Service Life Evaluation of Curved Intercity Rail Bridges Based on Fatigue Failure

Abstract

1. Introduction

2. Dynamic Stress Calculation of Bridges

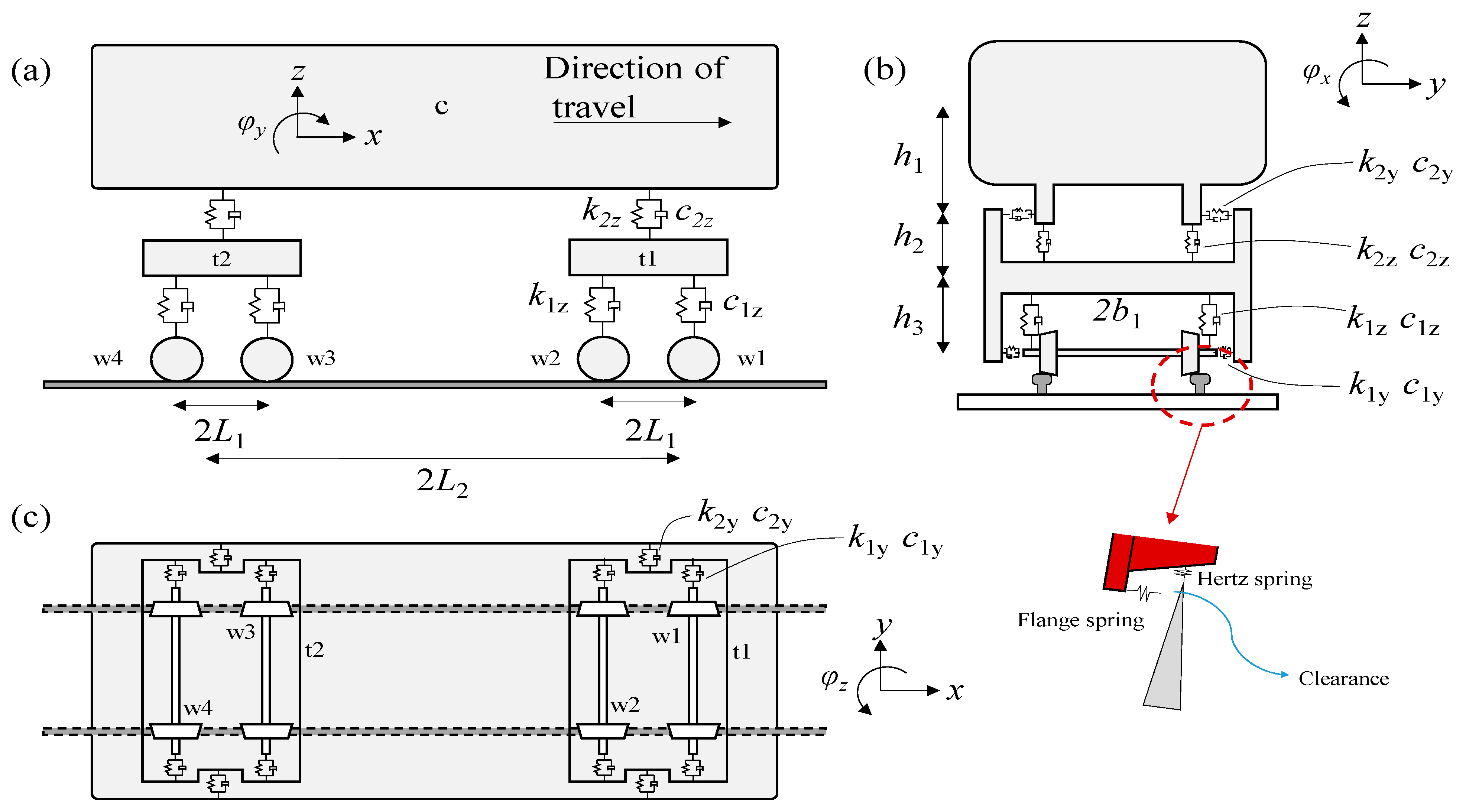

2.1. Curved Train–Bridge Coupled System

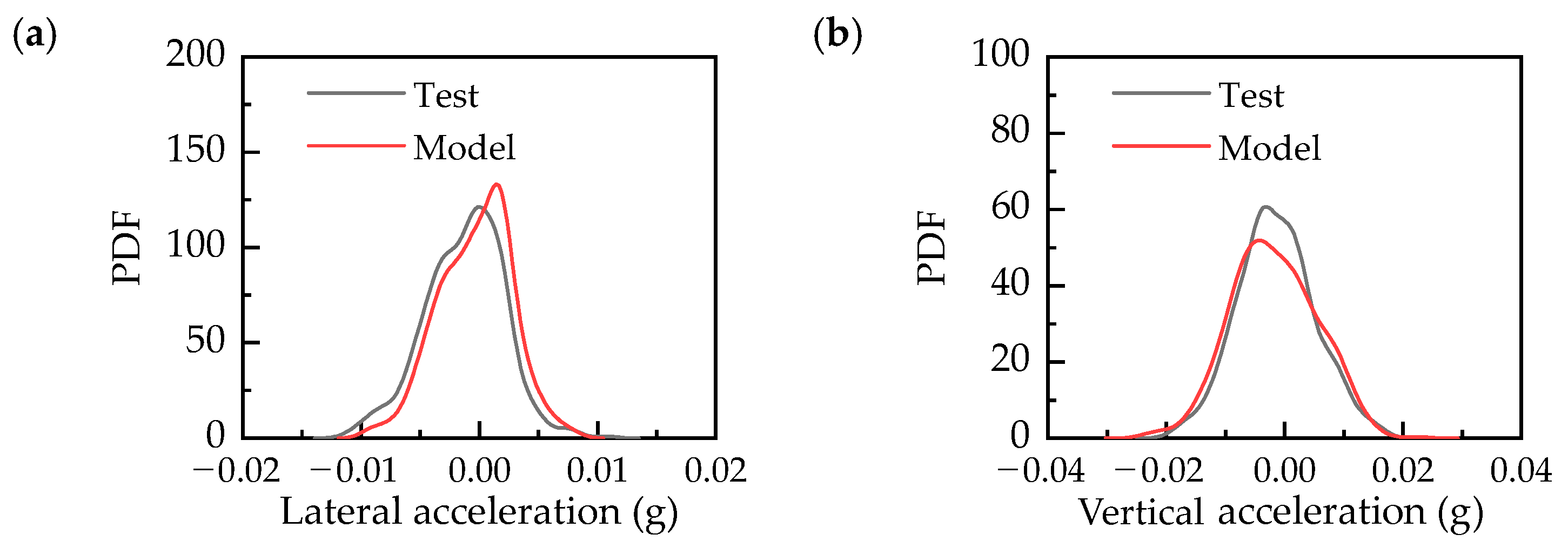

2.2. Validation of CTBCSM

2.3. Stress Calculation

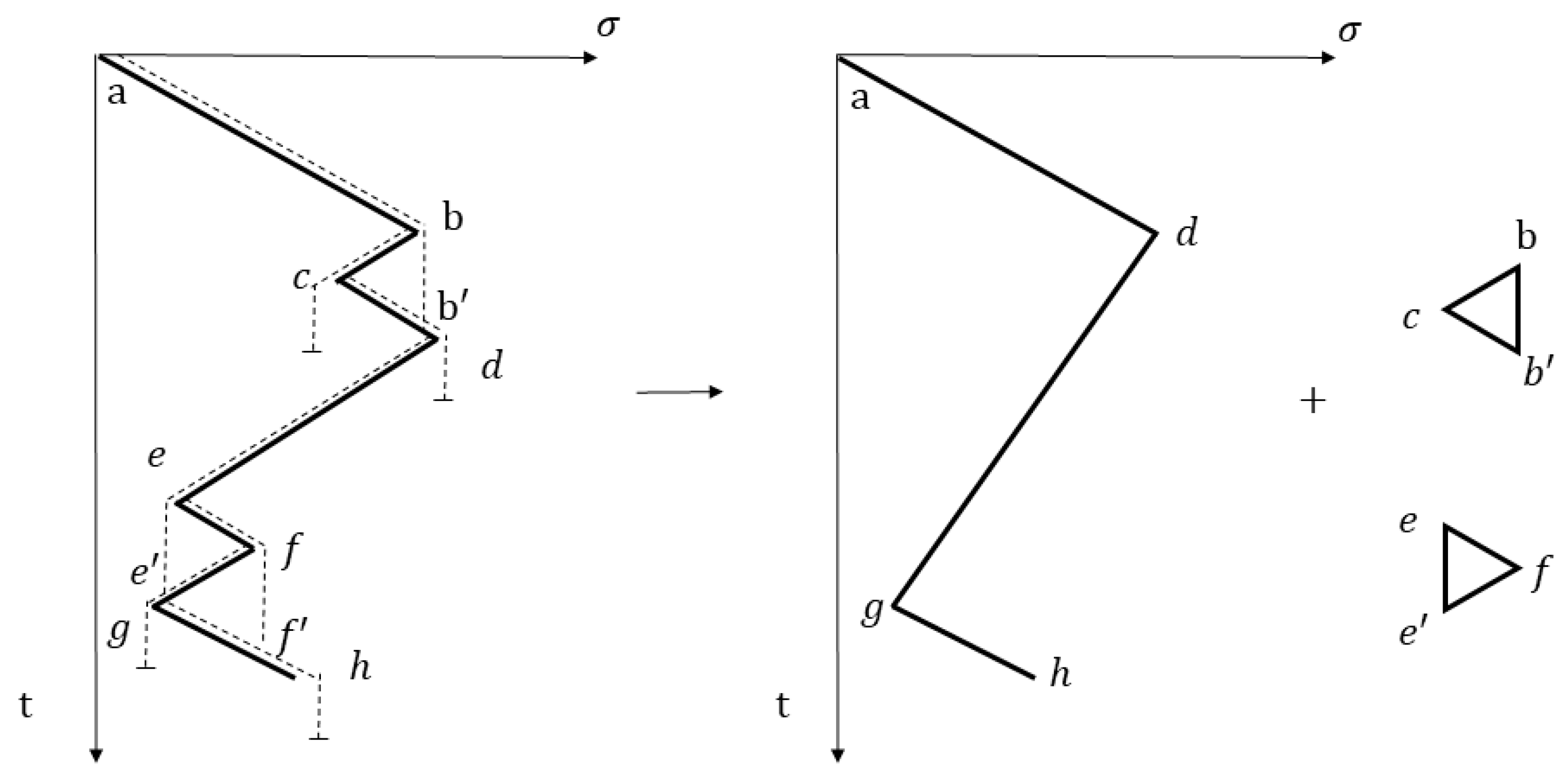

2.4. Stress Amplitude

3. Case Study

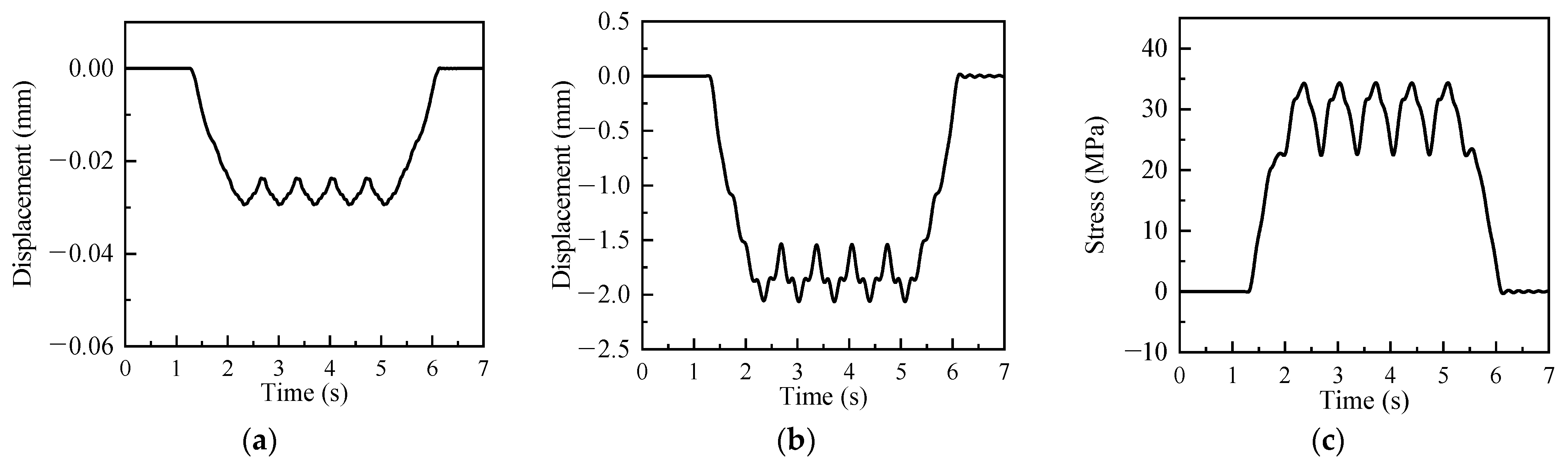

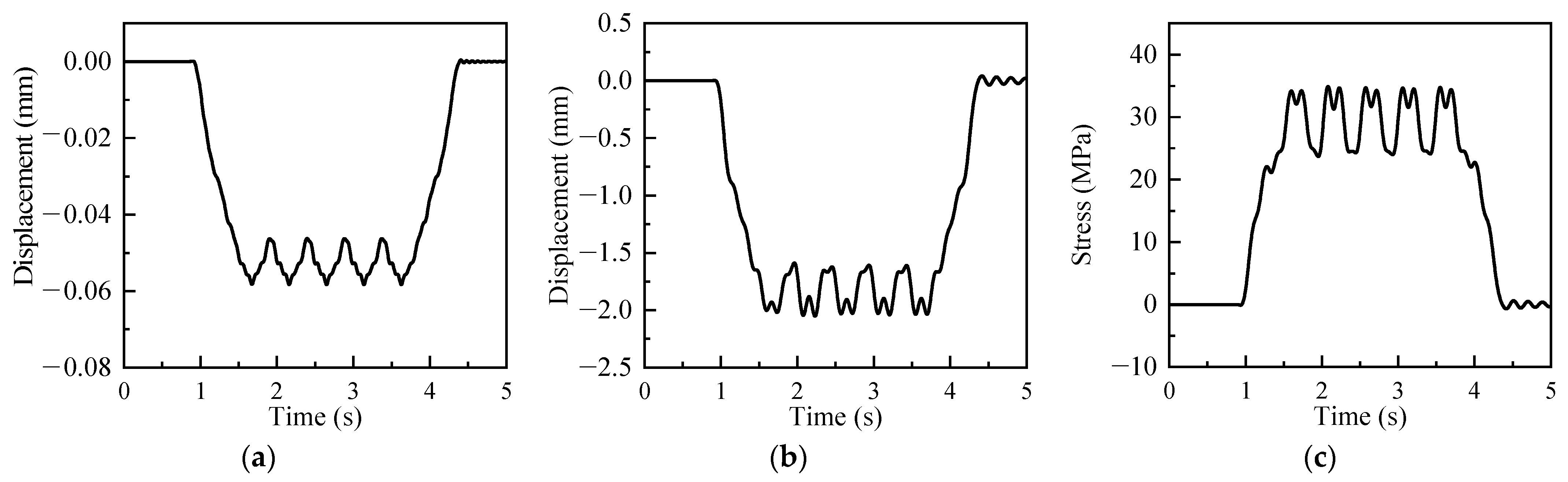

3.1. Time History Response

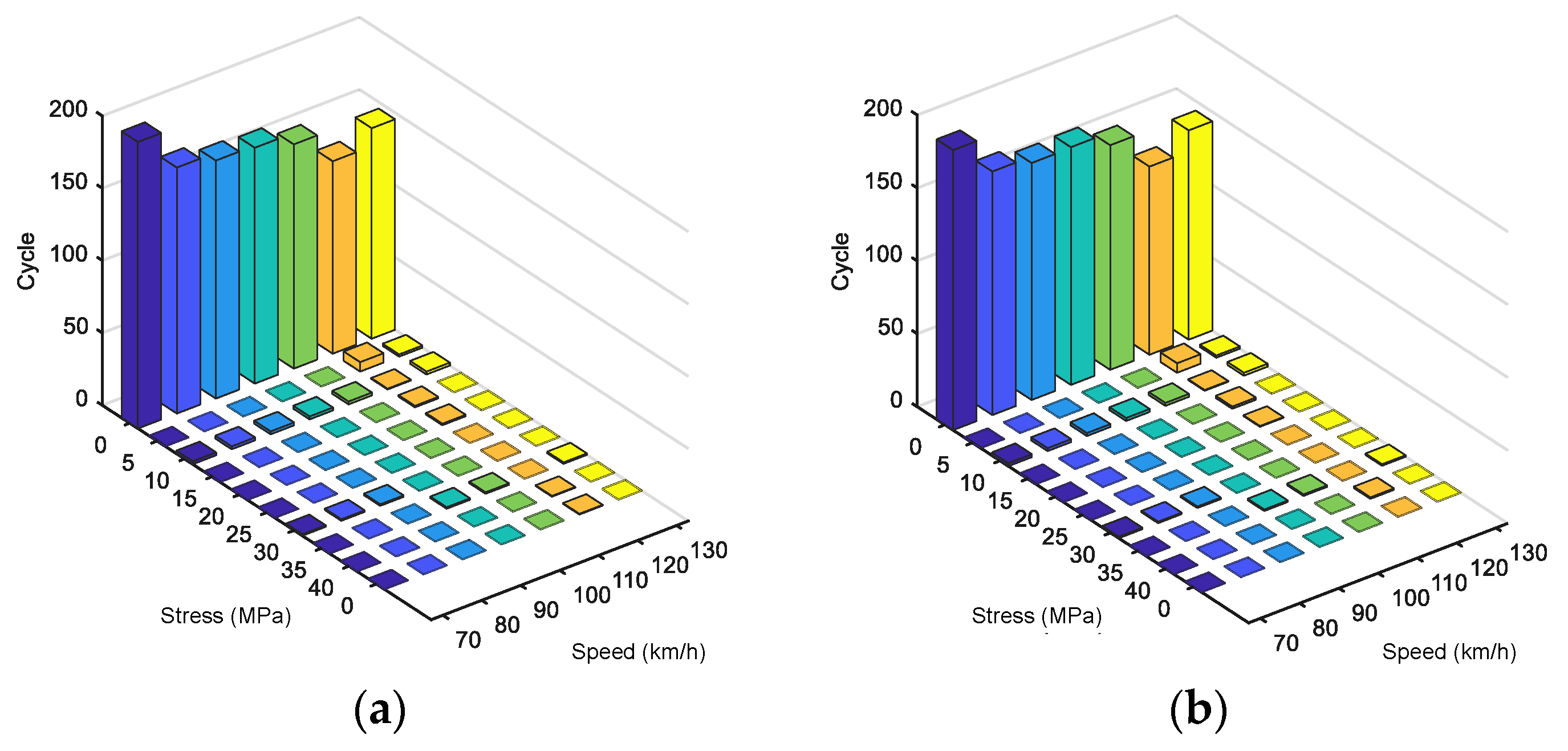

3.2. Stress Amplitude

3.3. Cumulative Damage

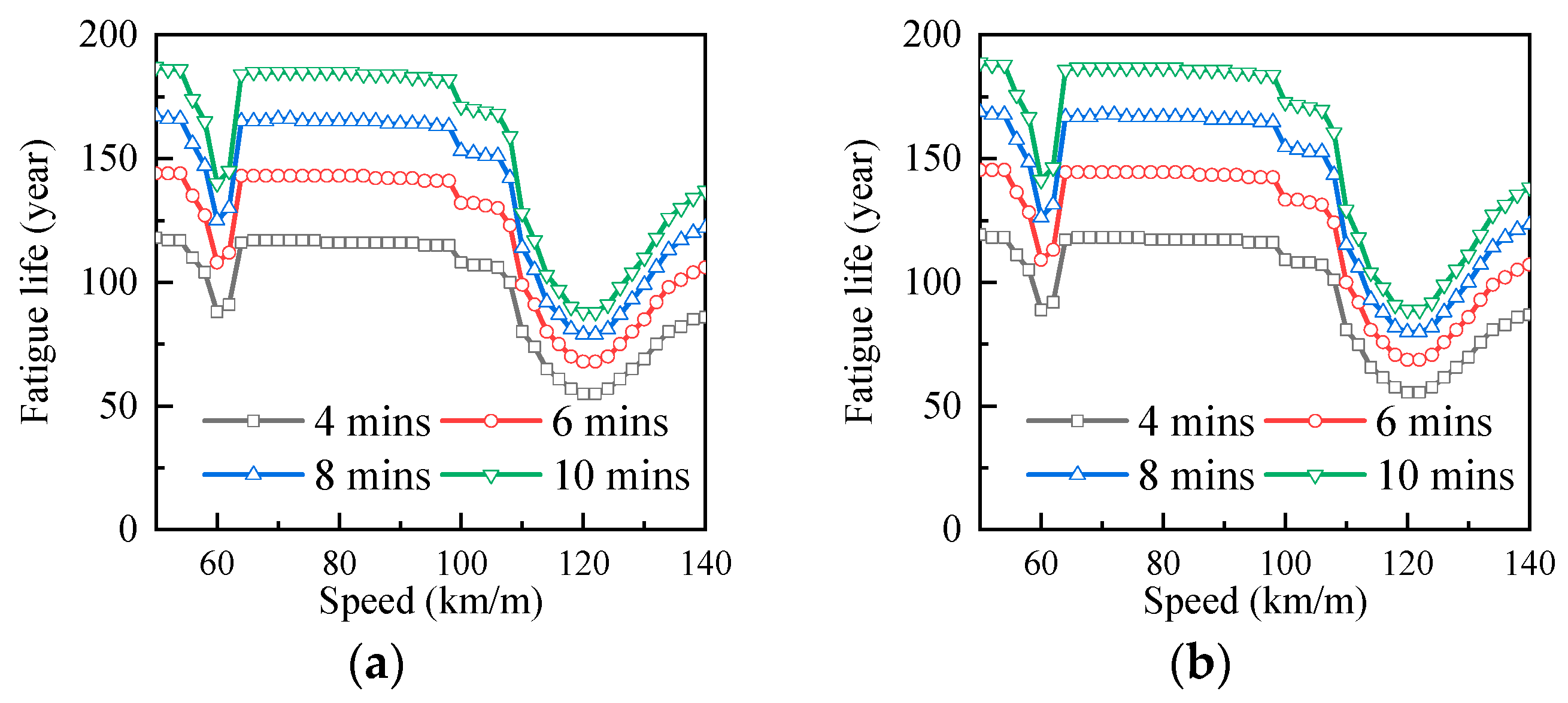

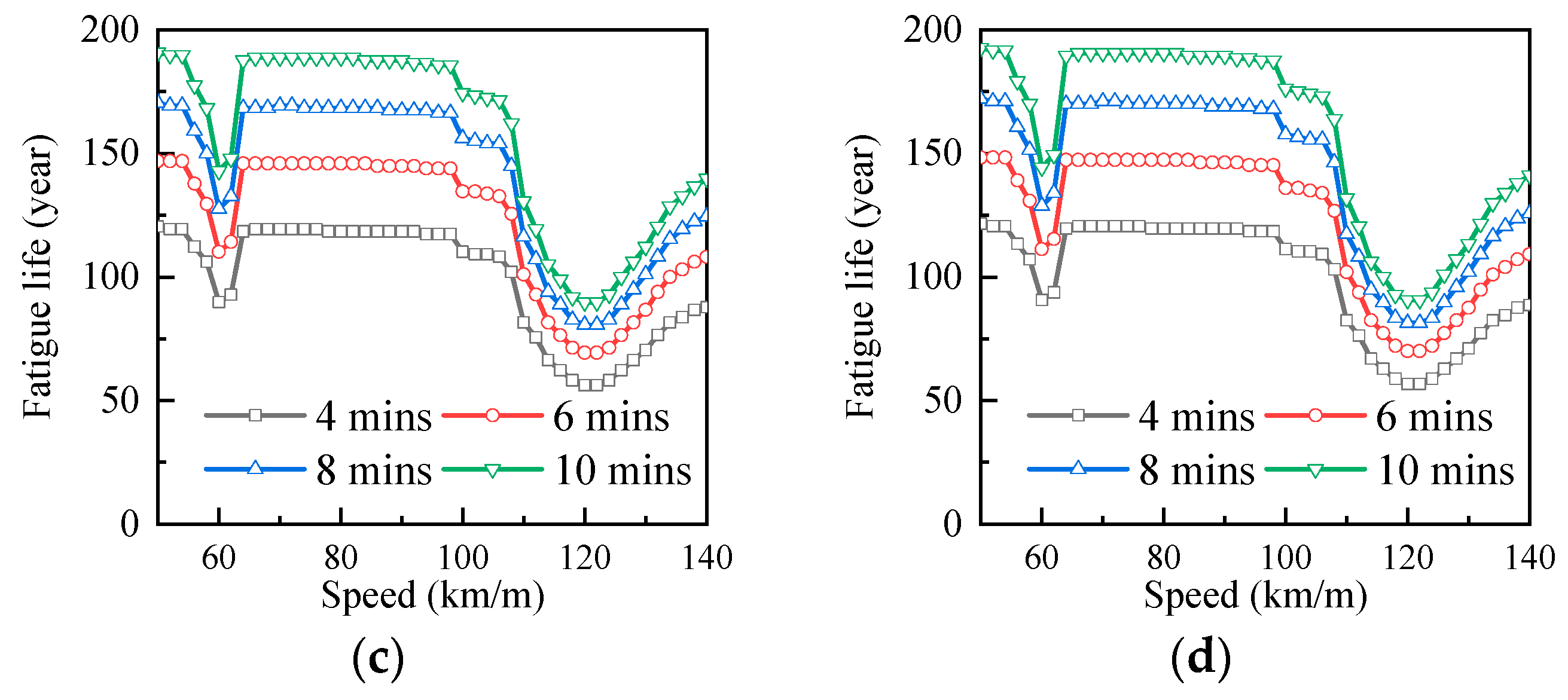

3.4. Evaluation of Lifetime

4. Conclusions

- (1)

- The stress amplitude of the reinforcing bars of the bridge was mainly concentrated within 10 MPa, which was mainly due to the control of vertical load. However, the influence of centrifugal force in the case of a small curve radius and large train speed could not be ignored.

- (2)

- The cumulative damage of a curved bridge presented an exponential growth trend with the increase in operation time, and the shorter the interval time was, the faster the growth rate. The cumulative damage was mainly affected by the bridge span and train speed, especially when the train speed was close to the resonance speed.

- (3)

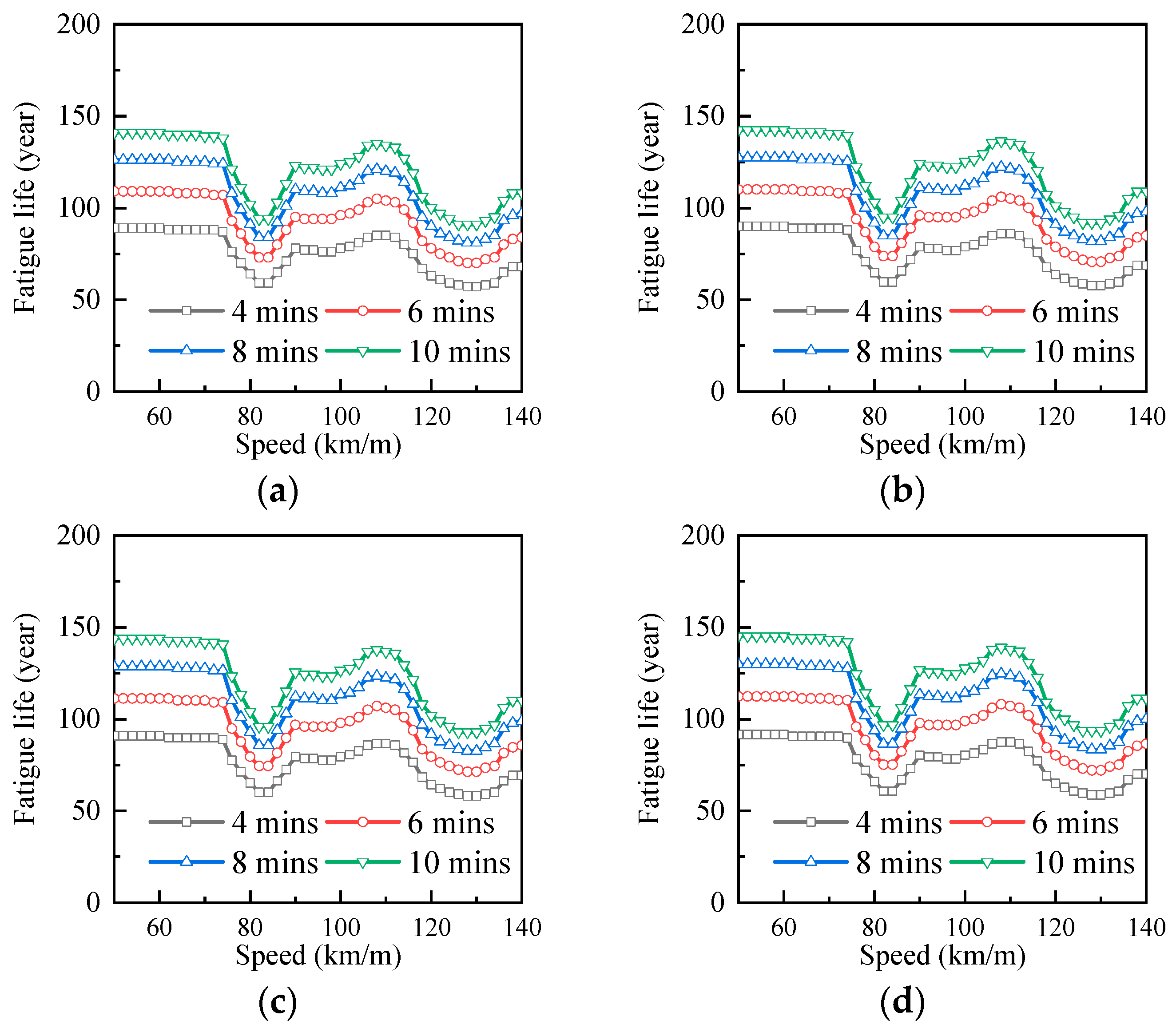

- When the bridge span was 20 m, the train speed had little effect on the fatigue life, and the fatigue life increased with the increase in the train operation interval.

- (4)

- When the bridge span was 25 m, 30 m, and 35 m, the train speed had a great influence on the fatigue life, and at different speed stages, the fatigue life of the bridge changes differently from the train speed, mainly because the dynamic load of the train causes the bridge resonance at some speeds. It was suggested that the design speed of the curved bridge with a span of 25 m should be set in the range of 70 to 106 km/h; the speed of the curved bridge with a span of 30 m was avoided within the range of 78 to 86 km/h; the design speed of the curved bridge with a span of 35 m was set near 75 km/h.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, L.; Cui, C.; Liu, J.; Yu, Z.; Jiang, L. Corrosion-Fatigue Life Assessment of RC Plate Girder in Heavy-Haul Railway under Combined Carbonation and Train Loads. Int. J. Fatigue 2021, 151, 106368. [Google Scholar] [CrossRef]

- Zhao, L.; Zhou, L.; Yu, Z.; Mahunon, A.D.; Peng, X.; Zhang, Y. Experimental Study on CRTS II Ballastless Track-Bridge Structural System Mechanical Fatigue Performance. Eng. Struct. 2021, 244, 112784. [Google Scholar] [CrossRef]

- Rageh, A.; Eftekhar Azam, S.; Linzell, D.G. Steel Railway Bridge Fatigue Damage Detection Using Numerical Models and Machine Learning: Mitigating Influence of Modeling Uncertainty. Int. J. Fatigue 2020, 134, 105458. [Google Scholar] [CrossRef]

- Feng, Q.; Zhu, Z.; Tong, Q.; Yu, Y.; Zheng, W. Dynamic Responses and Fatigue Assessment of OSD in Heavy-Haul Railway Bridges. J. Constr. Steel Res. 2023, 204, 107873. [Google Scholar] [CrossRef]

- Horas, C.S.; De Jesus, A.M.P.; Calçada, R. Efficient Progressive Global-Local Fatigue Assessment Methodology for Existing Metallic Railway Bridges. J. Constr. Steel Res. 2022, 196, 107431. [Google Scholar] [CrossRef]

- Zeng, Q.; Yang, Y.B.; Dimitrakopoulos, E.G. Dynamic Response of High Speed Vehicles and Sustaining Curved Bridges under Conditions of Resonance. Eng. Struct. 2016, 114, 61–74. [Google Scholar] [CrossRef]

- Wang, J.; Cui, C.; Liu, X.; Wang, M. Dynamic Impact Factor and Resonance Analysis of Curved Intercity Railway Viaduct. Appl. Sci. 2022, 12, 2978. [Google Scholar] [CrossRef]

- Briseghella, B.; Fa, G.; Aloisio, A.; Pasca, D.; He, L.; Fenu, L.; Gentile, C. Dynamic Characteristics of a Curved Steel–Concrete Composite Cable-Stayed Bridge and Effects of Different Design Choices. Structures 2021, 34, 4669–4681. [Google Scholar] [CrossRef]

- Xin, L.; Mu, D.; Choi, D.; Li, X.; Wang, F. General conditions for the resonance and cancellation of railway bridges under moving train loads. Mech. Syst. Signal Process. 2023, 183, 109589. [Google Scholar] [CrossRef]

- Li, W.; Ma, H.; Wei, M.; Xiang, P.; Tang, F.; Gao, B.; Zhou, Q. Dynamic Responses of Train-Symmetry-Bridge System Considering Concrete Creep and the Creep-Induced Track Irregularity. Symmetry 2023, 15, 1846. [Google Scholar] [CrossRef]

- Wu, Z.; Li, C.; Liu, W.; Li, D.; Wang, W.; Zhu, B. Analysis of Vibration Responses Induced by Metro Operations Using a Probabilistic Method. Symmetry 2024, 16, 145. [Google Scholar] [CrossRef]

- Dimitrakopoulos, E.G.; Zeng, Q. A Three-Dimensional Dynamic Analysis Scheme for the Interaction between Trains and Curved Railway Bridges. Comput. Struct. 2015, 149, 43–60. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, L.; Xiang, P.; Lai, Z.; Liu, L.; Cao, S.; Zhou, W. Probability Analysis of Train-Bridge Coupled System Considering Track Irregularities and Parameter Uncertainty. Mech. Based Des. Struct. Mach. 2021, 51, 2918–2935. [Google Scholar] [CrossRef]

- Cheng, Y.-C.; Chen, C.-H.; Hsu, C.-T. Derailment and Dynamic Analysis of Tilting Railway Vehicles Moving Over Irregular Tracks Under Environment Forces. Int. J. Struct. Stab. Dyn. 2017, 17, 1750098. [Google Scholar] [CrossRef]

- Muñoz, S.; Aceituno, J.F.; Urda, P.; Escalona, J.L. Multibody Model of Railway Vehicles with Weakly Coupled Vertical and Lateral Dynamics. Mech. Syst. Signal Process. 2019, 115, 570–592. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, L.; Xiang, P.; Lai, Z.; Feng, Y.; Cao, S. Dynamic Response Limit of High-Speed Railway Bridge under Earthquake Considering Running Safety Performance of Train. J. Cent. South Univ. 2021, 28, 968–980. [Google Scholar] [CrossRef]

- Lai, Z.; Jiang, L.; Zhou, W.; Yu, J.; Zhang, Y.; Liu, X.; Zhou, W. Lateral Girder Displacement Effect on the Safety and Comfortability of the High-Speed Rail Train Operation. Veh. Syst. Dyn. 2021, 60, 3215–3239. [Google Scholar] [CrossRef]

- Li, H.; Frangopol, D.M.; Soliman, M.; Xia, H. Fatigue Reliability Assessment of Railway Bridges Based on Probabilistic Dynamic Analysis of a Coupled Train-Bridge System. J. Struct. Eng. 2016, 142, 04015158. [Google Scholar] [CrossRef]

- Li, C.; Jie, J.; Jiang, L.; Tang, T. Theory and Implementation of a Two-Step Unconditionally Stable Explicit Integration Algorithm for Vibration Analysis of Structures. Shock. Vib. 2016, 2831206. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, L.; Xiang, P.; Jiang, L.; Lai, Z. Safety and Comfort Assessment of a Train Passing over an Earthquake-Damaged Bridge Based on a Probability Model. Struct. Infrastruct. Eng. 2021, 19, 525–536. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.; Tu, Y.; Sabourova, N.; Grip, N.; Blanksvärd, T.; Elfgren, L. Fatigue Assessment of a Reinforced Concrete Railway Bridge Based on a Coupled Dynamic System. Struct. Infrastruct. Eng. 2020, 16, 861–879. [Google Scholar] [CrossRef]

- Song, L.; Hou, J.; Yu, Z. Fatigue and post-fatigue monotonic behaviour of partially prestressed concrete beams. Mag. Concr. Res. 2016, 68, 109–117. [Google Scholar] [CrossRef]

- Miner, M.A. Cumulative Damage in Fatigue. J. Appl. Mech. 1945, 12, A159–A164. [Google Scholar] [CrossRef]

- Yang, Y.B.; Wu, Y.S.; Yao, Z.D. Vehicle-Bridge Interaction Dynamics: With Applications to High-Speed Railways; World Scientific: Singapore, 2004. [Google Scholar]

| Order | Vertical | Lateral |

|---|---|---|

| 1st | 5.30 Hz | 13.73 Hz |

| 2nd | 21.16 Hz | 54.89 Hz |

| 3rd | 47.59 Hz | 123 Hz |

| Symbol | Meaning | Value |

|---|---|---|

| mc | Mass of car-body | 21,920 kg |

| mt | Mass of bogie | 2550 kg |

| mw | Mass of wheelset | 1420 kg |

| 2L1 | Spacing of two wheelsets | 2.2 m |

| 2L2 | Spacing of two bogies | 12.5 m |

| Lv | Length of carriage | 19 m |

| Length of Span | i = 1 | i = 2 | i = 3 | i = 4 |

|---|---|---|---|---|

| 20 m | 566 km/h | 283 km/h | 189 km/h | 141 km/h |

| 2261 km/h | 1131 km/h | 754 km/h | 565 km/h | |

| 5083 km/h | 2541 km/h | 1694 km/h | 1271 km/h | |

| 25 m | 363 km/h | 181 km/h | 121 km/h | 91 km/h |

| 1447 km/h | 724 km/h | 482 km/h | 362 km/h | |

| 3255 km/h | 1628 km/h | 1085 km/h | 814 km/h | |

| 30 m | 252 km/h | 126 km/h | 84 km/h | 63 km/h |

| 1005 km/h | 503 km/h | 335 km/h | 251 km/h | |

| 2261 km/h | 1131 km/h | 754 km/h | 565 km/h | |

| 35 m | 185 km/h | 92 km/h | 62 km/h | 46 km/h |

| 739 km/h | 369 km/h | 246 km/h | 185 km/h | |

| 1661 km/h | 831 km/h | 554 km/h | 415 km/h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Chen, S.; Zhang, W.; Liu, X. Service Life Evaluation of Curved Intercity Rail Bridges Based on Fatigue Failure. Infrastructures 2024, 9, 139. https://doi.org/10.3390/infrastructures9090139

Zhang H, Chen S, Zhang W, Liu X. Service Life Evaluation of Curved Intercity Rail Bridges Based on Fatigue Failure. Infrastructures. 2024; 9(9):139. https://doi.org/10.3390/infrastructures9090139

Chicago/Turabian StyleZhang, Hongwei, Shaolin Chen, Wei Zhang, and Xiang Liu. 2024. "Service Life Evaluation of Curved Intercity Rail Bridges Based on Fatigue Failure" Infrastructures 9, no. 9: 139. https://doi.org/10.3390/infrastructures9090139

APA StyleZhang, H., Chen, S., Zhang, W., & Liu, X. (2024). Service Life Evaluation of Curved Intercity Rail Bridges Based on Fatigue Failure. Infrastructures, 9(9), 139. https://doi.org/10.3390/infrastructures9090139