Abstract

The paper presents a state-of-the-art review of turbine trailing edge flows, both from an experimental and numerical point of view. With the help of old and recent high-resolution time resolved data, the main advances in the understanding of the essential features of the unsteady wake flow are collected and homogenized. Attention is paid to the energy separation phenomenon occurring in turbine wakes, as well as to the effects of the aerodynamic parameters chiefly influencing the features of the vortex shedding. Achievements in terms of unsteady numerical simulations of turbine wake flow characterized by vigorous vortex shedding are also reviewed. Whenever possible the outcome of a detailed code-to-code and code-to-experiments validation process is presented and discussed, on account of the adopted numerical method and turbulence closure.

1. Introduction

The first time the lead author came in touch with the problematic of turbine trailing edge flows was in 1965 when, as part of his diploma thesis, which consisted mainly in the measurement of the boundary layer development around a very large scale HP steam turbine nozzle blade, he measured with a very thin pitot probe a static pressure at the trailing edge significantly below the downstream static pressure. This negative pressure difference explained the discrepancy between the losses obtained from downstream wake traverses and the sum of the losses based on the momentum thickness of the blade boundary layers and the losses induced by the sudden expansion at the trailing edge. Pursuing his curriculum at the von Kármán Institute the author was soon in charge of building a small transonic turbine cascade tunnel with a test section of 150 × 50 mm, the C2 facility, which was intensively used for cascade testing for industry and in-house designed transonic bladings for gas and steam turbine application. These tests allowed systematic measurements of the base pressure as part of the blade pressure distribution for a large number of cascades which were first presented at the occasion of a Lecture Series held at the von Kàrmàn Institute (VKI) in 1976 and led to the publication of the well-known VKI base pressure correlation published in 1980. This correlation has served ever since for comparison with new base pressure data obtained in other research labs. Among these let us already mention in particular the investigations carried out on several turbine blades at the University of Cambridge, published in 1988, at the University of Carlton, published between 2001 and 2004, and at the Moscow Power Institute, published between 2014 and 2018.

In parallel to these steady state measurements, the arrival of short duration flow visualizations and the development of fast measurement techniques in the 1970’s allowed to put into evidence the existence of the von Kármán vortex streets in the wakes of turbine blades. Pioneering work was performed at the DLR Göttingen in the mid-1970’s, with systematic flow visualizations revealing the existence of von Kármán vortices on a large number of turbine cascades in the mid-seventies. This was the beginning of an intense research on the effect of vortex shedding on the trailing edge base pressure. A major breakthrough was achieved in the frame of two European research projects. The first one, initiated in 1992, Experimental and Numerical Investigation of Time Varying Wakes Behind Turbine Blades (BRITE/EURAM CT92-0048, 1992–1996) included very large-scale cascade tests in a new VKI cascade facility with a much larger test section allowing the testing of a 280 mm chord blade in a three bladed cascade at a moderate subsonic Mach number, with emphasis on flow visualizations and detailed unsteady trailing edge pressure measurements. The VKI tests were completed by low speed tests at the University of Genoa on the same large-scale profile for unsteady wake measurements using LDV. In the follow-up project Turbulence Modelling of Unsteady Flows on Flat Plate and Turbine Cascades in 1996 (BRITE/EURAM CT96-0143, 1996-1999) VKI extended the blade pressure measurements on a 50% reduced four bladed cascade model to a high subsonic Mach number, Both programs not only contributed to an improved understanding of unsteady trailing edge wake flow characteristics, of their effect on the rear blade surface and on the trailing edge pressure distribution, but also offered unique test cases for the validation of unsteady Navier-Stokes flow solvers.

A special and unexpected result of the research on unsteady turbine blade wakes was the discovery of energy separation in the wake leading to non-negligible total temperature variations within the wake. This effect was known from steady state tests on cylindrical bodies since the early 1940’s, but its first discovery in a turbine cascade was made at the NRAC, National Research Aeronautical Laboratory of Canada, in the mid-1990s within the framework of tests on the performance of a nozzle vane cascade at transonic outlet Mach numbers. The experimental results of the total temperature distribution in the wake of cascade at supersonic outlet Mach number served many researchers, in particular from the University of Leicester, for elaborating on the effect of energy separation.

The paper starts with the evaluation of the VKI base pressure correlation (Section 2) in view of new experiments. This is followed with a review of the advances in the understanding of unsteady trailing edge wake flows (Section 3), the observation and explanation of energy separation in turbine blade wakes (Section 4), the effect of vortex shedding on the blade pressure distribution (Section 5) and the effect of Mach number and boundary layer state on the vortex shedding frequency (Section 6). This experimental part is complemented with a review of the numerical methods and modelling concepts as applied to the simulation of unsteady turbine wake characteristics using advanced Navier-Stokes solvers. Available numerical data documenting significant vortex shedding affecting the turbine performance even in a time averaged sense, are collected and compared on a code-to-code and code-to-experiments basis in Section 7.

2. Turbine Trailing Edge Base Pressure

Traupel [1], was probably the first to present in his book Thermische Turbomaschinen, a detailed analysis of the profile loss mechanism for turbine blades at subsonic flows conditions. The total losses comprised three terms: the boundary losses including the downstream mixing losses for infinitely thin trailing edges, the loss due to the sudden expansion at the trailing edge (Carnot shock) for a blade with finite trailing edge thickness taking into account the trailing edge blockage effect and a third term which did take into account that the static pressure at the trailing edge differed from the average static pressure between the pressure side (PS) and the suction side (SS) trailing edges across one pitch. Thus, the profile loss coefficient reads:

where:

is the dimensionless average momentum thickness, and:

the dimensionless thickness of the trailing edge. The constant appearing at the right-hand-side of Equation (1) depends on the ratio:

that is, for and for , while a linear variation of is used for . Terms containing squares and products of were considered to be negligible.

Most researchers are, however, more familiar with a similar analysis of the loss mechanism by Denton [2], who introduced in the loss coefficient expression , the term quantifying the trailing edge base pressure contribution, with:

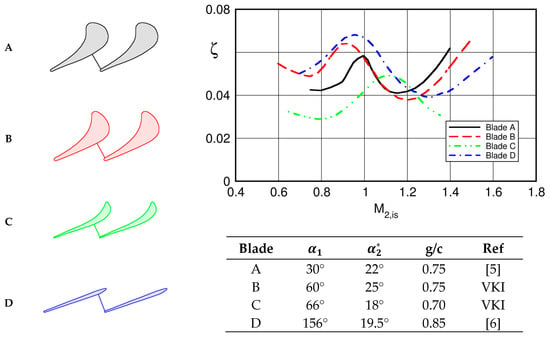

For commodity may be taken as the isentropic downstream velocity . However, there was a big uncertainty as regards the magnitude of this term, although it appeared that it could become very important in the transonic range and explain the presence of a strong local loss maximum as demonstrated in Figure 1, which presents a few examples of early transonic cascades measurements performed at VKI and the DLR.

Figure 1.

Blade profile losses versus isentropic outlet Mach number for four transonic turbines. Blade A data from [5], blade B and C unpublished data from VKI, blade D data from [6].

Pioneering experimental research concerning the evolution of the turbine trailing edge base pressure from subsonic to supersonic outlet flow conditions was carried out at the von Kármán Institute. In 1976, at the occasion of the VKI Lecture Series Transonic Flows in Axial Turbines, Sieverding presented base pressure data for eight different cascades for gas and steam turbine blade profiles over a wide range of Mach numbers [3] and in 1980 Sieverding et al. [4] published a base pressure correlation (also referred to as BPC) based on a total of 16 blade profiles.

All tests were performed with cascades containing typically 8 blades and care was taken to ensure in all cases, and over the whole Mach range, a good periodicity. The latter was quantified to be 3%, in the supersonic range, in terms of the maximum difference between the pitch-wise averaged Mach number (based on 10 wall pressure tappings per pitch) of each of the three central passages and the mean value computed over the same three passages. The correlation covered blades with a wide range of cascade parameters, as outlined in Table 1:

Table 1.

Parameters range for Sieverding’s correlation.

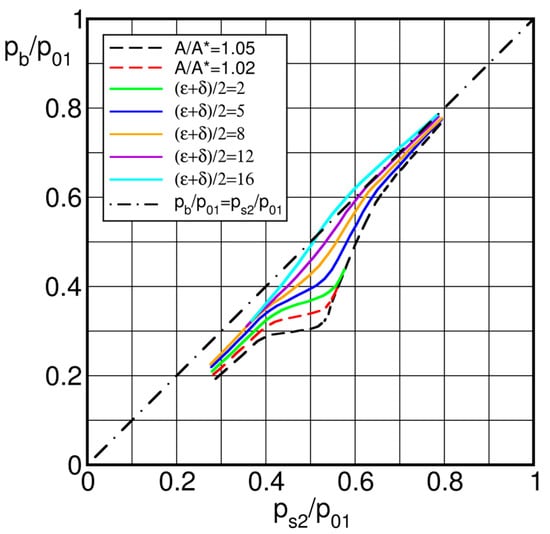

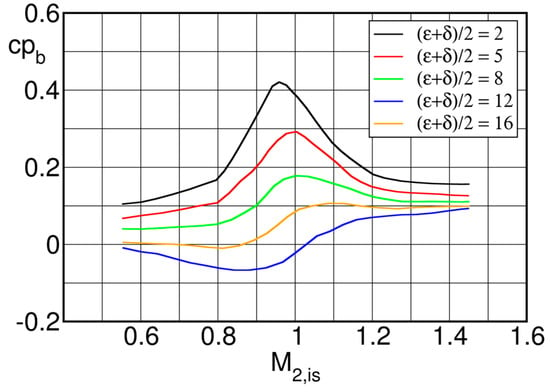

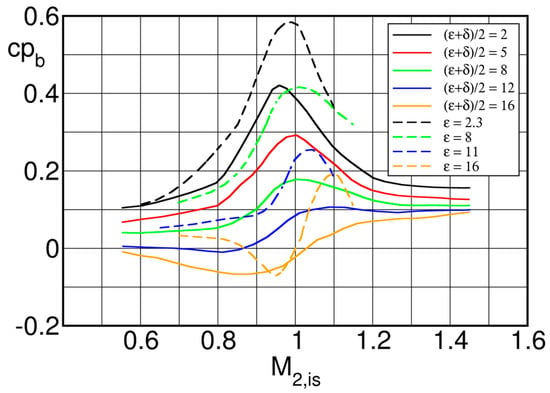

Of all cascade parameters only the rear suction side turning angle and the trailing edge wedge angle appeared to correlate convincingly the available data, although the latter were insufficient to differentiate their respective influence. In fact, in many blade designs both parameters are closely linked to each other and, for two thirds of all convergent blades with convex rear suction side, both and were of the same order of magnitude. For this reason, it was decided to use the mean value as parameter. The relation , is graphically presented in Figure 2. The curves cover a range from to , but flow conditions characterized by a suction side shock interference with the trailing edge wake region are not considered. Comparing the experiments with the correlation (results not shown herein), it turned out that 80% of all data fall within a bandwidth and 96% within .

Figure 2.

Sieverding’s base pressure correlation; solid lines (resp. dashed lines) denote convergent blades (resp. convergent-divergent blades) [4].

An explanation for the significance of for the trailing edge base pressure is seen in Figure 3, presenting the blade velocity distribution for two convergent blades with different rear suction side turning angles of = 20° and 4.5°, blade A and B, together with a convergent/divergent blade with an internal passage area increase of , blade C. The curves end at because beyond, the pressure distribution is influenced by the acceleration around the trailing edge.

Figure 3.

Surface isentropic Mach number distribution for two convergent and one convergent/divergent blades at , based on data from [3].

The rear suction side turning angle ε has a remarkable effect on the pressure difference across the blade near the trailing edge. For blade A one observes a strong difference between the SS and PS isentropic Mach numbers, respectively pressures, while the difference is very small for blade B. On the contrary, for blade C the pressure side curve crosses the SS curve well ahead of the trailing edge and the PS isentropic Mach number near the trailing edge exceeds considerably that of the SS. The base pressure is function of the blade pressure difference upstream of the trailing edge.

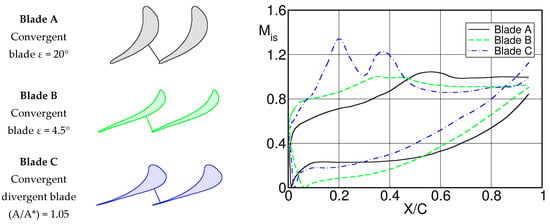

It is also worthwhile mentioning that also plays an important role for the optimum blade design in function of the outlet Mach number. Figure 4 presents design recommendations for the rear suction side curvature with increasing Mach number from subsonic to low supersonic Mach numbers as successfully used at VKI.

Figure 4.

Recommended values of (a) and (b) for the design of the blade rear suction side for increasing outlet Mach numbers. Full (c) and close-up (d) view of the parameters characterizing the turbine geometry.

The rear suction turning angle for convergent blades should decrease with increasing Mach number reaching a minimum of at (maximum Mach number for convergent blades). Note that similar trends can be derived from the loss correlation by Craig and Cox [7]. They showed that in order to minimize the blade profile losses the rear suction side curvature, expressed by the ratio , where represents the pitch and the radius of a circular arc approximating the rear suction side curvature, should decrease with increasing Mach number.

For a given rear suction side angle ε the designer is free as regards the evolution of the surface angle from the throat to the trailing edge. It appears to be a good design practice to subdivide the rear suction side length into two parts, a first part along which the blade angle asymptotically decreases to the value of the trailing edge angle, followed by a second entirely straight part of length , see Figure 4. With increasing outlet Mach number, the length of the straight part, that is the ratio increases, but it does never extend up to the throat.

For calculating the trailing edge losses induced by the difference between the base pressure and the downstream pressure, Fabry & Sieverding [8], presented the data for the convergent blades in Figure 2 in terms of the base pressure coefficient , defined by Equation (2), see Figure 5.

Figure 5.

Base pressure coefficients corresponding to the base pressure curves of Figure 2 [8].

Since the base pressure losses are proportional to the base pressure coefficient , the curves give immediately an idea of the strong variation of the profile losses in the transonic range. As regards the low Mach number range, the contribution of the base pressure loss is implicitly taken into account by all loss correlations. Therefore the base pressure loss is not to be added straight away to the profile losses as predicted for example with the methods by Traupel [1] and Craig and Cox [7] but rather as a difference with respect to the profile losses at :

Martelli and Boretti [9], used the VKI base pressure correlation for verifying a simple procedure to compute losses in transonic turbine cascades. The surface static pressure distribution for a given downstream Mach number is obtained from an inviscid time marching flow calculation.

An integral boundary layer calculation is used to calculate the momentum thickness at the trailing edge before separation. The trailing edge shocks are calculated using the base pressure correlation. Two examples are shown in Figure 6. Calculation of eight blades showed that 80% of the predicted losses were within the range of the experimental uncertainty.

Figure 6.

Example of profile loss prediction for transonic turbine cascade, adapted from [9]; (a) low pressure steam turbine tip section, (b) high pressure gas turbine guide vane.

Besides the data reported by Sieverding et al. in [4,6], the only authors who published recently a systematic investigation of the effect of the rear suction side curvature on the base pressure were Granovskij et al. of the Moscow Power Institute [10]. The authors investigated 4 moderately loaded rotor blades (, , , ) with different unguided turning angles ( to 16°) in the frame of the optimization of cooled gas turbine blades. A direct comparison with the VKI base pressure correlation is difficult because the authors omitted to indicate the trailing edge wedge angle . Nevertheless, a comparison appeared to be useful. Figure 7 presents the comparison, after conversion, of the base pressure coefficient:

used by Granovskij et al. [10], to the base pressure coefficient (2) based on , used by Fabry and Sieverding at VKI [8]. The data of Granovskij et al. [10] (dashed lines) confirm globally the overall trends of the VKI base pressure correlation (solid lines). However, the peaks in the transonic range are much more pronounced.

Figure 7.

Comparison of Granovskij’s base pressure data (dashed lines) with the VKI base pressure correlation (solid lines).

Also, cascade data reported by Dvorak et al. in 1978 [11] on a low pressure steam turbine rotor tip section, and by Jouini et al. in 2001 [12] for a relatively high turning rotor blade (, and a smaller pitch to chord ratio ), are in fair agreement with the VKI base pressure correlation, although the latter authors state that below , their data drop below those of the BPC.

However, some other cascade measurements deviate very significantly from the VKI curves. Deckers and Denton [13], for a low turning blade model and Gostelow et al. [14] for a high turning nozzle guide vane, report base pressure data far below those of Sieverding’s BPC, while Xu and Denton [15], for a very highly loaded HP gas turbine rotor blade ( and ) report base pressure data far above those of the BPC.

The simplicity of Sieverding’s base pressure correlation was often criticized because it was felt that aspects as important as the state of the boundary layer, the ratio of boundary layer momentum to trailing edge thickness and the trailing edge blockage effects (trailing edge thickness to throat opening) should play an important role.

As regards the state of the boundary layer and its thickness, tests on a flat plate model at moderate subsonic Mach numbers in a strongly convergent channel by Sieverding and Heinemann [16], showed that the difference of the base pressure for laminar and turbulent flow conditions was only of the order of 1.5–2% of the dynamic head of the flow before separation from the trailing edge. For the case of supersonic trailing edge flows, Carriere [17], demonstrated, that for turbulent boundary layers the base pressure would increase with increasing momentum thickness. On the contrary, supersonic flat plate model tests simulating the overhang section of convergent turbine cascades with straight rear suction sides showed that for fully expanded flow along the suction side (limit loading condition) an increase of the ratio of the boundary layer momentum to the trailing edge thickness by a factor of two, obtained roughening the blade surface, did not affect the base pressure, Sieverding et al. [18]. Note, that for both the smooth and rough surface the boundary layer was turbulent. Similarly, roughening the blade surface in case of shock boundary layer interactions on the blade suction side did not affect the base pressure as compared to the smooth blade, Sieverding and Heinemann [16]. However, a comparison of the base pressure for the same Mach numbers before separation at the trailing edge for a fully expanding flow and a flow with shock boundary layer interaction on the suction side before the TE showed an increase of the base pressure by 10–25 % in case of shock interaction before the TE. Since it was shown before that an increase of the momentum thickness did not affect the base pressure, the difference may be attributed to (a) different total pressures due to shock losses for the shock interference curve, (b) differences in the boundary layer shape factor and (c) differences in pressure gradients in stream-wise direction in the near wake region.

A systematic investigation of possible effects of changes in shape factor and boundary layer momentum thickness on the base pressure in cascades is difficult. Hence, the investigations are mostly confined to variations of the incidence angle which, via a modification of the blade velocity distribution, should have an impact on both the shape factor and the boundary layer momentum thickness. Based on linear transonic cascade tests on two high turning rotor blades Jouini et al. [19] at Carlton University, (blade HS1A: = 0.73, 0.082, , , , ; blade HS1B is similar to HS1A, but with less loading on the front side and ) concluded that discrepancies in the base region did not appear to be strongly related to changes of the inlet angle by , however in broad terms the weakest base pressure drop in the transonic range were obtained for high positive incidence. Similarly, experiments at VKI on a high turning rotor blade ( = 0.49, 0.082, , , , ) did not show any effect on the base pressure for incidence angle changes of [3].

In conclusion it appears that for conventional blade designs, changes in the boundary layer thickness alone, as induced by incidence variations, do not affect significantly the base pressure. Therefore, we need to look for possible other influence factors.

Figure 3 showed that the effect of the blade rear suction side blade turning angle ε on the base pressure was in fact function of the pressure difference across the blade near the trailing edge. Inversely, one should be able to deduct from the rear blade loading the tendency of the base pressure. The higher the blade loading at the trailing edge, the higher the base pressure. Corollary, a low or even negative blade loading near the trailing edge causes increasingly lower base pressures. This might help in explaining the large differences with respect to the BPC as found by Xu and Denton [15] on one side and Deckers et al. [13] and Gostelow et al. [14], mentioned before, on the other side.

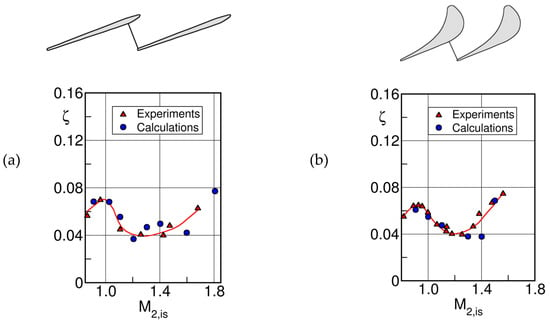

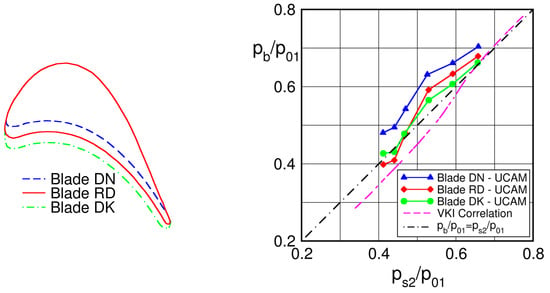

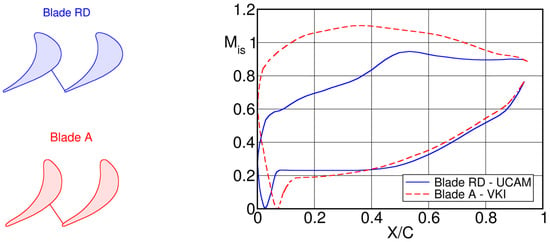

To illustrate this, Figure 8 presents the base pressure data of Xu and Denton [15] for three of a family of four very highly loaded gas turbine rotor blades with a blade turning angle of and a pitch-to-chord , tested with three different trailing edge thicknesses. The blades are referred to as blade RD, for the datum blade, and blades DN and DK for changes of 0.5 and 1.5 times the trailing edge thickness with respect to the datum case.

Figure 8.

Base pressure variation for blades of Xu & Denton; blade RD datum case, blade DK thick trailing edge, blade DN thin trailing edge. Adapted from [15].

The base pressures are overall much higher than those of the BPC which are indicated in the figure by the dashed line for a mean value of .

A possible explanation for the large differences is given by comparing the blade Mach number distribution of the datum blade with that of a VKI blade with a taken from [6], see Figure 9. To enable the comparison, the blade Mach number distribution of Xu & Denton (solid line) presented originally in function of the axial chord , had to be replotted in function of . The comparison is done for an isentropic outlet Mach number .

Figure 9.

Comparison of blade Mach number distribution for blade RD of Xu and Denton [15], (solid curve, ) with VKI blade (dashed curve, ).

Note that the geometric throat for the Xu & Denton blade is situated at , while for the VKI blade at . At the trailing edge, the Mach number difference between pressure and suction side for both blades are exactly the same, but contrary to the nearly constant Mach number for the VKI blade downstream of the throat, the blade of Xu and Denton is characterized by a very strong adverse pressure gradient in this region. As pointed out by the authors, this causes the suction side boundary layer to be either separated or close to separation up-stream of the trailing edge. Clearly, Sieverding’s correlation cannot deal with blade designs characterized by very strong adverse pressure gradients on the rear suction side causing boundary layer separation before the trailing edge.

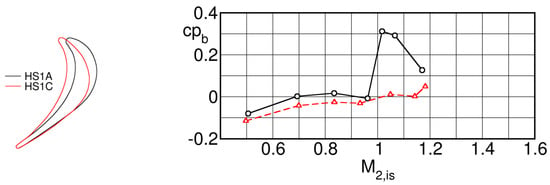

The possible effect of boundary layer separation resulting from high rear suction side diffusion resulting in high base pressures was also mentioned by Corriveau and Sjolander in 2004 [20], comparing their nominal mid-loaded rotor blade HS1A, mentioned already before, with an aft- loaded blade HS1C with an increase of the suction side unguided turning angle from 11.5° to 14.5°. It appears that the increased turning angle could cause, in the transonic range, shock induced boundary layer transition near the trailing edge with, as consequence, a sharp increase of the base pressure, i.e., a sudden drop in the base pressure coefficient as seen in Figure 10. Note that the reported in the figure has been converted to of the original data.

Figure 10.

Base pressure coefficient for mid-loaded (solid line) and aft-loaded (dashed line) rotor blade. Symbols:  HS1A geometry,

HS1A geometry,  HS1C geometry. Adapted from [20].

HS1C geometry. Adapted from [20].

HS1A geometry,

HS1A geometry,  HS1C geometry. Adapted from [20].

HS1C geometry. Adapted from [20].

As regards the base pressure data by Deckers and Denton [13] for a low turning blade model and Gostelow et al. [14] for a high turning nozzle guide vane, who report base pressure data far below those of Sieverding’s BPC, their blade pressure distribution resembles that of the convergent/divergent blade C in Figure 3 with a negative blade loading near the trailing edge which would explain the very low base pressures. In addition, the blade of Deckers and Denton has a blunt trailing edge, and there is experimental evidence that, compared to a circular trailing edge, the base pressure for blades with blunt trailing edge might be considerably lower. Sieverding and Heinemann [16] report for flat plate tests at moderate subsonic Mach numbers a drop of the base pressure coefficient by 11% for a plate with squared trailing edge compared to that with a circular trailing edge.

It is important to remember that the measurement of the base pressure carried out with a single pressure tapping in the trailing edge base region implies the assumption of an isobaric trailing edge pressure distribution. However, in 2003 Sieverding et al. [21] demonstrated that at high subsonic Mach numbers the pressure distribution could be highly non-uniform with a marked pressure minimum at the center of the trailing edge base, as will be shown later in Section 5. Under these conditions it is likely that the base pressure measured with a single pressure hole does not reflect the true mean pressure. In addition, the measured pressure would depend on the ratio of the pressure hole to trailing edge diameter , which is typically in the range . This fact was also recognized by Jouini et al. [12], who mentioned the difficulties for obtaining representative trailing edge base pressures measurements: “It should also be noted that at high Mach numbers the base pressure varies considerably with location on the trailing edge and the single tap gives a somewhat limited picture of the base pressure behavior”. It is probably correct to say that differences between experimental base pressure data and the base pressure correlation may at least partially be attributed to the use of different pressure hole to trailing edge diameters by the various researchers.

Finally, it is important to mention that the trailing edge pressure is sensitive to the trailing edge shape as demonstrated by El Gendi et al. [22] who showed with the help of high fidelity simulation that the base pressure for blades with elliptic trailing edges was higher than for blades with circular trailing edges. Melzer and Pullan [23] proved experimentally that designing blades with elliptical trailing edges improved the blade performance. The reason is that an elliptic trailing edge reduces not only the wake width but causes also an increase of the base pressure compared to that of blades with a circular trailing edge. This suggests that inaccuracies in the machining of blades with thin trailing edges could easily lead to deviations from the designed circular trailing edge shape and thus contribute to the differences in the base pressure.

3. Unsteady Trailing Edge Wake Flow

The mixing process of the wake behind turbine blades has been viewed for a long time as a steady state process although it was well known that the separation of the boundary layers at the trailing edge is a highly unsteady phenomenon which leads to the formation of large coherent structures, known as the von Kármán vortex street. The unsteady character of turbine blade wakes is best illustrated by flow visualizations.

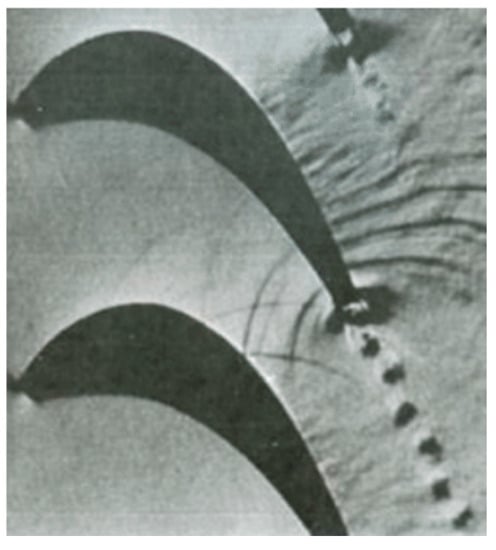

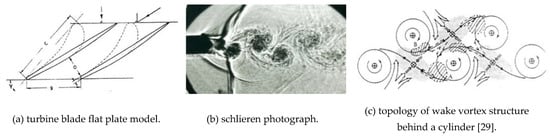

Lawaczeck and Heinemann [24], and Heinemann and Bütefisch [25], were probably the first to perform some systematic schlieren visualizations on transonic flat plate and cascades with different trailing edge thicknesses using a flash light of 20 nano-seconds only, and deriving from the photos the vortex shedding frequencies and Strouhal numbers. The schlieren picture in Figure 11 shows impressively that the shedding of each vortex from the trailing edge generates a pressure wave which travels upstream.

Figure 11.

Schlieren picture of turbine rotor blade wake at [24].

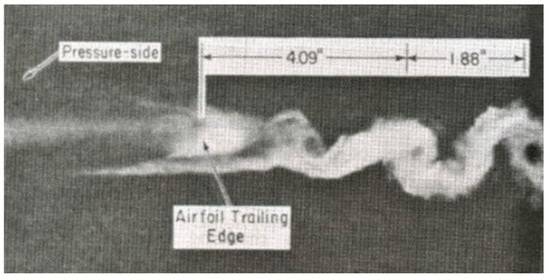

In 1982 Han and Cox [26], performed smoke visualizations on a very large-scale nozzle blade at low speed (Figure 12). The authors found much sharper and well-defined contours of the vortices from the pressure side and concluded that this implied stronger vortex shedding from this side and attributed this to the circulation around the blade.

Figure 12.

Smoke visualization of the vortex shedding from a low speed nozzle blade [26].

Beretta-Piccoli [27] (reported by Bölcs and Sari [28]) was possibly the first to use interferometry to visualize the vortex formation at the blunt trailing edge of a blade at transonic flow conditions.

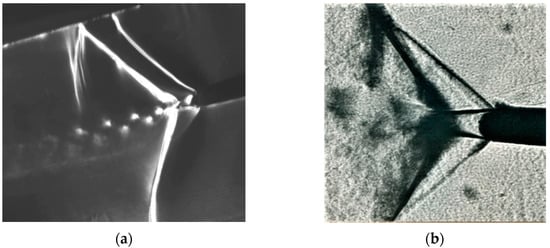

Besides the problem of time resolution for measuring high frequency phenomena, there was also the problem of spatial resolution for resolving the vortex structures behind the usually rather thin turbine blade trailing edges. First tests on a large scale flat late model simulating the overhang section of a cascade allowed to visualize impressively details of the vortex shedding at transonic outlet Mach number (Figure 13a,b).

Figure 13.

Vortex shedding at transonic exit flow conditions [30].

Following Hussain and Hayakawa [29], the wake vortex structures can be described by a set of centers which characterize the location of a peak of coherent span-wise vortices and saddles located between the coherent vorticity structures and defined by a minimum of coherent span-wise vorticity. The successive span-wise vortices are connected by ribs, that are longitudinal smaller scale vortices of alternating signs.

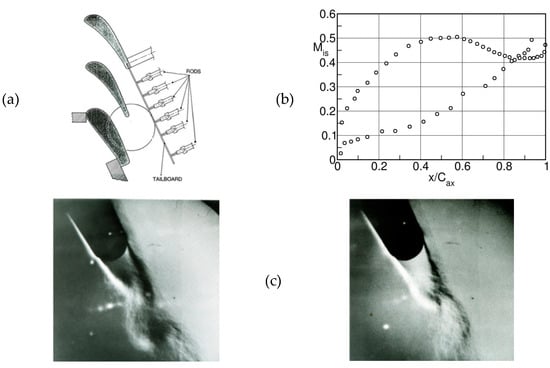

A significant progress was made in the 1990’s in the frame of two European Research Projects, i.e., Experimental and Numerical Investigations of Time Varying Wakes behind Turbine Blades (BRITE/EURAM CT-92-0048) and Turbulence Modeling for Unsteady Flows in Axial Turbines (BRITE/EURAM CT-96-0143) in which the von Kármán Institute, the University of Genoa and the ONERA of Lille used short duration flow visualizations and fast response instrumentation in combination with large scale blade models to improve the understanding of the formation of the vortical structures at the turbine blade trailing edges and their impact on the unsteady wake flow characteristics. Results of these research projects are reported by Ubaldi et al. [31], Cicatelli and Sieverding [32], Desse [33], Sieverding et al. [34], Ubaldi and Zunino [35] and Sieverding et al. [21,36].

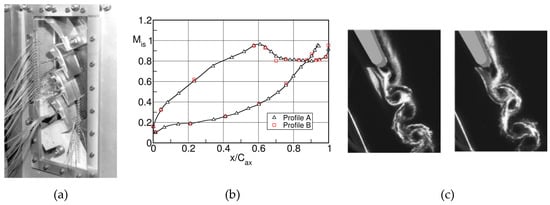

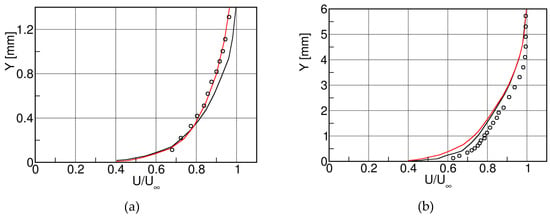

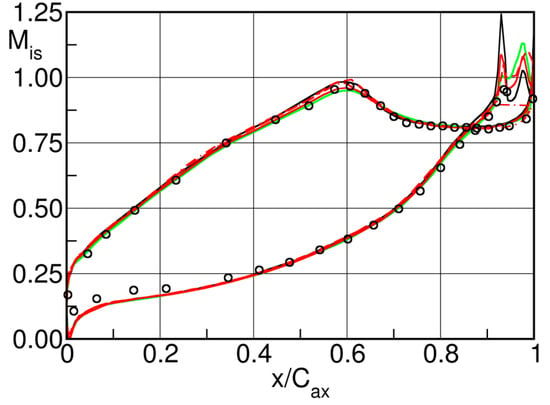

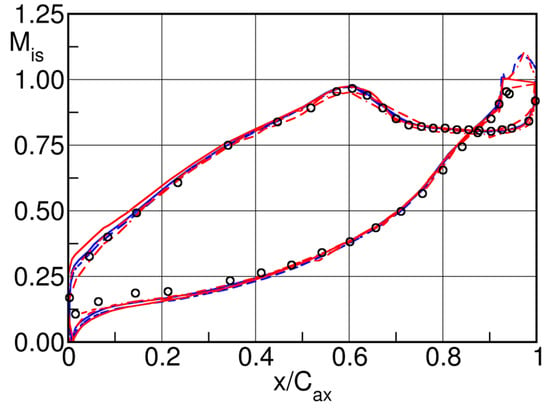

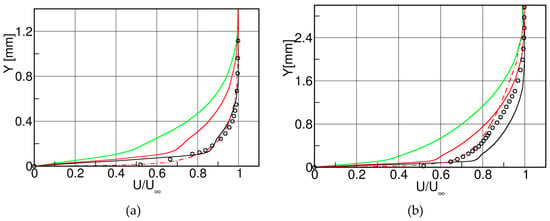

The large-scale turbine guide vane used in these experiments was designed at VKI (Table 2) and released in 1994 [37]. The blade design features a front-loaded blade with an overall low suction side turning in the overhang section and, in particular, a straight rear suction side from halfway downstream of the throat, Figure 14. Due to mass flow restrictions in the VKI blow down facility, the three-bladed cascade with a chord length mm was limited to investigations at a relatively low subsonic outlet Mach number of . The suction side boundary layer undergoes natural transition at . On the pressure side the boundary layer was tripped at . The boundary layers at the trailing edge with shape factors of 1.64 and 1.41 for the pressure and suction sides respectively, were clearly turbulent. The schlieren photographs in Figure 14 were taken with a Nanolite spark source, with . The dominant vortex shedding frequency was 2.65 kHz and the corresponding Strouhal number, defined as:

was .

Table 2.

VKI LS-94 large scale nozzle blade geometric characteristics [32].

Figure 14.

Very large-scale turbine nozzle guide vane (VKI LS-94); case. (a) test section, (b) surface isentropic Mach number distribution, (c) schlieren photographs. Adapted from [32].

Figure 14c presents two instances in time of the vortex shedding process. The left flow visualization shows the enrolment of the pressure side shear layer into a vortex, the right one the formation of the suction side vortex. Note that the pressure side vortex appears to be much stronger than the suction side one, which confirms the observations made by Han and Cox [26].

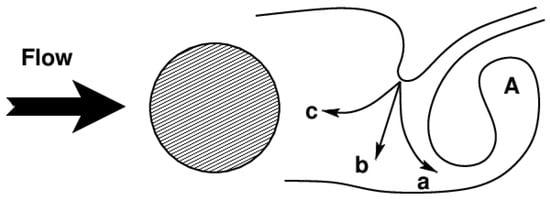

Gerrard [38], describes the vortex formation for the flow behind a cylinder as follows, Figure 15. The growing vortex (A) is fed by the circulation existing in the upstream shear layer until the vortex is strong enough to entrain fluid from the opposite shear layer bearing vorticity of the opposite circulation. When the quantity of entrained fluid is sufficient to cut off the supply of circulation to the growing vortex—the opposite vorticity of the fluid in both shear layers cancel each other—then the vortex is shed off.

Figure 15.

Vortex formation mechanism; adapted from [38].

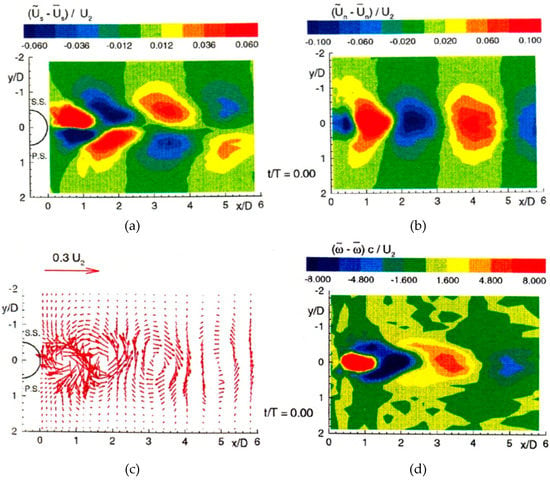

Contrary to the blow down tunnel at VKI, the Istituto di Macchine e Sistemi Energetici (ISME) at the University of Genoa used a continuous running low speed wind tunnel. Miniature cross-wire hot-wire probe and a four-beam laser Doppler velocimeter are used for the measurements of the unsteady wake. An example of the instantaneous patterns of the ensemble averaged periodic wake characteristics is presented in Figure 16. A detailed description is given by Ubaldi and Zunino [35]. The streamwise periodic component of the velocity, in Figure 16 (upper left), shows asymmetric periodic patterns of alternating positive and negative velocity components issued from the pressure to the suction side. As already shown schematically in Figure 13, saddle points separating groups of four cores, are located along the wake center line. On the contrary, the periodic parts of the transverse component (upper right) appear as cores of positive and negative values, approximately centered in the wake which alternate, enlarging in streamwise direction. The combination of the two velocity components give rise to the rolling up of the periodic flow into a row of vortices rotating in opposite direction as shown by the velocity vector plots (lower left).

Figure 16.

Instantaneous realization of the ensemble averaged streamwise velocity (a), transversal velocity (b), velocity vector (c) and vorticity patterns (d) of the periodic flow [35].

As illustrated by Gerrard [38] (see Figure 15), the vortex formation is driven by the vorticity in the suction and pressure side boundary layers. The vorticity terms and in the wake have been determined taking respectively the curl of the phase averaged and time averaged velocity field: and , Figure 16 (lower right). The local maxima and minima and saddle regions (the points where the vorticity changes its sign) define the location, extension, rotation and intensity of the vortices.

With increasing downstream Mach number, the vortices become much more intense as demonstrated in Figure 17 on a half scale model of the blade already presented in Figure 14 and Table 2, at an outlet Mach number in a four bladed cascade, Sieverding et al. [36]. Contrary to schlieren photographs which visualize density changes, the smoke visualizations in Figure 17 show the instantaneous flow patterns and are therefore particular well suited to visualize the enrolment of the vortices. A close look at the vortex structures reveals that the distances between successive vortices change. In fact, the distance between a pressure side vortex and a suction side vortex is always smaller than the distance between two successive pressure side vortices. A possible reason is that the pressure side vortex plays a dominant role and exerts an attraction on the suction side vortex as already found by Han and Cox [26].

Figure 17.

VKI LS94 turbine blade, case. (a) four blades cascade, (b) surface isentropic Mach number distribution and (c) smoke visualizations. Adapted from [36].

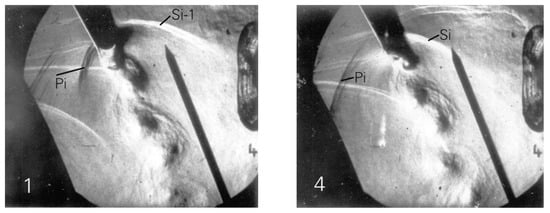

The vortex formation and subsequent shedding is accompanied by large angle fluctuations of the separating shear layers which does not only lead to large pressure fluctuations in the zone of separations but also induces strong acoustic waves. The latter travel upstream on both the pressure and suction side as shown in the corresponding schlieren photographs obtained this time with a continuous light source, a high speed rotating drum and rotating prism camera from ONERA with a maximum frame rate of 35,000 frames per second (see Figure 18), as reported by Sieverding et al. [21].

Figure 18.

Schlieren photographs of vortex shedding at two instances in time; [21].

In image 1 of Figure 18 the suction side shear layer has reached its farthest inward position and the local pressure just upstream of the separation point has reached its minimum value. Conversely, on the pressure side the separating shear layer has reached its most outward position. A pressure wave denoted Pi originates from the point where the boundary layer separates from the trailing edge. Upstream of Pi is the pressure wave from the previous cycle. It interferes with the suction side of the neighboring blade from where it is reflected. In image 4 of Figure 18, the suction side shear layer is at its most outward position. A pressure wave originates at the point of separation, denoted Si. The pressure wave further upstream is due to the previous cycle. On the pressure side the pressure wave Pi extends now to the suction side of the neighboring blade. The wave interference point of the previous cycle has moved up-stream. It can therefore be expected that the suction side pressure distribution near the throat region is highly unsteady.

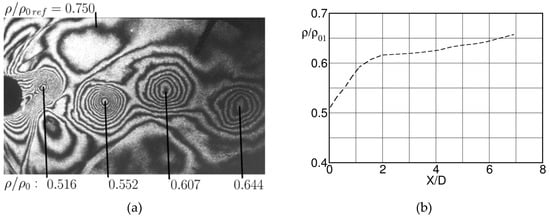

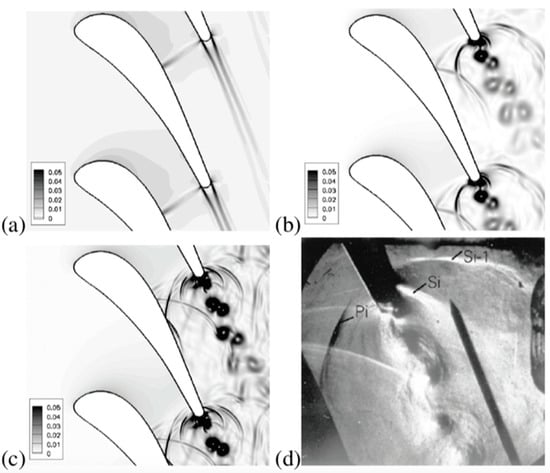

Holographic interferometric density measurements, performed at VKI at by Sieverding et al. [36], give further information about the formation and the shedding process of the von Kármán vortices. The reference density is evaluated from pressure measurements with a fast response needle static pressure probe positioned just outside of the wake assuming the total temperature to be constant outside the wake.

The interferogram in Figure 19 shows the suction side vortex (upper blade surface) in its out most outward position i.e., at the start of the shedding phase. On the pressure side the density patterns point to the start of the formation of a new pressure side vortex. The pressure side vortex of the previous cycle is situated at a trailing edge distance of . This vortex is defined by ten fringes. With a relative density change between two successive fringes of the total relative density change from the outside to the vortex center is . The minimum in the vortex center is compared to an isentropic downstream static to total density ratio of .

Figure 19.

Instantaneous density distribution (a) and variation of density minima with trailing edge distance (b) at ; adapted from [36].

Based on a large number of tests with holographic interferometry and white light interferometry, see Desse [33], Figure 19 shows the variation of the vortex density minima non-dimensionalized by the upstream total density , in function of the trailing edge distance . There are two distinct regions for the evolution of the vortex minima: a rapid linear density rise-up to distance followed by a much slower rise further downstream.

Comparing the vortex formation at and 0.79 shows that with increasing Mach number the vortices form much closer to the trailing edge. This tendency goes crescendo with further increase of the downstream Mach number as already shown in Figure 13 where normal shocks oscillate close to the trailing edge forward and backward with the alternating shedding of the vortices. A further increase of the outlet flow leads gradually to the formation of an oblique shock system at the convergence of the separating shear layers at short distance behind the trailing edge, causing a delay of the vortex formation to this region as demonstrated by Carscallen and Gostelow [39], in the high speed cascade facility of the NRC Canada. The high speed schlieren pictures revealed some very unusual types of wake vortex patterns as shown in Figure 20. Besides the regular von Kármán vortex street (left), the authors visualized other vortex patterns, such as e.g. couples or doublets, on the right. In other moments in time they observed what they called hybrid or random or no patterns. The schlieren photos in Figure 20 show the existence of an unexpected shock emanating from the trailing edge pressure side at the beginning of the trailing edge circle. Questioning Bill Carscallen [40] recently about the origin of this shock it appeared that the shock was simply due to an inaccuracy in the blade manufacturing of the trailing edge circle.

Figure 20.

Occurrence of different vortex patters in wake of transonic blade at . (a) regular vortex street, (b) couples, (c) doublets [39].

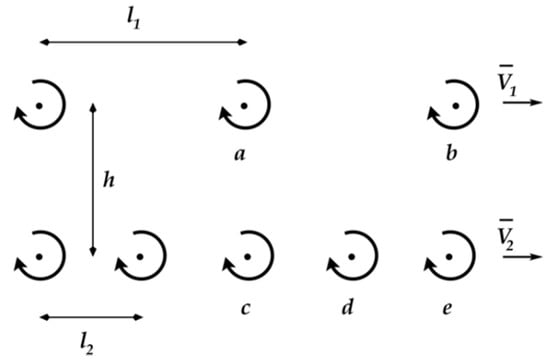

The question whether in distinction of the conventional von Kármán vortex street, a double row vortex street of unequal vortex strength may exist, was treated by Sun in 1983 [41]. Figure 21 presents an example of a double row vortex street with unequal vortex strength and vortex distances. The author demonstrated that such configurations are basically unstable.

Figure 21.

An example of vortex street with unequal vortex strengths and unequal vortex spacings; adapted from [41].

4. Energy Separation in the Turbine Blade Wakes

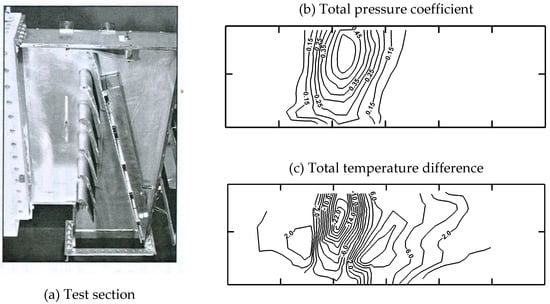

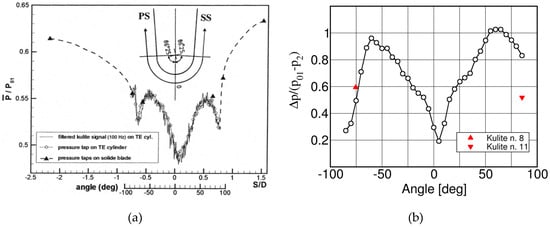

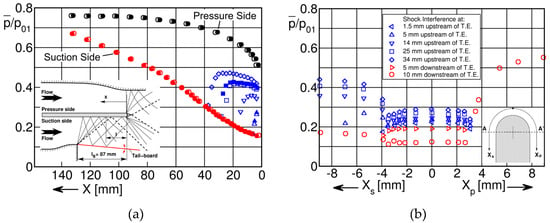

In the course of a joint research program between the National Research Council of Canada and Pratt & Whitney Canada of the flow through an annular transonic nozzle guide vane in the 1980s certain experiments revealed a non-uniform total temperature distribution downstream of the uncooled blades, Carscallen and Oosthuizen [42]. Considering the importance of the existence of a non-uniform total temperature distribution at the exit of uncooled stator blade row for the aerothermal aspects of the downstream rotor, the Gasdynamics Laboratory of the National Research Council, Canada decided to build a continuously running suction type large scale planar cascade tunnel (chord length 175.3 mm, turning angle 76°, trailing edge diameter 6.35 mm) and launched an extensive research program aiming at the understanding of the mechanism causing the occurrence of total temperature variations downstream of a fixed blade row, determine their magnitude and evaluate their significance for the design of the downstream rotor. Downstream traverses with copper constantan thermocouples reported by Carscallen et al. [43] in 1996 showed that the total temperature contours correlated perfectly with the total pressure wake profiles, Figure 22.

Figure 22.

Total pressure coefficient and temperature contours downstream of a nozzle guide vane at a pressure ratio PR = 1.9; adapted from [42].

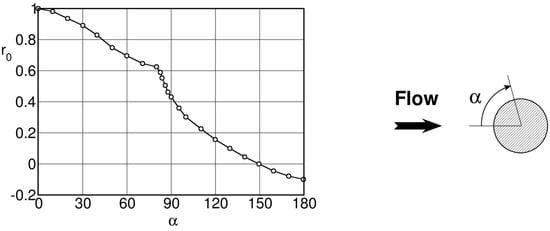

In the wake center the total temperature dropped significantly below the inlet total temperature while higher values were recorded near the border of the wake. The differences increased with Mach number and reached a maximum at sonic outlet conditions. The question was then to elucidate the reasons for these temperature variations. The research on flows across cylinders was already more advanced in this respect. Measurements of the temperature distribution around a cylinder for a flow normal to the axis of the cylinder, performed at the Aeronautical Institute of Braunschweig in the late 1930’s and reported by Eckert and Weise [44] in 1943, showed that the recovery temperature at the base of the cylinder reduced below the true (static) temperature of the incoming flow, so that the recovery factor:

attained negative values in the base region (see Figure 23).

Figure 23.

Evolution of the recovery factor in the azimuthal direction from the stagnation point (°) to the rear side of the cylinder (); adapted from [44].

The authors suspected that the low values were possibly due to the intermittent separation of vortices from the cylinder. These results were confirmed by Ryan [45] in 1951 at Ackeret’s Institute in Zürich who clearly related this low temperature to the periodic vortex shedding behind the cylinder as cause for the energy separation in the fluctuating wake. He also noticed that the energy separation was particularly large when a strong sound was generated by the flow.

The existence of a low temperature field at the base of a cylinder was also observed by Sieverding in 1985, who used an infrared camera to visualize through a germanium window in the side wall of a blow down wind tunnel the wall temperature field around a 15 mm diameter cylinder at , see Figure 24. Unfortunately, due to a lack of time it was not possible to determine the absolute temperature values.

Figure 24.

Side wall temperature field around a cylinder recorded by an infrared camera.

Eckert [46] explained the mechanism of energy separation along a flow path with the help of the unsteady energy equation:

The change of the total temperature with time depends on: (a) the partial derivative of the pressure with time, (b) on the energy transport due to heat conduction between regions of different temperatures and (c) on the work due to viscous stresses between regions of different velocities. As regards the flow behind bluff bodies the two latter terms are considered small compared the pressure gradient term and Equation (4) then reduces to:

The occurrence of total temperature variations in the vortex streets behind cylinders was e.g. extensively described by Kurosaka et al. [47], Ng et al. [48] and Sunduram et al. [49].

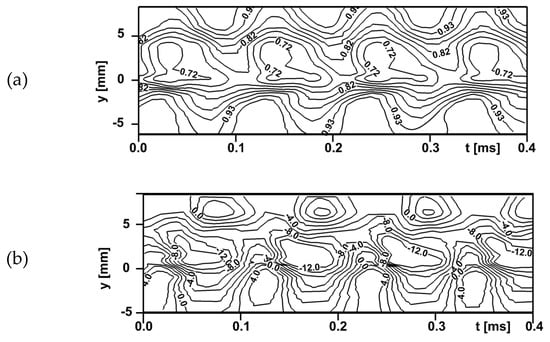

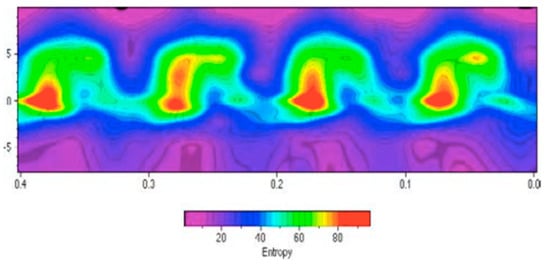

The progress in the understanding of the mechanism was boosted with the arrival of fast temperature probes as for example the dual sensor thin film platinum resistance thermometer probe developed by Buttsworth and Jones [50] in 1996 at Oxford. Using their technique Carscallen et al. [51,52] were the first to measure the time varying total pressure and temperature in the wake of their turbine vane. Figure 25 presents the results for an isentropic outlet Mach number and a vortex shedding frequency of the order of 10 kHz. The probe traverse plane was normal to the wake at a distance of 5.76 trailing edge diameters from the vane trailing edge. In a later paper concerning the same cascade, Gostelow and Rona [53], published also the corresponding entropy variations from the Gibb’s relation:

Figure 25.

Contour plots of phase averaged total pressure (a) and total temperature (b) behind turbine vane; adapted from [51].

The results are presented in Figure 26.

Figure 26.

Time resolved measurements of entropy increase [53].

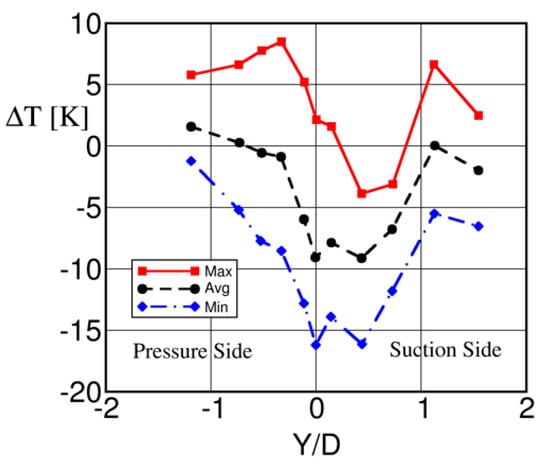

The variation of the maxima and minima of the total temperature in the center of the wake vary between a minimum of −15° to a maximum of −4° with respect to the inlet ambient temperature, Figure 27. At the border of the wake the temperature raises considerably above the inlet temperature, while the time averaged temperature in the wake center is about −10°.

Figure 27.

Variation of total temperature maxima and minima through the wake; adapted from [51].

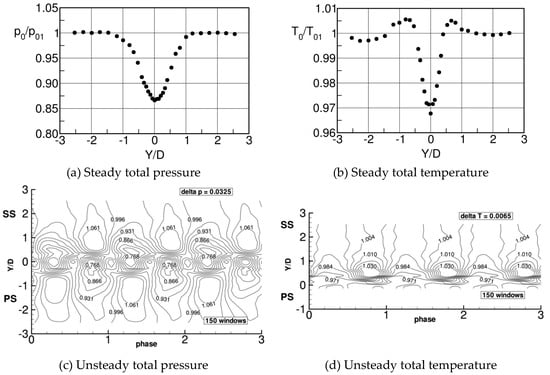

In 2004, Sieverding et al. [36] published very similar results for the turbine vane shown in Figure 17. The wake traverse was performed at a trailing edge distance of only in direction of the tangent to the blade camber line, which forms an angle of 66° with the axial direction. The traverse is made normal to this tangent.

The steady state total pressure and total temperature measurements are presented in Figure 28. Similar to the results obtained at the NRC Canada, the wake center is characterized by a pronounced total temperature drop of 3% of the inlet value of 290 K which corresponds to about −9°, a variation which is of the same order as that reported in Figure 27. On the borders of the wake, total temperature peaks in excess of the inlet temperature are also recorded. The mass integrated total temperature value across the wake (denoted with a ) should be such that <, but lack of information on the local velocity did not allow to perform this integration.

Figure 28.

Steady and time varying phase lock averaged total pressure and total temperature through turbine vane wake at ; adapted from [36].

For the measurement of the time varying temperature a fast 2 μm cold wire probe, developed by Denos and Sieverding [54], was used. Numerical compensation allowed to extend the naturally low frequency response of the probe to much higher ranges for adequate restitution of the nearly sinusoidal temperature variation associated with the vortex shedding frequency of 7.6 kHz at a downstream isentropic Mach number of . As regards the total pressure variation , minimum values of 0.768 are reached in the wake center while at the wake border maximum values of 1.061 are recorded. As regards the total temperature the authors quote maximum and minimum total temperature ratios of and , respectively. With a the maximum total temperature variations are of the order of 24°, similar to those reported by Carscallen et al. [51]. However, the flow conditions were different: at VKI, versus 0.95 at NRC Canada, and a distance of the wake traverses with respect to the trailing edge of 2.5 diameters at VKI, versus 5.76 at NRC.

5. Effect of Vortex Shedding on Blade Pressure Distribution

The previous section focused on the unsteady character of turbine blade wake flows, the visualization of the von Kármán vortices through smoke visualizations, schlieren photographs and interferometric techniques. The measurement of the instantaneous velocity fields using LDV and PIV techniques allowed to determine the vorticity distribution and the measurement of the unsteady total pressure and temperature distribution putting into evidence the energy separation effect in the wakes due to the von Kármán vortices.

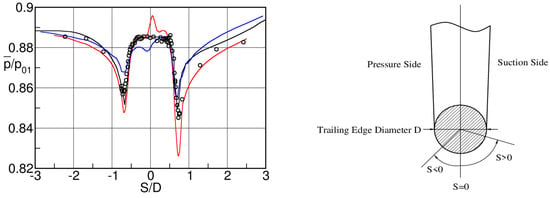

Naturally the vortex shedding affects also the trailing edge pressure distribution and, beyond that, the suction side pressure distribution. The following is entirely based on research work carried out at the VKI by the team of the lead author, who was the only one to measure with high spatial resolution the pressure distribution around the trailing edge of a turbine blade.

5.1. Effect on Trailing Edge Pressure Distribution

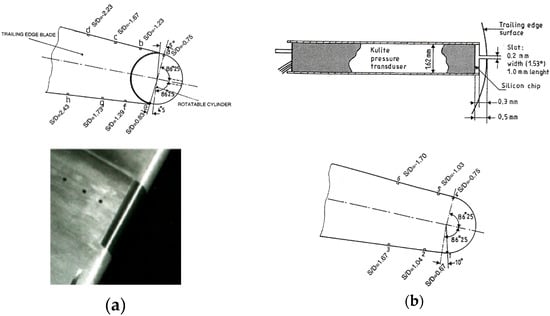

The very large-scale turbine guide vane designed and tested at the von Kármán Institute with a trailing edge thickness of 15 mm did allow an innovative approach for obtaining a high spatial resolution for the pressure distribution around the trailing edge. Cicatelli and Sieverding [32], fitted the blade with a rotatable 20 mm long cylinder in the center of the blade (Figure 29). The cylinder was equipped with a single Kulite fast response pressure sensor side by side with an ordinary pneumatic pressure tapping. The pressure sensor was mounted underneath the trailing edge surface with a slot width of only 0.2 mm to the outside, the same width as the pressure tapping, reducing the angular sensing area to only 1.53°. To control any effect of the rear facing step between the blade lip and the rotatable trailing edge, a second blade was equipped with additional pressure sensors placed at, and slightly up-stream of, the trailing edge.

Figure 29.

Blade instrumented with rotatable trailing edge (a: blade A) and control blade (b: blade B); adapted from [32].

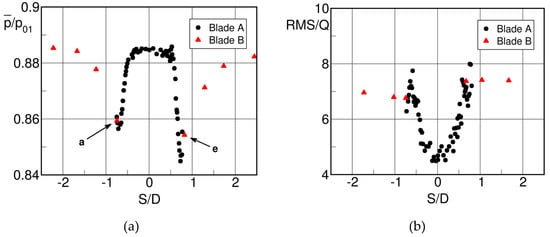

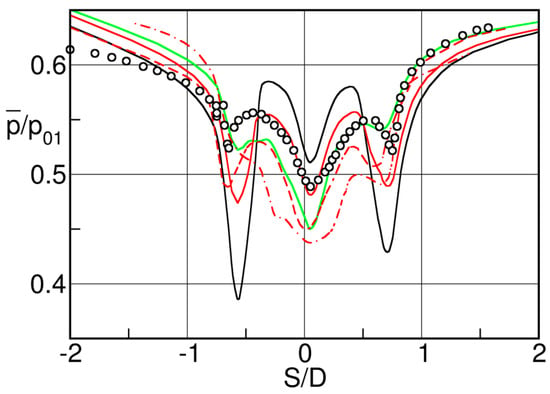

The time averaged base pressure distribution, non-dimensionalized by the inlet total pressure, is presented in Figure 30. The circles denote data obtained with the rotatable trailing edge cylinder on blade A, while the triangles are measured with pressure tappings on blade B (see Figure 29), except for the two points “a” and “e” which are taken from the pressure tappings positioned aside the rotating cylinder on blade A (see Figure 30, left panel). The flow approaching the trailing edge undergoes, both on the pressure and suction side, a strong acceleration before separating from the trailing edge circle. The authors attribute the asymmetry to differences in the blade boundary layers and to the blade circulation, which, following Han and Cox [26], strengthens the pressure side vortex shedding. Compared to the downstream Mach number , the local peak numbers are as high as and 0.47, respectively. These high over-expansions are incompatible with a steady state boundary layer separation and are attributed to the effect of the vortex shedding.

Figure 30.

Phase lock averaged trailing edge pressure distribution (a) and root mean square values of the pressure fluctuations (b) for the VKI turbine blade at ; adapted from [32].

Figure 30, right panel, presents the corresponding root mean square of the pressure signal. Maximum pressure fluctuations of the order of 8% occur near the locations of the pressure minima, i.e., close to the boundary layer separation points, while the RMS/Q drops to nearly half this value in the central region of the trailing edge base. It is also worth noting that the pressure fluctuations affect also the flow upstream of the trailing edge. In the center of the base region there is an extended constant pressure plateau (Figure 30). The base pressure coefficient corresponding to this plateau agrees well with the Sieverding’s base pressure correlation.

The base pressure distribution changes dramatically at high subsonic downstream Mach numbers as illustrated by Sieverding et al. [21], Figure 31. The pressure distribution is characterized by the presence of three minima: the two pressure minima associated with the over-expansion of the suction and pressure side flows before separation from the trailing edge, and an additional minimum around the center of the trailing edge circle. The pressure minima related to the overexpansion from suction and pressure sides are of the order of for both sides, i.e., the local peak Mach numbers are close to 1. Contrary to the low Mach number flow condition of Figure 30, the recompression following the over-expansion does not lead to a pressure plateau but gives way to a new strong pressure drop reaching a minimum of at +7°. This is the result of the enrolment of the separating shear layers into a vortex right at the trailing edge; the vortex core approaches the wake centerline and its distance to the trailing edge becomes less than half the trailing edge diameter, see smoke visualization and interferogram in Figure 17 and Figure 19.

Figure 31.

Steady state trailing edge pressure distribution (a) and phase locked average pressure fluctuation (b) around trailing edge; adapted from [21].

The phase lock averaged pressure fluctuations around the trailing edge in Figure 31 are impressive. They are naturally highest near the separation points of the boundary layer from the trailing edge where maximum values of around 100% of the dynamic pressure () are recorded. The minimum pressure in a given position corresponds to the maximum inward motion of the separating shear layer, the maximum pressure to the maximum outward motion of the separating shear layer. The maximum local instantaneous Mach number at the point of the most inward position can be as high as . The authors assumed that the curvature driven supersonic trailing edge expansion is the real reason for the formation of the vortex so close to the trailing edge, with the entrainment of high-speed free stream fluid into the trailing edge base region. In the center of the trailing edge the fluctuations drop to 20% of the dynamic head.

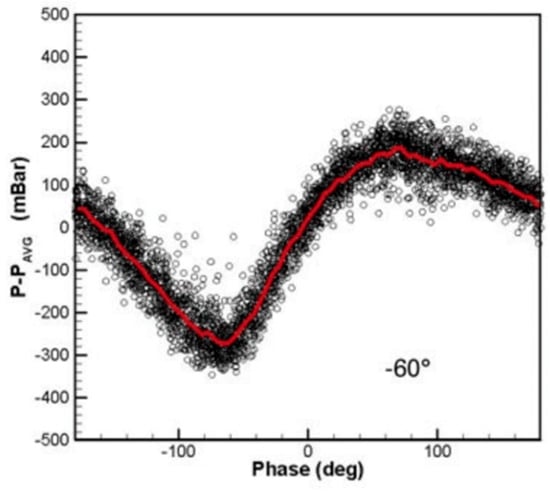

The authors provide also some interesting information on the evolution of the pressure signal on the trailing edge circle over one complete vortex shedding cycle. This is demonstrated in Figure 32 showing the evolution for the phase locked average pressure at the angular position of 60° on the pressure side of the trailing edge circle. A decrease of the pressure indicates an acceleration of the flow around the trailing edge i.e., the separating shear layer moves inwards, the vortex is in its formation phase. An increase of the pressure indicates on the contrary an outwards motion of the shear layer, the vortex is in its shedding phase. Surprisingly, the pressure rise time is much shorter than the pressure fall time, i.e., the time for the vortex formation is longer than that for the vortex shedding. The same was observed for the pressure evolution on the opposite side of the trailing edge, but of course with 180° out of phase.

Figure 32.

Phase locked average pressure variation at trailing edge at an angular position of −60° [21].

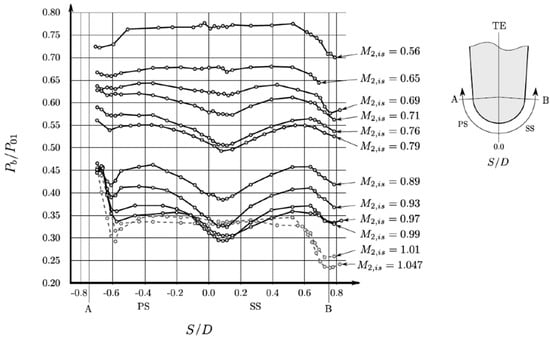

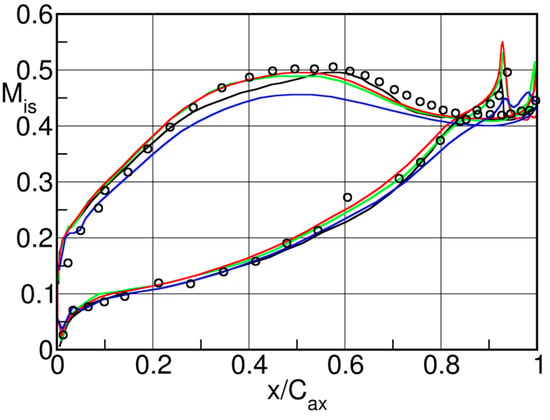

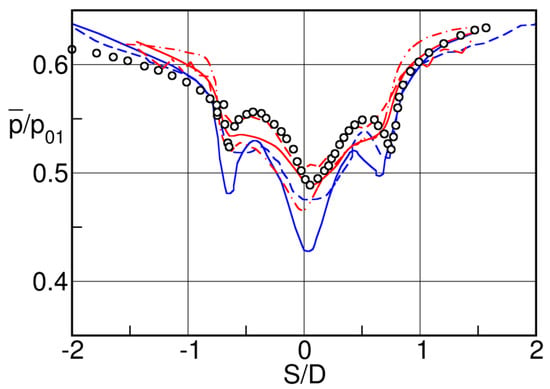

The change of an isobaric pressure zone over an extended region at the base of the trailing edge at an exit Mach number to a highly non-uniform pressure distribution with a strong pressure minimum at the center of the trailing edge circle at , did of course raise the question about the evolution of the trailing edge pressure distribution over the entire Mach number range, from low subsonic to transonic Mach numbers. To respond to this lack of information a research program was carried out by Mateos Prieto [55] at VKI as part of his diploma thesis in 2003. For various reasons, the data were not published at that time but only in 2015, as part of the paper of Vagnoli et al. [56] on the prediction of unsteady turbine blade wake flow characteristics and comparison with experimental data, see Figure 33.

Figure 33.

Effect of downstream Mach number on trailing edge Mach number distribution [56].

The figure puts clearly into evidence the effect of the vortex shedding on the trailing edge pressure distribution. Up to about the trailing edge base region is characterized by an extended, nearly isobaric, pressure plateau which implies that the vortex formation occurs sufficiently far downstream not to affect the trailing edge base region. With increasing Mach number, the enrolment of the shear layers into vortices occurs gradually closer to the trailing edge causing an increasingly non-uniform pressure distribution with a marked pressure minimum at the center of the trailing edge. To characterize the degree of non-uniformity the authors define a factor :

where is the maximum pressure following the recompression after the separation of the shear layer from the trailing edge and the minimum pressure near the center of the trailing edge. The maximum degree of non-uniformity is reached at with a value of 21%. At this Mach number the minimum pressure reaches a value of for a downstream pressure . With further increase of the Mach number, starts to decrease rapidly. It decreases to = 12% at and drops to zero at . For this Mach number the local trailing edge conditions are such that oblique shocks emerge from the region of the confluence of the suction and pressure side shear layers and the vortex formation is delayed to after this region as shown e.g. in the schlieren picture by Carscallen and Gostelow [39] at the NRC Canada in Figure 34, left, and another schlieren picture taken at VKI in Figure 34, right (unpublished).

Figure 34.

At fully established oblique trailing edge shock system the vortex formation is delayed to after the point of confluence of the blade shear layers. NRC blade (a) [39], VKI blade (b).

As already pointed out at the end of Section 2 the departure from the generally assumed isobaric trailing edge base region may explain the differences of base pressure data published by different authors at high subsonic/transonic downstream Mach numbers. The scatter between experimental data from different research organizations may be partially due to the use of very different ratios of the diameter of the trailing edge pressure hole to the trailing edge diameter, . Small ratios may lead to an overestimation of the base pressure effect. Hence, base pressure measurements should be taken with a ratio as large as possible.

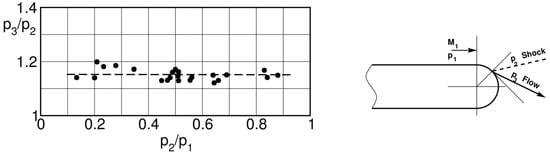

The existence of an isobaric base pressure region for supersonic trailing edge flows, i.e., for blades with a well-established oblique trailing edge shock system as those in Figure 34, was already known from flat plate model tests simulating the overhang section of convergent turbine blades with straight rear suction side since 1976 [18], see Figure 35. The tests were performed for a gauging angle . The inclination of the tail board attached to the lower nozzle block allows to increase the downstream Mach number which entails of course the displacement of the suction side shock boundary interaction along the blade suction side towards the trailing edge.

Figure 35.

Surface (a) and trailing edge (b) pressure distribution for flat plate model tests; adapted from [18].

The schlieren photograph on the right in Figure 34 shows the occurrence of so-called lip shocks at the separation of the shear layers from the trailing edge due to a slight overturning and a non-tangential separation of the flow from the trailing edge surface. In a later test series with a denser instrumentation of the trailing edge, Sieverding et al. [4] showed that the trailing edge shock strength was however weak. In Figure 36 the pressure increase across the lip shock is presented in function of the expansion ratio around the trailing edge , where is the pressure before the start of the expansion around the trailing edge and the pressure before the lip shock. All data are within a bandwidth of .

Figure 36.

Strength of the trailing edge lip shocks; adapted from [4].

Raffel and Kost [57] performed similar large-scale tests on a flat plate with a slotted trailing edge to investigate the effect of trailing edge blowing on the formation of the trailing edge vortex street. Their trailing edge pressure distributions taken at zero coolant flow ejection for downstream Mach numbers of confirm the existence of an isobaric pressure trailing edge base region, but the measurements are unfortunately not dense enough to extract consistent data about the strength of the lip shock. A few data allow to conclude that in their experiments the maximum lip shock strength is of the order of .

5.2. Effect on Blade Suction Side Pressure Distribution

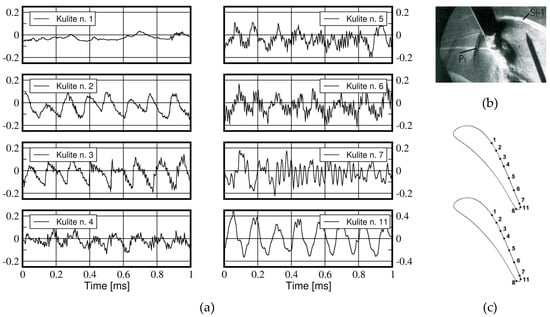

In the discussion of the schlieren photographs in Figure 18 it was shown that the outwards motion of the oscillating shear layers at the blade trailing edge does not only lead to large pressure fluctuations in the zone of separations, but it does also induce strong acoustic pressure waves travelling upstream on both the suction and pressure side of the blade. To facilitate the understanding of the suction side pressure fluctuations in Figure 37, the left photo of the schlieren pictures in Figure 18 is reproduced at the right of the pressure curves. The wave Pi generated at the pressure side will interact with the suction side of the neighboring blade causing significant unsteady pressure variations as measured by fast response pressure sensors implemented between the throat and the trailing edge of this blade, see Figure 37. The pressure wave induced by the outwards motion of the pressure side shear layer of the neighboring blade intersects the suction side between the sensors 3 and 4. It moves then successively upstream across the sensors 3 and 2. The signals are asymmetric, characterized by a sharp pressure rise followed by a slow decay. The amplitude of the pressure fluctuations is important with up to of () at sensor 3, and at sensor 2, while the pressure signal is flat at sensor 1 situated slightly up-stream of the geometric throat where the blade Mach number reaches . The pressure waves observed at sensor 4 and further downstream at sensors 5 and 6 are more sinusoidal in nature and of smaller amplitude. The authors suggested that these fluctuations are likely to be caused by the downstream travelling vortices of the neighboring blade.

Figure 37.

Unsteady pressure variations along rear suction side (a); schlieren photograph (b); kulite sensor positioning (c). Adapted from [21].

The periodicity of the pressure signal at position 7, slightly upstream of the trailing edge, is rather poor and only phase lock averaging provides useful information on its periodic character. The reason is most likely the result of a superposition of waves induced by the von Kármán vortices in the wake of the neighboring blade and upstream travelling waves induced by the oscillation of the suction side shear layer designated by “S” in the schlieren photographs. Right at the trailing edge, position 11, we have, as expected, strong periodic signals associated with the oscillating shear layers.

6. Turbine Trailing Edge Vortex Frequency Shedding

Besides the importance of trailing edge vortex shedding for the wake mixing process and the trailing edge pressure distribution discussed before, vortex shedding deserves also special attention due to its importance as excitation for acoustic resonances and structural vibrations. Heinemann & Bütefisch [25], investigated 10 subsonic and transonic turbine cascades: two flat plate turbine tip sections, three mid-sections with nearly axial inlet (one blade tested with three different trailing edge thicknesses) and 3 high turning hub sections. The trailing edge thickness varied from 0.8% to 5%. The vortex shedding frequency was determined with an electronic-optical method developed at the DFVLR-AVA by Heinemann et al. [58].

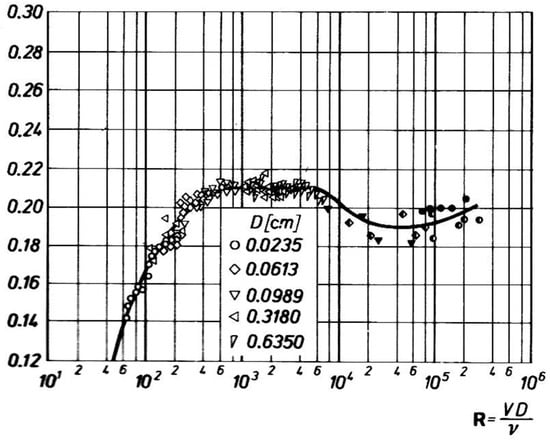

The corresponding Strouhal numbers defined in (3) covered a wide range: for a Reynolds number range based on trailing edge thickness and downstream isentropic velocity of . The Strouhal numbers for flows from cylinders over the same Reynolds number range are of the order of and 0.21 as shown in Figure 38.

Figure 38.

Strouhal numbers in sub-critical Reynolds number range for flow over cylinders; adapted from [59].

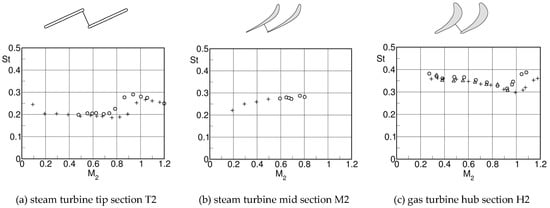

Figure 39 presents the Strouhal numbers for 3 of the 10 turbine blade sections investigated by Heinemann and Bütefisch [25]. The comparison with the flow across cylinders is limited to the subsonic range. The Strouhal numbers for the flat plate tip section T2 are of the order of = 0.2 in the Mach range = 0.2 to 0.8 and therewith very close to the those of the flow over cylinders. On the other side, the hub section H2 with a high rear suction side curvature distinguishes itself by Strouhal numbers as high as 0.38 − 0.3, with a decreasing tendency from = 0.2 to 0.9. For the mid-section M2 with low rear suction side turning, the authors report Strouhal numbers increasing from = 0.22 to 0.29 for a Mach range 0.2 to 0.8.

Figure 39.

Strouhal number for 3 blade sections.  : and based on isentropic downstream velocity.

: and based on isentropic downstream velocity.  : and based on homogeneous downstream velocity. Adapted from [25].

: and based on homogeneous downstream velocity. Adapted from [25].

: and based on isentropic downstream velocity.

: and based on isentropic downstream velocity.  : and based on homogeneous downstream velocity. Adapted from [25].

: and based on homogeneous downstream velocity. Adapted from [25].

Additional information on turbine blade trailing edge frequency measurements were published by Sieverding [60] who used fast response pressure sensors implemented in the blade trailing edge and in a total pressure probe positioned at short distance from the trailing edge, while Bryanston-Cross and Camus [61] made use of a 20 MHz bandwidth digital correlator combined with conventional schlieren optics. The Strouhal numbers of Sieverding’s rotor blade with a straight rear suction side were in the lower part of the band width of the DFVLR-AVA data, while those of Bryanston-Cross and Camus rotor blades with higher suction side curvature resided in the upper part.

The large range of Strouhal numbers were possibly due to differences in the state of the boundary layers at the point of separation. Besides that, the vortex shedding frequency does not simply depend on the trailing edge thickness augmented by the boundary layer displacement thickness, which, however, is in general not known, but rather on the effective distance between the separating shear layers which could be significantly smaller than the trailing edge thickness. Patterson & Weingold [62], simulating a compressor airfoil trailing edge flow field on a flat plate, concluded that, compared to the effective distance between the separating upper and lower shear layers, the state of the boundary layer before separation played a much more important role.

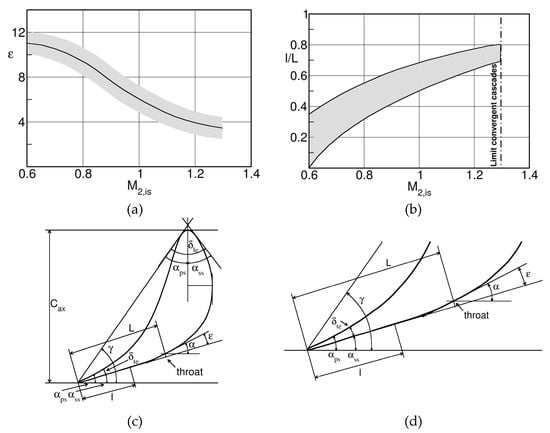

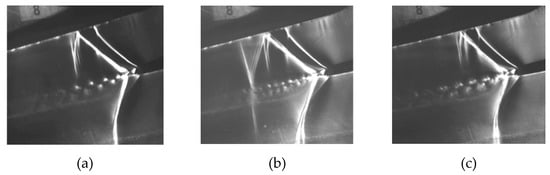

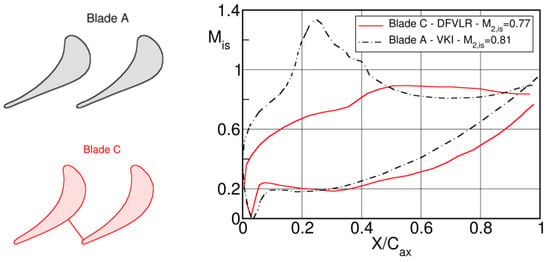

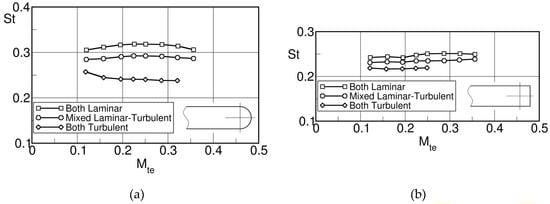

The influence of the boundary layer state and of the effective distance of the separating shear layers was specifically addressed in a series of cascade and flat plate tests investigated by Sieverding & Heinemann [16], at VKI and DLR. Figure 40 shows the blade surface isentropic Mach number distributions of a front loaded blade, with the particularity of a straight rear suction side (blade A), and a rear loaded blade (blade C), characterized by a high rear suction side turning angle, at a downstream Mach number of .

Figure 40.

Blade Mach number distributions for front and rear-loaded blades; adapted from [16].

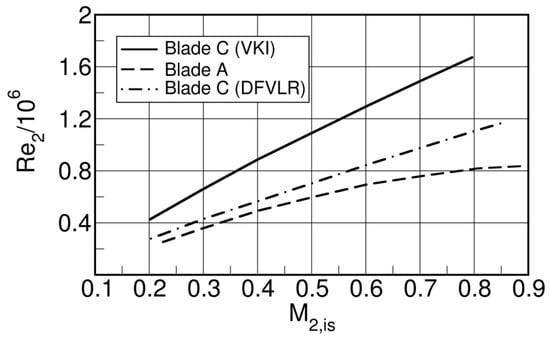

The early suction side velocity peak on blade A will cause early boundary layer transition. On the contrary, considering the weak velocity peak on the rear suction side followed by a very moderate recompression, the suction side boundary layer of blade C is likely to be laminar at the trailing edge over a large range of Reynolds numbers. As regards the pressure sides of both blades, the strong acceleration over most part of the surface is likely to guarantee laminar conditions at the trailing edge on both blades and trip wires had to be used to enforce transition and turbulent boundary layers at the trailing edge, if desired so. The blades were tested from low subsonic to high subsonic outlet Mach numbers. Due to the use of blow down and suction tunnels at VKI and DLR, respectively, the Reynolds number increases with Mach number as shown in Figure 41.

Figure 41.

Variation of Reynolds number in function of downstream Mach number; adapted from [16].

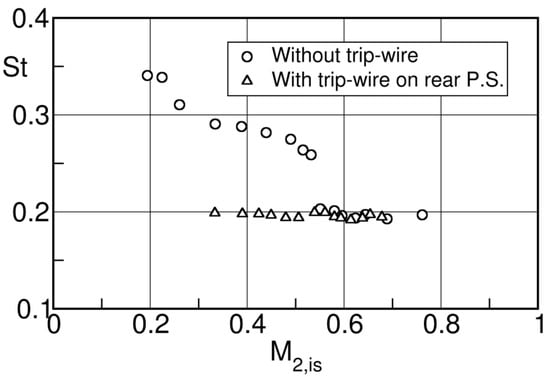

The tests for the front-loaded blade A are presented in Figure 42. In case of forced transition on the pressure side through a trip wire at 24% of the chord length, the Strouhal number is nearly constant and roughly equal to over the entire Mach range. In absence of a trip wire, the evolution of is quite different. Starting from the low Mach number and Reynolds number end, the Strouhal number decreases from at to at . At this point the drops suddenly to the level of all turbulent cases. This sudden change obviously indicates that boundary layer transition has taken place on the pressure side. The slow decrease before the sudden jump points to a progressive change from a laminar to a transitional boundary layer which is obviously related to the increasing Reynolds number.

Figure 42.

Strouhal number variation with downstream Mach number for cascade A; adapted from [16].

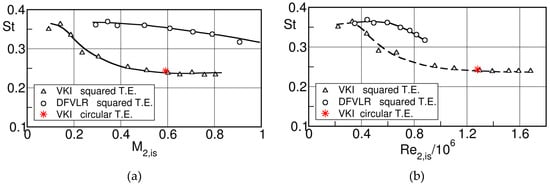

Cascade C was tested with a circular trailing edge at DLR and a squared trailing edge at VKI over a range = 0.2 to 0.9. The two series of test differed not only by their trailing edge geometry but also, at the same Mach number, by a higher Reynolds number in the VKI tests, see Figure 41. Note, that in the case of the squared trailing edge the distance between the separating shear layers is well defined. However, this is not the case for the rounded trailing edge in which case the distance should be in any way smaller. But one single test, at = 0.59, was run at VKI also with a rounded trailing edge to eliminate any bias between the tests at DLR and VKI.

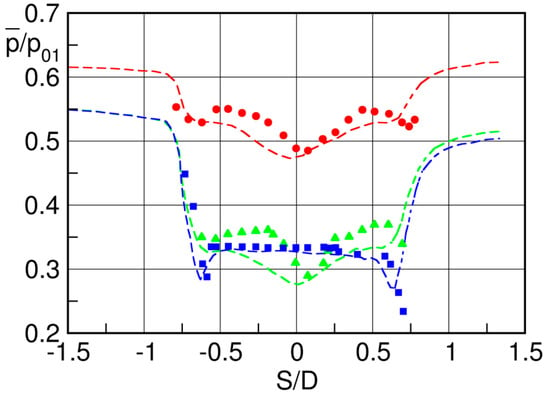

Figure 43 presents the Strouhal number for blade C both in function of the downstream Mach number and the Reynolds number. Both data sets show a plateau of at low Mach number and Reynolds number which is characteristic for a fully laminar trailing edge boundary layer separation. The Strouhal number starts to decrease with increasing Reynolds number, the drop of occurring earlier at for the squared trailing edge, instead of for the circular trailing edge. At the squared trailing edge data reach a plateau with . Note that the single rounded trailing edge test at VKI indicated by a star in the graph is right in line with the squared trailing edge data. Extrapolating the DLR data to higher Reynolds number one may expect that they will reach the plateau of = 0.24 at .

Figure 43.

Strouhal number variation with Mach number (a) and Reynolds number (b) for cascade C; adapted from [16].

Comparing the two curves in Figure 43 raises of course the question as to the reasons for the differences between them. The possible influence of the different distance between the separating shear layers was already mentioned before, but, if this would be the case, then the Strouhal number for the VKI tests with squared trailing edge should be higher than those of the DLR tests with rounded trailing edge. There must be therefore a different reason. The key for the understanding comes from flat plate tests presented in [16], see Figure 44, which showed that the difference of the Strouhal number between a full laminar and full turbulent flow conditions was much bigger for tests with rounded trailing edges than squared trailing edges, 30% instead of 13%.

Figure 44.

Strouhal numbers for vortex shedding from flat plates with rounded (a) and squared (b) trailing edges; adapted from [16].

This different behavior can be explained if one assumes that the shape of the trailing edge may strongly affect the evolution of the shear layer, and that it is the state of the shear layer rather than that of the boundary layer which plays the most important role in the generation of the vortex street. Of course, a sharp corner will not necessarily induce immediately full transition, but transition will occur over a certain length, and this length affects the length of the enrolment of the vortex and therewith its frequency. The transition length of the shear layer will be affected by both the Reynolds number and the Mach number.

Contrary to the vortex shedding for subsonic flow conditions discussed above, where the vortices are generated by the enrolment of the separating shear layers close to the blade trailing edge, the situation changes with the emergence of oblique shocks from the region of the confluence of the pressure and suction side shear layers for transonic outlet Mach numbers. In this case the vortex formation is delayed to after this region as shown already in the schlieren pictures in Figure 34.

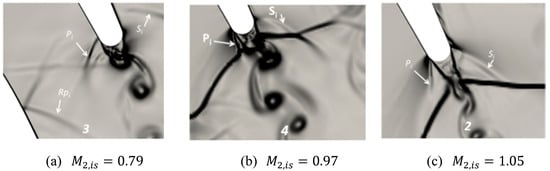

This is even more clearly demonstrated in Figure 45 presenting the evolution of the wake density gradients predicted with a LES by Vagnoli et al. [56], for the turbine blade shown in Figure 17, from high subsonic to low supersonic outlet Mach numbers. For the vortex shedding frequency is not any more conditioned by the trailing edge thickness but by the distance between the feet of the trailing edge shocks emanating from the region of the confluence of the two shear layers.

Figure 45.

Change of wake density gradients from subsonic to supersonic exit Mach numbers as predicted by LES [56].

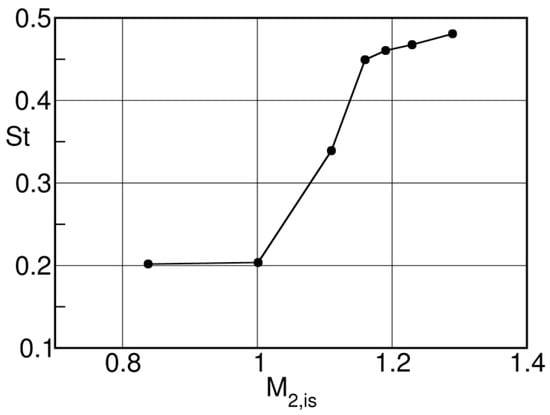

Consequently, one observes a sudden increase of the vortex shedding frequency as for example recorded by Carscallen et al. [43], on their nozzle guide vane, see Figure 46.

Figure 46.

Strouhal number versus downstream Mach number; adapted from [43].

7. Advances in the Numerical Simulation of Unsteady Turbine Wake Characteristics

The numerical simulation of unsteady turbine wake flow is relatively young, and the first contributions appeared in the mid-80s. The decade 1980–1990 has in fact seen the final move from the potential flow models to the Euler and Navier-Stokes equations whose numerical solutions were tackled with new, revolutionary for the time, techniques. Those were also the years of the first vector and parallel super-computers capable of a few sustained gigaflops (CRAY YMP, IBM SP2, NEC SX-3, to quote a few examples), and of the beginning of the massive availability of computing resources obeying Moore’s law (transistor count doubling every two years). Since then the progresses have been huge both on the numerical techniques and on the turbulence modelling side. Indeed, the most advanced option, that is the Direct Numerical Simulation (DNS) approach, where all turbulent scales are properly space-time resolved down to the dissipative one, has also recently entered the turbomachinery community starting from the pioneering work of Jan Wissink in 2002 [63]. Unfortunately, because of the very severe resolution requirements, there is still no DNS study of turbine wake flow (TWF) at realistic Reynolds and Mach numbers, that is Re ~ and high subsonic and transonic outlet Mach numbers with shocked flow conditions, although improvements have been recently attained [64]. With the development of highly parallelizable codes and the help of very large-scale computing hardware such a simulation is likely to appear soon, as the result of some cutting-edge scientific research. In the meantime, and within the foreseeable future, the industrial world and the designers interested in tangled aspects of TWF for stage performance enhancement will certainly run unsteady flow simulations where turbulence is handled through advanced modeling. Many of those simulations will rely on in-house developed research codes and turbomachinery oriented commercial packages, which, indeed, have improved significantly since the very first unsteady TWF simulation. Yet, there are two areas where important challenges still need to be satisfactorily faced before the presently available (lower fidelity) computations could be considered reliable and successful. They can be, loosely speaking, termed of numerical and modeling nature. We shall try to review both, in the context of the presently discussed unsteady turbine wake flow subject category, presenting a short overview of the available technologies. A more specialized review study on high-fidelity simulations as applied to turbomachinery components has recently been published by Sandberg et al. [65].

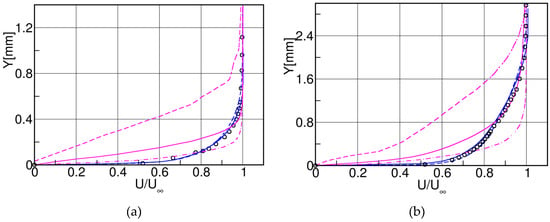

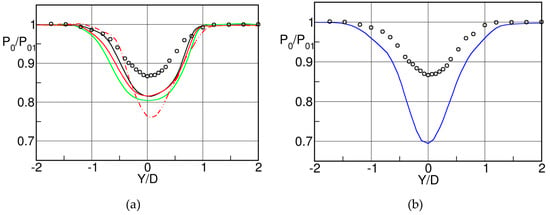

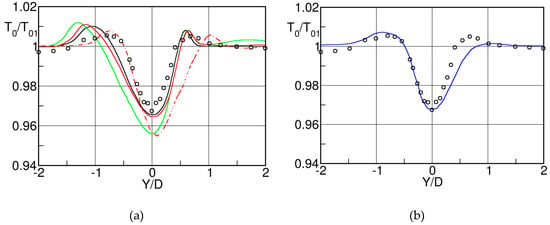

7.1. Numerical Aspects