Review of a Custom-Designed Optical Sensing System for Aero-Engine Applications

Abstract

1. Introduction

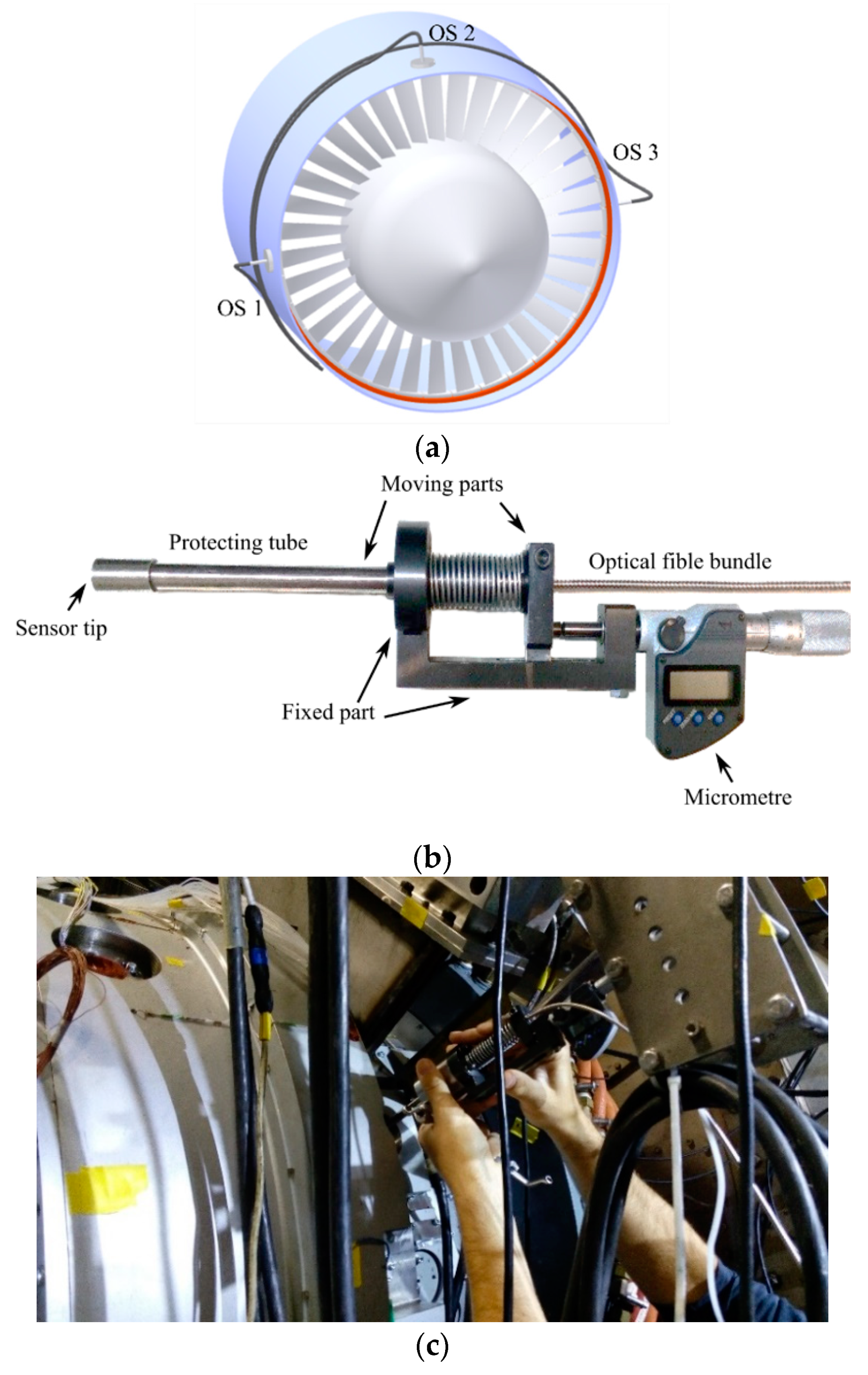

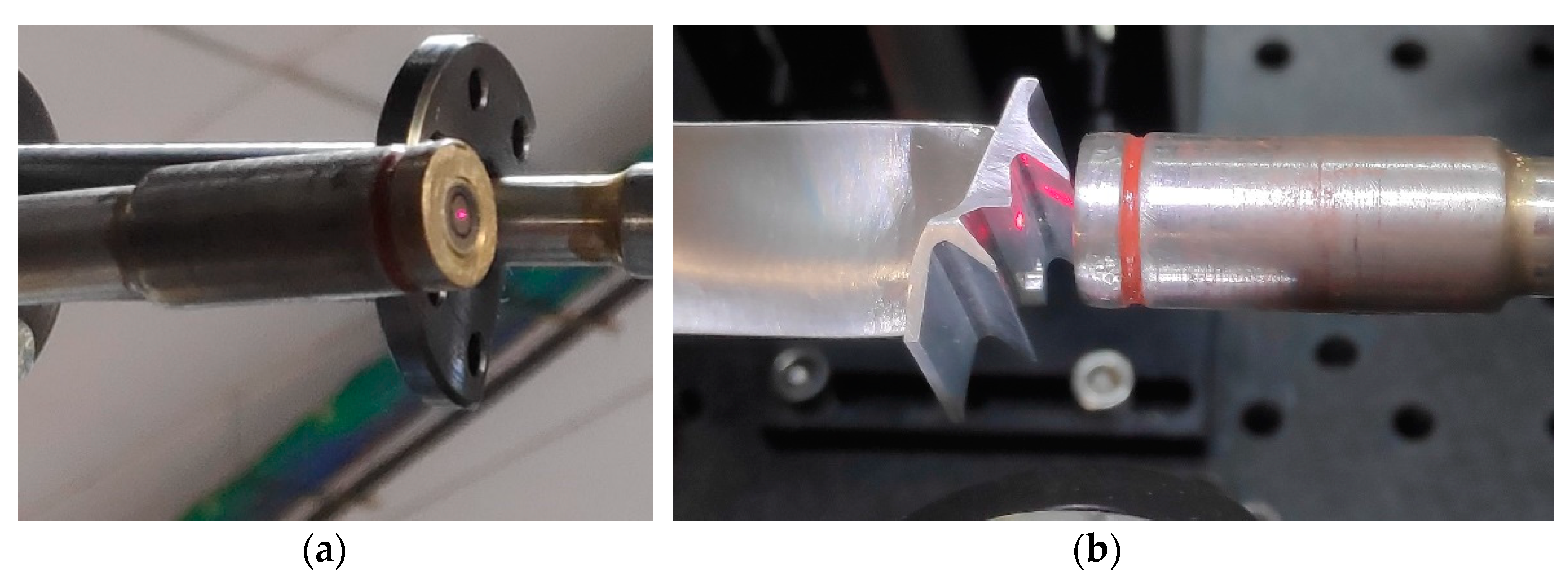

2. Materials and Methods

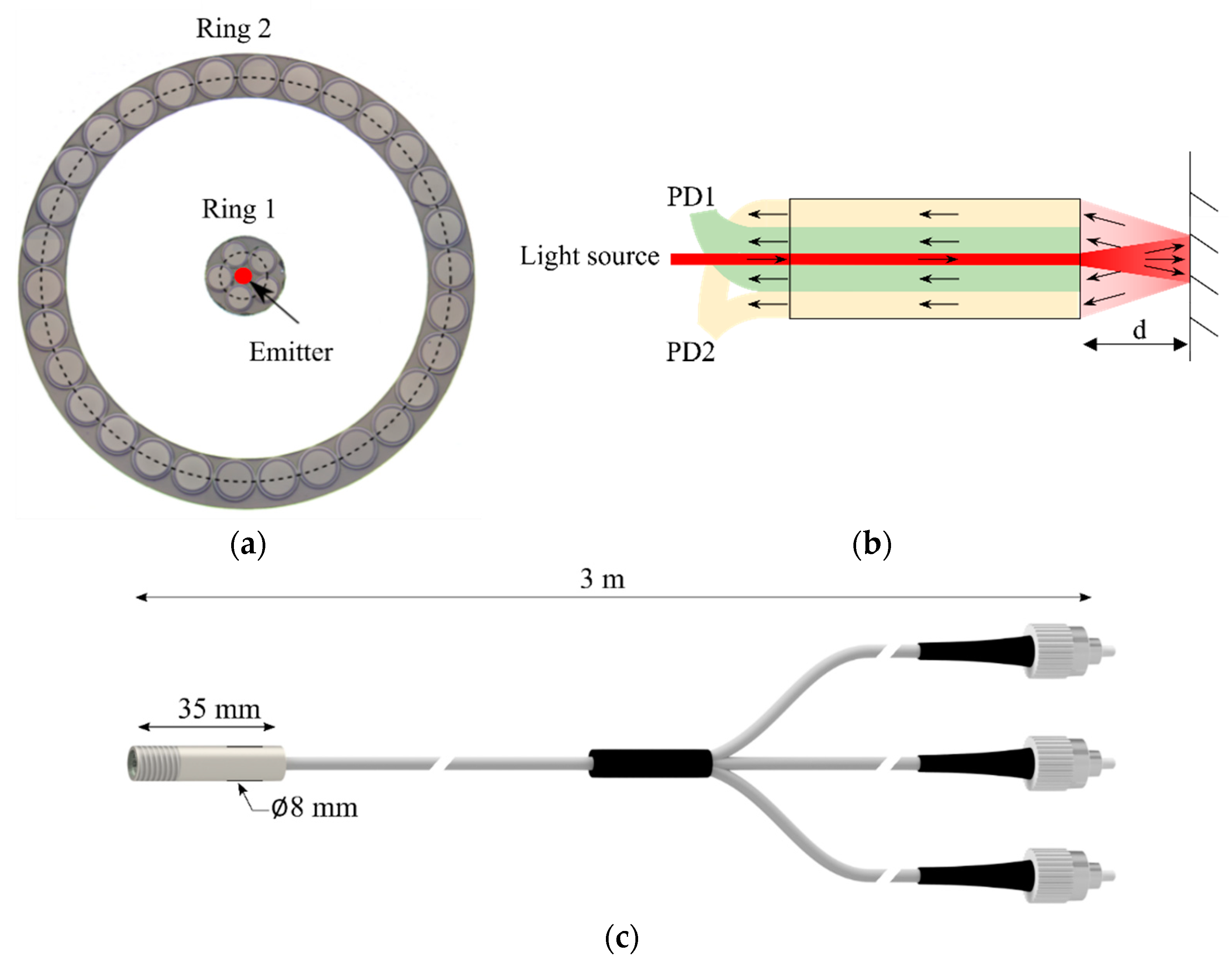

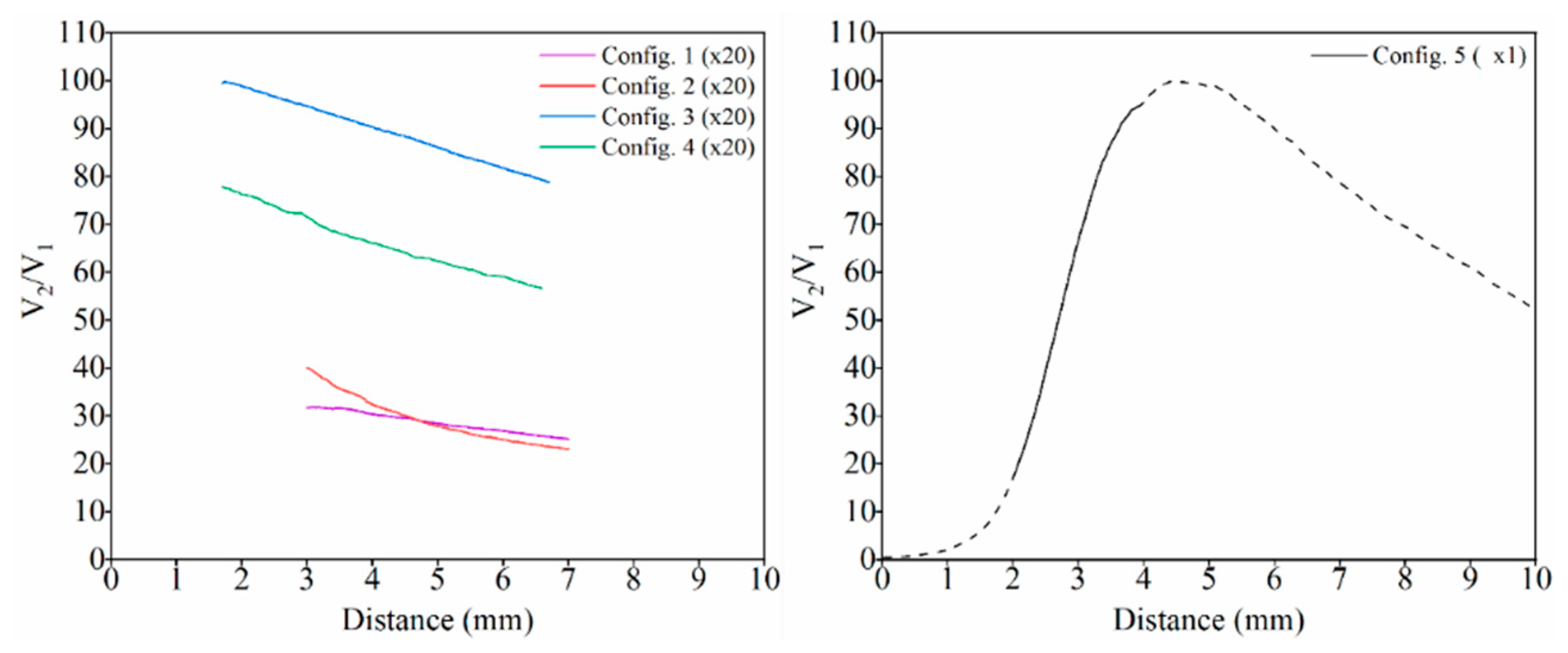

- The fluctuations in the light source and the variations in the reflectivity on the target surface are effectively cancelled by performing the quotient of the light intensities collected by the receiving fibres of each ring.

- Its sensitivity has been improved by using an asymmetric gain configuration in the photodetectors.

- The outer ring has been calculated so that the sensor works in the first and most steep positive slope of the response curve for these test particular conditions.

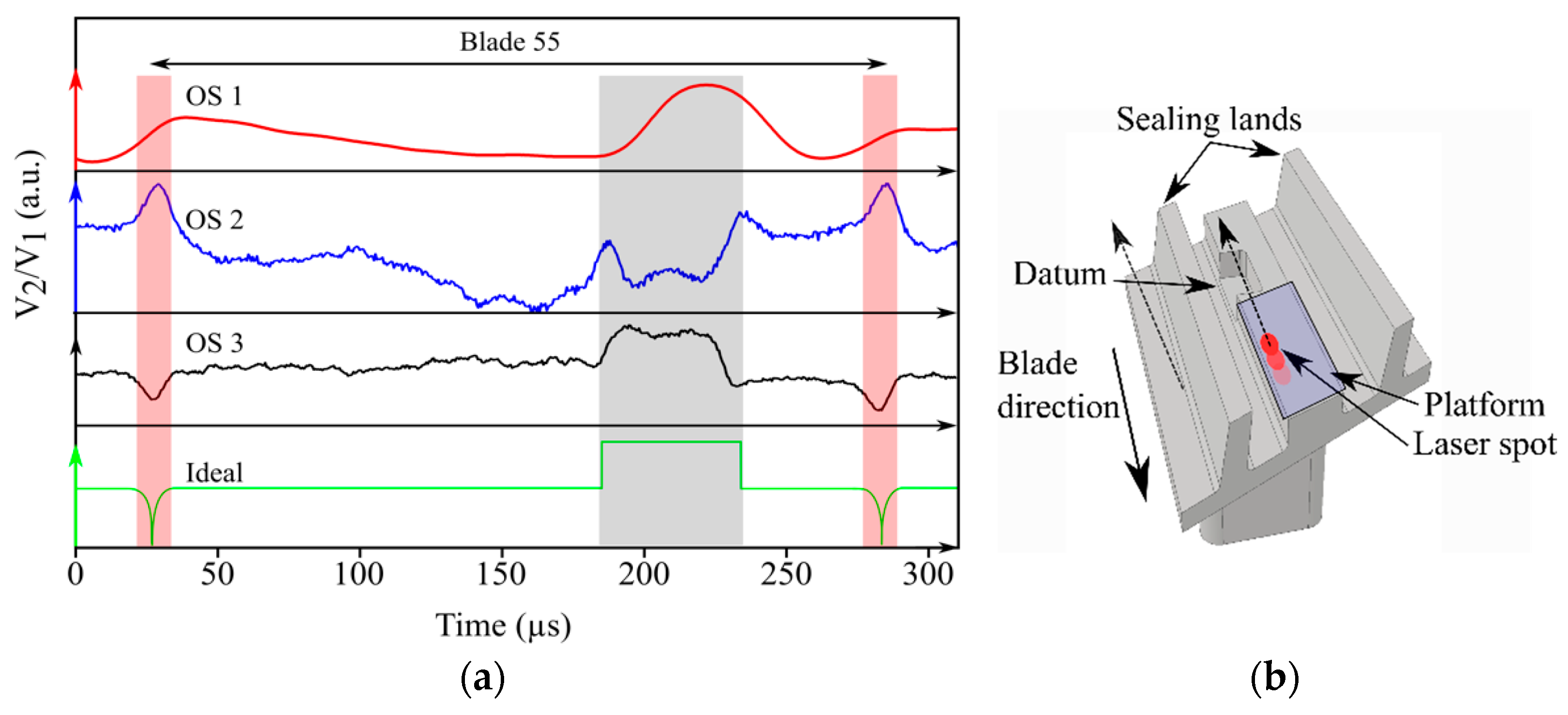

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wiseman, M.W.; Guo, T.-H. An investigation of life extending control techniques for gas turbine engines. Proc. Am. Control Conf. 2001, 5, 3706–3707. [Google Scholar] [CrossRef]

- Sheard, A.G.; O’Donnell, S.G.; Stringfellow, J.F. High Temperature Proximity Measurement in Aero and Industrial Turbomachinery. J. Eng. Gas Turbines Power 1997, 121, 167–173. [Google Scholar] [CrossRef]

- Roeseler, C.; Flotow, A.W.; Tappert, P. Monitoring blade passage in turbomachinery through the engine case (no holes). In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 9–16 March 2002; p. 6. [Google Scholar] [CrossRef]

- Du, L.; Zhu, X.; Zhe, J. A high sensitivity inductive sensor for blade tip clearance measurement. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Barranger, J.P.; Ford, M.J. Laser-Optical Blade Tip Clearance Measurement System. J. Eng. Power 1981, 103, 457–460. [Google Scholar] [CrossRef]

- Cao, S.Z.; Duan, F.J.; Zhang, Y.G. Measurement of Rotating Blade Tip Clearance with Fibre-Optic Probe. J. Phys. Conf. Ser. 2006, 48, 873–877. [Google Scholar] [CrossRef]

- Vakhtin, A.B.; Chen, S.-J.; Massick, S.M. Optical Probe for Monitoring Blade Tip Clearance. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar] [CrossRef]

- Sheard, A.G. Blade by Blade Tip Clearance Measurement. Int. J. Rotating Mach. 2011, 2011, 516128. [Google Scholar] [CrossRef]

- Haase, W.C.; Haase, Z.S. High-Speed, capacitance-based tip clearance sensing. In Proceedings of the 2013 IEEE Aerospace Conference, Big Sky, MT, USA, 2–9 March 2013; pp. 1–8. [Google Scholar] [CrossRef]

- Ye, D.-C.; Duan, F.-J.; Guo, H.-T.; Li, Y.; Wang, K. Turbine blade tip clearance measurement using a skewed dual-beam fiber optic sensor. Opt. Eng. 2012, 51. [Google Scholar] [CrossRef]

- Schicht, A.; Schwarzer, S.; Schmidt, L.-P. Tip Clearance Measurement Technique for Stationary Gas Turbines Using an Autofocusing Millimeter-Wave Synthetic Aperture Radar. IEEE Trans. Instrum. Meas. 2012, 61, 1778–1785. [Google Scholar] [CrossRef]

- Violetti, M.; Skrivervik, A.K.; Xu, Q.; Hafner, M. New microwave sensing system for blade tip clearance measurement in gas turbines. In Proceedings of the 2012 IEEE Sensors, Taipei, Taiwan, 28–31 October 2012; pp. 1–4. [Google Scholar]

- Szczepanik, R.; Przysowa, R.; Spychała, J.; Rokicki, E.; Kazmierczak, K.; Majewski, P. Application of Blade-Tip Sensors to Blade-Vibration Monitoring in Gas Turbines. In Thermal Power Plants; Rasul, M., Ed.; IntechOpen: London, UK, 2012; ISBN 978-953-307-952-3. [Google Scholar] [CrossRef]

- Kempe, A.; Schlamp, S.; Rösgen, T.; Haffner, K. Spatial and Temporal High-Resolution Optical Tip-Clearance Probe for Harsh Environments. In Proceedings of the 13th International Symposium on Applications of Laser Techniques to Fluid Mechanics, Lisboa, Portugal, 26–29 June 2006. [Google Scholar]

- García, I.; Zubia, J.; Durana, G.; Aldabaldetreku, G.; Illarramendi, M.A.; Villatoro, J. Optical Fiber Sensors for Aircraft Structural Health Monitoring. Sensors 2015, 15, 15494–15519. [Google Scholar] [CrossRef] [PubMed]

- López-Higuera, J.M. Introduction to Fibre Optic Sensing Technology. In Handbook of Optical Fibre Sensing Technology; López-Higuera, J.M., Ed.; Wiley: Hoboken, NJ, USA, 2002. [Google Scholar]

- Przysowa, R.; Garcia, I.; Zubia, J. Tip-clearance measurement in a legacy turbojet with the use of an optical fiber sensor. In Proceedings of the EVI-GTI and PIWG Joint Conference on Gas Turbine Instrumentation, Berlin, Germany, 27–29 September 2016. [Google Scholar]

- García, I.; Przysowa, R.; Amorebieta, J.; Zubia, J. Tip-Clearance Measurement in the First Stage of the Compressor of an Aircraft Engine. Sensors 2016, 16, 1897. [Google Scholar] [CrossRef] [PubMed]

- BingHui, J.; Lei, H. An Optical Fiber Measurement System for Blade Tip Clearance of Engine. Int. J. Aerosp. Eng. 2017, 2017, 1–9. [Google Scholar] [CrossRef]

- Ma, Y.-Z.; Zhang, Y.-K.; Li, G.-P.; Liu, H.-G. Tip clearance optical measurement for rotating blades. MSIE 2011 2011, 1206–1208. [Google Scholar] [CrossRef]

- Savović, S.; Djordjevich, A. Calculation of the coupling coefficient in step index glass optical fibers. Appl. Opt. 2009, 48, 4496–4500. [Google Scholar] [CrossRef] [PubMed]

- Yoshimura, T. Statistical properties of dynamic speckles. J. Opt. Soc. Am. A 1986, 3, 1032–1054. [Google Scholar] [CrossRef]

- Daino, B.; De Marchis, G.; Piazzolla, S. Analysis and measurement of modal noise in an optical fibre. Electron. Lett. 1979, 15, 755. [Google Scholar] [CrossRef]

- Garcia, I.; Zubia, J.; Berganza, A.; Beloki, J.; Arrue, J.; Illarramendi, M.A.; Mateo, J.; Vazquez, C.; Vazquez, M.C. Different configurations of a reflective intensity-modulated optical sensor to avoid modal noise in tip-clearance measurements. J. Light. Technol. 2015, 33, 1. [Google Scholar] [CrossRef]

- Durana, G.; Amorebieta, J.; Fernandez, R.; Beloki, J.; Arrospide, E.; Garcia, I.; Zubia, J. Design, Fabrication and Testing of a High-Sensitive Fibre Sensor for Tip Clearance Measurements. Sensors 2018, 18, 2610. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, R.; Amorebieta, J.; Durana, G.; Beloki, J.; Zubia, J. Perf ormance comparison among three optical fibre-based displacement sensors for Blade Tip Clearance measurements. In Proceedings of the 5th IEEE International Workshop on Metrology for AeroSpace (MetroAeroSpace), Rome, Italy, 20–22 June 2018; pp. 657–662. [Google Scholar]

- Cao, H.; Chen, Y.; Zhou, Z.; Zhang, G. Theoretical and experimental study on the optical fiber bundle displacement sensors. Sens. Actuators Phys. 2007, 136, 580–587. [Google Scholar] [CrossRef]

| 1st Sensor Configuration | 2nd Sensor Configuration | 3rd Sensor Configuration | 4th Sensor Configuration | 5th Sensor Configuration | |

|---|---|---|---|---|---|

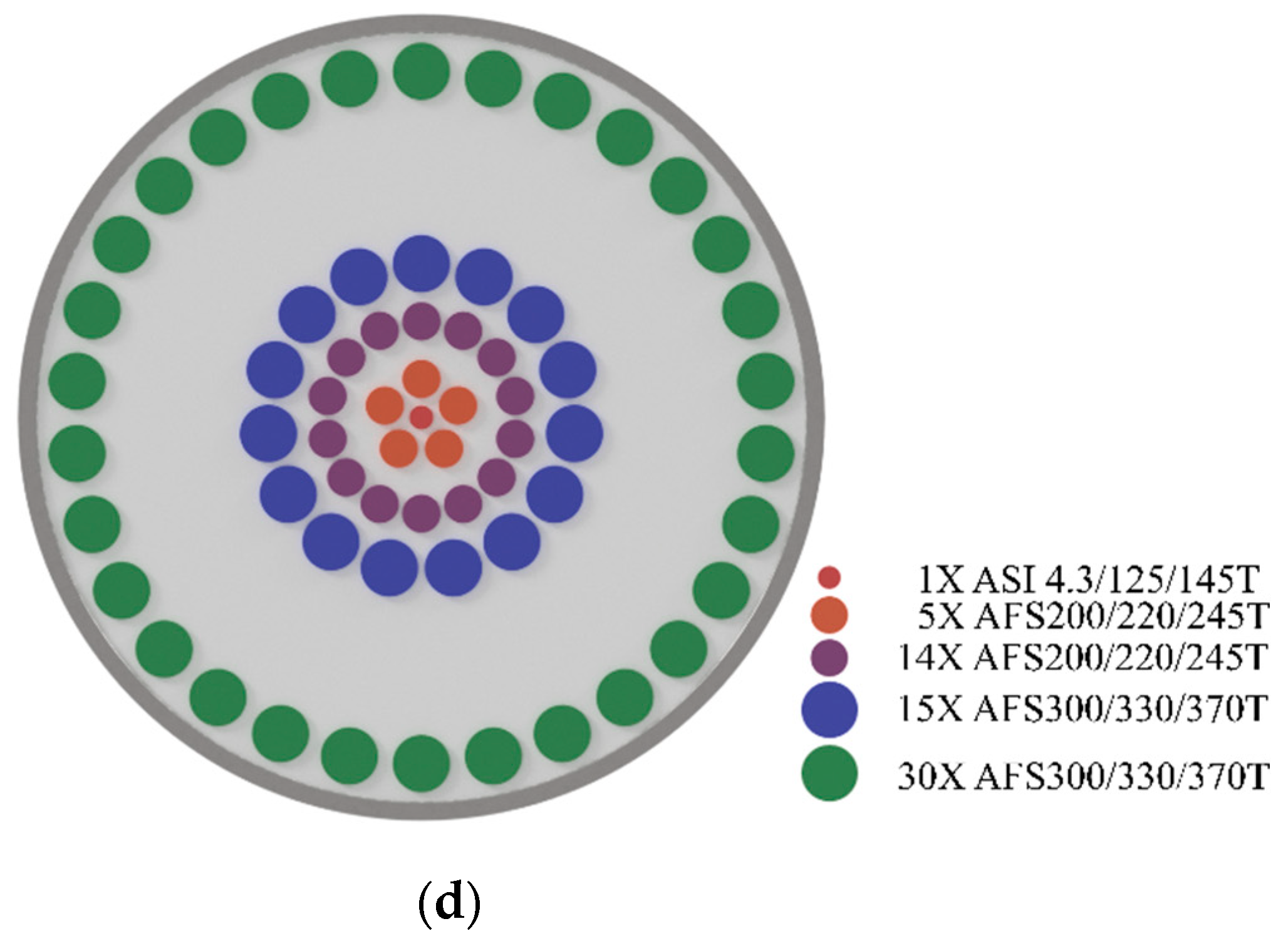

| Emitter fibre | Multimode NA = 0.22 fibre Ø100 µm | Scrambler + Multimode NA = 0.22 fibre Ø100 µm | POF Multimode NA = 0.5 fibre Ø240 µm | Single-mode NA = 0.12 fibre Ø4.3 µm | Single-mode NA = 0.12 fibre Ø4.3 µm |

| Receive fibres | Multimode NA = 0.22 fibre Ø100 µm | Multimode NA = 0.22 fibre Ø100 µm | POF, Multimode NA = 0.5 fibre Ø240 µm | Multimode NA = 0.22 fibre Ø100 µm | Multimode NA = 0.22 fibre Ø200 µm fibre Ø300 µm |

| Max. operational temperature for fibres | 350 °C | 350 °C | 60 °C | 350 °C | 350 °C |

| Gain of each photodetector | G1 = G2 = 0.75 × 104 V/A | G1 = 0.75 × 105 V/A G2 = 2.38 × 105 V/A | G1 = 0.75 × 105 V/A G2 = 2.38 × 105 V/A | G1 = 0.75 × 105 V/A G2 = 2.38 × 105 V/A | G1 = 1.51 × 103 V/A G2 = 1.51 × 105 V/A |

| Range of working distance | 3–7 mm | 3–7 mm | 0–5 mm | 0–5 mm | 2.5–4.3 mm |

| Calibration curve | V2/V1 = −0.089d + 1.8783 R2 = 0.9945 | V2/V1 = −0.2002d + 2.4578 R2 = 0.9455 | V2/V1 = −0.213d + 5.0064 R2 = 0.9997 | V2/V1 = −0.2167d + 3.8448 R2 = 0.9882 | V2/V1 = 43.36d − 67.57 |

| Cross-section |  |  |  |  |  |

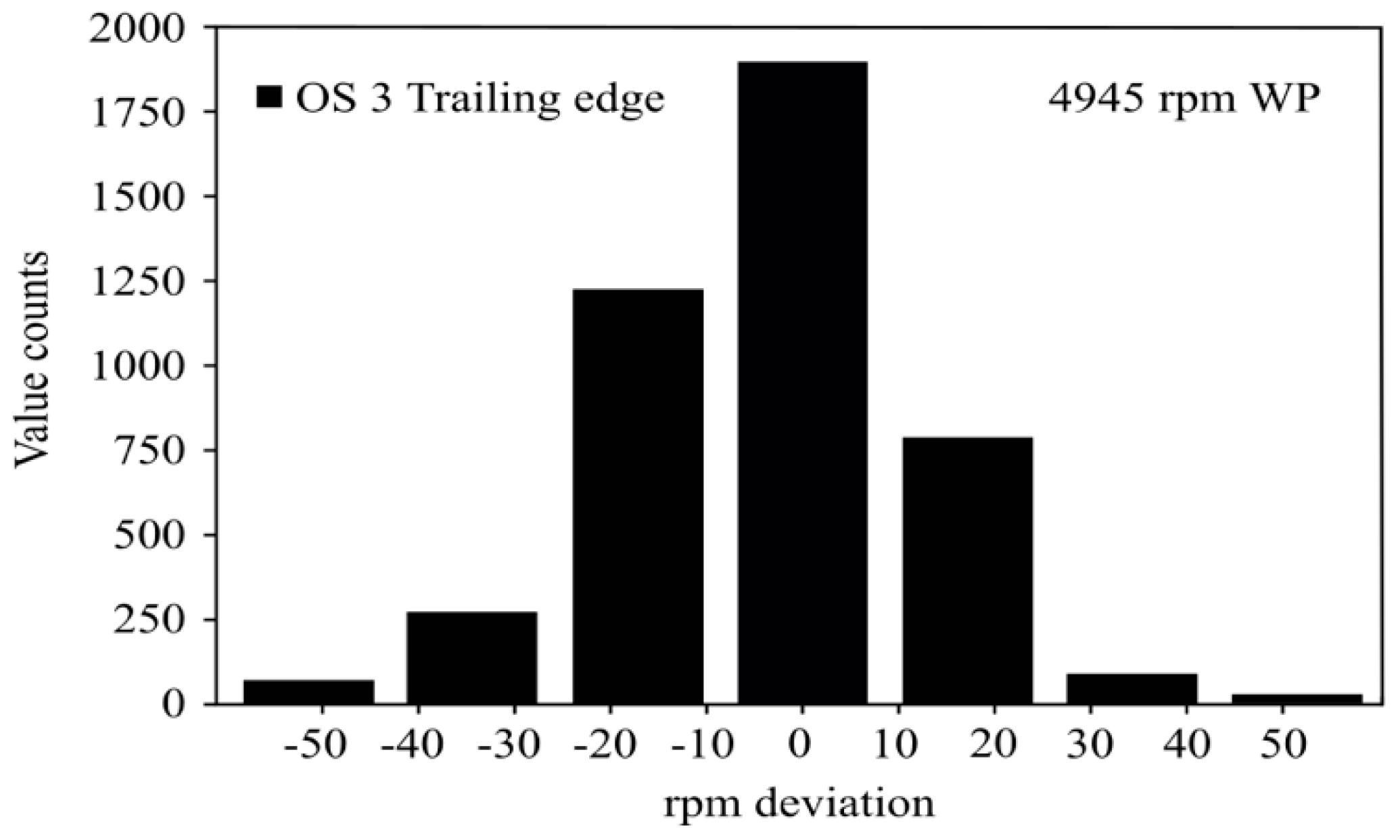

| OS 1 Leading Edge | OS 1 Trailing Edge | OS 2 Leading Edge | OS 2 Trailing Edge | OS 3 Leading Edge | OS 3 Trailing Edge |

|---|---|---|---|---|---|

| 91% | 77% | 53% | 70% | 6% | 2% |

| Sensor | Mean (rpm) | Standard Deviation of the Mean (rpm) |

|---|---|---|

| OS 1 | −21.37 | ±3.06 |

| OS 2 | −141.74 | ±7.13 |

| OS 3 | 0.09 | ±0.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Fernández, R.; Amorebieta, J.; García, I.; Aldabaldetreku, G.; Zubia, J.; Durana, G. Review of a Custom-Designed Optical Sensing System for Aero-Engine Applications. Int. J. Turbomach. Propuls. Power 2021, 6, 3. https://doi.org/10.3390/ijtpp6010003

Fernández R, Amorebieta J, García I, Aldabaldetreku G, Zubia J, Durana G. Review of a Custom-Designed Optical Sensing System for Aero-Engine Applications. International Journal of Turbomachinery, Propulsion and Power. 2021; 6(1):3. https://doi.org/10.3390/ijtpp6010003

Chicago/Turabian StyleFernández, Rubén, Josu Amorebieta, Iker García, Gotzon Aldabaldetreku, Joseba Zubia, and Gaizka Durana. 2021. "Review of a Custom-Designed Optical Sensing System for Aero-Engine Applications" International Journal of Turbomachinery, Propulsion and Power 6, no. 1: 3. https://doi.org/10.3390/ijtpp6010003

APA StyleFernández, R., Amorebieta, J., García, I., Aldabaldetreku, G., Zubia, J., & Durana, G. (2021). Review of a Custom-Designed Optical Sensing System for Aero-Engine Applications. International Journal of Turbomachinery, Propulsion and Power, 6(1), 3. https://doi.org/10.3390/ijtpp6010003