Through-Thickness Microstructure Characterization in a Centrifugally Cast Austenitic Stainless Steel Nuclear Reactor Primary Loop Pipe Using Time-of-Flight Neutron Diffraction

Abstract

1. Introduction

2. Materials and Methods

- Three background parameters and one scale parameter were fit for each histogram.

- The phase fraction of alpha was fixed at 10 at% as an initial guess and E-WIMV representation of the orientation distribution function (ODF) was applied with a resolution of 3.75. The instrument parameters describing the conversion from time-of-flight to d-spacing, so-called DIFC, [29] were also refined during this step. To break the corrleation between the DIFCs and lattice parameters, the DIFC of select high-angle histograms were fixed. This processes identifies peak positions and essentially recalibrates the sample position for each slice to compensate for slight misalignment of the sample while simultaneously producing high-quality lattice parameters.

- Scale factors were fixed in the third step and an arbitrary texture model (LeBail fit) was utilized while refining the background, lattice parameters, microstrain and crystallite size parameters.

- In the final refinement, histogram scale factors, background parameters, and phase fractions were varied and the E-WIMV texture model was again introduced at a resolution of 3.75. Isotropic atomic displacement parameters (Biso) for α and γ phases were also refined at this time.

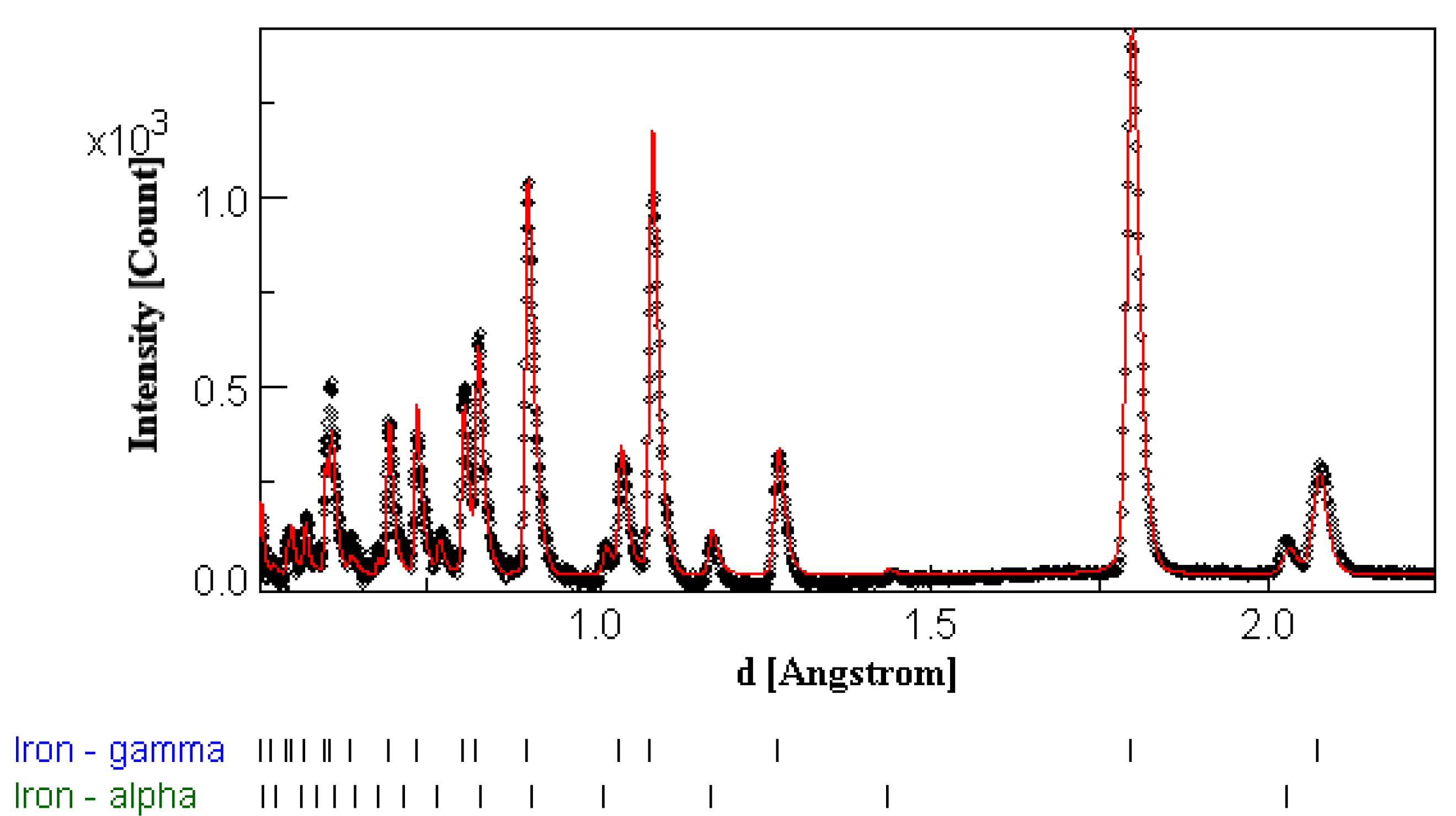

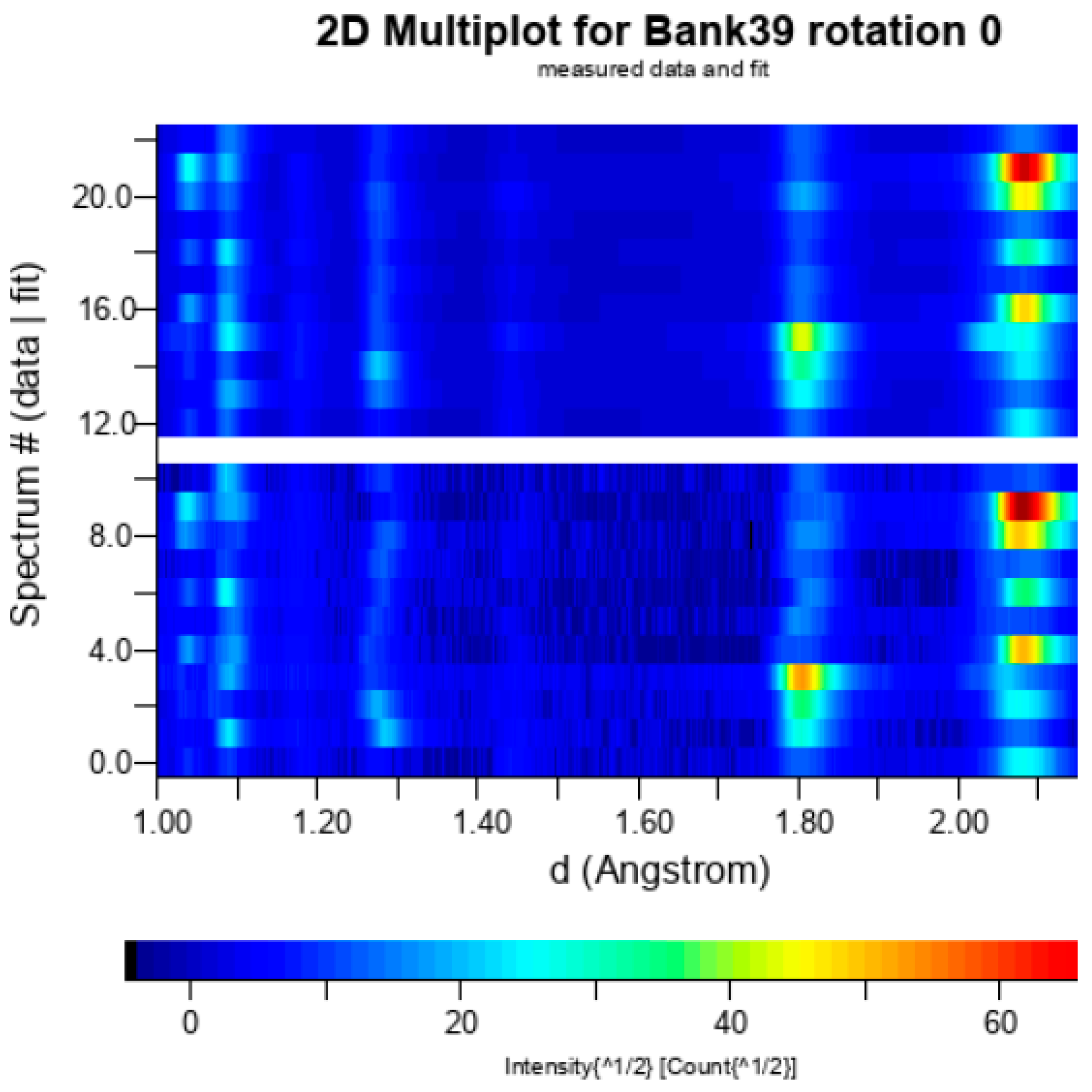

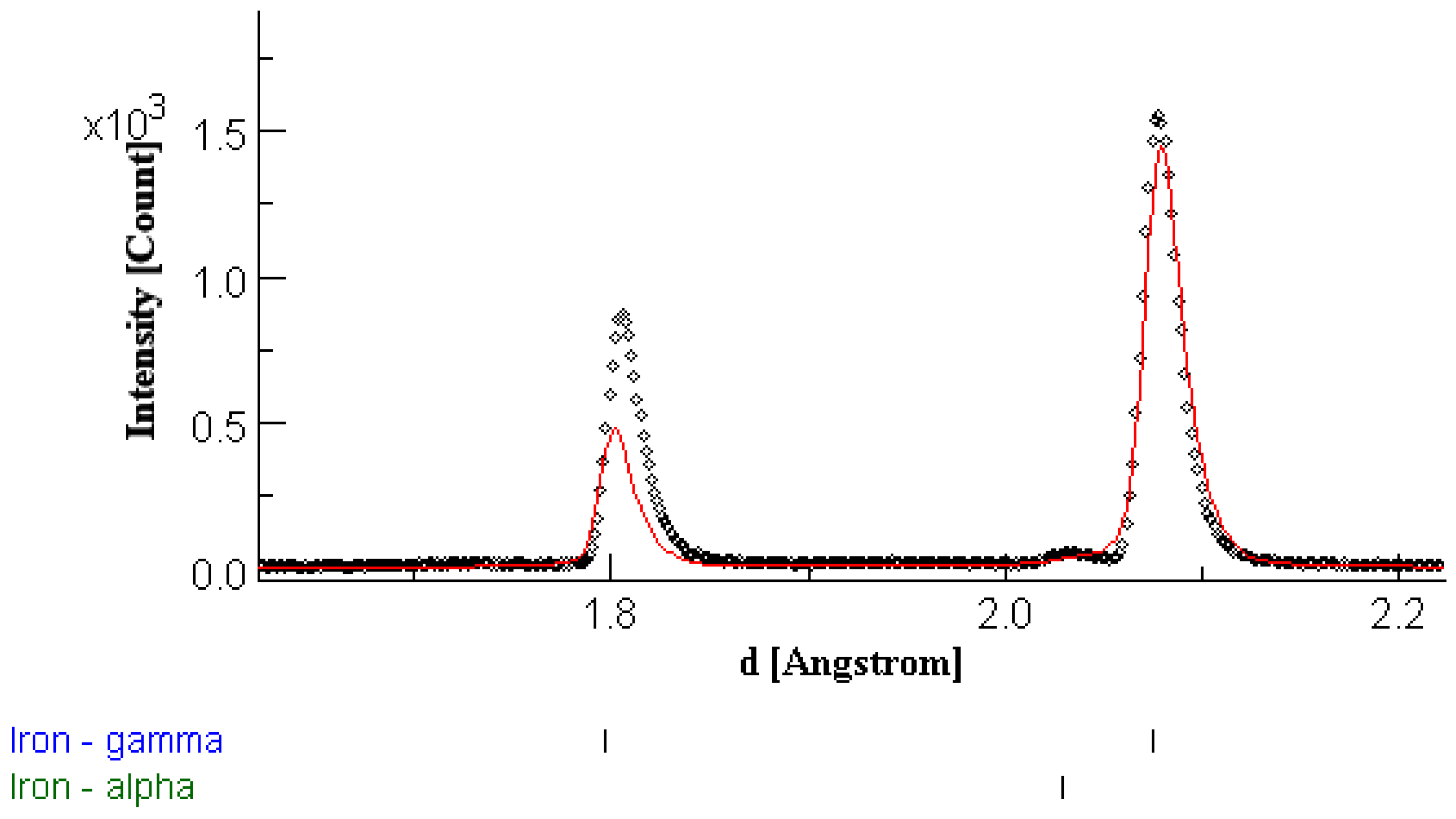

3. Results

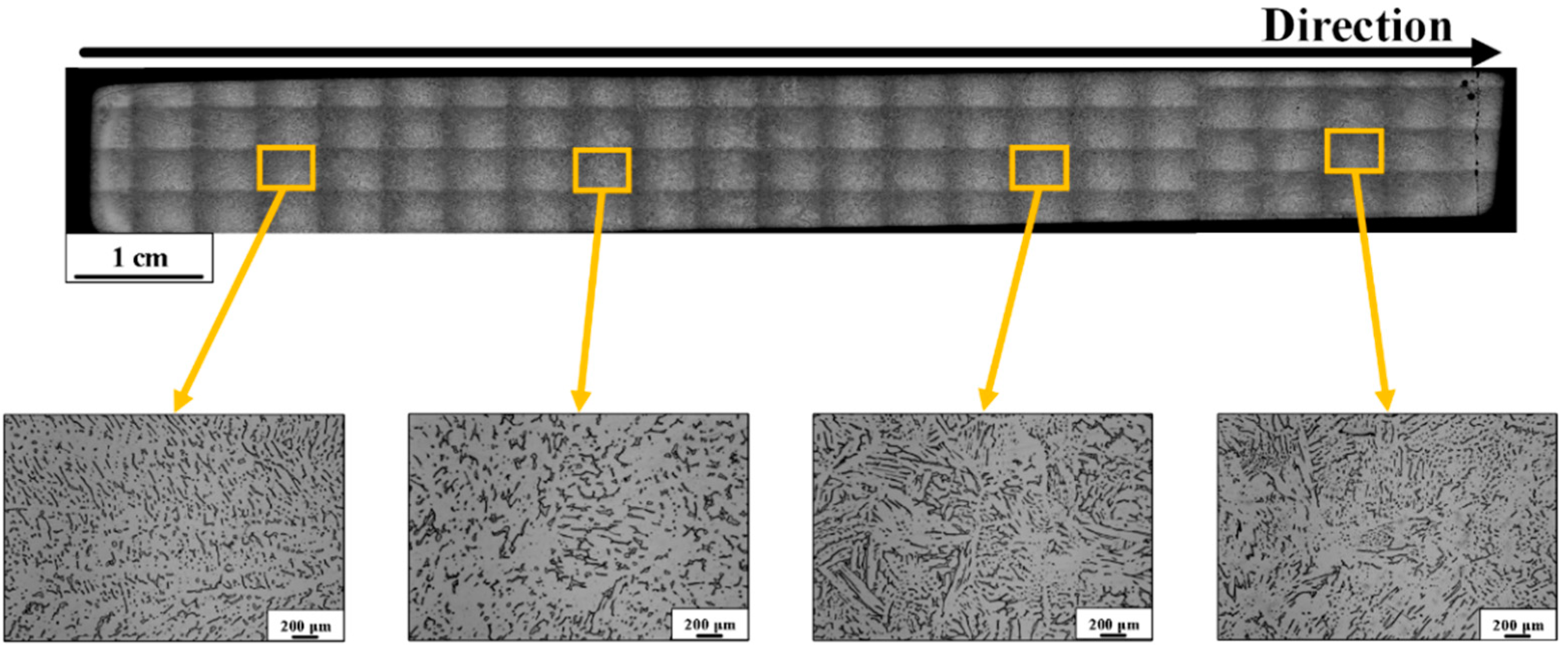

3.1. Metallography

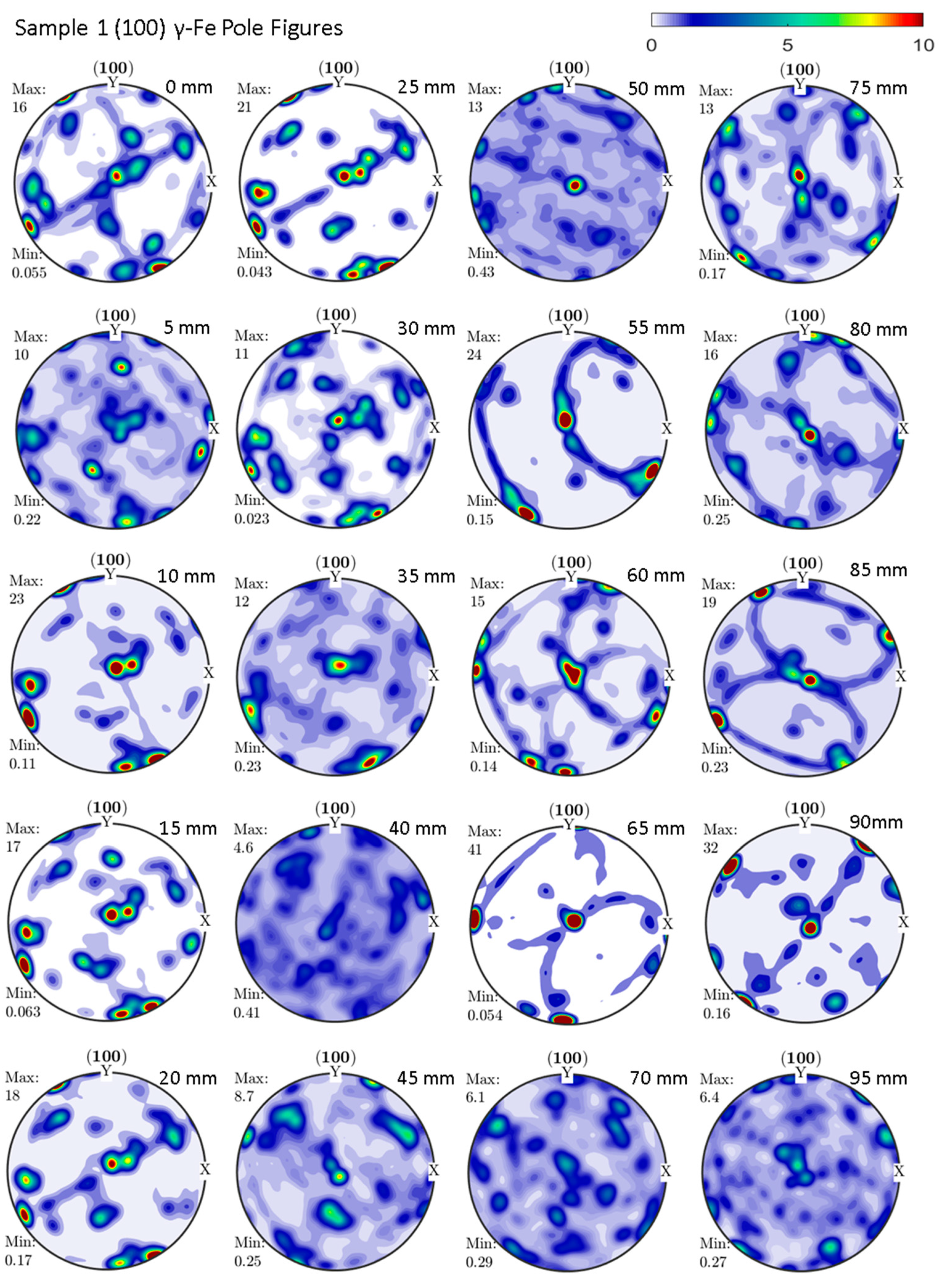

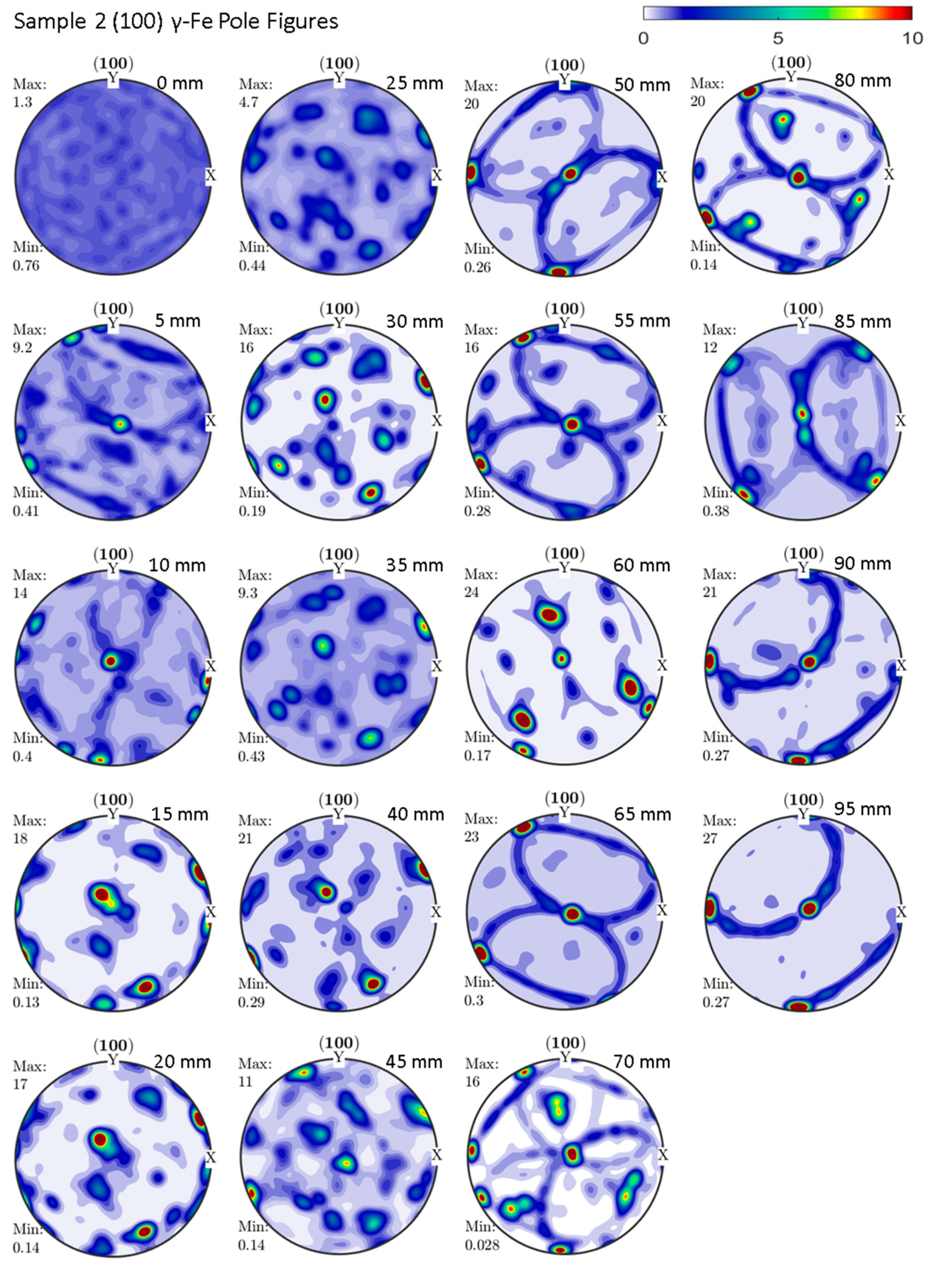

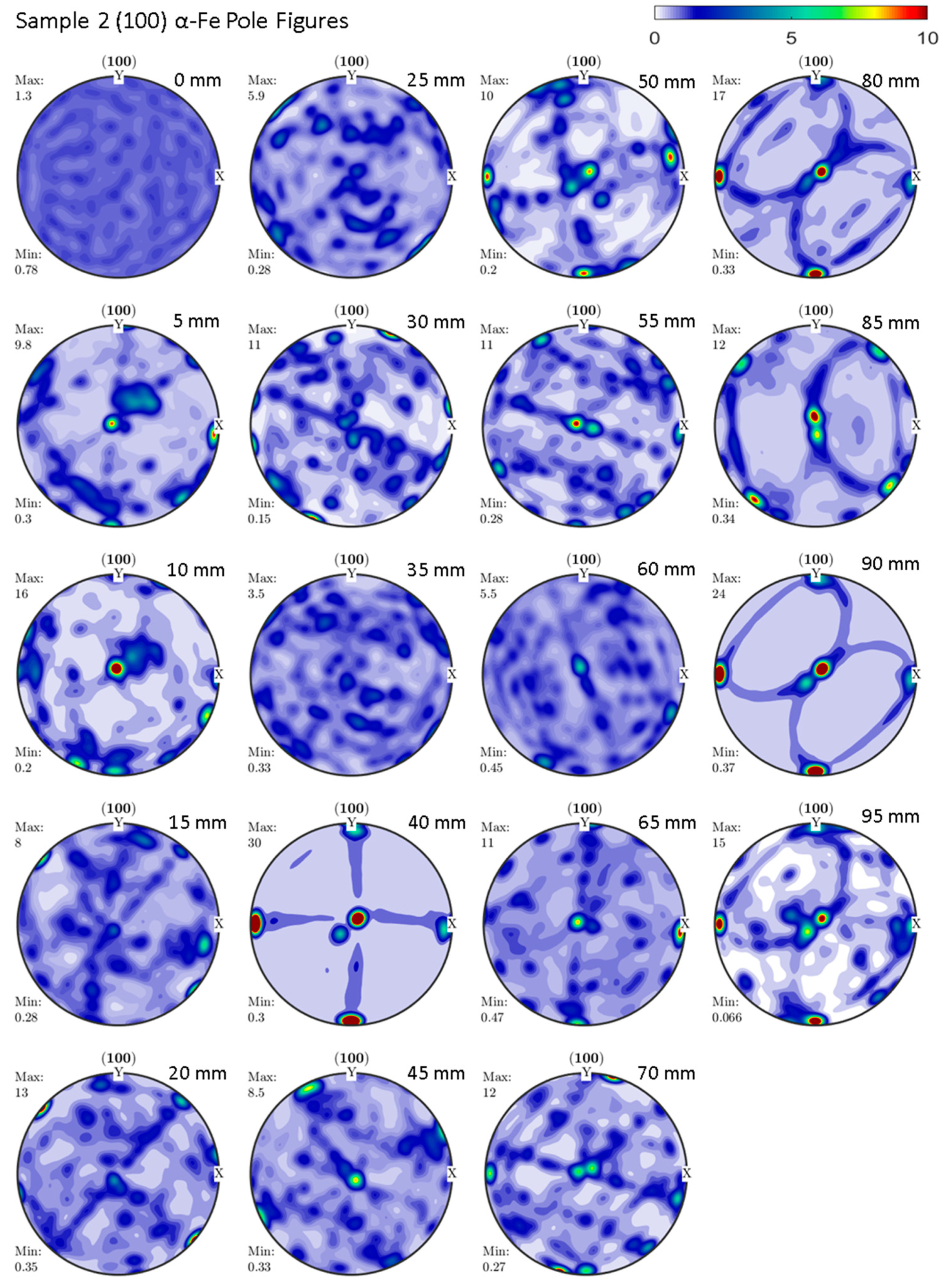

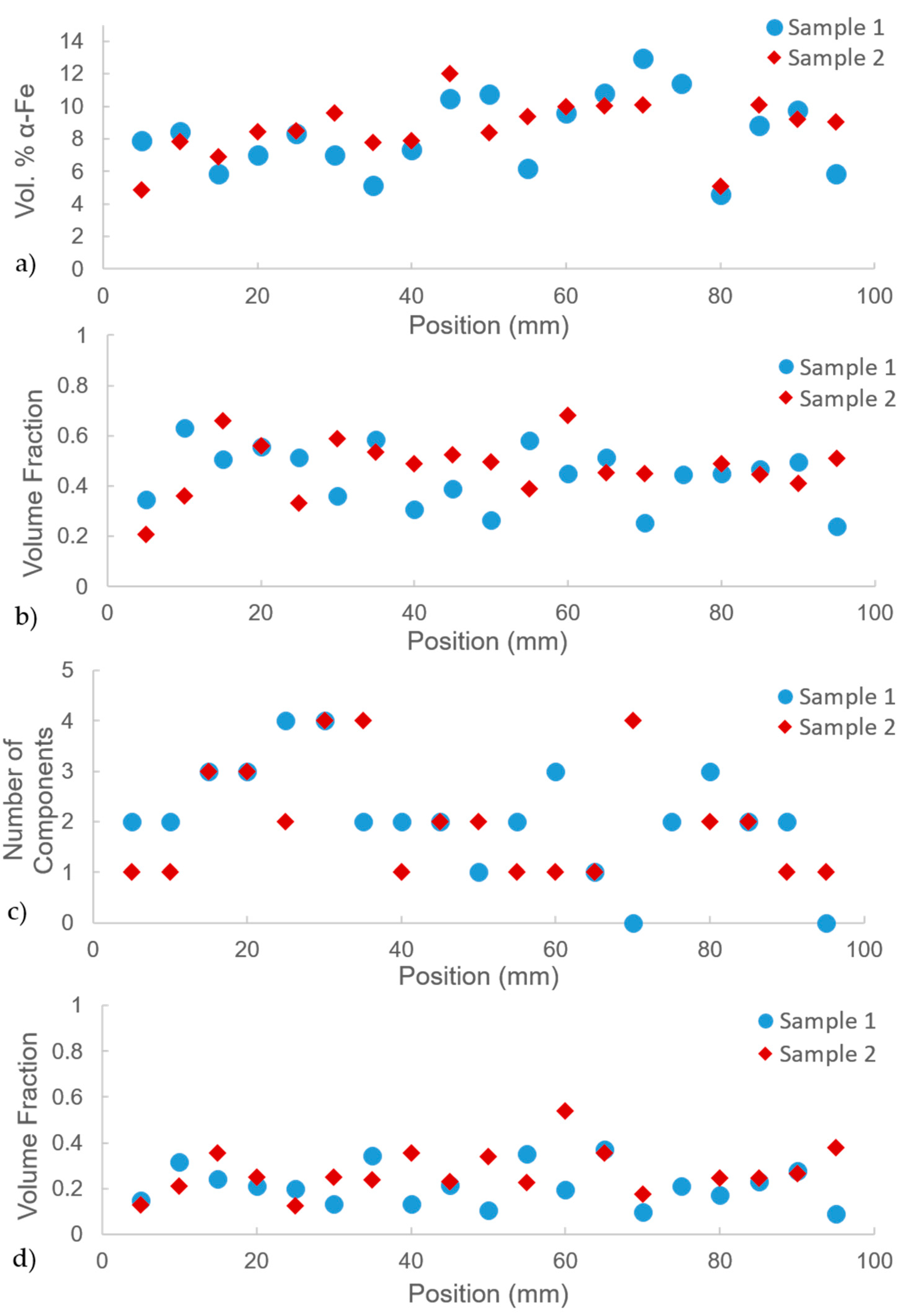

3.2. Texture Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jacob, R.E.; Crawford, S.L.; Moran, T.L.; Larche, M.R.; Prowant, M.S.; Diaz, A.A.; Nove, C.A. NDE Reliability Issues for the Examination of CASS Components; Pacific Northwest National Lab.(PNNL): Richland, WA, USA, 2019.

- Ruud, C.; Diaz, A.; Anderson, M. Grain Structure Identification and Casting Parameters of Austenitic Stainless Steel (Cass) Piping; PNNL-19002; Pacific Northwest National Laboratory: Richland, WA, USA, 2009.

- Ramuhalli, P.; Good, M.S.; Diaz, A.A.; Anderson, M.T.; Watson, B.E.; Peters, T.J.; Dixit, M.; Bond, L.J. Ultrasonic Characterization of Cast Austenitic Stainless Steel Microstructure: Discrimination between Equiaxed-and Columnar-Grain Material—An Interim Study; Pacific Northwest National Lab.(PNNL): Richland, WA, USA, 2009.

- Boiler, A.; Code, P.V. Section XI, Rules for Inservice Inspection of Nuclear Power Plant Components; American Society of Mechanical Engineering: New York, NY, USA, 1992. [Google Scholar]

- Wenk, H.-R.; Lutterotti, L.; Vogel, S. Texture analysis with the new HIPPO TOF diffractometer. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2003, 515, 575–588. [Google Scholar] [CrossRef]

- Takajo, S.; Brown, D.W.; Clausen, B.; Gray, G.T., III; Knapp, C.M.; Martinez, D.T.; Trujillo, C.P.; Vogel, S.C. Spatially Resolved Texture and Microstructure Evolution of Additively Manufactured and Gas Gun Deformed 304L Stainless Steel Investigated by Neutron Diffraction and Electron Backscatter Diffraction; Los Alamos National Lab.(LANL): Los Alamos, NM, USA, 2018; ISSN 0885-7156.

- Xu, P.; Tomota, Y.; Arakaki, Y.; Harjo, S.; Sueyoshi, H. Evaluation of austenite volume fraction in TRIP steel sheets using neutron diffraction. Mater. Charact. 2017, 127, 104–110. [Google Scholar] [CrossRef]

- Tomota, Y. Crystallographic characterization of steel microstructure using neutron diffraction. Sci. Technol. Adv. Mater. 2019, 20, 1189–1206. [Google Scholar] [CrossRef]

- McCusker, L.; Von Dreele, R.; Cox, D.; Louër, D.; Scardi, P. Rietveld refinement guidelines. J. Appl. Crystallogr. 1999, 32, 36–50. [Google Scholar] [CrossRef]

- Wenk, H.-R.; Van Houtte, P. Texture and anisotropy. Rep. Prog. Phys. 2004, 67, 1367. [Google Scholar] [CrossRef]

- Madsen, I.C.; Scarlett, N.V.; Cranswick, L.M.; Lwin, T. Outcomes of the International Union of Crystallography Commission on powder diffraction round robin on quantitative phase analysis: Samples 1a to 1h. J. Appl. Crystallogr. 2001, 34, 409–426. [Google Scholar] [CrossRef]

- ASTM A351/A351M-18e1. Standard Specification for Castings, Austenitic, for Pressure-Containing Parts; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM A743/A743M-19. Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, for General Application; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM A744/A744M-20a. Standard Specification for Castings, Iron-Chromium-Nickel, Corrosion Resistant, for Severe Service; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Losko, A.S.; Vogel, S.C.; Reiche, H.M.; Nakotte, H. A six-axis robotic sample changer for high-throughput neutron powder diffraction and texture measurements. J. Appl. Crystallogr. 2014, 47, 2109–2112. [Google Scholar] [CrossRef]

- Vogel, S.C.; Hartig, C.; Lutterotti, L.; Von Dreele, R.B.; Wenk, H.-R.; Williams, D.J. Texture measurements using the new neutron diffractometer HIPPO and their analysis using the Rietveld method. Powder Diffr. 2004, 19, 65–68. [Google Scholar] [CrossRef]

- Lisowski, P.W.; Schoenberg, K.F. The Los Alamos neutron science center. Nucl. Instrum. Methods Phys. Res. Sect. A: Accel. Spectrometers Detect. Assoc. Equip. 2006, 562, 910–914. [Google Scholar] [CrossRef]

- Ino, T.; Ooi, M.; Kiyanagi, Y.; Kasugai, Y.; Maekawa, F.; Takada, H.; Muhrer, G.; Pitcher, E.J.; Russell, G.J. Measurement of neutron beam characteristics at the Manuel Lujan Jr. neutron scattering center. Nucl. Instrum. Methods Phys. Res. Sect. A: Accel. Spectrometers Detect. Assoc. Equip. 2004, 525, 496–510. [Google Scholar] [CrossRef]

- Takajo, S.; Vogel, S.C. Determination of pole figure coverage for texture measurements with neutron time-of-flight diffractometers. J. Appl. Crystallogr. 2018, 51, 895–900. [Google Scholar] [CrossRef]

- Savage, D.J.; McWilliams, B.A.; Vogel, S.C.; Trujillo, C.P.; Beyerlein, I.J.; Knezevic, M. Mechanical behavior and texture evolution of WE43 magnesium-rare earth alloy in Split-Hopkinson Pressure Bar and Taylor Impact Cylinder Testing. Int. J. Impact Eng. 2020, 143, 103589. [Google Scholar] [CrossRef]

- Matthies, S.; Pehl, J.; Wenk, H.-R.; Lutterotti, L.; Vogel, S. Quantitative texture analysis with the HIPPO neutron TOF diffractometer. J. Appl. Crystallogr. 2005, 38, 462–475. [Google Scholar] [CrossRef]

- Carpenter, J.; Liu, X.; Darbal, A.; Nuhfer, N.; McCabe, R.; Vogel, S.; LeDonne, J.; Rollett, A.; Barmak, K.; Beyerlein, I. A comparison of texture results obtained using precession electron diffraction and neutron diffraction methods at diminishing length scales in ordered bimetallic nanolamellar composites. Scr. Mater. 2012, 67, 336–339. [Google Scholar] [CrossRef]

- Onuki, Y.; Hoshikawa, A.; Nishino, S.; Sato, S.; Ishigaki, T. Rietveld Texture Analysis for Metals Having Hexagonal Close-Packed Phase by Using Time-of-Flight Neutron Diffraction at iMATERIA. Adv. Eng. Mater. 2018, 20, 1700227. [Google Scholar] [CrossRef]

- Onuki, Y.; Hoshikawa, A.; Sato, S.; Ishigaki, T.; Tomida, T. Quantitative phase fraction analysis of steel combined with texture analysis using time-of-flight neutron diffraction. J. Mater. Sci. 2017, 52, 11643–11658. [Google Scholar] [CrossRef]

- Lutterotti, L. Maud: A Rietveld analysis program designed for the internet and experiment integration. Acta Crystallogr. A 2000, 56, s54. [Google Scholar] [CrossRef]

- Wenk, H.-R.; Lutterotti, L.; Vogel, S. Rietveld texture analysis from TOF neutron diffraction data. Powder Diffr. 2010, 25, 283–296. [Google Scholar] [CrossRef]

- Lutterotti, L. Quantitative Rietveld Analysis in Batch Mode with Maud. Structures of Minute Crystallites with Exceptional Properties and Frontiers of Powder Diffraction 2011. Available online: http://www.ing.unitn.it/~maud/tutorial/Maudbatch.pdf (accessed on 15 January 2021).

- Peng, L.-M.; Ren, G.; Dudarev, S.; Whelan, M. Debye–Waller factors and absorptive scattering factors of elemental crystals. Acta Crystallogr. Sect. A Found. Crystallogr. 1996, 52, 456–470. [Google Scholar] [CrossRef]

- Larson, A.C.; Von Dreele, R.B. GSAS—General Structure Analysis System. In Los Alamos National Laboratory Report LAUR 86-748; Regents of the University of California: Oakland, CA, USA, 1994. [Google Scholar]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture analysis with MTEX–free and open source software toolbox. Proc. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- Rafailov, G.; Caspi, E.a.N.; Hielscher, R.; Tiferet, E.; Schneck, R.; Vogel, S.C. Visualization of texture components using MTEX. J. Appl. Crystallogr. 2020, 53. [Google Scholar] [CrossRef]

- MATLAB. R2020a; The MathWorks Inc.: Natick, MA, USA, 2020. [Google Scholar]

- Abràmoff, M.D.; Magalhães, P.J.; Ram, S.J. Image processing with ImageJ. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Papadopulos, F.; Spinelli, M.; Valente, S.; Foroni, L.; Orrico, C.; Alviano, F.; Pasquinelli, G. Common tasks in microscopic and ultrastructural image analysis using ImageJ. Ultrastruct. Pathol. 2007, 31, 401–407. [Google Scholar] [CrossRef]

- Toby, B.H. R factors in Rietveld analysis: How good is good enough? Powder Diffr. 2006, 21, 67–70. [Google Scholar] [CrossRef]

- Wang, X.-L.; Wang, Y.; Richardson, J. Experimental error caused by sample displacement in time-of-flight neutron diffractometry. J. Appl. Crystallogr. 2002, 35, 533–537. [Google Scholar] [CrossRef]

- Wenk, H.-R.; Vasin, R.; Kern, H.; Matthies, S.; Vogel, S.; Ivankina, T. Revisiting elastic anisotropy of biotite gneiss from the Outokumpu scientific drill hole based on new texture measurements and texture-based velocity calculations. Tectonophysics 2012, 570, 123–134. [Google Scholar] [CrossRef]

- Evans, J.A.; Sturtevant, B.T.; Clausen, B.; Vogel, S.C.; Balakirev, F.F.; Betts, J.B.; Capolungo, L.; Lebensohn, R.A.; Maiorov, B. Determining elastic anisotropy of textured polycrystals using resonant ultrasound spectroscopy. J. Mater. Sci. 2021, 56, 10053–10073. [Google Scholar] [CrossRef]

- Cereser, A.; Strobl, M.; Hall, S.A.; Steuwer, A.; Kiyanagi, R.; Tremsin, A.S.; Knudsen, E.B.; Shinohara, T.; Willendrup, P.K.; da Silva Fanta, A.B. Time-of-flight three dimensional neutron diffraction in transmission mode for mapping crystal grain structures. Sci. Rep. 2017, 7, 9561. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmitt, M.M.; Savage, D.J.; Wall, J.J.; Yeager, J.D.; Lee, C.; Vogel, S.C. Through-Thickness Microstructure Characterization in a Centrifugally Cast Austenitic Stainless Steel Nuclear Reactor Primary Loop Pipe Using Time-of-Flight Neutron Diffraction. Quantum Beam Sci. 2021, 5, 12. https://doi.org/10.3390/qubs5020012

Schmitt MM, Savage DJ, Wall JJ, Yeager JD, Lee C, Vogel SC. Through-Thickness Microstructure Characterization in a Centrifugally Cast Austenitic Stainless Steel Nuclear Reactor Primary Loop Pipe Using Time-of-Flight Neutron Diffraction. Quantum Beam Science. 2021; 5(2):12. https://doi.org/10.3390/qubs5020012

Chicago/Turabian StyleSchmitt, Matthew M., Daniel J. Savage, James J. Wall, John D. Yeager, Chanho Lee, and Sven C. Vogel. 2021. "Through-Thickness Microstructure Characterization in a Centrifugally Cast Austenitic Stainless Steel Nuclear Reactor Primary Loop Pipe Using Time-of-Flight Neutron Diffraction" Quantum Beam Science 5, no. 2: 12. https://doi.org/10.3390/qubs5020012

APA StyleSchmitt, M. M., Savage, D. J., Wall, J. J., Yeager, J. D., Lee, C., & Vogel, S. C. (2021). Through-Thickness Microstructure Characterization in a Centrifugally Cast Austenitic Stainless Steel Nuclear Reactor Primary Loop Pipe Using Time-of-Flight Neutron Diffraction. Quantum Beam Science, 5(2), 12. https://doi.org/10.3390/qubs5020012