Assessing Energy Consumption and Treatment Efficiency Correlation: The Case of the Metamorphosis Wastewater Treatment Plant in Attica, Greece

Abstract

1. Introduction

2. Materials and Methods

- Assess energy consumption patterns at the Metamorphosis WWTP by evaluating total energy use and its variations across different operational periods in 2022 and 2023.

- Examine treatment efficiency by analyzing the removal rates of key wastewater quality parameters—including BOD5, COD, and TSS—in relation to energy consumption.

- Compare annual performance trends to identify potential factors influencing changes in energy use and treatment outcomes between 2022 and 2023.

- Investigate the impact of influent characteristics on energy requirements and pollutant removal efficiency, taking into account seasonal and operational variations.

- Explore additional factors influencing energy demand, such as operational adjustments, climatic conditions, and variations in wastewater composition, to better understand the drivers of energy consumption in WWTPs.

- Identify opportunities for energy optimization by evaluating operational strategies and technologies that could enhance efficiency while maintaining compliance with environmental and regulatory standards.

Metamorphosis Wastewater and Septic Sewage Treatment Plant

- Influent and effluent analysis, which involves a comprehensive examination of variations in water quality parameters across different treatment stages.

- Removal efficiency calculations. This analysis quantifies the effectiveness of various treatment processes in diminishing pollutant concentrations.

- Energy consumption analysis, evaluating the energy requirements associated with the operation of the treatment plant.

- Statistical analysis. This involves applying statistical methods to identify and evaluate correlations and trends that influence both energy consumption and treatment efficiency.

- Graphical representation of key metrics, including the creation of visual aids to enhance clarity and understanding of the data.

- Comparison of annual trends, identifying variations in pollutant removal efficiency and energy consumption over the specified years.

- Evaluation of influencing factors, providing insights into the parameters that affect energy usage within the treatment facility.

3. Results and Discussion

3.1. Latest Developments in Energy-Efficient Technologies for Wastewater Treatment

| Technology | Description | Application/Example | Results | Reference |

|---|---|---|---|---|

| MABR | Utilizes hollow fiber membranes to transfer oxygen directly to biofilms, reducing the need for bubble aeration. | No specific examples of installations where MABR technology has been applied are mentioned. | 40% reduction in electricity consumption, 18% higher energy production. | [29,35] |

| Anaerobic Digestion & CHP | Organic carbon is diverted to anaerobic digestion, producing biogas, which is used in CHP systems. | Strass Plant, Strass im Zillertal, Austria. | Biogas production at 1.6 kJ g−1 COD removed; energy neutrality achieved. | [29,30,38,39] |

| Enhanced Primary Treatment (EPT) | Utilizes rotating belt sieves to remove organic matter, enhancing flexibility in nutrient removal processes. | Not widely implemented; potential in pilot projects. | Improves efficiency in organics removal and reduces sludge load. | [29,42,43] |

| Alternate Nitrogen Removal Pathways | Utilizes techniques such as nitrite shunt and anammox to reduce oxygen demand for nitrogen removal. | Applied mainly in pilot studies and side-stream treatments for nitrogen-rich wastewater; however, it is not yet widely implemented in full-scale municipal WWTPs. | Partial nitrification–anammox systems have demonstrated a 47% reduction in energy consumption for nitrogen removal, with nitrogen removal efficiencies reaching up to 90% in certain configurations. | [29,38] |

| MFCs | Microbial systems harness microbes to generate electricity directly from wastewater, offering an innovative approach to energy recovery. | Pilot-scale implementation (1000 L) has shown effectiveness, reaching a 7–60 W m−3 power density with significant COD removal. | Demonstrated power density of up to 7–60 W m−3 and up to 62.93 mW m−2 in hybrid MFC systems, with an 18% increase in performance. | [31,38,39,40] |

| Algae-based Technology | Utilizes microalgae for nutrient removal and bioenergy production, integrating wastewater treatment with carbon sequestration. | Pilot trials in photobioreactors and open pond systems. Example: 70% COD reduction in PBR using Chlorella species; other trials showed nutrient removal >90%. | Energy consumption reduced to 0.2 kWh m−3 (50% lower than traditional methods); high Energy Return on Investment (EROI) of 2.1–2.4, with significant nutrient uptake. | [36,37,38] |

| Biogas Energy Generation | Produces biogas from wastewater decomposition, providing energy autonomy for WWTPs. | Davyhulme plant, Manchester, UK. | Covers up to 96% of the plant’s energy needs. | [32] |

| Photovoltaic Energy Generation | Solar panels generate electricity to cover the energy demands of WWTPs. | Plant in eastern China with 800,000 tons/day capacity. | Generates 1.04 × 107 kWh, covering 84% of energy needs. | [32,41] |

| Water Source Heat Pump Technology | Extracts thermal energy from wastewater for heating and cooling purposes. | Stockholm WWTP, Stockholm, Sweden. | Produces 5.97 × 108 kWh annually, reducing energy consumption. | [32,41] |

| Green Infrastructure & Ecologically Advanced Treatment Technologies | Eco-friendly treatment methods, such as constructed wetlands, provide effective wastewater treatment while simultaneously enhancing biodiversity. | Various applications in Europe and North America. | Low cost and high efficiency, with additional environmental benefits. | [32,41] |

| Advanced Aeration Control | Utilizes sensors and automation to optimize aeration, the most energy-consuming process in WWTPs. | In use at WWTPs in Germany and Japan | Energy consumption for aeration reduced by 20–30%. | [42,44] |

| Energy Benchmarking and Monitoring | Compares energy use with benchmarks to identify inefficiencies and set energy efficiency goals. | Implemented in Canadian and Australian WWTPs. | Significant energy reductions achieved through targeted interventions. | [44] |

| Energy Recovery from Sewage Sludge | Converts sludge into syngas, bio-oil, or biochar using processes like pyrolysis and gasification. | Bekkelaget WWTP, Oslo, Norway. | Saved approximately 40,000–94,000 kWh annually. | [30,39] |

3.2. Reducing Energy Consumption in WWTPs, a Key Strategy for Lowering the Carbon Footprint

3.3. Impact of Stricter Environmental Regulations on Effluent Quality and Energy Consumption

3.4. The Cost of Energy Consumption in WWTPs and How It Can Impact the Pricing of Water Supply and Wastewater Services

3.5. National or European Policies Promoting Sustainable Wastewater Management

3.6. Assessment of Energy Consumption and Effluent Quality Performance

3.7. Analysis of Energy Consumption vs. Removal Efficiencies (2023)

3.7.1. Early 2023 (January–April 2023)

3.7.2. Mid 2023 (May–August 2023)

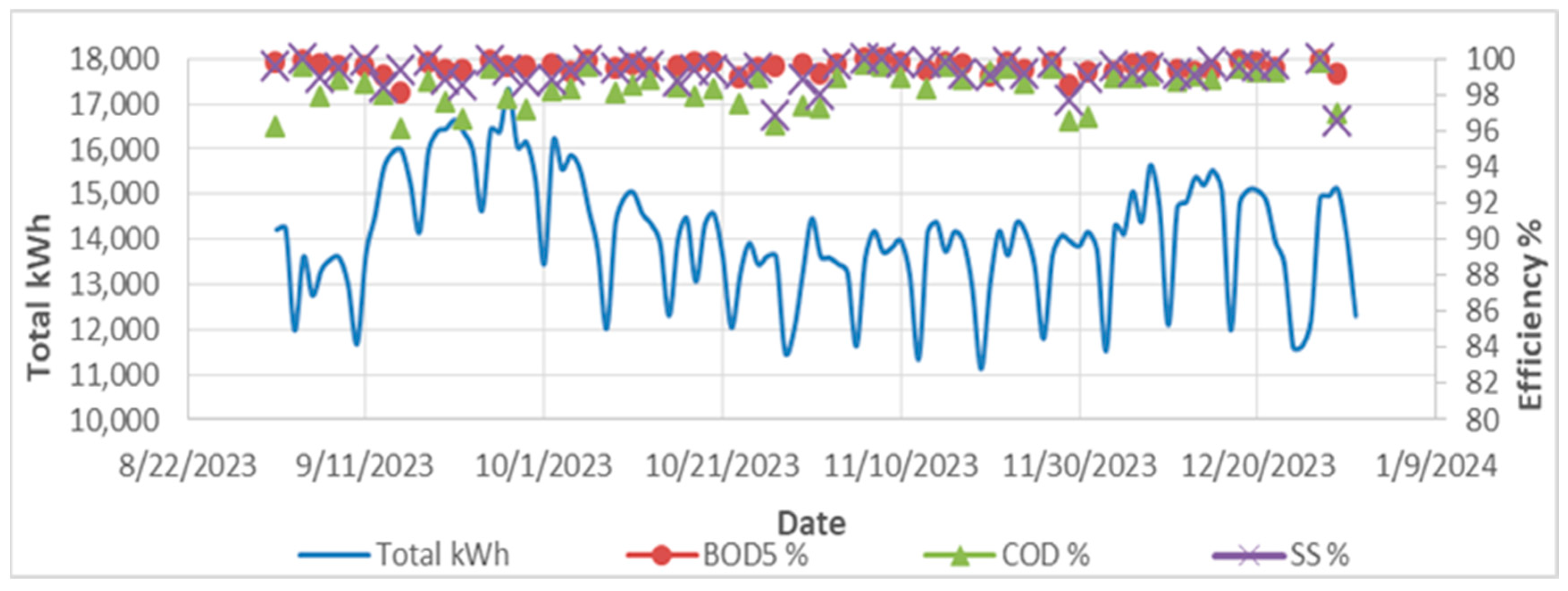

3.7.3. Late 2023 (September–December 2023)

3.7.4. Annual Overview

3.8. Analysis of Energy Consumption vs. Removal Efficiencies (2022)

3.8.1. Early 2022 (January–April 2022)

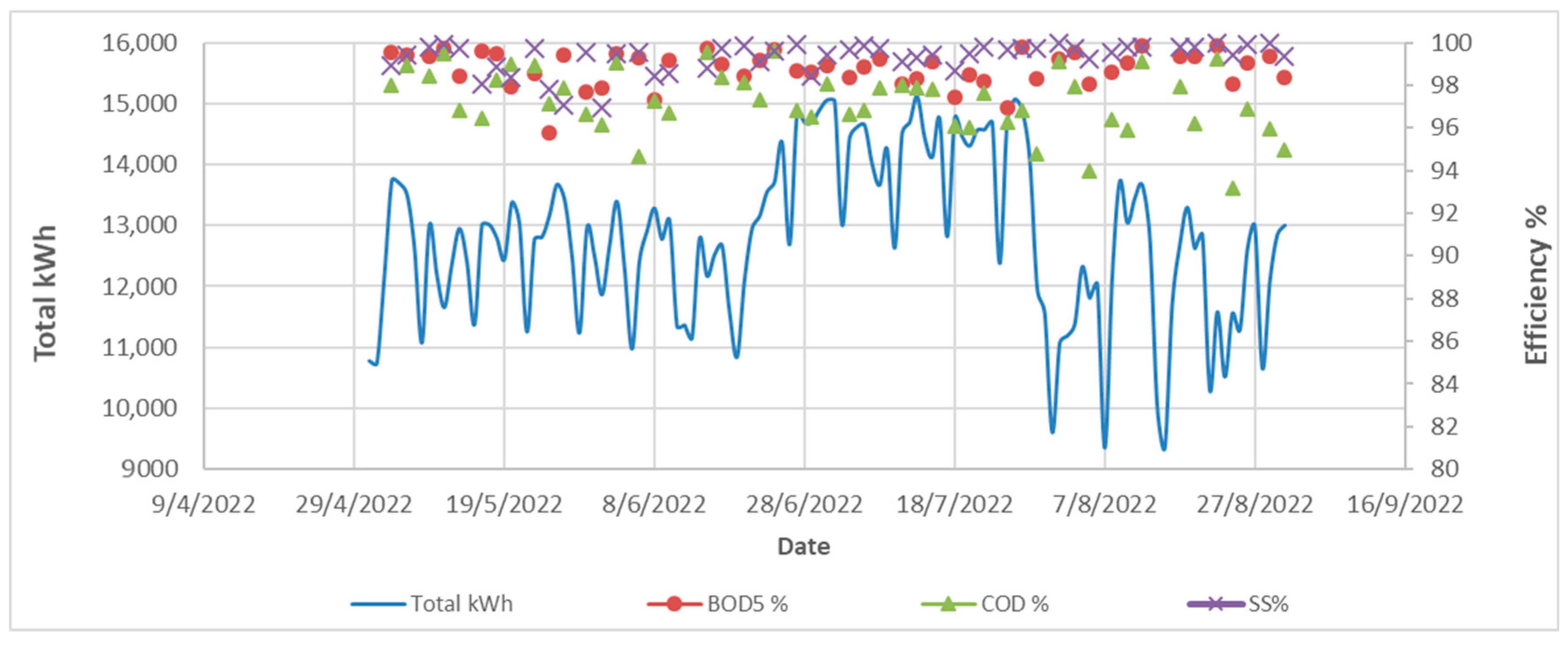

3.8.2. Mid 2022 (May–August 2022)

3.8.3. Late 2022 (September–December 2022)

3.8.4. Overall Assessment for 2022

3.8.5. Performance and Compliance: 2022 vs. 2023

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AOPS | Advanced Oxidation Processes |

| BOD5 | Biochemical Oxygen Demand |

| BNR | Biological Nutrient Removal |

| CH4 | Methane |

| CHP | Combined Heat and Power |

| COD | Chemical Oxygen Demand |

| CO2 | Carbon Dioxide |

| DS | Dry Solids |

| EC | Energy Consumption |

| EEC | European Economic Community |

| EPT | Enhanced Primary Treatment |

| EROI | Energy Return on Investment |

| GHG | Greenhouse Gas |

| kWh | kilowatt-hour |

| MABR | Membrane-Aerated Biofilm Reactors |

| MFCs | Microbial Fuel Cells |

| MWWTP | Metamorphosis Wastewater Treatment Plant |

| NH3 | Ammonia |

| NO2 | Nitrite Nitrogen |

| NO3 | Nitrate Nitrogen |

| N2O | Nitrous Oxide |

| PE | Population Equivalent |

| SCADA | Supervisory Control and Data Acquisition |

| SS | Suspended Solids |

| TN | Total Nitrogen |

| TP | Total Phosphorus |

| UK | United Kingdom |

| UV | Ultraviolet |

| WWTP(s) | Wastewater Treatment Plants |

References

- The Energy Sector Should Care About Wastewater—Analysis—IEA. Available online: https://www.iea.org/commentaries/the-energy-sector-should-care-about-wastewater (accessed on 16 February 2025).

- Daw, J.; Hallett, K.; DeWolfe, J.; Venner, I. Energy Efficiency Strategies for Municipal Wastewater Treatment Facilities; National Renewable Energy Laboratory: Golden, CO, USA, 2012. [CrossRef]

- World Bank Group Energy Efficiency Investments in Urban Water and Wastewater Utilities. Available online: https://www.worldbank.org/en/topic/water/publication/energy-efficiency-investments-in-urban-water-and-wastewater-utilities?utm (accessed on 14 May 2025).

- Independent Statistics and Analysis U.S. Energy Information Administration. What Is U.S. Electricity Generation by Energy Source? Available online: https://www.eia.gov/tools/faqs/faq.php?id=427&t=2&utm (accessed on 14 May 2025).

- IEA WEO-2016 Special Report: Water-Energy Nexus—Analysis—IEA. Available online: https://www.iea.org/reports/water-energy-nexus?utm (accessed on 14 May 2025).

- Gong, A.; Wang, G.; Qi, X.; He, Y.; Yang, X.; Huang, X.; Liang, P. Energy Recovery and Saving in Municipal Wastewater Treatment Engineering Practices. Nat. Sustain. 2025, 8, 112–119. [Google Scholar] [CrossRef]

- Wang, D.; Ye, W.; Wu, G.; Li, R.; Guan, Y.; Zhang, W.; Wang, J.; Shan, Y.; Hubacek, K. Greenhouse Gas Emissions from Municipal Wastewater Treatment Facilities in China from 2006 to 2019. Sci. Data 2022, 9, 317. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, S.; Guo, Z.; Wu, N.; Liang, J.; Zhao, R.; Hao, L.; Zeng, M. Insight into Greenhouse Gases Emissions and Energy Consumption of Different Full-Scale Wastewater Treatment Plants via ECAM Tool. Int. J. Environ. Res. Public Health 2022, 19, 13387. [Google Scholar] [CrossRef]

- Mamais, D.; Noutsopoulos, C.; Dimopoulou, A.; Stasinakis, A.; Lekkas, T.D. Wastewater Treatment Process Impact on Energy Savings and Greenhouse Gas Emissions. Water Sci. Technol. 2015, 71, 303–308. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Wang, Z.; Zhang, X.; Lu, H. Assessing Greenhouse Gas Emission Factors in Wastewater Treatment. Sustainability 2025, 17, 1488. [Google Scholar] [CrossRef]

- Chai, C.; Zhang, D.; Yu, Y.; Feng, Y.; Wong, M. Carbon Footprint Analyses of Mainstream Wastewater Treatment Technologies under Different Sludge Treatment Scenarios in China. Water 2015, 7, 918–938. [Google Scholar] [CrossRef]

- Wu, Z.; Duan, H.; Li, K.; Ye, L. A Comprehensive Carbon Footprint Analysis of Different Wastewater Treatment Plant Configurations. Environ. Res. 2022, 214, 113818. [Google Scholar] [CrossRef] [PubMed]

- Yao, H.; Gao, X.; Guo, J.; Wang, H.; Zhang, L.; Fan, L.; Jia, F.; Guo, J.; Peng, Y. Contribution of Nitrous Oxide to the Carbon Footprint of Full-Scale Wastewater Treatment Plants and Mitigation Strategies—A Critical Review. Environ. Pollut. 2022, 314, 120295. [Google Scholar] [CrossRef]

- The Paris Agreement|United Nations. Available online: https://www.un.org/en/climatechange/paris-agreement (accessed on 19 February 2025).

- Maktabifard, M.; Al-Hazmi, H.E.; Szulc, P.; Mousavizadegan, M.; Xu, X.; Zaborowska, E.; Li, X.; Mąkinia, J. Net-Zero Carbon Condition in Wastewater Treatment Plants: A Systematic Review of Mitigation Strategies and Challenges. Renew. Sustain. Energy Rev. 2023, 185, 113638. [Google Scholar] [CrossRef]

- Ramli, N.A.; Abdul Hamid, M.F. Analysis of Energy Efficiency and Energy Consumption Costs: A Case Study for Regional Wastewater Treatment Plant in Malaysia. J. Water Reuse Desalination 2017, 7, 103–110. [Google Scholar] [CrossRef]

- Sharawat, I.; Dahiya, R.; Dahiya, R.P. Analysis of a Wastewater Treatment Plant for Energy Consumption and Greenhouse Gas Emissions. Int. J. Environ. Sci. Technol. 2021, 18, 871–884. [Google Scholar] [CrossRef]

- Amiel, C.; Nawawi-Lansade, D.; Sorensen, K. An Optimal Solution to Achieve the Energy Neutral Waste Water Treatment Plant. Water Pract. Technol. 2011, 6, wpt20110068. [Google Scholar] [CrossRef]

- Gupta, A.S.; Khatiwada, D. Investigating the Sustainability of Biogas Recovery Systems in Wastewater Treatment Plants—A Circular Bioeconomy Approach. Renew. Sustain. Energy Rev. 2024, 199, 114447. [Google Scholar] [CrossRef]

- Twi-Yeboah, N.; Osei, D.; Dontoh, W.H.; Asamoah, G.A.; Baffoe, J.; Danquah, M.K. Enhancing Energy Efficiency and Resource Recovery in Wastewater Treatment Plants. Energies 2024, 17, 3060. [Google Scholar] [CrossRef]

- Ghimire, U.; Sarpong, G.; Gude, V.G. Transitioning Wastewater Treatment Plants toward Circular Economy and Energy Sustainability. ACS Omega 2021, 6, 11794–11803. [Google Scholar] [CrossRef]

- Tsalas, N.; Golfinopoulos, S.K.; Samios, S.; Katsouras, G.; Peroulis, K. Optimization of Energy Consumption in a Wastewater Treatment Plant: An Overview. Energies 2024, 17, 2808. [Google Scholar] [CrossRef]

- Skoczko, I. Energy Efficiency Analysis of Water Treatment Plants: Current Status and Future Trends. Energies 2025, 18, 1086. [Google Scholar] [CrossRef]

- SEDAC; Illinois Sustainable Technology Center; Illinois Environmental Protection Agency; US Department of Energy. The Path to Resilience: Maximizing Energy Savings at Wastewater Treatment Plants. 2024. Available online: https://smartenergy.illinois.edu/wp-content/uploads/2024/06/WWTPResiliencePublication_Final2.pdf (accessed on 14 May 2025).

- General Secretariat of Waste Management Coordination Wastewater Treatment Plants Monitoring Database. Available online: https://astikalimata.ypeka.gr/wtp (accessed on 22 February 2025).

- Flowchart Maker & Online Diagram Software. Available online: https://app.diagrams.net/ (accessed on 1 March 2025).

- EYDAP, S.A. Metamorfosi Wastewater Treatment Plant. p. 2. Available online: https://www.eydap.gr/userfiles/c3c4382d-a658-4d79-b9e2-ecff7ddd9b76/Fact-sheet-MWWTP.PDF (accessed on 22 February 2025).

- Google Earth. Available online: https://www.google.com/intl/el/earth/index.html (accessed on 1 March 2025).

- Peeters, J.; Vicevic, G.; Koops, G.H.; Côté, P. The Role of Innovative Technologies in Achieving Energy-Neutral Wastewater Treatment. Water Pract. Technol. 2016, 11, 691–701. [Google Scholar] [CrossRef]

- Silva Thomsen, L.B.; Carvalho, P.N.; Dos Passos, J.S.; Anastasakis, K.; Bester, K.; Biller, P. Hydrothermal Liquefaction of Sewage Sludge; Energy Considerations and Fate of Micropollutants during Pilot Scale Processing. Water Res. 2020, 183, 116101. [Google Scholar] [CrossRef]

- Esfandyari, M.; Jafari, D.; Azami, H. Microbial Fuel Cells for Energy Production in Wastewater Treatment Plants—A Review. Biofuels 2024, 15, 743–753. [Google Scholar] [CrossRef]

- Guo, Z.; Sun, Y.; Pan, S.-Y.; Chiang, P.-C. Integration of Green Energy and Advanced Energy-Efficient Technologies for Municipal Wastewater Treatment Plants. Int. J. Environ. Res. Public Health 2019, 16, 1282. [Google Scholar] [CrossRef] [PubMed]

- Directive—91/271—EN—EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:31991L0271 (accessed on 16 February 2025).

- European Commission Circular Economy Action Plan—European Commission. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 1 March 2025).

- Tian, H.; Zhang, J.; Zheng, Y.; Zheng, G.; Li, Y.; Yan, Y.; Li, Z.; Hui, M. Evaluating the Performance of an Integrated Membrane-Aerated Biofilm Reactor (MABR) System for High-Strength Brewery Wastewater Treatment. Environ. Sci. Water Res. Technol. 2023, 9, 2053–2064. [Google Scholar] [CrossRef]

- Arashiro, L.T.; Ferrer, I.; Rousseau, D.P.L.; Van Hulle, S.W.H.; Garfí, M. The Effect of Primary Treatment of Wastewater in High Rate Algal Pond Systems: Biomass and Bioenergy Recovery. Bioresour. Technol. 2019, 280, 27–36. [Google Scholar] [CrossRef] [PubMed]

- Arashiro, L.T.; Montero, N.; Ferrer, I.; Acién, F.G.; Gómez, C.; Garfí, M. Life Cycle Assessment of High Rate Algal Ponds for Wastewater Treatment and Resource Recovery. Sci. Total Environ. 2018, 622–623, 1118–1130. [Google Scholar] [CrossRef] [PubMed]

- Daverey, A.; Pandey, D.; Verma, P.; Verma, S.; Shah, V.; Dutta, K.; Arunachalam, K. Recent Advances in Energy Efficient Biological Treatment of Municipal Wastewater. Bioresour. Technol. Rep. 2019, 7, 100252. [Google Scholar] [CrossRef]

- Stamatelatou, K.; Tsagarakis, K.P. Sewage Treatment Plants: Economic Evaluation of Innovative Technologies for Energy Efficiency; IWA Publishing: London, UK, 2015; ISBN 978-1-78040-502-5. [Google Scholar]

- Aghababaie, M.; Farhadian, M.; Jeihanipour, A.; Biria, D. Effective Factors on the Performance of Microbial Fuel Cells in Wastewater Treatment—A Review. Environ. Technol. Rev. 2015, 4, 71–89. [Google Scholar] [CrossRef]

- Lima, D.; Li, L.; Appleby, G. A Review of Renewable Energy Technologies in Municipal Wastewater Treatment Plants (WWTPs). Energies 2024, 17, 6084. [Google Scholar] [CrossRef]

- Jallouli, S.; Wali, A.; Buonerba, A.; Zarra, T.; Belgiorno, V.; Naddeo, V.; Ksibi, M. Efficient and Sustainable Treatment of Tannery Wastewater by a Sequential Electrocoagulation-UV Photolytic Process. J. Water Process Eng. 2020, 38, 101642. [Google Scholar] [CrossRef]

- Bezirgiannidis, A. Development of Emerging Technologies for a Low Carbon Footprint Wasewater Treatment; Democritus University of Thace: Dragana Alexandroupolis, Greece, 2021; Available online: http://hdl.handle.net/10442/hedi/50134 (accessed on 15 March 2025).

- Clos, I.; Krampe, J.; Alvarez-Gaitan, J.P.; Saint, C.P.; Short, M.D. Energy Benchmarking as a Tool for Energy-Efficient Wastewater Treatment: Reviewing International Applications. Water Conserv. Sci. Eng. 2020, 5, 115–136. [Google Scholar] [CrossRef]

- Ochuko, M. Ojo A Review of Selected Energy-Efficient Technologies for Wastewater Treatment. J. Energy Technol. Environ. 2024, 6, 188–197. [Google Scholar] [CrossRef]

- Shamshad, J.; Ur Rehman, R. Innovative Approaches to Sustainable Wastewater Treatment: A Comprehensive Exploration of Conventional and Emerging Technologies. Environ. Sci. Adv. 2025, 4, 189–222. [Google Scholar] [CrossRef]

- PORVOO 7 Energy-Efficient Wastewater Treatment Methods—PORVOO Clean-Tech. Available online: https://porvoo.com.cn/blog/7-energy-efficient-wastewater-treatment-methods/ (accessed on 21 May 2025).

- Tabibi, A. Energy-Efficient Wastewater Treatment Systems. Available online: https://green.org/2024/01/30/energy-efficient-wastewater-treatment-systems/ (accessed on 21 May 2025).

- Ghoneim, W.A.M.; Helal, A.A.; Abdel Wahab, M.G. Minimizing Energy Consumption in Wastewater Treatment Plants. In Proceedings of the 2016 3rd International Conference on Renewable Energies for Developing Countries (REDEC), Zouk Mosbeh, Lebanon, 13–15 July 2016; IEEE: Zouk Mosbeh, Lebanon, 2016; pp. 1–8. [Google Scholar]

- Goliopoulos, N.; Mamais, D.; Noutsopoulos, C.; Dimopoulou, A.; Kounadis, C. Energy Consumption and Carbon Footprint of Greek Wastewater Treatment Plants. Water 2022, 14, 320. [Google Scholar] [CrossRef]

- Płuciennik-Koropczuk, E.; Myszograj, S.; Mąkowski, M. Reducing CO2 Emissions from Wastewater Treatment Plants by Utilising Renewable Energy Sources—Case Study. Energies 2022, 15, 8446. [Google Scholar] [CrossRef]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving Energy Neutrality in Wastewater Treatment Plants through Energy Savings and Enhancing Renewable Energy Production. Rev. Env. Sci. Biotechnol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Bailey, J.R.; Ahmad, S.; Batista, J.R. The Impact of Advanced Treatment Technologies on the Energy Use in Satellite Water Reuse Plants. Water 2020, 12, 366. [Google Scholar] [CrossRef]

- Rodziewicz, J.; Mielcarek, A.; Bryszewski, K.; Janczukowicz, W.; Kłobukowska, K. Energy Consumption for Nutrient Removal from High-Nitrate and High-Phosphorus Wastewater in Aerobic and Anaerobic Bioelectrochemical Reactors. Energies 2022, 15, 7251. [Google Scholar] [CrossRef]

- Rizzo, L.; Fiorentino, A.; Anselmo, A. Advanced Treatment of Urban Wastewater by UV Radiation: Effect on Antibiotics and Antibiotic-Resistant E. Coli Strains. Chemosphere 2013, 92, 171–176. [Google Scholar] [CrossRef]

- González, Y.; Gómez, G.; Moeller-Chávez, G.E.; Vidal, G. UV Disinfection Systems for Wastewater Treatment: Emphasis on Reactivation of Microorganisms. Sustainability 2023, 15, 11262. [Google Scholar] [CrossRef]

- Zăbavă, B.-Ș.; Voicu, G.; Ungureanu, N.; Dincă, M.; Vladut, V. UV Disinfection—A Method of Purifying Wastewater from Farms—A Review. In Proceedings of the 14th Annual Meeting “Durable Agriculture–Agriculture of the Future”, Craiova, Romania, 27–29 September 2018. [Google Scholar]

- Collivignarelli, M.C.; Abbà, A.; Miino, M.C.; Caccamo, F.M.; Torretta, V.; Rada, E.C.; Sorlini, S. Disinfection of Wastewater by UV-Based Treatment for Reuse in a Circular Economy Perspective. Where Are We At? Int. J. Environ. Res. Public Health 2020, 18, 77. [Google Scholar] [CrossRef]

- Miklos, D.B.; Remy, C.; Jekel, M.; Linden, K.G.; Drewes, J.E.; Hübner, U. Evaluation of Advanced Oxidation Processes for Water and Wastewater Treatment—A Critical Review. Water Res. 2018, 139, 118–131. [Google Scholar] [CrossRef]

- Cardoso, B.J.; Rodrigues, E.; Gaspar, A.R.; Gomes, Á. Energy Performance Factors in Wastewater Treatment Plants: A Review. J. Clean. Prod. 2021, 322, 129107. [Google Scholar] [CrossRef]

- Li, Z.; Zou, Z.; Wang, L. Analysis and Forecasting of the Energy Consumption in Wastewater Treatment Plant. Math. Probl. Eng. 2019, 2019, 8690898. [Google Scholar] [CrossRef]

- Bodík, I.; Kubaská, M. Energy and Sustainability of Operation of a Wastewater Treatment Plant. Environ. Protect. Eng. 2013, 39, 15–24. [Google Scholar] [CrossRef]

- Gandiglio, M.; Lanzini, A.; Soto, A.; Leone, P.; Santarelli, M. Enhancing the Energy Efficiency of Wastewater Treatment Plants through Co-Digestion and Fuel Cell Systems. Front. Environ. Sci. 2017, 5, 70. [Google Scholar] [CrossRef]

- Hamawand, I. Energy Consumption in Water/Wastewater Treatment Industry—Optimisation Potentials. Energies 2023, 16, 2433. [Google Scholar] [CrossRef]

- Pakenas, L.J. Energy Efficiency in Municipal Wastewater Treatment Plants; New York State Energy Research and Development Authority (NYSERDA): Albany, NY, USA, 1995.

- WAREG—European Water Regulators. Impacts of the Energy Crisis on the Price of Water Services; WAREG—European Water Regulators: Milan, Italy, 2023; Available online: https://www.wareg.org/documents/energy-report-wareg/ (accessed on 16 February 2025).

- Chapin, F.T.; Bolorinos, J.; Mauter, M.S. Electricity and Natural Gas Tariffs at United States Wastewater Treatment Plants. Sci. Data 2024, 11, 113. [Google Scholar] [CrossRef]

- Trapote, A.; Albaladejo, A.; Simón, P. Energy Consumption in an Urban Wastewater Treatment Plant: The Case of Murcia Region (Spain). Civ. Eng. Environ. Syst. 2014, 31, 304–310. [Google Scholar] [CrossRef]

- Santos, E.; Albuquerque, A.; Lisboa, I.; Murray, P.; Ermis, H. Economic Assessment of Energy Consumption in Wastewater Treatment Plants: Applicability of Alternative Nature-Based Technologies in Portugal. Water 2022, 14, 2042. [Google Scholar] [CrossRef]

- Regulation—2020/741—EN—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/reg/2020/741/oj/eng (accessed on 16 February 2025).

- Legislation—Ministry of Environment and Energy. Available online: https://ypen.gov.gr/diacheirisi-apovliton/astika-lymata/nomothesia/ (accessed on 16 February 2025).

- Directive—2000/60—EN—Water Framework Directive—EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32000L0060 (accessed on 16 February 2025).

- Siatou, A.; Manali, A.; Gikas, P. Energy Consumption and Internal Distribution in Activated Sludge Wastewater Treatment Plants of Greece. Water 2020, 12, 1204. [Google Scholar] [CrossRef]

- Zou, L.; Li, H.; Wang, S.; Zheng, K.; Wang, Y.; Du, G.; Li, J. Characteristic and Correlation Analysis of Influent and Energy Consumption of Wastewater Treatment Plants in Taihu Basin. Front. Environ. Sci. Eng. 2019, 13, 83. [Google Scholar] [CrossRef]

| Parameter | Concentration (mg L−1) | Minimum Removal Efficiency (%) * |

|---|---|---|

| BOD5 | ≤25 | 70–90 |

| COD | ≤125 | 75 |

| SS | ≤35 >10,000 PE ≤60 2000–10,000 PE | 90 70 |

| Sensitive areas (The above limits apply, along with the following additional requirements) | ||

| Total Phosphorus (TP) | ≤2 10,000–100,000 PE ≤1 >100,000 PE | 80 |

| Total Nitrogen (TN) ** | ≤15 10,000–100,000 PE ≤10 >100,000 PE | 70–80 |

| Inlet (mg L−1) | Outlet (mg L−1) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TN | TP | BOD5 | COD | TSS | TN | TP | BOD5 | COD | TSS | EC (kWh) | |

| Average | 106.0 | 17.0 | 1122.3 | 2594.4 | 1421.2 | 16.7 | 2.6 | 4.7 | 25.2 | 3.5 | 13,126.1 |

| Standard deviation | 22.0 | 5.4 | 770.8 | 2012.1 | 1985.6 | 6.6 | 1.5 | 2.8 | 4.4 | 2.1 | 1396.6 |

| Inlet | Outlet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| TN | TP | BOD5 | COD | TSS | TN | TP | BOD5 | COD | TSS |

| 149 | 149 | 149 | 149 | 149 | 148 | 148 | 251 | 251 | 251 |

| Inlet (mg L−1) | Outlet (mg L−1) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TN | TP | BOD5 | COD | TSS | TN | TP | BOD5 | COD | TSS | EC (kWh) | |

| Average | 107.1 | 14.2 | 992.8 | 1925.4 | 1280.8 | 20.2 | 2.4 | 6.1 | 23.8 | 2.4 | 13,044.9 |

| Standard deviation | 20.7 | 4.9 | 649.6 | 1252.6 | 1610.4 | 8.6 | 1.9 | 3.1 | 7.7 | 1.7 | 1217.2 |

| Inlet | Outlet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| TN | TP | BOD5 | COD | TSS | TN | TP | BOD5 | COD | TSS |

| 145 | 145 | 145 | 145 | 145 | 144 | 148 | 246 | 246 | 246 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsalas, N.; Golfinopoulos, S.K.; Samios, S. Assessing Energy Consumption and Treatment Efficiency Correlation: The Case of the Metamorphosis Wastewater Treatment Plant in Attica, Greece. Urban Sci. 2025, 9, 201. https://doi.org/10.3390/urbansci9060201

Tsalas N, Golfinopoulos SK, Samios S. Assessing Energy Consumption and Treatment Efficiency Correlation: The Case of the Metamorphosis Wastewater Treatment Plant in Attica, Greece. Urban Science. 2025; 9(6):201. https://doi.org/10.3390/urbansci9060201

Chicago/Turabian StyleTsalas, Nikolaos, Spyridon K. Golfinopoulos, and Stylianos Samios. 2025. "Assessing Energy Consumption and Treatment Efficiency Correlation: The Case of the Metamorphosis Wastewater Treatment Plant in Attica, Greece" Urban Science 9, no. 6: 201. https://doi.org/10.3390/urbansci9060201

APA StyleTsalas, N., Golfinopoulos, S. K., & Samios, S. (2025). Assessing Energy Consumption and Treatment Efficiency Correlation: The Case of the Metamorphosis Wastewater Treatment Plant in Attica, Greece. Urban Science, 9(6), 201. https://doi.org/10.3390/urbansci9060201