Mechanical Performance of a Hot Mix Asphalt Modified with Biochar Obtained from Oil Palm Mesocarp Fiber

Abstract

1. Introduction

2. Materials and Methods

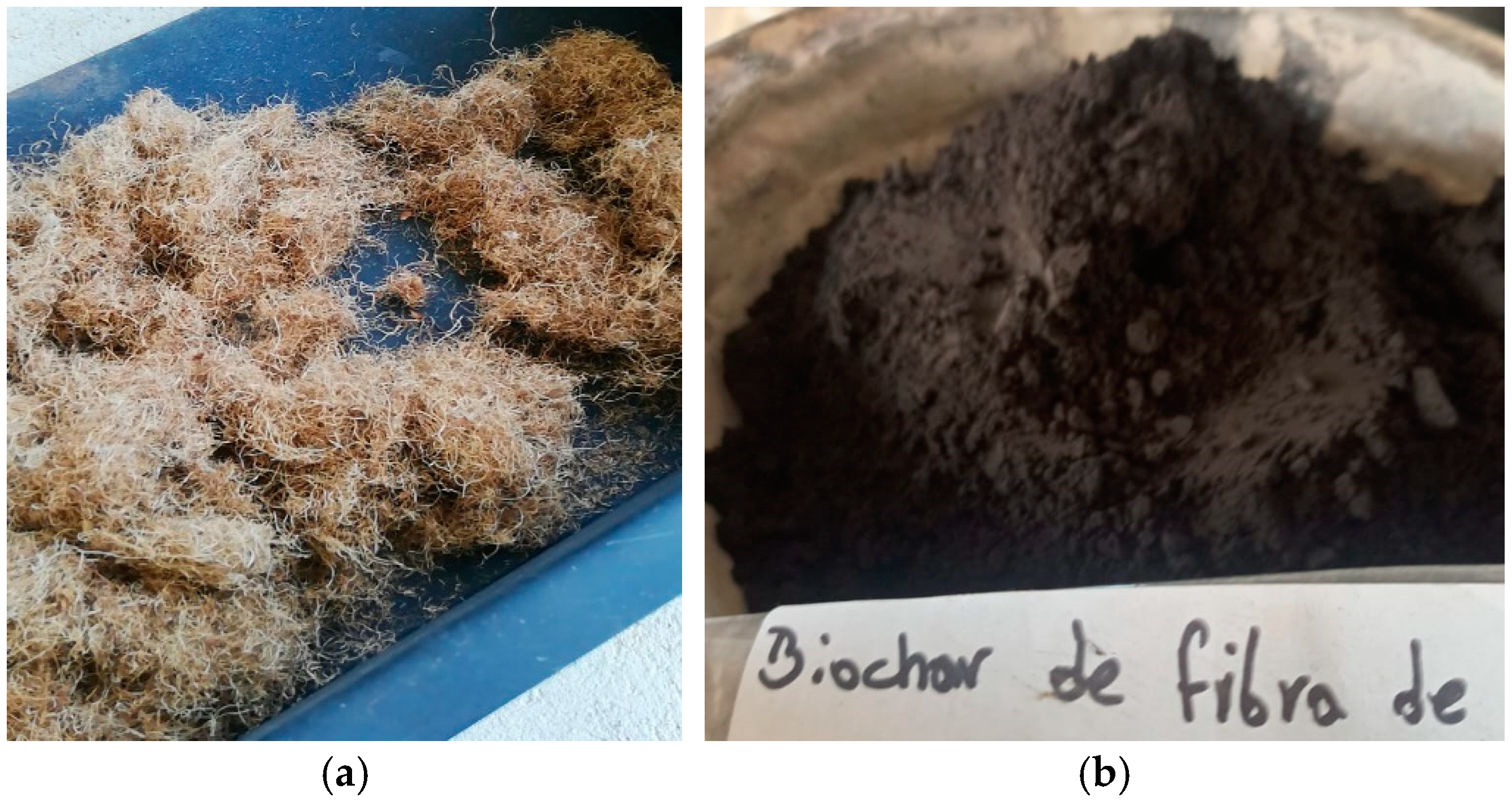

2.1. Materials

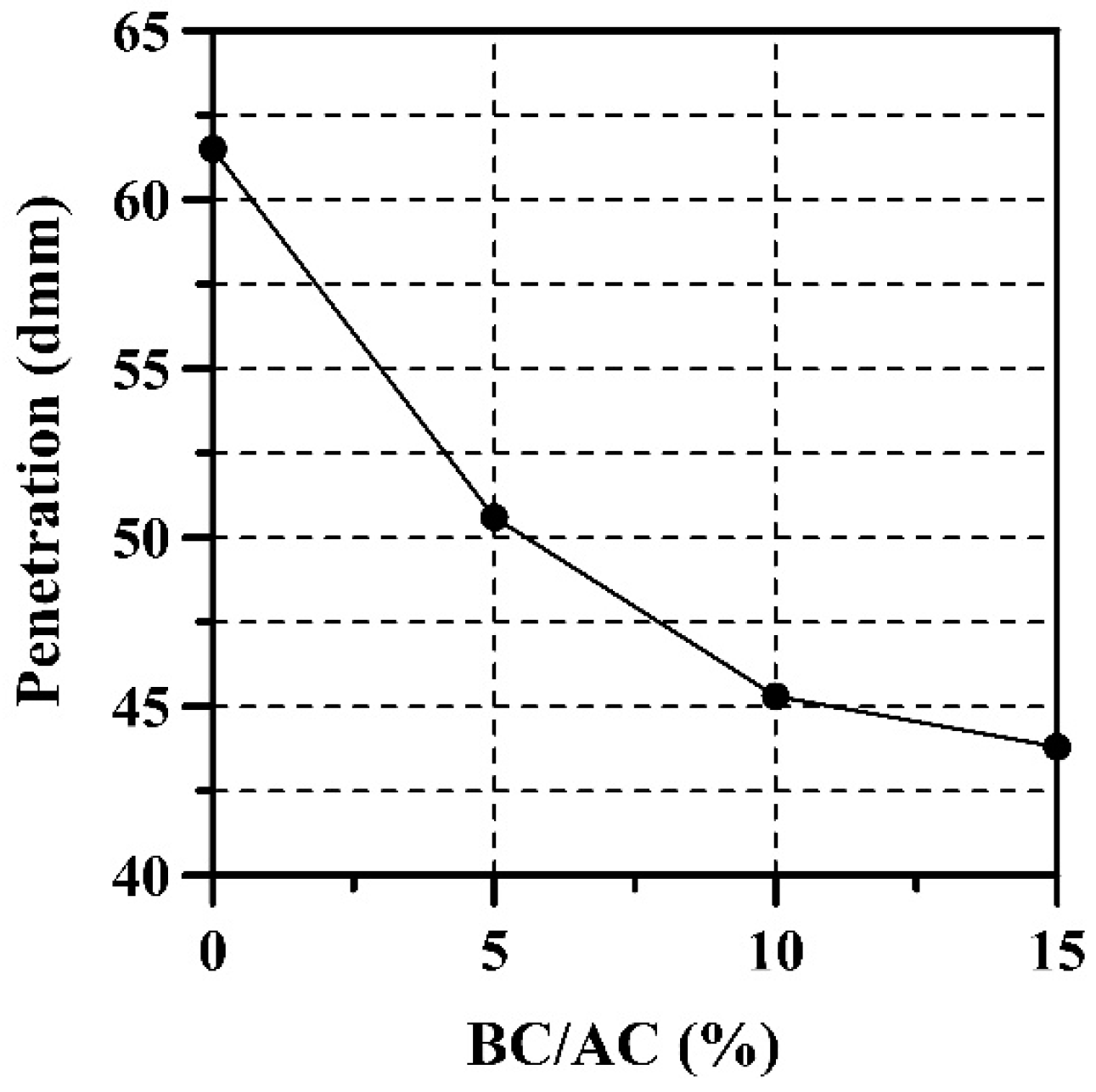

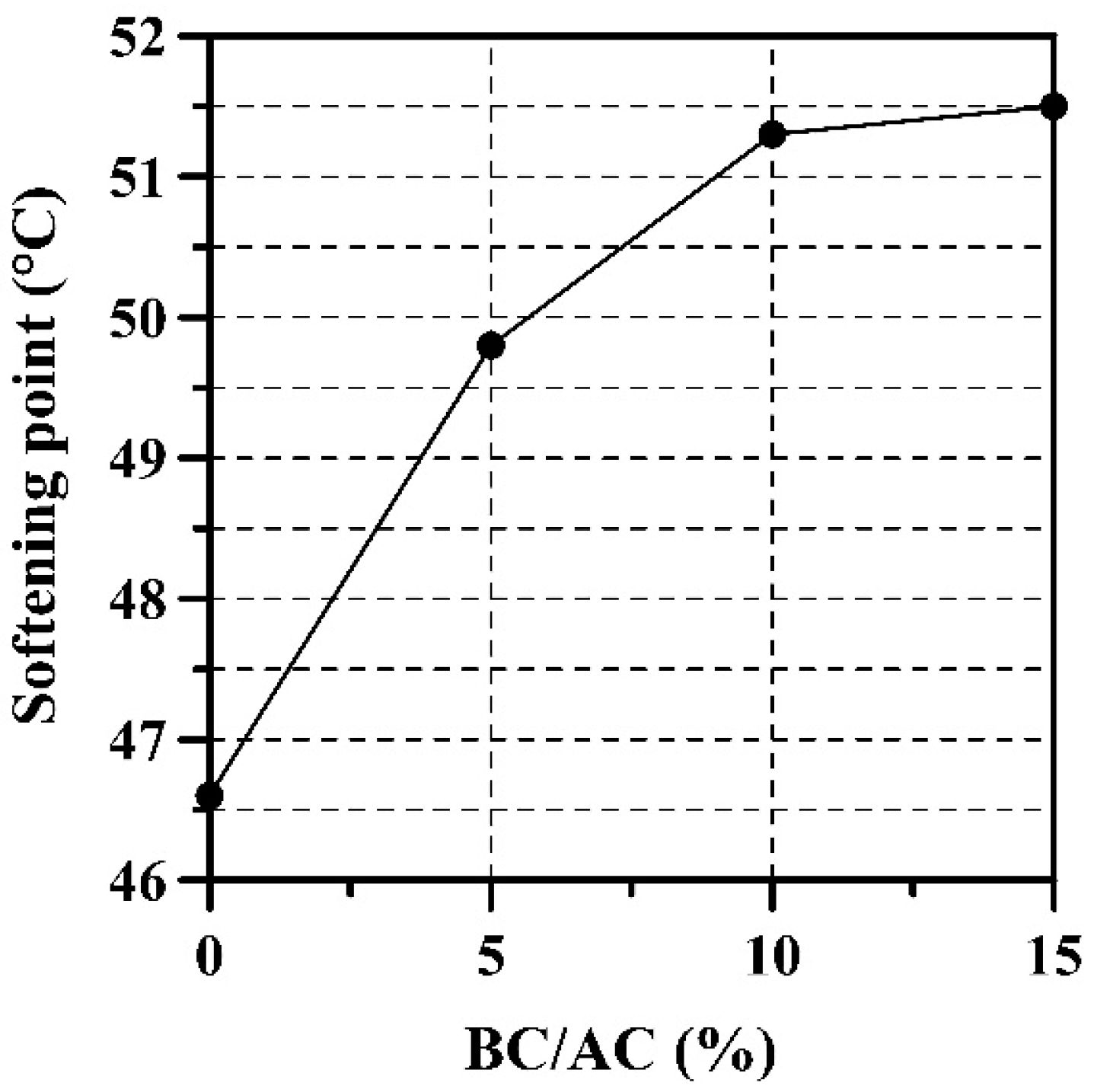

2.2. Modification and Properties of Modified Asphalt Binder

2.3. Asphalt Mix Design Procedure

2.4. Mechanical Resistance Tests

3. Results and Analysis

3.1. Asphalt Mix Design

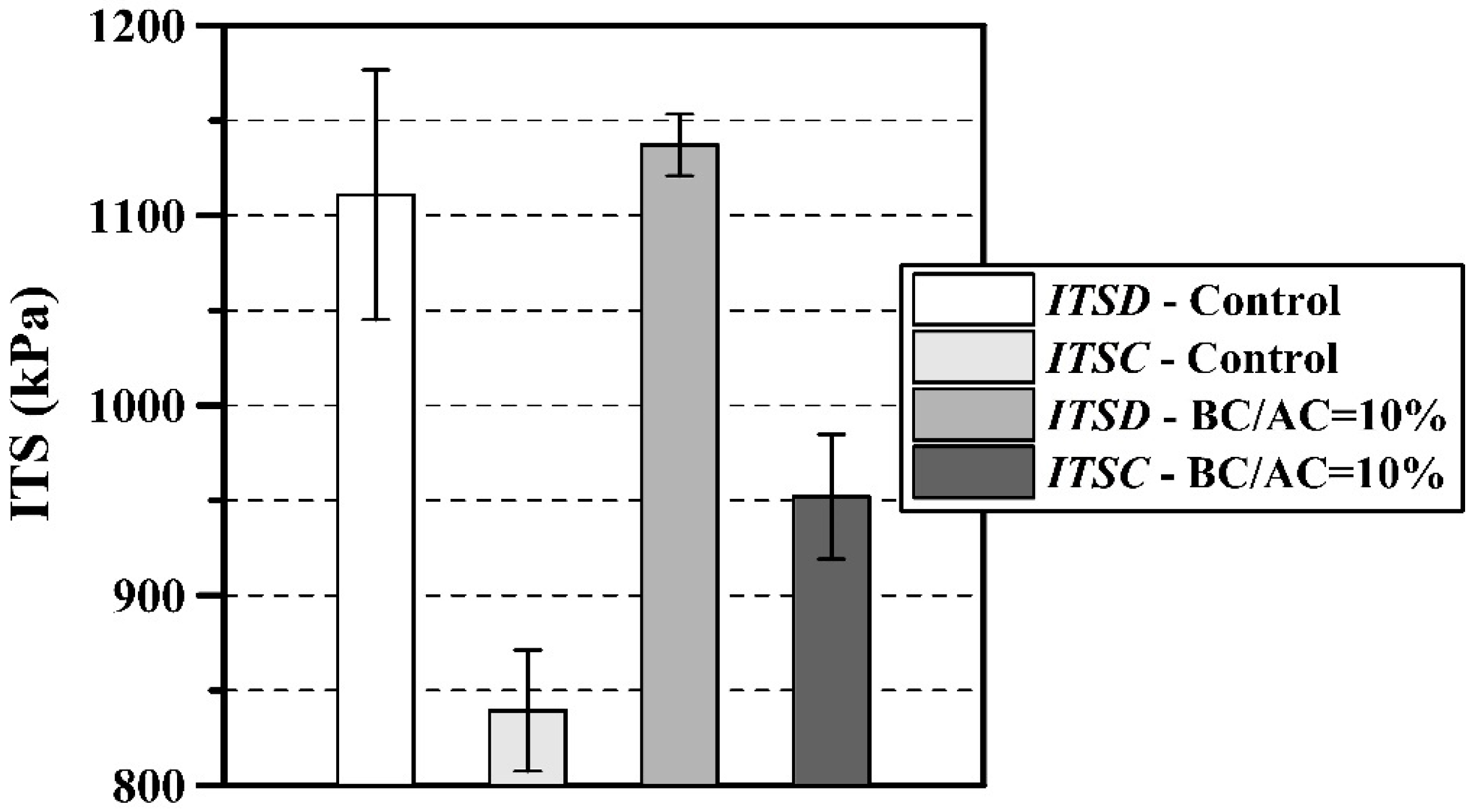

3.2. Indirect Tensile Strength and Cantabro Tests

3.3. Resilient Modulus and Permanent Deformation Tests

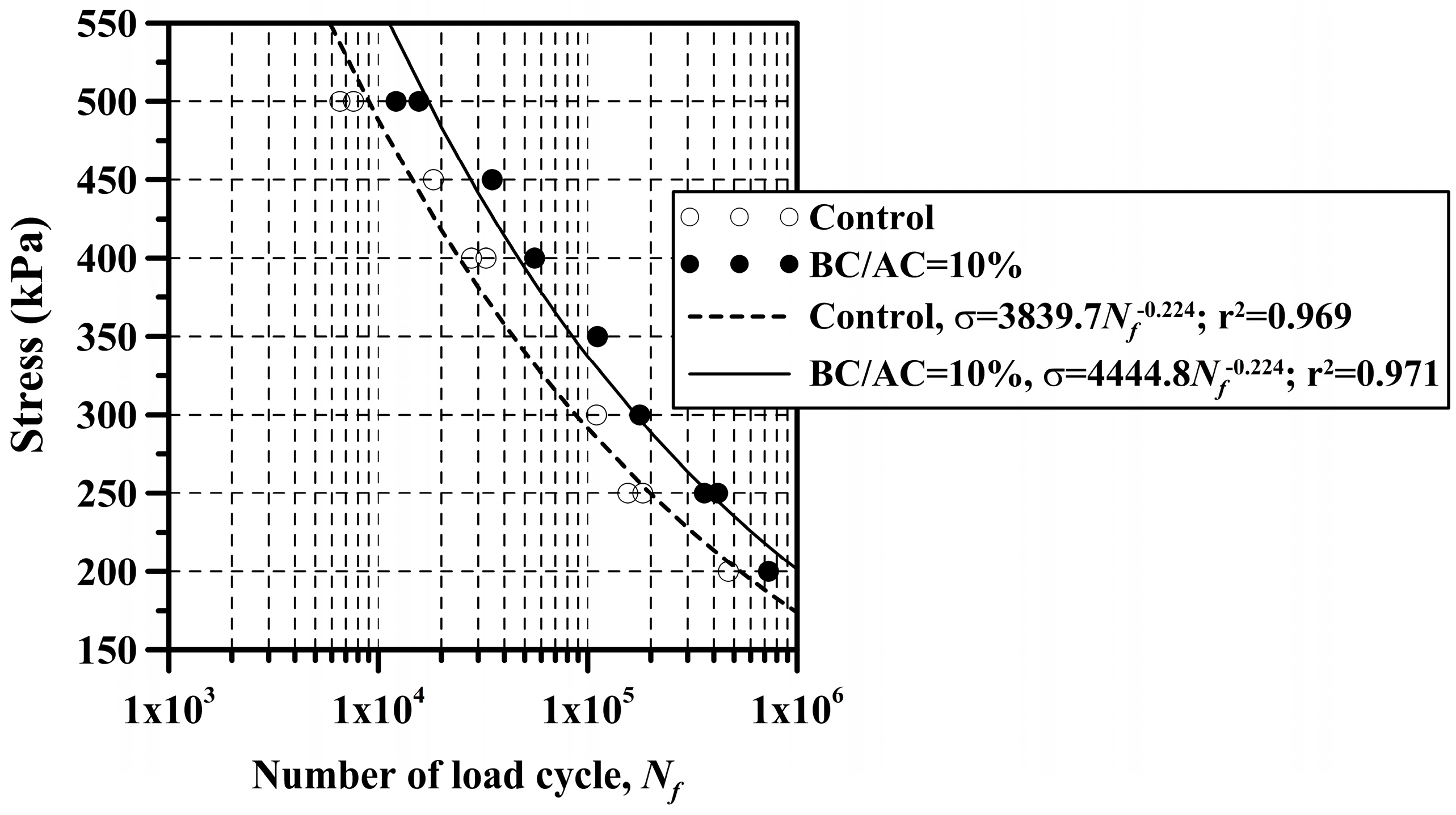

3.4. Fatigue Resistance Test

4. Conclusions

- The optimum BC-OPMF content was 10% by mass (BC/AC = 10%).

- The binder stiffness and the performance grade (PG) at high temperatures increased. No changes were observed in the PG at intermediate service temperatures.

- With BC/AC = 10%, no lump formation was observed. There was also no loss of workability in the binder.

- The increase in stiffness of the modified binder generated a modified HMA that was stiffer under cyclic loading (increased resilient modulus and resistance to permanent deformation) and monotonic loading (higher S/F ratio in the Marshall test).

- The modified HMA mix (BC/AC = 10%) had a higher ITSD, ITSC, TSR, a, σ6, σ7, and a lower CL compared to the control HMA.

- The BC-OPMF helped generate a binder that bonded better with aggregates, generating an HMA that tends to be more resistant to moisture damage, raveling, and fatigue under the stress-controlled mode.

- The use of a modified HMA is recommended in hot temperature climates and in the construction of thick asphalt layers where a stress-controlled mode is more effective to evaluate fatigue resistance.

- According to ANOVA analysis, the BC-OPMF generated statistically significant changes in the measured and evaluated properties of the HMAs, except for their volumetric composition.

- Rheological characterization tests show that BC-OPMF could help to increase the resistance to thermo-oxidative aging of the base binder. However, to confirm this conclusion, further tests should be performed.

- BC-OPMF might be considered as a potential environmentally sustainable modifier for AC that can increase the stiffness and rutting resistance of HMAs in high-temperature regions, maintaining performance levels at intermediate temperatures.

- BC-OPMF improves resistance to moisture damage, raveling, and fatigue without requiring an increase in the OAC, altering the volume composition, and/or raising the mixing and compaction temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mensah, R.A.; Shanmugam, V.; Narayanan, S.; Razavi, S.M.J.; Ulfberg, A.; Blanksvärd, T.; Sayahi, F.; Simonsson, P.; Reinke, B.; Försth, M.; et al. Biochar-Added cementitious materials—A review on mechanical, thermal, and environmental properties. Sustainability 2021, 13, 9336. [Google Scholar] [CrossRef]

- Legan, M.; Gotvajn, A.Ž.; Zupan, K. Potential of biochar use in building materials. J. Environ. Manag. 2022, 309, 114704. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Napiah, M.; Usman, A.; Jagaba, A.H.; Al-Sabaeei, A.M. Application and circular economy prospects of palm oil waste for eco-friendly asphalt pavement industry: A review. J. Road Eng. 2022, 2, 309–331. [Google Scholar] [CrossRef]

- Boloy, R.A.M.; da Cunha Reis, A.; Rios, E.M.; Martins, J.A.S.; Soares, L.O.; de Sá Machado, V.A.; de Moraes, D.R. Waste-to-energy technologies towards circular economy: A systematic literature review and bibliometric analysis. Water Air Soil Poll. 2021, 232, 306. [Google Scholar] [CrossRef]

- Cheah, W.Y.; Siti-Dina, R.P.; Leng, S.T.K.; Er, A.C.; Show, P.L. Circular bioeconomy in palm oil industry: Current practices and future perspectives. Environ. Technol. Innov. 2023, 30, 103050. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Urena, L.J.; Cortes-García, F.J.; Camacho-Ferre, F. Agricultural waste: Review of the evolution, approaches and perspectives on alternative uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Jagaba, A.H.; Kutty, S.R.M.; Hayder, G.; Baloo, L.; Noor, A.; Yaro, N.S.A.; Saeed, A.A.H.; Lawal, I.M.; Birniwa, A.H.; Usman, A.K. A systematic literature review on waste-to-resource potential of palm oil clinker for sustainable engineering and environmental applications. Materials 2021, 14, 4456. [Google Scholar] [CrossRef]

- Harun, N.Y.; Han, T.J.; Vijayakumar, T.; Saeed, A.; Afzal, M.T. Ash deposition characteristics of industrial biomass waste and agricultural residues. Mater. Today Proc. 2019, 19, 1712–1721. [Google Scholar] [CrossRef]

- Quintero-López, L.A.; Torrez-Pérez, C.I. Análisis de residuos sólidos de palma africana, como alternativa de aprovechamiento de energías renovables en el departamento del Cesar. Ing. USBMed 2019, 10, 8–18. [Google Scholar] [CrossRef]

- Potter, L. Colombia’s oil palm development in times of war and ‘peace’: Myths, enablers and the disparate realities of land control. J. Rural Stud. 2020, 78, 491–502. [Google Scholar] [CrossRef]

- Millán-Quijano, J.; Pulgarín, S. Oiling up the field. Forced internal displacement and the expansion of palm oil in Colombia. World Dev. 2023, 162, 106130. [Google Scholar] [CrossRef]

- Van Dam, J. Subproductos de la Palma de Aceite Como Materias Primas de Biomasa. Palmas 2016, 37, 149–156. Available online: https://fedepalma.org/conferenciainternacional/wp-content/uploads/2022/09/M_2_15_-Subproductos-de-la-palma.pdf (accessed on 3 May 2024).

- Al-Sabaeei, A.M.; Al-Fakih, A.; Noura, S.; Yaghoubi, E.; Alaloul, W.; Al-Mansob, R.A.; Khan, M.I.; Yaro, N.S.A. Utilization of palm oil and its by-products in bio-asphalt and bio-concrete mixtures: A review. Constr. Build. Mater. 2022, 337, 127552. [Google Scholar] [CrossRef]

- Nabila, R.; Hidayat, W.; Haryanto, A.; Hasanudin, U.; Iryani, D.A.; Lee, S.; Kim, S.; Kim, S.; Chun, D.; Choi, H.; et al. Oil palm biomass in Indonesia: Thermochemical upgrading and its utilization. Renew. Sustain. Energy Rev. 2023, 176, 113193. [Google Scholar] [CrossRef]

- Sierra-Márquez, J.; Sierra-Márquez, L.; Olivero-Verbel, J. Economic potential of the oil palm (Elaeis guineensis Jacq). Agron. Mesoam. 2017, 28, 523–534. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Napiah, M.B.; Sutanto, M.H.; Usman, A.; Saeed, S.M. Performance evaluation of waste palm oil fiber reinforced stone matrix asphalt mixtures using traditional and sequential mixing processes. Case Stud. Constr. Mater. 2021, 15, e00783. [Google Scholar] [CrossRef]

- Hernandez, J.C.B.; Gutierrez, A.S.; Ramírez-Contreras, N.E.; Eras, J.J.C.; García-Nunez, J.A.; Agudelo, O.R.B.; Lora, E.E.S. Biomass-based energy potential from the oil palm agroindustry in Colombia: A path to low carbon energy transition. J. Clean. Prod. 2024, 449, 141808. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.A.; Syamsir, A.; Nurazzi, N.M.; Sabaruddin, F.A.; Shazleen, S.S.; Norrrahim, M.N.F.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Mechanical properties of oil palm fibre-reinforced polymer composites: A review. J. Mater. Res. Technol. 2022, 17, 33–65. [Google Scholar] [CrossRef]

- Gan, S.; Chen, R.S.; Padzil, F.N.M.; Moosavi, S.; Tarawneh, M.A.; Loh, S.K.; Idris, Z. Potential valorization of oil palm fiber in versatile applications towards sustainability: A review. Ind. Crops Prod. 2023, 199, 116763. [Google Scholar] [CrossRef]

- Siddiqui, V.U.; Sapuan, S.M.; Isah, A.; Yusuf, J.; Khan, A. Advancements in multiscale oil palm fiber composites: Manufacturing techniques, performance evaluation, and industrial applications. Ind. Crops Prod. 2024, 213, 118399. [Google Scholar] [CrossRef]

- Amartey, B.H.S.; Kumator, T.J.; Amartey, Y.D.; Ali, A. The use of oil palm fibre as an additive in concrete. Mater. Today Proc. 2023, 86, 111–115. [Google Scholar] [CrossRef]

- Iqbal, S.M.; Zainal, S.; Abel, M.; Durai, D.; Rizalman, A.N.; Sulaiman, M.F. Experimental investigation on the mechanical properties of cement mortar containing recycled tire crumbs reinforced with polypropylene, oil palm and banana fibers. J. Build. Eng. 2024, 92, 109728. [Google Scholar] [CrossRef]

- Muniandy, R.; Huat, B.B. Laboratory diameteral fatigue performance of stone matrix asphalt with cellulose oil palm fiber. Am. J. Appl. Sci. 2006, 3, 20052010. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Napiah, M.; Usman, A.; Jagaba, A.H.; Al-Sabaeei, A.M. Modeling and optimization of asphalt content, waste palm oil clinker powder and waste rice straw ash for sustainable asphalt paving employing response surface methodology: A pilot study. Clean. Mater. 2023, 8, 100187. [Google Scholar] [CrossRef]

- Syammaun, T.; Rani, H.A. Resilient modulus of porous asphalt using oil palm fiber. IOP Conf. Ser. Mater. Sci. Eng. 2018, 403, 012023. [Google Scholar] [CrossRef]

- Tayh, S.A.; Yousif, R.A.; Banyhussan, Q.S. A comparative study of physical properties using various grades asphalt binder with different type of fibers. J. Eng. Res. 2020, 17, 34–40. [Google Scholar] [CrossRef]

- Aprianti, N.; Kismanto, A.; Supriatna, N.K.; Yarsono, S.; Nainggolan, L.M.T.; Purawiardi, R.I.; Fariza, O.; Ermada, F.J.; Zuldian, P.; Raksodewanto, A.A.; et al. Prospect and challenges of producing carbon black from oil palm biomass: A review. Bioresour. Technol. 2023, 23, 101587. [Google Scholar] [CrossRef]

- Torres-Morales, E.; Khatiwada, D.; Xylia, M.; Johnson, F.X. Investigating biochar as a net-negative emissions strategy in Colombia: Potentials, costs, and barriers. Curr. Res. Environ. Sustain. 2023, 6, 100229. [Google Scholar] [CrossRef]

- Zhou, Y.; Shen, C.; Wang, T.; Xue, Y. Inhibition effect of three types of biochar on volatile organic compounds from asphalt: Revealing chemical adsorption as the primary mechanism. Constr. Build. Mater. 2024, 411, 134322. [Google Scholar] [CrossRef]

- Zhou, X.; Moghaddam, T.B.; Chen, M.; Wu, S.; Adhikari, S. Biochar removes volatile organic compounds generated from asphalt. Sci. Total Environ. 2020, 745, 141096. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, T.; Yang, J.; Qi, J.; Zhang, L.; Liu, T.; Dai, S.; Zhao, Y.; Huang, Q.; Liu, Z.; et al. A review on the roles of biochar incorporated into cementitious materials: Mechanisms, application and perspectives. Constr. Build. Mater. 2023, 409, 134204. [Google Scholar] [CrossRef]

- Mousavi, M.; Park, K.; Kim, J.; Fini, E.H. Metal-rich biochar as an asphalt modifier to improve sustainability and reduce VOC emissions. Sustain. Mater. Technol. 2024, 40, e00903. [Google Scholar] [CrossRef]

- Yaphary, Y.L.; He, M.; Lu, G.; Zou, F.; Liu, P.; Tsang, D.C.W.; Leng, Z. Experiment and multiscale molecular simulations on the Cu absorption by biochar-modified asphalt: An insight into removal capability and mechanism of heavy metals from stormwater runoff. Chem. Eng. J. 2023, 462, 142205. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Farid, M.A.A.; Andou, Y.; Ramli, I.; Hassan, M.A. Production of biochar and activated carbon from oil palm biomass: Current status, prospects, and challenges. Ind. Crops Prod. 2023, 199, 116767. [Google Scholar] [CrossRef]

- Zhu, H.; An, Q.; Nasir, A.S.M.; Babin, A.; Saucedo, S.L.; Vallenas, A.; Li, L.; Baldwin, S.A.; Lau, A.; Bi, X. Emerging applications of biochar: A review on techno-environmental-economic aspects. Bioresour. Technol. 2023, 388, 129745. [Google Scholar] [CrossRef] [PubMed]

- Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Chaves-Pabón, S.B.; Bastidas-Martínez, J.G.; Zafra-Mejía, C.A. Use of Biochar in Asphalts: Review. Sustainability 2022, 14, 4745. [Google Scholar] [CrossRef]

- Singhal, S. Biochar as a cost-effective and eco-friendly substitute for binder in concrete: A review. Eur. J. Environ. Civ. Eng. 2023, 27, 984–1009. [Google Scholar] [CrossRef]

- Spokas, K.A. Review of the stability of biochar in soils: Predictability of O:C molar ratios. Carbon Manag. 2010, 1, 289–303. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Factors determining the potential of biochar as a carbon capturing and sequestering construction material: Critical review. J. Mater. Civ. Eng. 2017, 29, 04017086. [Google Scholar] [CrossRef]

- Restuccia, L.; Ferro, G.A.; Suarez-Riera, D.; Sirico, A.; Bernardi, P.; Belletti, B.; Malcevschi, A. Mechanical characterisation of different biochar-based cement composites. Procedia Struct. Integr. 2020, 25, 226–233. [Google Scholar] [CrossRef]

- Maljaee, H.; Madadi, R.; Paiva, H.; Tarelho, L.; Ferreira, V.M. Incorporation of biochar in cementitious materials: A roadmap of biochar selection. Constr. Build. Mater. 2021, 283, 122757. [Google Scholar] [CrossRef]

- He, L.; Tao, M.; Liu, Z.; Cao, Z.; Zhu, J.; Gao, J.; Van den bergh, W.; Chailleux, E.; Huang, Y.; Vasconcelos, K.; et al. Biomass valorization toward sustainable asphalt pavements: Progress and prospects. Waste Manag. 2023, 165, 159–178. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Huang, B.; Ye, X.P.; Shu, X.; Jia, X. Utilizing bio-char as a bio-modifier for asphalt cement: A sustainable application of bio-fuel by-product. Fuel 2014, 133, 52–62. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Ye, P. Laboratory investigation of biochar-modified asphalt mixture. Transp. Res. Rec. 2014, 2445, 56–63. [Google Scholar] [CrossRef]

- Çeloğlu, M.E.; Mehmet, Y.; Kök, B.V.; Yalçin, E. Effects of Various Biochars on the High Temperature Performance of Bituminous Binder. In Proceedings of the 6th Euraphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar] [CrossRef][Green Version]

- Kumar, A.; Choudhary, R.; Narzari, R.; Kataki, R.; Shukla, S.K. Evaluation of bio-asphalt binders modified with biochar: A pyrolysis by-product of Mesua ferrea seed cover waste. Cogent Eng. 2018, 5, 1548534. [Google Scholar] [CrossRef]

- Gan, X.; Zhang, W. Application of biochar from crop straw in asphalt modification. PLoS ONE 2021, 16, e0247390. [Google Scholar] [CrossRef]

- Ma, F.; Dai, J.; Fu, Z.; Li, C.; Wen, Y.; Jia, M.; Wang, Y.; Shi, K. Biochar for asphalt modification: A case of high-temperature properties improvement. Sci. Total Environ. 2022, 804, 150194. [Google Scholar] [CrossRef]

- Wu, Y.; Cao, P.; Shi, F.; Liu, K.; Wang, X.; Leng, Z.; Tan, Z.; Zhou, C. Modeling of the complex modulus of asphalt mastic with biochar filler based on the homogenization and random aggregate distribution methods. Adv. Mater. Sci. Eng. 2020, 2020, 2317420. [Google Scholar] [CrossRef]

- Walters, R.C.; Fini, E.H.; Abu-Lebdeh, T. Enhancing asphalt rheological behavior and aging susceptibility using biochar and Nano-clay. Am. J. Appl. Sci. 2014, 7, 66–76. [Google Scholar] [CrossRef]

- Walters, R.C.; Begum, S.A.; Fini, E.H.; Abu-Lebdeh, T. Investigating bio-char as flow modifier and water treatment agent for sustainable pavement design. Am. J. Appl. Sci. 2015, 8, 138–146. [Google Scholar] [CrossRef]

- Zhang, R.; Dai, Q.; You, Z.; Wang, H.; Peng, C. Rheological performance of bio-char modified asphalt with different particle sizes. Appl. Sci. 2018, 8, 1665. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Ji, J.; Wang, H. Viscoelastic properties, rutting resistance, and fatigue resistance of WasteWood-based biochar-modified asphalt. Coatings 2022, 12, 89. [Google Scholar] [CrossRef]

- Zhou, X.; Adhikari, S. Flow-induced crystallization of biochar in bio-asphalt under various aging conditions. Sci. Total Environ. 2019, 695, 133943. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhao, G.; Wu, S.; Tighe, S.; Pickel, D.; Chen, M.; Adhikari, S.; Gao, Y. Effects of biochar on the chemical changes and phase separation of bio-asphalt under different aging conditions. J. Clean. Prod. 2020, 263, 121532. [Google Scholar] [CrossRef]

- Zhou, X.; Moghaddam, T.B.; Chen, M.; Wu, S.; Zhang, Y.; Zhang, X.; Adhikari, S.; Zhang, X. Effects of pyrolysis parameters on physicochemical properties of biochar and bio-oil and application in asphalt. Sci. Total Environ. 2021, 780, 146448. [Google Scholar] [CrossRef]

- Huari, R.A. Evaluación del Desempeño Físico-Químico y Reológico de un Asfalto Convencional Modificado por vía Húmeda con Biochar de Palma Africana y Cascara de Arroz. Master’s Thesis, Trabajo de Maestría en Ingeniería Civil, Pontificia Universidad Javeriana, Bogotá, Colombia, 2024. [Google Scholar]

- Rondón-Quintana, H.A.; Romero-Patiño, N.E.; Bastidas-Martínez, J.G. Performance properties of a hot-mix asphalt modified with oil palm kernel shell based biochar for road pavements. J. Transp. Eng. B Pavements 2025. Accepted to publish. [Google Scholar]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Usman, A.; Tanjung, L.E.; Aliyu, I.; Jagaba, A.H. Optimizing biochar-based geopolymer composites for enhanced water resistance in asphalt mixes: An experimental, microstructural, and multi-objective analysis. J. Eng. Appl. Sci. 2023, 70, 151. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Zafra-Mejía, C.A.; Urazán-Bonells, C.F. Aging resistance evaluation of an asphalt mixture modified with zinc oxide. Infrastructures 2024, 9, 81. [Google Scholar] [CrossRef]

- Rajib, A.; Saadeh, S.; Katawal, P.; Mobasher, B.; Fini, E.H. Enhancing biomass value chain by utilizing biochar as a free radical scavenger to delay ultraviolet aging of bituminous composites used in outdoor construction. Resour. Conserv. Recycl. 2021, 168, 105302. [Google Scholar] [CrossRef]

- INVIAS–Instituto Nacional de Vías. Especificaciones Generales de Construcción de Carreteras; INVIAS–Instituto Nacional de Vías: Bogotá, Colombia, 2022. [Google Scholar]

- IDU-Instituto de Desarrollo Urbano. Especificaciones Técnicas Generales de Materiales y Construcción para Proyectos de Infraestructura Vial y de Espacio Público en Bogotá D.C.; IDU-Instituto de Desarrollo Urbano: Bogotá, Colombia, 2018. [Google Scholar]

- Doyle, J.D.; Howard, I.L. Characterization of dense-graded asphalt with the Cantabro test. J. Test. Eval. 2016, 44, 77–88. [Google Scholar] [CrossRef]

- Cox, B.C.; Smith, B.T.; Howard, I.L.; James, R.S. State of knowledge for Cantabro testing of dense graded asphalt. J. Mater. Civ. Eng. 2017, 29, 04017174. [Google Scholar] [CrossRef]

- Elmagarhe, A.; Lu, Q.; Alamri, M.; Alharthai, M.; Elnihum, A. Laboratory performance evaluation of porous asphalt mixture containing recycled concrete aggregate and fly ash. Case Stud. Constr. Mater. 2024, 20, e02849. [Google Scholar] [CrossRef]

- Lim, S.M.; He, M.; Hao, G.; Ng, T.C.A.; Ong, G.P. Recyclability potential of waste plastic-modified asphalt concrete with consideration to its environmental impact. Constr. Build. Mater. 2024, 439, 137299. [Google Scholar] [CrossRef]

- Saadeh, S.; Al-Zubi, Y.; Zaatarah, B. Performance Testing of Hot Mix Asphalt Containing Biochar. Final Report 20–28; Mineta Transportation Institute: San Jose, CA, USA, 2020. [Google Scholar] [CrossRef]

- Saadeh, S.; Al-Zubi, Y.; Katawal, P.; Zaatarah, B.; Fini, E. Biochar effects on the performance of conventional and rubberized HMA. Road Mater. Pavement Des. 2023, 24, 156–172. [Google Scholar] [CrossRef]

- Usman, K.R.; Hainin, M.R.; Satar, M.K.I.M.; Warid, M.N.M.; Kamarudin, S.N.N.; Abdulrahman, S. Palm oil fuel ash application in cold mix dense-graded bituminous mixture. Constr. Build. Mater. 2021, 287, 123033. [Google Scholar] [CrossRef]

- Karati, S.; Roy, T.K. Assessment of temperature impact on SDA modified bituminous concrete by non-destructive test. Mater. Today Proc. 2022, 65 Pt 8, 3417–3423. [Google Scholar] [CrossRef]

- Barman, M.; Ghabchi, R.; Singh, D.; Zaman, M.; Commuri, S. An alternative analysis of indirect tensile test results for evaluating fatigue characteristics of asphalt mixes. Constr. Build. Mater. 2018, 166, 204–213. [Google Scholar] [CrossRef]

- Bharath, G.; Reddy, K.S.; Tandon, V.; Reddy, M.A. Aggregate gradation effect on the fatigue performance of recycled asphalt mixtures. Road Mater. Pavement Des. 2021, 22, 165–184. [Google Scholar] [CrossRef]

- Bastidas-Martinez, J.G.; Camapum de Carvalho, J.; Cristhiane, L.L.; Muniz de Farias, M.; Rondón-Quintana, H.A. Effects of iron ore tailing on performance of hot-mix asphalt. J. Mater. Civ. Eng. 2022, 34, 04021405. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Rondón-Quintana, H.A. Assessment of asphalt binder content, temperature and loading rate in indirect tensile strength and resilient modulus tests of a hot-mix asphalt—Comparison with Marshall design method. Constr. Build. Mater. 2024, 426, 136158. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Ruge-Cárdenas, J.C.; Reyes-Lizcano, F.A.; Bastidas-Martínez, J.G.; Zafra-Mejía, C.A. Mechanical resistance of hot-mix asphalt using phosphorite as filler. J. Mater. Civ. Eng. 2023, 35, 04023274. [Google Scholar] [CrossRef]

- Muniz de Farias, M.; Quiñonez Sinisterra, F.; Rondón-Quintana, H.A. Behavior of a hot mix asphalt made with recycled concrete aggregate and crumb rubber. Can. J. Civ. Eng. 2018, 46, 544–551. [Google Scholar] [CrossRef]

| Test | Standard | Unit | Requirement | Result |

|---|---|---|---|---|

| Specific gravity | AASHTO T 228 | - | - | 1.024 |

| Penetration (25 °C, 100 g, 5 s) | ASTM D-5 | dmm | 60–70 | 61.5 |

| Softening point | ASTM D-36 | °C | 46–54 | 46.6 |

| Absolute viscosity (60 °C) | ASTM D-4402 | Pa-s | 140–240 | 175 |

| Ductility (25 °C, 5 cm/min) | ASTM D-113 | cm | Minimum 100 | 122 |

| Ignition point | ASTM D-92 | °C | Minimum 232 | 267 |

| Mass loss | ASTM D 2872 | % | Maximum 0.80 | 0.17 |

| Test | Standard | Requirement | Result |

|---|---|---|---|

| Specific gravity of fine aggregate | AASHTO T 84 | - | 2.580 |

| Absorption of fine aggregate | AASHTO T 84 | - | 1.35% |

| Specific gravity of coarse aggregate | AASHTO T 85 | - | 2.623 |

| Absorption of coarse aggregate | AASHTO T 85 | - | 1.77% |

| Fractured particles (1 side) | ASTM D5821 | 85% minimum | 92.2% |

| Soundness (magnesium sulfate) | AASHTO T 104 | 18.0% maximum | 4.8% |

| Plasticity index | ASTM D4318 | Not plastic | Not plastic |

| 10% of fines (dry resistance) | DNER-ME 096 | 100 kN minimum | 266.3 kN |

| 10% of fines (wet resistance) | DNER-ME 096 | 75 kN minimum | 234.7 kN |

| Micro-Deval | AASHTO T 327 | 20% maximum | 7.3% |

| Abrasion in Los Angeles machine | AASHTO T 96 | 25% maximum | 18.0% |

| Temperature (°C) | BC/AC (%) | |||

|---|---|---|---|---|

| 0 | 5 | 10 | 15 | |

| |G*|/sinδ (kPa)-Unaged asphalt binder | ||||

| 58 | 2.42 | 4.48 | 4.70 | 4.72 |

| 64 | 1.11 | 1.98 | 2.74 | 2.80 |

| 70 | 0.55 | 0.99 | 1.33 | 1.40 |

| |G*|/sinδ (kPa)-After RTFO test | ||||

| 58 | 4.75 | 7.65 | 8.55 | 9.11 |

| 64 | 2.26 | 3.16 | 4.19 | 4.68 |

| 70 | 1.14 | 1.76 | 2.39 | 2.97 |

| |G*| sinδ (kPa)-After RTFOT + PAV (Pressure Aging Vessel) | ||||

| 16 | 6253 | 6084 | 6201 | 6812 |

| 19 | 4618 | 4621 | 4758 | 4989 |

| 22 | 3252 | 3515 | 3660 | 3890 |

| Sieve (mm) | 19 | 12.5 | 9.5 | 4.75 | 2.0 | 0.425 | 0.180 | 0.075 | Bottom |

| Passing (%) | 100 | 87.5 | 79.0 | 57.0 | 37.0 | 19.5 | 12.5 | 6.0 | 0.0 |

| Retained (%) | 0 | 12.5 | 8.5 | 22.0 | 20.0 | 17.5 | 7.0 | 6.5 | 6.0 |

| AC (%) | FT | |||||

|---|---|---|---|---|---|---|

| Va (%) | VMA (%) | VFA (%) | S (kN) | F (mm) | S/F (kN/mm) | |

| 4.5 | 0.89 | 2.61 | 0.28 | 11.29 | 1.80 | 1.76 |

| 5.0 | 0.16 | 1.71 | 0.01 | 11.62 | 0.25 | 4.98 |

| 5.5 | 0.12 | 0.01 | 0.23 | 8.02 | 4.50 | 7.86 |

| 6.0 | 22.47 | 14.2 | 22.83 | 2.03 | 1.00 | 0.05 |

| Analysis | 10 °C | 20 °C | 30 °C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 2.5 Hz | 5 Hz | 10 Hz | 2.5 Hz | 5 Hz | 10 Hz | 2.5 Hz | 5 Hz | 10 Hz | |

| FT | |||||||||

| Control vs. BC/AC = 10% | 20.9 | 14.1 | 14.8 | 10.0 | 7.2 | 8.0 | 12.2 | 13.7 | 14.2 |

| Mixture | VTM (%) | R-Squared (r2) | a | b | σ6 (kPa) | σ7 (kPa) |

|---|---|---|---|---|---|---|

| Control | 4.71 ± 0.11 | 0.969 | 3839.7 | −0.224 | 173.9 | 103.8 |

| BC/AC = 10% | 4.93 ± 0.19 | 0.971 | 4444.8 | −0.224 | 201.3 | 120.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaves-Pabón, S.B.; Rondón-Quintana, H.A.; Bastidas-Martínez, J.G. Mechanical Performance of a Hot Mix Asphalt Modified with Biochar Obtained from Oil Palm Mesocarp Fiber. Infrastructures 2024, 9, 156. https://doi.org/10.3390/infrastructures9090156

Chaves-Pabón SB, Rondón-Quintana HA, Bastidas-Martínez JG. Mechanical Performance of a Hot Mix Asphalt Modified with Biochar Obtained from Oil Palm Mesocarp Fiber. Infrastructures. 2024; 9(9):156. https://doi.org/10.3390/infrastructures9090156

Chicago/Turabian StyleChaves-Pabón, Saieth Baudilio, Hugo Alexander Rondón-Quintana, and Juan Gabriel Bastidas-Martínez. 2024. "Mechanical Performance of a Hot Mix Asphalt Modified with Biochar Obtained from Oil Palm Mesocarp Fiber" Infrastructures 9, no. 9: 156. https://doi.org/10.3390/infrastructures9090156

APA StyleChaves-Pabón, S. B., Rondón-Quintana, H. A., & Bastidas-Martínez, J. G. (2024). Mechanical Performance of a Hot Mix Asphalt Modified with Biochar Obtained from Oil Palm Mesocarp Fiber. Infrastructures, 9(9), 156. https://doi.org/10.3390/infrastructures9090156