Review of EDM-Based Machining of Nickel–Titanium Shape Memory Alloys

Abstract

1. Introduction

1.1. Introduction to Shape Memory Alloys (SMAs)

- Medical devices: stents (especially nitinol), orthodontic archwires, surgical tools, and guidewires;

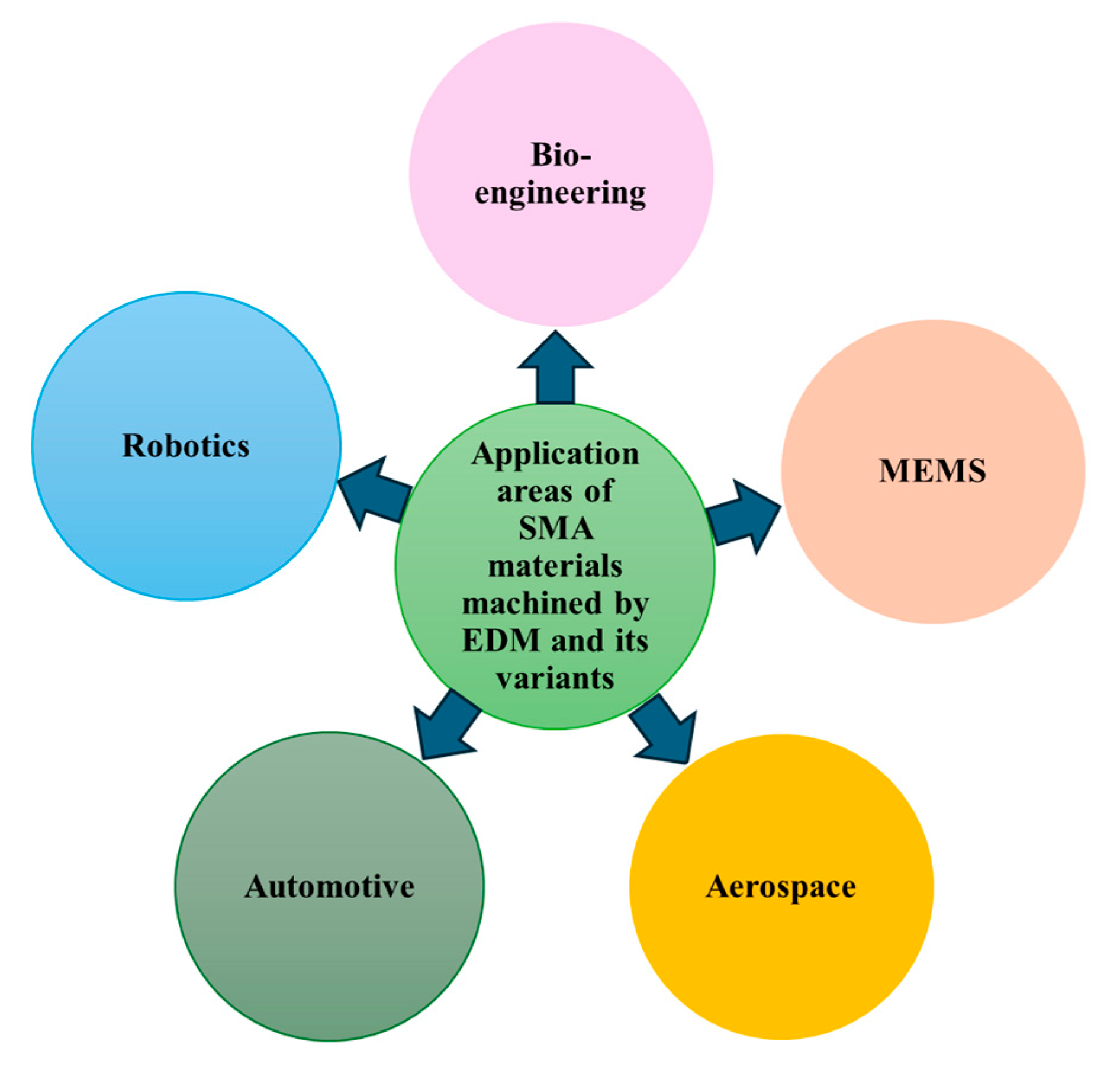

- Aerospace: actuators for morphing structures, temperature-activated couplings, and fasteners;

- Automotive systems: temperature control actuators, crash sensors, and variable-geometry engine components;

- Robotics and automation: micro-actuators, soft robotics, and artificial muscles;

- Consumer electronics: shape-retaining eyeglass frames and mobile device components (e.g., lens actuators);

- Civil engineering: seismic dampers in buildings and self-healing structures.

1.2. Machining Challenges of SMA (NiTi Alloy)

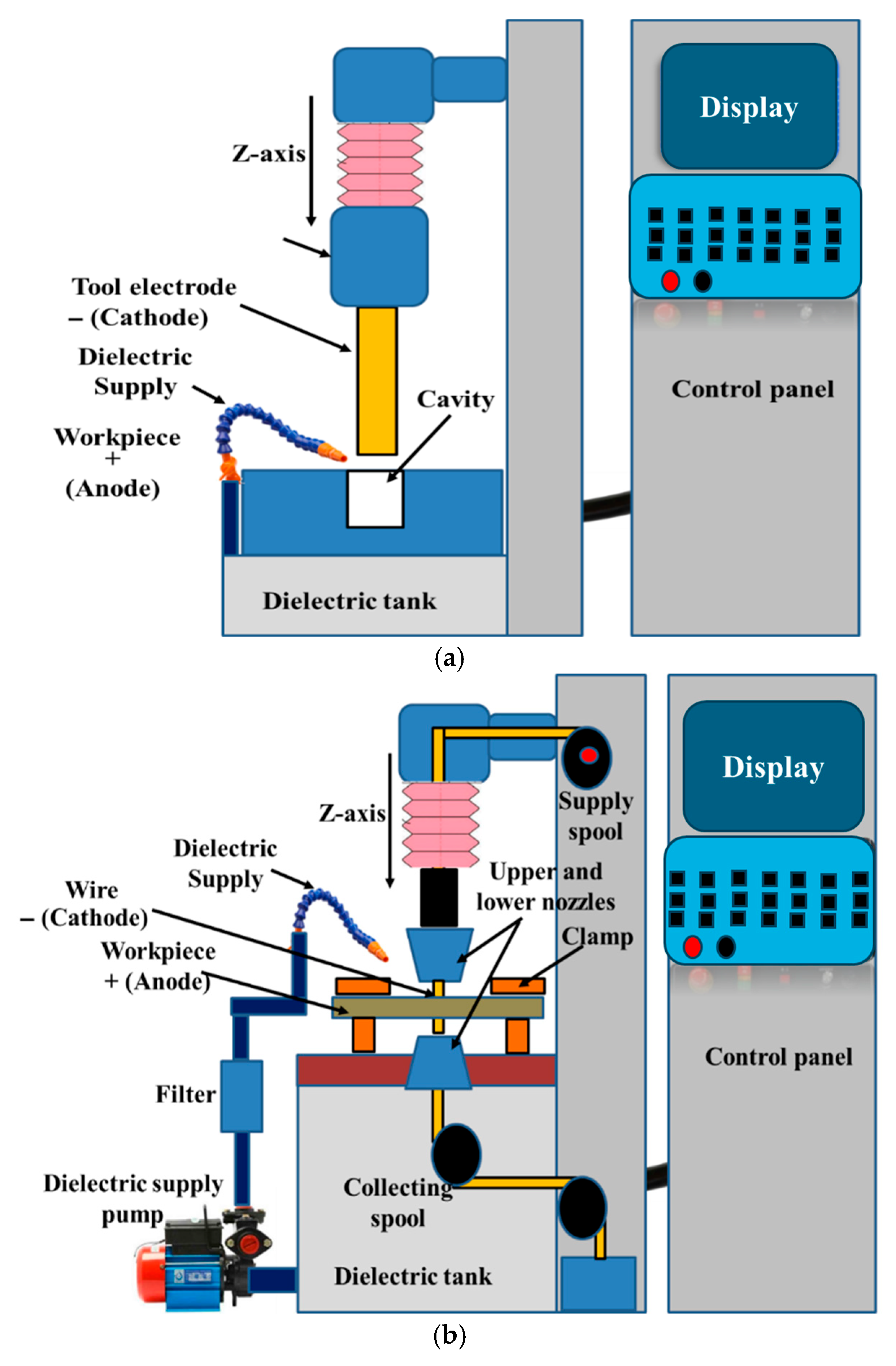

1.3. Introduction of EDM Processes

1.3.1. Fundamentals and Working Principles of EDM-Based Machining Processes

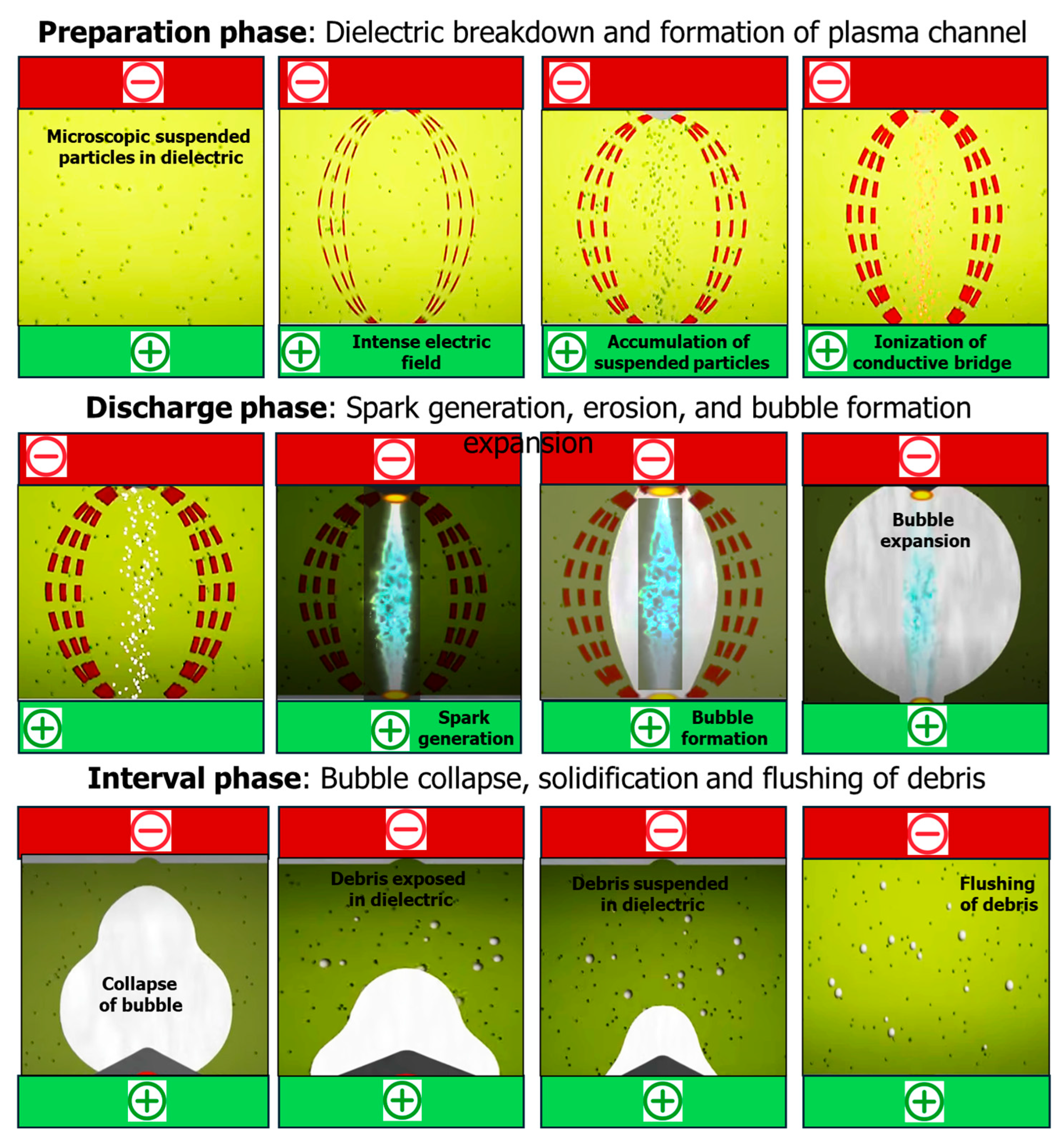

1.3.2. Material Removal Mechanism of EDM-Based Processes

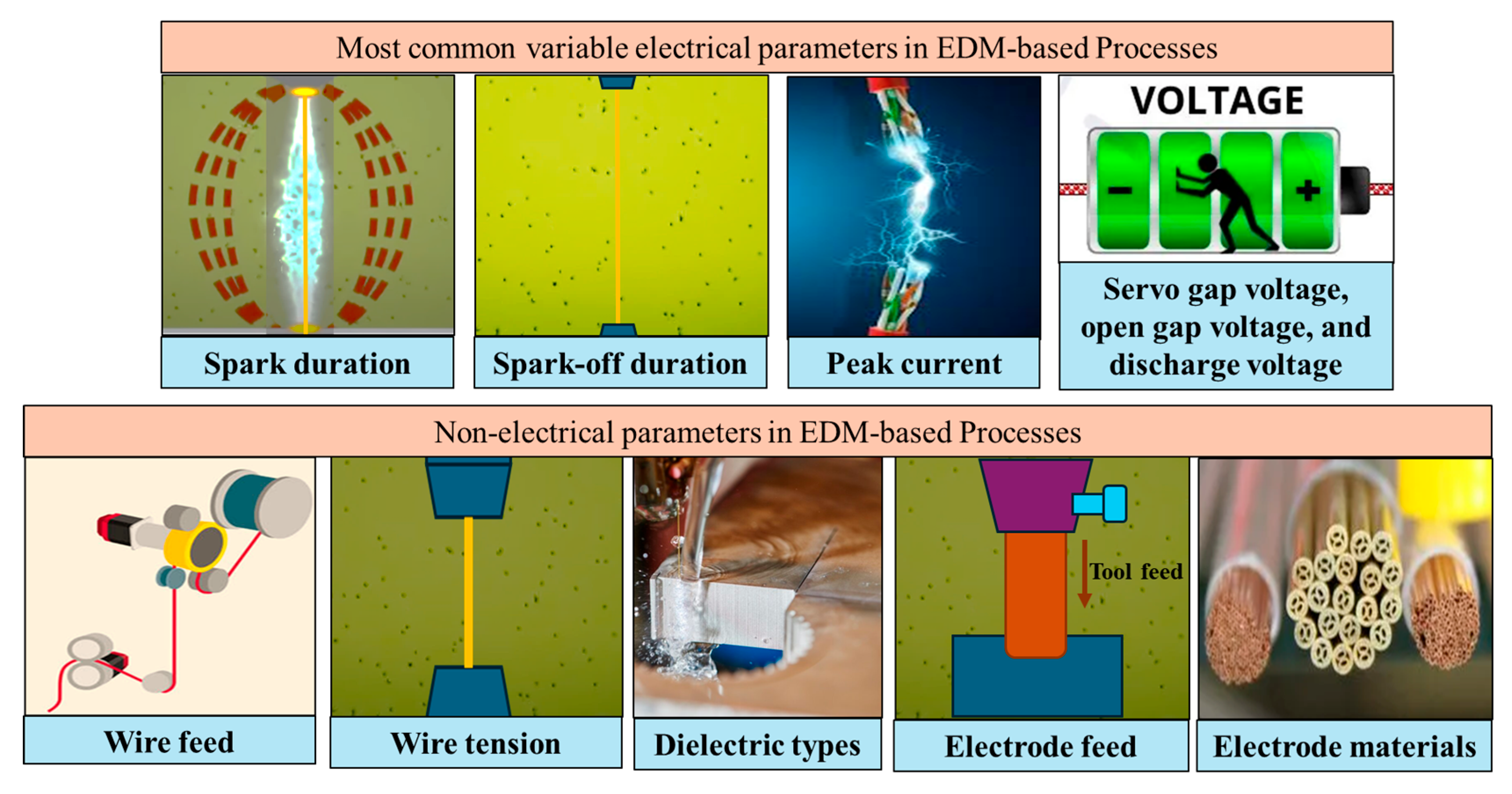

1.3.3. Key Variable Parameters and Their Functional Roles in EDM-Based Processes

1.3.4. Benefits and Applications of EDM-Based Processes for SMAs

1.3.5. Effect of EDM-Based Processes on Phase Transformation of NiTi-SMA

1.4. Other Non-Traditional Processes for Machining SMAs

2. Past Research Work on Machining SMAs by EDM and Allied Processes

2.1. Past Work on Machining SMAs Using Conventional EDM and Its Variants

2.2. Past Work on Advanced and Hybrid-EDM Processes for SMA

2.3. Optimization of EDM and Variants for Machining SMAs

3. Conclusions and Future Research Directions

- EDM-based processes, especially WEDM, have been widely used for machining NiTi alloys, mainly in biomedical applications.

- Spark duration, current, and voltage have been identified as the machining variable parameters significantly affecting the MRR, surface roughness, tool wear, dimensional deviation, and overcut in machining SMAs by EDM-based processes.

- Powder-mixed EDM has shown improved efficiency and productivity.

- WEDT has enabled the fabrication of cylindrical NiTi components.

- Various optimization techniques, such as GA, ANN, NSGA-II, and TOPSIS, have been successfully used for multi-objective optimization of EDM, particularly in addressing conflicting responses related to productivity and quality.

- Hybrid and AI-based methods have effectively improved surface quality and reduced thermal damage.

- There is still a need for in-situ monitoring and adaptive control to enhance EDM precision, repeatability, and overall efficiency.

- Surface integrity studies have largely focused on roughness and recast layer thickness; limited work exists on geometrical profile, microhardness, defects, and microstructural changes, including the heat-affected zone.

- Few efforts have been made to address the multi-objective optimization of conflicting machining goals (e.g., surface quality vs. productivity).

- The impact of the electrode material on thermal damage, phase transformation, and shape memory retention remains underexplored.

- Limited research exists on fabricating complete engineering components using EDM for NiTi alloys.

- Integrating EDM with other advanced machining processes, such as additive processes, for improved capabilities.

- Employing artificial intelligence (AI) and machine learning (ML) for process optimization, especially to balance conflicting responses.

- Developing in situ monitoring and adaptive control systems for real-time parameter adjustment.

- Studying NiTi phase transformation under EDM thermal cycles.

- Exploring the effects of Ni/Ti alloy composition on surface integrity and functional behavior.

- Investigating eco-friendly EDM approaches (e.g., dry-EDM and green dielectrics).

- Conducting life cycle and sustainability analyses of EDM processes.

- Evaluating energy usage, emissions, and resource efficiency in EDM of NiTi.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Authors (Year) [Ref. No.] | Methodology and Optimization | Machining Details (i.e., Workpiece and Tool Materials) | Selected Process Parameters | Selected Responses | Key Findings |

|---|---|---|---|---|---|

| Machining of NiTi-SMA using WEDM | |||||

| Chaudhari et al. (2021) [42] | Straight cutting, L16 (44) OA, TLBO, and MOTLBO | Φ 6 mm NiTi rod Molybdenum wire (φ: 0.18 mm) Deionized water mixed with MWCNTs | Current, spark duration (Ton), spark-off duration (Toff), and powder concentration | MRR, SR (Ra), and RLT |

|

| Manjaiah and Laubscher (2016) [43] | Curved cutting | Ti50Ni40Cu10 SMA Zinc-coated brass wire (φ: 0.25 mm) Dielectric: deionized water | Spark duration, spark-off duration, and servo voltage | RLT and residual stress |

|

| Vakharia et al. [39] (2022) [44] | 2 mm thick straight cutting, and L9 (33) OA replicate twice | Ni55.8Ti SMA (Φ 6 mm); Molybdenum wire Dielectric: deionized water | Current, spark duration, and spark-off duration | SR and surface morphology |

|

| Goyal and Rahman (2021) [45] | Straight cutting, Taguchi L27 (54), ANN, and DFA | NiTi-SMA (100 mm × 100 mm × 6 mm) Brass wire (φ: 0.25 mm) Dielectric: deionized water | Spark duration, spark-off duration, peak current, wire speed, and wire rigidity | SR and kerf width |

|

| Bisaria and Shandilya (2023) [46] | Straight cutting | Ni55.95Ti44.05 SMA Brass wire (φ: 0.25 mm) Dielectric: deionized water | Spark frequency, spark energy density, and spark gap voltage | Surface roughness (SR) |

|

| Bisaria and Shandilya (2018) [47] | Straight cutting | Ni55.7Ti) SMA, Brass wire (φ: 0.25 mm) Dielectric: deionized water | Peak current, spark duration, and spark-off duration | Wire wear ratio (WWR) and dimensional deviation (DD) |

|

| Chaudhari et al. (2022) [48] | 1.5 mm thick straight cutting, Pareto analysis, heat transfer search (HTS) algorithm | Ni55.8Ti SMA (φ 6 mm) Brass wire (φ: 0.25 mm) Dielectric: deionized water | Current, spark duration, and spark-off duration | MRR, SR, and microhardness (MH) |

|

| Kowalczyk and Tomczyk (2022) [49] | Straight cutting | NiTi-SMA Brass wire (φ: 0.25 mm) Dielectric: deionized water | Amplitude of the current, voltage, and energy | SR (i.e., Ra and Rz) |

|

| Roy et al. (2020) [50] | Straight cutting and factorial design | TiNiCu SMA Brass wire (φ: 0.25 mm) Dielectric: deionized water | Peak current and pulse peak voltage | SR (i.e., Ra and Rz) |

|

| Roy et al. (2021) [51] | Taper cutting and RSM | NiTi-SMA (φ: 8 mm) Zn-coated brass wire (φ: 0.25 mm) Dielectric: deionized water | Spark duration, spindle rotational speed, and inclination angle | Volumetric material removal rate (VMRR) and Ra |

|

| Kesavan et al. (2021) [52] | Straight cutting, Taguchi L27, and TOPSIS | NiTi-SMA Brass wire (ϕ 0.25 mm) Deionized water | Power, wire speed, spark duration, and spark-off duration | MRR and Ra |

|

| Kulkarni (2022) [53] | Straight cutting and RSM | NiTi-SMA plate (800 mm × 160 mm × 2 mm) Zn-coated brass wires (diffused wires) (ϕ = 0.25 mm) Deionized water | Spark duration, spark-off duration, wire feed, servo voltage, and different diffused wires | TWR and SR (Ra) |

|

| Gupta and Dubey (2022) [54] | Straight cutting, Taguchi L27 OA, GA, and ANN | Ni54.1Ti45.9 SMA Zn-coated brass wire (ϕ = 0.25 mm) Dielectric: deionized water | Wire feed rate, wire rigidity, spark duration, spark-off duration, and peak current | MRR and SR |

|

| Hou et al. (2022) [55] | Multistage straight cutting (trim cut) | NiTi-SMA Brass wire (ϕ = 0.25 mm) Dielectric: deionized water | Spark duration, spark-off duration, and peak current | SR (Ra) |

|

| Xu et al. (2022) [56] | Straight cutting, Taguchi L27 OA, multiple regression (MLR) model, BPNN, and bat algorithm (BA) | NiTi-SMA, Brass wire (ϕ = 0.25 mm) Dielectric: deionized water | Peak current, discharge frequency, wire tension, flushing pressure, and wire speed | Cutting speed (CS) and kerf width (KW) |

|

| George et al. (2023) [57] | Straight cutting, Taguchi, 3 level each parameter | NiTi-SMA (φ 15 mm and width of cut of 5 mm) Half-hard brass wire (ϕ = 0.25 mm) Dielectric: deionized water | Spark duration, spark-off duration, and voltage | MRR and SR (Ra) |

|

| Authors (Year) [Ref. No.] | Methodology and Optimization | Machining Details (i.e., Workpiece and Tool Materials) | Selected Process Parameters | Selected Responses | Key Findings |

|---|---|---|---|---|---|

| Machining of NiTi SMA using EDM, µ-EDM, and PMEDM | |||||

| Faheem et al. (2023) [58] | Full-factorial design of experiment (33): 27 experiments, 0.5 mm depth of cut, and NSGA-II with TOPSIS | Ni55.65Ti-SMA plate (150 mm × 130 mm × 5 mm) Copper tool electrode (face size: 12 mm × 25 mm) | Spark duration, duty factor, and peak current | MRR and SR |

|

| Abidi et al. (2017) [59] | Micro-hole drilling, grey–Taguchi method, and grey-PCA | µ-EDM NiTi-SMA (3 mm × 1.5 mm × 0.5 mm) Tungsten and brass electrodes (ϕ = 100 µm) Dielectric: kerosene oil | Capacitance, discharge voltage, and electrode materials | Overcut, taper angle, and SR (Ra) |

|

| Abidi et al. (2017) [60] | Micro-hole drilling and MOGA-II | µ-EDM NiTi-SMA (3 mm × 1.5 mm × 0.5 mm), Tungsten and brass electrodes (ϕ = 100 µm) Dielectric: kerosene oil | Capacitance, discharge voltage, and electrode materials | MRR, TWR, and SR (Ra) |

|

| Gaikwad et al. (2015) [61] | Drilling a 3 mm square hole | EDM Cryogenic-treated NiTi-SMA Dielectric: kerosene oil | Gap current, spark duration, and spark-off duration | MRR and TWR |

|

| Gaikwad et al. (2021) [62] | Blind cavity, L9 OA, and Buckingham’s pie theorem | EDM NiTi-SMA Dielectric: kerosene oil | Current, voltage, spark duration, and spark-off duration | RLT |

|

| Vora et al. (2022) [63] | Taguchi’s L9(34) replicate thrice, and HST algorithm | PMEDM NiTi-SMA Dielectric: kerosene oil | Current, spark duration, spark-off duration, and nanographene powder concentration (PC) | MRR, SR, and dimensional deviation (DD) |

|

| Singh et al. (2022) [64] | Central composite design (CCD), DFA, TLBO, and PSO techniques | EDM Fe-based SMA Copper electrode Dielectric: kerosene oil | Spark duration, spark-off duration, peak current, and gap voltage | MRR and SR |

|

| Chaudhary et al. (2017) [65] | Taper drilling and Taguchi L18 OA | Die-sinking EDM NiTi-SMA Copper electrode Dielectric: EDM oil | Polarity, peak current, spark duration, and spark-off duration | MRR and taper angle |

|

| Authors (Year) [Ref. No.] | Methodology and Optimization | Machining Details (i.e., Workpiece and Tool Materials) | Selected Process Parameters | Selected Responses | Key Findings |

|---|---|---|---|---|---|

| Om and Singh et al. (2017) [66] | Drilling and one-factor-at-a-time (OFAT) | EDD NiTiCu10 SMA Dielectric: EDM oil | Pulse current, gap voltage, spark duration, spark-off duration, and rotational speed of the tool electrode | MRR, TWR, and SR |

|

| Chaudhary and Haribhakta et al. (2017) [67] | Micro-hole (through or blind) | EDD SMA Dielectric: EDM oil | - | - |

|

| Mane and Jadhav (2024) [68] | Drilling, Taguchi L18 OA, and RSM | USV-EDM NiTi-SMA Copper electrode Dielectric: EDM oil | Low-frequency ultrasonic vibration | SR |

|

| Wang et al. (2018) [69] | USV-MF complex-assisted WEDM-LS TiNi01 SMA Copper electrode Dielectric: EDM oil | Spark duration, spark-off duration, and current | MRR and SR |

| |

| Huang et al. (2003) [70] | Drilling micro-holes | USV µ-EDM NiTi-SMA Dielectric: EDM oil | - | Machining efficiency |

|

| Kumar et al. (2023) [71] | Drilling and DFA | Electrochemical arc machining (ECAM) Ni55.7Ti SMA Molybdenum electrode | Supply voltage | Overcut and TWR |

|

| Chaudhari et al. (2022) [72] | Straight cutting, BBD, and TLBO | Near-dry WEDM NiTi-SMA Molybdenum wire (φ 0.18 mm) Dielectric: compressed gas | Current, spark duration, and spark-off duration | MRR and SR |

|

| Muniraju and Talla (2024) [73] | - | Dry-EDM NiTi-SMA | - | - |

|

| Jatti and Singh (2014) [74] | EDM Cryogenic-treated NiTi-SMA Dielectric: EDM oil | - | MRR and TWR |

|

References

- Wellmann, P.J. The Search for New Materials and the Role of Novel Processing Routes. Discover Mater. 2021, 1, 14. [Google Scholar] [CrossRef]

- Hossain, N.; Mahmud, M.Z.A.; Hossain, A.; Rahman, M.K.; Islam, M.S.; Tasnim, R.; Mobarak, M.H. Advances of Materials Science in MEMS Applications: A Review. Results Eng. 2024, 22, 102115. [Google Scholar] [CrossRef]

- Alem, S.A.A.; Sabzvand, M.H.; Govahi, P.; Poormehrabi, P.; Azar, M.H.; Siouki, S.S.; Rashidi, R.; Angizi, S.; Bagherifard, S. Advancing the Next Generation of High-Performance Metal Matrix Composites through Metal Particle Reinforcement. Adv. Compos. Hybrid Mater. 2025, 8, 3. [Google Scholar] [CrossRef]

- Wederni, A.; Daza, J.; Ben Mbarek, W.; Saurina, J.; Escoda, L.; Suñol, J.-J. Crystal Structure and Properties of Heusler Alloys: A Comprehensive Review. Metals 2024, 14, 688. [Google Scholar] [CrossRef]

- Ahmad, S.; Hashmi, A.W.; Singh, J.; Arora, K.; Tian, Y.; Iqbal, F.; Al-Dossari, M.M.; Khan, M.I. Innovations in Additive Manufacturing of Shape Memory Alloys: Alloys, Microstructures, Treatments, Applications. J. Mater. Res. Technol. 2024, 32, 4136–4197. [Google Scholar] [CrossRef]

- Del Core, L.; Attolico, M.A.; Moramarco, V.; Casavola, C. Shape Memory Alloys for Reversible Restoration of Ancient Monuments. Shape Mem. Superelasticity 2025, 11, 44–65. [Google Scholar] [CrossRef]

- Naresh, C.; Bose, P.S.C.; Rao, C.S.P. Shape Memory Alloys: A State of the Art Review. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012054. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Reconciling Viability and Cost-Effective Shape Memory Alloy Options—A Review of Copper and Iron-Based Shape Memory Metallic Systems. Eng. Sci. Technol. Int. J. 2016, 19, 1582–1592. [Google Scholar] [CrossRef]

- Ryklina, E.P.; Prokoshkin, S.D.; Khmelevskaya, I.Y.; Shakhmina, A.A. One-Way and Two-Way Shape Memory Effect in Thermomechanically Treated TiNi-Based Alloys. Mater. Sci. Eng. A 2008, 481–482, 134–137. [Google Scholar] [CrossRef]

- Basak, S.; Dasgupta, P.; Bandyopadhyay, A. One-Way Shape Memory Polyesters—Evolution, Growth, Developments, and Current Trends. Polym.-Plast. Technol. Mater. 2023, 62, 2286–2317. [Google Scholar] [CrossRef]

- Wang, W.; Xiang, Y.; Yu, J.; Yang, L. Development and Prospect of Smart Materials and Structures for Aerospace Sensing Systems and Applications. Sensors 2023, 23, 1545. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.-S.; Heo, J.-K.; Rodrigue, H.; Lee, H.-T.; Pané, S.; Han, M.-W.; Ahn, S.-H. Shape Memory Alloy (SMA) Actuators: The Role of Material, Form, and Scaling Effects. Adv. Mater. 2023, 35, 2208517. [Google Scholar] [CrossRef]

- Stachiv, I.; Alarcon, E.; Lamac, M. Shape Memory Alloys and Polymers for MEMS/NEMS Applications: Review on Recent Findings and Challenges in Design, Preparation, and Characterization. Metals 2021, 11, 415. [Google Scholar] [CrossRef]

- Vasudha, N.; Rao, K.U. Shape Memory Alloy Properties, Modelling Aspects and Potential Applications—A Review. J. Phys. Conf. Ser. 2020, 1706, 012190. [Google Scholar] [CrossRef]

- Anbalagan, A.; Sampath, S.; Chandrasekaran, B.; Nair, A.M.; Sabarish, R.S.S.; Shravan, P.V.; Vigneshwar, A. Development of a Shape-Memory-Alloy-Based Overheating Protection System. Eng. Proc. 2024, 61, 31. [Google Scholar] [CrossRef]

- Lokesh, N.; Mallik, U.S.; Shivasiddaramaiaha, A.G.; Mohith, T.N.; Praveen, N. Characterization and Evaluation of Shape Memory Effect of Cu-Zn-Al Shape Memory Alloy. J. Mines Met. Fuels 2022, 70, 324–331. [Google Scholar] [CrossRef]

- Santosh, S.; Pavithran, M. Iron-Based Smart Alloys for Critical Applications: A Review on Processing, Properties, Phase Transformations, and Current Trends. J. Mater. Sci. Mater. Eng. 2024, 19, 8. [Google Scholar] [CrossRef]

- Qiang, X.; Wu, Y.; Wang, Y.; Jiang, X. Research Progress and Applications of Fe-Mn-Si-Based Shape Memory Alloys on Reinforcing Steel and Concrete Bridges. Appl. Sci. 2023, 13, 3404. [Google Scholar] [CrossRef]

- Jania, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A Review of Shape Memory Alloy Research, Applications, and Opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Ou, S.-F.; Wang, Y.-H.; Huang, H.-M.; Chen, C.-F. Effects of Superelasticity and Shape Memory Ability of NiTi-Based Alloys on Deposition Efficiency of Ultrasonic-Assisted Coating. J. Alloys Compd. 2023, 937, 168189. [Google Scholar] [CrossRef]

- Costanza, G.; Tata, M.E. Shape Memory Alloys for Aerospace, Recent Developments, and New Applications: A Short Review. Materials 2020, 13, 1856. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Venezuela, J.; Dargusch, M. Biodegradable Shape Memory Alloys: Progress and Prospects. Biomaterials 2021, 279, 121215. [Google Scholar] [CrossRef]

- Shukla, U.; Garg, K. Journey of Smart Material from Composite to Shape Memory Alloy (SMA), Characterization and Their Applications—A Review. Smart Mater. Med. 2023, 4, 227–242. [Google Scholar] [CrossRef]

- Dutta, S.; Sarma, D.K.; Vora, J.; Chaudhari, R.; Bhowmik, A.; Samal, P.; Khanna, S. A State-of-the-Art Review on Micro-Machining of Nitinol Shape Memory Alloys and Optimization of Process Variables Considering the Future Trends of Research. J. Manuf. Mater. Process. 2025, 9, 183. [Google Scholar] [CrossRef]

- Zadafiya, K.; Dinbandhu; Kumari, S.; Chatterjee, S.; Kumar, A. Recent Trends in Non-Traditional Machining of Shape Memory Alloys (SMAs): A Review. CIRP J. Manuf. Sci. Technol. 2021, 32, 217–227. [Google Scholar] [CrossRef]

- Qudeiri, J.E.A.; Zaiout, A.; Mourad, A.-H.I.; Abidi, M.H.; Elkaseer, A. Principles and Characteristics of Different EDM Processes in Machining Tool and Die Steels. Appl. Sci. 2020, 10, 2082. [Google Scholar] [CrossRef]

- Ishfaq, K.; Anwar, S.; Ali, M.A.; Raza, M.H.; Farooq, M.U.; Ahmad, S.; Pruncu, C.I.; Saleh, M.; Salah, B. Optimization of WEDM for Precise Machining of Novel Developed Al6061-7.5% SiC Squeeze-Casted Composite. Int. J. Adv. Manuf. Technol. 2020, 111, 2031–2049. [Google Scholar] [CrossRef]

- Ho, K.H.; Newman, S.T. State of the Art Electrical Discharge Machining (EDM). Int. J. Mach. Tools Manuf. 2003, 43, 1287–1300. [Google Scholar] [CrossRef]

- Nadda, R.; Nirala, C.K. EDM Recent Developments in Spark Erosion–Based Machining Processes: A State of the Art in Downscaling of Electric Discharge Based Machining Processes. In Advanced Machining and Finishing; Gupta, M.K., Pramanik, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 177–215. [Google Scholar]

- Benedict, G.F. Nontraditional Manufacturing Processes; Marcel Dekker Inc.: New York, NY, USA, 1987; ISBN 0-8247-7352-7. [Google Scholar]

- Singh, H.; Singh, J.; Kumar, S. Effect of Processing Conditions and Electrode Materials on the Surface Roughness of EDM-Processed Hybrid Metal Matrix Composites. Int. J. Lightweight Mater. Manuf. 2024, 7, 480–493. [Google Scholar] [CrossRef]

- Jain, V.K. Advanced Machining Processes; Allied Publishers: New Delhi, India, 2002. [Google Scholar]

- Pandey, P.C.; Shan, H.S. Modern Machining Processes; Tata McGraw Hill Education Pvt. Ltd.: New Delhi, India, 2013. [Google Scholar]

- Srivastava, S.; Vishnoi, M.; Gangadhar, M.T.; Kukshal, V. An Insight on Powder Mixed Electric Discharge Machining: A State-of-the-Art Review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 237, 657–690. [Google Scholar] [CrossRef]

- Schumacher, B.M.; Krampitz, R.; Kruth, J.-P. Historical Phases of EDM Development Driven by the Dual Influence of “Market Pull” and “Science Push”. Procedia CIRP 2013, 6, 5–12. [Google Scholar] [CrossRef]

- Pachaury, Y.; Tandon, P. An Overview of Electric Discharge Machining of Ceramics and Ceramic-Based Composites. J. Manuf. Process. 2017, 25, 369–390. [Google Scholar] [CrossRef]

- Ho, K.H.; Newman, S.T.; Rahimifard, S.; Allen, R.D. State of the Art in Wire Electrical Discharge Machining (WEDM). Int. J. Mach. Tools Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Shastri, R.K.; Mohanty, C.P.; Dash, S.; Gopal, K.M.P.; Annamalai, A.R.; Jen, C.-P. Reviewing Performance Measures of the Die-Sinking Electrical Discharge Machining Process: Challenges and Future Scopes. Nanomaterials 2022, 12, 384. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.F.; Guo, Y.B. Process Capability of Wire-EDM of NiTi Shape Memory Alloy at Main Cut and Trim Cut Modes. Procedia Manuf. 2015, 1, 904–914. [Google Scholar] [CrossRef]

- Hou, Y.; Li, C.; Sun, L.; Wang, J.; Li, X.; Shi, S.; Xu, J. Phase Transformation Behavior and Shape Memory Effect of Nickel-Titanium Shape Memory Alloy Using the Magnetic Field Assisted Wire Electrical Discharge Machining. Mater. Today Commun. 2024, 39, 109287. [Google Scholar] [CrossRef]

- Jain, N.K.; Chaubey, S.K. Review of Miniature Gear Manufacturing. In Comprehensive Materials Finishing; Hashmi, M.S.J., Ed.; Elsevier: Oxford, UK, 2016; Volume 1, pp. 504–538. [Google Scholar] [CrossRef]

- Chaudhari, R.; Khanna, S.; Vora, J.; Patel, V.K.; Paneliya, S.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Experimental Investigations and Optimization of MWCNTs-Mixed WEDM Process Parameters of Nitinol Shape Memory Alloy. J. Mater. Res. Technol. 2021, 15, 2152–2169. [Google Scholar] [CrossRef]

- Mallaiah, M.; Laubscher, R.F. Study on Recast Layer Thickness and Residual Stress During WEDM of SMAs. Emerg. Mater. Res. 2017, 6, 82–88. [Google Scholar] [CrossRef]

- Vakharia, V.; Vora, J.; Khanna, S.; Chaudhari, R.; Shah, M.; Pimenov, D.Y.; Giasin, K.; Prajapati, P.; Wojciechowski, S. Experimental Investigations and Prediction of WEDMed Surface of Nitinol SMA Using SinGAN and DenseNet Deep Learning Model. J. Mater. Res. Technol. 2022, 18, 325–337. [Google Scholar] [CrossRef]

- Goyal, A.; Rahman, H.U.R. Experimental Studies on Wire EDM for Surface Roughness and Kerf Width for Shape Memory Alloy. Sādhanā 2021, 46, 160. [Google Scholar] [CrossRef]

- Bisaria, H.; Shandilya, P. Surface Integrity of NiTi-SMA During WEDM: Effect of Spark Parameters. Mater. Manuf. Process. 2023, 38, 1676–1684. [Google Scholar] [CrossRef]

- Bisaria, H.; Shandilya, P. Experimental Study on Response Parameters of Ni-Rich NiTi Shape Memory Alloy During Wire Electric Discharge Machining. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012070. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Patel, V.; Lacalle, L.N.L.D.; Parikh, D.M. Effect of WEDM Process Parameters on Surface Morphology of Nitinol Shape Memory Alloy. Materials 2020, 13, 4943. [Google Scholar] [CrossRef] [PubMed]

- Kowalczyk, M.; Tomczyk, K. Assessment of Measurement Uncertainties for Energy Signals Stimulating the Selected NiTi Alloys During the Wire Electrical Discharge Machining. Precis. Eng. 2022, 76, 133–140. [Google Scholar] [CrossRef]

- Roy, A.; Narendranath, S.; Pramanik, A. Effect of Peak Current and Peak Voltage on Machined Surface Morphology During WEDM of TiNiCu Shape Memory Alloys. J. Mech. Sci. Technol. 2020, 34, 3957–3961. [Google Scholar] [CrossRef]

- Roy, B.K.; Mandal, A. An Investigation into the Effect of Wire Inclination in Wire-Electrical Discharge Turning Process of NiTi-60 Shape Memory Alloy. J. Manuf. Process. 2021, 64, 739–749. [Google Scholar] [CrossRef]

- Kesavan, J.; Velmurugan, C.; Senthilkumar, V.; Dinesh, S. Optimization of WEDM Parameters on Surface Integrity Characteristics of NiTi Shape Memory Alloy. Mater. Today Proc. 2021, 43, 183–190. [Google Scholar] [CrossRef]

- Kulkarni, V.N.; Gaitonde, V.N.; Mallaiah, M.; Karnik, R.S.; Davim, J.P. Tool Wear Rate and Surface Integrity Studies in Wire Electric Discharge Machining of NiTiNOL Shape Memory Alloy Using Diffusion Annealed Coated Electrode Materials. Machines 2022, 10, 138. [Google Scholar] [CrossRef]

- Gupta, D.K.; Dubey, A.K. Modeling and Optimization of Wire–EDM Parameters for Machining of Ni54.1Ti45.9 Shape Memory Alloy Using Hybrid Approach. Proc. Inst. Mech. Eng. E J. Process Mech. Eng. 2022, 236, 2176–2186. [Google Scholar] [CrossRef]

- Hou, Y.; Xu, J.; Lian, Z.; Zhai, C.; Li, M.; Yang, S.; Yu, H. Research on Surface Microstructures and Properties of NiTi Shape Memory Alloy After Wire Electrical Discharge Machining. Mater. Today Commun. 2022, 31, 103521. [Google Scholar] [CrossRef]

- Xu, J.; Li, M.; Zhong, J.; Hou, Y.; Xia, S.; Yu, P. Process Parameter Modeling and Multi-Response Optimization of Wire Electrical Discharge Machining NiTi Shape Memory Alloy. Mater. Today Commun. 2022, 33, 104252. [Google Scholar] [CrossRef]

- George, E.; Khan, M.A.; Duraipandi, C.; Jappes, J.T.W.; Haider, J. Assessing Machinability and Surface Characteristics of a Shape Memory Alloy (SMA) Processed Through Wire Electro Discharge Method. Arch. Metall. Mater. 2022, 67, 921–930. [Google Scholar] [CrossRef]

- Faheem, A.; Hasan, F.; Khan, A.A.; Singh, B.; Ayaz, M.; Shamim, F.; Saxena, K.K.; Eldin, S.M. Parametric Optimization of Electric Discharge Machining of Ni55.65Ti-Based Shape Memory Alloy Using NSGA-II with TOPSIS. J. Mater. Res. Technol. 2023, 26, 1306–1324. [Google Scholar] [CrossRef]

- Abidi, M.H.M.; Al-Ahmari, A.; Siddiquee, A.N.; Mian, S.H.; Mohammed, M.K.; Rasheed, M.S. An Investigation of the Micro-Electrical Discharge Machining of Nickel–Titanium Shape Memory Alloy Using Grey Relations Coupled with Principal Component Analysis. Metals 2017, 7, 486. [Google Scholar] [CrossRef]

- Abidi, M.H.M.; Al-Ahmari, A.; Ummer, S.; Rasheed, M.S. Multi-Objective Optimization of Micro-Electrical Discharge Machining of Nickel–Titanium-Based Shape Memory Alloy Using MOGA-II. Measurement 2018, 125, 336–349. [Google Scholar] [CrossRef]

- Gaikwad, V.; Jatti, V.S.; Singh, T.P. Electric Discharge Machining of Cryo-Treated NiTi Alloys. Appl. Mech. Mater. 2015, 787, 366–370. [Google Scholar] [CrossRef]

- Gaikwad, M.U.; Krishnamoorthy, A.; Jatti, V.S. Semi-Empirical Modeling and Jaya Optimization of White Layer Thickness During Electrical Discharge Machining of NiTi Alloy. In Metaheuristic Algorithms in Industry 4.0; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Vora, J.; Khanna, S.; Chaudhari, R.; Patel, V.K.; Paneliya, S.; Pimenov, D.Y.; Giasin, K.; Prakash, C. Machining Parameter Optimization and Experimental Investigations of Nano-Graphene Mixed Electrical Discharge Machining of Nitinol Shape Memory Alloy. J. Mater. Res. Technol. 2022, 19, 653–668. [Google Scholar] [CrossRef]

- Singh, R.; Singh, R.P.; Tehran, R. Electrical Discharge Machining of Fe-Based Shape Memory Alloy: Parametric Evaluation with Microstructure Analysis. Proc. Inst. Mech. Eng. E J. Process Mech. Eng. 2022, 237, 2475–2487. [Google Scholar] [CrossRef]

- Chaudhary, S.K.; Sarkar, B.R.; Bhattacharyya, B. Analysis and Optimisation of Performances of Electro Discharge Machining of Shape Memory Alloy (Nitinol). Int. J. Adv. Res. Eng. Technol. 2025, 16, 95–110. [Google Scholar] [CrossRef]

- Om, H.; Singh, S. Experimental Study on Electro-Discharge Drilling of NiTiCu10 Shape Memory Alloy. J. Mol. Eng. Mater. 2024, 12, 2440014. [Google Scholar] [CrossRef]

- Chaudhary, K.; Haribhakta, V.K. Micro-Drilling on Shape Memory Alloys—A Review. MethodsX 2024, 13, 102968. [Google Scholar] [CrossRef]

- Mane, A.; Jadhav, P.V. Optimization of Ultrasonic Assisted Electro-Discharge Machining Process Parameters Through Surface Response. In Techno-Societal 2022; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.; Ding, Z.; He, D.; Xiong, W.; Chen, S.; Li, Z. Study on the Mechanism and Key Technique of Ultrasonic Vibration and Magnetic Field Complex Assisted WEDM-LS Thick Shape Memory Alloy Workpiece. J. Mater. Process. Technol. 2018, 261, 251–265. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, H.; Zhou, L.; Zheng, H.Y. Ultrasonic Vibration Assisted Electro-Discharge Machining of Microholes in Nitinol. J. Micromech. Microeng. 2003, 13, 693. [Google Scholar] [CrossRef]

- Kumar, N.; Kumar, A.; Das, S.R. Electrochemical Arc Drilling of Nickel–Titanium Shape Memory Alloy Using Molybdenum Electrode: Investigation, Modeling and Optimization. Surf. Rev. Lett. 2023, 30, 2350057. [Google Scholar] [CrossRef]

- Chaudhari, R.; Kevalramani, A.; Vora, J.; Khanna, S.; Patel, V.K.; Pimenov, D.Y.; Giasin, K. Parametric Optimization and Influence of Near-Dry WEDM Variables on Nitinol Shape Memory Alloy. Micromachines 2022, 13, 1026. [Google Scholar] [CrossRef]

- Muniraju, M.; Talla, G. Exploring Sustainable Machining Processes for Nitinol Shape Memory Alloy: A Review of Eco-Friendly EDM and Other Techniques. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 85. [Google Scholar] [CrossRef]

- Jatti, V.S.; Singh, T.P. Effect of Deep Cryogenic Treatment on Machinability of NiTi Shape Memory Alloys in Electro Discharge Machining. Appl. Mech. Mater. 2014, 592–594, 197–201. [Google Scholar] [CrossRef]

| Algorithm | Efficiency | Accuracy | Application |

|---|---|---|---|

| NSGA-II | High | High | Multi-objective optimization |

| GA-ANN | Moderate | Very high (prediction and optimization) | Predictive modeling and optimization |

| PSO | Very high | High | Fast, single-objective, or hybrid optimization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaubey, S.K.; Gupta, K. Review of EDM-Based Machining of Nickel–Titanium Shape Memory Alloys. Quantum Beam Sci. 2025, 9, 28. https://doi.org/10.3390/qubs9040028

Chaubey SK, Gupta K. Review of EDM-Based Machining of Nickel–Titanium Shape Memory Alloys. Quantum Beam Science. 2025; 9(4):28. https://doi.org/10.3390/qubs9040028

Chicago/Turabian StyleChaubey, Sujeet Kumar, and Kapil Gupta. 2025. "Review of EDM-Based Machining of Nickel–Titanium Shape Memory Alloys" Quantum Beam Science 9, no. 4: 28. https://doi.org/10.3390/qubs9040028

APA StyleChaubey, S. K., & Gupta, K. (2025). Review of EDM-Based Machining of Nickel–Titanium Shape Memory Alloys. Quantum Beam Science, 9(4), 28. https://doi.org/10.3390/qubs9040028