1. Introduction

Because of the near-term risk of extreme weather events and other adverse consequences from climate change and, in the longer term at least, global fossil fuel depletion, there is worldwide interest in shifting to noncarbon energy sources, especially renewable energy (RE). Although the ability of RE to provide for expected future global energy levels is hotly debated, some researchers have argued that RE cannot take over from fossil fuels (FF) [

1,

2,

3,

4,

5,

6]. They have variously argued that land constraints will limit output and that several existing forms of RE, especially bioenergy and hydro, have their own serious environmental problems. Further, the intermittent nature of the output of the two most promising sources, wind and solar, will necessitate energy conversion and storage [

7,

8]. Not only will costs rise because of the extra equipment needed, but energy losses at each stage (for example, converting intermittent electricity from wind turbines into hydrogen via electrolysis for storage, and perhaps later followed by reconversion into electricity) will significantly lower the system energy return on energy invested (EROI).

Researching new alternatives to conventional RE is, therefore, worthwhile, and this paper examines several cutting-edge RE technologies. In any case, as an eponymous 2019 article in

New Scientist [

9] documents, “The renewables revolution is stalling”. Furthermore, CO

2 emissions from fossil fuel (FF) combustion, far from falling, are still growing [

10]. Partly because of this disappointing growth in RE, a large number of even more ambitious schemes to counter global warming have been proposed. These include various carbon dioxide (CO

2) removal schemes, either biological (reforestation, etc.) or mechanical (CO

2 removal from fossil fuel stacks, or even directly from the air, followed by sequestration). Geoengineering proposals would aim to directly increase the planetary or regional albedo—the proportion of insolation directly reflected back into space—with solar radiation management the most popular proposal [

8]. This paper does not discuss these any further, but they remain as possible alternatives to either conventional or new RE.

A vast number of alternatives to conventional non-fossil fuels sources have been proposed, and many of these have been tried [

11]. Some are conventional technologies that are freed from ground-based constraints, moving to the troposphere (airborne wind energy systems), or even into space (solar satellite power). Humans have long tapped the kinetic energy of moving fluids, as in wind energy and hydropower. New proposed energy sources from moving fluids include wave energy and tidal and ocean current energy. New energy gradient sources for heat engines could include ocean thermal energy conversion (OTEC), enhanced geothermal systems and even the temperature gradient between earth and space. Yet others would shift from the millennia-old use of bioenergy from complex plants (trees, shrubs and grasses) to unicellular plants like microalgae and cyanobacteria. Even the osmotic transition between river fresh water at estuaries and the ocean could be a source of energy. Nuclear fission power is now in its seventh decade, but serious (and ambitious) attempts are now being made to harness fusion energy. Finally, existing technologies can be combined: as an example, photovoltaic (PV) cell technology can be combined with electrolysis in photolysis.

Given the large range of choices, a selection had to be made. The rest of this review paper has the following organization:

Section 2 outlines the criteria used for selecting the three new RE technologies chosen from the above list, and the criteria used in evaluating these technologies.

Section 3,

Section 4 and

Section 5 critically discuss, in turn, microalgae for fuels, photolysis and airborne wind energy systems. The details of each novel technology are first described, followed by an analysis of their suitability. The overall finding is that these new technologies will have difficulty in meeting the expectations of their supporters.

Section 6 discusses the findings, and

Section 7 draws general conclusions, which are potentially relevant for the introduction of possible other high-technology solutions in the energy field.

2. Methods

As already discussed, one new energy technology was selected from each of the three key RE technologies: biomass, solar, wind. Other RE technologies, such as tapping the osmotic transition between rivers and ocean is novel, but its potential is minor, no greater than the hydropower potential of the same rivers [

12]. The paper is based on a literature search of articles on the relevant topics available in English. Given the large number of articles available for the chosen technologies, preference was usually given to recent research articles, since these are likely to include the latest technological and scientific advances, as well as a discussion of important earlier papers.

The new technologies for examination were chosen using the following criteria as guidelines:

The technologies must be genuinely novel, with no commercial plants in operation;

Stated large technical energy potential for the technology;

Potentially could solve one or more problems facing the more conventional forms of that RE source, such as intermittency or land take-up;

Potentially could compete on costs with conventional RE technology.

Based on these criteria, three new technologies were selected: microalgae for fuel production, photolysis and airborne wind turbines. These three are novel forms of bioenergy, wind energy and solar energy, respectively. Other possible bioenergy/solar/wind technologies did not meet all these selection criteria. Cellulosic liquid fuels, PV cells integrated into building materials and offshore wind were considered, but none are novel. Satellite power systems [

13], although discussed for four decades, face too many difficulties to be considered a viable energy source.

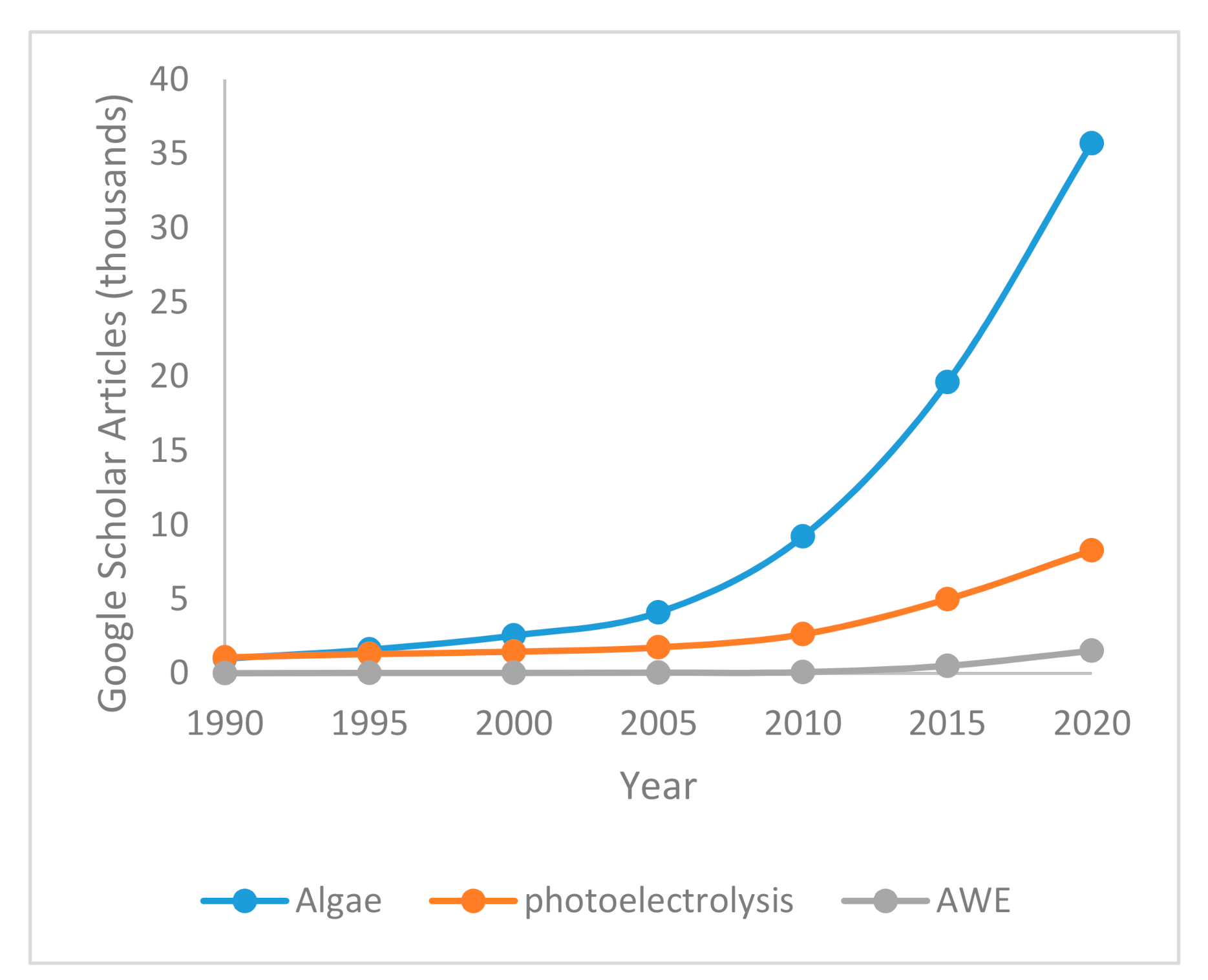

Figure 1 shows cumulative growth in Google Scholar articles over the years 1990–2020. The search terms used were “microalgae” + “fuel”; “photoelectrolysis” +”photoelectrochemistry”; and “airborne wind energy” (AWE), respectively. “Fuel” rather than “energy” was used to qualify microalgae, and “photoelectrolysis” + ”photoelectrochemistry” was used instead of the general term “photolysis” (used for simplicity in this paper) in order to eliminate papers not concerned with energy production. The research literature on airborne wind turbines is much smaller, but a number of commercial companies have entered the field [

14,

15], and research and development on the topic is being undertaken at a large number of institutions [

16].

Where information was available, each of the new technologies chosen was examined using the following criteria:

Energy return on energy invested (EROI) and comparisons with conventional RE sources;

Economic cost per unit of fuel and comparisons with conventional RE sources;

Resource requirements (mainly land use, but also water and key materials where relevant) per unit of energy;

Climate change and other environmental implications.

An important point to remember when comparing the new technologies with their conventional RE technologies is to compare like with like. Since none of the new technologies is operational (with the exception of low-volume microalgae, but even here only for special high-priced products, not energy), there is a tendency to compare ideal systems with actual operation of existing ground-based wind farms, for example. This can give an unrealistic view of costs and EROI for the new technologies. On the other hand, it is inevitable that early production costs for new technologies will be higher than that for established ones with large production runs.

3. Microalgae for Fuels

Although, similar to fossil fuels, conventional bioenergy can be readily stored and so is available on a continuous basis, some researchers doubt that conventional bioenergy can be a major RE source in the future because of competition for fertile land and water from agricultural production needed for food (e.g., [

17]). At present, all liquid biofuels are derived from food crops, even though global basic nutritional needs are not being met even today. Some researchers have argued that microalgal energy production can overcome this problem, since microalgae can utilize land not suited for agriculture and can use brackish water or even wastewater in need of purification [

18,

19]. Davis et al. [

20] have even discussed Saudi Arabia as a suitable location for large-scale microalgae cultivation. Further, microalgae can be selected to produce high percentages of oil, which can be directly used in vehicles in a manner similar to biodiesel. Microalgae, along with bacteria, can also be selected or genetically engineered to produce hydrogen [

21,

22,

23,

24], possibly a key future fuel.

Microalgae are very simple organisms, and 50,000 species have so far been described from the hundreds of thousands that are estimated to exist. These single-celled organisms, together with bacteria, form the base of the food web. Unlike higher plants such as trees, shrubs or grasses, microalgae do not need any roots, supporting stems or leaves. The whole of the plant can thus be harvested, unlike land-based bioenergy crops, where roots and often stover from cereal crops must be left in place to maintain soil fertility and prevent soil erosion.

A number of reviews of microalgae for fuels are available, including several published in 2020 (e.g., [

18,

25,

26,

27]). However, none of them cover all four of the criteria for evaluating novel RE sources listed in

Section 2. They cannot, therefore, give a complete picture for microalgae fuel prospects.

Ketzer et al. [

24] recently reviewed the EROI for energy production from microalgae in both shallow open ponds and closed reactors. The energy inputs were mainly for cultivation and downstream processing, with a lesser input for harvesting. The studies reviewed showed very low EROI for production from closed reactors—all six studies had EROI values much less than 1.0, with several below 0.1. For open ponds, the values were higher, but only in three of the 17 studies reviewed did the EROI exceed 1.0. However, the high EROI value of Campbell et al. [

28] was mainly the result of a very high estimate of annual microalgal yield of 109.6 ton per hectare. Larkum [

29] and Walker [

30] are both very skeptical of such high yield values, with Larkum pointing out that the natural primary production of microalgae (phytoplankton) in lakes and oceans is “very low”.

Reasons for such low natural production include a low level of natural stirring (from wind or ocean currents) and a low level of available nutrients. The leaves of higher plants are very efficient for CO2 diffusion from air, but such is not the case for CO2 diffusion in a water medium. Energy intensive mechanical stirring is thus needed for both CO2 and nutrients to be available to microalgae. However, if ponds were located next to fossil fuel plants, flue gas CO2 could be used for CO2 fertilization.

The unit costs for microalgal biomass are presently very high, mainly because the production is chiefly for specialty products produced in bioreactors. Fernandez et al. [

31] have reported costs “ranging from minimum values of 5 €/kg for raceway reactors to 50 €/kg for tubular photobioreactors”. (The equivalent US costs are about USD 5.65 and USD 56.5 per kg, respectively.) Roles et al. [

32], in a detailed cost analysis of biodiesel in an Australian context, found that estimated prices would be several times current prices for diesel but could be reduced to current levels given (optimistic) improvements. Although shallow ponds have much lower costs [

33] and higher EROI than closed reactors, they have two significant disadvantages. Shallow ponds inevitably suffer from evaporation losses, a problem if water is scarce [

34]. Deeper ponds such as used in raceways (typically around 0.3 m deep) would suffer smaller annual losses as a proportion of total water. Regardless of configuration, the need of sunlight for photosynthesis limits depth. While showing much larger production rates than ponds, bioreactors are similarly limited but in reactor solar tube diameter, with 0.1 m being a typical value [

35]. Because of these restrictions, microalgal cultivation on a grand scale would still have high land requirements.

Relative to land-based crops, energy production per unit land area from microalgae is greater, but it remains lower relative to other land use options such as PV. On an energy equivalent basis, depending on algae type and whether production occurs in a pond or bioreactor [

35], in areas with moderate to high average insolation (20 MJ/m

2/day), 2–6% of the available solar energy could be expected to be returned as energy in the liquid fuel produced. If used as a transport fuel, the low efficiency of combustion engines would result in an even lower return on the insolation via the liquid fuel relative to use of the insolation via PVs to power electric vehicles.

Many of the papers published on microalgae for fuels stress its potential role in directly providing biodiesel for transport, without the conversion needed for bioethanol from terrestrial plants. However, many cities and countries have plans to banish internal combustion engine vehicles, some as early as 2030 [

36]. In this case, liquid algae-based fuels, which cannot be expected to be produced in quantity for at least a decade, would have no future, even as a stopgap fuel. Nevertheless, algae-based hydrogen and air transport fuels would remain possibilities. There is a further problem: similar to all plant matter, microalgae need nutrients for growth. Reijnders [

37] has pointed to the key fertilizer, phosphorus, being a limiting factor in future.

A 2010

New Scientist article [

33] acknowledged the much higher cost of bioreactor-produced fuels, but for shallow pond cultivation presented a graph comparing the cost of conventional diesel and microalgal biodiesel. In 2009, biodiesel was estimated as 10 times more expensive, but by 2017, microalgal biodiesel was projected to be cheaper than conventional diesel. Similarly, Wesoff [

38] has detailed the rush to microalgae by venture capitalists between 2005 and 2012. He discussed some of the optimistic projections from that time as follows: “Jim Lane of Biofuels Digest authored what was possibly history’s least accurate market forecast, projecting that algal biofuel capacity would reach 1 billion gallons by 2014. In 2009, Solazyme promised competitively priced fuel from algae by 2012. Algenol planned to make 100 million gallons of ethanol annually in Mexico’s Sonoran Desert by the end of 2009 and 1 billion gallons by the end of 2012 at a production rate of 10,000 gallons per acre.”

As with the low-cost forecast in

New Scientist, these forecasts had no basis in reality, and the companies still involved are (again) concentrating on high-cost pharmaceuticals and food additives. Although inevitable disillusionment has set in, the hype cycle may yet repeat itself, as has happened with other technologies such as electric vehicles and hydrogen as a fuel. Notwithstanding the exit of (most) venture capital, research has continued seemingly unabated, as evidenced by the thousands of articles published since 2012 (see

Figure 1).

4. Photolysis

The potential for solar energy appears enormous, since the quantity of annual solar radiation intercepted at the top of Earth’s atmosphere is four orders of magnitude larger than present global primary energy consumption [

39]. (Nevertheless, de Castro et al. [

2,

3] argued that the technical potential for solar electricity is far less than usually estimated.) As is also a problem for wind power, solar energy is intermittent, though more predictable than wind. Particularly in regions with pronounced winters, solar energy output will be very low for several months each year and zero at night for all regions [

5].

All the fossil fuels we use, as well as bioenergy, are ultimately products of photosynthesis. Nicola Jones [

40] defined this process as follows: “Photosynthesis is all about using the sun’s energy to split water into its constituents, hydrogen and oxygen, and rearranging them into chemically more energetic molecules—in the case of plants, carbohydrates made with the help of atmospheric carbon dioxide”. With bioenergy, intermittency is not a problem, as the energy can be naturally stored as standing biomass or harvested and stored such as coal. Therefore, although plant photosynthesis for land-based crops averages only about one percent efficiency compared with 15–20% for commercially available PV cells, plants store their energy in the form of chemical bonds—fuel—rather than electrons [

41]. The problem with natural plant photosynthesis is not only its low efficiency, but also that the products contain carbon as well as hydrogen; when combusted, they produce climate-changing CO

2 as well as water. Although the CO

2 produced will be recycled during the next growth, net reduction in CO

2 from the atmosphere requires the carbon to be permanently stored in the biomass. The aim now is to employ artificial photosynthesis to produce a carbon-free fuel—hydrogen—leaving biomass to act as a carbon store, rather than a recycler of carbon.

One possible solution to this intermittency problem is to use excess solar electricity (or other intermittent RE electricity surplus to grid needs) to power water hydrolysis to produce hydrogen. This hydrogen can then be compressed and stored or used directly in hydrogen fuel cells for stationary or vehicular power, or even mixed at low concentrations and fed into existing reticulated natural gas systems [

36]. Although coupling such excess electricity to electrolysers for hydrogen production, then using the hydrogen directly as a fuel has greater overall efficiency than re-conversion of the stored hydrogen back to electricity (50–60% compared with 27–38% for the full cycle) [

42], the overall efficiency could still be improved. (Of course, if overall efficiency is measured as the ratio of H

2 output to solar energy input, the resulting figure is much lower.) A variant of this is to have the PV array dedicated to the electrolyser, which enables both optimization of the PV array for electrolysis and possible use of direct current, but in this case, hydrogen transport is needed. In either case, the arrangement is known as photovoltaic-driven electrolysis, and, in terms of components, at least, is a mature technology. Liquid electrolyte alkaline electrolysers have now been available commercially for over a century [

43].

Photolysis (also called photoelectrolysis or photo-electrochemistry) is seen by many researchers (e.g., [

40,

43,

44]) as a means of improving this efficiency, by integrating the electricity production and electrolysis steps. Nikolaidis and Poullikkas [

45] have offered a simple description: “Photolysis, in general, is effected when the energy of visible light is absorbed with the help of some photo-catalysts and is then utilized to decompose water into H

2 and O

2 [...]. In photo-electrolysis, the sunlight is absorbed through some semiconducting materials and the process of water splitting is similar to electrolysis.” Dincer and Acar [

46] reported a recent production cost estimate for photolysis hydrogen of 10.4 USD/kg, far higher than for any other H

2 production method. (Nevertheless, Singh et al. [

23] in the same year presented H

2 production costs much higher than USD10.4/kg for nearly all production methods, including the use of conventional PV arrays and electrolysers. It appears that no H

2 costs can be taken as given).

An important question is whether integrating PV cells and electrolysis is worth doing. Its obvious competitors have already been mentioned: PV arrays dedicated to physically separate electrolysers, or electrolysers run off mixed RE electricity sources. Can PV-electrolyser integration both increase large-scale system EROI and lower costs compared with these alternatives? At the present early stage of development, these questions are difficult to answer. Land needs should be similar to those for conventional PV farms.

The problem is in choosing the right semiconductor materials, and large numbers have been tried. For direct water dissociation to occur, the semiconductor material has to simultaneously meet a number of exacting chemical criteria [

44]. This may explain, why, even after four decades of research, water photolysis can still be regarded as being in the early stages, particularly with regard to the ultimate aim of large scale H

2 production. For large-scale commercial application, of course, the materials must be readily available at low cost, and the optimal tradeoff between efficiency and cost determined. A further factor acting to limit large-scale development is that while traditional electrolysis systems can operate under low light conditions and even overnight if coupled to a RE supplied grid or to a standalone RE system such as concentrating solar power with heat storage, photoelectrolysis systems can only operate when there is sufficient light.

As mentioned, an important advantage of being able to physically separate the production of electricity from the electrolysis of water is that the hydrogen can be produced on site (for example, at a truck freight depot). The electricity transmission and distribution networks are vast, but the existing pipeline network for H2 is limited. Further, there is then no limit on the size of the electrolyser plants; they are presently commercially available in sizes ranging from a fraction of an MW size up to multi-MW size. If grid electricity is used, the electrolyser plants can also be run continuously.

5. Airborne Wind Energy Systems

Several major problems hinder conventional wind power development. In many regions, average wind speeds are too low to give an adequate EROI for wind farms erected there. Even if average wind speeds are sufficient to give an adequate EROI, the wind is variable, with periods of low to zero output. Land-based wind farms also face a number of environmental problems, including bat and bird collisions with turbines, and opposition from nearby residents because of perceived visual obtrusion on the landscape or turbine noise and vibration. One solution is to move windfarms offshore, and an increasing number of these are being constructed, particularly in the North Sea off Europe.

A more radical solution to these problems is to make the wind turbines airborne. Marvel et al. [

47] found that a global potential of 400 terawatt (TW = 10

12 watt) was available from ground-based turbines, but vastly more (1800 TW) from airborne devices, compared with about 18 TW of global primary power consumption from all energy sources today. They concluded that human extraction of wind energy would have little effect on Earth’s climate. Research on Airborne Wind Energy Systems (AWESs) started in the 1970s was almost abandoned in the 1990s but has seen rapid growth in recent years [

48].

Wind turbines constructed close to the ground encounter a variable vertical wind profile and lower wind speeds compared with higher altitudes [

49]. Winds are also less intermittent at high altitudes. Other possible advantages are that towers and heavy foundations necessary for ground-based turbines can be dispensed with. Further, maintenance can be done on the ground, as all designs are tethered and can be winched back to the surface. The ground stations themselves can be fixed or can even move in pre-determined, coordinated patterns. For example, the ground stations, each connected to an AWES, could move along a closed-loop or open-loop rail line [

49].

Three basic types of AWESs have been considered, a large variety of prototypes have been designed and tested [

15,

50,

51] and hundreds of patents have been granted. A review by Watson et al. [

48] contains a full classification and description of the various approaches possible for AWESs but warned that “convergence towards the best architecture has not yet been achieved.” (Given the risk these may pose, the emphasis is on engineering design in patents for AWESs, in contrast to the other two new, more science-based, technologies discussed in this paper.) Hence, unlike ground-based wind turbines, no standardized designs are on the horizon, which makes any possible large-scale implementation decades away. The simplest AWES is to fix one or more turbines to a large helium balloon. This approach is restricted to relatively low altitudes (around 200–600 m), because at higher altitudes not only must the size of the blimp increase for a fixed payload, but blimps also encounter higher wind speeds and so considerable drag [

52]. Similar to all AWESs, the blimp must be tethered to a winch on the ground by a strong cable, which (except for kite designs) must also be able to conduct electric power from the turbines. For all airborne types, high tech materials with a high tensile strength to weight ratio will be needed to reduce the weight of the tethers, which could be up to several kilometers long. Tethered balloons are already used for other purposes, so the technology is well established, as are aviation laws governing their safe use, although the prospect of a live tethered cable could require additional regulation.

A second approach to AWESs employs a tethered “aircraft” (or rotorcraft) with one or more wind turbines to generate electricity on-board, then transmit this to a fixed or moveable ground station. The aircraft produce electric power except when taking off and landing, when they are net power consumers. For all AWESs, there is a conflict between the higher wind speeds available at greater altitudes, and safety and cable drag considerations, which favor lower altitudes. A paper by Roberts et al. [

53] has discussed one such approach: “At 15,000 ft (4600 m) and above, tethered rotorcraft, with four or more rotors mounted on each unit, could give individual rated outputs of up to 40 MW. These aircrafts would be highly controllable and could be flown in arrays, making them a large-scale source of reliable wind power”.

The technology that departs most from conventional turbines would employ kites to generate energy. The tethered kite (an airfoil) is connected to a ground-based generator with two cables. When the kite is released into the air, tension in one cable as the kite ascends can be used to drive a generator. In the second phase, the kite is reeled in, using the generator as a motor; the angle of attack of the kite is reduced, thus lowering line tension. The energy generated during the “reel out” part of the cycle exceeds the energy needed for the “reel in” part [

15,

51]. Unlike other AWES designs, no power cable is needed, but sophisticated control systems are essential. Arrays of these could operate in pairs to achieve stable supply over the two phases of operation.

Lunney et al. [

50] examined the feasibility, potential and costs of air borne turbines in a Northern Irish context. They found that at a fixed altitude of 3000 m, turbines could be flown over 5110 km

2 of the region, which has a total area of 14,130 km

2 and lies roughly between 54–55° North. These authors attempted an initial cost estimate for a 2 MW “pumping” kite device. They calculated a total cost GBP 1.75 million, or GBP 0.875 million for each MW, which cost they regarded as comparable with conventional wind turbines. At 2016 exchange rates and prices, this comes to USD 1.34 million per MW.

Costs were also estimated in the paper by Roberts et al. The costs were for a 100 MW array, consisting of individual 3.4 MW output “flying electrical generators”, each weighing 9.5 ton. Including ground base costs, each 3.4 MW unit was estimated to cost USD 2.26 million, assuming production rates of 250 per year. Including balance-of-system costs brought total costs for 100 MW to USD 71.2 million, or USD 0.712 million per one MW, presumably in 2006 money values. Expressed in 2016 values [

54], a value of around USD 0.85 million per MW is obtained, less than the estimated unit cost of the Northern Irish pumping kite. The difference may be due to the Roberts et al. paper assuming volume production of the units. Estimated costs for conventional wind turbines in 2016 were somewhat higher [

55] but included several cost items missing from the AWES analyses.

In the Roberts et al. paper, an energy analysis was also performed for three possible sites in the US. For the best site, above Topeka, Kansas, in the Great Plains, a capacity factor of 91% was calculated. Although downtime for storms, maintenance, etc., would reduce capacity factors, they should still be far higher than conventional ground turbines, with a capacity factor of typically around 30% or less. For an EROI calculation, input and operating energy costs are needed as well as output energy, but these were not calculated. For a conventional turbine with 3.0 MW rated output, Crawford [

56] has estimated that tower and foundation materials only accounted for around 25% of total embodied energy. AWES would not need a tower, and the heavy foundation could be replaced by a lighter cable anchor, but energy costs of the cable, ground station and far longer road and transmission network would more than neutralize these savings. Until such AWES are operational, their EROI must remain speculative.

Safety is a key consideration for airborne modules. For both safety and environmental reasons in the Lunney et al. analysis, areas above, for example, towns and cities, transport corridors and nature reserves, were excluded. Air transport corridors and airports represent a special hazard, as airborne device heights will overlap with aircraft heights. Power lines are another obvious hazard; lightning strikes will also pose a potential risk. During storms it may be necessary to reel the AWESs back to ground. Clearly, at a minimum, the maximum tether length provides the radius for exclusion zones for each AWES. Within each airborne wind farm the minimum device spacing is also the maximum tether length. Depending on length and materials used, the tethers themselves could weigh several tons.

6. Discussion

It is useful to distinguish between “known unknowns” and “unknown unknowns” [

57]. This review has already discussed some of the former, but they may also be “unknown unknowns” facing any radically new technology. An important example of the latter is the use of chlorofluorocarbons (CFCs) for refrigerants, which were safer to use than the existing ones. Many decades later, such CFCs were found to damage the ozone layer, which helps shield us from ultraviolet radiation.

Both sets of problems can arise for any of several reasons. Given the current growth in atmospheric CO

2 concentrations, the world is unlikely to stay beyond the 2 °C above pre-industrial limit, let alone the more ambitious 1.5 °C limit. Hence, climate change will be ongoing; the climate in several decades time could be very different from that of today—a “no-analogue” climate. Even the next 0.5 °C rise in global temperatures could lead to a very different world [

58]. Such a change could have adverse consequences for conventional RE sources [

8], which,

ceteris paribus, should encourage development of the new RE technologies such as those discussed here. On the other hand, these could also be adversely affected. For example, both surface wind patterns and upper tropospheric wind patterns could shift under climate change, but such changes are difficult to predict [

59]. Another possible factor that could act to alter the future for these technologies could arise from the need to use scarce, exotic or expensive materials, for example in the catalysts used in photolytic plants or in the materials used for the tethering cables of the airborne wind turbines. As Van den Bergh and colleagues argued [

60], we may merely be exchanging one environmental problem for another.

Table 1 summarizes how each of the three technologies fare against the four criteria listed in

Section 2. In a sense, the entries in the table, given the findings in this paper, are optimistic; none of the systems are in commercial operation and experience with new energy technologies suggests that yet unknown problems will present themselves. For example, costs and EROI for these new technologies will be a tug-of-war between technological advances, which should improve both, and unexpected problems that inevitably arise from attempting to scale up from laboratory experiments to deployment of real large-scale systems.

Experience with fusion technology illustrates this point. The multi-national ITER reactor being built in Cadarache, France, was initially estimated to cost USD 11 billion and to be operational by 2006, but by 2016, costs had blown out to around three times the initial estimate, and it is now expected to be operational by 2025 at the earliest, and likely later [

61]. On the other hand, it is also at least possible that unexpected events could favor these new RE technologies.

7. Conclusions

For commercial success, the new technologies have to prove themselves as superior in important respects (such as costs or efficiency) to the conventional RE technologies they hope to displace, or at least complement. Sampaio and Gonzalez [

62] have discussed recent advances in conventional PVs. It is clear that these are far from reaching a dead end. A range of new materials have been shown to be feasible, and the efficiency of PV cells is still rising. Annual PV cell installed capacity is now large enough (at 98 GW in 2019, with a 2019 growth rate of 20% [

10]) to economically support a variety of PV cell types. It may be that the further step, photolysis, is just too complex for large-scale implementation. Each of the technologies promised to solve a key problem with existing the RE: land availability for microalgae fuel; the need for separate electrolysers for converting intermittent PV output to H2; the variability of wind speeds for ground-based turbines. However, in each case, fresh problems arose, calling into question their overall feasibility.

Another important consideration is the timing for introduction of the new RE technologies. If a temperature rise of 1.5 °C above the preindustrial is taken as the limit for avoiding severe anthropogenic climate change [

58], then the remaining global CO

2 budget is very small; on present trends, it will be exceeded as early as 2022 [

63]. Smil [

64] has argued that it takes decades for new energy technologies to establish themselves. As we have shown, for each of the three RE technologies considered, there is presently no consensus on the best approach to tapping any of these novel energy sources. Many are still at the laboratory or simulation stage, so that large-scale commercial production is decades away. As the comparatively recent introduction of wind and solar energy show, new energy sources can succeed. Nevertheless, this paper shows the difficulty in attempting to introduce, on a large scale, competitors to established (and successful) forms of renewable energy.