Hybrid Data-Driven and Physics-Based Modeling for Gas Turbine Prescriptive Analytics

Abstract

:1. Introduction

1.1. Physics-Based Approach

- Subsystems designed with simplified differential equations are not accurate enough for realistic simulation of a system’s dynamics. For instant, control systems can use a simplified dynamic model of the engines, but these models usually can not describe abnormal behavior, which corresponds to some developing malfunctions.

- Usually, operators and predictive system developers do not have subsystems and component characteristics (e.g., performance maps of compressors and turbines) required for physics-based model development.

1.2. Data-Driven Approach

1.3. Digital Twin

2. Materials and Methods

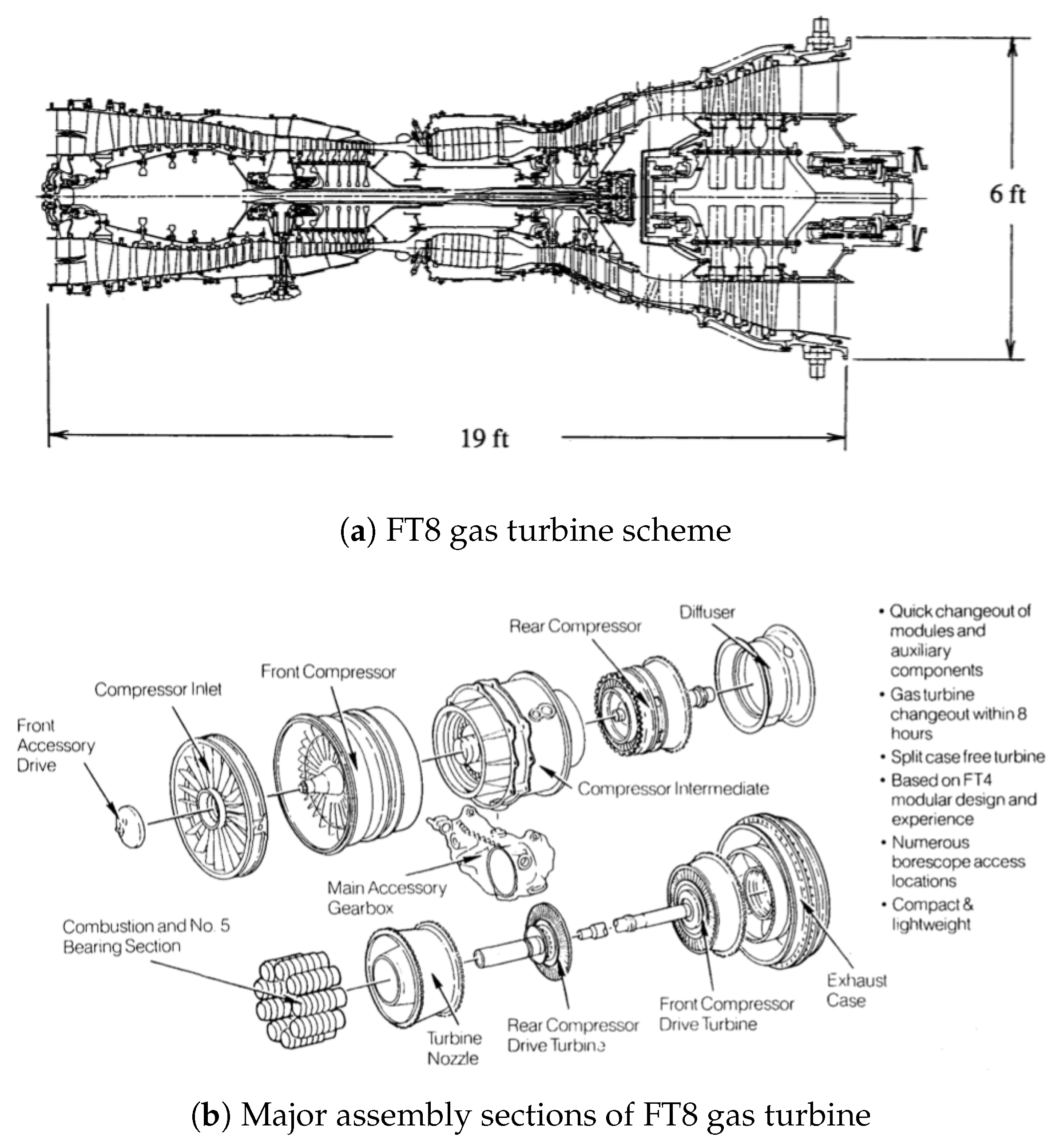

2.1. Problem Statement

- Two years of real FT8 gas turbine field data;

- 24 features, such as pressures and temperatures in different parts of the turbine, environment conditions, shafts’ rotary speed.;

- moments of time when flame tubes were repaired;

- numbers of flame tubes which were broken.

2.2. Physics-Based Model of a Gas Turbine

- An engineer defines a type of the considered compressor or turbine.

- A component of the same type with a known performance map (reference map) is taken.

- The reference map is scaled by mass flow rate, pressure ratio, rotary speed, and isentropic efficiency factors to obtain an actual performance map.

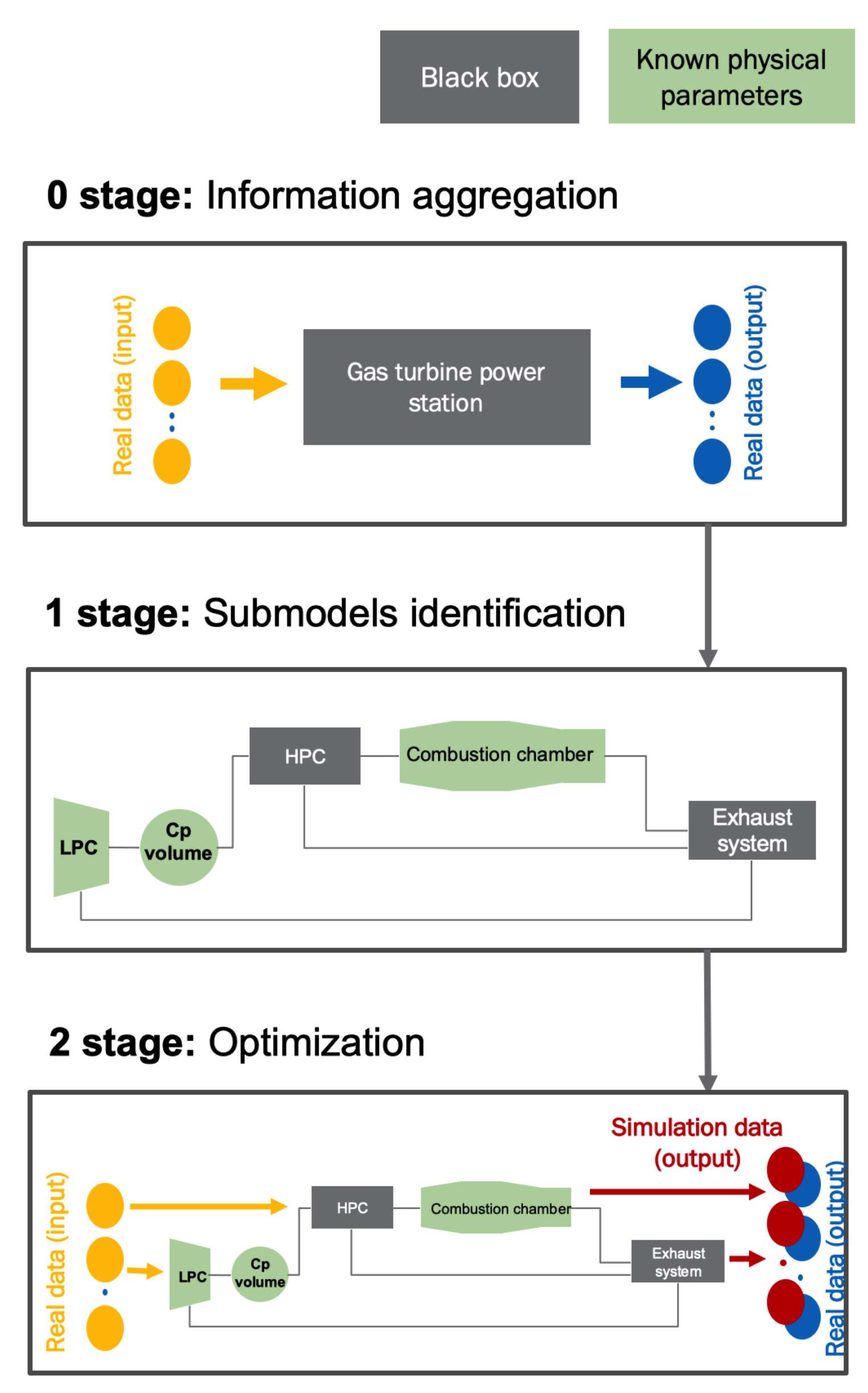

2.3. Workflow for Physical Model Development

- The model is represented as a black box. Only the input parameters and output parameters are known. The field data and model documentation are collected.

- Some subsystems are identified using papers, documentation, and measurements, while subsystems remain as black boxes.

- Optimization algorithms are used to tune the parameters of unknown subsystems using field data.

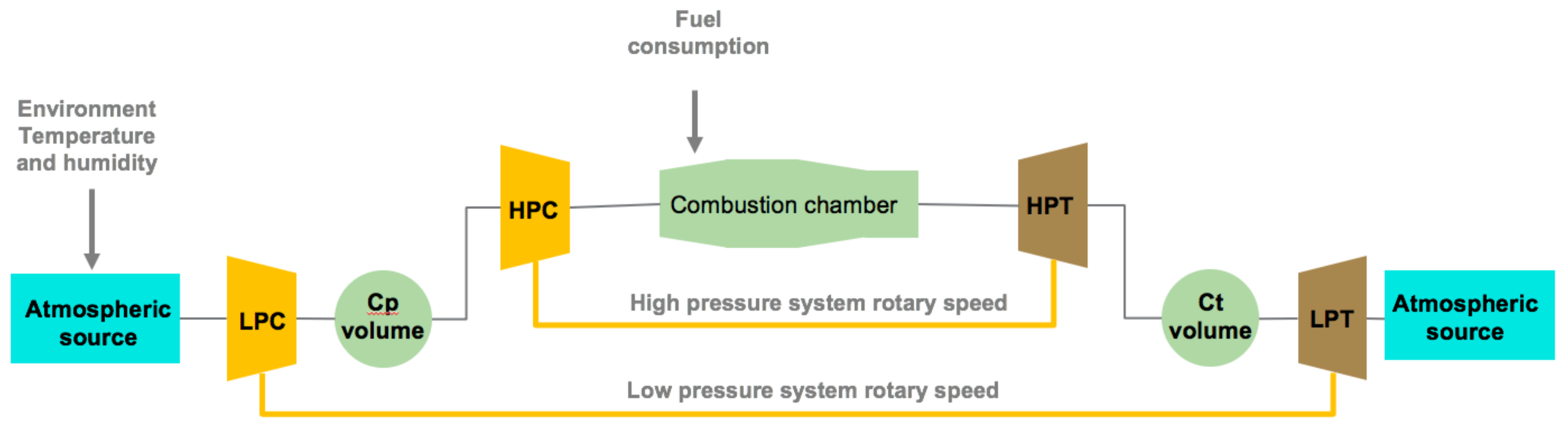

2.3.1. Subsystems Description

2.3.2. Atmospheric Source

2.3.3. Chamber with Constant Volume

2.3.4. Compressor

2.3.5. Combustion Chamber

2.3.6. Turbine

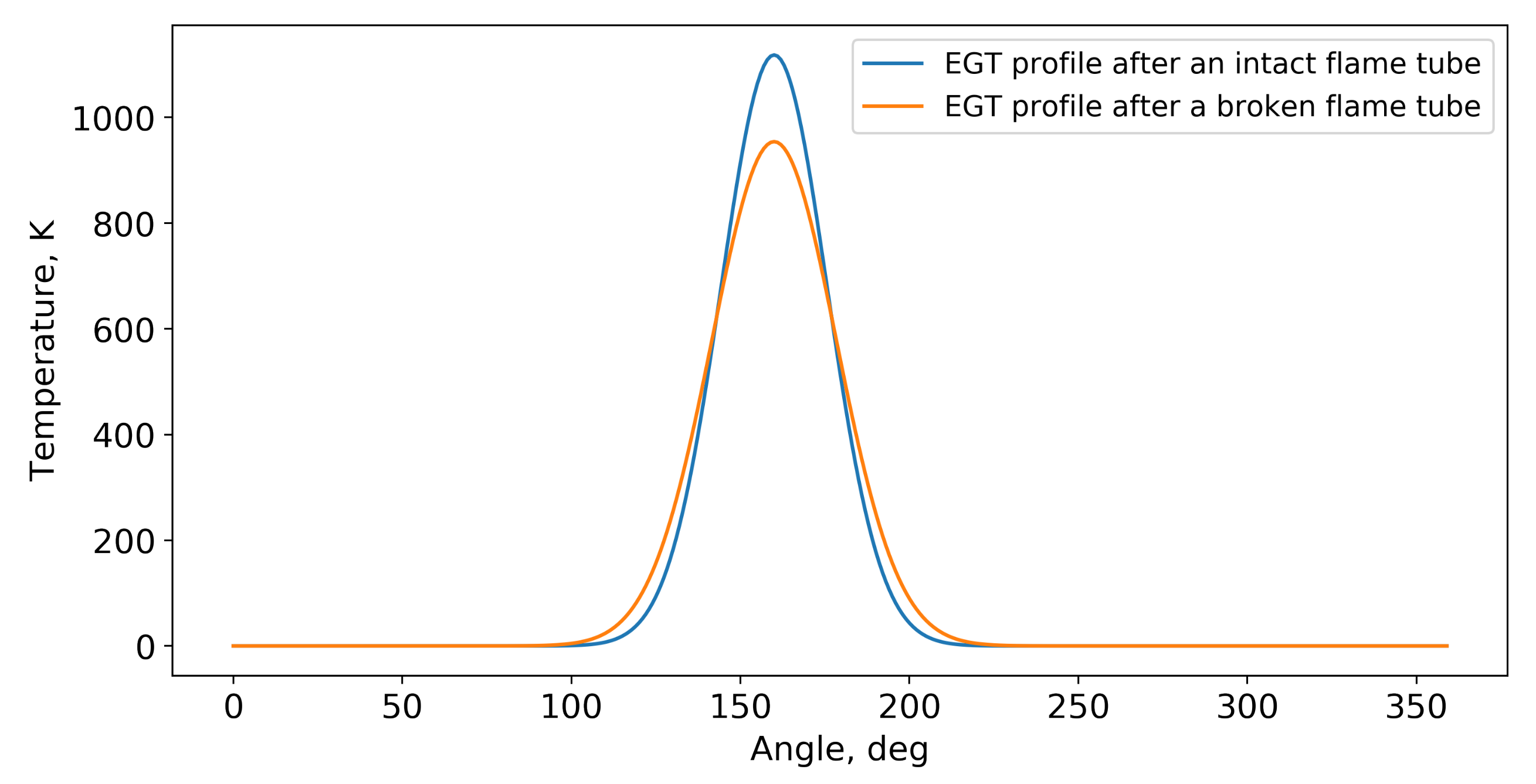

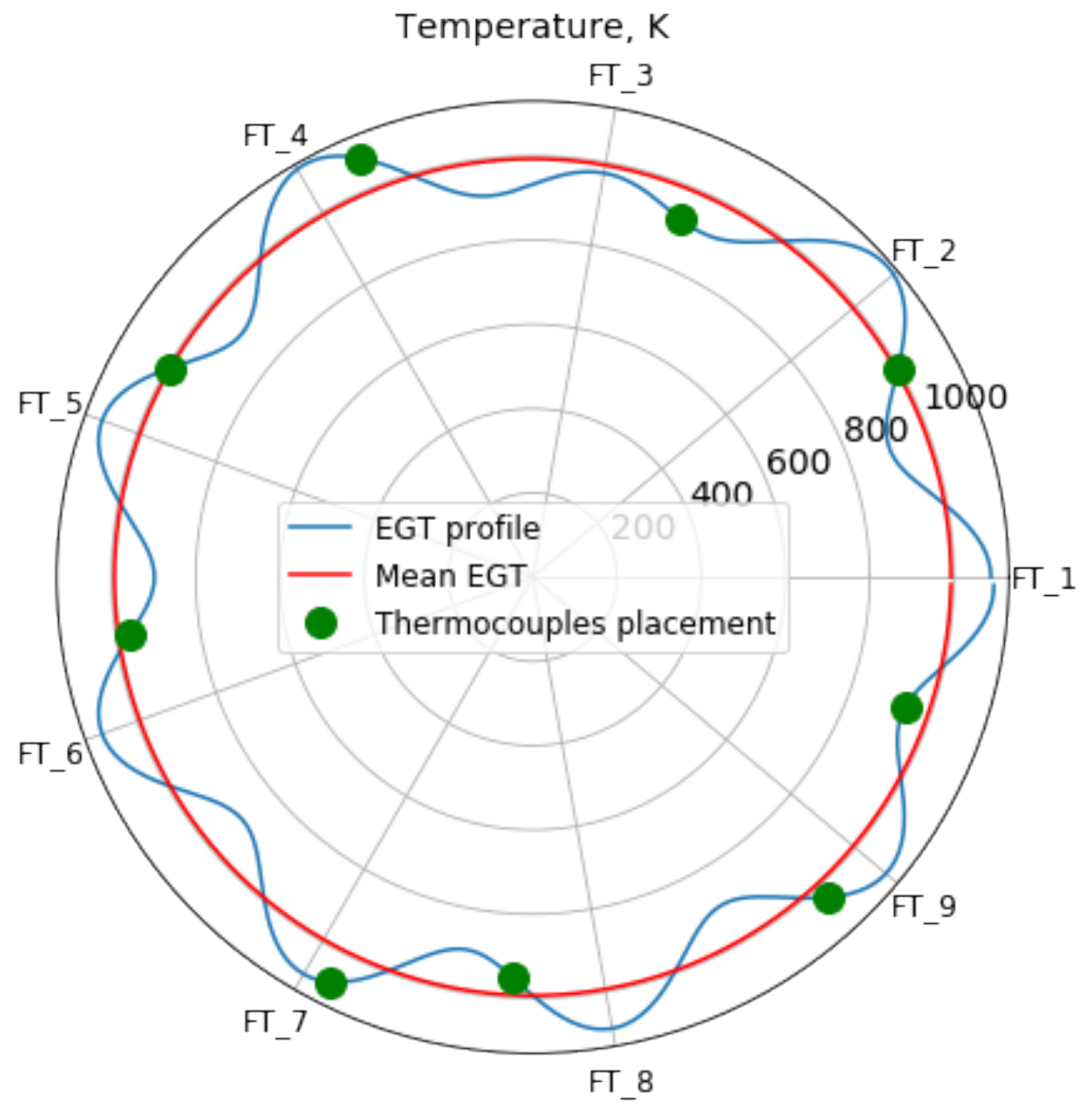

2.3.7. Exhaust Gas Temperature Distribution

2.4. Tuning of the Gas Turbine Physical Model

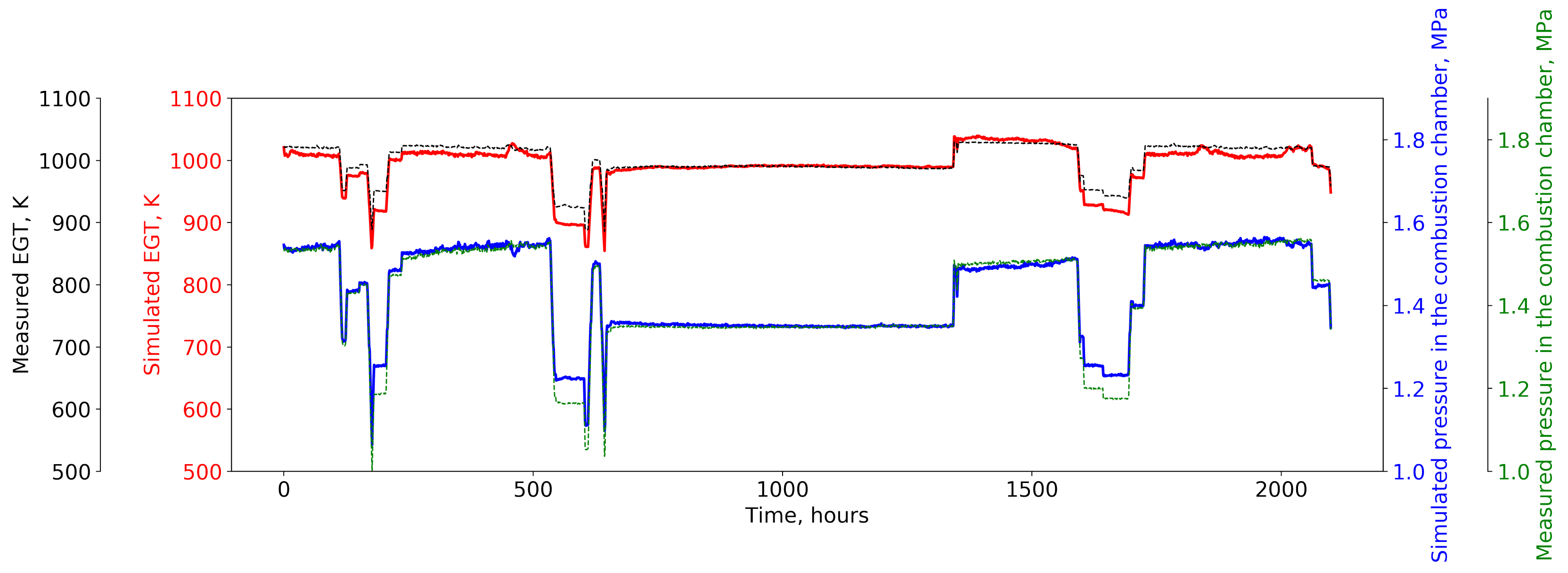

2.5. Model Validation

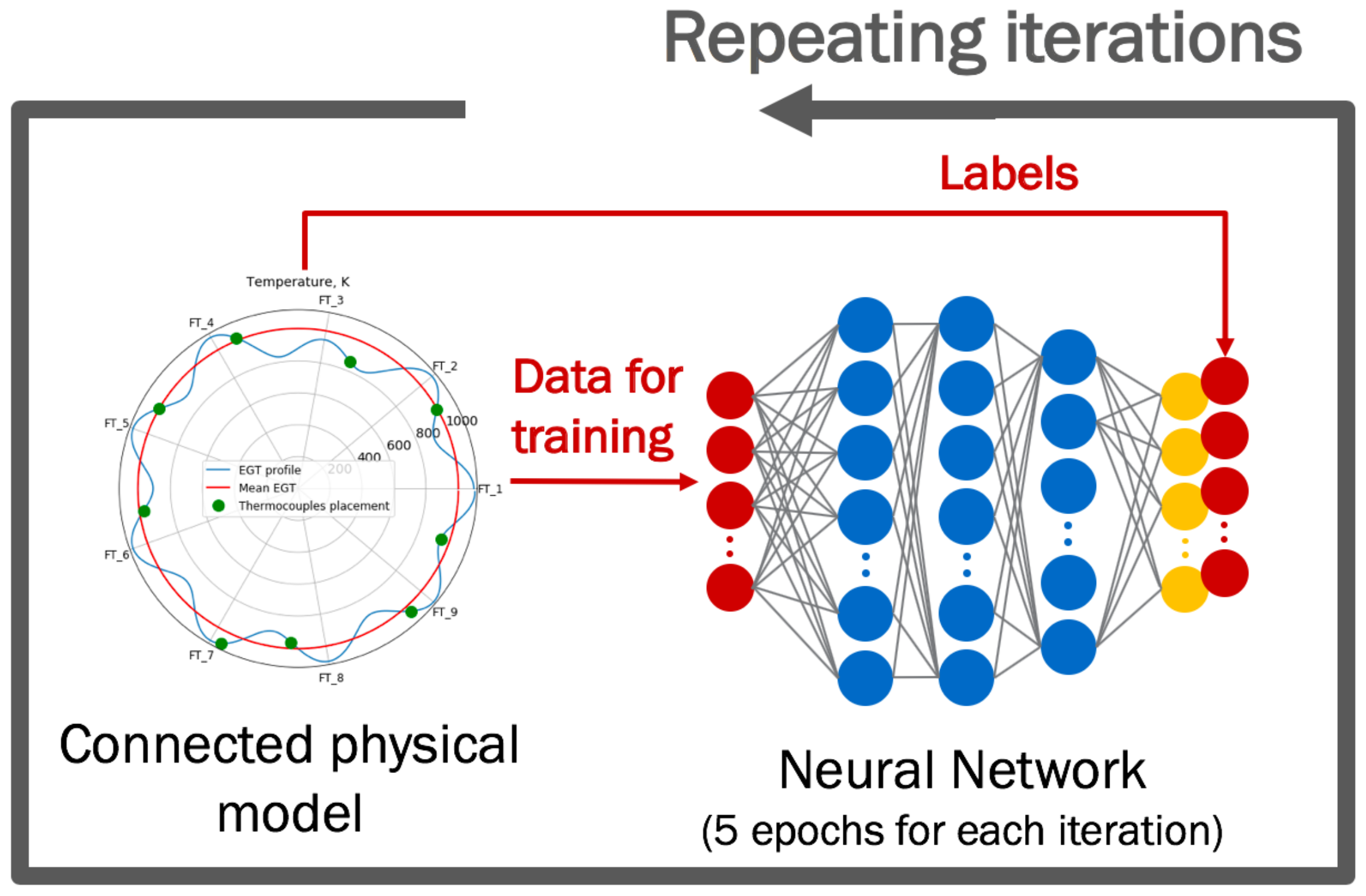

2.6. Hybrid Modeling

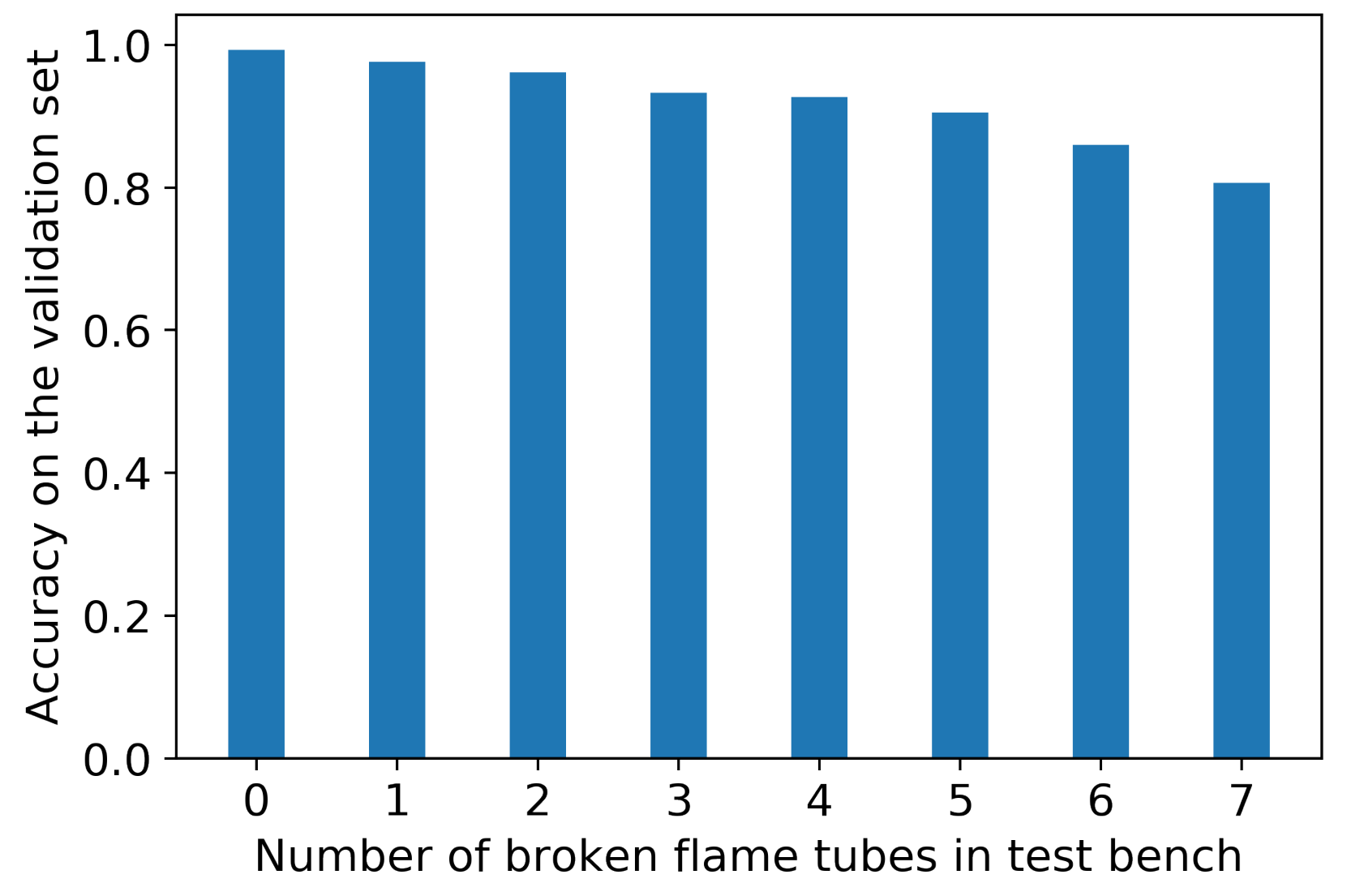

- Nine flame tubes were placed in the combustion chamber. Each could be broken in the same period of time (in the present case study, seven flame tubes were broken simultaneously). The number of broken flame tubes at a given moment may range from zero to nine with unknown probability.

- Malfunction of the flame tubes led to changes in the temperature profile of the EGT probes.

- Malfunction of the different flame tubes led to unique differences in the temperature profile of the EGT probes.

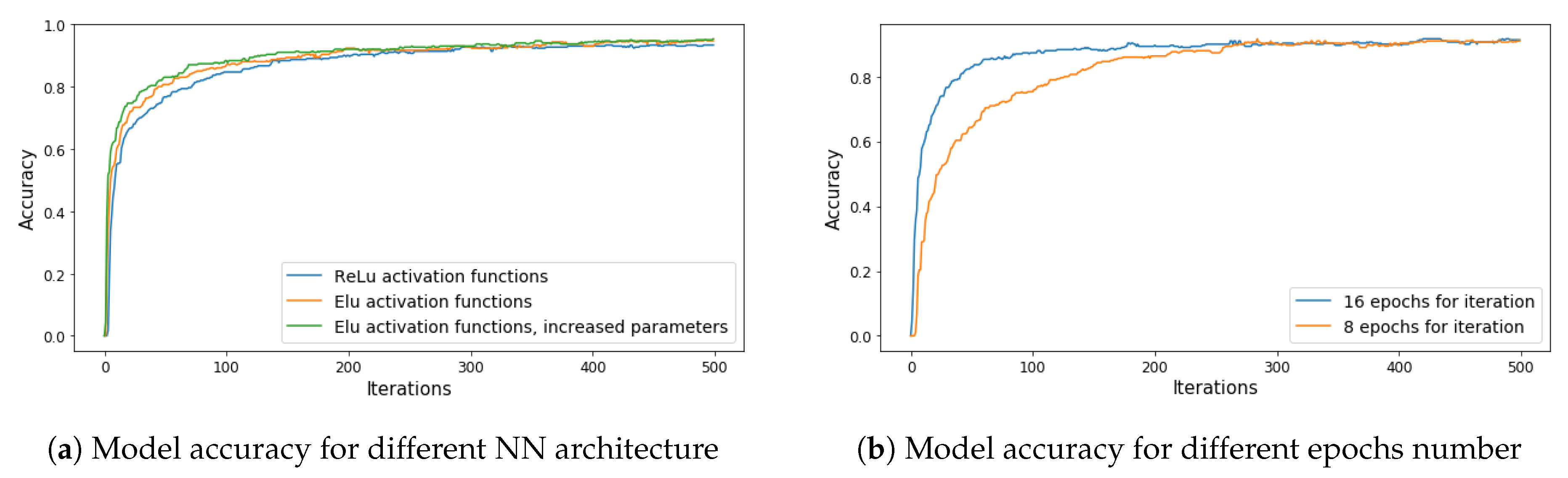

- , dropout = 0.1, ReLU activation function in hidden layers

- , dropout = 0.1, ELU activation function in hidden layers

- , dropout = 0.1, ELU activation function in hidden layers

2.6.1. Combination of Approaches for Flame Tubes Health Monitoring

- The physics-based model chose a random number N from zero to nine, which determined the amount of broken flame tubes in the data sample.

- Random flame tubes were defined as broken.

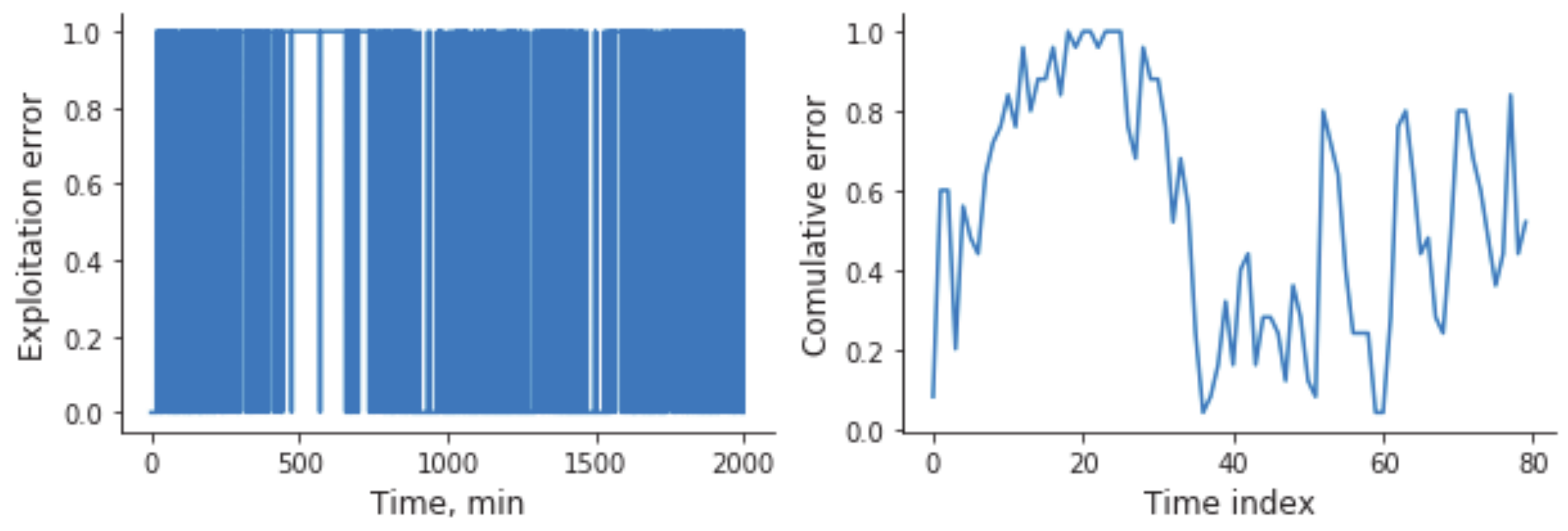

- Malfunction in each flame tube was simulated as the increased variance of the temperature distribution. Figure 8 shows an example of the simulated malfunction in the third flame tube.

- The physics-based model simulated the steady-state working conditions of the turbine and calculated the EGT distribution.

| Algorithm 1: Training algorithm |

|

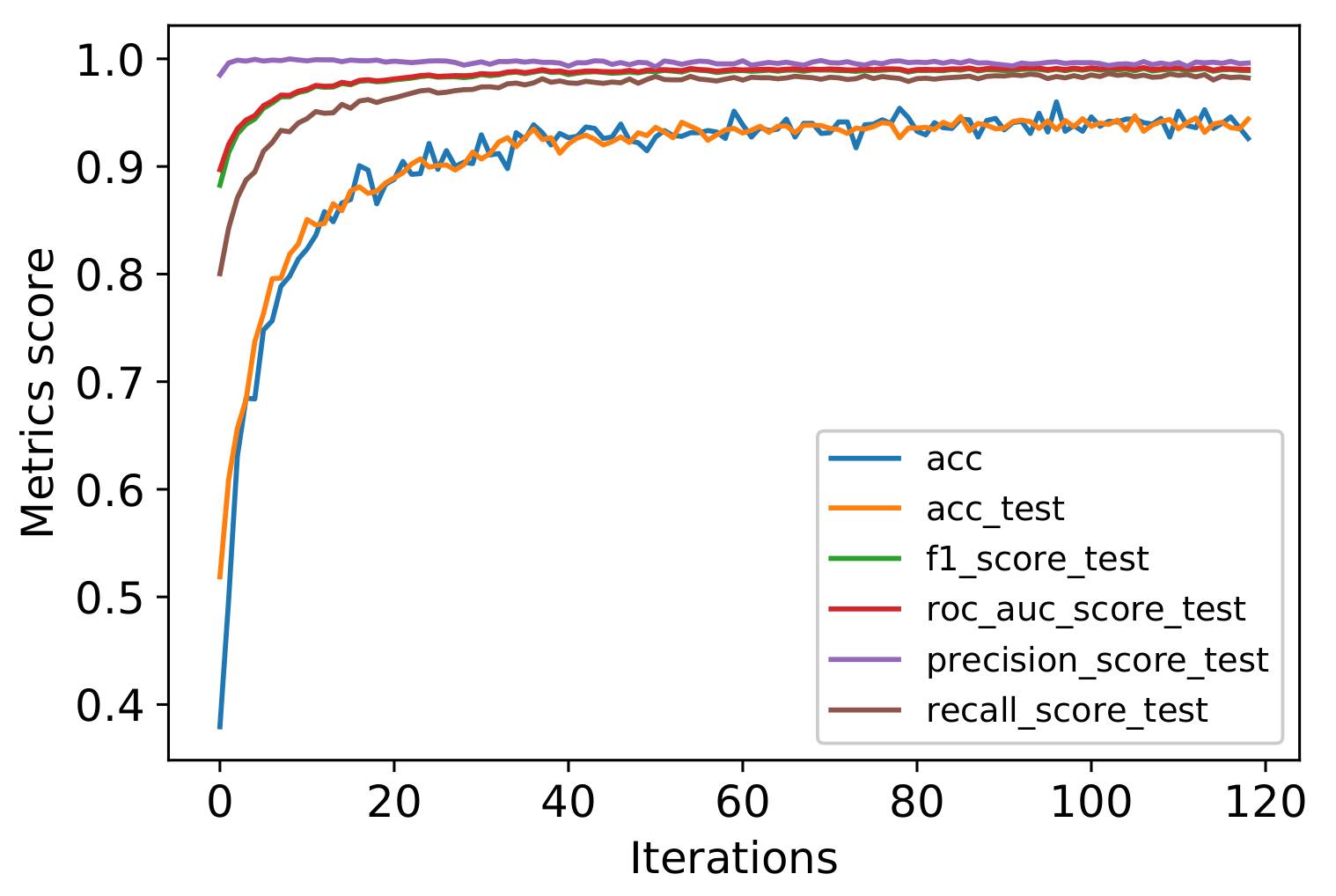

2.6.2. Model Training and Architectures Comparison

- Epochs number—16.

- Batch size—40.

- Mean time of the dataset generation = 9.6 s for 900 labeled data points.

- Mean time of the neural network training = 1.22 s for 16 epochs.

3. Results and Discussion

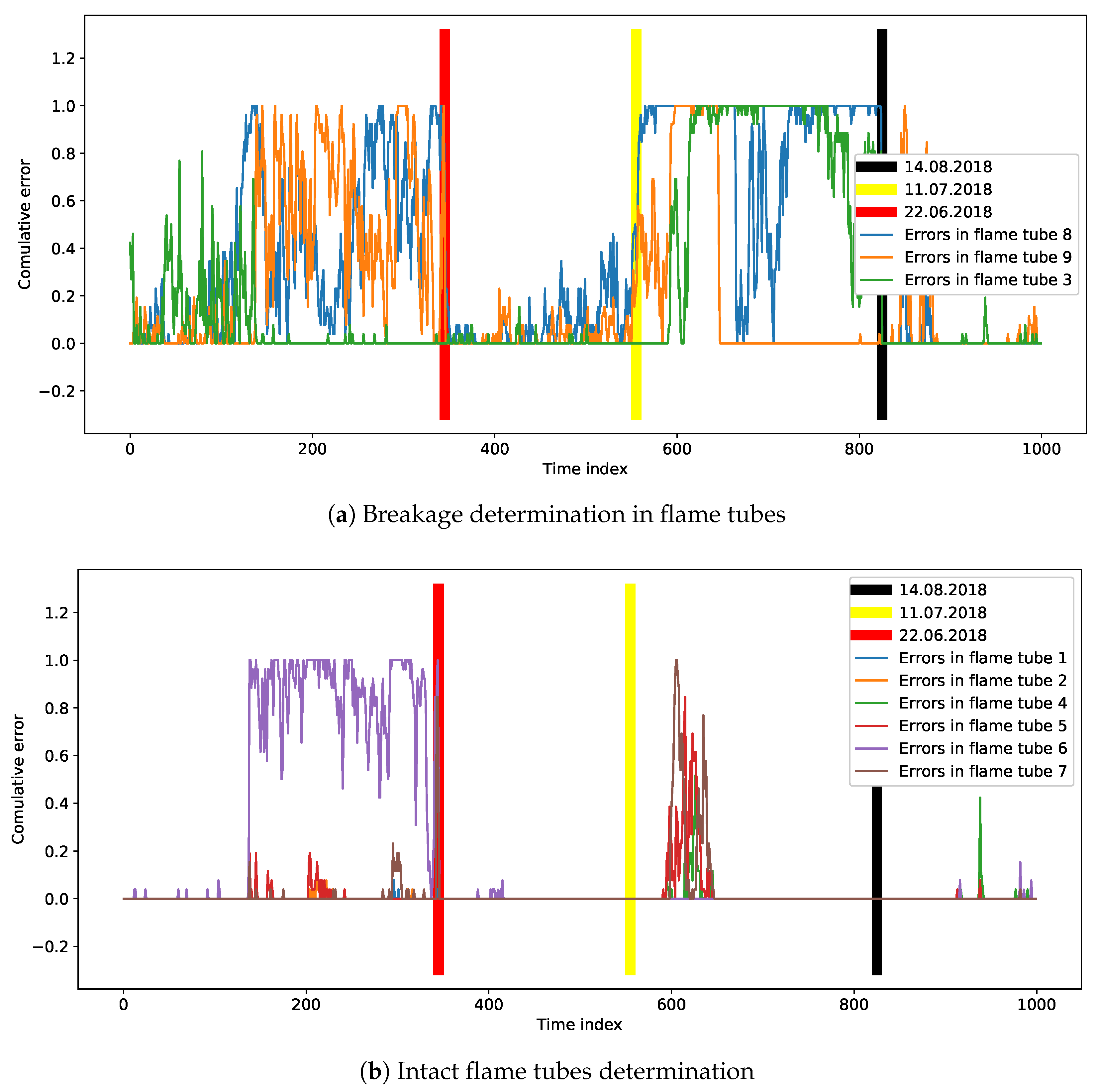

3.1. Prescriptive Results

- Black color—14 August 2018. The day when flame tubes 1, 2, 3, 4, 6, 8, 9 were repaired.

- Yellow color—11 July 2018. The day when flame tubes have broken, according to the model prediction.

- Red color—22 June 2018. A previous repair of flame tubes, according to the model prediction.

3.2. Advantages of Combined Approach

- Only a small amount of the field data is needed to adjust the model to a real turbine. In the case of the FT8 gas turbine, we worked with only 10 data points to identify the performance maps. This means that the model could be tuned to new turbines after a day of operation, which indicates the scalability of the approach.

- Compared with a purely data-driven approach, the combined model allows operators to detect not only the abnormal behavior of gas turbines but also the reasons for it.

- Many malfunctions can be simulated. As soon as the physical model is validated, we can simulate many types of faults.

4. Conclusions

- Lack of engineering data is the main limitation in the development of a physics-based model. It is not possible to develop a model without performance maps for the compressors and turbines.

- Unknown malfunctions or other malfunctions not taken into during machine learning model training, could be identified incorrectly.

- If the construction of a gas turbine is changed (for instance, if the EGT probes are placed differently), the model has to be adjusted.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Latin Symbols | ||

| prediction accuracy | − | |

| prediction for i flame tube in j experiment out of M | − | |

| label for i flame tube in j experiment out of M | − | |

| specific heat at constant pressure of i-th gas component | ||

| gas mixture specific heat at constant pressure | ||

| gas mixture specific heat at constant volume | ||

| specific heat at constant volume of i-th gas component | ||

| enthalpy of formation of i-th gas component | J | |

| output enthalpy | J | |

| mass flow rate | ||

| M | number of experiments | − |

| inlet pressure | Pa | |

| outlet pressure | Pa | |

| Q | heat flow | Pa |

| gas mixture individual gas constant | ||

| inlet temperature | K | |

| outlet temperature | K | |

| V | volume | m |

| i-th component of the gas mixture | − | |

| Greek Symbols | ||

| angular placement of the k-th thermocouple | rad | |

| heat capacity ratio | − | |

| isentropic efficiency | − | |

| initial mix density | kg/m | |

| pressure of the i-th mix component | kg/m | |

| standard deviation of the exhaust gas temperature distribution | K | |

| compressor rotary speed | rad/s | |

| Abbreviations | ||

| AUC ROC | Area under receiver operating characteristic | |

| CAE | Computer-aided engineering | |

| CFD | Computational fluid dynamics | |

| EGT | Exhaust gas temperature | |

| ELU | Exponential Linear Unit | |

| HPC | High pressure compressor | |

| HPT | High pressure turbine | |

| LPC | Low pressure compressor | |

| LPT | Low pressure turbine | |

| NN | Neural network | |

| PLM | Product lifecycle management | |

| PT | Pressure turbine | |

| ReLU | Rectified Linear Unit | |

| RP | Resizing parameters | |

| SPDM | Simulation process and data management | |

| SVM | Support vector machine | |

| SysML | Systems modeling language | |

| TC | Temperature at a thermocouple | |

| Subscripts | ||

| in | inlet | |

| init | initial | |

| mix | gas mixture | |

| out | outlet | |

References

- Definition of Prescriptive Analytics—Gartner Information Technology Glossary. Available online: https://www.gartner.com/en/information-technology/glossary/prescriptive-analytics (accessed on 24 October 2020).

- Lepenioti, K.; Bousdekis, A.; Apostolou, D.; Mentzas, G. Prescriptive analytics: Literature review and research challenges. Int. J. Inf. Manag. 2020, 50, 57–70. [Google Scholar] [CrossRef]

- Deshpande, P.S.; Sharma, S.C.; Peddoju, S.K. Predictive and Prescriptive Analytics in Big-data Era. In Security and Data Storage Aspect in Cloud Computing; Springer: Berlin/Heidelberg, Germany, 2019; pp. 71–81. [Google Scholar]

- Matyas, K.; Nemeth, T.; Kovacs, K.; Glawar, R. A procedural approach for realizing prescriptive maintenance planning in manufacturing industries. CIRP Ann. 2017, 66, 461–464. [Google Scholar] [CrossRef]

- Martins, D.R. Off-Design Performance Prediction of the CFM56-3 Aircraft Engine. Master’s Thesis, Tecnico Lisboa, Lisboa, Portugal, 2015. [Google Scholar]

- Ghose, P.; Patra, J.; Datta, A.; Mukhopadhyay, A. Prediction of soot and thermal radiation in a model gas turbine combustor burning kerosene fuel spray at different swirl levels. Combust. Theory Model. 2016, 20, 457–485. [Google Scholar] [CrossRef]

- Durante, A.; Pena-Vergara, G.; Curto-Risso, P.; Medina, A.; Hernández, A.C. Thermodynamic simulation of a multi-step externally fired gas turbine powered by biomass. Energy Convers. Manag. 2017, 140, 182–191. [Google Scholar] [CrossRef] [Green Version]

- Bilgen, E. Exergetic and engineering analyses of gas turbine based cogeneration systems. Energy 2000, 25, 1215–1229. [Google Scholar] [CrossRef]

- Allen, C.W.; Holcomb, C.M.; de Oliveira, M. Gas Turbine Machinery Diagnostics: A Brief Review and a Sample Application. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2017; Volume 50916, p. V006T05A028. [Google Scholar]

- Wong, P.K.; Yang, Z.; Vong, C.M.; Zhong, J. Real-time fault diagnosis for gas turbine generator systems using extreme learning machine. Neurocomputing 2014, 128, 249–257. [Google Scholar] [CrossRef]

- Mulewicz, B.; Marzec, M.; Morkisz, P.; Oprocha, P. Failures prediction based on performance monitoring of a gas turbine: A binary classification approach. Schedae Inform. 2017, 26, 21. [Google Scholar]

- Yan, W.; Yu, L. On Accurate and Reliable Anomaly Detection for Gas Turbine Combustors: A Deep Learning Approach. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Coronado, CA, USA, 18–24 October 2015; Volume 6, pp. 59–71. [Google Scholar] [CrossRef]

- Digital Twin: Manufacturing Excellence through Virtual Factory Replication—White Paper by M. Grieves. Available online: https://www.researchgate.net/publication/275211047_Digital_Twin_Manufacturing_Excellence_through_Virtual_Factory_Replication (accessed on 11 August 2020).

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging digital twin technology in model-based systems engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- Prario, A.; Voss, H. FT8A, a New High Performance 25 MW Mechanical Drive Aero Derivative Gas Turbine. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 1990; Volume 79061, p. V003T07A004. [Google Scholar]

- Day, W.H. FT8: A High Performance Industrial and Marine Gas Turbine Derived from the JT8D Aircraft Engine. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 1987; Volume 79245, p. V002T03A005. [Google Scholar]

- Allegorico, C.; Mantini, V. A data-driven approach for on-line gas turbine combustion monitoring using classification models. In Proceedings of the Second European Conference of the Prognostics and Health Management Society, Nantes, France, 8–10 July 2014; pp. 92–100. [Google Scholar]

- Gas Turbine Power Plants. Available online: https://www.isisvarese.edu.it/wp-content/uploads/2016/03/first-law-of-thermodynamics-for-an-open-system-.pdf (accessed on 11 August 2020).

- GE primer on GE Gas Turbine Performance Characteristics. Available online: http://ncad.net/Advo/CinerNo/ge6581b.pdf (accessed on 11 August 2020).

- Dai, X.; Breikin, T.; Gao, Z.; Wang, H. Dynamic modelling and Robust Fault Detection of a gas turbine engine. In Proceedings of the 2008 American Control Conference, Seattle, WA, USA, 11–13 June 2008; pp. 2160–2165. [Google Scholar]

- Turan, O.; Aydin, H. Exergy-based Sustainability Analysis of a Low-bypass Turbofan Engine: A Case Study for JT8D. Energy Procedia 2016, 95, 499–506. [Google Scholar] [CrossRef] [Green Version]

- Bălănescu, D.-T.; HriţCu, C.E.; Talif, S.G. Aeroderivative Pratt & Whitney FT8-3 gas turbine—An interesting solution for power generation. Incas Bull. 2011, 3, 9–14. [Google Scholar]

- Kurzke, J.; Riegler, C. A new compressor map scaling procedure for preliminary conceptional design of gas turbines. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2000; Volume 78545, p. V001T01A006. [Google Scholar]

- Cumpsty, N. Jet Propulsion: A Simple Guide to the Aerodynamics and Thermodynamic Design and Performance of Jet Engines; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar] [CrossRef]

- Energy Efficient Engine High Pressure Compressor—Component Performance Report. Available online: https://ntrs.nasa.gov/citations/19850025825 (accessed on 11 August 2020).

- Broichhausen, K. Aerodynamic Design of Turbomachinery Components—CFD in Complex Systems; AGARD Lecture Series 195; NATO Science and Technology Organization: Brussels, Belgium, 1994. [Google Scholar]

- Extended Parametric Representation of Compressor Fans and Turbines. Volume 3: MODFAN User’s Manual (Parametric Modulating Flow Fan). Available online: https://ntrs.nasa.gov/citations/19860014467 (accessed on 11 August 2020).

- Performance of a High-Work Low Aspect Ratio Turbine Tested with a Realistic Inlet Radial Temperature Profile. Available online: https://ntrs.nasa.gov/citations/19910010813 (accessed on 11 August 2020).

- NASA Report: Coefficients for Calculating Thermodynamic and Transport Properties of Individual Species. Available online: https://ntrs.nasa.gov/citations/19940013151 (accessed on 16 October 2020).

- Ding, C.H.; Dubchak, I. Multi-class protein fold recognition using support vector machines and neural networks. Bioinformatics 2001, 17, 349–358. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhardwaj, A.; Tiwari, A.; Bhardwaj, H.; Bhardwaj, A. A genetically optimized neural network model for multi-class classification. Expert Syst. Appl. 2016, 60, 211–221. [Google Scholar] [CrossRef]

- Clevert, D.; Unterthiner, T.; Hochreiter, S. Fast and Accurate Deep Network Learning by Exponential Linear Units (ELUs). In Proceedings of the 4th International Conference on Learning Representations, ICLR 2016, San Juan, PR, USA, 2–4 May 2016. [Google Scholar]

- Pedamonti, D. Comparison of non-linear activation functions for deep neural networks on MNIST classification task. arXiv 2018, arXiv:1804.02763. [Google Scholar]

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

- Understanding Binary Cross-Entropy/Log Loss: A Visual Explanation. Available online: https://towardsdatascience.com/understanding-binary-cross-entropy-log-loss-a-visual-explanation-a3ac6025181a (accessed on 11 August 2020).

- Shung, K.P. Accuracy, Precision, Recall or F1? 2018. Available online: https://towardsdatascience.com/accuracy-precision-recall-or-f1-331fb37c5cb9 (accessed on 11 August 2020).

- McClish, D.K. Analyzing a portion of the ROC curve. Med. Decis. Mak. 1989, 9, 190–195. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belov, S.; Nikolaev, S.; Uzhinsky, I. Hybrid Data-Driven and Physics-Based Modeling for Gas Turbine Prescriptive Analytics. Int. J. Turbomach. Propuls. Power 2020, 5, 29. https://doi.org/10.3390/ijtpp5040029

Belov S, Nikolaev S, Uzhinsky I. Hybrid Data-Driven and Physics-Based Modeling for Gas Turbine Prescriptive Analytics. International Journal of Turbomachinery, Propulsion and Power. 2020; 5(4):29. https://doi.org/10.3390/ijtpp5040029

Chicago/Turabian StyleBelov, Sergei, Sergei Nikolaev, and Ighor Uzhinsky. 2020. "Hybrid Data-Driven and Physics-Based Modeling for Gas Turbine Prescriptive Analytics" International Journal of Turbomachinery, Propulsion and Power 5, no. 4: 29. https://doi.org/10.3390/ijtpp5040029

APA StyleBelov, S., Nikolaev, S., & Uzhinsky, I. (2020). Hybrid Data-Driven and Physics-Based Modeling for Gas Turbine Prescriptive Analytics. International Journal of Turbomachinery, Propulsion and Power, 5(4), 29. https://doi.org/10.3390/ijtpp5040029