)

- Use “” number of equal pressure ratio segments..

- (4)

- Use Equation (29) to estimate the initial value of segment outlet temperature. (This requires a solution to the cubic polynomial endpoint method).Note: steps 1 through 4 are only required for the initialization of the solution algorithm.

- (5)

- Calculate segment temperature rise,

- (6)

- Calculate the segment polytropic efficiency using the relationship (45).

- (7)

- Calculate efficiency deviation from the initially estimated polytropic efficiency from step 1.

- (8)

- Iterate segment outlet temperature to match assumed efficiency.Note: different root finding algorithms may be used to optimize iterations for segment outlet temperature.Note: the acceptable efficiency convergence should be set less than

- (9)

- Move to next segment using outlet conditions of previous segment as inlet conditions.

- (10)

- Repeat steps 5 through 9 for each segment.

- (11)

- Compare final discharge temperature with the given value,

- (12)

- If step 11 result is not within a small tolerance, iterate efficiency and determine new values for coefficients A, B, C and D.

- (13)

- Repeat steps 5 through 11 until agreement is reached within the tolerance.Note: the acceptable convergence from the given discharge temperature should be set less than

In the Taher–Evans Cubic Polynomial method, intermediate points are determined by setting one thermodynamic variable (such as pressure or entropy) at each end of a segment and calculating other thermodynamic variables to force the segment endpoint to lie on a constant efficiency path via nested recursive algorithms (within a small error tolerance). Using cubic polynomial approximants, the polytropic path slope can be accurately calculated since the first derivative of each segmental polynomial can be determined at each intermediate point (see Ei and in Equation (42)).

The difference between final segment calculated discharge temperature and the known discharge temperature, Td, can be minimized by iterating efficiency. These nested iterations of efficiency (inner loop) and the final segment discharge temperatures (outer loop) converge quickly.

When a final efficiency is determined, summations of enthalpy changes and losses can be performed for the entire set of segments. The cubic polynomial multi-segment method provides intermediate points along the constant efficiency temperature-entropy path that have been forced to coincide with the actual path. Additionally, the path slope at each intermediate point is equal at the end of the th segment and the beginning of the i+1 segment. See Table 1.

Table 1.

Cubic polynomial 5-segment method as applied for Case 10 using AspenTech Hysys V.10 [27] and PR-LK equation of state. See Table A1 in the Appendix B for gas compositions and compressor inlet and discharge conditions for Case 10.

3.4.2. Distinction between Cubic Interpolation and Approximation

As the final point in this section, it should be noted that the approximation of functions is different from interpolation. In the case of interpolation, at certain intermediate points, the value of an unknown function is given (such as measured values at intermediate points), but the function itself is not known. Interpolating cubic splines are used to interpolate between known intermediate points, which is irrelevant in the problem of approximating an unknown function without any given intermediate point. Accordingly, the descriptor “spline” is not applied in this paper as it usually is thought of as being used to approximate a curve passing through previously known knots.

4. Polytropic Path on Temperature-Entropy Diagram

For an uncooled compressor section, entropy increases along the polytropic path. The rate of change of temperature with entropy at each point along the polytropic path is determined with the relationship (A10) from Appendix A.

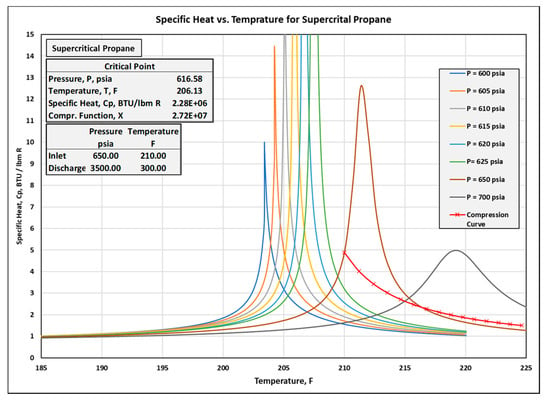

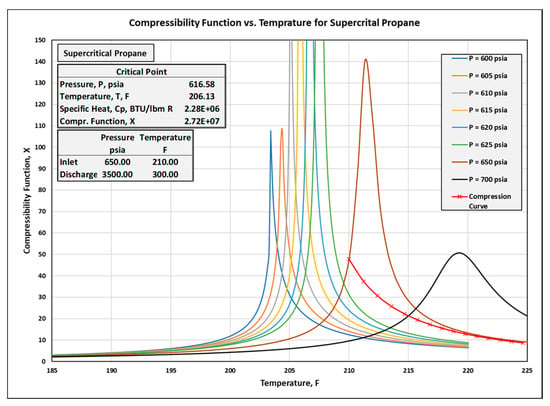

The change of temperature with entropy from the compressor section inlet to discharge varies as temperature, specific heat, , and compressibility function, , change at each point along the compression path. At conditions near to the critical point, the rate of change of and is usually large. This has significant impact on the change of temperature with entropy as the relationship (A10) suggests. The supercritical propane example case has inlet conditions extremely close to the critical point and the thermodynamic properties are varying rapidly as compression begins. Figure 8 and Figure 9 illustrate the variation of specific heat, , and compressibility function, , respectively, in the vicinity of the critical point. Each isobar has a distinct peak. The inlet conditions lie in an area on the flank of a peak while discharge conditions (not shown) are far removed from the critical area peaks. Equations (15) and (16) would show a large difference in slope of the T-s path between inlet, , and discharge, , as documented in Table A2. These large differences are one indicator of the difficulty of a compression case.

Figure 8.

Change of specific heat, , along the polytropic path for supercritical propane example. Moreover, the change of specific heat, , with temperature at different inlet pressures is shown.

Figure 9.

Change of compressibility function, , along the polytropic path for supercritical propane example. Furthermore, the change of compressibility function, , with temperature at different inlet pressures is shown.

While the change of temperature with entropy along the compression path of an uncooled compressor section is always positive , the curvature of the polytropic path on the T-s diagram may change sign (from concave upward to downward or vice versa). A change in sign happens when equals to zero at any point along the compression path which indicates a change of curvature (as seen in the case of HP Ethylene in Appendix B).

The cubic polynomial endpoint method can be used to approximate the concavity of the actual T-s polytropic path. No other endpoint methods can provide such a mathematical and thermodynamic insight about the behavior of the actual T-s polytropic path from known thermodynamic conditions at the inlet and discharge of the compressor section.

The concavity of the polynomial approximant can be examined using the second derivative test of the path equation with the following criteria:

- If is out of the range of and the upward concavity of the cubic polynomial approximant, is unchanged along the path. See Figure 10 curve I.

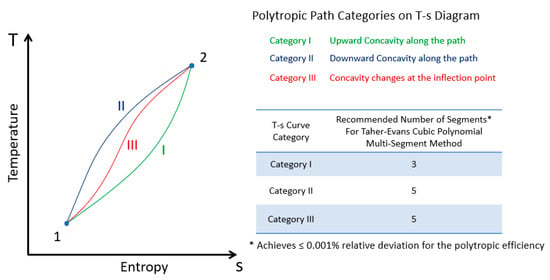

Figure 10. Three different categories are identified based upon polytropic compression path shapes on the T-s diagram. The number of cubic polynomial segments required to achieve ≤0.001% relative deviation for the polytropic efficiency is shown.

Figure 10. Three different categories are identified based upon polytropic compression path shapes on the T-s diagram. The number of cubic polynomial segments required to achieve ≤0.001% relative deviation for the polytropic efficiency is shown. - If is out of the range of and the downward concavity of the cubic polytropic approximant, is unchanged along the path. See Figure 10 curve II.

- If the concavity of the cubic polytropic approximant, changes at the inflection point . See Figure 10 curve III.

Downward concavity is an indication of increased difficulty for the compression case as shown and confirmed by example cases in Appendix B. See Appendix B for several compression cases evaluated.

The actual location of the inflection point on the T-s polytropic path can be more precisely approximated by applying the cubic polynomial multi-segment method.

The rate of change of with entropy can be considered as a screening criterion to determine the difficulty of a compression case.

The curve shape of the polytropic path as predicted by the cubic polynomial endpoint method provides an easy to apply criteria to determine how many multi-segments to employ to assure an acceptable relative deviation. Based on 115 cases covering 22 fluids (7 pure fluids and 15 mixtures reviewed in Appendix C) studied by Evans [3], the number of cubic polynomial segments required to achieve ≤0.001% relative deviation for the polytropic efficiency is three segments for Category I and five segments for Categories II and III.

5. Enthalpy Change with Entropy along the Polytropic Path

The relationship (2) can be rearranged to

As the efficiency of the polytropic process is constant, the slope of the tangent to the path increases as the temperature rises along the compression path (. Rearranging the relationship (47) and taking the derivative with respect to gives:

By replacing with , the second derivative of the function h(s) along the polytropic compression path appears:

For an uncooled compressor section, . Therefore, > 0. As shown in Figure 1, the polytropic compression path defined with function h(s) is always concave upward along the compression path since the second derivative is positive in an uncooled compressor section. Equation (A11) in Appendix A provides the thermodynamic value of at any point along the polytropic compression path.

The change of enthalpy with entropy at any point along the polytropic path can be approximated by substituting the relationship of temperature from (12) to (47):

By integrating (50), the relationship of enthalpy and entropy can be approximated at any point along the polytropic path:

where, represents any entropy value between compressor section inlet, and section discharge, .

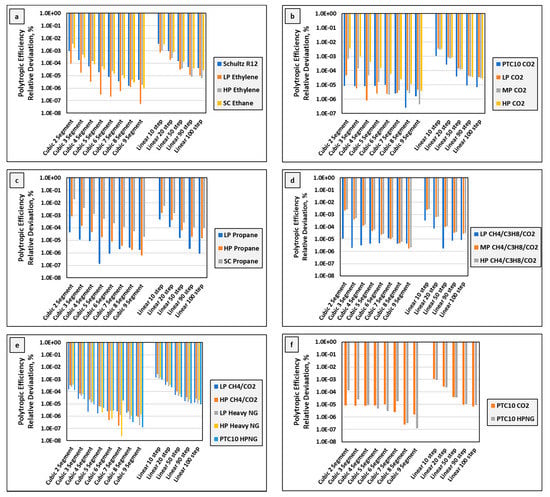

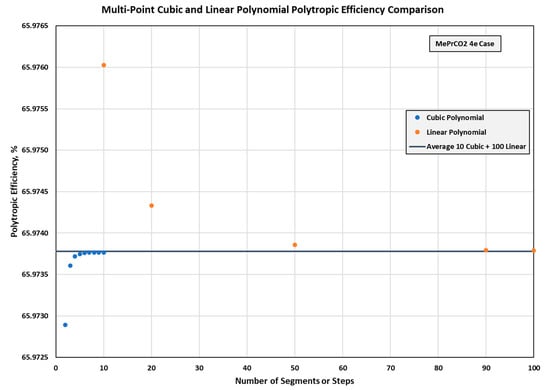

6. Comparison of Cubic and Linear Polynomial Results

The Taher–Evans Cubic Polynomial 10 segment method is used as a comparison standard to determine relative deviations in polytropic efficiency for all other methods. See Equation (A12) for the relative deviation definition. The number of recommended cubic segments based upon T-s path curve shapes listed in Figure 10 was developed from results reported by Evans [3]. Figure 11 shows that determining a similar set of recommendations for the number of linear polynomial steps required was not possible. The wide scatter of the linear methods’ results that would yield similar accuracy to the cubic methods was very random.

Figure 11.

Cubic and linear polynomial solution results comparison for 115 example cases.

Appendix B and Appendix C discuss example cases and compare various polytropic calculation methods. The 19 example cases in Appendix B were selected for illustration of a range of relatively easy and difficult polytropic efficiency calculation applications. Several of these are used to show various characteristics of the calculation results. Appendix C is a review of 115 example cases studied by Evans [3], and includes the 19 example cases from Appendix B. This larger population further confirms and documents the trends discovered when applying the multi-segment cubic and multi-step linear polynomial methods.

7. Conclusions

- The Taher–Evans Cubic Polynomial method (TE-CP), defined, described and tested herein, illustrates that a highly accurate calculation method for real gas centrifugal compressor polytropic performance efficiency has been developed and implemented that employs a temperature—entropy cubic polynomial path function.

- ○

- Both endpoint and sequential segment versions are described and tested.

- ○

- Previously published polytropic efficiency calculation methods including first degree linear polynomial methods are shown to be less accurate and/or slower to achieve a solution than Taher–Evans Cubic Polynomial methods.

- ○

- The TE-CP methods’ superior results are due to the cubic polynomial path having additional thermodynamic constraints applied to more accurately approximate the actual path slope at any point along the path. Determination of path slope at the compression endpoints is independent of performance calculation method.

- ○

- T-s polytropic path curve shapes can be determined from derivatives of the cubic polynomial path equation and are indicative of calculation relative difficulty. The curve shape is used as a criterion to select the required number of cubic segments. No other polytropic method can provide such a mathematical and thermodynamic insight into the fluid compression process.

- ○

- The number of T-s path cubic polynomial segments required to achieve an acceptable relative deviation ≤0.001% for polytropic efficiency is three segments for category I and five segments for categories II and III curve shapes.

- ○

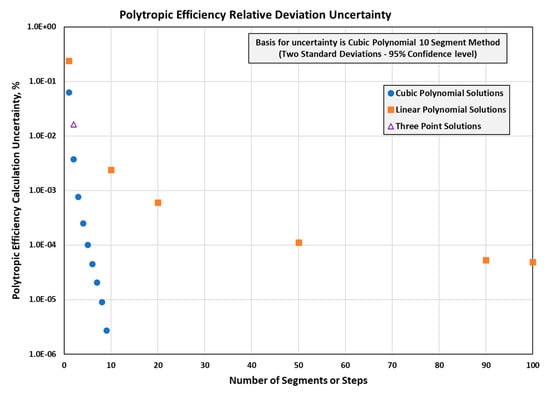

- As shown in Figure A10, the cubic polynomial methods provide low uncertainty with only a few cubic segments. Uncertainty is based upon polytropic efficiency relative deviation, and its magnitude is related to the size of the statistical population.

- ○

- Cubic polynomial methods provide continuous equations to plot the polytropic path on T-s and h-s diagrams. This is a very unique feature of the cubic polynomial method that enables visualizing the polytropic path.

- ○

- The cubic path coefficients (A, B, C, and D) in Equation (12) provide meaningful insights about the behavior of the polytropic path on the temperature-entropy diagram.

- ○

- The Taher–Evans Cubic Polynomial methods are highly suitable for application to compressor performance testing according to ASME PTC 10 [4].

- Cubic and linear polynomial calculation methods have been extensively documented and compared.

- ○

- Polytropic efficiency calculations have been reviewed for 17 methods across 115 example cases yielding a total of 1955 independent calculations that validate superior results are achieved when using both endpoint and sequential segment Taher–Evans Cubic Polynomial (TE-CP) polytropic path methods. A total of 22 fluids were employed including seven pure fluids and 15 fluid mixtures to cover wide ranges of mole weight and critical pressures and temperatures.

- ○

- Cubic polynomial endpoint path methods were demonstrated to achieve better accuracy than any other endpoint polytropic efficiency calculation method.

- ○

- Cubic polynomial sequential segment path methods were demonstrated to achieve high accuracy acceptable polytropic efficiency results significantly faster with fewer segments required than linear polynomial path methods based upon 115 compression example cases.

- ○

- For all 115 example cases, T-s polytropic paths agreed between 10 cubic segments and 100 linear steps which confirmed the validity of using the result of 10-segment cubic polynomial approximants as the standard for comparison for polytropic efficiency relative deviation and uncertainty.

- ○

- Cubic polynomial path methods show that the required number of segments to achieve an acceptable result remains within a maximum of five segments or less for all the cases studied. For the linear polynomial path method, the required number of steps did not follow a regular pattern as shown in Figure 11. No rule or algorithm can be determined for the required number of linear polynomial steps to achieve an acceptable result.

- ○

- While both cubic and linear polynomial methods can reach acceptable results, the cubic methods require fewer repetitive iterations and are completed much faster. Sequential segment cubic polynomial method calculations are typically at least an order of magnitude faster than sequential step linear polynomial methods. This is a clear advantage for cubic methods when processing compressor performance test data in real time.

- ○

- The cubic polynomial methods provide an order of magnitude lower uncertainty with significantly fewer cubic segments than linear polynomial methods. (See Figure A10).

- ○

- The cubic polynomial methods’ uncertainty rapidly decreases as the number of segments increases while the linear polynomial methods illustrate a much more gradual decrease in uncertainty as they approach an asymptote. The linear polynomial methods uncertainty asymptote appears to be more than an order of magnitude greater than the cubic methods.

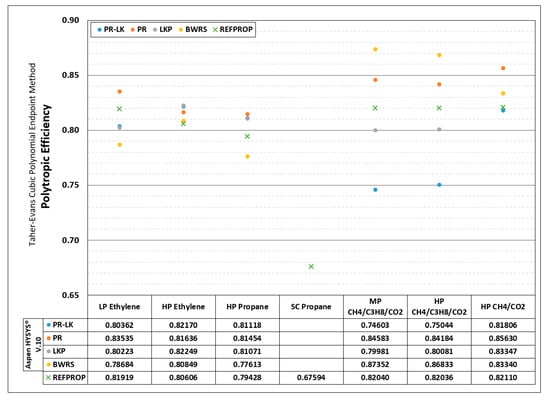

- Identical calculations for selected example cases using several different equations of state to obtain thermodynamic state point data for application of cubic and linear polynomial methods revealed significant differences in results for efficiency can occur based upon the chosen EOS. See Appendix D for selective examples.

Recommendations

- When rapid, highly accurate, low uncertainty, centrifugal compressor polytropic efficiency calculations are required, the Taher–Evans Cubic Polynomial methods (TE-CP) should be used.

- Due to significant differences found between results when employing various equations of state, it is recommended that a project use the same equation of state throughout the project timeline to avoid potential discrepancies.

Author Contributions

Conceptualization and methodology, M.T.; software, validation, formal analysis, writing—original draft preparation, writing—review and editing, M.T. and F.E.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| A | Polynomial approximant coefficient |

| B | Polynomial approximant coefficient |

| b | Linear approximant coefficient |

| Isobaric expansivity, | |

| BWRS | Benedict–Webb–Rubin EOS as modified by K. E. Starling |

| C | Polynomial approximant coefficient |

| CH4 | Methane |

| CO2 | Carbon Dioxide |

| C3H8 | Propane |

| CP | Cubic Polynomial |

| Cp | heat capacity at constant pressure |

| D | Polynomial approximant coefficient |

| E | Slope of the polytropic path on the T-s diagram, |

| EOS | Equation of State |

| Deviation of polytropic efficiency | |

| Deviation of approximated temperature | |

| Deviation of approximated | |

| EOS | Equation of State |

| h | Specific enthalpy |

| HP | High pressure |

| OEM | Original Equipment Manufacturer |

| PR | Peng-Robinson EOS |

| PR-LKP | Peng-Robinson EOS and the Lee-Kesler EOS for the calculation of enthalpies |

| LP | Linear Polynomial, or Low Pressure |

| LKP | Lee-Kesler-Plöcker EOS |

| m | Linear approximant coefficient |

| MP | Medium Pressure |

| Schultz [6] polytropic volume exponent as applied in | |

| T | Temperature |

| TE-CP | Taher–Evans Cubic Polynomial |

| REFPROP | Reference properties EOS software |

| s | Specific entropy |

| SC | Supercritical |

| Specific volume | |

| Compressibility function, | |

| Schultz method using compressibility functions and | |

| Polytropic efficiency | |

| Subscripts and Superscripts | |

| indicates the ith segment | |

| total number of segments | |

| degree of the polynomial approximant Example: indicates the cubic polynomial approximant, which is used to approximate the segment number 6 of a polytropic path that is divided into 10 segments. This symbology provides a clear way to compare different methods discussed in this paper. | |

| inf | inflection |

| p | Polytropic, or pressure |

| r | ratio |

| d | compressor section discharge (measured) |

| 1 | compressor section inlet |

| 2 | compressor section discharge |

Appendix A. Temperature Change with Entropy along the Polytropic Path

Derivation of the following two important relationships, and along the polytropic compression path is explained in this appendix.

Choose the entropy to be a function of temperature and pressure. Writing the differential of gives:

The first partial derivative in (A1) can be written as follows:

where and from the first partial derivate of the Gibbs relationship

The second partial derivative in (A1) is one of the Maxwell relations:

Substituting the first and second partial derivatives in (A1) from (A2) and (A3) yields:

Using the definition of isobaric expansivity for the second partial derivative gives:

Employing the Gibbs relationship for a polytropic process and substituting with gives:

Substituting from (A5) to (A4) yields:

This can be further simplified to

From (A8) the slope of the polytropic path on a T-s diagram is determined:

Substituting with the Schultz compressibility function gives:

By replacing from (A10) to (47) gives:

The relationships (A10) and (A11) were developed and presented for the first time by Taher [1].

The relationship (A11) shows that the polytropic path on the enthalpy-entropy diagram is concave upward since the second derivative is positive in an uncooled compressor section.

Appendix B. Comparative Numeric Examples of Application of the Taher–Evans Cubic Polynomial Methods

The Taher–Evans Cubic Polynomial method for calculation of centrifugal compressor polytropic performance has been applied to 19 compression example cases which are comprised of five pure fluids and four hydrocarbon fluid mixtures. Eight cases are considered low pressure while eleven cases are considered medium or high pressure. Input data for ten cases came from existing literature references while nine cases are new. All cases were chosen based upon the desire to explore a wide range of process conditions for fluids common to the hydrocarbon industry.

The fluids and process conditions selected represent a combination of relatively easy and difficult calculations for centrifugal compressor polytropic performance. Table A1 lists input data for the 19 cases. The “easy cases” are found by the results listed below to be low pressure versions for CO2, C3H8 and CH4/C3H8/CO2. The most difficult case is supercritical propane due to inlet conditions.

Using results of the above referenced analyses, this appendix will review polytropic efficiency calculation method comparisons for following three categories:

- Endpoint methods

- ○

- Schultz (two variations) [6];

- ○

- Mallen Saville [9];

- ○

- Cubic Polynomial;

- ○

- Linear polynomial.

- Three point methods

- ○

- Cubic Polynomial two segment;

- ○

- Huntington’s three point [13].

- Multi-step and multi-segment methods

- ○

- Cubic Polynomial—sequential segments (2 through 10 segments);

- ○

- Linear Polynomial—sequential steps (10, 20, 50, 90 and 100 steps).

The Taher–Evans Cubic Polynomial 10 segment method is used as a comparison standard to determine relative deviations in polytropic efficiency for all other methods. The validity of using this standard is confirmed below. Equation (A12) documents the relative deviation calculation.

Industry standardized compressor data sheets document operating conditions and performance characteristics with polytropic efficiency shown as a percentage, typically with two decimal places of accuracy, such as 68.25%. One criterion applied in the example cases below is that the deviation should be known to be less than 0.001% of an acceptable standard. Since all polytropic efficiency calculation methods are approximations, a standard determines the magnitude of the difference between two calculations.

As mentioned in the paper (see also Appendix D), polytropic performance results can be impacted by the choice of an equation of state (EOS). The REFPROP (version 10) software package [28] produced by the National Institute of Science and Technology (NIST) was employed for calculations in this appendix. REFPROP provides reference quality, multi parameter, real gas equations of state for thermodynamic and transport properties of individual fluids. REFPROP applies optimized binary interaction parameters via mixing rules to determine mixture properties.

When using the REFPROP software package, all example case inlet and discharge state point phases are single phase and either superheated or supercritical. For some example cases, the close proximity of inlet conditions to a fluid’s critical point yielded two phase or liquid phases for some other equations of state used in Appendix D. The polytropic performance methods discussed in this paper are neither designed nor recommended for two phase flows. The impact of equation of state choices will be reviewed in Appendix D.

Table A1.

Example case input data.

Table A1.

Example case input data.

| Case Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| Case Name | Schultz R12 | LP Ethylene | HP Ethylene | SC Ethane | PTC10 CO2 | LP CO2 | MP CO2 | HP CO2 | LP Propane | HP Propane | SC Propane | |

| Composition, mol % | Ethane | 1.0000 | ||||||||||

| Propane | 1.0000 | 1.0000 | 1.0000 | |||||||||

| Carbon Dioxide | 1.0000 | 1.0000 | 1.0000 | 1.0000 | ||||||||

| Ethylene | 1.0000 | 1.0000 | ||||||||||

| R12 | 1.0000 | |||||||||||

| Compression Conditions | , psia | 10 | 360 | 362.5 | 750 | 300.01 | 400 | 500 | 1100.1 | 17.99 | 300 | 650 |

| , bara | 0.689 | 24.821 | 24.993 | 51.710 | 20.685 | 27.579 | 34.474 | 75.849 | 1.240 | 20.684 | 44.816 | |

| , °F | −10 | 50 | 98.3 | 110 | 100 | 100 | 75 | 98.3 | −31.36 | 200 | 210 | |

| , °C | −23.33 | 10 | 36.833 | 43.333 | 37.778 | 37.778 | 23.88 | 36.833 | −35.2 | 93.333 | 98.889 | |

| , psia | 130 | 1000 | 7250 | 3500 | 487.76 | 1200 | 3000 | 6000.3 | 60 | 1000 | 3500 | |

| , bara | 8.963 | 68.948 | 499.870 | 241.316 | 33.630 | 82.737 | 206.843 | 413.706 | 4.137 | 68.948 | 241.316 | |

| , °F | 210 | 195 | 566.3 | 285 | 201.59 | 325 | 400 | 368.3 | 60 | 330 | 300 | |

| , °C | 98.889 | 90.556 | 296.833 | 140.556 | 94.217 | 162.778 | 204.444 | 186.833 | 15.556 | 165.556 | 148.889 | |

| Case Number | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||

| Case Name | LP CH4/C3H8/CO2 | MP CH4/C3H8/CO2 | HP CH4/C3H8/CO2 | LP CH4/CO2 | HP CH4/CO2 | LP Heavy NG | HP Heavy NG | PTC10 HPNG | ||||

| Composition, mol % | Methane | 0.30294 | 0.30294 | 0.30294 | 0.256274 | 0.256274 | 0.688671 | 0.688671 | 0.8600 | |||

| Ethane | 0.03748 | 0.03748 | 0.03748 | 0.022871 | 0.022871 | 0.119957 | 0.119957 | 0.1125 | ||||

| Propane | 0.43533 | 0.43533 | 0.43533 | 0.005691 | 0.005691 | 0.102964 | 0.102964 | 0.0075 | ||||

| isoButane | 0.00222 | 0.00222 | 0.00222 | 0.000001 | 0.000001 | 0.031432 | 0.031432 | |||||

| Butane | 0.00218 | 0.00218 | 0.00218 | 0.000001 | 0.000001 | 0.027541 | 0.027541 | |||||

| isoPentane | 0.000001 | 0.000001 | 0.008927 | 0.008927 | ||||||||

| Pentane | 0.000001 | 0.000001 | 0.005563 | 0.005563 | ||||||||

| Hexane | 0.000175 | 0.000175 | ||||||||||

| Nitrogen | 0.00399 | 0.00399 | 0.00399 | 0.002629 | 0.002629 | 0.002477 | 0.002477 | 0.0040 | ||||

| Carbon Dioxide | 0.21586 | 0.21586 | 0.21586 | 0.712356 | 0.712356 | 0.012468 | 0.012468 | 0.0160 | ||||

| Compression Conditions | , psia | 650 | 2071 | 2071 | 500 | 1649.7 | 500 | 1750 | 2520.6 | |||

| , bara | 44.816 | 142.790 | 142.790 | 34.474 | 113.743 | 34.474 | 120.658 | 173.789 | ||||

| , °F | 115 | 160 | 160 | 50 | 101.2 | 100 | 50 | 100 | ||||

| , °C | 46.111 | 71.111 | 71.111 | 10 | 38.444 | 37.778 | 10 | 37.778 | ||||

| , psia | 2200 | 10,025.70 | 11,010.80 | 1700 | 8189.70 | 1800 | 4375 | 6500 | ||||

| , bara | 151.685 | 691.248 | 759.168 | 117.211 | 564.660 | 124.106 | 301.646 | 448.159 | ||||

| , °F | 270 | 291.9 | 301.5 | 250 | 316.2 | 295 | 125 | 280 | ||||

Appendix B.1. Endpoint Methods

Schultz [6] described several alternative versions of his methodology in his original ASME paper all of which applied a path equation of . The variations involved calculating his “polytropic head factor”, , in various ways as well as multiple methods of averaging his “polytropic volume exponent”,. For the comparisons below, the following two variations of Schultz’s method are included for examination since they were included in the 1997 version of ASME PTC10 [4].

- Schulz—with based upon the endpoints of compression

- ○

- Schultz average n—with averaged based upon individual calculations at inlet and discharge

- ○

Mallen and Saville [9] employed a path equation of . Path equations are described above in this paper for the liner and cubic polynomial methods.

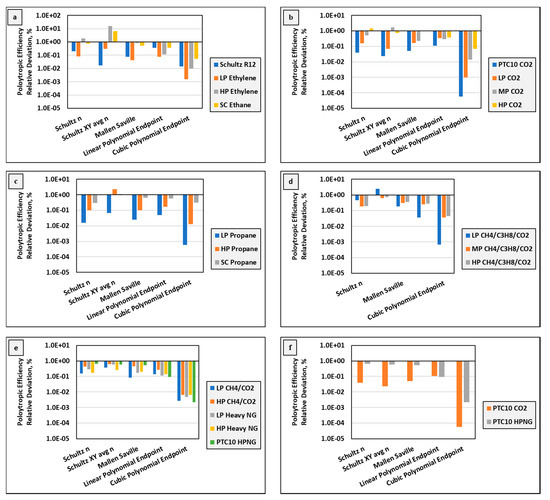

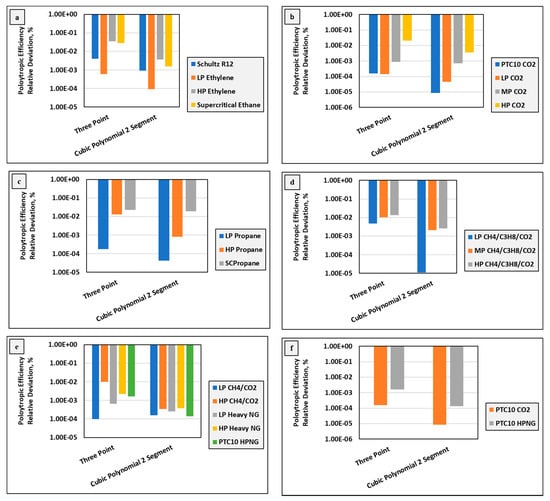

Figure A1a–e illustrate polytropic efficiency relative deviation results for endpoint methods for the 19 example cases. The Taher–Evans endpoint method provides superior results compared to the other endpoint methods for all example cases. Example cases PTC10 CO2, LP CO2, LP propane and LP CH4/C3H8/CO2 are considered easy cases since the Taher–Evans Cubic Polynomial endpoint method achieves deviations from the 10-segment method of less than 0.001%. Thus, using multi-segment analyses would not be required for these cases. The two Schultz based methods show significant errors for some example cases and do not exhibit a consistent pattern. Figure A1f directly compares two related cases in that the PTC10 CO2 case represents a Type 2 test designed for the HPNG example case. The PTC10 CO2 case is a low-pressure case and deviations are seen to be smaller than for the HPNG case as expected. However, the Taher–Evans endpoint method provides better accuracy for the PTC 10 HPNG case. The HPNG case requires more segments to achieve less than a 0.001% deviation level.

Notable comparisons for endpoint methods:

- ○

- HP ethylene; Mallen and Saville [9] highlighted their improvements over Schultz’s method for high pressure, but still have an approximate 1% deviation;

- ○

- LP and HP ethylene; typical and expected patterns for cubic and linear polynomials.

- Figure A1b,c

- ○

- CO2 and propane; as pressure increases accuracy decreases is a typical pattern

- ○

- CH4/C3H8/CO2; medium and high pressure cases are very similar since discharge conditions are close

- ○

- PTC10; the HPNG case will require more cubic segments to achieve sufficient accuracy than the Type 2 test design using CO2

Figure A1.

(a–f) Summary comparison of relative deviation results for endpoint methods.

Table A2 lists the T-s path inlet and discharge slope and curve category for the 19 example cases. Five cases show that an inflection point in curvature exists along the path. For these five cases, endpoint analyses do not provide sufficient polytropic efficiency accuracy and multi-segment analyses are recommended. Changes in path slope and curvature can be used as criteria for determining how many cubic segments are needed to provide sufficient accuracy (See Section 4, Figure 10 and Appendix C).

Table A2.

Taher–Evans Cubic Polynomial endpoint method T-s path slope and curvature.

Table A2.

Taher–Evans Cubic Polynomial endpoint method T-s path slope and curvature.

| Case Number | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 |

| T-s Slope at Inlet, , lbm.R2/BTU | 14,168 | 10,442 | 9383 | 14,537 | 7026 |

| T-s Slope at Discharge, , lbm.R2/BTU | 19,822 | 12,253 | 8302 | 7946 | 7881 |

| T-s Slope Change, % | 39.90 | 17.34 | −11.52 | −45.34 | 12.17 |

| T-s Curve Shape Category | I | I | III | II | I |

| Entropy at Inflection Point, BTU/lbm.R | - | - | 0.65070 | - | - |

| Temperature at Inflection Point, °F | - | - | 304.71 | - | - |

| Case Number | Case 6 | Case 7 | Case 8 | Case 9 | Case 10 |

| T-s Slope at Inlet, , lbm.R2/BTU | 8551 | 15,181 | 10,553 | 7178 | 10,330 |

| T-s Slope at Discharge, , lbm.R2/BTU | 10,744 | 19,708 | 8887 | 8151 | 15,523 |

| T-s Slope Change, % | 25.66 | 29.82 | −15.79 | 13.57 | 50.28 |

| T-s Curve Shape Category | I | I | II | I | I |

| Entropy at Inflection Point, BTU/lbm.R | - | - | - | - | - |

| Temperature at Inflection Point, °F | - | - | - | - | - |

| Case Number | Case 11 | Case 12 | Case 13 | Case 14 | Case 15 |

| T-s Slope at Inlet, , lbm.R2/BTU | 14,053 | 10,664 | 11,513 | 11,509 | 13,135 |

| T-s Slope at Discharge, , lbm.R2/BTU | 3773 | 9986 | 5526 | 5352 | 16,183 |

| T-s Slope Change, % | −73.15 | −6.36 | −52.01 | −53.50 | 23.20 |

| T-s Curve Shape Category | III | III | III | III | I |

| Entropy at Inflection Point, BTU/lbm.R | 0.48820 | 0.64410 | 0.55540 | 0.55670 | - |

| Temperature at Inflection Point, °F | 288.95 | 176.68 | 286.75 | 294.07 | - |

| Case Number | Case 16 | Case 17 | Case 18 | Case 19 | |

| T-s Slope at Inlet, , lbm.R2/BTU | 18,783 | 5147 | 4601 | 2786 | |

| T-s Slope at Discharge, , lbm.R2/BTU | 12,049 | 5762 | 3362 | 2632 | |

| T-s Slope Change, % | −35.85 | 11.94 | −26.94 | −5.53 | |

| T-s Curve Shape Category | II | I | II | II | |

| Entropy at Inflection Point, BTU/lbm.R | - | - | - | - | |

| Temperature at Inflection Point, °F | - | - | - | - |

Appendix B.2. Three Point Methods

Figure A2a–e provide a summary of the polytropic efficiency deviation results comparing the Taher–Evans Cubic Polynomial 2 segment method with Huntington’s three-point method [13]. The two-segment cubic polynomial method shows sufficient accuracy for 13 of 19 example cases while Huntington’s three-point method shows sufficient accuracy for only 7 of 19 example cases based upon the 0.001% requirement. In all example cases, the cubic polynomial method is more accurate than Huntington’s method. Figure A2f compares PTC10 CO2 and HPNG cases. Both cubic and the Huntington’s three-point method are sufficient for the low-pressure test case but only the cubic polynomial is sufficient for the HPNG case.

Figure A2.

(a–f) Summary comparison of relative deviation results for three point methods.

Appendix B.3. Multi-Step and Multi-Segment Methods

Table A3 lists the polytropic efficiency calculated for Taher–Evans Cubic Polynomial 2 through 10 multi-segment methods, and linear polynomial 10, 20, 50, 90 and 100 multi-step methods. The general trend is that using more segments or steps yields higher accuracy. In many example cases, as more segments or steps are applied, the efficiency only changes beyond the fourth decimal place as highlighted in the table by the outlined values. The results are shown to have “stabilized” to four decimal places for additional segments or steps. In all example cases, the highest accuracy shown agrees between cubic and linear methods, but the linear method requires many more steps before “stabilizing”. The general trend of higher-pressure cases requiring more segments or steps to stabilize is confirmed.

Table A3.

Summary comparison of polytropic efficiency results for linear multi-step and cubic polynomial multi-segment methods.

Table A3.

Summary comparison of polytropic efficiency results for linear multi-step and cubic polynomial multi-segment methods.

| Case Number | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | Case 7 |

|---|---|---|---|---|---|---|---|

| Cubic Polynomial 2 Segment | 75.0442 | 81.9199 | 80.6174 | 79.9531 | 59.4118 | 65.2211 | 78.4933 |

| Cubic Polynomial 3 Segment | 75.0437 | 81.9200 | 80.6148 | 79.9521 | 59.4118 | 65.2211 | 78.4938 |

| Cubic Polynomial 4 Segment | 75.0436 | 81.9200 | 80.6146 | 79.9519 | 59.4118 | 65.2211 | 78.4939 |

| Cubic Polynomial 5 Segment | 75.0435 | 81.9200 | 80.6145 | 79.9519 | 59.4118 | 65.2211 | 78.4939 |

| Cubic Polynomial 6 Segment | 75.0435 | 81.9200 | 80.6145 | 79.9519 | 59.4118 | 65.2211 | 78.4939 |

| Cubic Polynomial 7 Segment | 75.0435 | 81.9200 | 80.6145 | 79.9519 | 59.4118 | 65.2211 | 78.4939 |

| Cubic Polynomial 8 Segment | 75.0435 | 81.9200 | 80.6145 | 79.9519 | 59.4118 | 65.2211 | 78.4939 |

| Cubic Polynomial 9 Segment | 75.0435 | 81.9200 | 80.6145 | 79.9519 | 59.4118 | 65.2211 | 78.4939 |

| Cubic Polynomial 10 Segment | 75.0435 | 81.9200 | 80.6145 | 79.9519 | 59.4118 | 65.2211 | 78.4939 |

| Linear Polynomial 10 step | 75.0408 | 81.9194 | 80.6153 | 79.9544 | 59.4111 | 65.2189 | 78.4916 |

| Linear Polynomial 20 step | 75.0428 | 81.9198 | 80.6147 | 79.9525 | 59.4116 | 65.2205 | 78.4933 |

| Linear Polynomial 50 step | 75.0434 | 81.9200 | 80.6145 | 79.9520 | 59.4118 | 65.2210 | 78.4938 |

| Linear Polynomial 90 step | 75.0435 | 81.9200 | 80.6145 | 79.9519 | 59.4118 | 65.2211 | 78.4939 |

| Linear Polynomial 100 step | 75.0435 | 81.9200 | 80.6145 | 79.9519 | 59.4118 | 65.2211 | 78.4939 |

| Case Number | Case 8 | Case 9 | Case 10 | Case 11 | Case 12 | Case 13 | Case 14 |

| Cubic Polynomial 2 Segment | 64.3513 | 81.0248 | 79.4381 | 67.7882 | 76.7610 | 82.0678 | 82.0695 |

| Cubic Polynomial 3 Segment | 64.3497 | 81.0247 | 79.4386 | 67.7984 | 76.7610 | 82.0692 | 82.0712 |

| Cubic Polynomial 4 Segment | 64.3493 | 81.0247 | 79.4387 | 67.8002 | 76.7610 | 82.0694 | 82.0714 |

| Cubic Polynomial 5 Segment | 64.3492 | 81.0247 | 79.4387 | 67.8007 | 76.7610 | 82.0695 | 82.0715 |

| Cubic Polynomial 6 Segment | 64.3491 | 81.0247 | 79.4387 | 67.8009 | 76.7610 | 82.0695 | 82.0715 |

| Cubic Polynomial 7 Segment | 64.3491 | 81.0247 | 79.4387 | 67.8010 | 76.7610 | 82.0695 | 82.0716 |

| Cubic Polynomial 8 Segment | 64.3491 | 81.0247 | 79.4387 | 67.8010 | 76.7610 | 82.0695 | 82.0716 |

| Cubic Polynomial 9 Segment | 64.3491 | 81.0247 | 79.4387 | 67.8011 | 76.7610 | 82.0695 | 82.0716 |

| Cubic Polynomial 10 Segment | 64.3491 | 81.0247 | 79.4387 | 67.8011 | 76.7610 | 82.0695 | 82.0716 |

| Linear Polynomial 10 step | 64.3512 | 81.0243 | 79.4375 | 67.8050 | 76.7612 | 82.0715 | 82.0738 |

| Linear Polynomial 20 step | 64.3496 | 81.0246 | 79.4384 | 67.8021 | 76.7610 | 82.0700 | 82.0721 |

| Linear Polynomial 50 step | 64.3491 | 81.0247 | 79.4387 | 67.8013 | 76.7610 | 82.0696 | 82.0717 |

| Linear Polynomial 90 step | 64.3491 | 81.0247 | 79.4387 | 67.8012 | 76.7610 | 82.0695 | 82.0716 |

| Linear Polynomial 100 step | 64.3491 | 81.0247 | 79.4387 | 67.8011 | 76.7610 | 82.0695 | 82.0716 |

| Case Number | Case 15 | Case 16 | Case 17 | Case 18 | Case 19 | ||

| Cubic Polynomial 2 Segment | 80.3316 | 82.1055 | 72.1215 | 71.3151 | 59.2985 | ||

| Cubic Polynomial 3 Segment | 80.3317 | 82.1052 | 72.1216 | 71.3153 | 59.2984 | ||

| Cubic Polynomial 4 Segment | 80.3317 | 82.1052 | 72.1217 | 71.3154 | 59.2984 | ||

| Cubic Polynomial 5 Segment | 80.3317 | 82.1052 | 72.1217 | 71.3154 | 59.2984 | ||

| Cubic Polynomial 6 Segment | 80.3317 | 82.1052 | 72.1217 | 71.3154 | 59.2984 | ||

| Cubic Polynomial 7 Segment | 80.3317 | 82.1052 | 72.1217 | 71.3154 | 59.2984 | ||

| Cubic Polynomial 8 Segment | 80.3317 | 82.1052 | 72.1217 | 71.3154 | 59.2984 | ||

| Cubic Polynomial 9 Segment | 80.3317 | 82.1052 | 72.1217 | 71.3154 | 59.2984 | ||

| Cubic Polynomial 10 Segment | 80.3317 | 82.1052 | 72.1217 | 71.3154 | 59.2984 | ||

| Linear Polynomial 10 step | 80.3306 | 82.1073 | 72.1209 | 71.3164 | 59.2990 | ||

| Linear Polynomial 20 step | 80.3315 | 82.1057 | 72.1215 | 71.3156 | 59.2986 | ||

| Linear Polynomial 50 step | 80.3317 | 82.1053 | 72.1216 | 71.3154 | 59.2984 | ||

| Linear Polynomial 90 step | 80.3317 | 82.1052 | 72.1217 | 71.3154 | 59.2984 | ||

| Linear Polynomial 100 step | 80.3317 | 82.1052 | 72.1217 | 71.3154 | 59.2984 |

For the supercritical ethane example case, the cubic method demonstrates a polytropic efficiency of 79.9519% for three segments and remains at that value for the four decimal places shown as the number of segments is increased. The linear method needs between 50 and 90 steps to reach the same accuracy for efficiency. In other words, the linear method approaches an asymptote much more slowly than the cubic method at the cost of increased computing resources and elapsed time to reach a solution. This illustrates the usefulness of the cubic method in being able to take advantage of matching the slope of the T-s path between sequential segments. Both the cubic and linear methods are approximants that can reach essentially the same level of approximation, but the cubic method employs more thermodynamic constraints to achieve the resulting polytropic efficiency much quicker.

It is not necessary to reach a “stabilized” polytropic efficiency to satisfy the maximum allowable deviation requirement of 0.001% as compared to the Taher–Evans Cubic Polynomial 10 segment results. Deviations are less than 0.001% for 13 of 19 example cases using 2 cubic segments while only 4 of 19 are less than 0.001% for 10 linear steps.

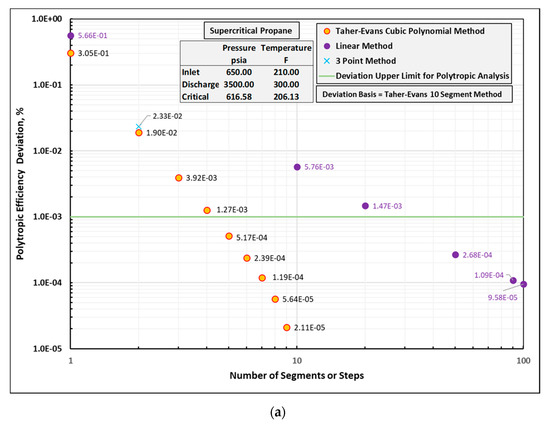

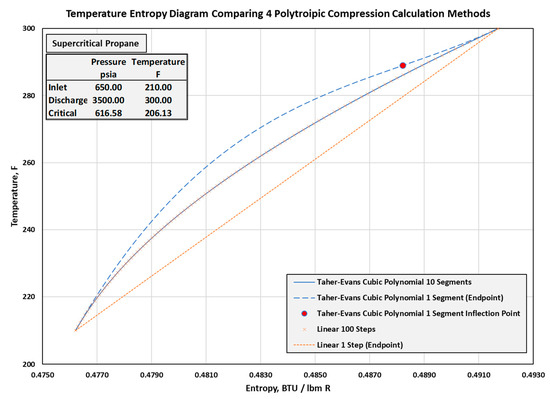

Figure A3a illustrates polytropic efficiency relative deviation results for all cubic multi-segment methods and linear multi-step methods for the supercritical propane example case. The more difficult an example case is, the more segments or steps it takes to achieve a relative deviation of 0.001% or less. This most difficult case achieves this target with 5 segments for the cubic polynomial method while it would take 44 steps for the linear polynomial method to reach the same deviation value as the 5 cubic segment method. The cubic polynomial method does not suffer from the requirement of a small step size for each segment as does the linear polynomial method.

Figure A3b shows the elapsed calculation times for 5 cubic segments and 44 linear steps are approximately 3.5 s and 55.8 s, respectively. Thus, the linear method takes 16 times longer to reach the same level of accuracy for this very difficult example case. For the six example cases that required more than 2 cubic segments to reach a deviation less of than 0.001%, the elapsed time ratio varied from 5 to 16 times longer for the linear method.

The elapsed time to reach a solution is dependent upon the algorithm employed to resolve the inner and outer nested, recursive loops for discharge temperature and efficiency. The algorithm used for both cubic and linear method results in this appendix is identical. Thus, while another algorithm might reach solutions faster or slower, the ratio between cubic and linear method elapsed times should remain approximately the same for a given example case.

Figure A3.

(a) Polytropic efficiency relative deviations for supercritical propane example. (b) elapsed time for supercritical propane example.

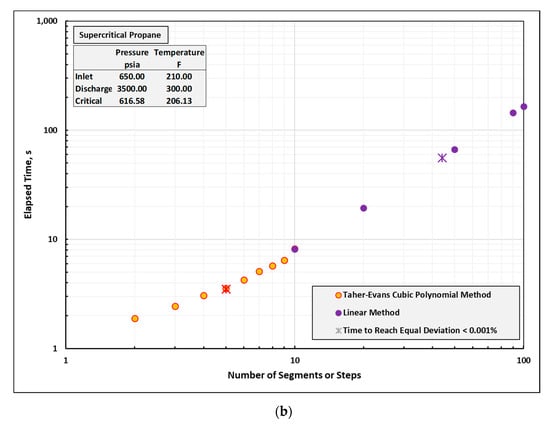

Figure A4a–e illustrate polytropic efficiency relative deviation results for all cubic multi-segment methods and linear multi-step methods for the 19 example cases. The 10 cubic segment results are used as the standard for comparison. For each case, fewer cubic segments are needed than linear steps to achieve the 0.001% required accuracy. Figure A4f directly compares the HPNG case and the PTC10 CO2 Type 2 performance test designed to prove the compressor should meet the design requirements within the tolerances allowed by the ASME PTC10 code [4].

Figure A4.

(a–f) Summary comparison of results for linear multi-step and cubic polynomial multi-segment methods.

Appendix B.4. High Pressure Ethylene Example

This example was first created by Mallen and Saville [9] to demonstrate differences between their polytropic work calculation method and Schultz’s method [6] at higher pressures. Since then, it has been used by many authors as a strong test of other methods due to its large pressure and temperature ranges. The high compression ratio and extreme discharge temperature for this case illustrate it would likely not be feasible to build a single section compressor to accomplish this application. However, its use as an example to test calculation methods has been documented.

Ethylene has been described as an unruly fluid by Brown, [29]. Evans and Huble, [22], postulated Brown’s comment could be due to the proximity of ethylene’s critical temperature to usual inlet temperature ranges for common applications causing rapid, large changes in specific heat, cp, and especially density with small inlet temperature changes. In the vicinity of the critical point, large changes in inlet density can occur due to small changes in inlet temperature causing a centrifugal compressor’s operating point to move from one side of its performance map to the other without any process operator control changes.

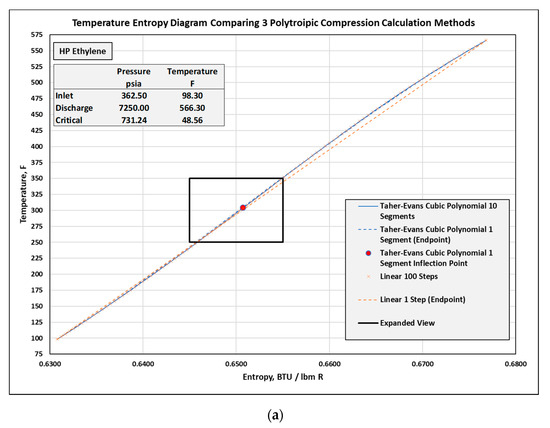

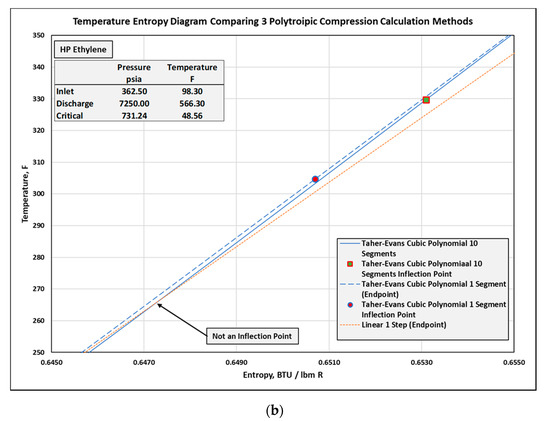

The Taher–Evans Cubic Polynomial method provides the ability to calculate and graphically display the T-s values at any point along the constant polytropic efficiency path between inlet and discharge. The HP ethylene example case serves to demonstrate the method’s usefulness to visualize the path, its curvature and an inflection point. Figure A5a shows paths for 1 and 10 segment cubic polynomial methods and 1 and 100 step linear polynomial methods. The 100-step linear method’s orange markers are seen to lie on top of the solid blue 10-segment cubic path. The one segment cubic dotted blue line shows an inflection point near the center of the graph. The 10-segment cubic polynomial path begins with an upward concavity that transitions to downward at the inflection point. The 100 step linear markers follow this pattern illustrating the accuracy of the cubic polynomial method’s path.

Figure A5b shows an expanded view of the area outlined by a black box in Figure A5a. The inflection point of the 10-segment cubic polynomial path is shown to occur at a slightly higher temperature for the more refined calculation. The 10-segment cubic polynomial begins with 5 upward concave segments, and ends with 4 downward concave segments. The 6th segment is “s” shaped since it starts out concave upward and shifts at the inflection point to concave downward. The curvature of the cubic segments is determined by values of the derivatives of the T-s path equation. The point where the blue 10-segment curve crosses the orange dotted linear endpoint line is not an inflection point, but rather just a crossing of the upward concave segments of the 10-segment cubic method path.

Figure A5.

(a) T-s compression paths for HP ethylene example case. (b) the location of inflection point on T-s compression polytropic path is compared for different methods—HP ethylene example case.

Appendix B.5. Supercritical Propane Example

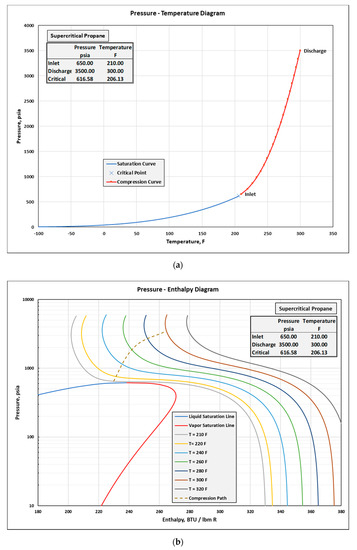

The results shown in Table A4 illustrated that the supercritical propane example case is the most difficult. The following discussion uses this case to shed light upon reasons performance calculations are more difficult for certain applications. Figure A6a,b are pressure-temperature and pressure-enthalpy diagrams for this example. Figure A6a shows inlet conditions are very near the critical point such that the reduced pressure and reduced temperature are very near 1.0. While these inlet conditions might not be recommended in normal compression industry practice, the example serves as an “acid test” for polytropic calculation methods. Figure A6b shows isotherms in the dense phase region are nearly horizontal at inlet but are nearly vertical at discharge. For the cubic polynomial compression curve shown in the figure, near the inlet, pressure changes are more rapid than enthalpy changes while the opposite is true near discharge conditions giving the path its shape. Near discharge, one value of enthalpy could be associated with two values of pressure at the same temperature making an EOS root finding algorithm more difficult to converge.

Figure 8 and Figure 9 in the main body of the paper illustrate the rapid variation of thermodynamic properties and in the vicinity of the critical point for this application. This causes large differences of path slope between the inlet and discharge (and ).

Figure A6.

(a) Pressure-temperature diagram for supercritical propane example. (b) pressure-enthalpy diagram for supercritical propane example.