Design of Enhanced Virtual Reality Training Environments for Industrial Rotary Dryers Using Mathematical Modeling

Abstract

1. Introduction

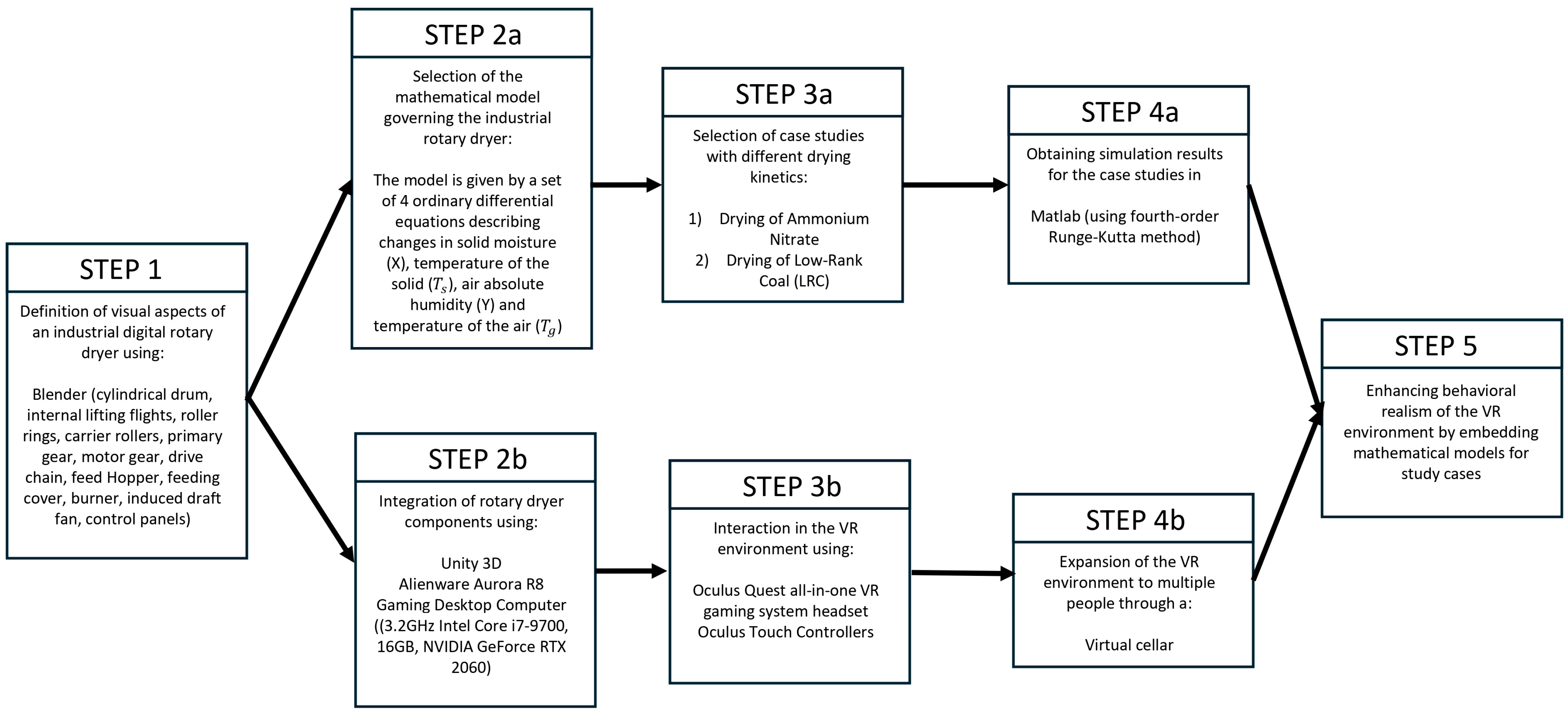

2. Materials and Methods

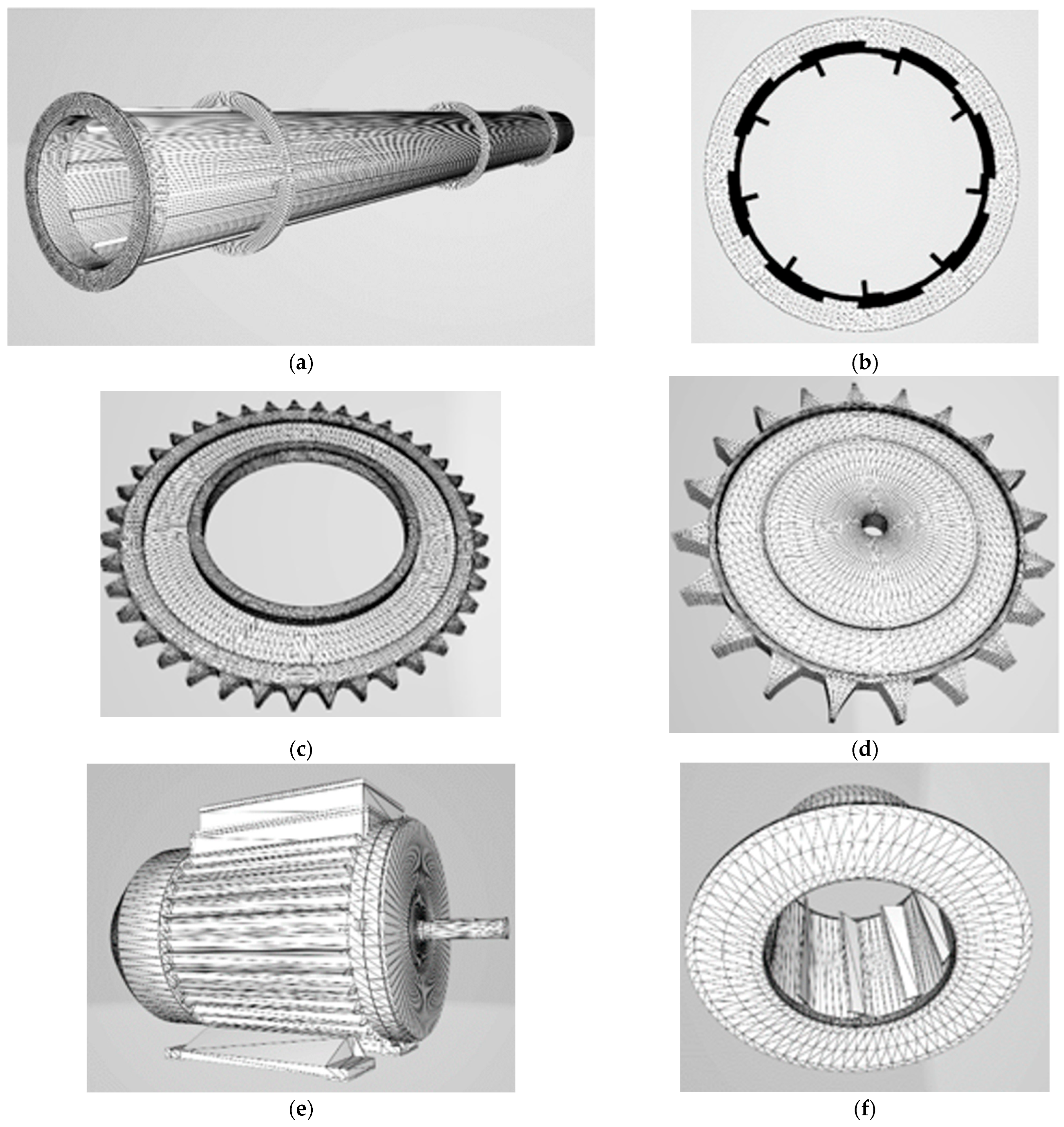

2.1. Visual Aspects of the Digital Rotary Dryer in the VR Environment

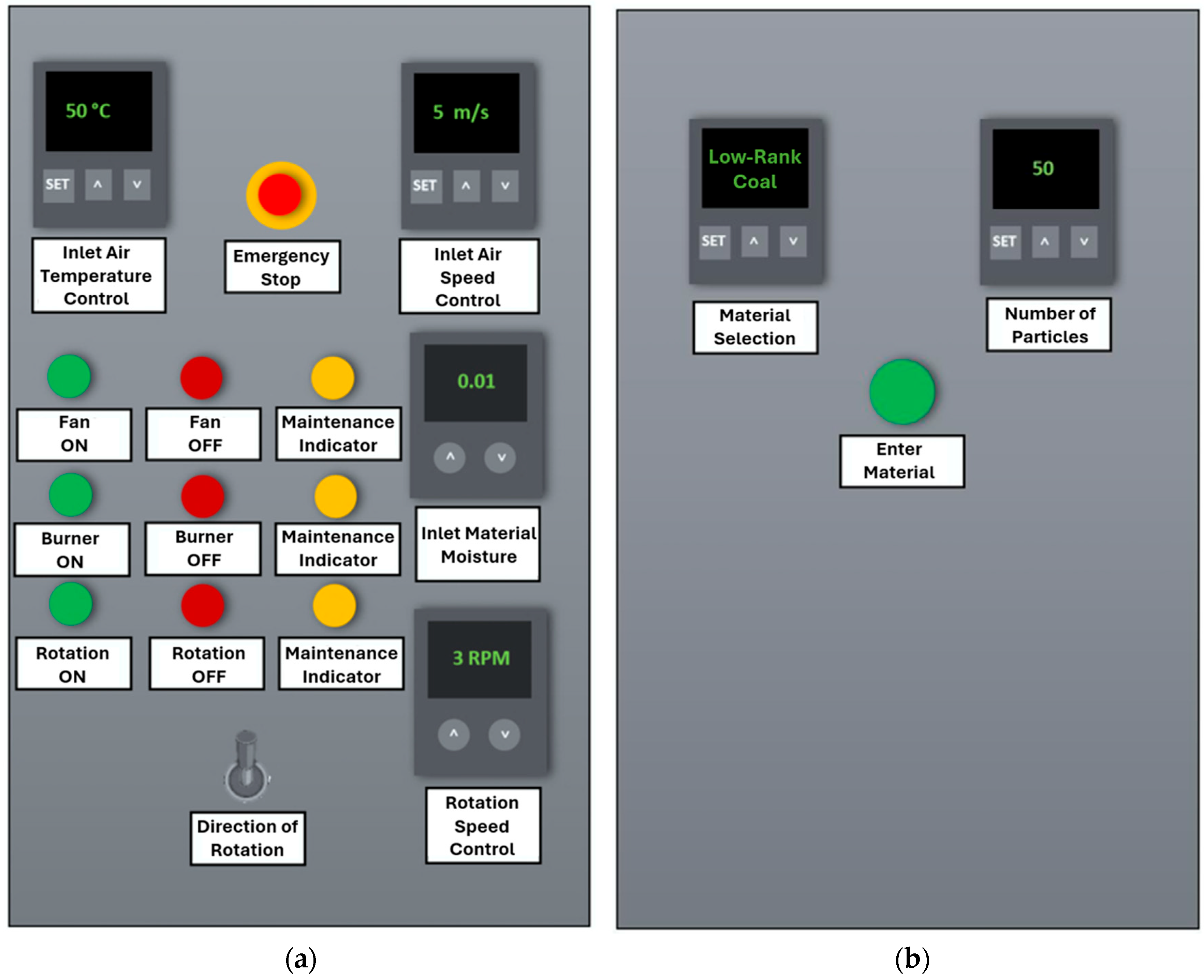

2.2. Behavioral Aspects of the Digital Rotary Dryer in the VR Environment

3. Case Studies

3.1. Case Study: Ammonium Nitrate Plant

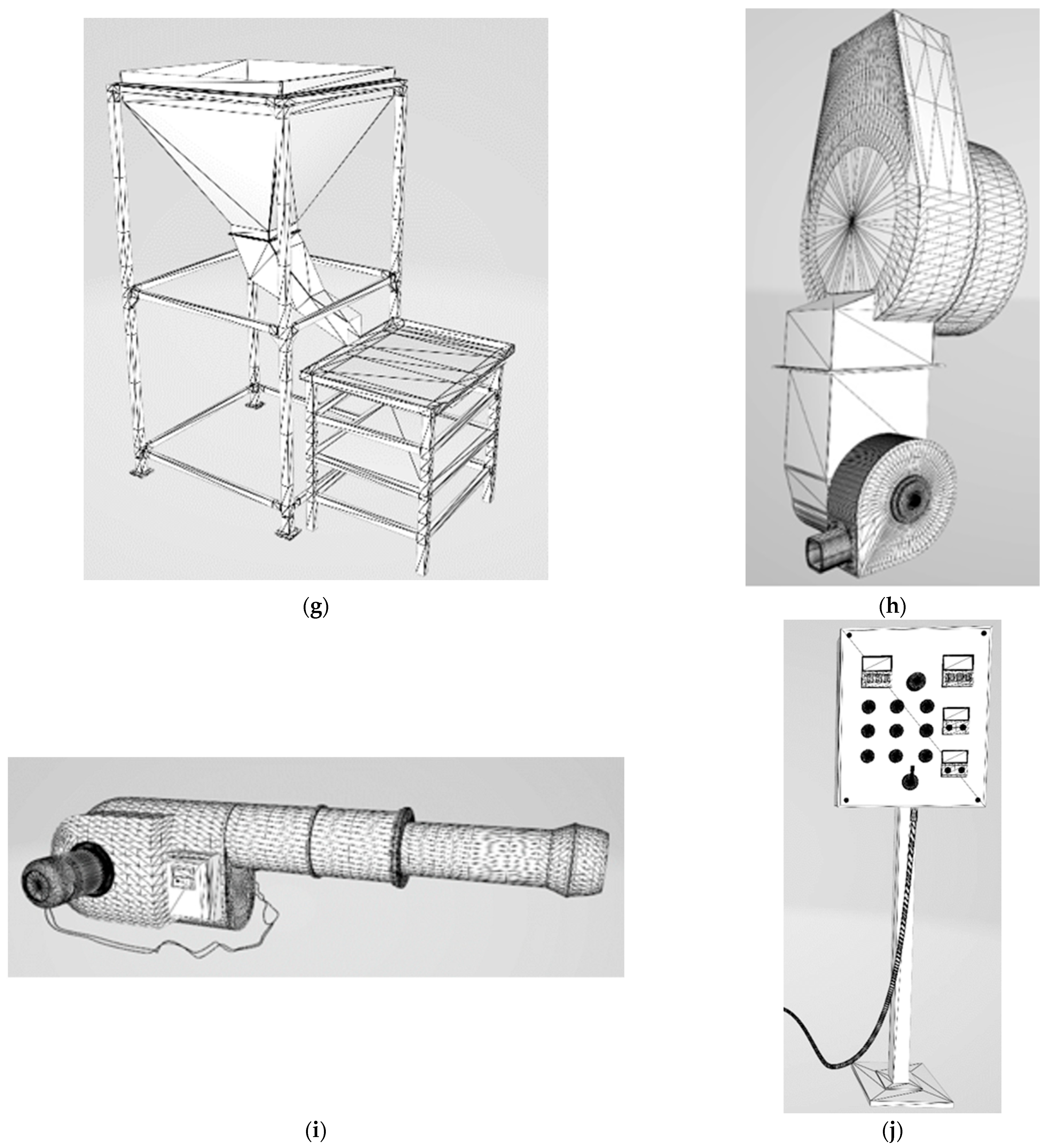

3.2. Case Study: Low-Rank Coal (LRC)

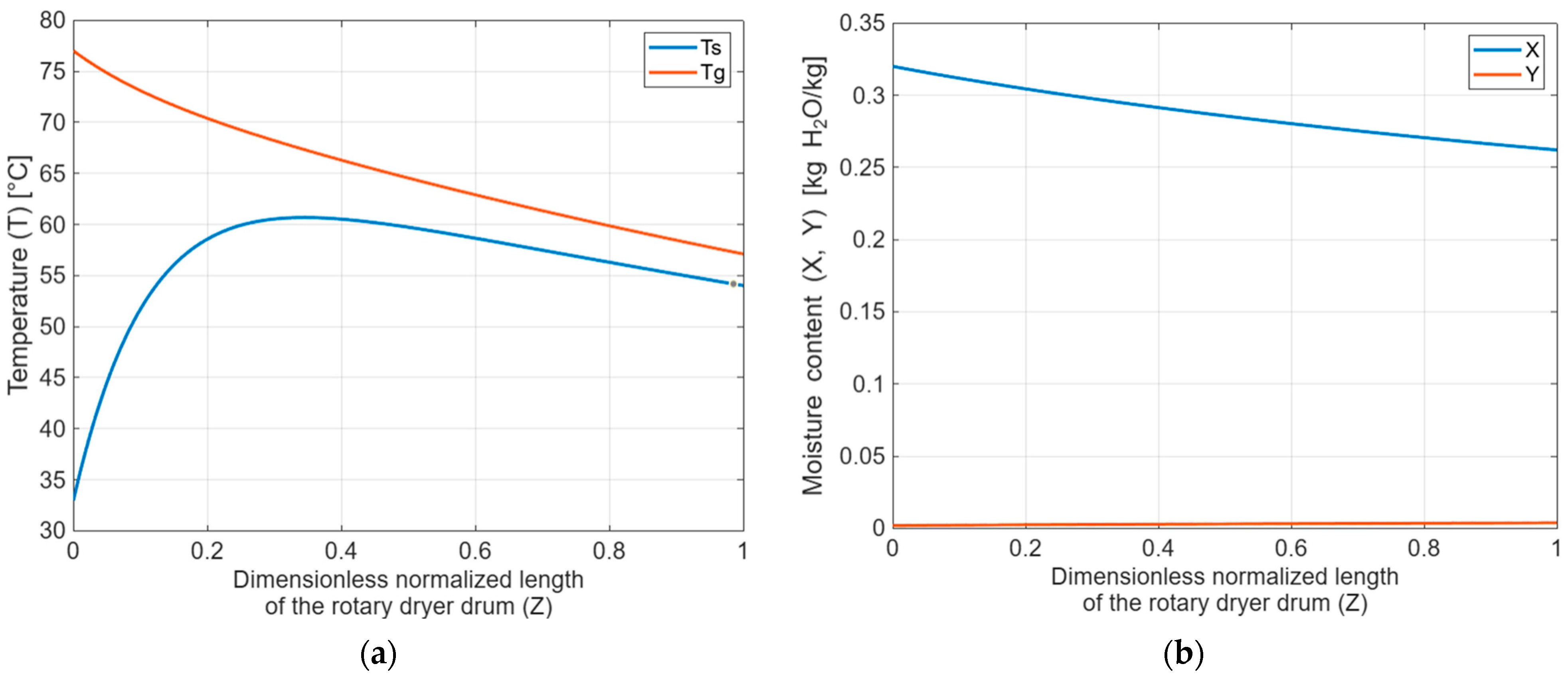

4. Results

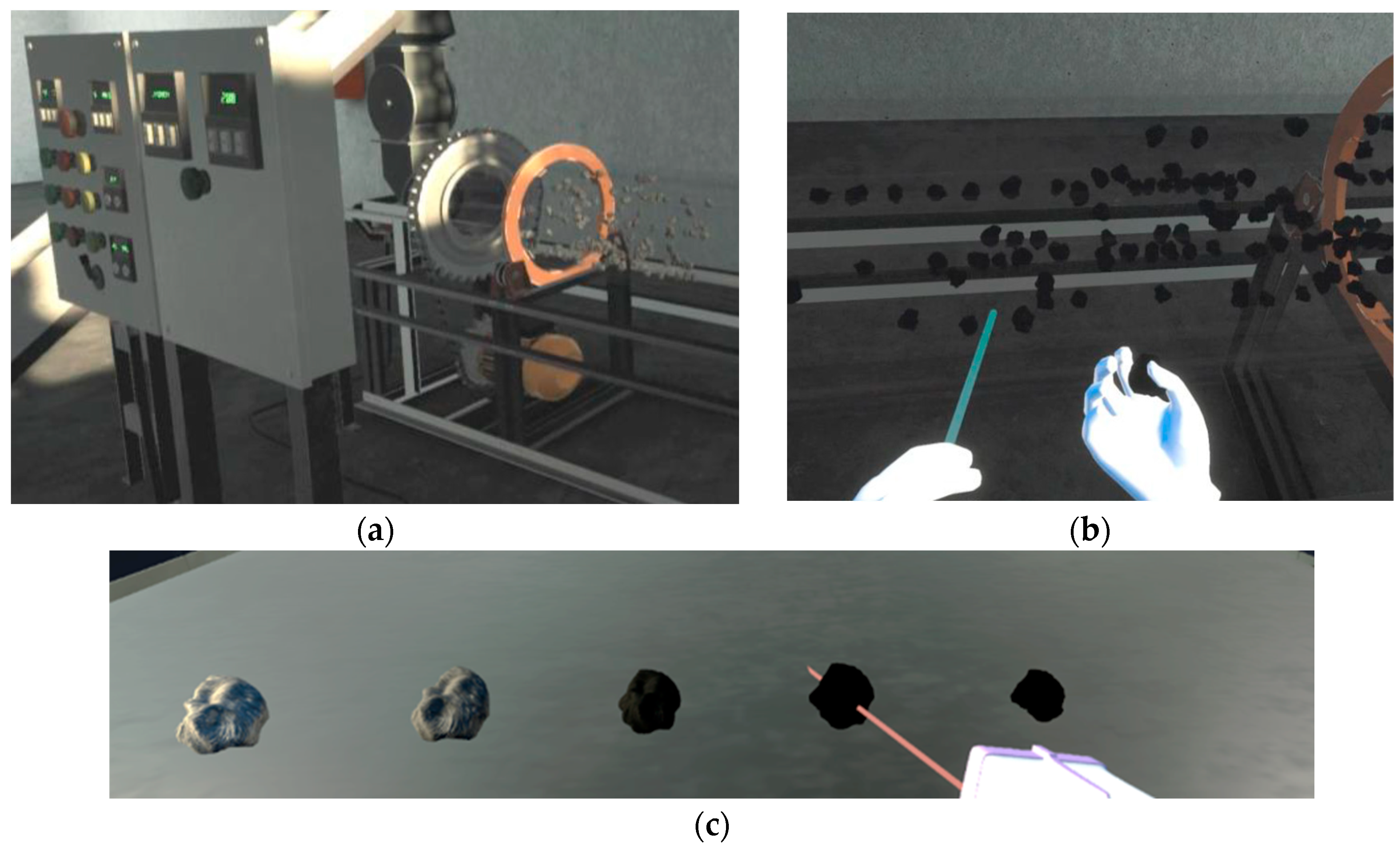

4.1. Results of Visual Aspects of the Proposed VR Environment

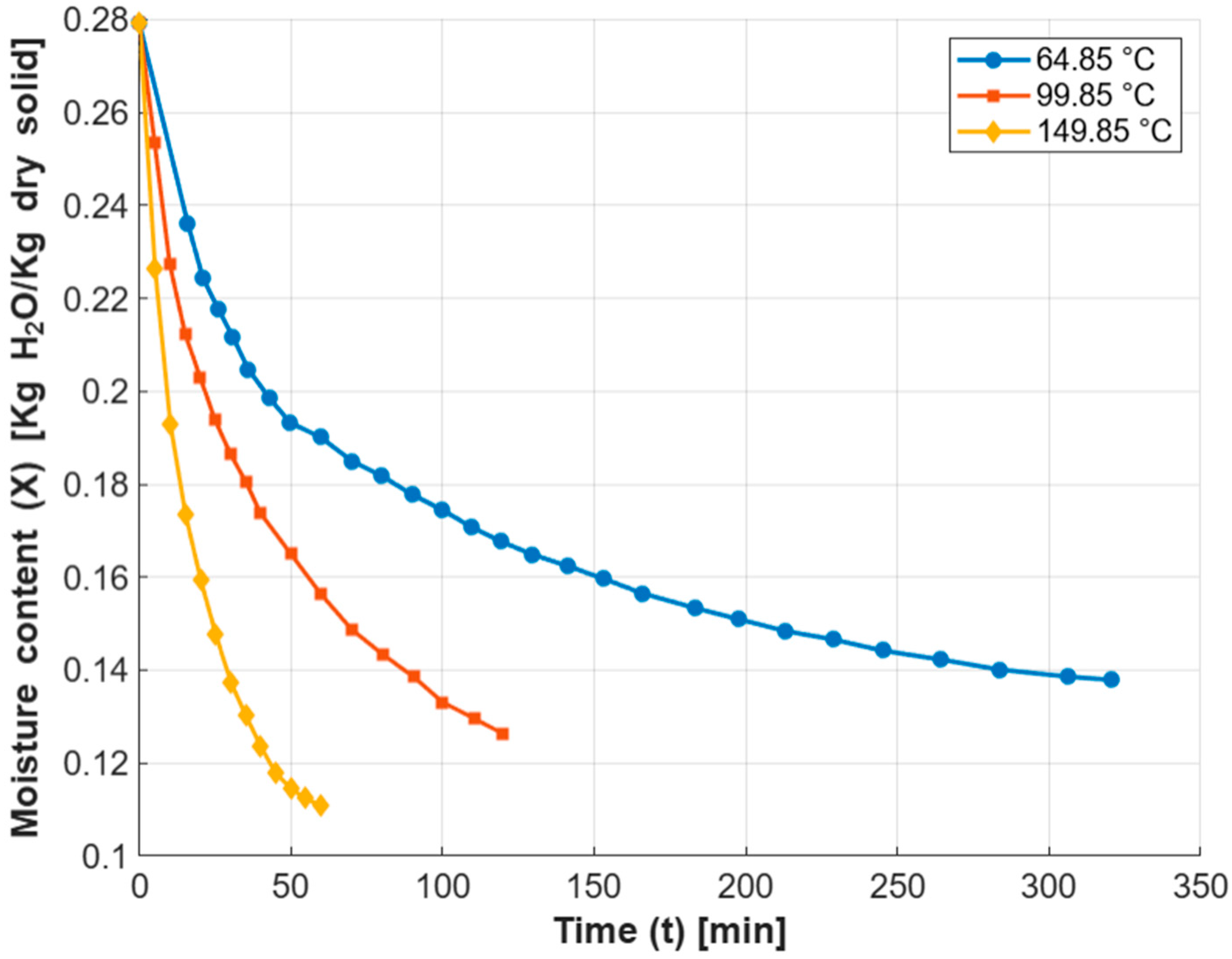

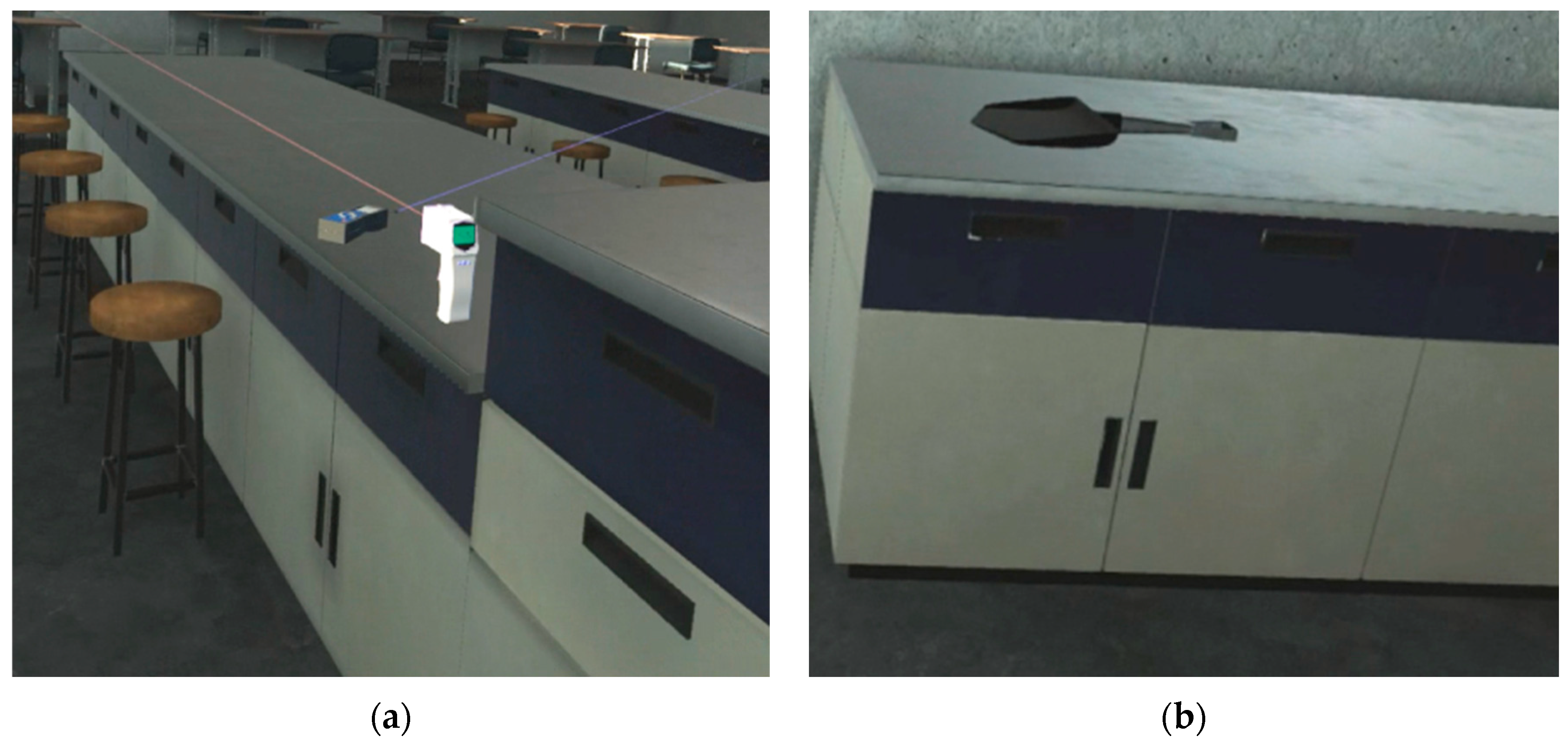

4.1.1. Description of VR Environment

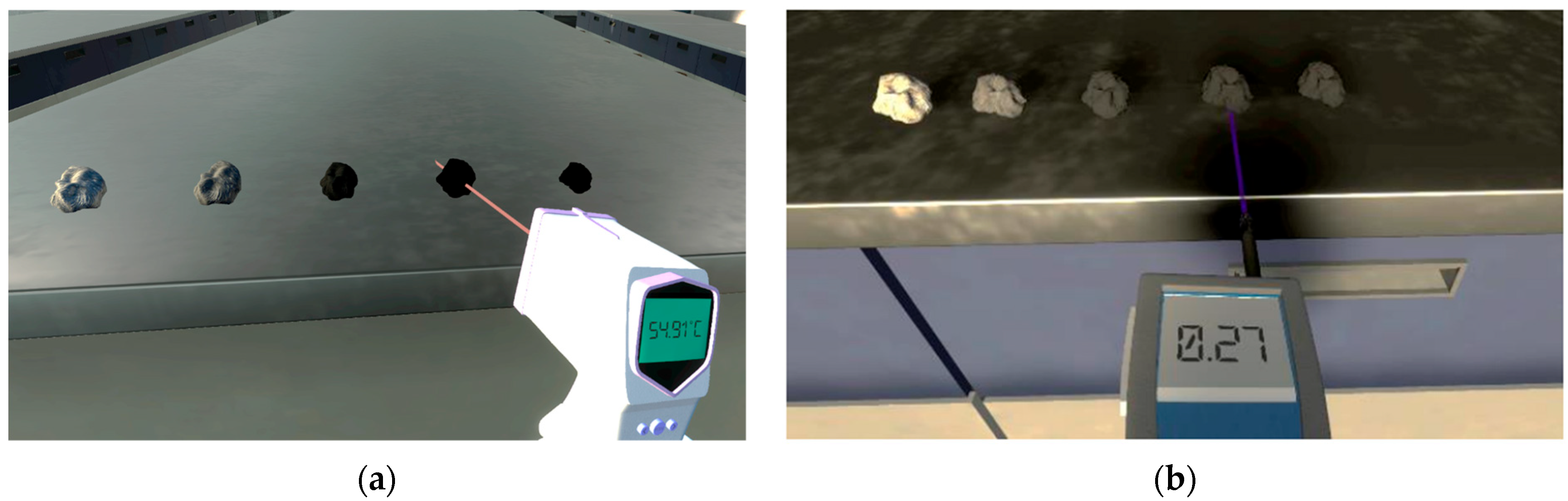

4.1.2. Interaction in the VR Environment

4.1.3. Expansion of the VR Environment

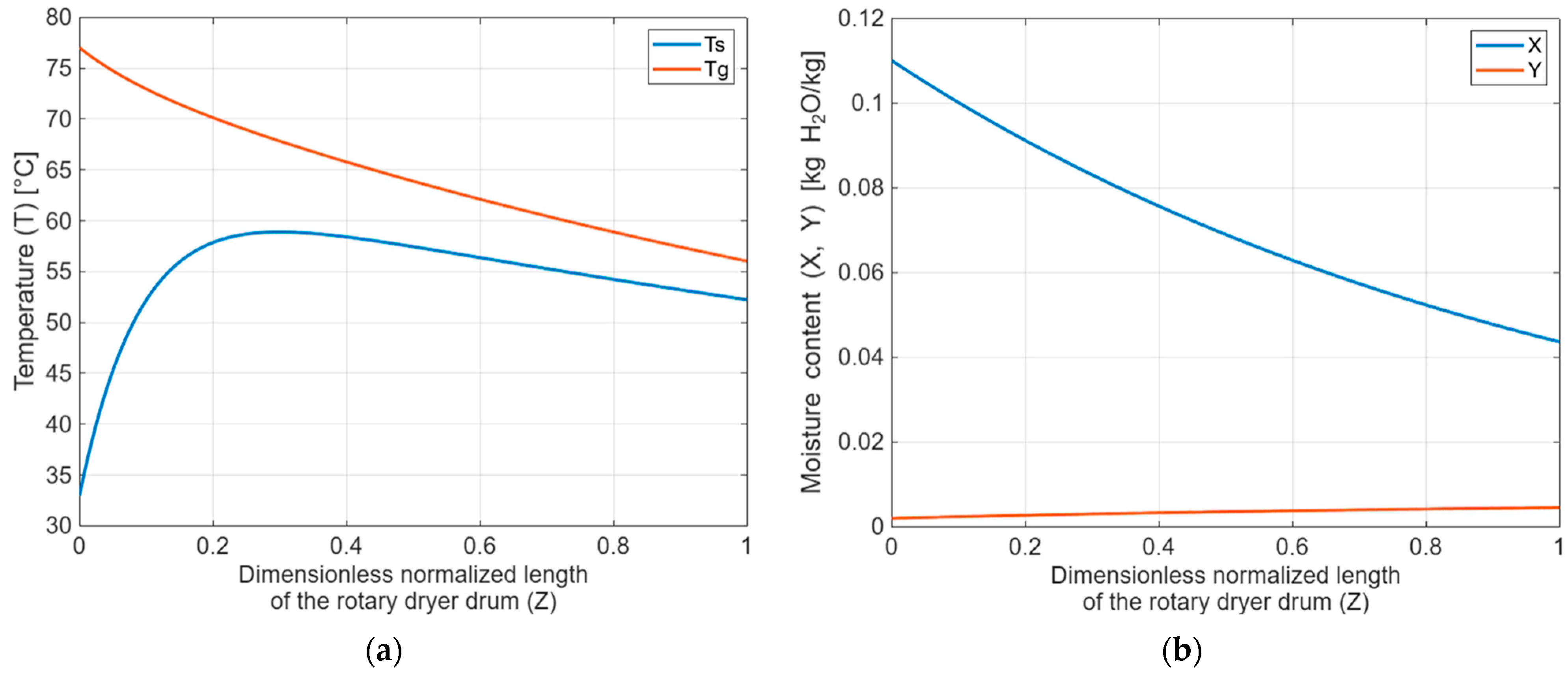

4.2. Results of Behavioral Aspects of the Proposed VR Environment

5. Discussion

5.1. On the Behavior of the State Variables

5.2. Enhancing the VR Environment

5.3. Comparison with Related Work

5.4. Workflow Diagram

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| VR | Virtual Reality |

| LRC | Low-Rank Coal |

| HMD | Head-Mounted Display |

References

- Malekjani, N.; Poureshmanan Talemy, F.; Zolqadri, R.; Jafari, S.M. Roller/drum dryers and rotary dryers. In Drying Technology in Food Processing; Jafari, S.M., Malekjani, N., Eds.; Woodhead Publishing: Cambridge, UK, 2023; pp. 47–66. [Google Scholar] [CrossRef]

- Rezaei, H.; Sokhansanj, S. A review on determining the residence time of solid particles in rotary drum dryers. Dry. Technol. 2021, 39, 1762–1772. [Google Scholar] [CrossRef]

- Gómez-de la Cruz, F.J.; Palomar-Torres, A.; Palomar-Carnicero, J.M.; Cruz-Peragón, F. Energy and exergy analysis during drying in rotary dryers from finite control volumes: Applications to the drying of olive stone. Appl. Therm. Eng. 2022, 200, 117699. [Google Scholar] [CrossRef]

- Deng, S.; Yu, Y.; Yao, L.; Liu, H.; Xu, J.; Huo, H.; Su, F.; Wen, Z. Energy efficiency analysis of a rotating-drum dryer using hot steel balls for converter sludge. Case Stud. Therm. Eng. 2023, 49, 103389. [Google Scholar] [CrossRef]

- Chun, Y.; Lim, M.; Yoshikawa, K. Development of a high-efficiency rotary dryer for sewage sludge. J. Mater. Cycles Waste Manag. 2012, 14, 239–246. [Google Scholar] [CrossRef]

- Hosseinabadi, H.Z.; Layeghi, M.; Berthold, D.; Doosthosseini, K.; Shahhosseini, S. Mathematical modeling the drying of poplar wood particles in a closed-loop triple pass rotary dryer. Dry. Technol. 2014, 32, 55–67. [Google Scholar] [CrossRef]

- Rojas Vargas, A.; Pérez García, L.; Sánchez Guillen, C.; AlJaberi, F.Y.; Salman, A.D.; Alardhi, S.M.; Le, P.-C. Performance evaluation of a flighted rotary dryer for lateritic ore in concurrent configuration. Heliyon 2023, 9, e21132. [Google Scholar] [CrossRef] [PubMed]

- A’yuni, D.; Subagio, A.; Prasetyaningrum, A.; Sasongko, S.; Djaeni, M. The optimization of paddy drying in the rotary dryer: Energy efficiency and product quality aspects analysis. Food Res. 2024, 8 (Suppl. S1), 125–135. [Google Scholar] [CrossRef]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Nowacka, M. Comparison of different drying techniques and their carbon emissions in green peas. Chem. Eng. Process. Process Intensif. 2021, 160, 108274. [Google Scholar] [CrossRef]

- Perazzini, H.; Perazzini, M.T.B.; Freire, F.B.; Freire, F.B.; Freire, J.T. Modeling and cost analysis of drying of citrus residues as biomass in rotary dryer for bioenergy. Renew. Energy 2021, 175, 167–178. [Google Scholar] [CrossRef]

- El-Qanni, A.; Alsayed, M.; Alsurakji, I.H.; Najjar, M.; Odeh, D.; Najjar, S.; Hmoudah, M.; Zubair, M.; Russo, V.; Di Serio, M. A technoeconomic assessment of biological sludge dewatering using a thermal rotary dryer: A case study of design applicability, economics, and managerial feasibility. Biomass Convers. Biorefin. 2024, 14, 13055–13069. [Google Scholar] [CrossRef]

- Markowski, A.S. Assessment of safety measures in drying systems. Dry. Technol. 2006, 24, 517–526. [Google Scholar] [CrossRef]

- Howard, M.C.; Gutworth, M.B.; Jacobs, R.R. A meta-analysis of virtual reality training programs. Comput. Hum. Behav. 2021, 121, 106808. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, J.; Hu, Y.; Li, X.; Wang, Z. The Impact of Virtual Reality on Practical Skills for Students in Science and Engineering Education: A Meta-Analysis. Int. J. STEM Educ. 2024, 11, 28. [Google Scholar] [CrossRef]

- Sung, H.; Kim, M.; Park, J.; Shin, N.; Han, Y. Effectiveness of Virtual Reality in Healthcare Education: Systematic Review and Meta-Analysis. Sustainability 2024, 16, 8520. [Google Scholar] [CrossRef]

- Wolfartsberger, J.; Zimmermann, R.; Obermeier, G.; Niedermayr, D. Analyzing the Potential of Virtual Reality-Supported Training for Industrial Assembly Tasks. Comput. Ind. 2022, 147, 103838. [Google Scholar] [CrossRef]

- Srinivasan, B.; Iqbal, M.U.; Shahab, M.A.; Srinivasan, R. Review of Virtual Reality (VR) Applications to Enhance Chemical Safety: From Students to Plant Operators. ACS Chem. Health Saf. 2022, 29, 246–262. [Google Scholar] [CrossRef]

- Arias, S.; Wahlqvist, J.; Nilsson, D.; Ronchi, E.; Frantzich, H. Pursuing behavioral realism in virtual reality for fire evacuation research. Fire Mater. 2021, 45, 462–472. [Google Scholar] [CrossRef]

- Hassan, M.; Montague, G.; Iqbal, M.Z.; Fahey, J. Virtual Reality-Based Bioreactor Digital Twin for Operator Training. Digit. Chem. Eng. 2024, 11, 100147. [Google Scholar] [CrossRef]

- Abbasfard, H.; Rafsanjani, H.H.; Ghader, S.; Ghanbari, M. Mathematical modeling and simulation of an industrial rotary dryer: A case study of ammonium nitrate plant. Powder Technol. 2013, 239, 499–505. [Google Scholar] [CrossRef]

- Arruda, E.B. Comparison of the Performance of the Roto-Fluidized Dryer and Conventional Rotary Dryer. Ph.D. Thesis, Federal University of Uberlândia, Uberlândia, Brazil, 2006. [Google Scholar]

- Watson, K.M. Thermodynamics of the liquid state—Generalized prediction of properties. Ind. Eng. Chem. 1943, 35, 398–406. [Google Scholar] [CrossRef]

- Gordon, S.; McBride, B.J. Computer Program for Calculation of Complex Chemical Equilibrium Compositions, Rocket Performance, Incident and Reflected Shocks, and Chapman-Jouguet Detonations. Interim Revision, March 1976; NASA Special Publication NASA. SP-273; U.S. Government Printing Office: Washington, DC, USA, 1976.

- Huang, J. A simple accurate formula for calculating saturation vapor. J. Appl. Meteorol. Climatol. 2018, 57, 1265–1272. [Google Scholar] [CrossRef]

- Rong, L.; Song, B.; Yin, W.; Bai, C.; Chu, M. Drying behaviors of low-rank coal under negative pressure: Kinetics and model. Dry. Technol. 2016, 35, 173–181. [Google Scholar] [CrossRef]

| Gas | (K−1) | (K−2) | (K−3) | (K−4) | |

|---|---|---|---|---|---|

| = Air | 3.653 | −1.337 | 3.294 | −1.913 | 0.2763 |

| = Water | 4.070 | −1.108 | 4.152 | −2.964 | 0.8070 |

| (°C) | ||

|---|---|---|

| 64.85 | 0.011827 | 0.135 |

| 99.85 | 0.024813 | 0.119 |

| 149.85 | 0.057254 | 0.105 |

| Boundary and Operational Conditions | Numerical Values or Equations |

|---|---|

| 33 °C | |

| 1 | 77 °C |

| 0.002 | |

| Velocity of wet air ) 1 | 3 m/s |

| Dry air mass flow rate (G) in kg/min | |

| ) | 5 Kg/s |

| ) in kg/min | |

| ) in kg of dry solid |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gutiérrez-Aguiñaga, R.A.; Rosales-Hernández, J.H.; Salinas-Santiago, R.; Escalante, F.M.E.; Aguilar-Garnica, E. Design of Enhanced Virtual Reality Training Environments for Industrial Rotary Dryers Using Mathematical Modeling. Multimodal Technol. Interact. 2025, 9, 102. https://doi.org/10.3390/mti9100102

Gutiérrez-Aguiñaga RA, Rosales-Hernández JH, Salinas-Santiago R, Escalante FME, Aguilar-Garnica E. Design of Enhanced Virtual Reality Training Environments for Industrial Rotary Dryers Using Mathematical Modeling. Multimodal Technologies and Interaction. 2025; 9(10):102. https://doi.org/10.3390/mti9100102

Chicago/Turabian StyleGutiérrez-Aguiñaga, Ricardo A., Jonathan H. Rosales-Hernández, Rogelio Salinas-Santiago, Froylán M. E. Escalante, and Efrén Aguilar-Garnica. 2025. "Design of Enhanced Virtual Reality Training Environments for Industrial Rotary Dryers Using Mathematical Modeling" Multimodal Technologies and Interaction 9, no. 10: 102. https://doi.org/10.3390/mti9100102

APA StyleGutiérrez-Aguiñaga, R. A., Rosales-Hernández, J. H., Salinas-Santiago, R., Escalante, F. M. E., & Aguilar-Garnica, E. (2025). Design of Enhanced Virtual Reality Training Environments for Industrial Rotary Dryers Using Mathematical Modeling. Multimodal Technologies and Interaction, 9(10), 102. https://doi.org/10.3390/mti9100102