A Life Cycle Assessment of HDPE Plastic Milk Bottle Waste Within Concrete Composites and Their Potential in Residential Building and Construction Applications

Abstract

1. Introduction

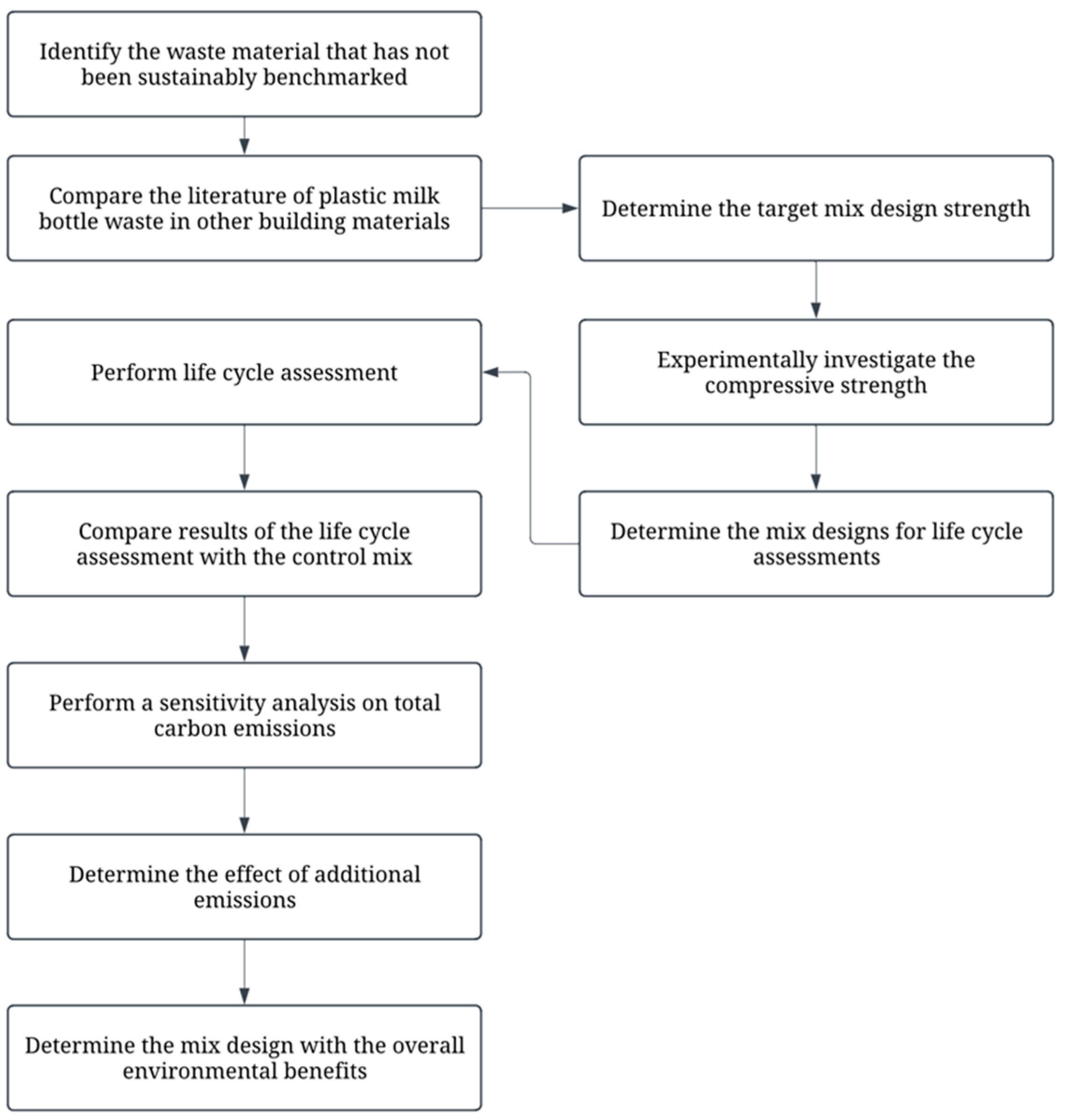

2. Research Methodology

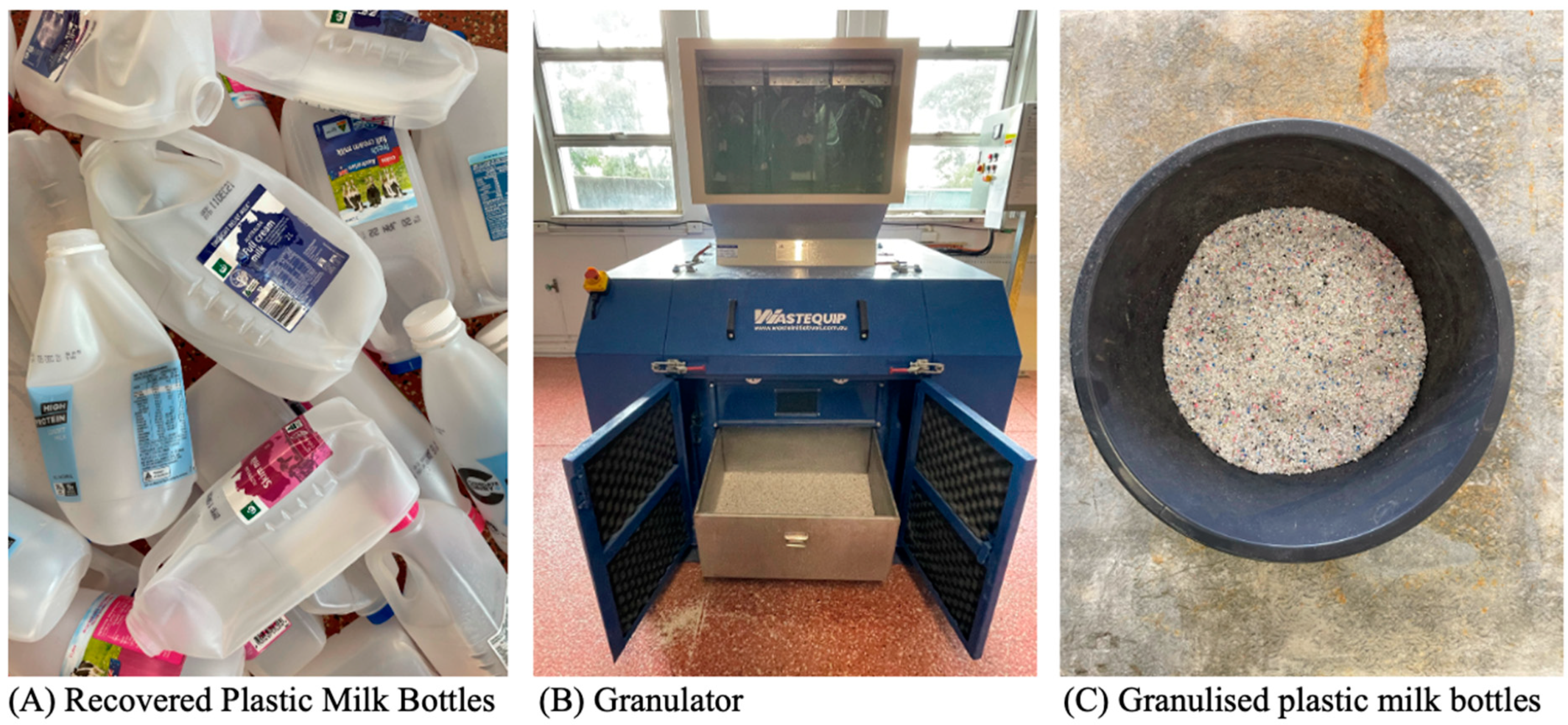

2.1. Materials and Mechanical Testing

2.2. Life Cycle Assessment

2.2.1. Scope, Functional Unit, and System Boundary

2.2.2. Life Cycle Inventory Analysis

2.2.3. Life Cycle Impact Assessment

2.2.4. Limitations and Assumptions

- It was assumed that the lifespan of the custom mix designs is the same as that of the control mix.

- This study did not account for end-of-life behaviours, assuming that all mix designs would have similar end-of-life considerations.

- The supply of processed waste plastic milk bottles was assumed to be locally available in sufficient quantities.

- In cases where emission inventories were unavailable, emission factors from published literature were used.

- The conversion of waste plastic milk bottles into granule material was assumed to occur at the waste recovery centre.

- An equal transportation distance of 21 km was assumed for delivering fine, coarse, and cement materials to the concrete batching plant.

- The mortar mixer was assumed to consume 4 kWh to produce 1 cubic meter of concrete.

- Conventional potable water treatment was assumed, with the corresponding emission inventories adopted from existing databases.

2.3. Sensitivity Analysis

- The minimum value;

- The maximum value;

- The most likely value.

3. Results and Discussion

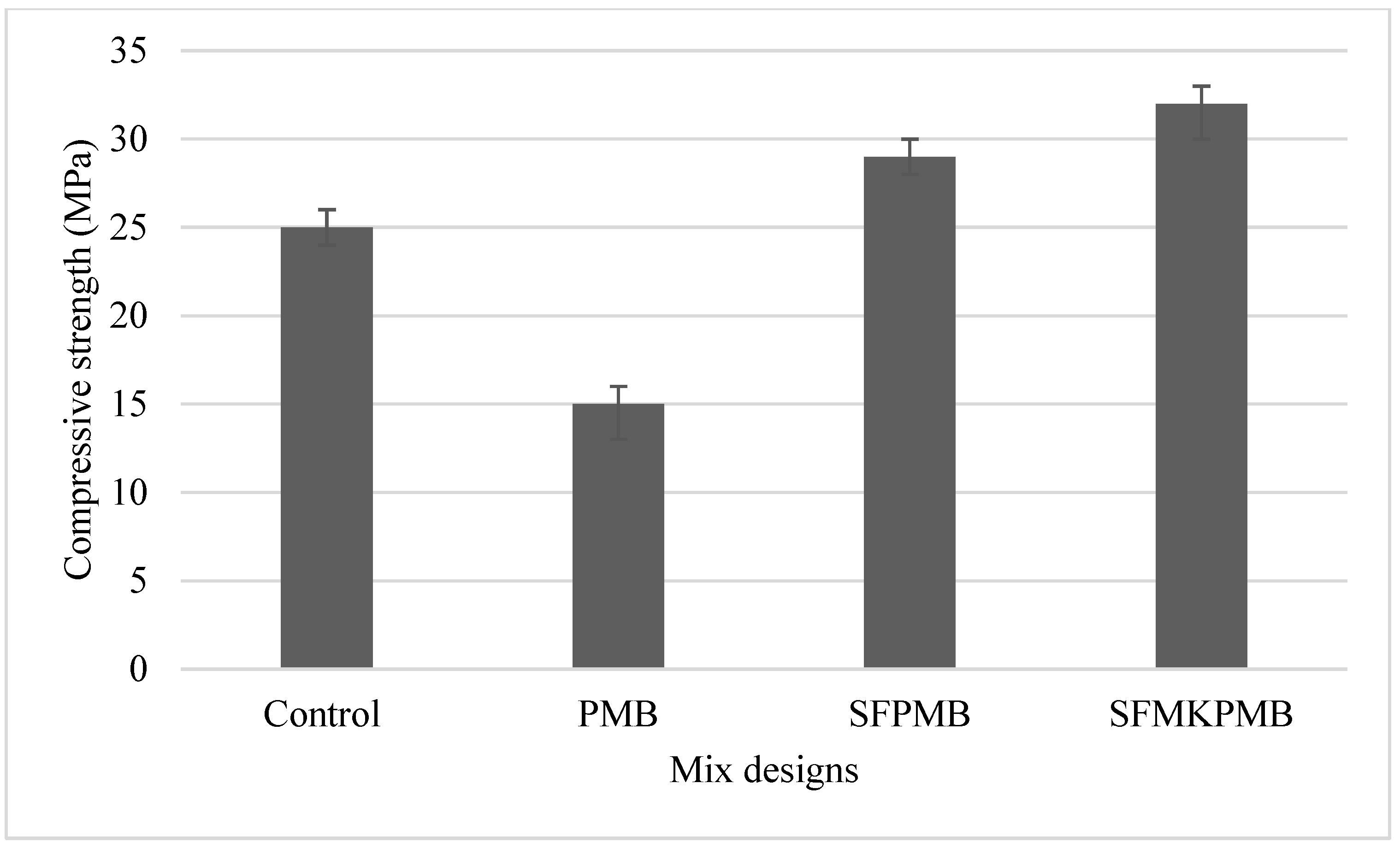

3.1. Mechanical Results

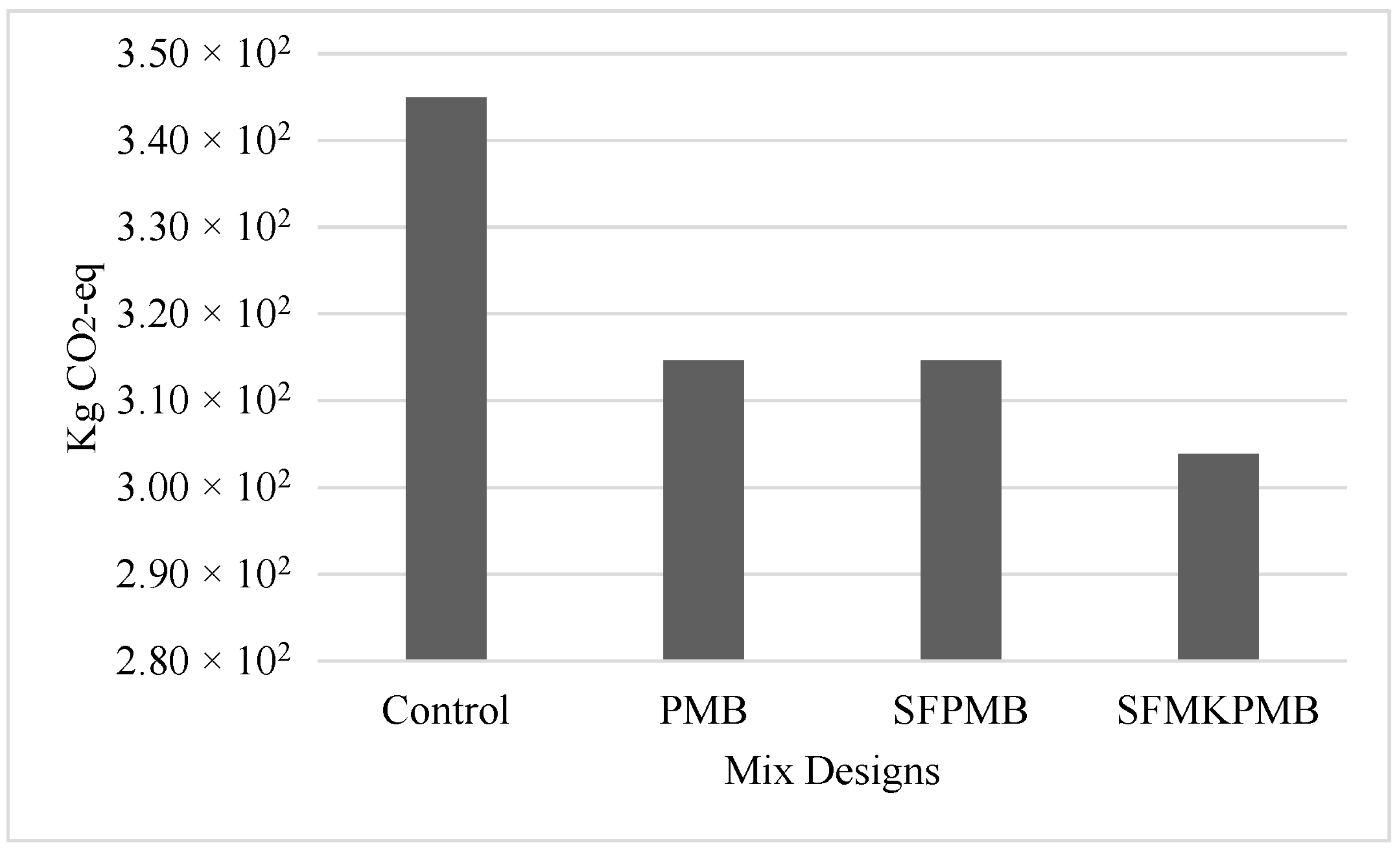

3.2. Life Cycle Assessment Results

3.3. Monte Carlo Simulation Results

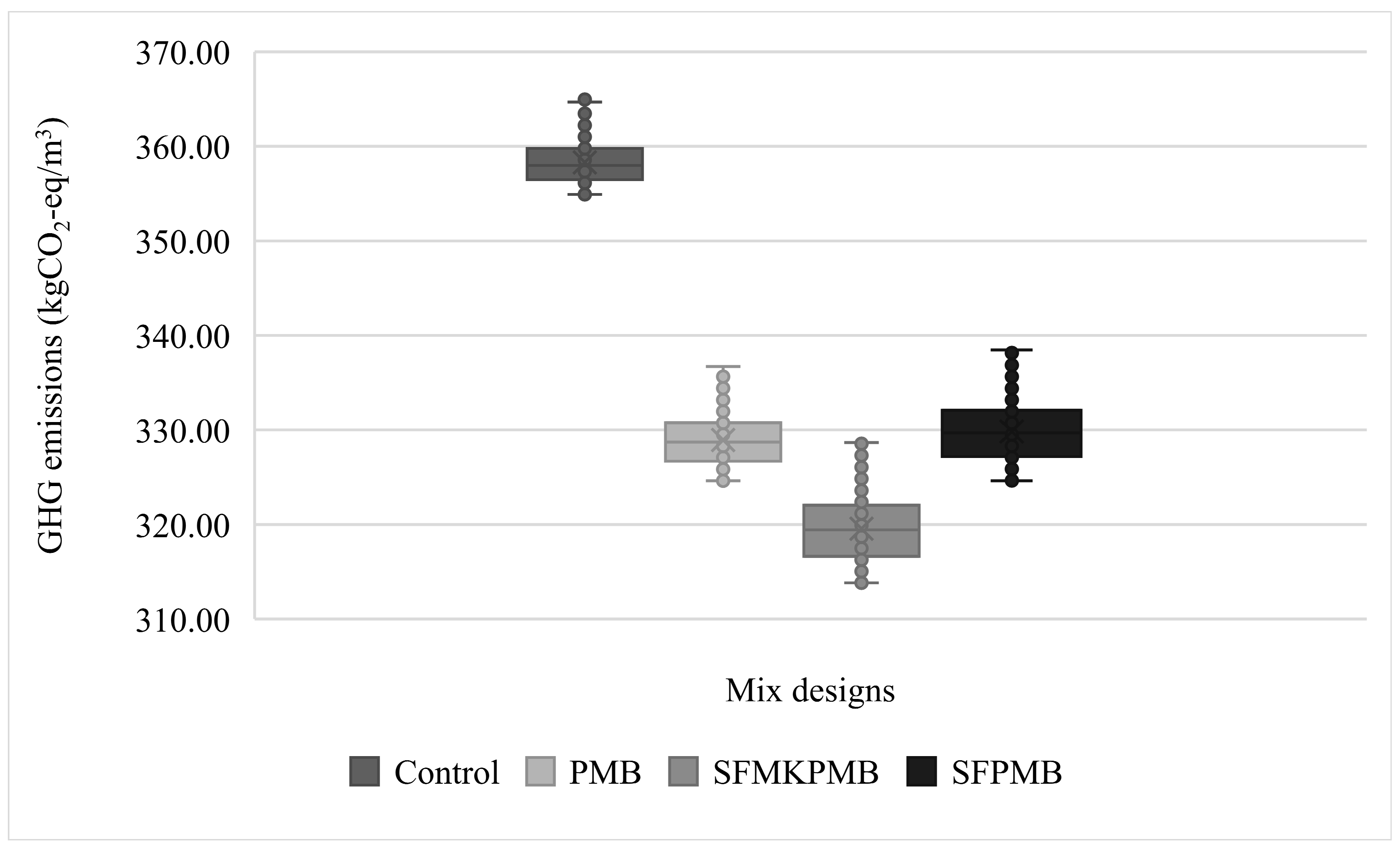

3.3.1. Transport Emissions

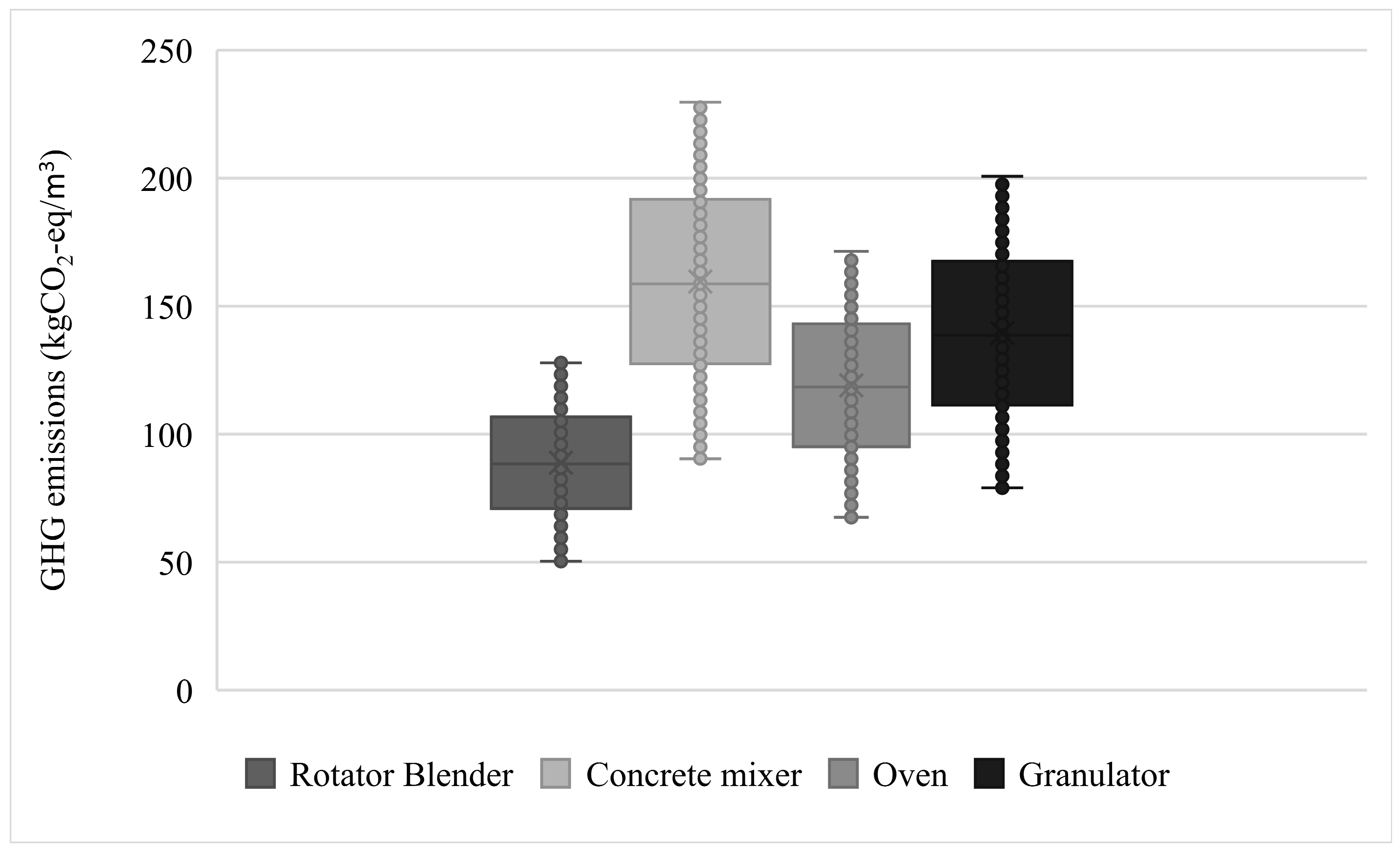

3.3.2. Energy Emissions

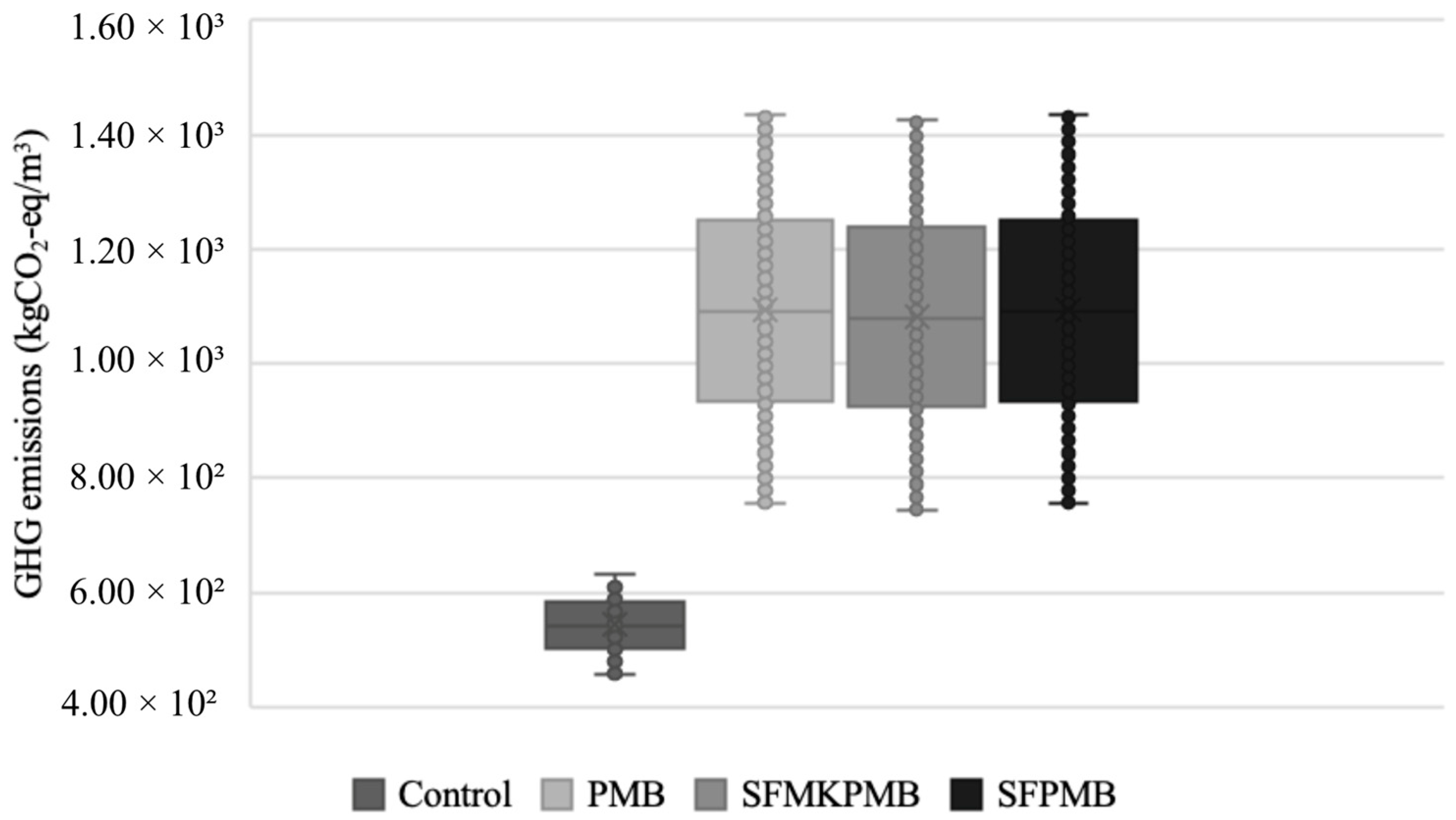

3.3.3. Total Energy and Transport and Materials

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nayanathara Thathsarani Pilapitiya, P.G.C.; Ratnayake, A.S. The world of plastic waste: A review. Clean. Mater. 2024, 11, 100220. [Google Scholar] [CrossRef]

- Benallel, A.; Tilioua, A.; Garoum, M. Development of thermal insulation panels bio-composite containing cardboard and date palm fibers. J. Clean. Prod. 2024, 434, 139995. [Google Scholar] [CrossRef]

- Dukare, A.; Yadav, R.; Kautkar, S.; Kuppusamy, P.; Sharma, K.; Shaikh, A.; Pawar, A.; Gadade, A.; Vigneshwaran, N.; Saxena, S.; et al. Waste to wealth: Microbial-based sustainable valorization of cotton biomass, processing waste and by-products for bioenergy and other value-added products to promote circular economy. Waste Manag. Bull. 2024, 2, 262–280. [Google Scholar] [CrossRef]

- Pongpunpurt, P.; Chawaloesphonsiya, N.; Poyai, T.; Guiraud, P.; Tiruta-Barna, L.; Rungsithong, R.; Leknoi, U.; Janjaroen, D.; Painmanakul, P. Exploring the circular business model for sustainable plastic waste management in shopping malls: Challenges, opportunities, and impacts in Thailand. Case Stud. Chem. Environ. Eng. 2024, 10, 100872. [Google Scholar] [CrossRef]

- Joe Pickin, J.M. National Waste and Resource Recovery Report 2024; Blue Environment: Melbourne, Australia, 2025. [Google Scholar]

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Mousania, Z.; Angulo, A.V.; Poon, J.P.H.; Atkinson, J.D. Quantifying the environmental impact of transportation for plastic film packaging end-of-life: Landfill, incineration, physical recycling, or chemical recycling. Resour. Conserv. Recycl. 2024, 207, 107681. [Google Scholar] [CrossRef]

- Crîstiu, D.; d’Amore, F.; Bezzo, F. Economic and environmental optimisation of mixed plastic waste supply chains in Northern Italy comparing incineration and pyrolysis technologies. Comput. Chem. Eng. 2024, 180, 108503. [Google Scholar] [CrossRef]

- Australia, W. Plastic Waste and Climate Change—Whats the Connection? Available online: https://wwf.org.au/blogs/plastic-waste-and-global-heating-what-is-the-connection/ (accessed on 3 June 2024).

- The_World_Bank. Solid Waste Management. Available online: https://www.worldbank.org/en/topic/urbandevelopment/brief/solid-waste-management (accessed on 4 January 2025).

- EPA. Plastics: Material—Specific Data. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/plastics-material-specific-data (accessed on 8 January 2025).

- World-Economic Forum. The New Plastics Economy-Rethinking the Future of Plastics. Available online: https://www3.weforum.org/docs/WEF_The_New_Plastics_Economy.pdf (accessed on 8 January 2025).

- Cox, K.D.; Covernton, G.A.; Davies, H.L.; Dower, J.F.; Juanes, F.; Dudas, S.E. Human Consumption of Microplastics. Env. Sci. Technol. 2019, 53, 7068–7074. [Google Scholar] [CrossRef]

- Yu, Z.; Nurdiawati, A.; Kanwal, Q.; Al-Humaiqani, M.M.; Al-Ghamdi, S.G. Assessing and mitigating environmental impacts of construction materials: Insights from environmental product declarations. J. Build. Eng. 2024, 98, 110929. [Google Scholar] [CrossRef]

- Kuz’min, M.P.; Larionov, L.M.; Kuz’mina, M.Y.; Kuz’mina, A.S.; Ran, J.Q.; Burdonov, A.E.; Zenkov, E.V. Production of portland cement using fluorine gypsum—Hydrofluoric acid waste. Mag. Civ. Eng. 2022, 111, 174. [Google Scholar] [CrossRef]

- Turk, O.; Yehia, S.; Abdelfatah, A.; Elchalakani, M. Sustainable concrete production: The potential of utilizing recycled waste materials. J. Build. Eng. 2024, 98, 111467. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Joseph, P.; Yaghoubi, E.; Vrcelj, Z. The mechanical and microstructural performance of waste textile and cardboard materials in concrete. Struct. Concr. 2024, 25, 4033–4047. [Google Scholar] [CrossRef]

- Xiang, Q.; Pan, H.; Ma, X.; Yang, M.; Lyu, Y.; Zhang, X.; Shui, W.; Liao, W.; Xiao, Y.; Wu, J.; et al. Impacts of energy-saving and emission-reduction on sustainability of cement production. Renew. Sustain. Energy Rev. 2024, 191, 114089. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current Sustainable Trends of Using Waste Materials in Concrete—A Decade Review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Haigh, R. A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway towards a Circular Economy. Waste 2023, 1, 935–959. [Google Scholar] [CrossRef]

- Abbas, S.N.; Qureshi, M.I. Improved fresh and hardened properties of concrete with high density polyethylene aggregates: Role of silica fume, steel fibers, macro synthetic fibers and variation of water cement ratio. Mater. Chem. Phys. Sustain. Energy 2025, 2, 100010. [Google Scholar] [CrossRef]

- Cao, J.; Zou, Z.; Zeng, P. Mechanical properties of fly ash concrete after the coupling effects of sustained load and sulphate erosion. Constr. Build. Mater. 2025, 460, 139866. [Google Scholar] [CrossRef]

- Yavuz, D.; Akbulut, Z.F.; Guler, S. Porous concrete modification with silica fume and ground granulated blast furnace slag: Hydraulic and mechanical properties before and after freeze-thaw exposure. Constr. Build. Mater. 2024, 447, 138099. [Google Scholar] [CrossRef]

- Kuz’min, M.P.; Larionov, L.M.; Kondratiev, V.V.; Kuz’mina, M.Y.; Grigoriev, V.G.; Kuz’mina, A.S. Use of the burnt rock of coal deposits slag heaps in the concrete products manufacturing. Constr. Build. Mater. 2018, 179, 117–124. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Tayeh, B.A. Metakaolin in ultra-high-performance concrete: A critical review of its effectiveness as a green and sustainable admixture. Case Stud. Constr. Mater. 2024, 21, e03967. [Google Scholar] [CrossRef]

- Nguyen, T.H.T.; Nguyen, T.-T.T.; Ha, N.-H.; Nguyen, K.L.P.; Bui, T.-K.L. Toward a circular economy for better municipal solid waste management in Can Gio district, Ho Chi Minh city. Sustain. Chem. Pharm. 2024, 38, 101480. [Google Scholar] [CrossRef]

- Vinod Kumar, R.; Rupesh Kumar, D.D. Recycled plastic (HDPE) coarse aggregate manufacturing method and performance in concrete. Mater. Today Proc. 2023, 92, 1304–1309. [Google Scholar] [CrossRef]

- Lim, S.M.; He, M.; Hao, G.; Ng, T.C.A.; Ong, G.P. Recyclability potential of waste plastic-modified asphalt concrete with consideration to its environmental impact. Constr. Build. Mater. 2024, 439, 137299. [Google Scholar] [CrossRef]

- Shaibur, M.R.; Sarwar, S.; Alshehri, M. Production and characterization of plastic bricks produced from PET, PP, and HDPE types of plastic wastes. Phys. Chem. Earth Parts A/B/C 2025, 138, 103859. [Google Scholar] [CrossRef]

- Heweidak, M.; Kafle, B.; Al-Ameri, R. Experimental and numerical analysis of self-compacting geopolymer concrete composite slab. Structures 2025, 71, 107942. [Google Scholar] [CrossRef]

- Pre-mix_Concrete_SA. Normal Class Concrete. Available online: https://premix.com.au/concrete-range/normal-class-concrete/#:~:text=(a)%20The%2020%20MPa%20and,%2C%20driveways%2C%20footings%20and%20footpaths (accessed on 2 February 2025).

- Youssf, O.; Mills, J.E.; Ellis, M.; Benn, T.; Zhuge, Y.; Ma, X.; Gravina, R.J. Practical Application of Crumb Rubber Concrete in Residential Slabs. Structures 2022, 36, 837–853. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, G.; Bhuiyan, M.A.; Agostino, J. Comparative life cycle assessment of kerbside collection methods for waste glass cullet for asphalt production. J. Clean. Prod. 2022, 374, 134055. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S. Comparative LCA of wood waste management strategies generated from building construction activities. J. Clean. Prod. 2018, 177, 387–397. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative LCA on using waste materials in the cement industry: A Hong Kong case study. Resour. Conserv. Recycl. 2017, 120, 199–208. [Google Scholar] [CrossRef]

- De Wolf, C.; Cordella, M.; Dodd, N.; Byers, B.; Donatello, S. Whole life cycle environmental impact assessment of buildings: Developing software tool and database support for the EU framework Level(s). Resour. Conserv. Recycl. 2023, 188, 106642. [Google Scholar] [CrossRef]

- Malviya, R.K.; Singh, R.K.; Purohit, R.; Sinha, R. Natural fibre reinforced composite materials: Environmentally better life cycle assessment—A case study. Mater. Today Proc. 2020, 26, 3157–3160. [Google Scholar] [CrossRef]

- Nascimento, F.; Gouveia, B.; Dias, F.; Ribeiro, F.; Silva, M.A. A method to select a road pavement structure with life cycle assessment. J. Clean. Prod. 2020, 271, 122210. [Google Scholar] [CrossRef]

- Zhao, J.; Li, S. Life cycle cost assessment and multi-criteria decision analysis of environment-friendly building insulation materials—A review. Energy Build. 2022, 254, 111582. [Google Scholar] [CrossRef]

- AS/NZS-1012.2; Methods of Testing Concrete. Preparing Concrete Mixes in the Laboratory. Australian Standard: Sydney, Australia, 2014.

- AS/NZS-3582.3; Supplementary Cementitious Materials. Part 3: Amorphous Silica. Australian Standard: Sydney, Australia, 2016.

- ASTM-C-618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM: Conshohocken, PA, USA, 2019.

- AS/NZS-1141.5; Methods for Sampling and Testing Aggregates—Particle Density and Water Absorption of Fine Aggregate. Australian Standard: Sydney, Australia, 2000.

- AS/NZS-1141.6.2; Methods for Sampling and Testing Aggregates—Particle Density and Water Absorption of Coarse Aggregate—Pycnometer Method. Australian Standard: Sydney, Australia, 2016.

- AS/NZS-3972; General Purpose and Blended Cements. Australian Standard: Sydney, Australia, 2010.

- AS/NZS-1012.8.2; Methods of Testing Concrete. Method for Making and Curing Concrete—Flexure Test Specimens. Australian Standard: Sydney, Australia, 2014.

- Ecoinvent. For the Availability of Envrionmental Data Worldwide. Available online: https://ecoinvent.org (accessed on 6 January 2025).

- OpenLCA. The Open Source Life Cycle and Sustainability Assessment Software. Available online: https://www.openlca.org (accessed on 6 January 2025).

- ISO 14044:2006; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Goyal, H.; Kumar, R.; Mondal, P. Life cycle analysis of paver block production using waste plastics: Comparative assessment with concrete paver blocks. J. Clean. Prod. 2023, 402, 136857. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A life cycle assessment of cardboard waste in low stress grade concrete applications. Environ. Manag. 2024, 354, 120428. [Google Scholar] [CrossRef]

- Manso-Morato, J.; Hurtado-Alonso, N.; Revilla-Cuesta, V.; Ortega-Lopez, V. Management of wind-turbine blade waste as high-content concrete addition: Mechanical performance evaluation and life cycle assessment. J. Environ. Manag. 2025, 373, 123995. [Google Scholar] [CrossRef]

- Ke, X.-j.; Chen, Z.-r.; Fu, W.-s. Waste rubber recycling in concrete-filled steel tube members: Mechanical performance, reliability and life cycle assessment. J. Build. Eng. 2024, 98, 111108. [Google Scholar] [CrossRef]

- Jin, Z.; Liang, K.; Liu, C.; Yang, G.; Cui, K.; Mao, S. Mechanical properties and life cycle assessment (LCA) of waste glass reinforced concrete. J. Build. Eng. 2024, 96, 110643. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A feasibility study of using coffee cup waste as a building material—Life cycle assessment and multi-objective optimisation. J. Clean. Prod. 2022, 339, 130498. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, W.; Wang, J.; Wang, Y.; Xu, Y.; Xiao, J. A review of life cycle assessment of recycled aggregate concrete. Constr. Build. Mater. 2019, 209, 115–125. [Google Scholar] [CrossRef]

- Haigh, R. The mechanical behaviour of waste plastic milk bottle fibres with surface modification using silica fume to supplement 10% cement in concrete materials. Constr. Build. Mater. 2024, 416, 135215. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. The durability performance of waste cardboard kraft fibre reinforced concrete. J. Build. Eng. 2023, 67, 106010. [Google Scholar] [CrossRef]

- Haigh, R.; Bouras, Y.; Sandanayake, M.; Vrcelj, Z. The mechanical performance of recycled cardboard kraft fibres within cement and concrete composites. Constr. Build. Mater. 2022, 317, 125920. [Google Scholar] [CrossRef]

- Harikaran, M.; Gokulakannan, S.; Loganathan, A.; Chandiran, R.D.; Ajith, M.; Dhanasekar, V. Metakaolin cement concrete evaluation using industrial by-products as fine aggregate. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Haw, T.T.; Hart, F.; Rashidi, A.; Pasbakhsh, P. Sustainable cementitious composites reinforced with metakaolin and halloysite nanotubes for construction and building applications. Appl. Clay Sci. 2020, 188, 105533. [Google Scholar] [CrossRef]

- Ecoinvent_Ecoquery. Cement, all Types to Generic Market for Cement, Unspecified. Available online: https://ecoquery.ecoinvent.org/3.10/cutoff/dataset/19768/documentation (accessed on 6 January 2025).

- Ecoinvent_Ecoquery. Kaolin Production. Available online: https://ecoquery.ecoinvent.org/3.10/cutoff/dataset/4048/documentation (accessed on 6 January 2025).

- Ecoinvent_Ecoquery. Sand Quarry Operation, Extraction from River Bed. Available online: https://ecoquery.ecoinvent.org/3.10/cutoff/dataset/20537/documentation (accessed on 6 January 2025).

- Ecoinvent_Ecoquery. Gravel Production, Crushed. Available online: https://ecoquery.ecoinvent.org/3.10/cutoff/dataset/830/documentation (accessed on 6 January 2025).

- Jafarikia, S.; Feghhi, S.A.H. Built in importance estimation in forward Monte Carlo calculations. Ann. Nucl. Energy 2022, 177, 109298. [Google Scholar] [CrossRef]

- Ita-Nagy, D.; Vazquez-Rowe, I.; Kahhat, R.; Quispe, I.; Chinga-Carrasco, G.; Clauser, N.M.; Area, M.C. Life cycle assessment of bagasse fiber reinforced biocomposites. Sci. Total Environ. 2020, 720, 137586. [Google Scholar] [CrossRef] [PubMed]

- Institute_for_Global_Environmental_Strategies. IGES List of Grid Emission Factors. Available online: https://www.iges.or.jp/en/pub/list-grid-emission-factor/en (accessed on 8 January 2025).

- IEA. Emission Factors 2022. Annual GHG Emission Factors for World Countries from Electricity and Heat Generation. Available online: https://www.iea.org/data-and-statistics/data-product/emissions-factors-2022 (accessed on 8 January 2025).

- EPA. Greenhouse Gases Equivalencies Calculator—Calculations and References. Available online: https://www.epa.gov/energy/greenhouse-gases-equivalencies-calculator-calculations-and-references (accessed on 8 January 2025).

- Lin, P.-C.; Wang, J.; Huang, S.-H.; Wang, Y.-T. Dispatching ready mixed concrete trucks under demand postponement and weight limit regulation. Autom. Constr. 2010, 19, 798–807. [Google Scholar] [CrossRef]

- Tzanetos, A.; Blondin, M. Systematic search and mapping review of the concrete delivery problem (CDP): Formulations, objectives, and data. Autom. Constr. 2023, 145, 104631. [Google Scholar] [CrossRef]

- Maghrebi, M.; Travis Waller, S.; Sammut, C. Optimality gap of experts’ decisions in concrete delivery dispatching. J. Build. Eng. 2015, 2, 17–23. [Google Scholar] [CrossRef]

- Ghafoori, N.; Diawara, H.; Hasnat, A. Remediation of loss in flow properties of self-consolidating concrete under various combinations of transportation time and temperature. Constr. Build. Mater. 2018, 192, 508–514. [Google Scholar] [CrossRef]

- Sakrete. Pro Tip: Mixing Concrete Using a Mixer. Available online: https://www.sakrete.com/blog/post/mixing-concrete-using-a-mixer/ (accessed on 8 January 2025).

- ScrewFix. How Long to Mix Concrete. Available online: https://community.screwfix.com/threads/how-long-to-mix-concrete.180903/ (accessed on 10 January 2025).

- Edisons. Baumr-AG 220L Portable Electric Concrete Cement Mixer. Available online: https://www.edisons.com.au/baumr-ag-220l-portable-electric-concrete-cement-mixer? (accessed on 10 January 2025).

- Forestwest. 80L Mortar Mixer Portable Screed Mixer 1100W BM691. Available online: https://forestwest.com.au/products/80l-portable-mortar-mixer-screed-mixer (accessed on 10 January 2025).

- Collections, N.A. Kartrite 850W Cement Concrete Mixer Sand Gravel Portable—200L. Available online: https://www.nordicaustraliacollections.com.au/products/kartrite-850w-cement-concrete-mixer-sand-gravel-portable-200l?srsltid=AfmBOopjHyl6gMMKMEn5n3H6-yzhCBpsIaWaVO-DELfux9EHsfHAsvbj (accessed on 10 January 2025).

- Pro_Plaster_Products. WallPro Powermix HD 1600w (Mixer). Available online: https://proplaster.com.au/products/wallpro-powermix-hd-1600w-mixer?srsltid=AfmBOooQxn0E7wk3PDrb_d04sTfV4JcY2IfAMzdSBsrds-izgY_YNKfH (accessed on 10 January 2025).

- Edisons. UNIMAC UM-PX9 Power Paddle Stirrer Mixer, Dual Gear, 7 Speed, for Plaster Cement Render Paint Tile Adhesive. Available online: https://www.edisons.com.au/unimac-um-px9-power-paddle-stirrer-mixer-dual-gear-7-speed-for-plaster-cement-render-paint-tile-adhesive?srsltid=AfmBOoqOblhrLHraCUD0m00wWjEZJV_TvZt4rUUuKFtY6BBMiA5fJBkS (accessed on 10 January 2025).

- ToolNation. Rubi 25940 Rubimix-9 N 1200W Mixer. Available online: https://www.toolnation.com/rubi-25940-24940-rubimix-9-n-mixer-1200-watt.html (accessed on 10 January 2025).

- Prosin. Small Sized Plastic Granulator/Plastic Grinder. Available online: https://www.sinoshredder.com/shredders/small-sized-plastic-granulator/ (accessed on 10 January 2025).

- Machines4u. Industrial Plastic Granulator 2.2kW. Available online: https://www.machines4u.com.au/view/advert/Industrial-Plastic-Granulator-2-2kW/819926/ (accessed on 10 January 2025).

- LabFriend. OVEN GP 60L 230V—OGS60. Available online: https://www.labfriend.com.au/oven-gp-60l-230v-ogs60 (accessed on 10 January 2025).

- LabDirect. Digital Laboratory Oven, 30 Litres Capacity, Max +200 °C. Available online: https://www.labdirect.com.au/digital-laboratory-oven-30-litres-capacity-max-200-c/ (accessed on 10 January 2025).

- Across_International. 200 °C 23L Digital Forced Air Convection Oven. Available online: https://www.acrossinternational.com.au/shop/fo19023-200degc-23l-digital-forced-air-convection-oven-423?category=87#attr=484,486 (accessed on 10 January 2025).

- Tao, Y.; Hadigheh, S.A.; Wang, Z. Void geometry analysis and multifaceted characterisation of cementitious mortar reinforced with short carbon and glass fibres—A comparative study. J. Build. Eng. 2024, 89, 109283. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Constr. Build. Mater. 2021, 297, 123759. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Yaghoubi, E.; Joseph, P.; Vrcelj, Z. The mechanical and microstructural investigations of concrete incorporating waste textile and cardboard fibers following thermal and freeze–thaw cycles. Struct. Concr. 2025, 1–16. [Google Scholar] [CrossRef]

- Morales, M.F.D.; Passuello, A.; Kirchheim, A.P.; Ries, R.J. Monte Carlo parameters in modeling service life: Influence on life-cycle assessment. J. Build. Eng. 2021, 44, 103232. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S.; Wanijuru, D. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

| Material | Portland Cement Clinker | Lime-Stone | Gypsum | Clinker Kiln Dust | Chromium (VI) Hexavalent |

|---|---|---|---|---|---|

| Formula | NA | CaCO3 | CaSO4·2H2O | NA | Cr6+ |

| Proportion | 92% | 0–7.5% | 3–8% | 0–2.5% | Trace |

| Mix Designs | Cement | Plastic Milk Bottle | Silica Fume | Metakaolin | Fine Aggregate | Coarse Aggregate | Water |

|---|---|---|---|---|---|---|---|

| Control | 355 | 733 | 1100 | 210 | |||

| PMB | 319.5 | 35.5 | 733 | 1100 | 210 | ||

| SFPMB | 319.5 | 35.5 | 0.71 | 733 | 1100 | 210 | |

| SFMKPMB | 301.7 | 35.5 | 0.71 | 17.8 | 733 | 1100 | 210 |

| Materials | Brown Coal | Black Coal | Crude Oil | Geothermal | Solar Energy | Water Power | Wind Power | Natural Gas | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 11.9 | 26.3 | 1506.27 | 5.18 | 0.24 | 2.07 | 0.30 | 44.1 | [47,62] |

| Metakaolin | 11.9 | 26.3 | 42.3 | - | - | - | - | 44.1 | [47,63] |

| Fine aggregate | 11.9 | 26.3 | 42.3 | 0.00003 | - | - | - | 44.1 | [47,64] |

| Coarse aggregate | 11.9 | 26.3 | 42.3 | 0.00011 | - | - | - | 44.1 | [47,65] |

| Impact Category | Data Source | Normalisation Factors | ||

|---|---|---|---|---|

| Unit | Value | Reference | ||

| Terrestrial acidification potential | USEtox 2017 | KgSO2-eq | 4.10 × 101 | [47,48] |

| Global warming potential | IPCC 2013 baseline | Kg CO2-eq | 7.99 × 103 | [47,48] |

| Terrestrial ecotoxicity potential | USEtox 2.0 | Kg 1,4-DCB-eq | 1.04 × 103 | [47,48] |

| Marine eutrophication potential | CML & EMEP/MSC-W | Kg N-eq | 1.95 × 101 | [47,48] |

| Human toxicity potential | USEtox 2.0 | Kg 1,4-DCB-eq | 2.77 × 100 | [47,48] |

| Ozone layer depletion potential | IPCC/WMO 2013 | Kg CFC-11-eq | 5.90 × 10−2 | [47,48] |

| Freshwater ecotoxicity potential | USEtox 2.0 | Kg 1,4-DCB-eq | 4.97 × 104 | [47,48] |

| Fossil depletion | CML | Kg oil-eq | 6.50 × 104 | [47,48] |

| Variable Parameter | Minimum | Maximum | Probability Distribution | Reference |

|---|---|---|---|---|

| Transportation truck emissions | 0.161 | 0.307 | Triangular | [68,69,70] |

| Coal (black and brown) emissions | 0.63 | 1.63 | Triangular | [68,69,70] |

| Gas emissions | 0.27 | 0.9 | Triangular | [68,69,70] |

| Renewable energy emissions | 0.03 | 0.09 | Triangular | [68,69,70] |

| Construction site distance (km) | 10 | 150 | Triangular | [71,72,73] |

| Production time of concrete (minutes) | 60 | 300 | Triangular | [74,75,76] |

| Capacity of cement mixer (kWh) | 0.8 | 1.1 | Triangular | [77,78,79] |

| Capacity of rotator blender (kWh) | 1.2 | 1.6 | Triangular | [80,81,82] |

| Capacity of granulator (kWh) | 2.2 | 4 | Triangular | [83,84] |

| Capacity of oven (kWh) | 0.5 | 1.8 | Triangular | [85,86,87] |

| Impact Category | Reference Unit | Mix Designs | |||

|---|---|---|---|---|---|

| Control | PMB | SFPMB | SFMKPMB | ||

| Terrestrial acidification (TAP100) | kg SO2-Eq | 7.58 × 10−1 | 7.08 × 10−1 | 7.08 × 10−1 | 6.99 × 10−1 |

| Global warming potential (GWP100) | kg CO2-Eq | 3.45 × 102 | 3.15 × 102 | 3.15 × 102 | 3.04 × 102 |

| Terrestrial ecotoxicity (TETP100) | kg 1,4-DCB-Eq | 1.21 × 10−2 | 1.16 × 10−2 | 1.16 × 10−2 | 1.16 × 10−2 |

| Marine eutrophication (MEP) | kg N-Eq | 2.51 × 10−1 | 2.33 × 10−1 | 2.33 × 10−1 | 2.27 × 10−1 |

| Human toxicity (HTP100) | kg 1,4-DCB-Eq | 7.76 × 101 | 7.38 × 101 | 7.38 × 101 | 7.39 × 101 |

| Ozone depletion (ODP100) | kg CFC-11-Eq | 1.13 × 10−5 | 1.05 × 10−5 | 1.05 × 10−5 | 1.04 × 10−5 |

| Freshwater ecotoxicity (FETP100) | kg 1,4-DCB-Eq | 1.77 × 100 | 1.67 × 100 | 1.67 × 100 | 1.63 × 100 |

| Fossil depletion (FDP) | kg oil-Eq | 4.03 × 101 | 3.75 × 101 | 3.75 × 101 | 3.76 × 101 |

| Impact Category | Reference Unit | PMB | SFPMB | SFMKPMB |

|---|---|---|---|---|

| Climate change (GWP100) | kg CO2-Eq | 3.04 × 101 | 3.04 × 101 | 4.12 × 101 |

| Terrestrial acidification (TAP100) | kg SO2-Eq | 5.04 × 10−2 | 5.04 × 10−2 | 5.94 × 10−2 |

| Terrestrial ecotoxicity (TETP100) | kg 1,4-DCB-Eq | 4.81 × 10−4 | 4.81 × 10−4 | 5.43 × 10−4 |

| Marine eutrophication (MEP) | kg N-Eq | 1.80 × 10−2 | 1.80 × 10−2 | 2.38 × 10−2 |

| Human toxicity (HTP100) | kg 1,4-DCB-Eq | 3.80 × 100 | 3.80 × 100 | 3.72 × 100 |

| Ozone depletion (ODP100) | kg CFC-11-Eq | 8.29 × 10−7 | 8.29 × 10−7 | 9.14 × 10−7 |

| Freshwater ecotoxicity (FETP100) | kg 1,4-DCB-Eq | 9.96 × 10−2 | 9.96 × 10−2 | 1.33× 10−1 |

| Fossil depletion (FDP) | kg oil-Eq | 2.83 × 100 | 2.83 × 100 | 2.71 × 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haigh, R. A Life Cycle Assessment of HDPE Plastic Milk Bottle Waste Within Concrete Composites and Their Potential in Residential Building and Construction Applications. Urban Sci. 2025, 9, 116. https://doi.org/10.3390/urbansci9040116

Haigh R. A Life Cycle Assessment of HDPE Plastic Milk Bottle Waste Within Concrete Composites and Their Potential in Residential Building and Construction Applications. Urban Science. 2025; 9(4):116. https://doi.org/10.3390/urbansci9040116

Chicago/Turabian StyleHaigh, Robert. 2025. "A Life Cycle Assessment of HDPE Plastic Milk Bottle Waste Within Concrete Composites and Their Potential in Residential Building and Construction Applications" Urban Science 9, no. 4: 116. https://doi.org/10.3390/urbansci9040116

APA StyleHaigh, R. (2025). A Life Cycle Assessment of HDPE Plastic Milk Bottle Waste Within Concrete Composites and Their Potential in Residential Building and Construction Applications. Urban Science, 9(4), 116. https://doi.org/10.3390/urbansci9040116