Socio-Economical Analysis of a Green Reverse Logistics Network under Uncertainty: A Case Study of Hospital Constructions

Abstract

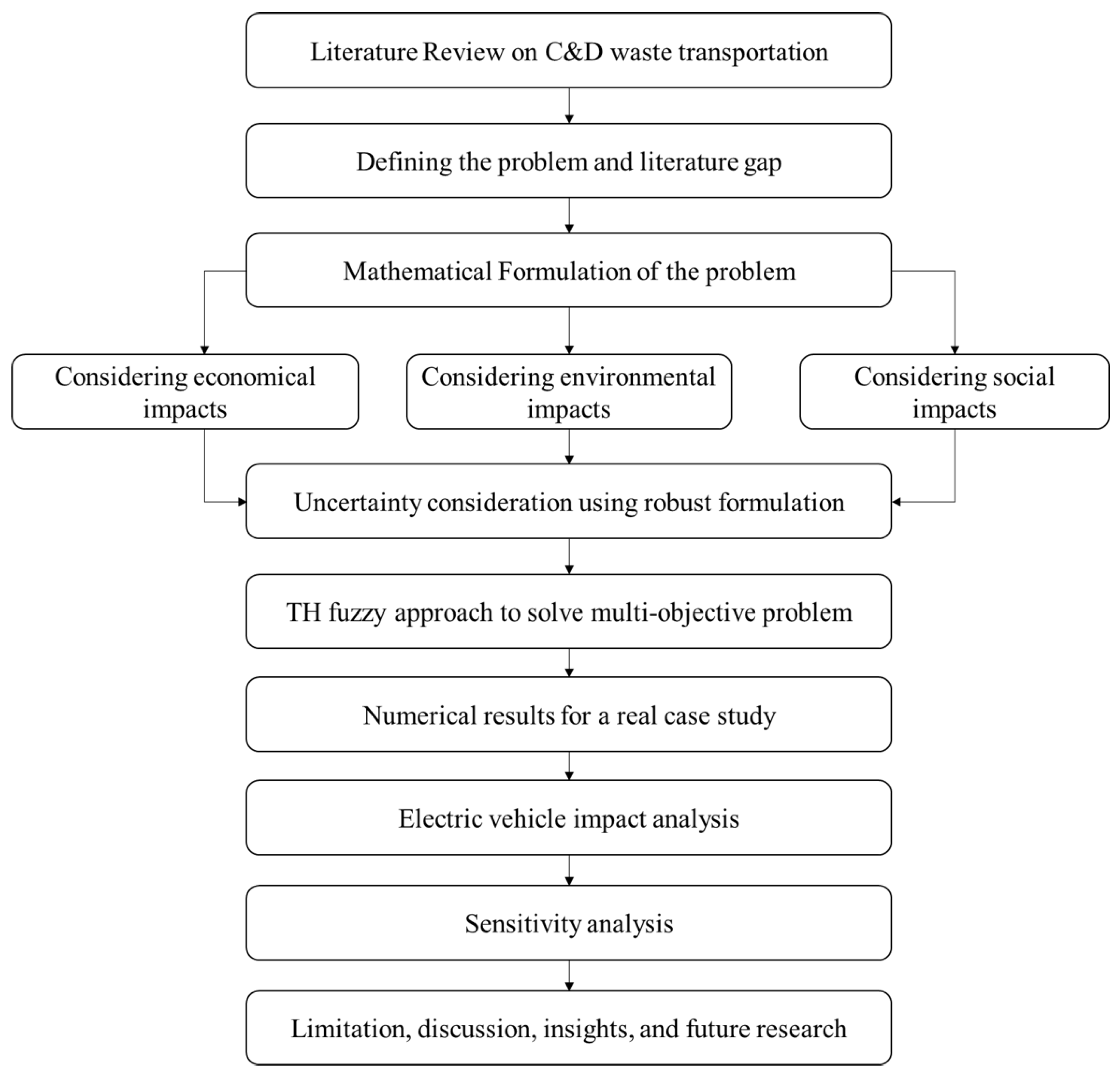

1. Introduction

- Designing a novel reverse logistics model under uncertainty that includes separation labs, incineration centers, recycling centers, and landfills.

- Using robust formulation to deal with uncertain constraints.

- Optimizing environmental and social impacts as well as economic aspects.

- Solving the problem in a fuzzy environment to analyze the importance of each factor.

- Analyzing the impact and disparity of using electric vehicles versus diesel in environmental and economic aspects.

- Focusing on LEED policies for the recycling of construction and demolition wastes and incorporating them into the mathematical modeling.

- Conducting a case study of constructional waste management in Tehran.

- Conducting a socio-economical analysis with respect to the environmental aspects to choose the best strategy and scenario.

2. Literature Review

2.1. Reverse Logistics, Supply Chain Management, and Sustainability

2.2. Electric Vehicles in Green Supply Chain and Logistics Networks

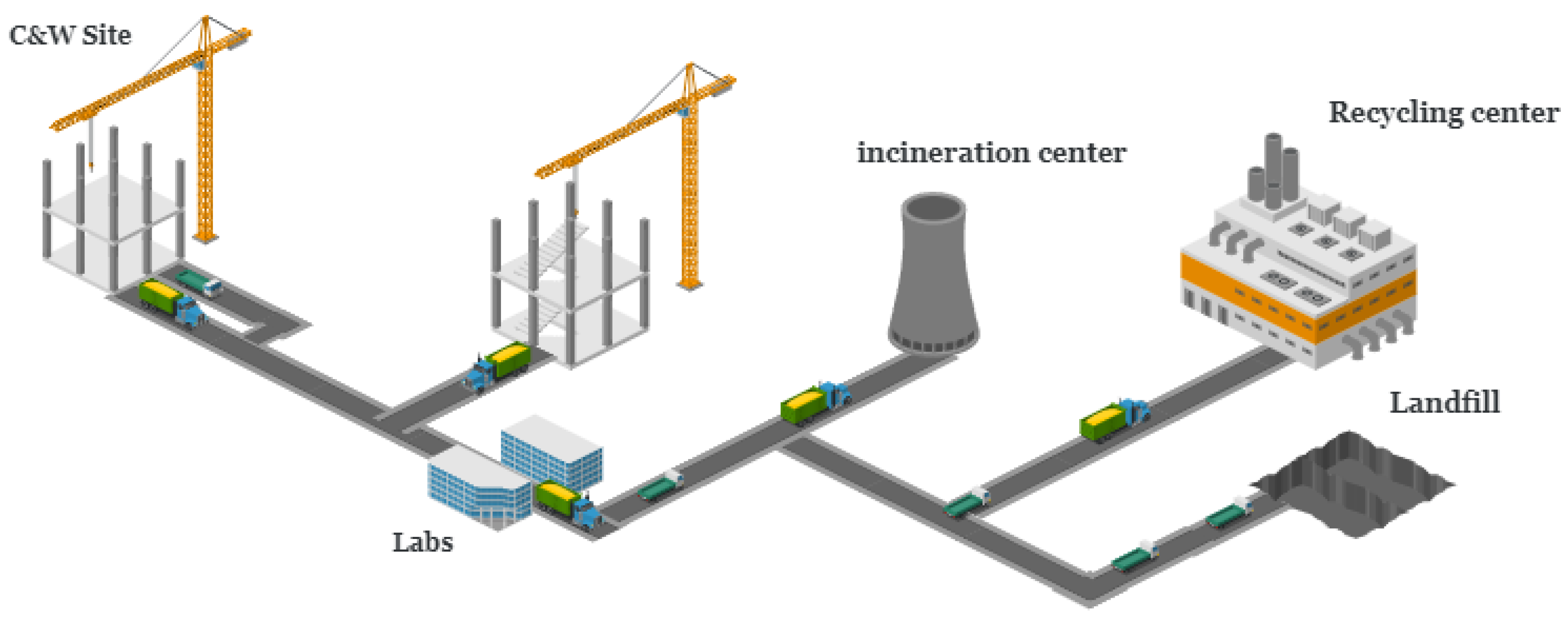

3. Problem Definition

3.1. Mixed Integer Linear Formulation

- -

- The fixed cost of laboratories:

- -

- The operating cost of laboratories:

- -

- The fixed cost of landfills:

- -

- The operating cost of landfills:

- -

- The fixed cost of incineration centers:

- -

- The operating cost of incineration centers:

- -

- The fixed cost of recycling centers:

- -

- The operating cost of recycling centers:

- -

- The operating cost of electric vehicles responsible for transporting the waste from construction sites to laboratories:

- -

- The operating cost of electric trucks responsible for transporting the waste from construction sites to laboratories:

- -

- The operating cost of electric vehicles responsible for transporting the waste from laboratories to landfills:

- -

- The operating cost of electric trucks responsible for transporting the waste from laboratories to landfills:

- -

- The operating cost of electric vehicles responsible for transporting the waste from laboratories to incineration centers:

- -

- The operating cost of electric trucks responsible for transporting the waste from laboratories to incineration centers:

- -

- The operating cost of electric vehicles responsible for transporting the waste from laboratories to recycling centers:

- -

- The operating cost of electric trucks responsible for transporting the waste from laboratories to recycling centers:

- -

- The power consumed by electric vehicles from C&W sites to laboratories:

- -

- The power consumed by electric trucks from C&W sites to laboratories:

- -

- The power consumed by electric vehicles from laboratories to landfills:

- -

- The power consumed by electric trucks from laboratories to landfills:

- -

- The power consumed by electric vehicles from laboratories to incineration centers:

- -

- The power consumed by electric trucks from laboratories to incineration centers:

- -

- The power consumed by electric vehicles from laboratories to recycling centers:

- -

- The power consumed by electric trucks from laboratories to recycling centers:

3.2. Robust Formulation

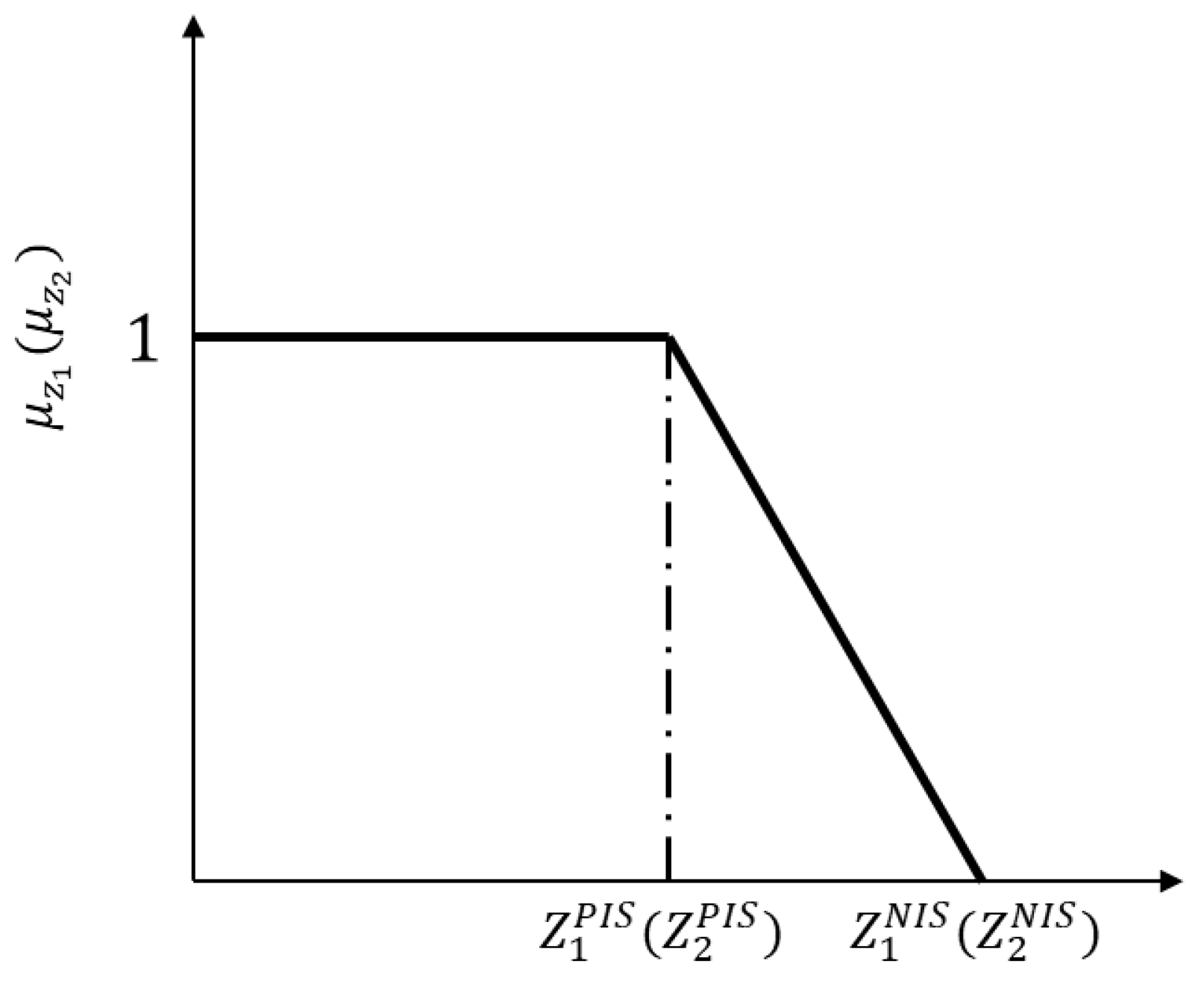

3.3. Interactive Fuzzy Optimization

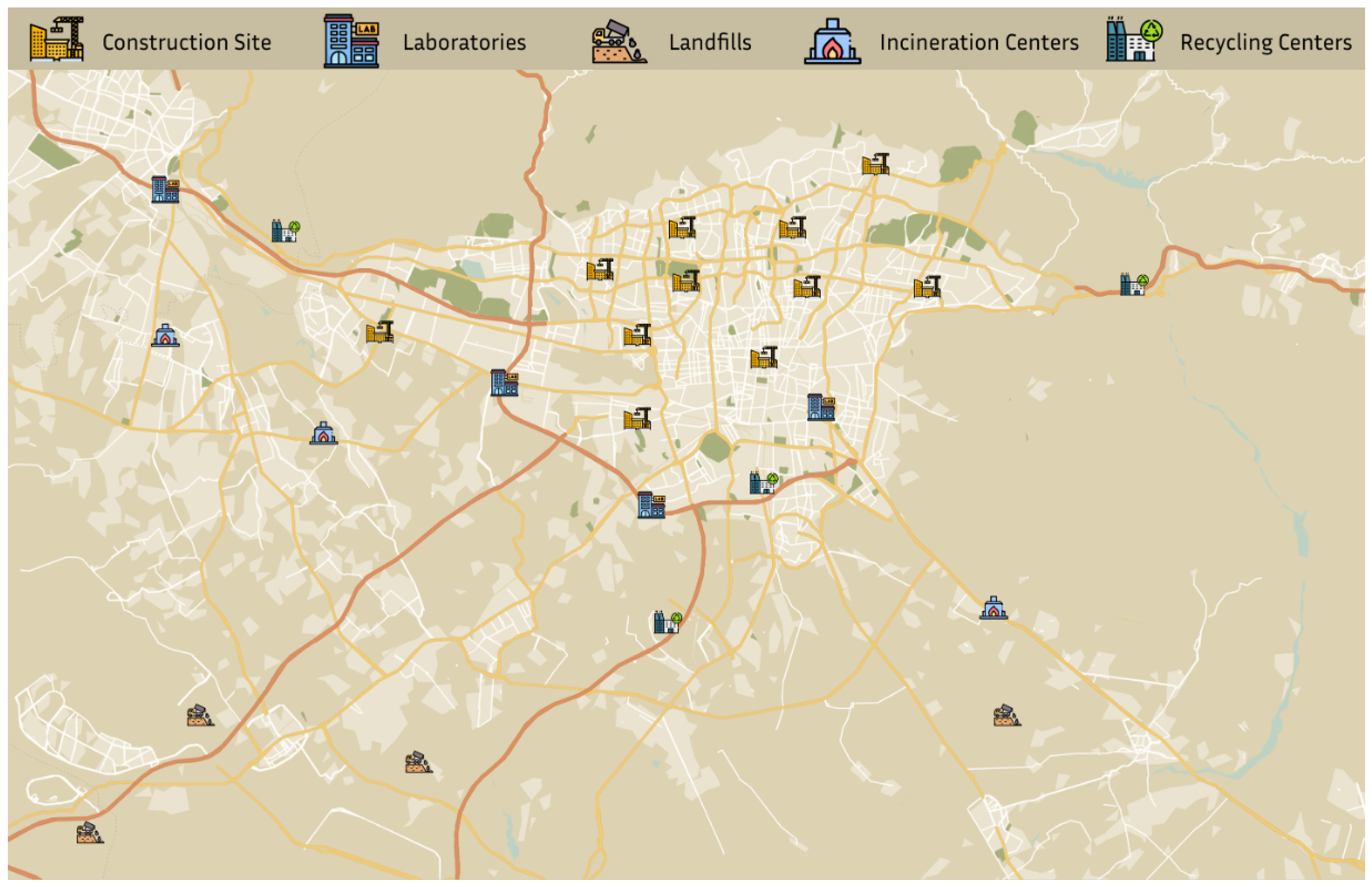

3.4. Tehran Case Study

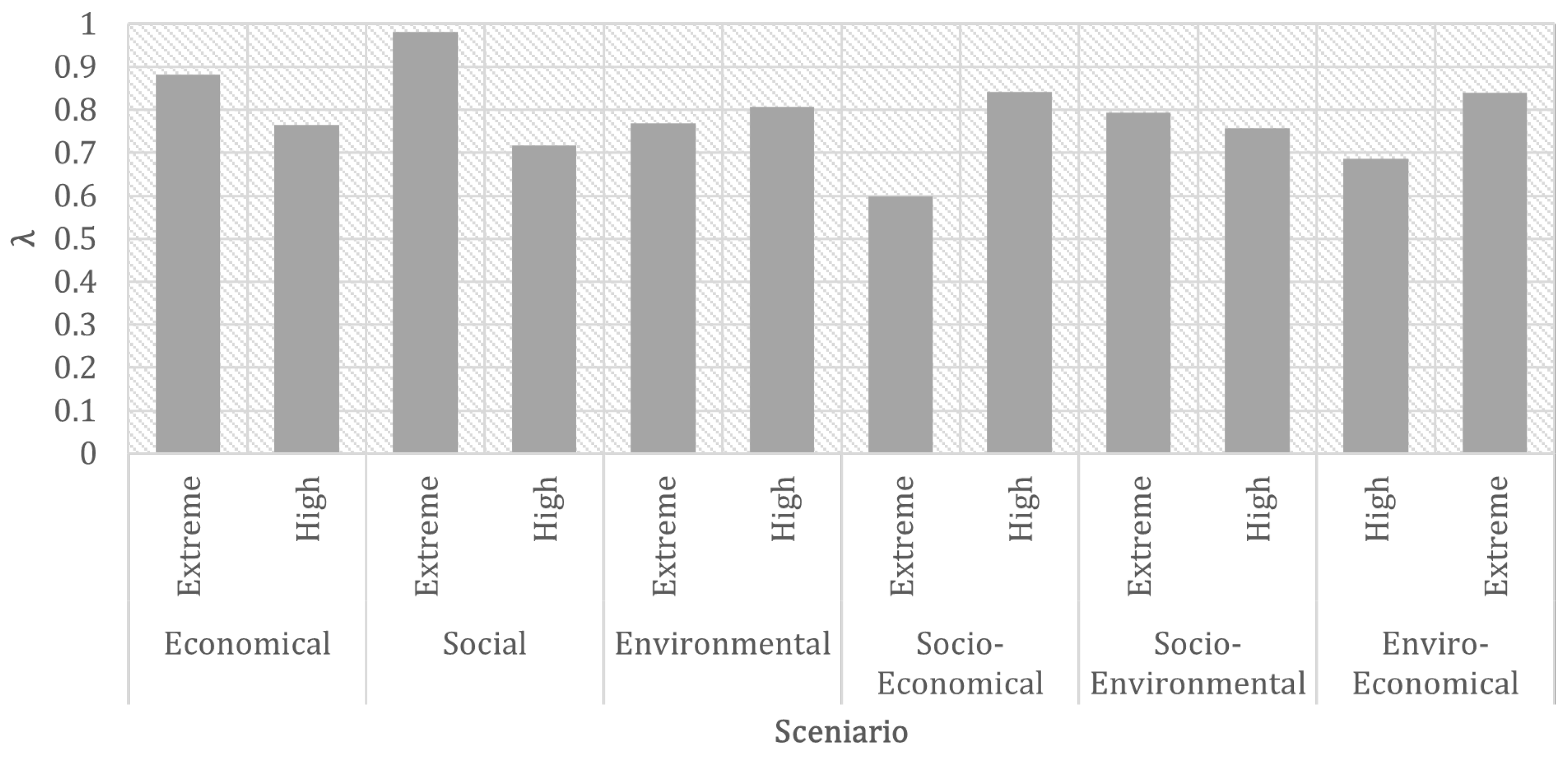

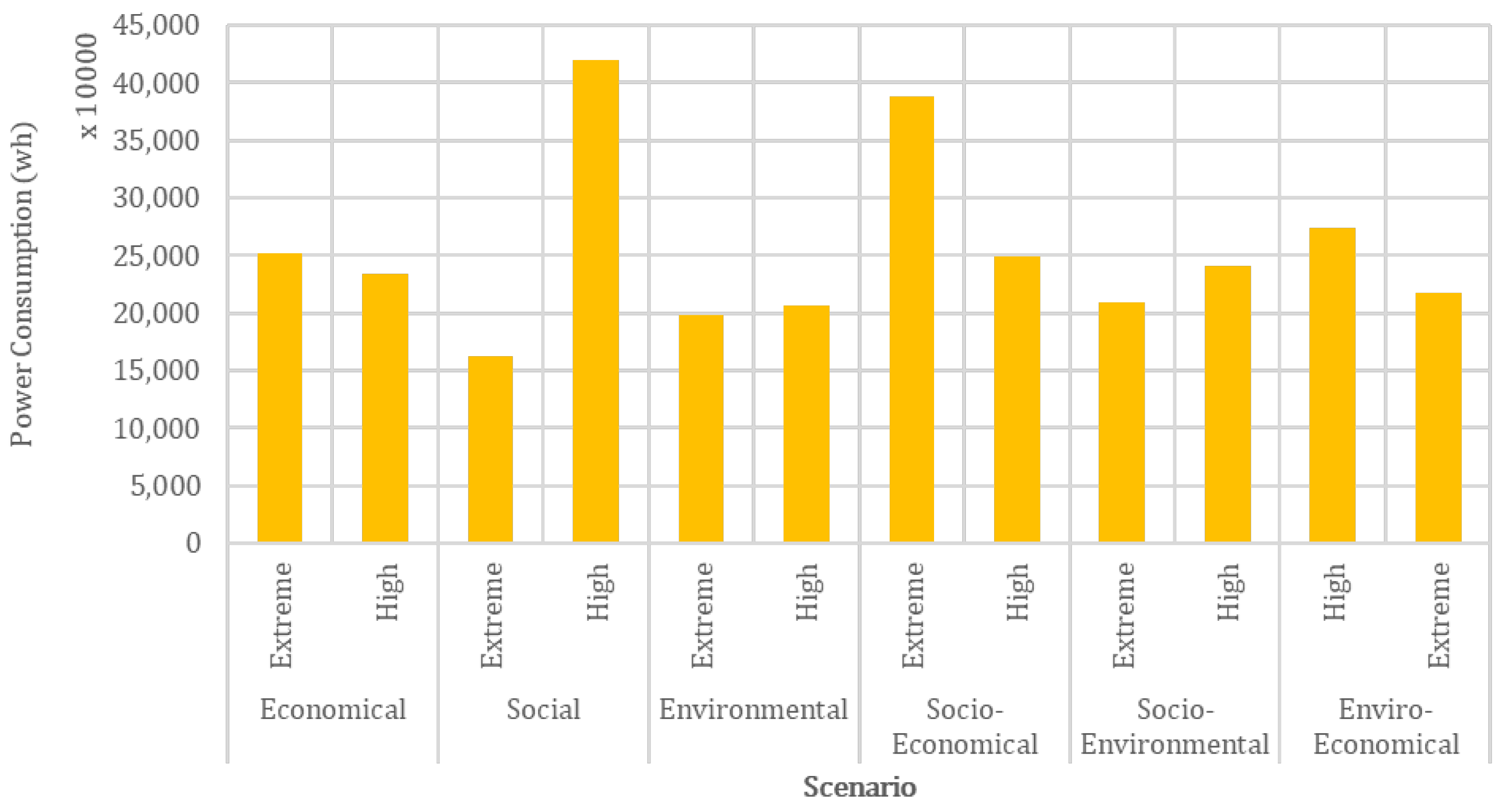

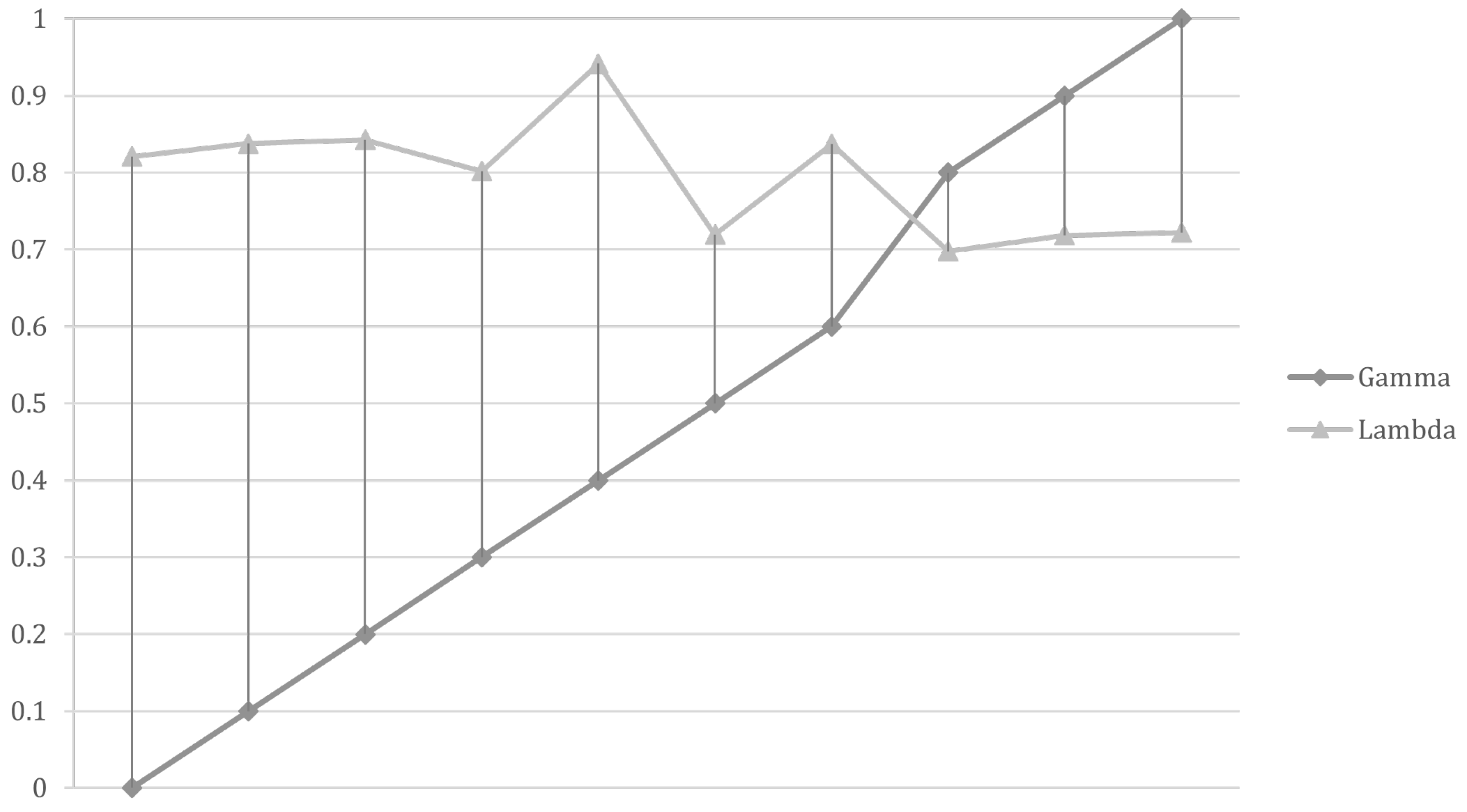

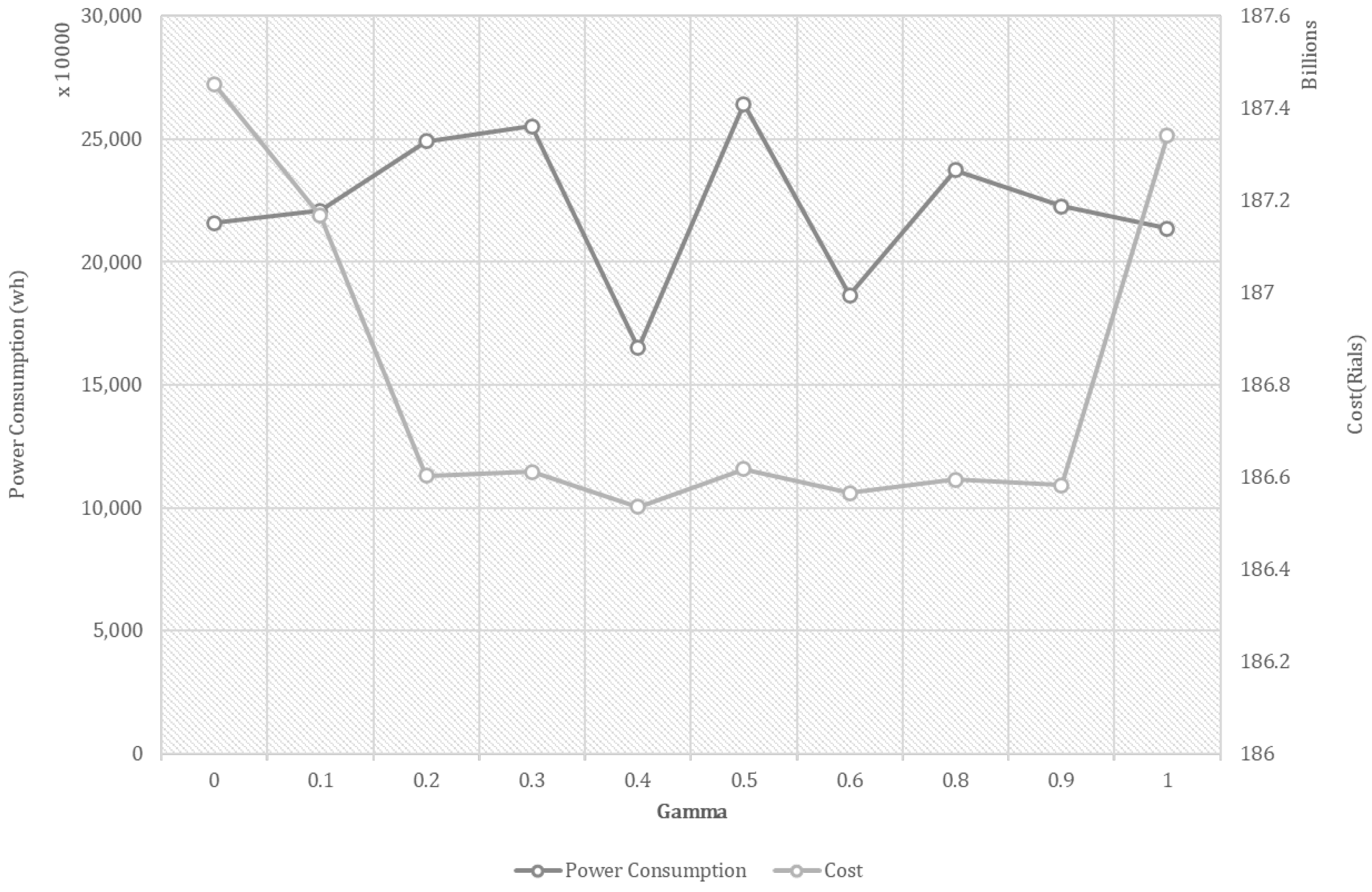

4. Numerical Results and Analysis

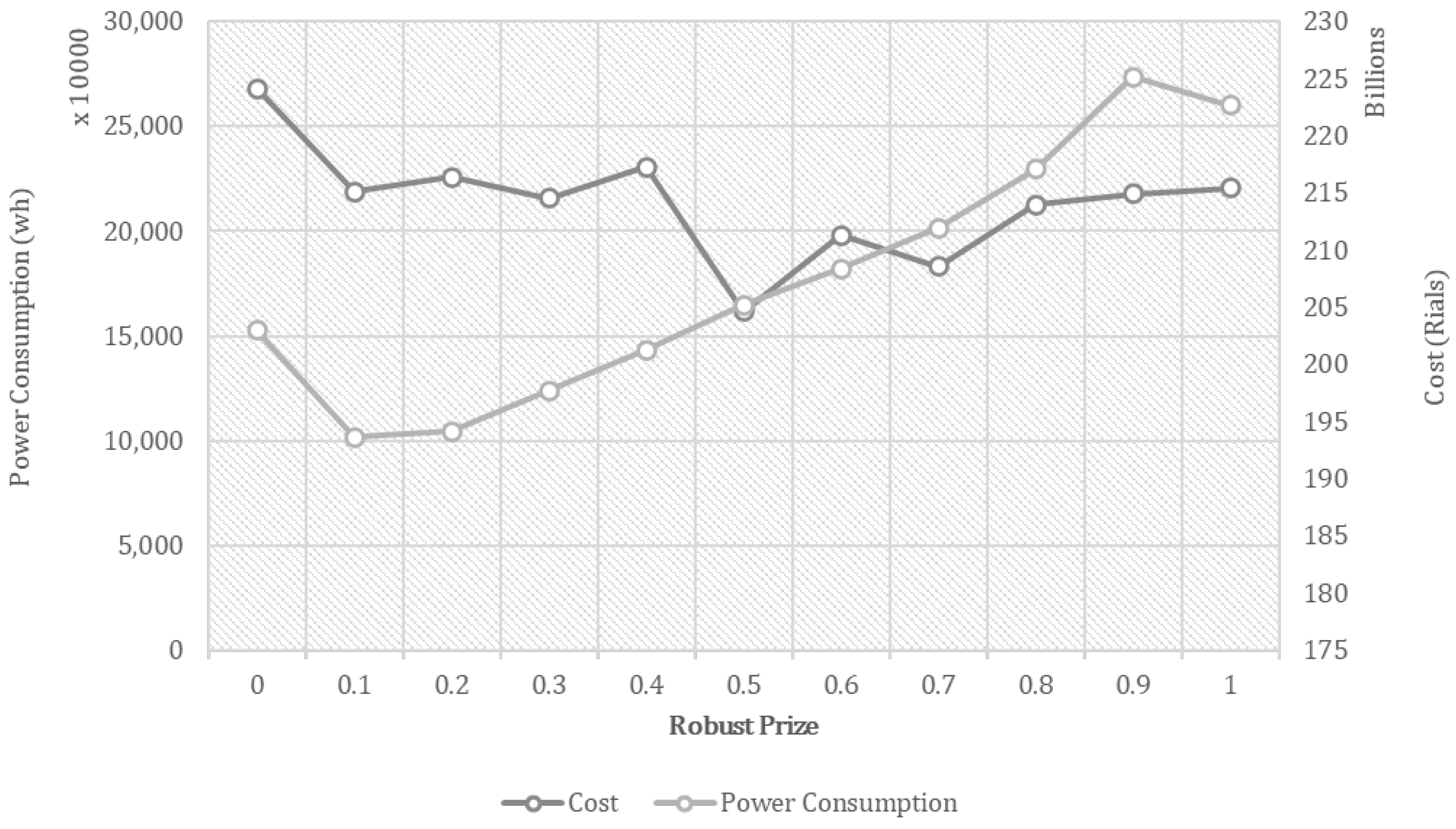

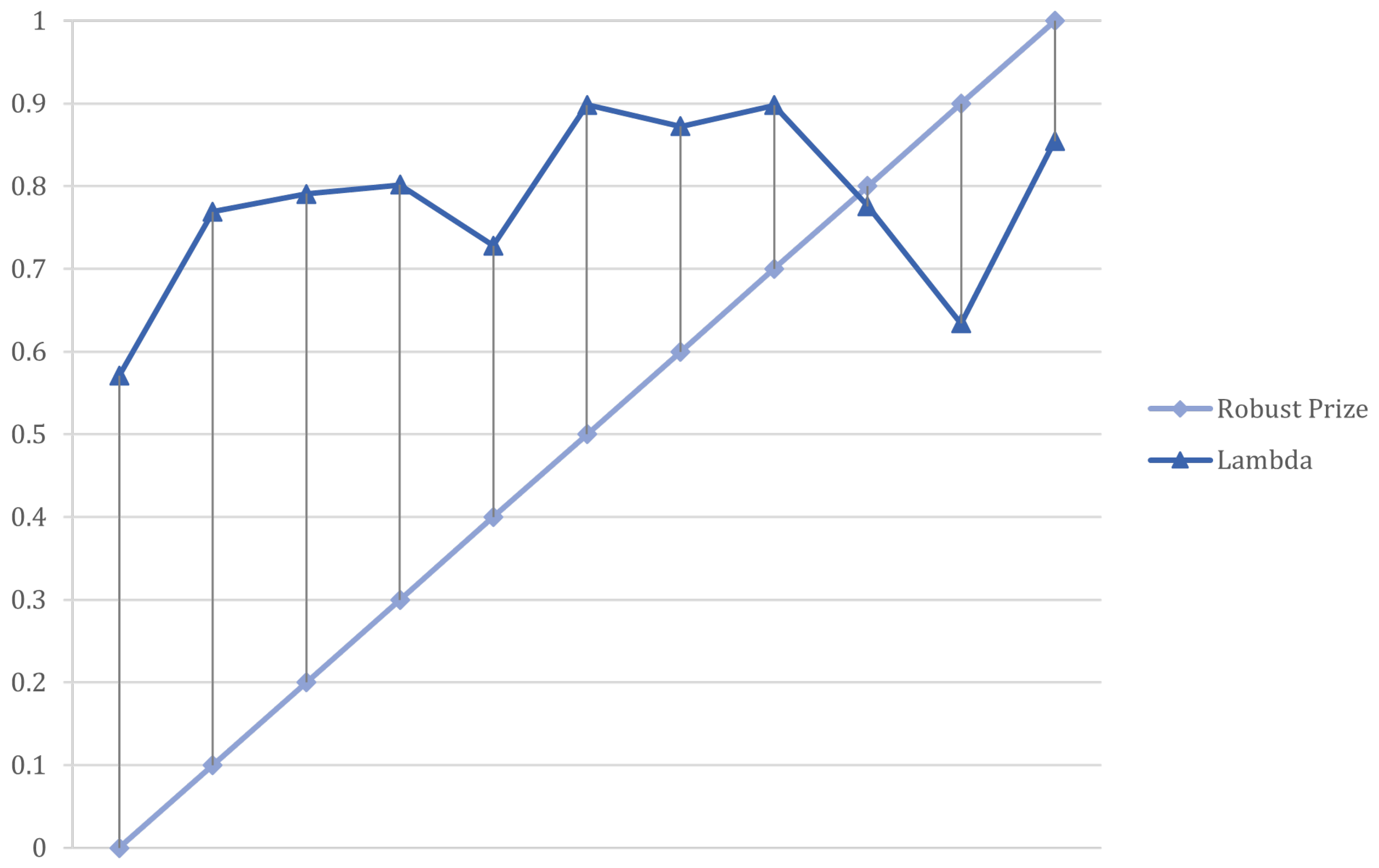

Data and Sensitivity Analysis

5. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Menegaki, M.; Damigos, D. A review on current situation and challenges of construction and demolition waste management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Skoyles, E.R. Waste Prevention on Site; BT Batsford Limited: London, UK, 1987. [Google Scholar]

- Umar, U.A.; Shafiq, N.; Malakahmad, A.; Nuruddin, M.F.; Khamidi, M.F. A review on adoption of novel techniques in construction waste management and policy. J. Mater. Cycles Waste Manag. 2017, 19, 1361–1373. [Google Scholar] [CrossRef]

- Chen, Z.; Li, H.; Wong, C.T. Environmental management of urban construction projects in China. J. Constr. Eng. Manag. 2000, 126, 320–324. [Google Scholar] [CrossRef]

- Cole, R.J. Building environmental assessment methods: Assessing construction practices. Constr. Manag. Econ. 2000, 18, 949–957. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, Y.; Xu, Y.; Nie, Q.; Yang, Z.; Sheng, W.; Qian, G. Municipal solid waste incineration residues recycled for typical construction materials—A review. RSC Adv. 2022, 12, 6279–6291. [Google Scholar] [CrossRef]

- Ponnada, M.R.; Kameswari, P. Construction and demolition waste management—A review. Safety 2015, 84, 19–46. [Google Scholar] [CrossRef]

- Chen, K.; Yang, M.; Zhou, X.; Liu, Z.; Li, P.; Tang, J.; Peng, C. Recent advances in carbon footprint studies of urban ecosystems: Overview, application, and future challenges. Environ. Rev. 2022, 30, 342–356. [Google Scholar] [CrossRef]

- Guarnieri, M. When cars went electric, part one [historical]. IEEE Ind. Electron. Mag. 2011, 5, 61–62. [Google Scholar] [CrossRef]

- Van de Graaf, T.; Colgan, J. Global energy governance: A review and research agenda. Palgrave Commun. 2016, 2, 1–12. [Google Scholar] [CrossRef]

- Yilmaz, M. Limitations/capabilities of electric machine technologies and modeling approaches for electric motor design and analysis in plug-in electric vehicle applications. Renew. Sustain. Energy Rev. 2015, 52, 80–99. [Google Scholar] [CrossRef]

- Oliver, R.K.; Webber, M. Supply Chain Management: Logistics Catches up with Strategy; Chapman and Hall: London, UK, 1982. [Google Scholar]

- Santoso, T.; Ahmed, S.; Goetschalckx, M.; Shapiro, A. A stochastic programming approach for supply chain network design under uncertainty. Eur. J. Oper. Res. 2005, 167, 96–115. [Google Scholar] [CrossRef]

- Bellman, R.E.; Zadeh, L.A. Decision-making in a fuzzy environment. Manag. Sci. 1970, 17, B-141–B-164. [Google Scholar] [CrossRef]

- U.S. Green Building Council. USGBC LEED Green Associate Study Guide; Pearson: Upper Saddle River, NJ, USA, 2011. [Google Scholar]

- Lin, Z.; Xie, Q.; Feng, Y.; Zhang, P.; Yang, Y. An optimal C&D waste logistics network design from contractors’perspective. J. Green Build. 2020, 15, 121–137. [Google Scholar]

- Hannan, M.; Akhtar, M.; Begum, R.; Basri, H.; Hussain, A.; Scavino, E. Capacitated vehicle-routing problem model for scheduled solid waste collection and route optimization using PSO algorithm. Waste Manag. 2018, 71, 31–41. [Google Scholar] [CrossRef]

- Pan, X.; Xie, Q.; Feng, Y. Designing recycling networks for construction and demolition waste based on reserve logistics research field. J. Clean. Prod. 2020, 260, 120841. [Google Scholar] [CrossRef]

- Ahmed, R.R.; Zhang, X. Multi-stage network-based two-type cost minimization for the reverse logistics management of inert construction waste. Waste Manag. 2021, 120, 805–819. [Google Scholar] [CrossRef]

- Shi, Y.; Huang, Y.; Xu, J. Technological paradigm-based construction and demolition waste supply chain optimization with carbon policy. J. Clean. Prod. 2020, 277, 123331. [Google Scholar] [CrossRef]

- Yu, H.; Solvang, W.D. A carbon-constrained stochastic optimization model with augmented multi-criteria scenario-based risk-averse solution for reverse logistics network design under uncertainty. J. Clean. Prod. 2017, 164, 1248–1267. [Google Scholar] [CrossRef]

- Liu, J.; Chai, Y.; Zheng, J.; Dai, J.; Wang, Z. Optimizing City-Scale Demolition Waste Supply Chain Under Different Carbon Policies. Environ. Sci. Pollut. Res. 2024, 31, 25787–25804. [Google Scholar] [CrossRef]

- Halvorsen, E.O.; Andersson, H. Optimizing environmental and economic aspects of collaborative transportation and logistics related to infrastructure projects–A case study from Norway. Waste Manag. 2023, 156, 159–167. [Google Scholar] [CrossRef]

- Akçalı, E.; Çetinkaya, S.; Üster, H. Network design for reverse and closed-loop supply chains: An annotated bibliography of models and solution approaches. Networks 2009, 53, 231–248. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Nagurney, A.; Nagurney, L.S. Sustainable supply chain network design: A multicriteria perspective. Int. J. Sustain. Eng. 2010, 3, 189–197. [Google Scholar] [CrossRef]

- Sarkis, J.; Helms, M.M.; Hervani, A.A. Reverse logistics and social sustainability. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 337–354. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Rabbani, M.; Torabi, S.A. A robust optimization approach to closed-loop supply chain network design under uncertainty. Appl. Math. Model. 2011, 35, 637–649. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Razmi, J. Environmental supply chain network design using multi-objective fuzzy mathematical programming. Appl. Math. Model. 2012, 36, 3433–3446. [Google Scholar] [CrossRef]

- Ramezani, M.; Bashiri, M.; Tavakkoli-Moghaddam, R. A robust design for a closed-loop supply chain network under an uncertain environment. Int. J. Adv. Manuf. Technol. 2013, 66, 825–843. [Google Scholar] [CrossRef]

- Zhang, Q.; Shah, N.; Wassick, J.; Helling, R.; van Egerschot, P. Sustainable supply chain optimisation: An industrial case study. Comput. Ind. Eng. 2014, 74, 68–83. [Google Scholar] [CrossRef]

- Sangwan, K.S. Key Activities, Decision Variables and Performance Indicators of Reverse Logistics. Procedia CIRP 2017, 61, 257–262. [Google Scholar] [CrossRef]

- Bal, A.; Satoglu, S.I. A goal programming model for sustainable reverse logistics operations planning and an application. J. Clean. Prod. 2018, 201, 1081–1091. [Google Scholar] [CrossRef]

- Zarbakhshnia, N.; Kannan, D.; Kiani Mavi, R.; Soleimani, H. A novel sustainable multi-objective optimization model for forward and reverse logistics system under demand uncertainty. Ann. Oper. Res. 2020, 295, 843–880. [Google Scholar] [CrossRef]

- Richnák, P.; Gubová, K. Green and Reverse Logistics in Conditions of Sustainable Development in Enterprises in Slovakia. Sustainability 2021, 13, 581. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Goh, M.; Fazlollahtabar, H.; Mamashli, Z. Modelling uncertainty in sustainable-green integrated reverse logistics network using metaheuristics optimization. Comput. Ind. Eng. 2022, 163, 107828. [Google Scholar] [CrossRef]

- Shi, Y.; Vanhaverbeke, L.; Xu, J. Electric vehicle routing optimization for sustainable kitchen waste reverse logistics network using robust mixed-integer programming. Omega 2024, 128, 103128. [Google Scholar] [CrossRef]

- Najm, H.; Asadi-Gangraj, E. Designing a robust sustainable reverse logistics to waste of electrical and electronic equipment: A case study. Int. J. Environ. Sci. Technol. 2024, 21, 1559–1574. [Google Scholar] [CrossRef]

- Lloyd, J.; McCarney, S.; Ouhichi, R.; Lydon, P.; Zaffran, M. Optimizing energy for a ‘green’ vaccine supply chain. Vaccine 2015, 33, 908–913. [Google Scholar] [CrossRef]

- Duarte, G.; Rolim, C.; Baptista, P. How battery electric vehicles can contribute to sustainable urban logistics: A real-world application in Lisbon, Portugal. Sustain. Energy Technol. Assess. 2016, 15, 71–78. [Google Scholar] [CrossRef]

- Wątróbski, J.; Małecki, K.; Kijewska, K.; Iwan, S.; Karczmarczyk, A.; Thompson, R.G. Multi-Criteria Analysis of Electric Vans for City Logistics. Sustainability 2017, 9, 1453. [Google Scholar] [CrossRef]

- Schiffer, M.; Walther, G. Strategic planning of electric logistics fleet networks: A robust location-routing approach. Omega 2018, 80, 31–42. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, X.; Zhou, X. Distribution Route Optimization for Electric Vehicles in Urban Cold Chain Logistics for Fresh Products under Time-Varying Traffic Conditions. Math. Probl. Eng. 2020, 2020, 9864935. [Google Scholar] [CrossRef]

- Akram, M.N.; Abdul-Kader, W. Electric vehicle battery state changes and reverse logistics considerations. Int. J. Sustain. Eng. 2021, 14, 390–403. [Google Scholar] [CrossRef]

- Zhao, C.; Ma, X.; Wang, K. The electric vehicle promotion in the cold-chain logistics under two-sided support policy: An evolutionary game perspective. Transp. Policy 2022, 121, 14–34. [Google Scholar] [CrossRef]

- Butt, A.S.; Ali, I.; Govindan, K. The role of reverse logistics in a circular economy for achieving sustainable development goals: A multiple case study of retail firms. Prod. Plan. Control. 2024, 35, 1490–1502. [Google Scholar] [CrossRef]

- Ala, A.; Deveci, M.; Bani, E.A.; Sadeghi, A.H. Dynamic capacitated facility location problem in mobile renewable energy charging stations under sustainability consideration. Sustain. Comp. Infor. Syst. 2024, 41, 100954. [Google Scholar]

- Li, Y.; Lim, M.K.; Xiong, W.; Huang, X.; Shi, Y.; Wang, S. An electric vehicle routing model with charging stations consideration for sustainable logistics. Ind. Manag. Data Syst. 2024, 124, 1076–1106. [Google Scholar] [CrossRef]

- Bertsimas, D.; Sim, M. The Price of Robustness. Oper. Res. 2004, 52, 35–53. [Google Scholar] [CrossRef]

- Torabi, S.; Hassini, E. An interactive possibilistic programming approach for multiple objective supply chain master planning. Fuzzy Sets Syst. 2008, 159, 193–214. [Google Scholar] [CrossRef]

- Ben-Tal, A.; El Ghaoui, L.; Nemirovski, A. Robust Optimization; Princeton University Press: Princeton, NJ, USA, 2009; Volume 28. [Google Scholar]

| Paper | Objective | Parameter Type | Aspects | Soloution Approach | Model | Transportation Vehicle | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Multi | Single | Deterministic | Stochastic | Economical | Social | Environmental | Policy | Exact | Hueritics | MILP | MINLP | Electric | Diesel | |

| Lin et al. (2020) [16] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| Hannan et al. (2018) [17] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| Pan et al. (2020) [18] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| Ahmed et al. (2021) [19] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| Shi et al. (2020) [20] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| Yu et al. (2017) [21] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| Liu et al. (2024) [22] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Halvorsen et al. (2023) [23] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| This Paper | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Name | Description |

|---|---|

| V | Set of construction sites; |

| L | Set of labs; |

| Set of landfills; | |

| Set of incineration centers; | |

| Set of recycle centers; |

| Name | Description |

|---|---|

| Waste generated by construction sites v | |

| Capacity of lab l | |

| Capacity of landfill | |

| Capacity of incineration center | |

| Unit operating cost of lab l | |

| Fixed cost of lab l | |

| Unit cost of landfill | |

| Fixed cost of landfill | |

| Unit cost of incineration center | |

| Fixed cost of incineration center | |

| Unit cost of recycling center | |

| Fixed cost of recycling center | |

| Transportation distance from v to l | |

| Transportation distance from l to | |

| Transportation distance from l to | |

| Transportation distance from l to | |

| Unit transportation cost for electric vehicles | |

| Unit transportation cost for electric trucks | |

| Proportion of recyclable material | |

| Proportion of non-recyclable material | |

| Electric vehicle capacity | |

| Electric truck capacity | |

| Electric vehicle distance limit | |

| Electric truck distance limit | |

| Electric vehicle number limit | |

| Electric truck number limit | |

| Electric truck power consumption in km | |

| Electric vehicle power consumption in km | |

| Employment of lab l | |

| Employment of incineration center | |

| Employment of recycling center | |

| Employment of landfill |

| Name | Description |

|---|---|

| 1 if lab l is used; 0 otherwise. | |

| 1 if landfill lf is used; 0 otherwise. | |

| 1 if incineration center ic is used; 0 otherwise. | |

| 1 if recycling centers are used; 0 otherwise. | |

| amount of waste transported from v to l | |

| amount of waste transported from l to | |

| amount of waste transported from l to | |

| amount of waste transported from l to | |

| number of electric vehicles used to transport waste from v to l | |

| number of electric vehicles used to transport waste from l to | |

| number of electric vehicles used to transport waste from l to | |

| number of electric vehicles used to transport waste from l to | |

| number of electric trucks used to transport waste from l to | |

| number of electric trucks used to transport waste from l to | |

| number of electric trucks used to transport waste from l to | |

| number of electric trucks used to transport waste from l to |

| Sites | Category | No. Floors | Concrete | Steel | Brick | Drywall | Square Feet | Total Weight in Pounds |

|---|---|---|---|---|---|---|---|---|

| 1 | Hospital | 12 | 65% | 20% | 10% | 5% | 6900 | 173,052,000 |

| 2 | Speciality Hospital | 6 | 80% | 15% | 5% | 5% | 8000 | 96,480,000 |

| 3 | Speciality Clinic | 9 | 70% | 20% | 10% | 10% | 7500 | 147,150,000 |

| 4 | Hospital | 9 | 60% | 30% | 5% | 5% | 5400 | 118,827,000 |

| 5 | Hospital | 7 | 75% | 15% | 5% | 5% | 9000 | 121,905,000 |

| 6 | Hospital | 12 | 80% | 5% | 5% | 10% | 4200 | 77,364,000 |

| 7 | Speciality Hospital | 17 | 50% | 30% | 10% | 10% | 6000 | 241,740,000 |

| 8 | Sports Clinic | 2 | 80% | 10% | 10% | 0% | 12,000 | 43,440,000 |

| 9 | Speciality Hospital | 9 | 80% | 15% | 5% | 5% | 8000 | 144,720,000 |

| 10 | Hospital | 3 | 60% | 30% | 10% | 0% | 18,000 | 134,460,000 |

| 11 | Hospital | 9 | 75% | 15% | 5% | 5% | 5000 | 87,075,000 |

| Landfills | Capacity (Pounds) | Labs | Capacity (Pounds) | IC Center | Capacity (Pounds) |

|---|---|---|---|---|---|

| 1 | 7,900,000 | 1 | 190,000,000 | 1 | 123,900,000 |

| 2 | 29,500,000 | 2 | 230,000,000 | 2 | 432,800,000 |

| 3 | 76,400,000 | 3 | 1,850,000,000 | 3 | 321,700,000 |

| 4 | 9,500,430 | 4 | 465,000,000 | - | - |

| Site/Lab (km) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 16 | 11 | 12 | 15 | 9 | 14 | 17 | 14 | 10 | 29 | 6 |

| 2 | 25 | 22 | 19 | 17 | 17 | 14 | 15 | 11 | 5 | 21 | 11 |

| 3 | 27 | 27 | 21 | 15 | 20 | 13 | 10 | 8 | 10 | 10 | 16 |

| 4 | 43 | 47 | 39 | 32 | 40 | 31 | 27 | 29 | 34 | 15 | 38 |

| Labs/Landfills (km) | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| 1 | 49 | 80 | 69 | 28 |

| 2 | 39 | 68 | 57 | 27 |

| 3 | 40 | 64 | 52 | 38 |

| 4 | 52 | 60 | 48 | 62 |

| Labs/Recycling Centers (km) | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| 1 | 21 | 4 | 12 | 41 |

| 2 | 33 | 8 | 4 | 33 |

| 3 | 40 | 19 | 15 | 22 |

| 4 | 59 | 43 | 40 | 3 |

| Labs/Incineration Centers (km) | 1 | 2 | 3 |

|---|---|---|---|

| 1 | 14 | 33 | 45 |

| 2 | 21 | 24 | 35 |

| 3 | 32 | 13 | 25 |

| 4 | 56 | 12 | 12 |

| Policy | Recycled | Disposed | Vehicles | Trucks | Power Consumption (wh) | Cost (Rials) | CO2 Emission (g) | |

|---|---|---|---|---|---|---|---|---|

| 1 | 25% | 75% | 76,996 | 358 | 161,625,600 | 205,198,000,000 | 55,428,200 | 0.89 |

| 2 | 50% | 50% | 90,000 | 833 | 363,030,500 | 305,857,000,000 | 50,197,950 | 0.48 |

| 3 | 75% | 25% | 78,299 | 99 | 236,678,900 | 429,797,000,000 | 58,875,050 | 0.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alibakhshi, A.; Saffarian, A.; Hassannayebi, E. Socio-Economical Analysis of a Green Reverse Logistics Network under Uncertainty: A Case Study of Hospital Constructions. Urban Sci. 2024, 8, 171. https://doi.org/10.3390/urbansci8040171

Alibakhshi A, Saffarian A, Hassannayebi E. Socio-Economical Analysis of a Green Reverse Logistics Network under Uncertainty: A Case Study of Hospital Constructions. Urban Science. 2024; 8(4):171. https://doi.org/10.3390/urbansci8040171

Chicago/Turabian StyleAlibakhshi, Alireza, Amirreza Saffarian, and Erfan Hassannayebi. 2024. "Socio-Economical Analysis of a Green Reverse Logistics Network under Uncertainty: A Case Study of Hospital Constructions" Urban Science 8, no. 4: 171. https://doi.org/10.3390/urbansci8040171

APA StyleAlibakhshi, A., Saffarian, A., & Hassannayebi, E. (2024). Socio-Economical Analysis of a Green Reverse Logistics Network under Uncertainty: A Case Study of Hospital Constructions. Urban Science, 8(4), 171. https://doi.org/10.3390/urbansci8040171