Use of 3D Laser Scanning and Additive Technologies for Reconstruction of Damaged and Destroyed Cultural Heritage Objects

Abstract

:1. Introduction

2. Replication and Reconstruction of Sculptures

3. Reconstruction of Damaged Cultural Heritage Objects

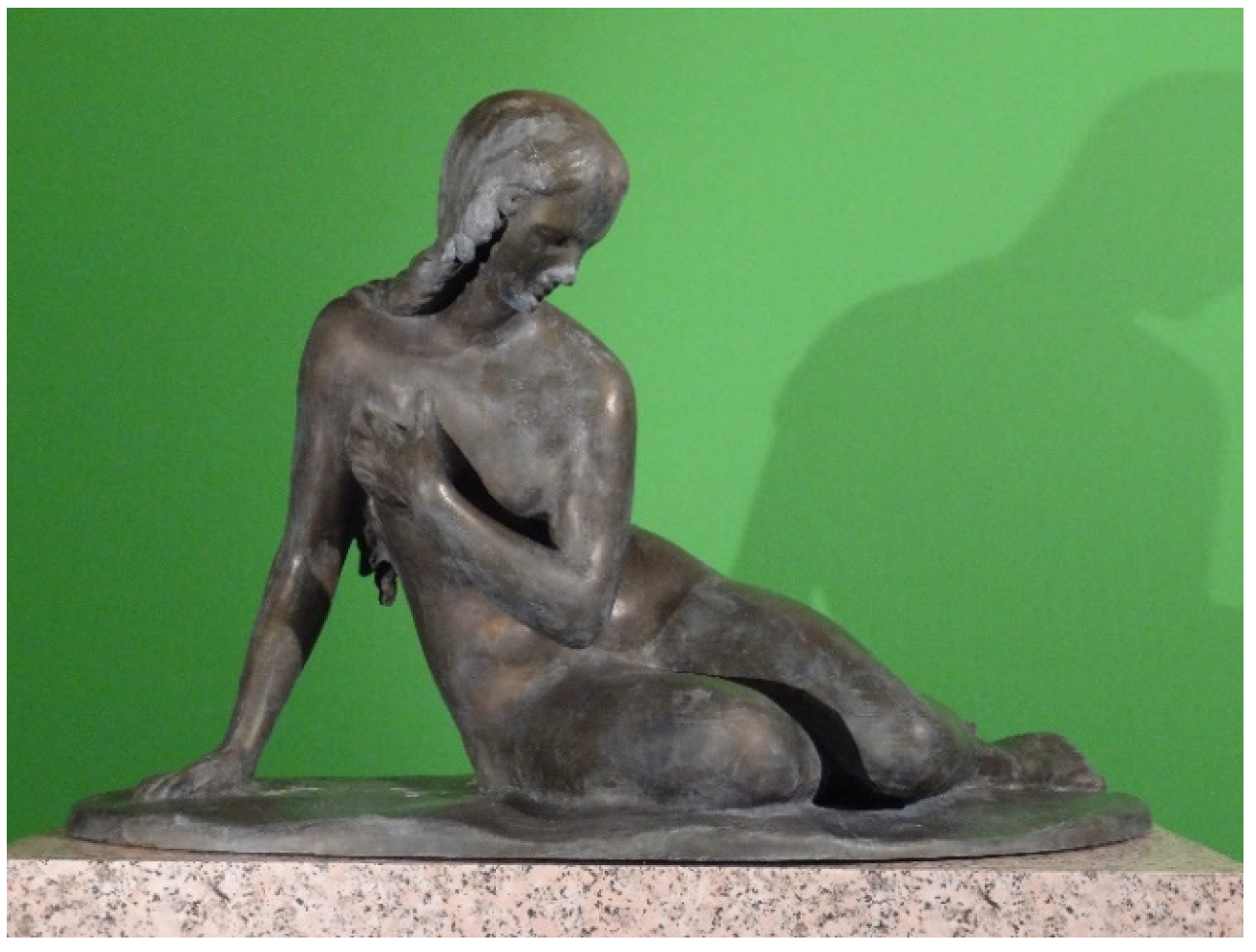

3.1. Case Study of Zinc Sculpture “Eve”

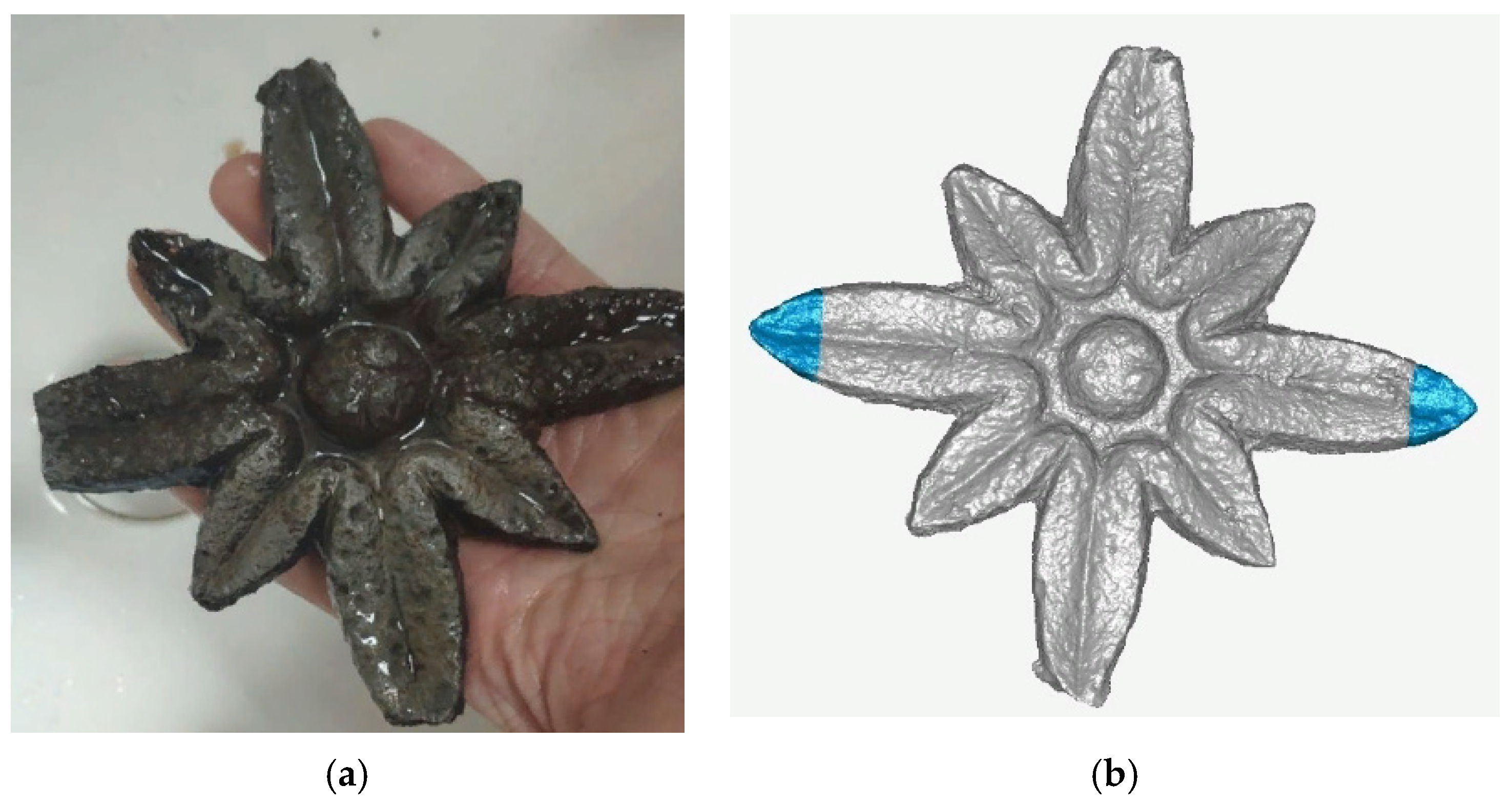

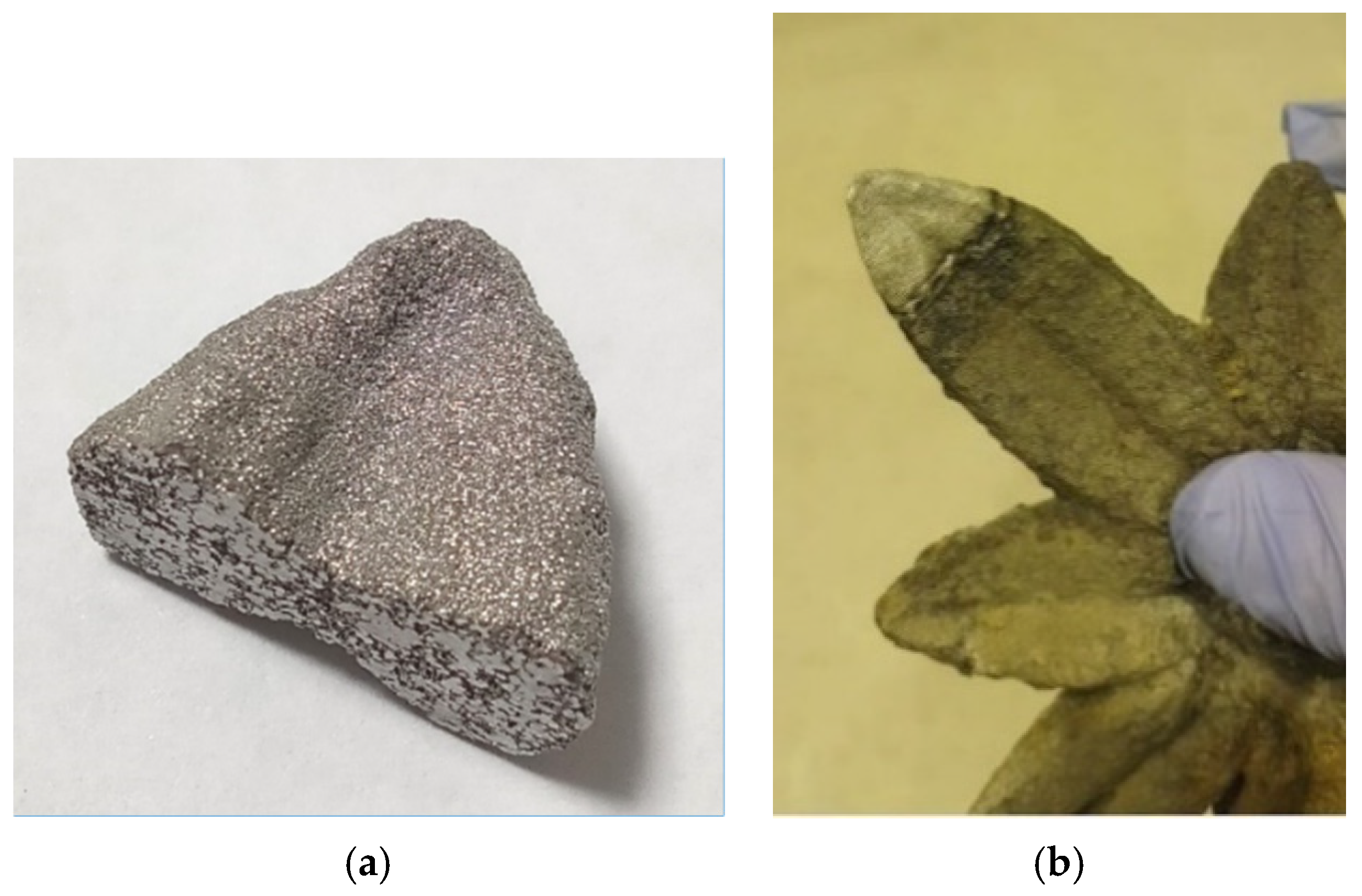

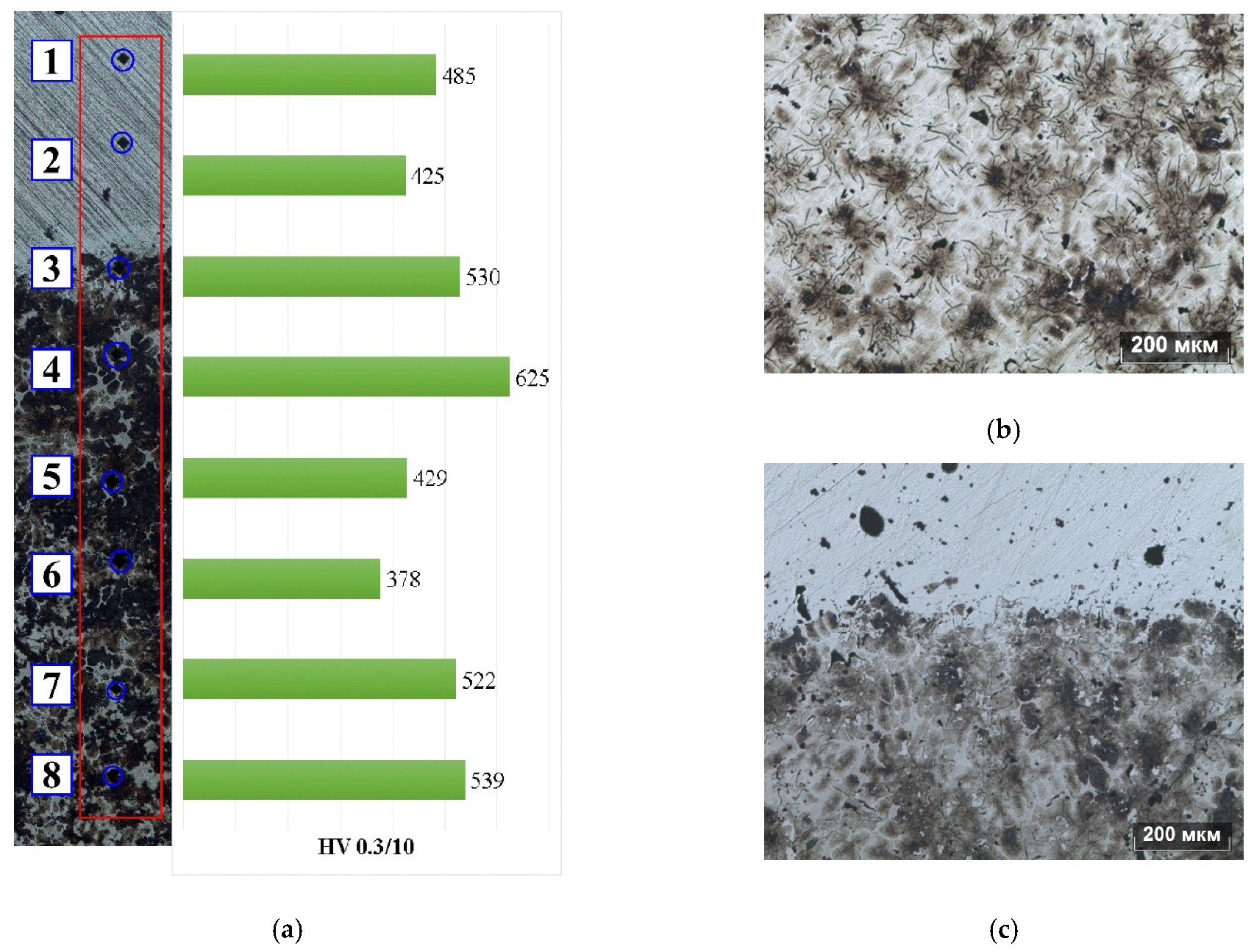

3.2. Case Study of Cast-Iron Star

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fowles, P.S. The Garden Temple at Ince Blundell: A Case Study in the Recording and Non-Contact Replication of Decayed Sculpture. J. Cult. Herit. 2000, 1, S89–S91. [Google Scholar] [CrossRef]

- la Pensée, A.; Parsons, J.; Cooper, M.; Broadbent, S.; Bingham, R. The Use of 3D Laser Scanning and 3D Modelling in the Realisation of an Artistic Vision; Production of Large Scale Public Art in Tudor Square, Sheffield. In Proceedings of the International Archives of Photogrammetry, Remote Sensing and Spatial Information Sciences, Newcastle upon Tyne, UK, 21–24 June 2010; Volume XXXVIII, pp. 375–380. [Google Scholar]

- Parfenov, V.A. Non-Contact Replication of Marble Sculptures Using Laser Technology. In Sculpture of XVIII-XIX Centuries in Out-Door Environment; St. Petersburg’s Museum of Urban Sculpture Publishing House: St. Petersburg, Russia, 2010; pp. 66–69. [Google Scholar]

- Skarlatos, D.; Theodoridou, S.; Hennings, D.; Ville, S. Replication of Marble Exhibits Using Photogrammetry and Laser Scanning (or How to Forge Exhibits). In Proceedings of the XIXth CIPA Symposium, Antalya, Turkey, 30 September–4 October 2003. [Google Scholar]

- Wachowiak, M.J.; Karas, B.V. 3d Scanning and Replication for Museum and Cultural Heritage Applications. J. Am. Inst. Conserv. 2009, 48, 141–158. [Google Scholar] [CrossRef]

- Cekus, D.; Kwiatoń, P.; Nadolski, M.; Sokół, K. Quality Assessment of a Manufactured Bell Using a 3D Scanning Process. Sensors 2020, 20, 7057. [Google Scholar] [CrossRef] [PubMed]

- Parfenov, V.A. Laser Techniques in Artworks Conservation in St.Petersburg. Rev. Cuba. Fis. 2016, 33, E29–E31. [Google Scholar]

- Parfenov, V.A. Use of Laser Technologies for Restoration, Documentation and Replication of Sculptural Monuments in Saint Petersburg. Insight Non-Destr. Test. Cond. Monit. 2020, 62, 129–133. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An Overview of Direct Laser Deposition for Additive Manufacturing; Part I: Transport Phenomena, Modeling and Diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Masaylo, D.V.; Orlov, A.V.; Igoshin, S.D. Effect of Heat Treatment on the Structure and Phase Composition of a High-Temperature Nickel Alloy Obtained by Laser Cladding. Met. Sci. Heat Treat. 2019, 60, 728–733. [Google Scholar] [CrossRef]

- Masaylo, D.V.; Popovich, A.A.; Sufiyarov, V.S.; Orlov, A.V.; Shamshurin, A.I. A Study of Structural Features of a Gradient Material from a Heat-Resistant Nickel Alloy Produced by Laser Cladding. Met. Sci. Heat Treat. 2019, 60, 739–744. [Google Scholar] [CrossRef]

- Schwendner, K.I.; Banerjee, R.; Collins, P.C.; Brice, C.A.; Fraser, H.L. Direct Laser Deposition of Alloys from Elemental Powder Blends. Scr. Mater. 2001, 45, 1123–1129. [Google Scholar] [CrossRef]

- Leyens, C.; Beyer, E. Innovations in Laser Cladding and Direct Laser Metal Deposition. In Laser Surface Engineering; Elsevier: Amsterdam, The Netherlands, 2015; pp. 181–192. [Google Scholar]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Zhang, D.; Bermingham, M.J.; Lui, E.W.; Brandt, M.; StJohn, D.H.; Qian, M. Grain Structure Control during Metal 3D Printing by High-Intensity Ultrasound. Nat. Commun. 2020, 11, 142. [Google Scholar] [CrossRef] [PubMed]

- Abioye, T.E.; Folkes, J.; Clare, A.T. A Parametric Study of Inconel 625 Wire Laser Deposition. J. Mater. Process. Technol. 2013, 213, 2145–2151. [Google Scholar] [CrossRef] [Green Version]

| Element | Fe | Si | Co | Mn | P | Zn | Pb | Ti | Ag | Other |

|---|---|---|---|---|---|---|---|---|---|---|

| Content, wt. % | 91.05 | 6.38 | 0.79 | 0.45 | 0.34 | 0.24 | 0.22 | 0.17 | 0.13 | 0.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parfenov, V.; Igoshin, S.; Masaylo, D.; Orlov, A.; Kuliashou, D. Use of 3D Laser Scanning and Additive Technologies for Reconstruction of Damaged and Destroyed Cultural Heritage Objects. Quantum Beam Sci. 2022, 6, 11. https://doi.org/10.3390/qubs6010011

Parfenov V, Igoshin S, Masaylo D, Orlov A, Kuliashou D. Use of 3D Laser Scanning and Additive Technologies for Reconstruction of Damaged and Destroyed Cultural Heritage Objects. Quantum Beam Science. 2022; 6(1):11. https://doi.org/10.3390/qubs6010011

Chicago/Turabian StyleParfenov, Vadim, Sergei Igoshin, Dmitriy Masaylo, Alexey Orlov, and Dzmitry Kuliashou. 2022. "Use of 3D Laser Scanning and Additive Technologies for Reconstruction of Damaged and Destroyed Cultural Heritage Objects" Quantum Beam Science 6, no. 1: 11. https://doi.org/10.3390/qubs6010011

APA StyleParfenov, V., Igoshin, S., Masaylo, D., Orlov, A., & Kuliashou, D. (2022). Use of 3D Laser Scanning and Additive Technologies for Reconstruction of Damaged and Destroyed Cultural Heritage Objects. Quantum Beam Science, 6(1), 11. https://doi.org/10.3390/qubs6010011