Development of a Non-Structural Prefabricated Panel Based on Construction and Demolition Waste for Sustainable Construction

Abstract

1. Introduction

1.1. Overview

1.2. Related Studies

1.3. Aim of This Work

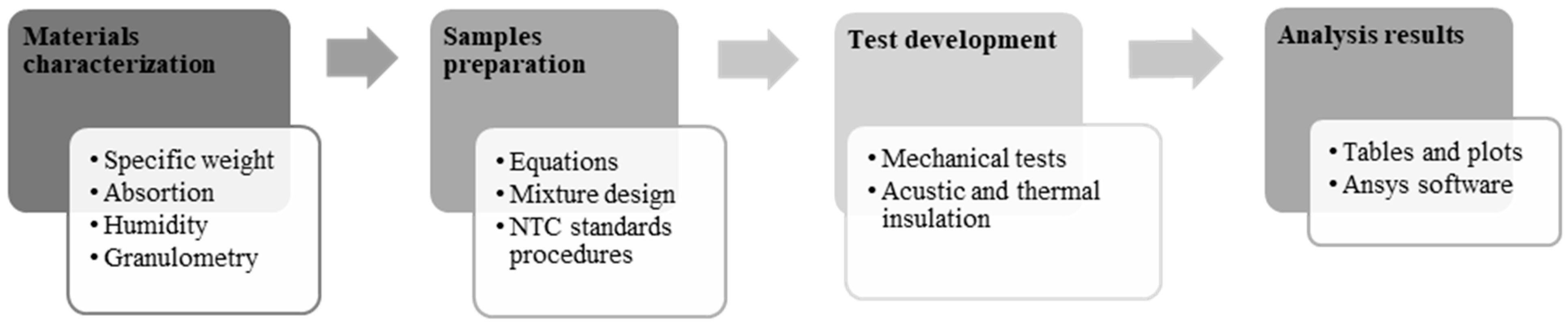

2. Materials and Methods

2.1. Cylinders for Compression Resistance Testing

2.2. Mixture Preparation

2.3. Compression Resistance Test

2.4. Development of the Concrete Partition Panel with the Addition of CDW and PET

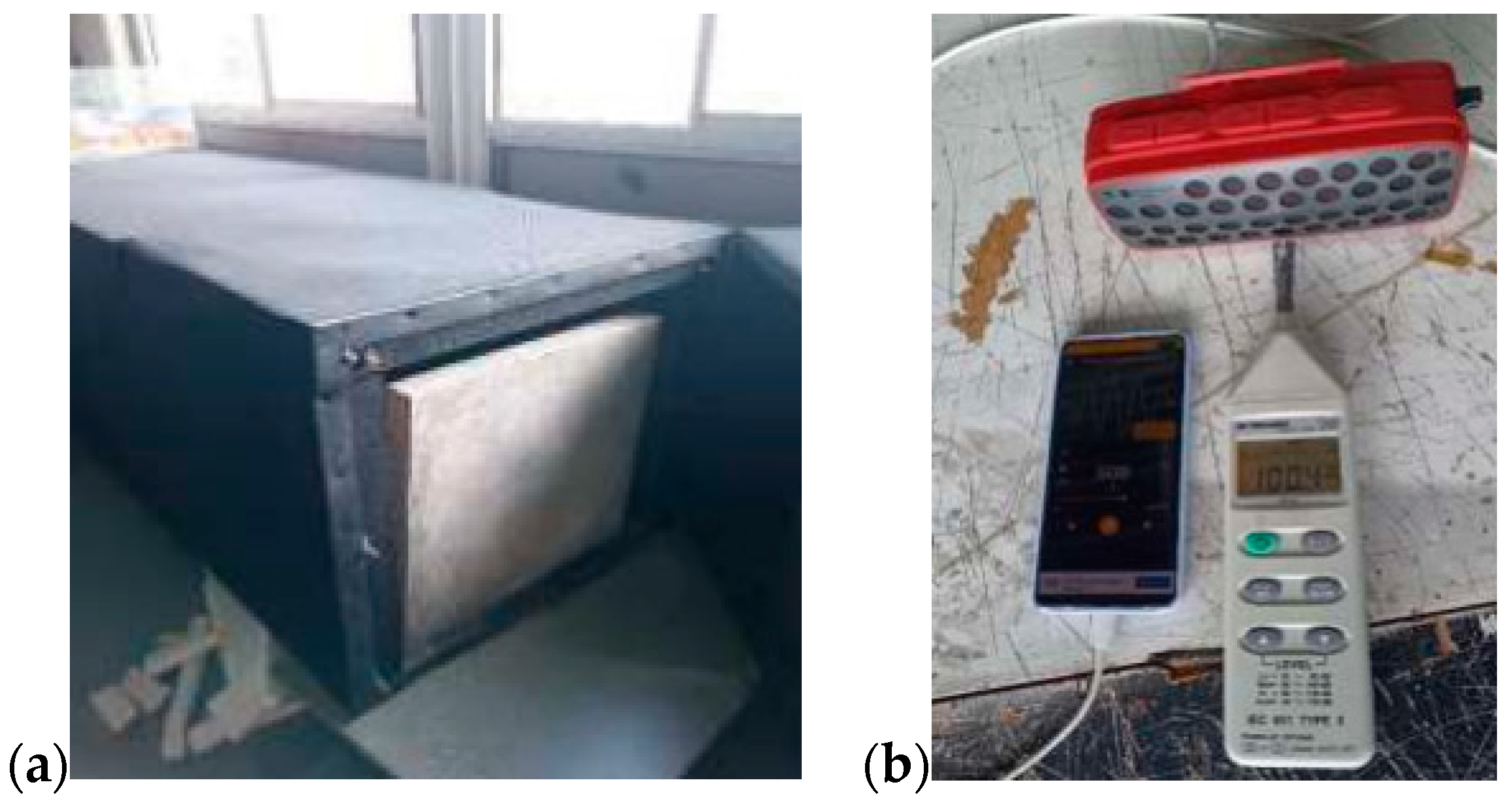

2.5. Thermal and Acoustic Tests

3. Results and Discussions

3.1. Specific Weight and Absorption of Fine Aggregate

3.2. Fine Aggregate Moisture

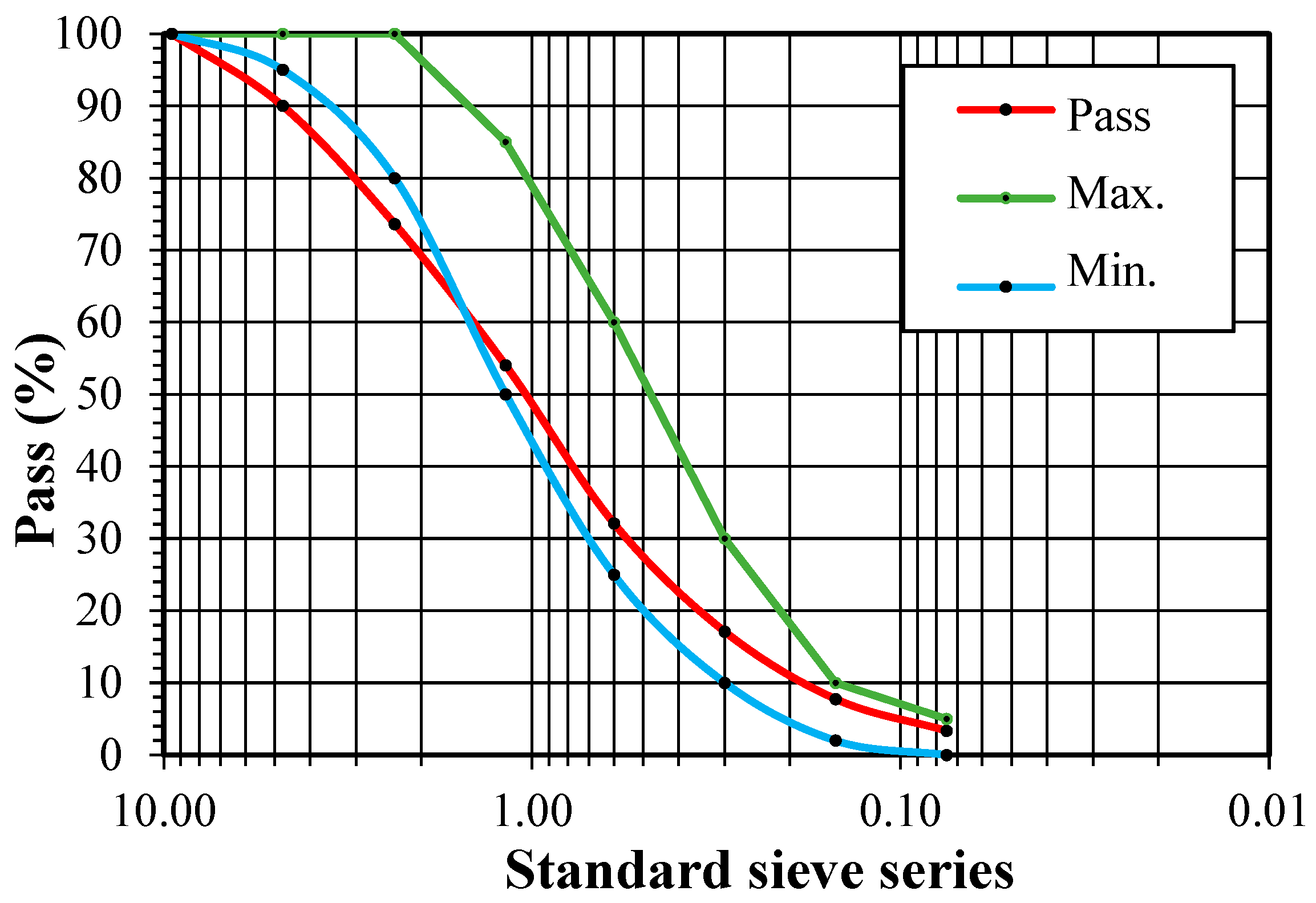

3.3. Granulometry of Fine Aggregate

3.4. Mixture Design

- ⮚

- Relative density (specific gravity) in saturated and superficially dry condition (SSS) (0% CDW) = 100% Relative density (specific gravity) in saturated and superficially dry condition of river sand.

- ⮚

- Relative density (specific gravity) in saturated and superficially dry condition (SSS) (10% CDW) = 90% Relative density (specific gravity) in saturated and superficially dry condition of river sand + 10% Relative density (specific gravity) in saturated and superficially dry condition of CDW sand.

- ⮚

- Relative density (specific gravity) in saturated and superficially dry condition (SSS) (20% CDW) = 80% Relative density (specific gravity) in saturated and superficially dry condition of river sand + 20% Relative density (specific gravity) in saturated and superficially dry condition of CDW sand.

- ⮚

- Relative density (specific gravity) in saturated and superficially dry condition (SSS) (30% CDW) = 70% Relative density (specific gravity) in saturated and superficially dry condition of river sand + 30% Relative density (specific gravity) in saturated and superficially dry condition of CDW sand.

3.5. General Results of the Compression Test

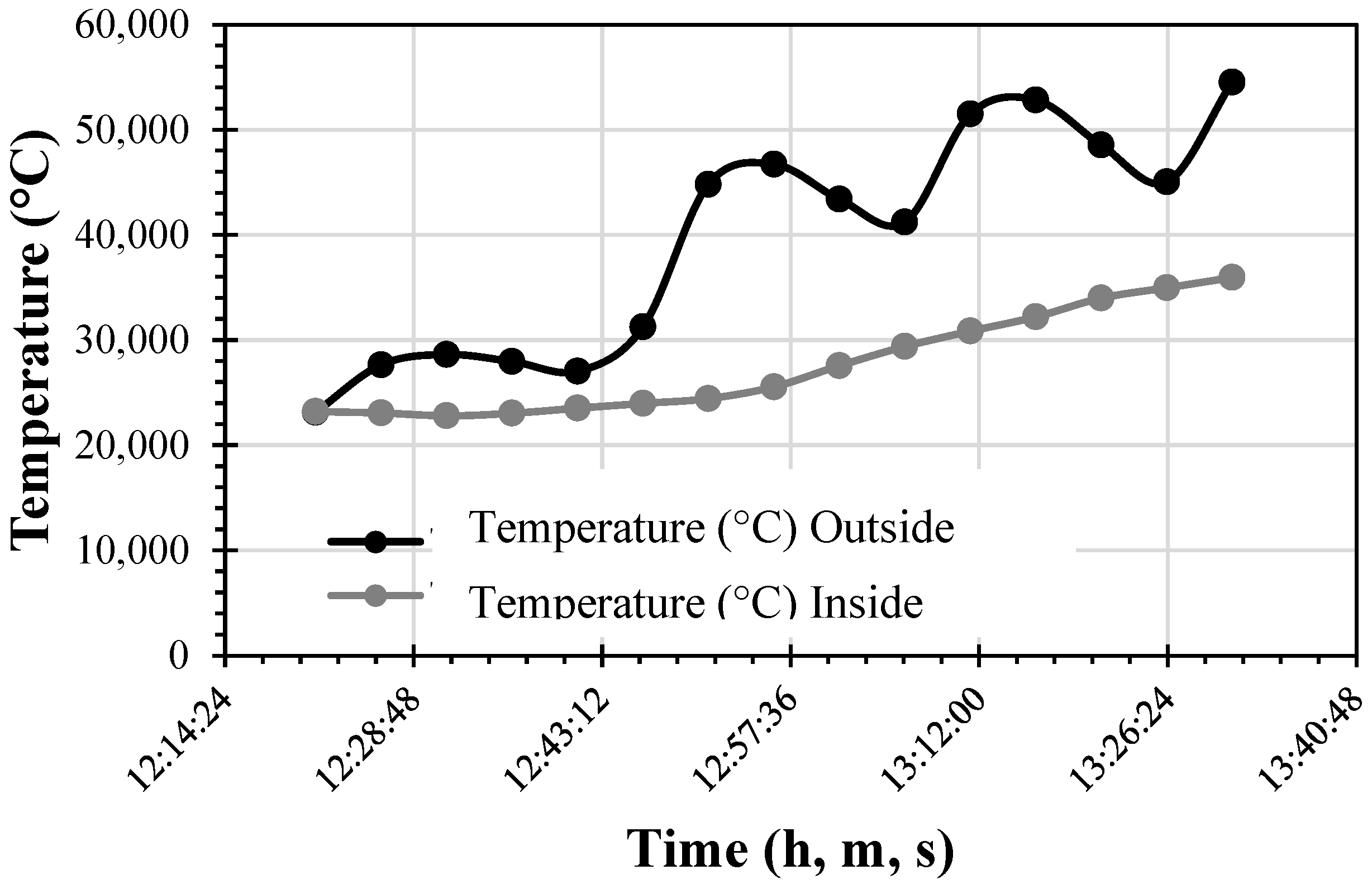

3.6. Thermal Test of the Concrete Partition Panel with the Addition of CDW and PET

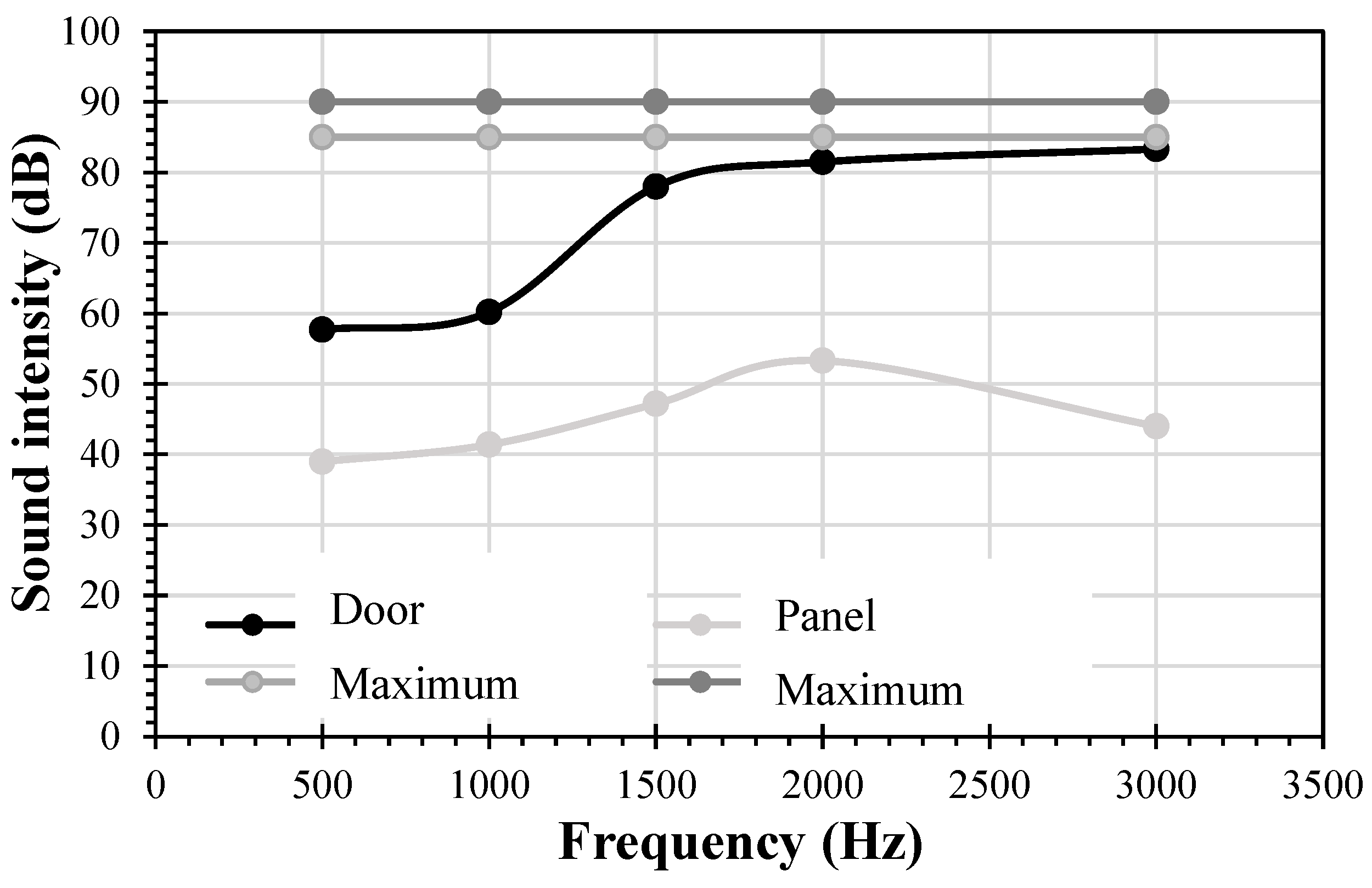

3.7. Acoustic Analysis Test of the Dividing Panel with Concrete and Recycled Plastic

3.8. Microstructural Analysis by Scanning Electron Microscopy

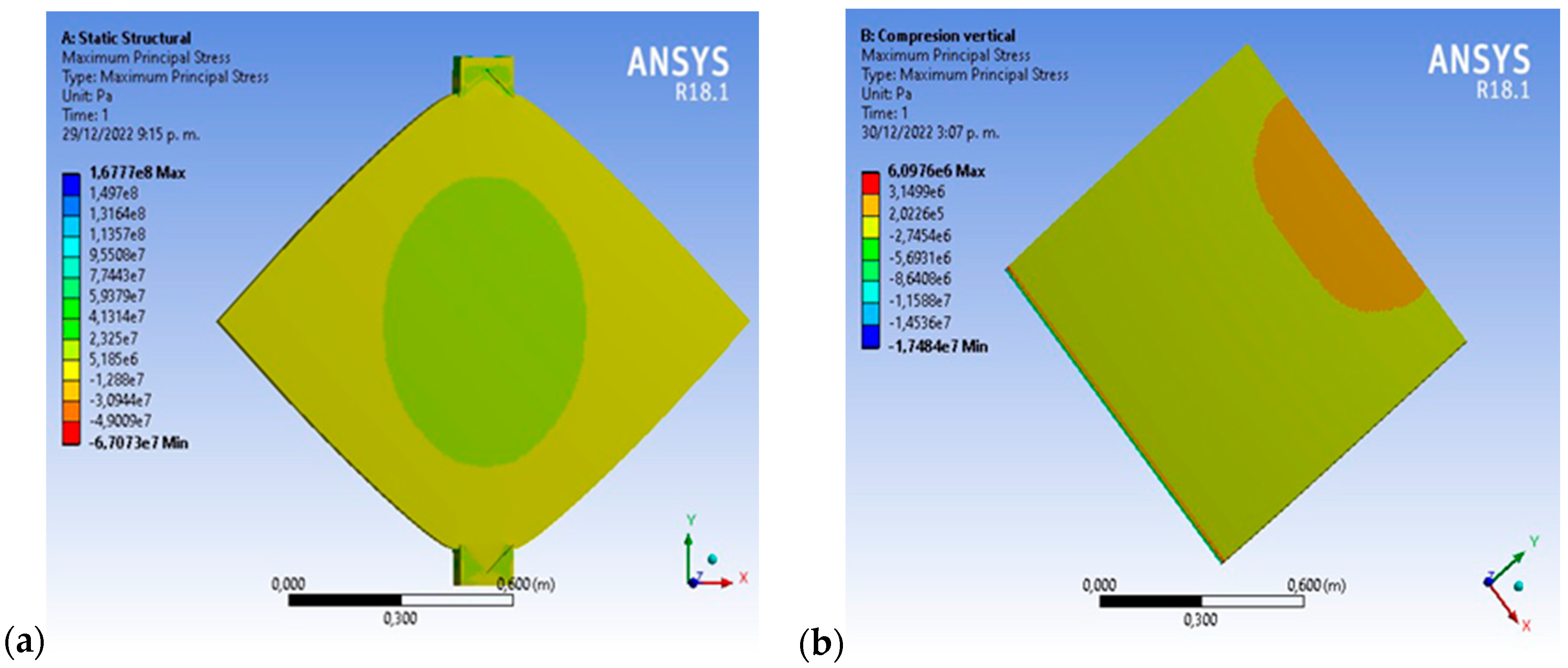

3.9. Simulation Test Using ANSYS

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef] [PubMed]

- Wasim, M.; Oliveira, O.; Ngo, T.D. Structural performance of prefabricated glass fibre concrete floor panel versus compressed fibre cement floor panel for an optimised volumetric module—A case study. J. Build. Eng. 2022, 48, 103819. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Silvestri, C.; Aquilani, B.; Silvestri, L. Is this a new story of the ‘Two Giants’? A systematic literature review of the relationship between industry 4.0, sustainability and its pillars. Technol. Forecast. Soc. Chang. 2022, 177, 121511. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Šaparauskas, J.; Antucheviciene, J. Sustainability in construction engineering. Sustainability 2018, 10, 2236. [Google Scholar] [CrossRef]

- Cherene, M.G.P.; de Castro Xavier, G.; da Silva Barroso, L.; de S. M. Oliveira, J.; de Azevedo, A.R.G.; Vieira, C.M.; Alexandre, J.; Monteiro, S.N. Technological and microstructural perspective of the use of ceramic waste in cement-based mortars. Constr. Build. Mater. 2023, 367, 130256. [Google Scholar] [CrossRef]

- Ilcan, H.; Sahin, O.; Kul, A.; Yildirim, G.; Sahmaran, M. Rheological properties and compressive strength of construction and demolition waste-based geopolymer mortars for 3D-Printing. Constr. Build. Mater. 2022, 328, 127114. [Google Scholar] [CrossRef]

- Muñoz Pérez, S.P.; Díaz Sánchez, D.M.; Gamarra Capuñay, E.E.; Chaname Bustamante, J.A. La Influencia de los RCD en reemplazo de los agregados para la elaboración de concreto: Una revisión de la literatura. Ecuadorian Sci. J. 2021, 5, 107–120. [Google Scholar] [CrossRef]

- Luis, A.; Rendón, N.; Korody, M.E. Polyethylene Teraftalate (PET)—Cement mixture designs. Rev. Fac. Ing. Univ. Cent. Venez. 2008, 23, 77–86. [Google Scholar]

- Smaoui, H.; Trabelsi, A.; Kammoun, Z.; Aouicha, B. Mechanical, physical, blast waves and ballistic impact resistance properties of a concrete incorporating thermally treated PET inclusions. Constr. Build. Mater. 2023, 365, 130088. [Google Scholar] [CrossRef]

- Borg, R.P.; Baldacchino, O.; Ferrara, L. Early age performance and mechanical characteristics of recycled PET fibre reinforced concrete. Constr. Build. Mater. 2016, 108, 29–47. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Tam, V.; Lambrincha, A.; Ding, Y.; De Brito, J. Handbook of Recycled Concrete and Demolition Waste; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Bravo-German, A.M.; Bravo-Gómez, I.D.; Mesa, J.A.; Maury-Ramírez, A. Mechanical Properties of Concrete Using Recycled Aggregates Obtained from Old Paving Stones. Sustainability 2021, 13, 44. [Google Scholar] [CrossRef]

- Otoko, G. Review of the Use of Construction and Demolition Waste in Concrete. Int. J. Eng. Technol. Res. 2014, 2, 1–8. [Google Scholar]

- Betancourt, J.; Cortés, F.; Rentería, J.; Díaz, A.; Vaquera, M. Comportamiento de mezclas de mortero con residuos de mármol (polvo), cáscara de nuez y mucílago de nopal. Rev. Arquit. Ing. 2019, 13, 1–16. [Google Scholar]

- Acosta, A.M.; Beltran, L.F. Determinar las Propiedades Mecánicas y el Uso de Cuesco de Palma Africana Para la Fabricación de Adoquines y Bloques Estructurales; Universidad Cooperativa de Colombia: Bogota, Colombia, 2017. [Google Scholar]

- García-León, R.A.; Flórez-Solano, E.; Rodríguez-Castilla, M. Diseño de mezclas para la fabricación de productos de mampostería en la industria cerámica. Rev. Politécnica 2018, 14, 19–28. [Google Scholar] [CrossRef][Green Version]

- Zhang, X.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialized residential building in China. Habitat Int. 2014, 41, 176–184. [Google Scholar] [CrossRef]

- Li, P.; Ran, J.; An, X.; Bai, H.; Nie, D.; Zhang, J.; Shao, K. An enhanced mix-design method for self-compacting concrete based on paste rheological threshold theory and equivalent mortar film thickness theories. Constr. Build. Mater. 2022, 347, 128573. [Google Scholar] [CrossRef]

- García-León, R.A.; Flórez-Solano, E.; Medina-Cárdenas, Y. Caracterización física de las arcillas utilizadas en la fabricación de productos de mampostería para la construcción en Ocaña Norte de Santander. Espacios 2018, 39, 1–6. [Google Scholar]

- Yuan, M.; Li, Z.; Li, X.; Luo, X. Managing stakeholder-associated risks and their interactions in the life cycle of prefabricated building projects: A social network analysis approach. J. Clean. Prod. 2021, 323, 129102. [Google Scholar] [CrossRef]

- Juan-Valdés, A.; Rodríguez-robles, D.; García-gonzález, J.; Sánchez, M.I.; Gómez, D.R.; Guerra-romero, M.I.; De Belie, N.; Pozo, J.M.M. Mechanical and microstructural properties of recycled concretes mixed with ceramic recycled cement and secondary recycled aggregates. Constr. Build. Mater. 2020, 270, 121455. [Google Scholar] [CrossRef]

- Ussa, Y.R.M.; Poveda, J.E. Fabricación de Adoquín a Partir de un Sistema de Aprovechamiento de Escombros en Obra; Universidad La Gran Colombia: Bogotá, Colombia, 2015. [Google Scholar]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Wagih, A.M.; El-Karmoty, H.Z.; Ebid, M.; Okba, S.H. Recycled construction and demolition concrete waste as aggregate for structural concrete. HBRC J. 2013, 9, 193–200. [Google Scholar] [CrossRef]

- García-León, R.A.; Sanchez-Torrez, A.; Rincon-Cardenas, W.; Afanador-García, N.; Moreno-Pacheco, L.; Lanziano-Barrera, M. Experimental study about the improvement of the mechanical properties of a concrete cobble using recyclable additives. DYNA 2023, 90, 45–55. [Google Scholar] [CrossRef]

- Akinyele, J.O.; Igba, U.T.; Adigun, B.G. Effect of waste PET on the structural properties of burnt bricks. Sci. Afr. 2020, 7, e00301. [Google Scholar] [CrossRef]

- Ascencio, E.; Montoya, L.; Campo, J. Diseño y Elaboracion de un Prototipo de Pavimento Articulado “Adoplas” a Base de Plastico Residual Recuperado PET y PP; Universidad Coperativa de Colombia: Bogotá, Colombia, 2021; Volume 15. [Google Scholar]

- Florez, C. Propiedades Fisico-Quimicas del Concreto de 24 MPa Con el Uso de Polietileno de Tereflalato Reciclado (botella PET) y el Concreto Convencional en la Ciudad de Cucuta; Universidad Francisco de Paula Santander: Cúcuta, Colombia, 2014. [Google Scholar]

- Gustavo Gamba, S.P. Caracterización de las Propiedades Mecánicas de Adoquines Producto, Concreto con Adición de Residuo de Caucho Reciclado Usadas, de Llantas. Ph.D. Thesis, Universidad Distrital Francisco José de Caldas, Bogotá, Colombia, 2015. [Google Scholar]

- NSR-10; Titulo A—Requisitos Generales de Diseño y Construcción Sismo Resistente. Sociedad Colombiana de Geotecnia: Bogota, Colombia, 2010; pp. 1–174.

- NTC-4024; Prefabricados de Concreto. Muestreo y Ensayo de Prefabricados de Concreto no Reforzados, Vibrocompactados. Icontec: Bogota, Colombia, 2001.

- NTC-3459; Concretos. Agua para la elaboracion de concreto. Icontec: Bogota, Colombia, 2001.

- Jaramillo, H.Y.; Vasco-Echeverri, O.H.; Moreno-Pacheco, L.A.; García-León, R.A. Biomaterials in Concrete for Engineering Applications: A Bibliometric Review. Infrastructures 2023, 8, 161. [Google Scholar] [CrossRef]

- García-León, R.A.; Gomez Camperos, J.; Jaramillo, H.Y. Physical, chemical and thermal characterization of a Colombian clay. Int. J. Mech. Mechatron. Eng. 2020, 20, 225–234. [Google Scholar]

- García-León, R.A.; Acevedo-Peñaloza, C.; Rojas-Suarez, J.P. Metodología Para la Fabricación del Bloque H-10 Para la Industria Cerámica de Norte de Santander; ECOE Ed.: Bogota, Colombia, 2019; ISBN 978-958-8489-98-8. [Google Scholar]

- García-León, R.A.; Afanador-García, N.; Guerrero-Gómez, G. Physical-Mechanical properties of H-10 blocks manufactured in Norte of Santander, Colombia: A case study. DYNA 2021, 88, 181–189. [Google Scholar] [CrossRef]

- NTC-1776; Método de Ensayo Para Determinar el Contenido Total de Humedad Evaporada por Secado de los Agrefados. Norma Técnica Colombia. pp. 1–11, 19AD. Available online: https://tienda.icontec.org/gp-metodo-de-ensayo-para-determinar-el-contenido-total-de-humedad-evaporable-por-secado-de-los-agregados-ntc1776-2019.html (accessed on 16 May 2024).

- NTC-77; Concretos. Método de Ensayo Para el Análisis por Tamizado de los Agregados Finos y Gruesos. Norma Técnica Colombia. 2018; pp. 1–12. Available online: https://tienda.icontec.org/gp-concretos-metodo-de-ensayo-para-el-analisis-por-tamizado-de-los-agregados-finos-y-gruesos-ntc77-2018.html (accessed on 16 May 2024).

- NTC-237; Método de Ensayo Para Determinar la Densidad Relativa (Gravedad Especifica) y la Absorción del Agregado Fino. Norma Técnica Colombia. 2020; pp. 1–10. Available online: https://tienda.icontec.org/gp-metodo-de-ensayo-para-determinar-la-densidad-relativa-gravedad-especifica-y-la-absorcion-del-agregado-fino-ntc237-2020.html (accessed on 16 May 2024).

- ASTM-C518-21; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. 2021; pp. 1–34. Available online: https://www.astm.org/standards/c518 (accessed on 16 May 2024).

- ASTM-E413; Classification for Rating Sound Insulation. ASTM, 2022; p. 4. Available online: https://www.astm.org/e0413-22.html (accessed on 16 May 2024).

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Manso, J.M. Effect of fine recycled concrete aggregate on the mechanical behavior of self-compacting concrete. Constr. Build. Mater. 2020, 263, 120671. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Marsiglio, L.; Cheng, S.; Falk, E.; Fugh, A.; Mulvaney, K.; Slocum, B.; Morris, D.; Balasubramanian, G.; Mehta, K. Comparing the Properties of Polyethylene Terephthalate (PET) Plastic Bricks to Conventional Concrete Masonry Units. In Proceedings of the 2020 IEEE Global Humanitarian Technology Conference (GHTC), Seattle, WA, USA, 29 October–1 November 2020; pp. 1–6. [Google Scholar]

- García-León, R.A.; Flórez-Solano, E.; Rodríguez-Castilla, M. Application of the procedure of the ISO 50001:2011 standard for energy planning in a company ceramic sector. DYNA 2019, 86, 120–126. [Google Scholar] [CrossRef]

- Ministerio de Ambiente, Vivienda y Desarrollo Territorial. Resolución 0627 de 2006; Ministerio de Ambiente, vivienda y Desarrollo Territorial: Bogota, Colombia, 2006; pp. 1–31.

- García-Léon, R.A.; Jaimes-Gonzalez, W.; Becerra, L.D.; Florez-Solano, E.; Cabellos-Martinez, M.; Meneses-Torres, D. Application of the QFD method to the design of a cocoa pulping machine. Int. J. Syst. Assur. Eng. Manag. 2021, 12, 1199–1220. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Mass in air of the oven-dried sample (g) | 613.5 ± 0.50 |

| Mass of the graduated pycnometer filled with water (g) | 670.1 ± 0.49 |

| Mass in air of the saturated and superficially dry sample (g) | 500.3 ± 0.42 |

| Total mass of pycnometer filled with sample and filled with water (g) | 977.8 ± 0.91 |

| Relative density (specific gravity) (SH) | 2.534 ± 0.02 |

| Relative density (specific gravity) in saturated and superficially dry (SSS) conditions | 2.598 ± 0.01 |

| Apparent relative density (apparent specific gravity) | 2.707 ± 0.01 |

| % absorption | 2.52 ± 0.02 |

| Item | Value |

|---|---|

| Mass in air of the oven-dried sample (g) | 595.2 ± 0.47 |

| Mass of the graduated pycnometer filled with water (g) | 670.1 ± 0.55 |

| Mass in air of the saturated and superficially dry sample (g) | 500.3 ± 0.39 |

| Total mass of pycnometer filled with sample and filled with water (g) | 965.4 ± 0.88 |

| Relative density (specific gravity) (SH) | 2.305 ± 0.03 |

| Relative density (specific gravity) in saturated and superficially dry (SSS) conditions | 2.44 ± 0.02 |

| Apparent relative density (apparent specific gravity) | 2.666 ± 0.05 |

| % absorption | 5.88 ± 0.03 |

| Item | Value | |

|---|---|---|

| River Sand (g) | CDW (g) | |

| Container weight (g) (p1) | 282.5 ± 0.99 | 290.8 ± 1.56 |

| Weight of container + Weight of moist soil (g) (p2) | 433.8 ± 1.25 | 3587 ± 3.69 |

| Weight of container + dry soil (g) (p3) | 415.7 ± 1.15 | 3330.00 ± 2.89 |

| Dry soil weight (g) | 133.2 ± 0.89 | 3039.20 ± 2.96 |

| Weight of water (g) | 18.10 ± 0.75 | 257.00 ± 1.48 |

| Moisture content (%) | 13.59 ± 0.66 | 8.46 ± 0.99 |

| Initial Weight | 2059.2 g | Fineness Module | 3.25 | ||||

|---|---|---|---|---|---|---|---|

| Sieve | Retained Weight (gr) | % Retained | % Retained Accumulated | % Pass | Specification | ||

| In | Mm | Min. | Max. | ||||

| 3/8” | 9.50 | 0.00 | 0.0 | 0.0 | 100.0 | 100 | 100 |

| No 4 | 4.75 | 205.50 | 10.0 | 10.0 | 90.0 | 95 | 100 |

| No 8 | 2.36 | 337.80 | 16.4 | 26.4 | 73.6 | 80 | 100 |

| No 16 | 1.18 | 403.60 | 19.6 | 46.0 | 54.0 | 50 | 85 |

| No 30 | 0.60 | 450.80 | 21.9 | 67.9 | 32.1 | 25 | 60 |

| No 50 | 0.30 | 309.10 | 15.0 | 82.9 | 17.1 | 10 | 30 |

| No 100 | 0.15 | 193.00 | 9.4 | 92.3 | 7.7 | 2 | 10 |

| No 200 | 0.075 | 90.40 | 4.4 | 96.6 | 3.4 | 0 | 5 |

| P200 | <0.075 | 69.00 | 3.4 | 100.0 | --- | --- | --- |

| Total | 2059.20 g | ||||||

| Initial Weight | 2350 g | Fineness Module | 3.59 | ||||

|---|---|---|---|---|---|---|---|

| Sieve | Retained Weight (gr) | % Retained | % Retained Accumulated | % Pass | Specification | ||

| In | mm | Min. | Max. | ||||

| 3/8″ | 9.50 | 3.40 | 0.2 | 0.2 | 99.8 | 100 | 100 |

| No 4 | 4.75 | 254.50 | 11.7 | 11.9 | 88.1 | 95 | 100 |

| No 8 | 2.36 | 528.40 | 24.4 | 36.3 | 63.7 | 80 | 100 |

| No 16 | 1.18 | 472.40 | 21.8 | 58.1 | 41.9 | 50 | 85 |

| No 30 | 0.60 | 341.70 | 15.8 | 73.8 | 26.2 | 25 | 60 |

| No 50 | 0.30 | 245.10 | 11.3 | 85.2 | 14.8 | 10 | 30 |

| No 100 | 0.15 | 176.40 | 8.1 | 93.3 | 6.7 | 2 | 10 |

| No 200 | 0.075 | 101.70 | 4.7 | 98.0 | 2.0 | 0 | 5 |

| P200 | <0.075 | 43.50 | 2.0 | 100.0 | --- | --- | --- |

| Total | 2167.10 g | ||||||

| Relative Density (Specific Gravity) in Saturated and Superficially Dry (SSS) Condition (% CDW) | Value |

|---|---|

| 0 | 2.598 |

| 10 | 2.58 |

| 20 | 2.57 |

| 30 | 2.55 |

| 100 | 2.44 |

| Variable | Value |

|---|---|

| Sand fineness modulus | 3.25 |

| Water cement ratio | 0.58 |

| Argos Structural cement density | 3.18 |

| 454 kg of cement | 3000 PSI |

| PET | 5% |

| PET plastic density | 1.35 |

| Equation | Variable | Calculation | Result |

|---|---|---|---|

| 1 | 142.77 kg | ||

| 2 | 263.32 kg | ||

| 3 | 15.89 kg | ||

| 4 | 16.81 kg | ||

| 5 | 0.561 kg |

| Proportion (% CDW) | Cement | Sand |

|---|---|---|

| 0 | 1 | 3.21 |

| 10 | 1 | 3.19 |

| 20 | 1 | 3.17 |

| 30 | 1 | 3.15 |

| 100 | 1 | 3.02 |

| %CDW | Cement (kg) | Sand (kg) | Water (kg) | PE (kg) | CDW (kg) | Washed Sand (kg) |

|---|---|---|---|---|---|---|

| 0 | 5 | 16.05 | 2.9 | 0.25 | 0.00 | 16.05 |

| 10 | 15.95 | 1.60 | 14.36 | |||

| 20 | 15.86 | 3.17 | 12.69 | |||

| 30 | 15.76 | 4.73 | 11.03 | |||

| 100 | 15.08 | 15.08 | 0.00 |

| Cylinder | High (mm) | Diameter (mm) | Sand (mm2) | Volume (mm3) | Weight (kg) | %CDW | Load (kN) | Resistance (MPa) |

|---|---|---|---|---|---|---|---|---|

| 1 | 204.14 | 110.28 | 9551.78 | 1,949,900.82 | 4.170 | 0 | 215.8 | 22.59 |

| 2 | 204.54 | 109.30 | 9382.77 | 1,919,152.44 | 4.116 | 10 | 254.4 | 27.11 |

| 3 | 201.18 | 104.80 | 8626.08 | 1,735,394.70 | 3.716 | 20 | 271.3 | 31.45 |

| 4 | 203.51 | 109.43 | 9405.11 | 1,914,033.13 | 4.054 | 30 | 241.0 | 25.62 |

| 5 | 202.92 | 104.95 | 8650.79 | 1,755,418.36 | 3.699 | 100 | 236.1 | 27.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaramillo, H.Y.; Gómez Camperos, J.A.; Afanador García, N. Development of a Non-Structural Prefabricated Panel Based on Construction and Demolition Waste for Sustainable Construction. Infrastructures 2024, 9, 135. https://doi.org/10.3390/infrastructures9080135

Jaramillo HY, Gómez Camperos JA, Afanador García N. Development of a Non-Structural Prefabricated Panel Based on Construction and Demolition Waste for Sustainable Construction. Infrastructures. 2024; 9(8):135. https://doi.org/10.3390/infrastructures9080135

Chicago/Turabian StyleJaramillo, Haidee Yulady, July Andrea Gómez Camperos, and Nelson Afanador García. 2024. "Development of a Non-Structural Prefabricated Panel Based on Construction and Demolition Waste for Sustainable Construction" Infrastructures 9, no. 8: 135. https://doi.org/10.3390/infrastructures9080135

APA StyleJaramillo, H. Y., Gómez Camperos, J. A., & Afanador García, N. (2024). Development of a Non-Structural Prefabricated Panel Based on Construction and Demolition Waste for Sustainable Construction. Infrastructures, 9(8), 135. https://doi.org/10.3390/infrastructures9080135