1. Introduction

Bitumens are petroleum-based binders widely used in many sectors of the economy. Road bitumens are intended for binding, gluing together the mineral components of an asphalt concrete mixture, giving them hydrophobic properties, and filling the pore space between the particles of these components. The physico-mechanical characteristics of bitumen determine the strength and durability of asphalt mixtures.

Direct exposure to sunlight and atmospheric oxygen, sudden temperature changes, and dynamic loads lead to bitumen’s gradual destruction [

1]. The composition of bitumen is destroyed and resinous asphaltene components are converted into carbenes and carboids. Bitumen becomes brittle, begins to crack and crumble, and loses adhesion to mineral materials: crushed stone, stone, and sand. This leads to a reduction in the service life of road surfaces, roofing, and pipeline insulation.

To improve the physico-mechanical characteristics of bitumen, modification with polymer materials is usually proposed [

2]. Polymers are obtained synthetically and have a high cost. The problem is solved by modifying bitumen with natural fine materials, which reduces the polymer content and improves the performance characteristics of the composite. The mineral offered as a natural material is shungite, which has fullerene particles in its structure and shows good adsorption characteristics [

3].

The purpose of this work was to study the influence of nanostructured samples of a natural mineral, shungite, from the Koksu deposit—on the rheological properties of bitumen. The novelty of this research lies in the fact that, for the first time, the rheological properties of bitumen modified with nanostructured ground shungite are studied. The literature review that follows supports this.

The main reserves of shungite are located in Russia and Kazakhstan, and the estimated resources of it are about 1 billion tons. At the Koksu deposit (Kazakhstan), the estimated reserves of shungite are more than 620 million tons [

4].

The technological applications and special properties of shungite are of significant interest due to its natural sources and industrial production. In shungite rocks, carbon has a disordered sp

2 structure, which determines its special physico-chemical properties and technological applications [

5].

Shungite has also been proposed for use in polymers and materials for the road industry [

6]. In one study, the introduction of shungite powder into bitumen, and the preparation of an asphalt concrete mixture with its addition, led to the formation of a stable structure with a large number of closed pores [

7]. In addition, asphalt concrete with the addition of shungite showed improved indicators of water resistance, fatigue strength, and water saturation. The high corrosion resistance of asphalt concrete is associated with the adhesive activity of shungite. The asphalt concrete mixture had good layability and compactability, which made it possible to ensure the specified characteristics of evenness and compaction coefficient when constructing road surfaces.

The positive effect of shungite on the properties of bitumen is explained by the active interaction of its surface molecules with organic compounds [

8]. Processes at the interface between bitumen and shungite lead to the formation of a strong adsorption layer necessary for the formation of a durable composite. The high strength properties of asphalt concrete are ensured by a large specific surface area and active centers on the surface of shungite.

The method for producing bitumen–polymer mastic [

9] includes introducing into the road bitumen with a composition of 7% dispersed shungite, 2.5–3.5% divinylstyrene thermoplastic elastomer, 2–9.4% industrial oil, 3–5% crumb rubber, and 0.001–0.006% single- or multi-walled carbon nanotubes. As a result, the heat resistance, extensibility, and elasticity of the composition are increased. Among modifiers, shungite has the highest content, but the method has not shown the effectiveness and necessity of adding carbon nanotubes in such a small amount.

Using Raman spectroscopy in the structure of natural bitumen, the transformation of the graphite-like phase into shungite-like phases was revealed [

10]. When bitumen was heated in a vacuum at 400–1000 °C, a decrease in the size of supramolecular particles was recorded and the samples acquired electrically conductive properties.

A study of the effect of shungite on the properties of low-density polyethylene showed strong characteristics of light reflection and absorption, and bactericidal properties of the composite [

11]. At the same time, the beginning of the thermal destruction process is observed at higher temperatures, which confirms the improvement in the strength properties of the polymer. However, this negatively affects its biodegradability.

The presence of graphite-like mineral structures in shungite made it possible to obtain graphene films from it by low-temperature ultrasonic treatment without the use of surfactants [

12]. Films with a surface length of 200 nm consisted of hexagonally centered graphene with a lattice pitch of 0.335 nm. However, such film sizes do not allow them to be classified as nano-sized materials.

The effect of shungite on the properties of bitumen, in combination with crumb rubber, has been studied [

13], as a result of which the content of the polymer modifier was reduced, but the viscosity, softening point, extensibility, and elasticity of the binder were increased. At the same time, it has been shown that the use of rubber–shungite composite gives the same effect as rubber without filler.

The influence of shungite on the properties of building materials was studied in [

14], where the features of cement systems modified with shungite, hardening during electrode heating at negative temperatures, were studied. The anomaly of the exothermic reaction of the cement stone samples provided the composites with higher strength and lower permeability.

Unlike other natural carbon-containing minerals, shungite rocks are characterized not only by a high content of carbon, but also of silicon dioxide. Nano-sized silicon dioxide (nanosilica) powders are also often proposed as a bitumen modifier to improve its properties.

By modifying natural bitumen from the Budun deposit with nanosilica, the performance of asphalt concrete at high and low temperatures was studied [

15]. The optimal contents of natural bitumen and nanosilica in the asphalt concrete composition were 25 and 5%, respectively. Nanosilica particles with natural bitumen formed a stable three-dimensional structure. However, converting silica into nanoscale form comes at a cost.

The main disadvantages of warm asphalt concrete mixtures are low values of aging resistance and durability, high values of susceptibility to moisture, which deteriorates the quality of the road surface and increases maintenance costs. This is explained by an increase in the amount of water entering the asphalt concrete at a low temperature of its preparation. To eliminate this problem, 2–6 wt.% nanosilica was added to the bitumen [

16]. As a result, the complex modulus of bitumen increased, the phase angle and rutting coefficient decreased with an increased percentage of nanosilica. Based on the results of rheological analysis, 6 wt.% nanosilica was selected as the optimal content. Colloidal silica nanoparticles have been proposed as a potential protective agent to increase the moisture content and aging sensitivity of asphalt binders [

17].

In [

18], nanosilica with a content of 2 to 8% was used in the modification of bitumen binder. The modification achieved a reduction in penetration, and an increase in the softening temperature and complex shear modulus of bitumen, which led to an increase in the strength and rigidity properties of bitumen. High nanosilica content resulted in higher rutting resistance.

The influence of the modifier on the performance of bitumen is also studied by determining its rheological properties. The viscoelastic properties of bitumen 80/100 were studied by modifying them with used plastic bottles [

19]. The properties of bitumen improved with increasing polymer content. The modified bitumen had a high softening point and viscosity, viscoelastic properties, such as a higher complex modulus and a lower phase angle. The G*/sin δ indicator confirmed the resistance of bitumen to rutting. The mixing of bitumen and waste polymer was carried out at 130 °C, at which uniform distribution of the polymer is usually not observed.

Lignin is also proposed as a carbon-containing natural modifier of bitumen, by analogy with shungite. The chemical and rheological effects of 10 wt.% lignin per bitumen prevented the aging process [

20]. Infrared spectroscopic analysis of lignin-modified bitumen showed a decrease in the content of carbonyl and sulfoxide compounds of bitumen after aging. The physical interaction of lignin with bitumen affected the rheology of the binder material. However, the study used only a dosage of 10% lignin by weight of bitumen.

Crumb rubber from waste tires containing black carbon, like shungite, is also widely offered as an environmentally friendly bitumen modifier. The rheological characteristics of bitumen modified with styrene-butadiene-styrene copolymer and desulfurized crumb rubber before and after aging have been studied [

21]. The resistance of the composite to fatigue cracking is increased after modification with desulfurized crumb rubber, but the loss of the fatigue characteristics of the composite is explained by condensation and disintegration of the polymer network structure.

The rheological and thermophysical properties of bitumen are determined by the resinous asphaltene, paraffin, and aromatic compounds of bitumen. Infrared spectroscopy, thermogravimetric analysis, and rheological indicators have revealed the characteristics of natural bitumen of various origins and genetic types [

22]. According to the parameters of waxiness, aromaticity, polarity, and branching of infrared spectra, bitumens are divided into resinous, paraffinic, and aromatic classes.

Thus, modification with additives of synthetic and natural origin is proposed to increase the resistance of bitumen to oxidative aging processes, improve adhesion to minerals, and prevent leaching of individual particles of the road surface under load. The choice of shungite as a modifier in this work is due to its natural origin and composition, which is mainly represented by carbon and silica. Carbon is close in origin to the organic components of bitumen, while silica is similar to mineral materials.

2. Materials and Methods

Road petroleum bitumen grade BND 100/130 from the Pavlodar Petrochemical Plant (Pavlodar, Kazakhstan) was used (

Figure 1). It has the following physico-mechanical characteristics: penetration at 25 °C—129.6 × 0.1 mm, softening point—46.9 °C, and ductility at 25 °C—111.6 cm.

Shungite from the Koksu deposit (Almaty region, Kazakhstan) was used as a bitumen modifier (

Figure 2) [

23].

Shungite samples were ground in a GT 300 mill (Powteq, Beijing Grinder Instrument Co., Ltd., Beijing, China) (

Figure 3) according to ASTM D4543-19 [

24] at different weight ratios of shungite samples and steel balls 1:1 and 1:2, with a rotation speed of 1600 rpm for 20, 40, and 60 min. To prevent particle aggregation, grinding was also carried out in an isopropanol environment at a mass ratio of shungite with alcohol and steel balls of 1.5:1:1.5 and with a rotation speed of 700 rpm for 20, 40, and 60 min.

The particle size of samples was measured using a Winner 2000E laser particle-size analyzer (Jinan Winner Particle Instruments Stock Co., Ltd., Jinan, China) (

Figure 4) according to ISO/DIS 13320 [

25]. Electron microscopic analysis was carried out on a Quanta 3D 200i scanning electron microscope (FEI Company, Hillsboro, OR, USA). The analysis of the elemental composition of the samples was carried out using energy-dispersive spectroscopy on an EDAX instrument (Ametek Inc., Berwyn, PA, USA).

To modify bitumen, bitumen was loaded into a metal glass containing a thermometer and a heated stirrer, and heated to 180 °C, then 1 wt.% shungite was added, with constant stirring occurring at a speed of 500–700 rpm from a mechanical stirrer (IKA RW20, Konigswinter, Germany) for 1 h. After mixing, samples were poured into a can to cool at room temperature to keep morphology. The sample aging procedure was carried out in a thin film oven (RTFOT) according to ASTM D1754 [

26] through heat treatment at 163 °C for 225 min [

27].

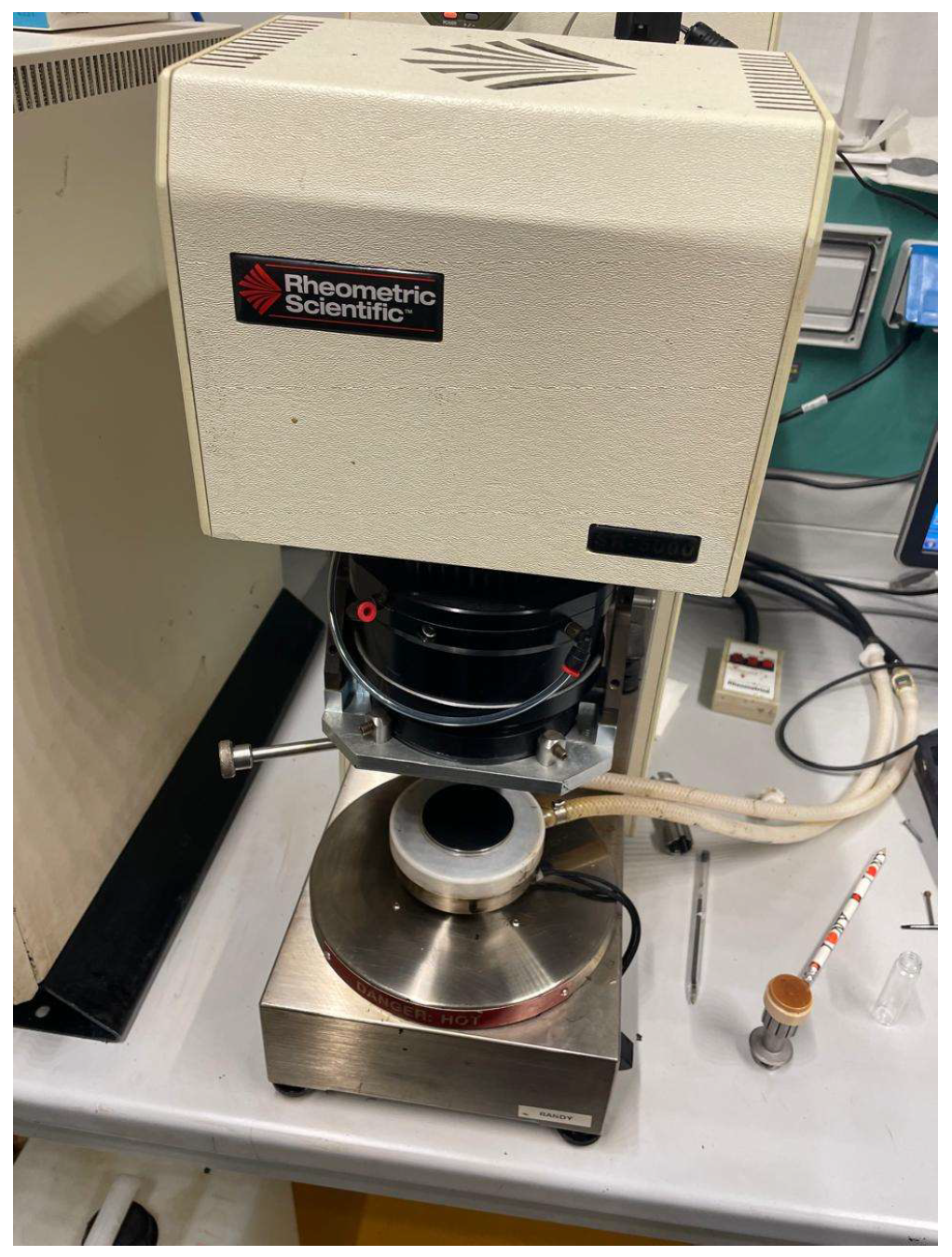

Rheological analysis was measured by a Dynamic Stress Rheometer SR-5000 (Rheometric Scientific, Piscataway, NJ, USA) (

Figure 5) according to ASTM D7175-15 [

28] using a plate with 25 mm diameter and a 2 mm gap. The frequency was set at 1 Hz and the stress at 100 Pa. A temperature sweep test or time cure test was conducted at between 25 and 110 °C, with a heating rate of 1 °C per minute. This type of measurement determines the transition temperature of bitumen from semi-solid to liquid state. As a result of the analysis, the elastic modulus G’ as a measure of reversible elastic energy and the loss modulus G” as a measure of irreversible viscous dissipation of mechanical energy were determined. The ratio of the loss modulus to the elastic modulus gives the loss tangent tan δ.

Asphaltenes from bitumen samples were obtained by melting 1 g of bitumen in 1 mL of chloroform and adding 40 mL of n-pentane.

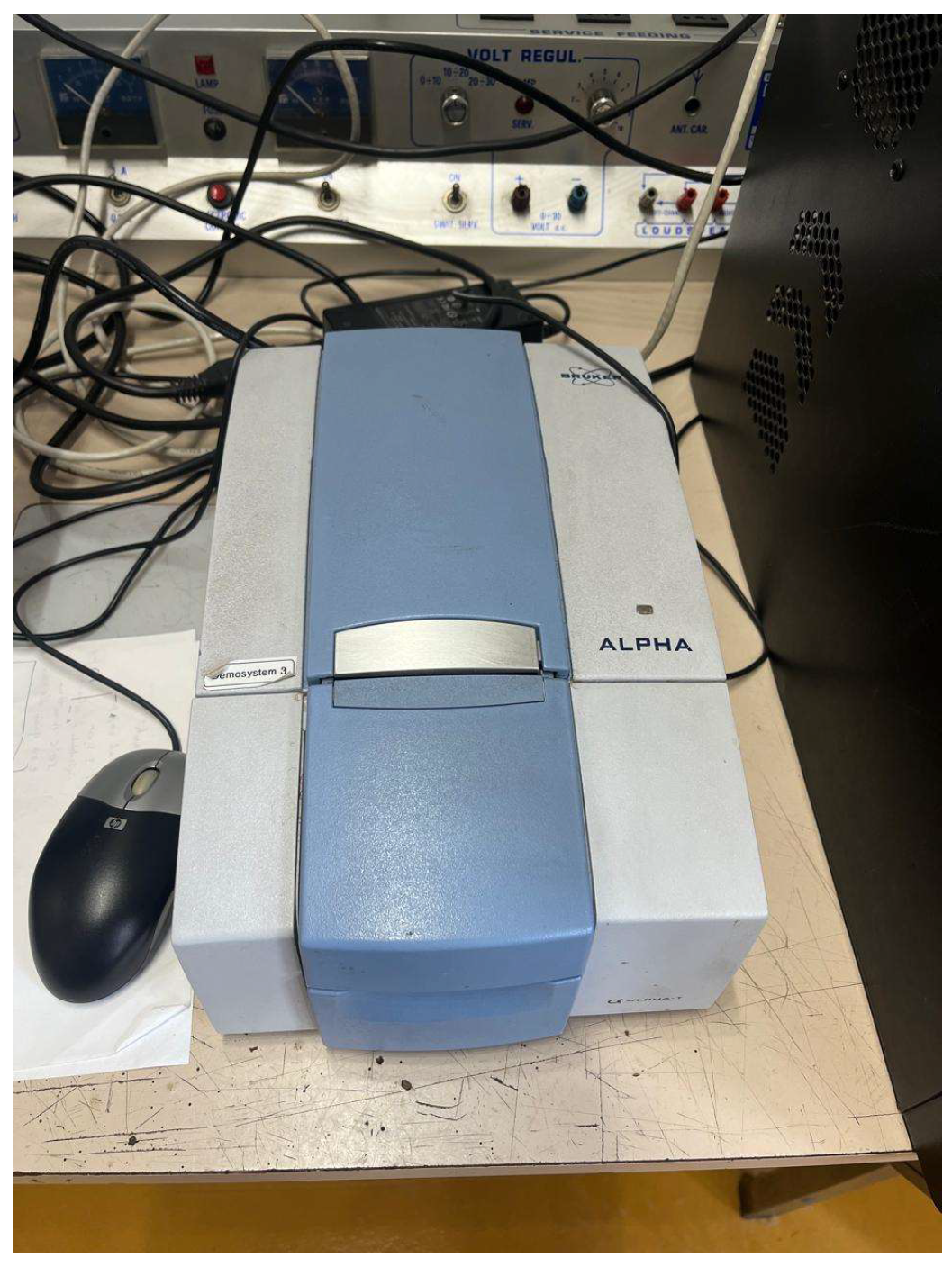

Infrared spectroscopic analysis was carried out with a Bruker Alpha spectrometer (Karlsruhe, Germany) (

Figure 6). The wavelength of the reflected beam is characteristic of each element and indicates the presence of specific functional groups. Samples for FTIR were prepared as potassium bromide (KBr) pellets, containing 0.1 to 0.8 wt.% of powdered sample. Mixtures of sample/KBr were prepared in a clean and dry agate mortar. The FTIR spectrum was obtained in the spectral range between 4000 and 400 cm

−1, with a scanning resolution of 4 cm

−1 averaging five scans for each measurement in order to increase the signal-to-noise ratio of the measurements. Then the spectrum was normalized to allow the quantitative analysis of the results.

Differential scanning calorimetric analysis of asphaltenes was carried out on a DSC 131 calorimeter (Setaram Instrumentation, Caluire-et-Cuire, France) in a constant flow of nitrogen in the temperature range 25–300 °C with a heating rate of 20 °C/min.

3. Results

To obtain finely dispersed samples and improve the effect on the properties of bitumen, shungite samples were first ground.

Table 1 presents the particle diameters of samples of 10% (d

10), 50% (d

50), and 90% (d

90) of the cumulative distribution, average particle diameters (d

av) by volume and on the surface, and surface area per unit volume S/V. The initial shungite samples had an average particle diameter by volume of 10.19 μm. After grinding, the average particle diameter by volume reached up to 5.26 μm. Grinding in isopropanol for 60 min at a ball rotation speed of 700 rpm led to a decrease in the average particle diameter by volume to 3.56 μm.

To modify the bitumen, further samples of ground shungite that had the smallest particle diameter were selected. These were shungite samples ground at a speed of 1600 rpm for 40 and 60 min at a weight ratio of shungite samples and balls of 1:2 and at a speed of 700 rpm for 60 min in an isopropanol environment. These samples exhibited maximum values of surface area per unit volume.

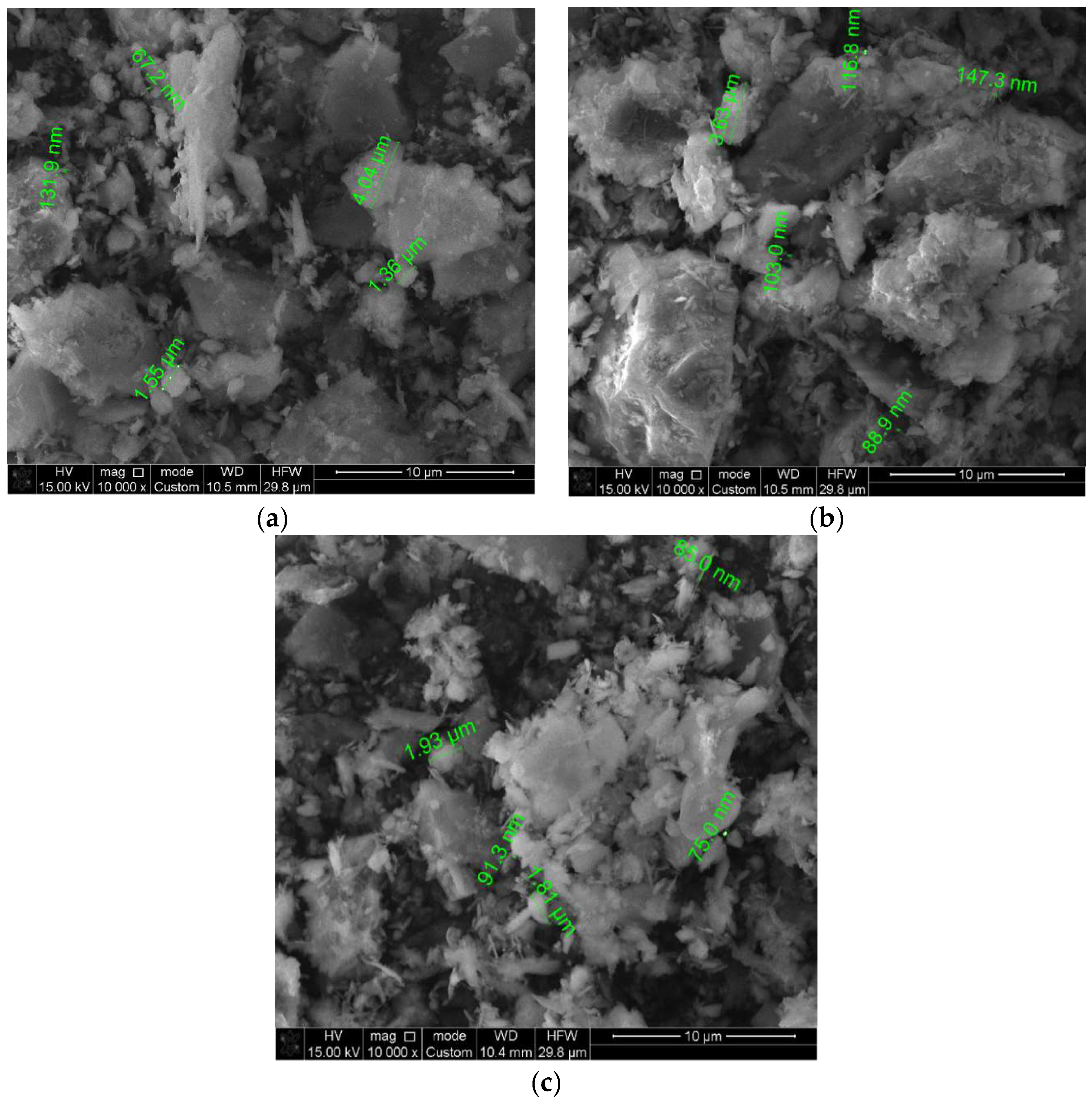

The morphology of ground shungite samples was studied using scanning electron microscopy. As it can be seen from

Figure 7, they were characterized by flocculent particles of individual agglomerates. The photographs revealed nanostructured shungite particles with sizes of 67.2 nm (

Figure 7a), 88.9 nm (

Figure 7b), 75.0 nm, 85.0 nm, and 91.3 nm (

Figure 7c). The formation of such nanostructured particles in the composition of ground shungite samples should have a beneficial effect on the properties of bitumen [

29].

Analysis of the elemental composition of shungite samples before and after grinding in

Table 2 showed that grinding led to a decrease in the content of carbon and oxygen, and an increase in the content of silicon, aluminum, and iron. The change in the content of carbon, silicon, and oxygen occurs due to the occurrence of reactions of mechanochemical activation of the surface of nanostructured samples. The increase in iron content is due to slight abrasion of the steel balls during grinding.

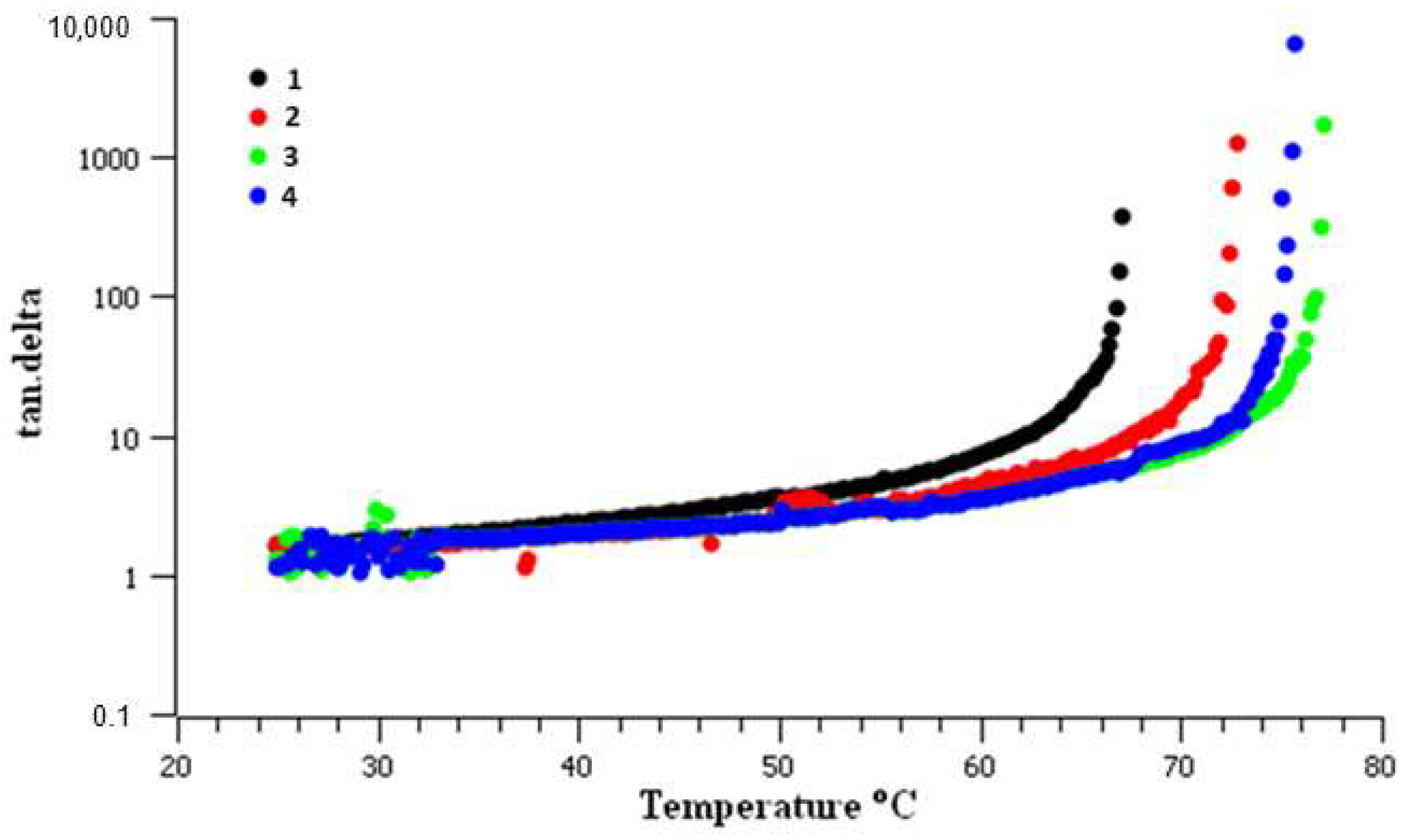

Bitumen is a viscoelastic substance and is characterized by viscous and elastic moduli. At the temperature of transition to the liquid state, it loses its elastic modulus, and this temperature is proportional to the loss tangent (tan δ), which is the ratio between the loss modulus (G”) and the elastic modulus (G’), i.e., G”/G’. To determine the shift in the transition temperature from the viscoelastic state to the liquid state, the temperature was measured and the change in the loss tangent was monitored at a constant heating rate of 1 °C per minute and a frequency of 1 Hz. As the temperature rose, the bitumen began to lose its elasticity and gradually became a viscous liquid.

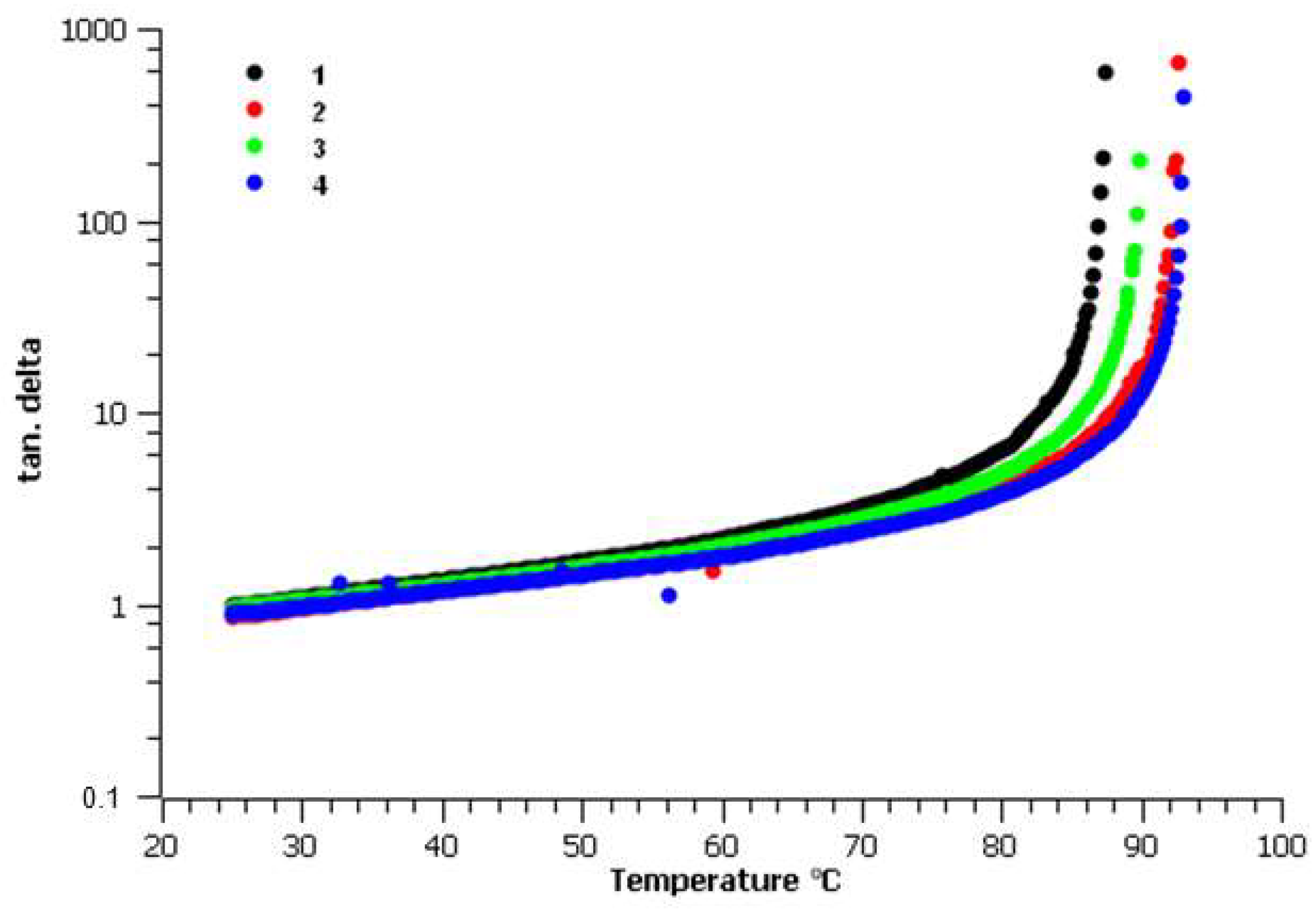

Figure 8 shows the dependences of the loss tangent of bitumen before and after modification with shungite, ground under various conditions. Modification with ground shungite led to a shift of the curves to the region of elevated temperatures. The largest shift in the curve was observed in the case of modifying bitumen with shungite, ground at a speed of 1600 rpm for 40 min and a mass ratio of shungite sample and balls of 1:2. Modification with shungite ground in an isopropanol medium, despite the minimum particle sizes, led to the smallest shift of the curve to the region of increasing temperature compared to other samples.

Next, the bitumen, before and after modification with shungite, was subjected to artificial aging using the RTFOT procedure. As bitumen ages, it becomes harder and its transition temperature increases.

As shown in

Figure 9, aging causes a shift in the loss tangent curves towards higher temperatures, indicating a change in rheological behavior consisting of an increase in stiffness accompanied by an increase in elastic response. The increase in transition temperature with aging occurs due to the oxidation of bitumen components and indicates higher thermal stability and strengthening of the overall chemical structure of the modified bitumen.

After aging, the largest shift in the bitumen loss tangent curve was observed in the case of modification with a shungite sample ground at a ball rotation speed of 1600 rpm for 60 min at a mass ratio of shungite sample and balls of 1:2. Modification of bitumen with shungite, ground in an isopropanol environment, also showed the greatest shift in the curve along with this sample.

Table 3 shows the transition temperatures of the samples determined from the rheological analysis. The temperature of transition from the viscoelastic state to liquid is defined as the extremum at which the elastic modulus decreases and, consequently, the loss tangent diverges.

As can be seen from

Table 3, the difference in transition temperatures of the modified bitumen after aging turned out to be smaller compared to unaged bitumen samples. For example, modification of bitumen with shungite ground for 40 min led to a temperature difference of 10.01 °C, while after modification with the same sample and aging, the transition temperature difference was only 2.17 °C. The same effects of transition temperature differences were observed for the other two samples. After aging, the transition temperature difference decreased compared to this value for the initial bitumen without aging. This indicates the positive effect of nanostructured shungite additives on the properties of bitumen after aging.

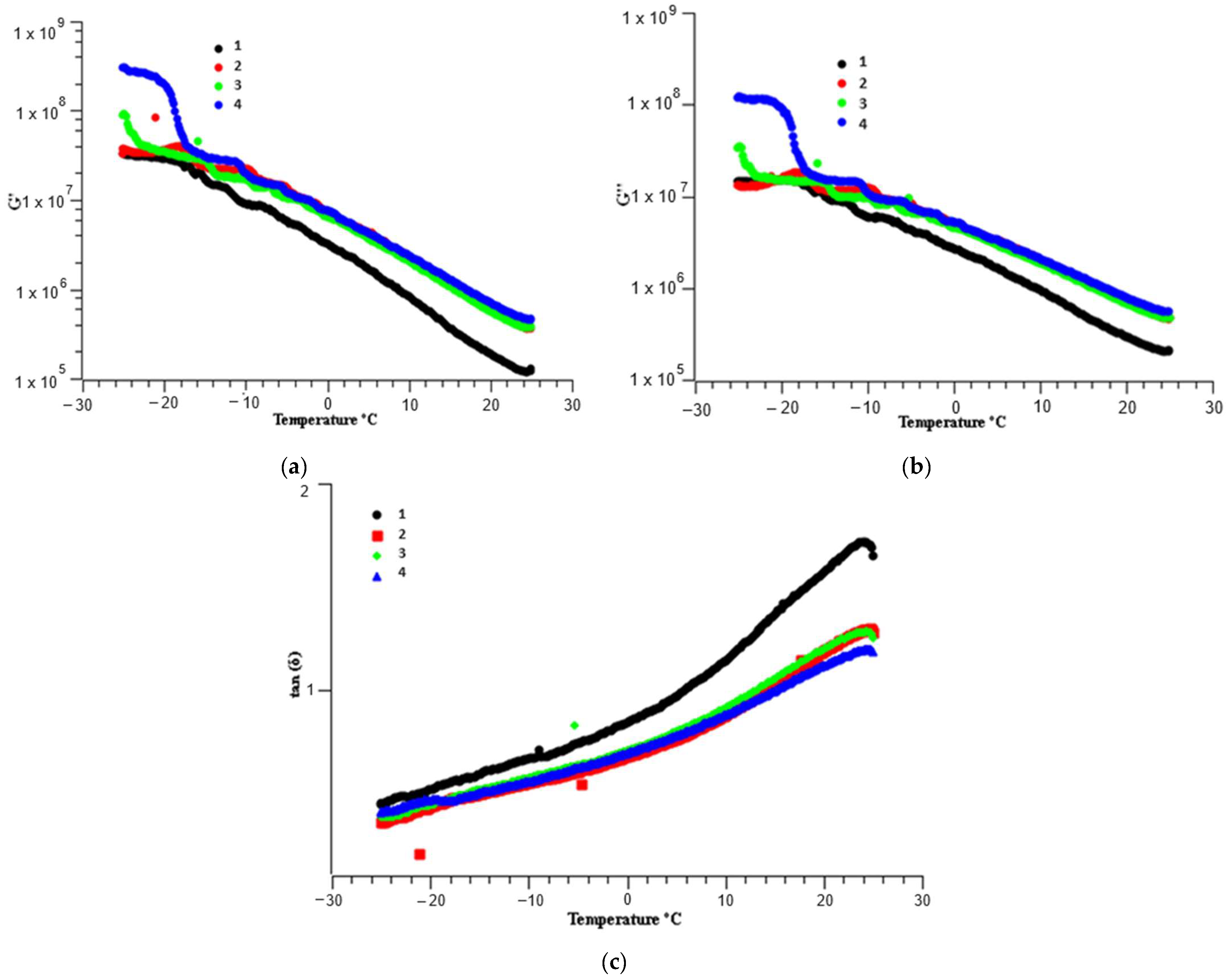

The rheological properties of modified bitumen were also studied at low to room temperatures (−30 to 25 °C) to determine the structural changes caused by increasing temperature and the potential effects of adding shungite.

The results obtained for pure and shungite-modified bitumen are shown in

Figure 10, which shows the dependences of the elastic modulus (G’) (

Figure 10a), loss modulus (G”) (

Figure 10b), and loss tangent (

Figure 10c) on temperature. The data indicate a corresponding change in the structure of bitumen with increasing temperature.

The elasticity and loss moduli of bitumen modified with shungite, ground for 60 min at a speed of 1600 rpm with a mass ratio of the shungite sample and balls of 1:2, showed a plateau at low temperatures from −30 to −20 °C, followed by a sharp decrease with increasing temperature. Loss tangent curves showed a continuous increase with increasing temperature. The loss tangent values at low temperatures were below 1, which confirms the predominant solid-state behavior of all samples.

Over the entire temperature range, samples of shungite-modified bitumen were characterized by higher values of G’ and G”, and a lower loss tangent compared to the original bitumen, which indicates a more structured and durable three-dimensional network. When comparing the curves of bitumen modified with shungite under different grinding conditions, no significant difference in the dependencies was observed. At low temperatures, samples of shungite-modified bitumen were characterized by a stronger and more structured network than the original bitumen.

IR spectroscopic and DSC studies of asphaltenes isolated from modified bitumen were carried out to assess the effect of ground shungite on the composition and properties of bitumen. In [

30], asphaltenes were proposed as an indicator of the influence of a rejuvenating agent on the properties of bitumen. When bitumen was modified, clusters of asphaltene molecules increased in size and imparted rigidity to the system. At the same time, their percentage in bitumen also increased. Therefore, it is reasonable to predict the composition and thermal properties of bitumen by studying the asphaltenes isolated from it. If the quality of bitumen improves, then asphaltenes restore their original thermal behavior.

Fourier transform infrared spectra of asphaltene samples isolated from pure and modified bitumen with ground shungite are shown in

Figure 11. The spectra of asphaltenes of pure and modified bitumen are almost identical—they differ only in the intensities of the absorption bands. As a result of the interpretation of the spectra, it was established that the chemical composition of asphaltenes contains functional groups of the following compounds: aromatic compounds (748, 807, 863, 1600 cm

−1); methylene (2921, 2851 cm

−1) and methyl (1455 and 1375 cm

−1) groups of aliphatic compounds; long alkyl chains containing more than four methylene groups (722 cm

−1); and a sulfoxide group (1031 cm

−1).

Table 4 shows the band transmission values in the IR spectra of asphaltenes of pure and shungite-modified bitumen. Modification of bitumen with shungite led to changes in band intensities in the spectra of asphaltenes. As can be seen from

Figure 11, a decrease in the transmission of the bands indicates an increase in their intensity. According to

Table 4, in the spectrum of bitumen asphaltenes after modification, an increase in the transmittance value and, accordingly, a decrease in the intensity of the bands, are observed.

Compared to the spectrum of bitumen, as a result of modification with shungite ground for 40 min at a speed of 1600 rpm at a mass ratio of 1:2, the transmission of lines of sulfoxide groups at 1030 cm−1 significantly decreased by 2.61%, and the intensity of their bands increased accordingly, which indicates an increase in the amount of sulfur-containing compounds in asphaltenes.

Modification of bitumen with shungite, ground for 60 min at a speed of 1600 rpm at a mass ratio of 1:2, led to a significant increase in the transmission values of the absorption bands of methylene (2921 and 2851 cm−1) and methyl (1455 and 1375 cm−1) groups; the change values ranged from 1.78 to 8.09%. This indicates a decrease in the content of saturated compounds in asphaltenes during modification. The intensities of the lines of functional groups of aromatic compounds (748, 807, 863, 1600 cm−1) also increased by 1.1–2.16%, which confirms a decrease in their number during modification.

The spectrum of bitumen modified with shungite, ground in isopropanol for 60 min at a speed of 700 rpm at a mass ratio of 1:1.5:1, is characterized by slight changes in transmittance values and, accordingly, line intensities.

Thus, as a result of IR spectroscopic analysis of asphaltenes, it was established that modification of bitumen with shungite leads to a change in the composition of asphaltenes with a decrease in the content of aliphatic and aromatic compounds, and an increase in the content of sulfur-containing components.

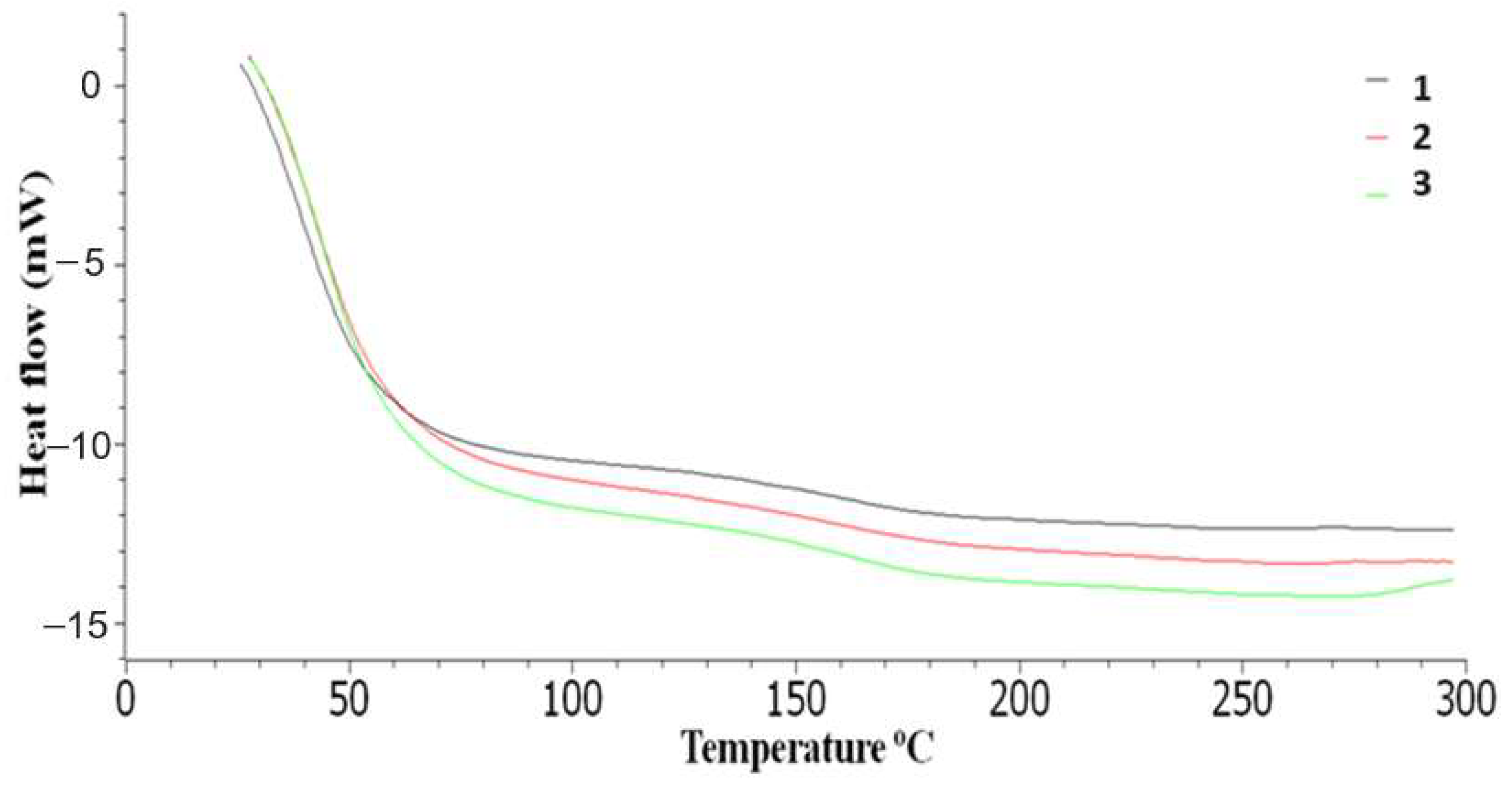

Carrying out calorimetric measurements of asphaltenes is necessary for identifying the mechanism of bitumen aging, since it makes it possible to establish the influence of modifiers on the structure of asphaltenes. This is due to the fact that, as bitumen ages, asphaltene molecules increase in size and form clusters, thereby imparting rigidity to the bitumen.

Calorimetric measurements were carried out on asphaltenes, since they impart hardness and viscoelastic properties to bitumen. During the oxidation of bitumen, the asphaltene content increases due to resins and the maltene fraction, consisting of oils. The rejuvenation of aged bitumen is confirmed by the restoration of the thermal properties of asphaltenes.

Figure 12 shows the differential scanning calorimetry (DSC) profiles of asphaltenes of pure and shungite-modified bitumens. The figure shows that, over 50 °C, the DSC curves of asphaltenes of modified bitumen are located below the curve of the original bitumen, which is associated with a slowing down of the conversion of light components into asphaltenes during the aging process.

4. Discussion

Aging significantly changes the chemical and physical properties of bitumen, which leads to a decrease in elasticity and an increase in hardness. As a result of the aging process, the oily components of bitumen volatilize or are absorbed by porous mineral aggregates. Bitumen oxidizes and the polarity of the medium increases, which leads to an increase in the interaction forces between molecules. As a result of oxidation by atmospheric oxygen, asphaltenes undergo aggregation, forming larger clusters. Increasing the size of asphaltene clusters in the bitumen matrix results in an increase in bitumen hardness.

By adding nanoparticles with a high surface-to-volume ratio to bitumen, bonding between bitumen particles is enhanced, and this creates a coating that can prevent bitumen from becoming viscous at high temperatures and slows down the transition from elastic behavior to the viscous region [

31]. This explains the increase in the values of elasticity and loss moduli.

The low-temperature behavior is due to the content of paraffins, which give the bitumen rigidity when decomposing into solid crystals, while the high-temperature properties are significantly influenced by the content of asphaltenes, which can form a three-dimensional network that gives the material its hard behavior [

32].

An increase in the modulus of elasticity and viscosity at low temperatures was observed, and the maximum value of G’ appeared when bitumen was modified with shungite, ground at a mass ratio of sample to balls of 1:2 for 60 min at a speed of 1600 rpm. The decrease in loss tangent with the addition of shungite indicates a harder behavior, likely due to the effect of nanostructured shungite particles on the asphaltene network.

Nanostructured materials easily form a network structure in the bitumen, which effectively improves the elasticity of bitumen and resistance to deformation at high temperatures [

33]. An increase in elasticity and loss moduli when bitumen is modified with nanostructured shungite demonstrates resistance to thermal–oxidative destruction and aging under the influence of ultraviolet radiation.

The high reactivity of nanostructured particles and the concentration of excess surface and internal energy in them provide an increase in low-temperature resistance, aggregate strength, and improvement in the rheological properties of bitumen [

34]. Due to nanoscale morphological characteristics, nanomaterials have unique properties such as high specific surface area, surface free energy, and dispersibility in bitumen and asphalt mixtures [

35]. Based on the structure of bitumen and knowledge of the nature of the interaction between the components and the asphaltene phase, it can be assumed that the particles of the rheological additive, interacting with the maltene medium, which is a polar organic solvent, swell and are attracted to the most polar particles of bitumen, asphaltenes, creating a stable buffer zone and preventing the processes of self-assembly of asphaltenes into structures of different dimensions [

36]. Such interaction will prevent the aggregation of asphaltenes and phase transitions of maltenes into asphaltenes, keeping the system stable over time under the influence of external factors, slowing down the processes of destruction in the structure of the bitumen binder, and making such a system less prone to aging processes.

Nanostructured shungite particles have a size relatively close to the size of asphaltenes. The particles are flaky globules and have a large specific surface area. Therefore, when shungite particles are mixed with bitumen, a layer of oils and resins is formed on its surface, and the voids are also filled. The result is a redistribution of bitumen components between structural units and the formation of new associates. The formation of additional dispersed particles strengthens the material matrix, increasing viscosity and strength. In addition, by binding the light components of bitumen, the nanomodifier slows down the aging process.

With the introduction of nanostructured shungite, the structure of bitumen becomes denser. This confirms the assumption that, when bitumen is modified, the number of associates increases and, consequently, the density of formation of the bitumen matrix increases, which in turn increases the rheological characteristics.

In [

37], shungite was used together with styrene-butadiene-styrene copolymer to modify bitumen, which led to an increase in the viscosity, softening point, strength, and elasticity of the composites. In comparison, in this work, ground shungite was used without adding a polymer. The results of bitumen modification showed an improvement in rheological characteristics such as elasticity, loss moduli, and loss tangent before and after aging.

The use of bitumen modified with nanostructured shungite makes it possible to replace the polymer modifier with a natural mineral to improve the quality of the road surface.