Flat Plate and Turbine Vane Film-Cooling Performance with Laid-Back Fan-Shaped Holes †

Abstract

1. Introduction

2. Experimental Apparatus

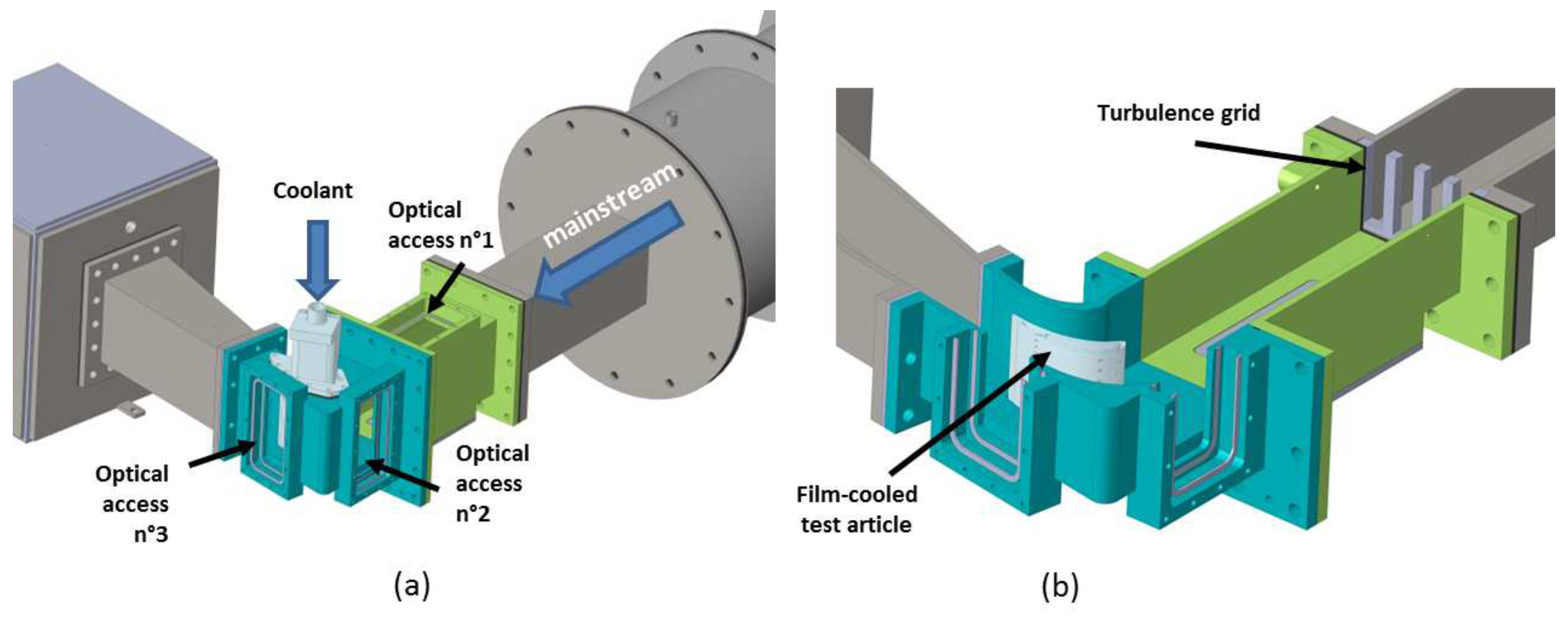

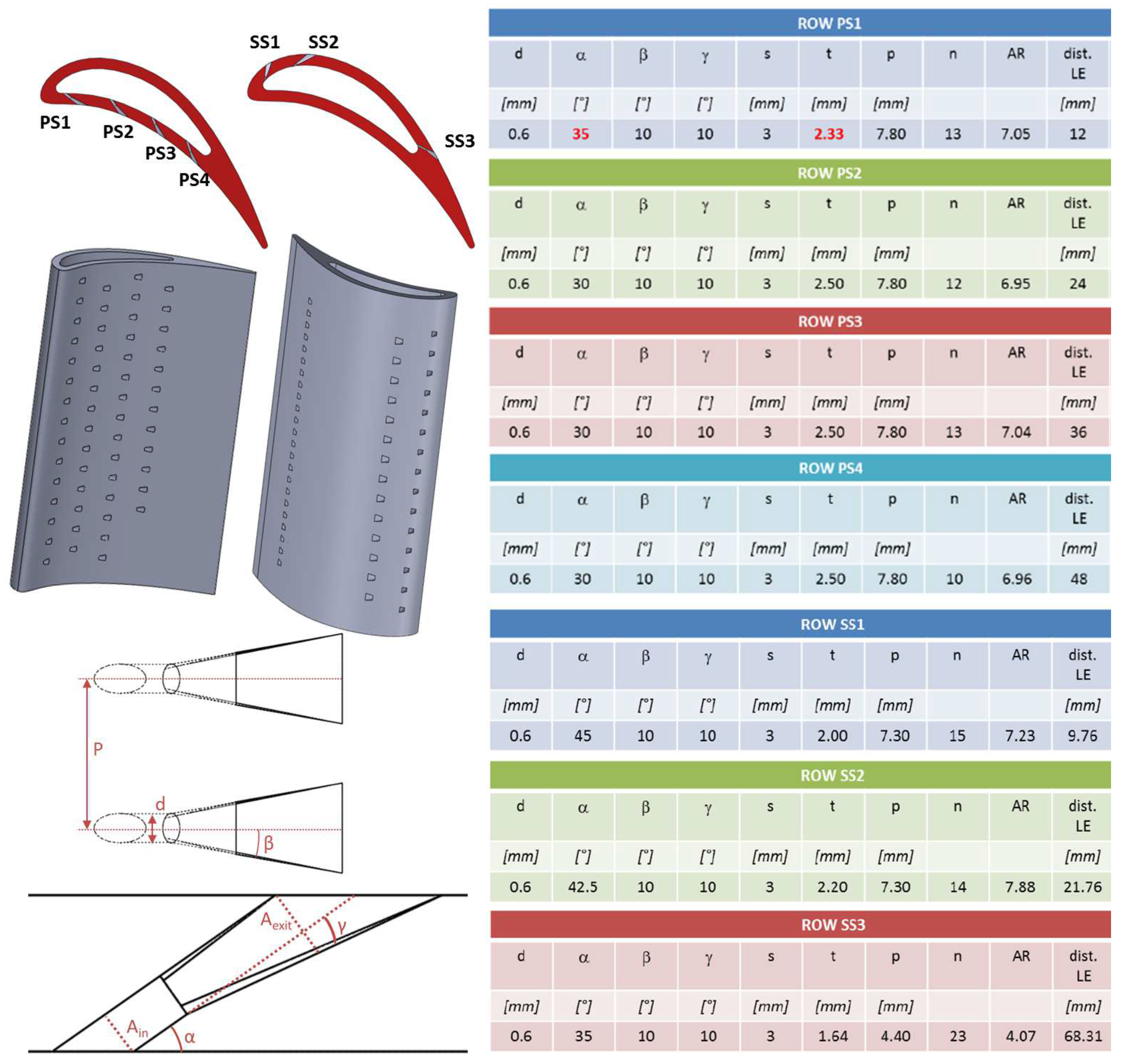

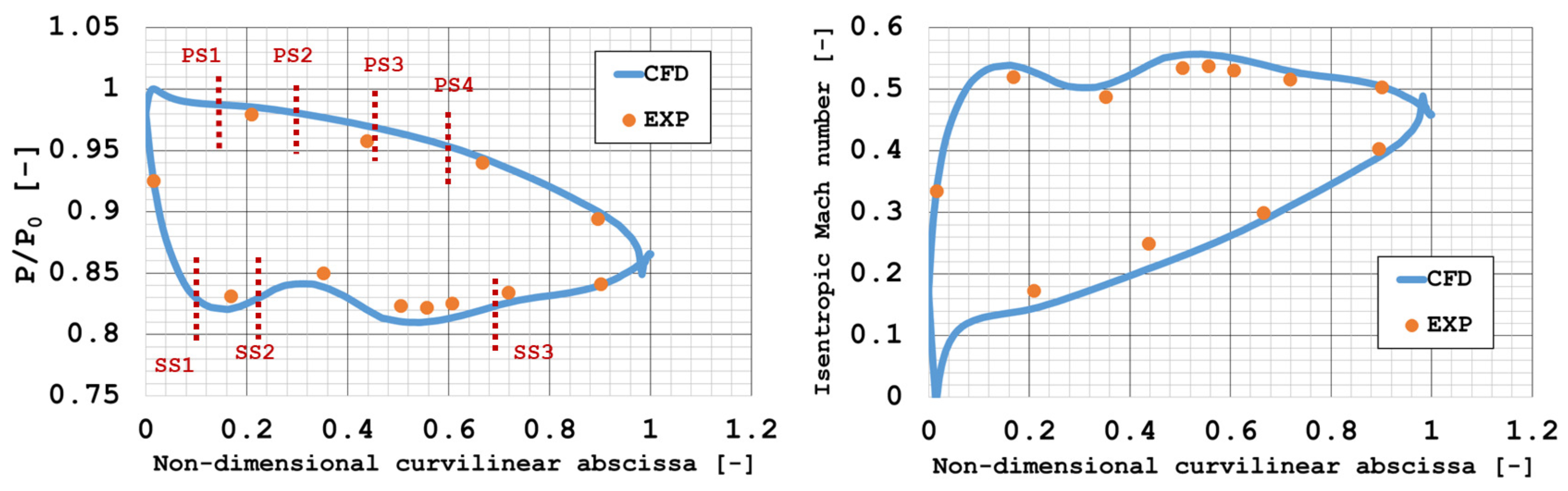

2.1. Cascade Test Rig

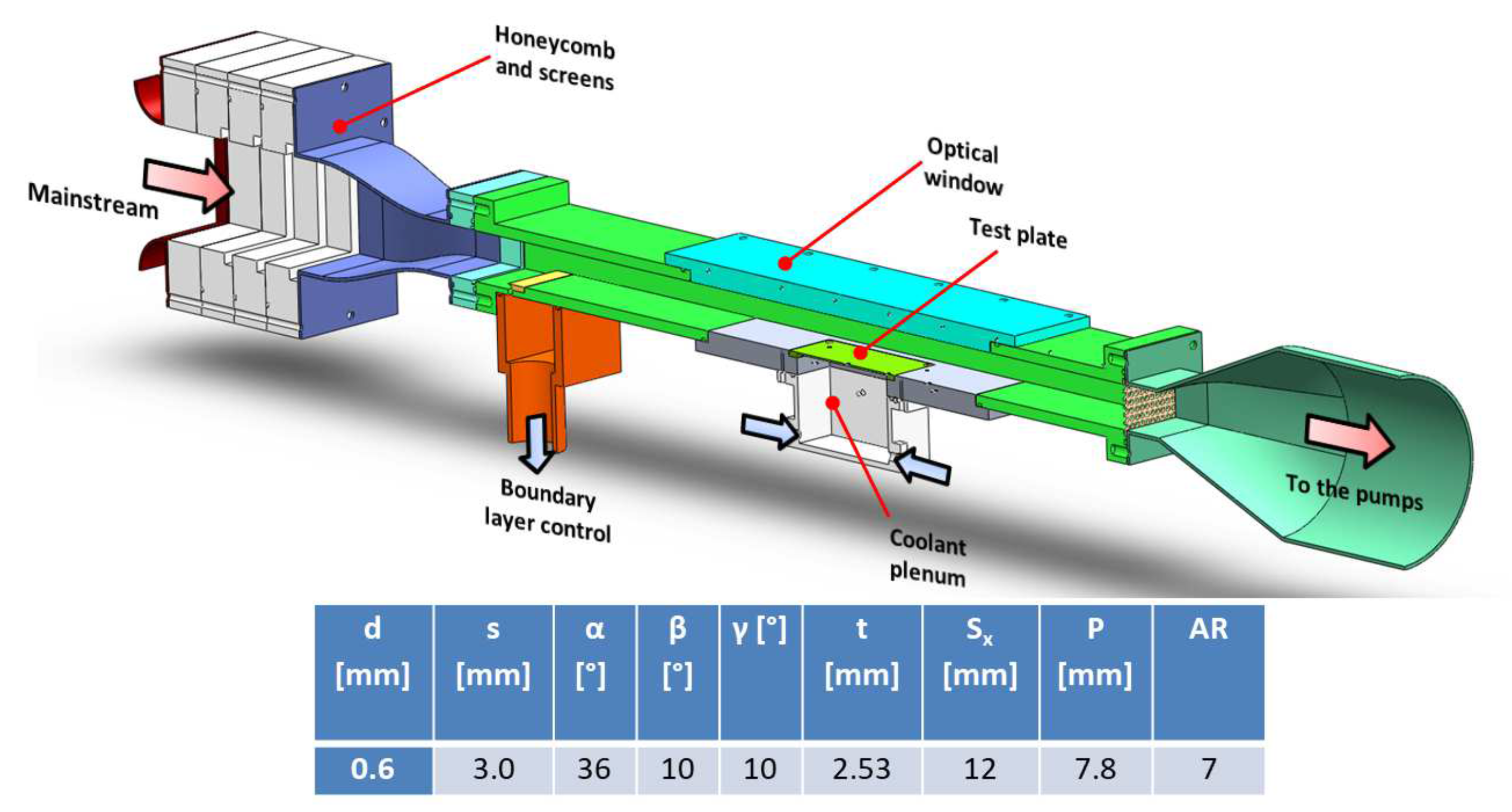

2.2. Flat Plate Test Rig

2.3. Operating Conditions

3. Experimental Technique and Data Reduction

4. Experimental Results

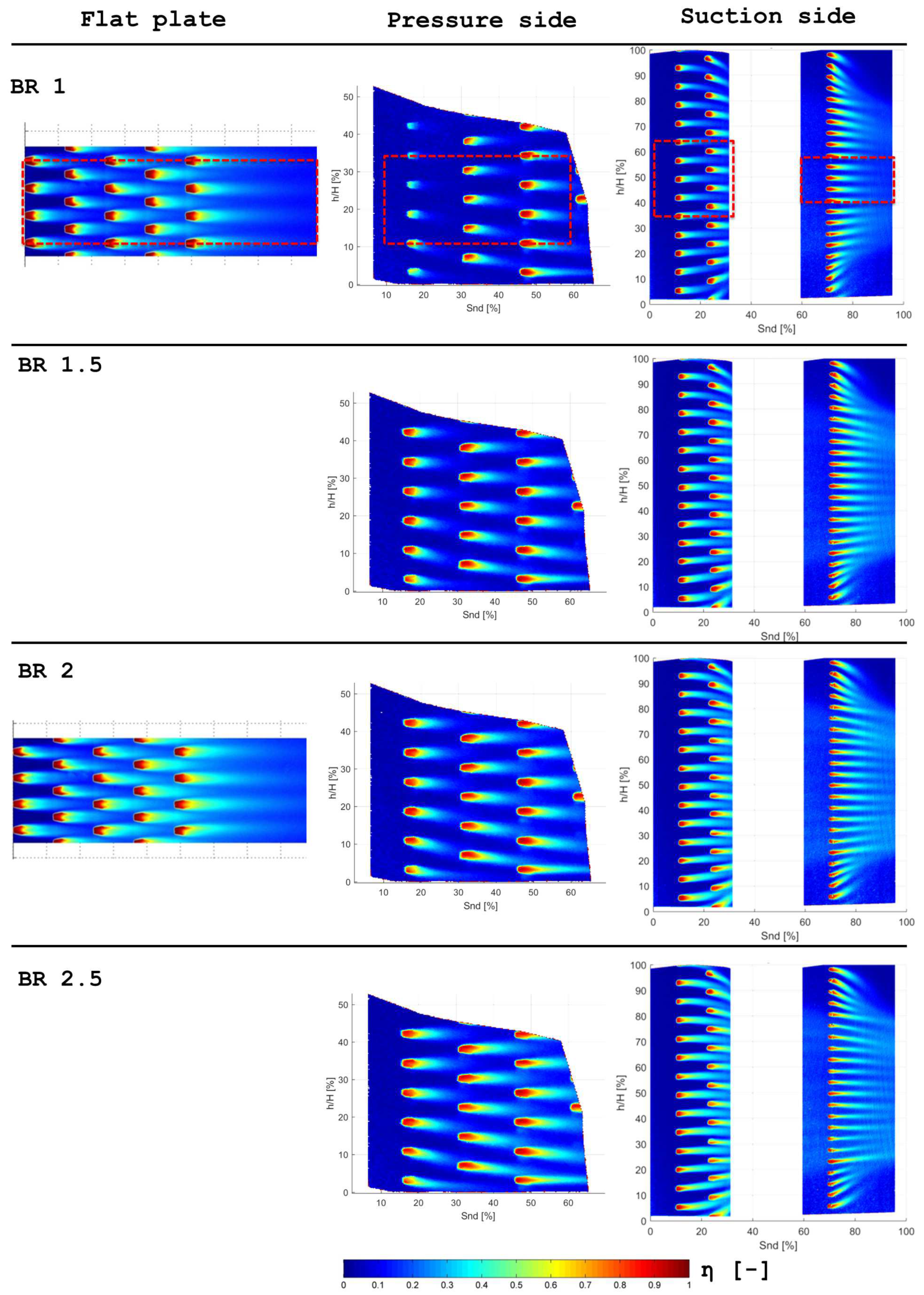

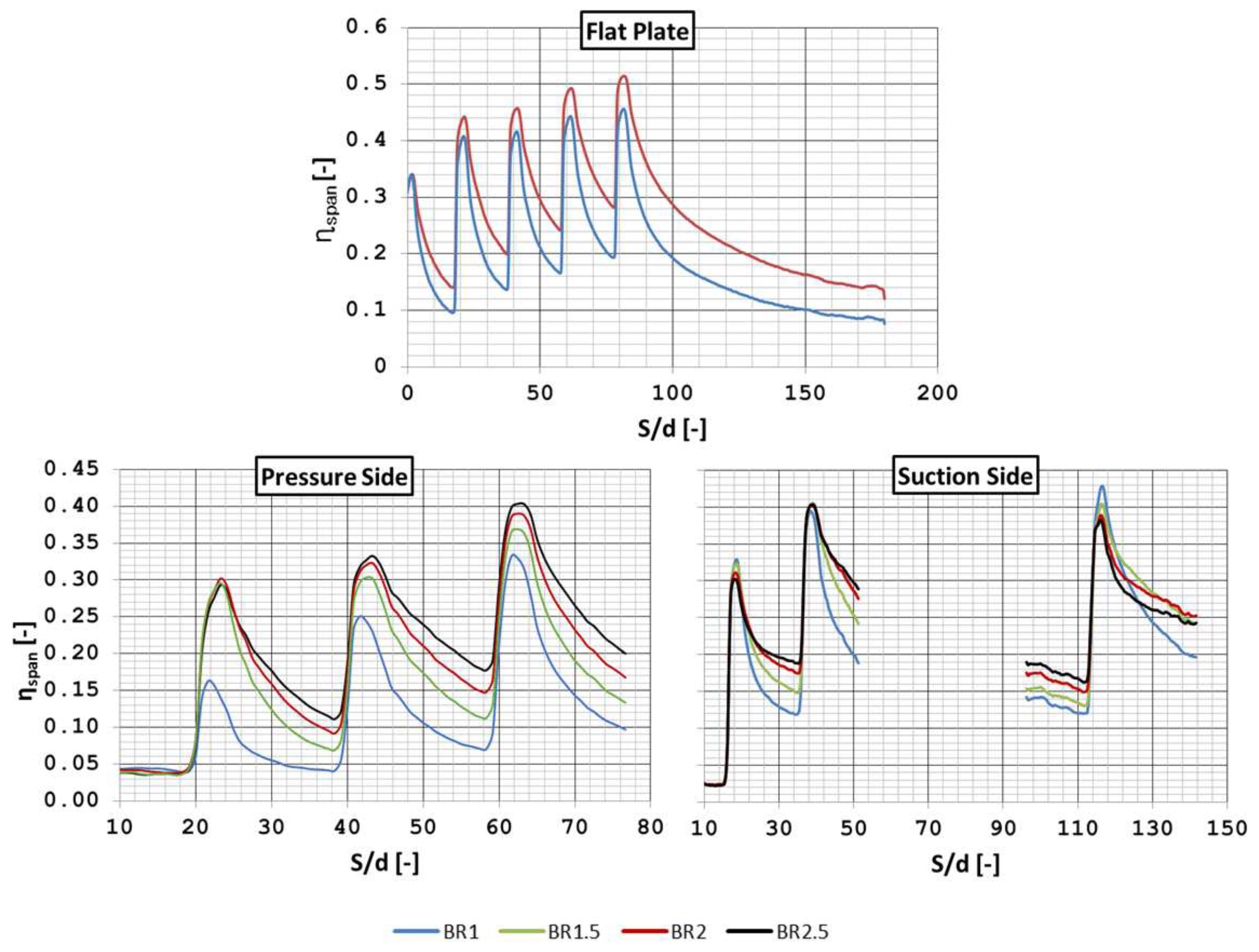

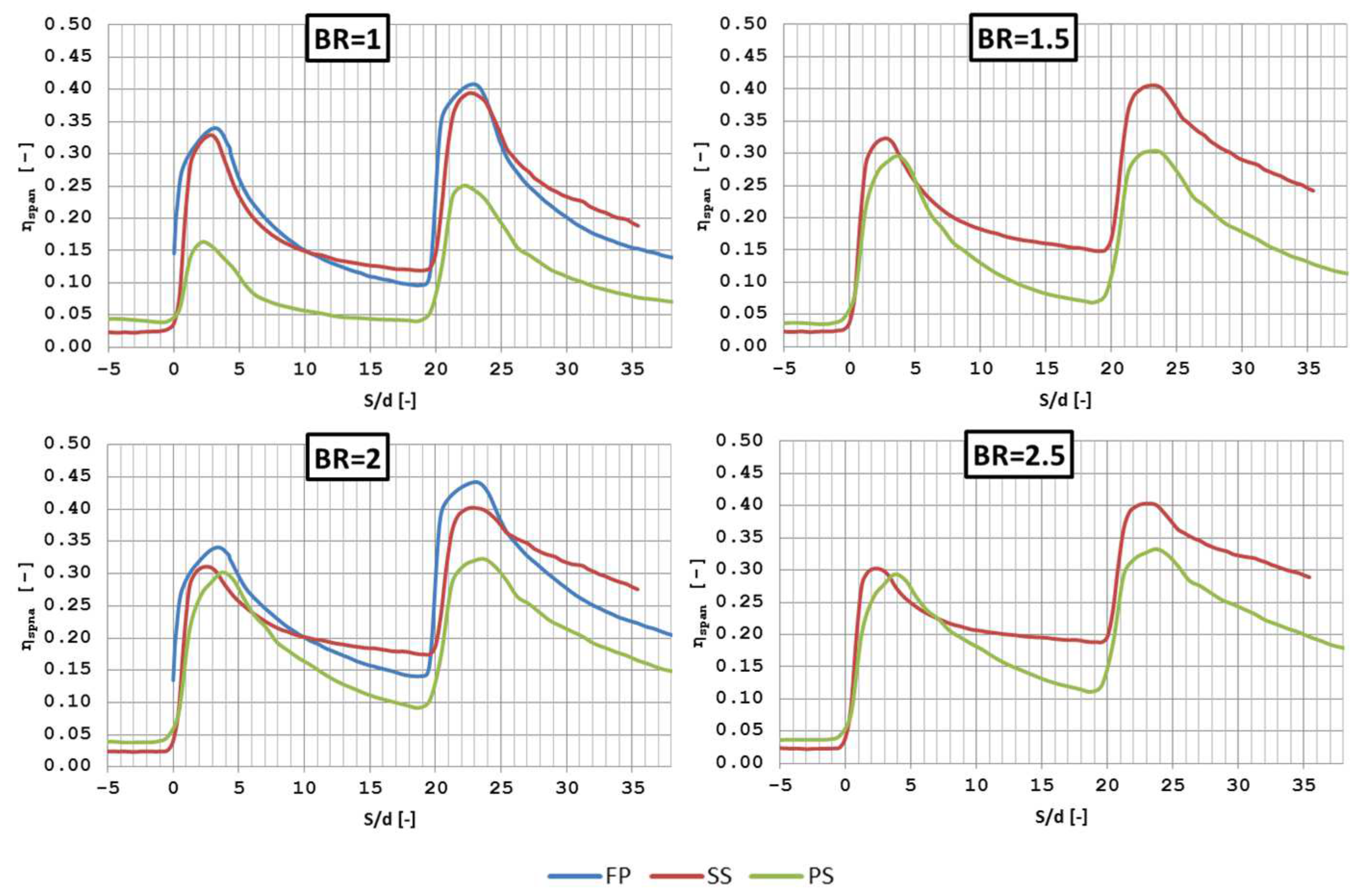

4.1. Adiabatic Effectiveness Measurements

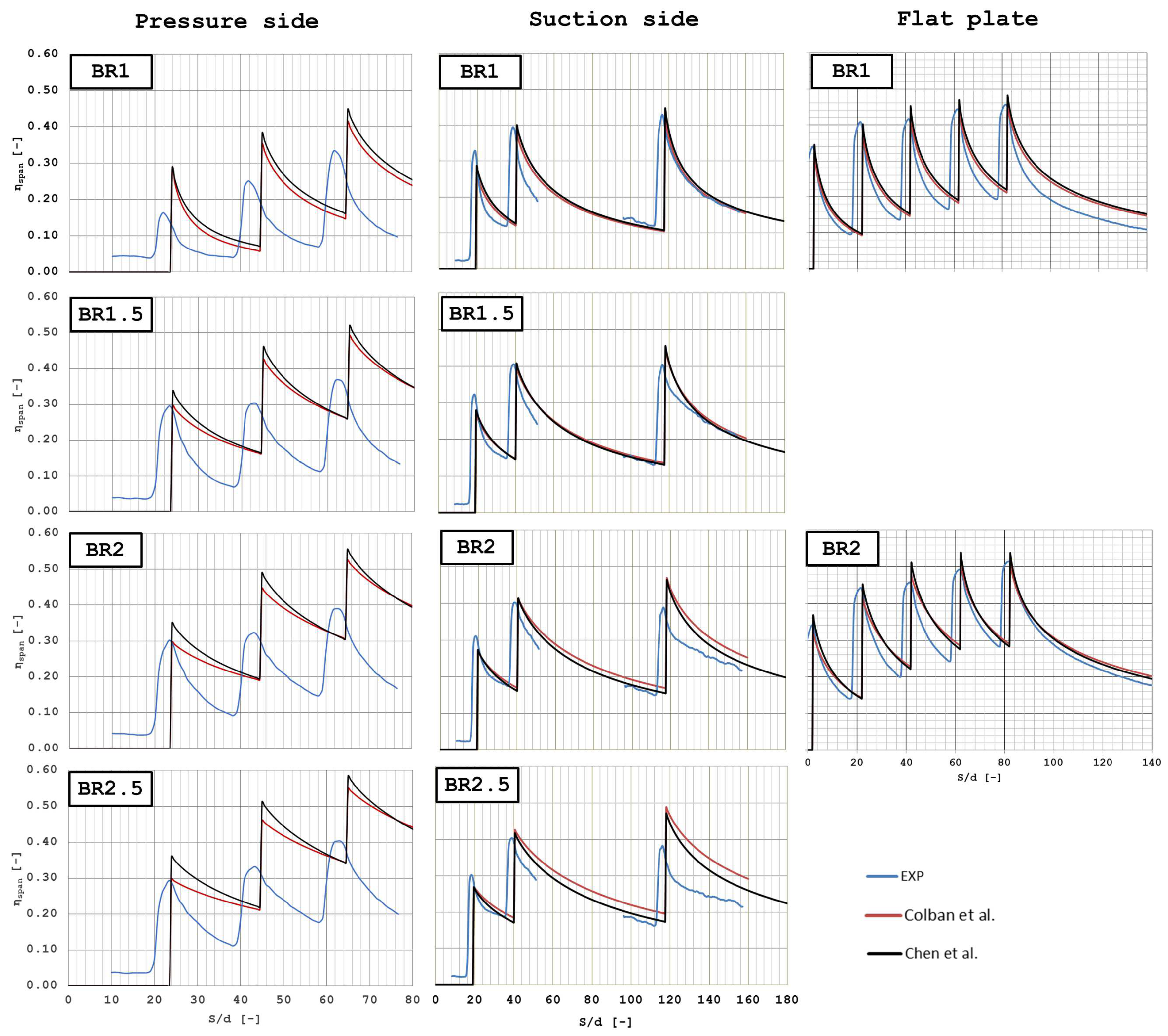

4.2. Comparison with Correlations

- Compare correlation predictions to a baseline flat plate configuration, in the case of film-cooling holes with aggressive shaping, so to assess their prediction capability.

- Remove the effect of the variations of fluid-dynamic and geometric parameters, from row to row and between different configurations, that could bias the FP-vane comparisons reported in Figure 7, since they are accounted for in the adopted correlations.

- Assess how the actual performance on the vane can deviate from what would be calculated through common correlations.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Blowing Ratio [-] | |

| Density Ratio [-] | |

| h | Vane height coordinate [m] |

| H | Vane height [m] |

| Reynolds number [-] | |

| P | Pressure [Pa] |

| Non-dimensional axial coordinate [-] | |

| Greeks | |

| Adiabatic Effectiveness | |

| Acronyms | |

| Flat plate | |

| Pressure Side | |

| Suction Side |

References

- Bunker, R. A Review of Shaped Hole Turbine FilmCooling Technology. ASME J. Heat Transf. 2005, 127, 441–453. [Google Scholar] [CrossRef]

- Colban, W.; Thole, K.; Bogard, D. A film-cooling correlation for shaped holes on a flat-plate surface. J. Turbomach. 2010, 133, 011002. [Google Scholar] [CrossRef]

- Chen, A.; Li, S.; Han, J. Film cooling for cylindrical and fan-shaped holes using pressure-sensitive paint measurement technique. J. Thermophys. Heat Transf. 2015, 29, 775–784. [Google Scholar] [CrossRef]

- Ito, S.; Goldstein, R.J.; Eckert, E. Film Cooling of a Gas Turbine Blade. ASME J. Eng. Power 1978, 100, 476–481. [Google Scholar] [CrossRef]

- Schwarz, S.; Goldstein, R. The Two-Dimensional Behavior of Film Cooling Jets on Concave Surfaces. ASME J. Turbomach. 1989, 111, 124–130. [Google Scholar] [CrossRef]

- Pedersen, D.; Eckert, E.; Goldstein, R.J. Film-Cooling with Large Density Differences Between the Mainstream and Secondary Fluid Measured by the Heat-Mass Transfer Analogy. ASME J. Heat Transf. 1977, 99, 620–627. [Google Scholar] [CrossRef]

- Han, J.; Dutta, S.; Ekkad, S. Gas Turbine Heat Transfer and Cooling Technology; Taylor & Francis: Abingdon, UK, 2000. [Google Scholar]

- Naik, S.; Krueckels, J.; Gritsch, M.; Schnieder, M. Multirow film cooling performancs of a high lift blade and vane. ASME J. Turbomach. 2013, 136, 051003. [Google Scholar] [CrossRef]

- Narzary, D.; Liu, K.; Rallabandi, A.; Han, J. Influence of Coolant Density on Turbine Blade Film-Cooling Using Pressure Sensitive Paint Technique. ASME J. Turbomach. 2011, 134, 031006. [Google Scholar] [CrossRef]

- Liu, K.; Yang, S.; Han, J. Influence of coolant density on turbine blade film-cooling with axial shaped holes. In Proceedings of the ASME Conference Proceedings, Copenhagen, Denmark, 11–15 June 2012. HT2012-58144. [Google Scholar]

- Gao, Z.; Narzary, D.; Han, J. Film cooling on gas turbine blade pressure side or suction side with axial shaped holes. Int. J. Heat Mass Transf. 2007, 51, 2139–2152. [Google Scholar] [CrossRef]

- Barigozzi, G.; Ravelli, S.; Armellini, A.; Mucignat, C.; Casarsa, L. Effects of injection conditions and Mach number on unsteadiness arising within coolant jets over a pressure side vane surface. Int. J. Heat Mass Transf. 2013, 67, 1220–1230. [Google Scholar] [CrossRef]

- Gritsch, M.; Schulz, A.; Wittig, S. Adiabatic wall effectiveness measurements of film-cooling holes with expanded exits. ASME J. Turbomach. 1998, 120, 450–456. [Google Scholar] [CrossRef]

- Bacci, T.; Gamannossi, A.; Mazzei, L.; Picchi, A.; Winchler, L.; Carcasci, C.; Andreini, A.; Abba, L.; Vagnoli, S. Experimental and CFD analyses of a highly-loaded gas turbine blade. Energy Procedia 2017, 126, 770–777. [Google Scholar] [CrossRef]

- Stimpson, C.; Snyder, J.; Thole, K.; Mongillo, D. Effects of Coolant Feed Direction on Additively Manufactured Film Cooling Holes. ASME J. Turbomach. 2018, 140, 111001. [Google Scholar] [CrossRef]

- Becchi, R.; Facchini, B.; Picchi, A.; Tarchi, L.; Coutandin, D.; Zecchi, S. Film cooling adiabatic effectiveness measurements of pressure side trailing edge cooling configurations. Propuls. Power Res. 2015, 4, 190–201. [Google Scholar] [CrossRef]

- Caciolli, G.; Facchini, B.; Picchi, A.; Tarchi, L. Comparison between psp and tlc steady state techniques for adiabatic effectiveness measurement on a multiperforated plate. Exp. Thermal Fluid Sci. 2013, 48, 122–133. [Google Scholar] [CrossRef]

- Sellers, J. Gaseous film cooling with multiple ejection stations. AIAA J. 1963, 1, 2154–2156. [Google Scholar] [CrossRef]

- Gritsch, M.; Colban, W.; Schar, H.; Dobbeling, K. Effect of hole geometry on the thermal perfomance of fan-shaped film cooling holes. ASME J. Turbomach. 2005, 127, 718–725. [Google Scholar] [CrossRef]

| Cascade Rig | Flat Plate | |||

|---|---|---|---|---|

| Mainstream | Mainstream | |||

| Inlet total pressure [Pa] | 125,000 | Inlet total pressure [Pa] | 90,300 | |

| Inlet total temp. [K] | 300 | Inlet total temp. [K] | 300 | |

| Mass flow [g/s] | 930 | Mass flow [g/s] | 250 | |

| Re inlet [-] | 5.62 × 10 | Re [-] | 9 × 10 | |

| Re throat [-] | 9.34 × 10 | |||

| Mach throat [-] | 0.54 | |||

| Coolant | Coolant | |||

| BR [-] | 1, 1.5, 2, 2.5 | BR [-] | 1, 2 | |

| DR [-] | 2.5 | DR [-] | 2.5 | |

| PS | SS | ||||||

|---|---|---|---|---|---|---|---|

| Average BR | PS1 | PS2 | PS3 | PS4 | SS1 | SS2 | SS3 |

| 1 | 0.8 | 0.99 | 1.08 | 1.13 | 1.01 | 1.04 | 0.95 |

| 1.5 | 1.76 | 1.51 | 1.39 | 1.34 | 1.57 | 1.46 | 1.46 |

| 2 | 2.61 | 2.05 | 1.76 | 1.59 | 2.13 | 1.9 | 1.97 |

| 2.5 | 3.4 | 2.59 | 2.14 | 1.87 | 2.68 | 2.35 | 2.47 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Bacci, T.; Picchi, A.; Facchini, B. Flat Plate and Turbine Vane Film-Cooling Performance with Laid-Back Fan-Shaped Holes. Int. J. Turbomach. Propuls. Power 2019, 4, 14. https://doi.org/10.3390/ijtpp4020014

Bacci T, Picchi A, Facchini B. Flat Plate and Turbine Vane Film-Cooling Performance with Laid-Back Fan-Shaped Holes. International Journal of Turbomachinery, Propulsion and Power. 2019; 4(2):14. https://doi.org/10.3390/ijtpp4020014

Chicago/Turabian StyleBacci, Tommaso, Alessio Picchi, and Bruno Facchini. 2019. "Flat Plate and Turbine Vane Film-Cooling Performance with Laid-Back Fan-Shaped Holes" International Journal of Turbomachinery, Propulsion and Power 4, no. 2: 14. https://doi.org/10.3390/ijtpp4020014

APA StyleBacci, T., Picchi, A., & Facchini, B. (2019). Flat Plate and Turbine Vane Film-Cooling Performance with Laid-Back Fan-Shaped Holes. International Journal of Turbomachinery, Propulsion and Power, 4(2), 14. https://doi.org/10.3390/ijtpp4020014