Abstract

The traffic volume and maintenance demand on Taiwan’s provincial highways have been steadily increasing. One of the most challenging issues in maintenance is determining the optimal timing and allocation of funds to avoid duplicative investments and maximize resource utilization. Currently, provincial highway maintenance units rely heavily on manual processes and paper-based records, using experiential methods to formulate maintenance strategies and conduct maintenance operations. This indicates a lack of objective maintenance strategies and pavement management systems in these units. This study aims to address this gap by integrating domestic and international literature on pavement maintenance decision-making. Existing approaches typically fall into two categories: “Pavement Indicator Rating” and “Pavement Maintenance Prioritization”. However, there has not been research integrating these methods for decision-making. Therefore, this research integrates these two approaches to establish a comprehensive maintenance strategy for Taiwan’s provincial highways. The Analytic Hierarchy Process (AHP) is employed as the decision-making theory, involving expert interviews to calculate maintenance weights for different pavement maintenance indicators. The results show that the pothole count, International Roughness Index (IRI), and Pavement Condition Index (PCI) are the three most critical maintenance indicators. The first phase of the maintenance strategy uses the “Pavement Indicator Rating“ to directly assess the pothole count, IRI, and PCI to categorize pavement sections as “maintenance sections” or “observation sections”. The second phase employs “Pavement Maintenance Prioritization”, integrating maintenance weights for each indicator to calculate maintenance scores. This phase prioritizes maintenance activities based on the results of the first phase’s rating for “maintenance sections”. Additionally, a provincial highway pavement management system is proposed to implement these strategies, enhancing maintenance management efficiency and ensuring the overall quality and longevity of provincial highway maintenance efforts.

1. Introduction

With the increasing density of road networks and advancements in technology, traditional pavement operations have shifted from new construction to maintenance-focused activities. Effective maintenance operations should include basic pavement data management, inspection data management, historical maintenance records management, and the development of corresponding maintenance strategies. However, provincial highway maintenance units have traditionally relied on manual methods and experiential approaches for maintenance decision-making, which are time-consuming, are labor-intensive, and lack objective analysis methods. Additionally, the volume of data is increasing annually, making traditional management methods unsustainable.

This study aims to establish a two-phase maintenance decision-making approach based on pavement maintenance indicators, incorporating “Pavement Indicator Rating” and “Pavement Maintenance Prioritization”. The concept of pavement management systems is introduced to enhance pavement maintenance management, maximize resource efficiency, and extend the overall lifecycle of road projects. The research methodology includes

- (1)

- Reviewing literature on pavement maintenance strategies and pavement management systems.

- (2)

- Conducting expert interviews and surveys to establish weights for pavement maintenance indicators.

- (3)

- Referring to concepts of maintenance decision-making from domestic and international sources to develop two-phase maintenance strategies.

- (4)

- Establishing databases for provincial highway basic data, inspection data, patrol data, and construction records.

- (5)

- Developing a provincial highway pavement management system and integrating the two-phase maintenance strategies into the system for practical application.

2. Current Situation Analysis and Literature Review

2.1. Provincial Highway Maintenance Management Status

2.1.1. Provincial Highway Pavement Maintenance

Indicators: The provincial highway maintenance units currently use the following factors as pavement maintenance: pipeline excavation records, annual repair and maintenance records, smoothness, manhole factors, pothole factors, and pavement damage. The details are as follows:

- (1)

- Pipeline Excavation Records

Contractors working on provincial highways conduct surface asphalt concrete milling and repaving after pipeline installations, leading to changes in pavement service quality. The deterioration time after repaving due to pipeline excavation is used as an assessment criterion, with longer times indicating a higher priority for maintenance.

- (2)

- Annual Repair and Maintenance Records

The maintenance units conduct periodic repairs and patchwork to maintain a certain service quality of the pavement. The deterioration time after maintenance is used as an assessment criterion, with longer times indicating a higher priority for maintenance.

- (3)

- Smoothness

The International Roughness Index (IRI) is used as a criterion for evaluating pavement smoothness. Higher IRI values indicate larger road surface fluctuations, poorer driving comfort, and a higher need for maintenance.

- (4)

- Manhole Factors

Differences in road surface levels due to manhole installations significantly impact driving smoothness. Therefore, the height difference of manholes is used as an assessment criterion, with larger differences indicating a higher need for maintenance.

- (5)

- Pothole Factors

Poor weather conditions or inferior road materials can lead to potholes, affecting road safety. The number of potholes is used as an assessment criterion, with more potholes indicating a higher need for maintenance.

- (6)

- Pavement Damage

The Pavement Condition Index (PCI) is used to assess pavement damage. A lower PCI value indicates more significant damage, which affects safety and indicates a higher need for maintenance.

2.1.2. Management Status Analysis

The provincial highway maintenance units primarily use the above six maintenance indicators for maintenance decision-making. The decision results for each road segment are classified as “maintenance sections” or “observation sections”. Maintenance operations are then conducted on “maintenance sections”, while the condition of “observation sections” is monitored for deterioration. However, the current maintenance decisions are largely experiential, lacking objective methods. Additionally, the management is paper-based, hindering efficient and objective maintenance management [1].

2.2. Domestic and International Pavement Maintenance Strategies

2.2.1. Using the Pavement Indicator Rating for Maintenance Decision-Making

- (1)

- Pavement Indicator—Pavement Condition Index (PCI)

The PCI is determined through ASTM D6433 standards for pavement distress surveys [2]. This standard categorizes flexible pavement distress into 19 types of damage, as shown in Table 1 Subsequently, manual surveys are conducted to record the type, extent, and severity of pavement damage. Points are then deducted based on the survey results to calculate the PCI score, which ranges from 0 to 100. A higher PCI value indicates a better pavement condition. ASTM D6433 standards classify pavements based on PCI scores, as shown in Table 2, enabling PCI indicator ratings based on this classification.

Table 1.

Types of flexible pavement damage.

Table 2.

PCI rating scale.

- (2)

- Pavement Indicator—International Roughness Index (IRI)

The International Roughness Index (IRI) is defined as a reference average slope correction, representing the cumulative elevation difference of a single wheel path on a test road segment divided by the length of the test road. In this study, the IRI is simulated by driving at a speed of 80 km per hour over the test road profile. The measurement unit for IRI is meters per kilometer (m/km), with testing conducted using commonly available inertial profilers. The testing unit is typically 100 m.

Key testing equipment includes

- ●

- Displacement Sensor: Measures elevation changes by emitting laser light that reflects off the pavement surface and is received by a sensor, with subsequent analysis by a signal processor.

- ●

- Distance Sensor: Mounted on the vehicle wheel to calculate the distance traveled based on the circumference of the wheel.

- ●

- Accelerometer: Records longitudinal vehicle acceleration to calculate displacement caused by vehicle vibrations.

A lower IRI value indicates higher road comfort, while a higher value indicates lower comfort. IRI tends to increase with repeated vehicle loading and aging of the road surface. When the IRI exceeds a certain threshold, the road’s driving quality may not meet basic requirements, necessitating reconstruction or maintenance to improve smoothness. According to a World Bank technical report [3], the relationship between the road grade and pavement smoothness range is shown in Table 3 It indicates that roads with an IRI greater than four fall into the damaged road grade category.

Table 3.

The relationship between road grades and IRI.

- (3)

- Maintenance Decision-making

- ●

- The Final Report—Update of Pavement Management Program [4] uses the Pavement Condition Index (PCI) and International Roughness Index (IRI) to evaluate and manage the city’s pavement network. The report reveals that South Gate’s overall pavement condition is classified as “Fair”, with a weighted average PCI of 51.6. Specifically, the arterial/collector network has a PCI of 61.5, while the local network has a PCI of 46.1. Based on these metrics, approximately 32% of the arterial network and 23% of the local network are suitable for slurry seal maintenance, whereas 50% of the arterial and 69% of the local network require overlay or reconstruction. The report outlines maintenance strategies, including preventive maintenance (e.g., slurry seals, crack sealing, overlays) and more extensive treatments for lower-PCI sections to improve structural integrity. Budget projections for the next five years indicate that maintaining the current PCI requires an annual budget of TWD 2 million, while improving the PCI to 57 within five years demands a higher budget. The report recommends proactive overlay and preventive maintenance, regular inspections, and continuous funding to manage deferred maintenance and enhance pavement conditions. This report bases its decision-making on the ratings according to ASTM D6433, yielding good results. Therefore, it is recommended that provincial highways refer to the ASTM D6433 ratings as a maintenance threshold for PCI.

- ●

- In 2012, the United States passed the Moving Ahead for Progress in the 21st Century (MAP-21) funding expenditure bill, which includes pavement maintenance strategies proposed by the Federal Highway Administration (FHWA) [5]. These strategies utilize the International Roughness Index (IRI) as one of the indicators, with the maintenance threshold for IRI set at 3.5, closely aligning with the World Bank’s technical report, as shown in Table 4. Therefore, this paper recommends that provincial highways refer to these established thresholds in the literature for setting the IRI maintenance threshold.

Table 4. Rating Intervals for Various Indicators.

Table 4. Rating Intervals for Various Indicators.

2.2.2. Using Pavement Maintenance Prioritization for Maintenance Decision-Making

- (1)

- Chang [6] proposed using the Analytic Hierarchy Process (AHP) to establish a hierarchical structure for analyzing and summarizing the main factors of airport pavement management systems. Through expert interviews, priorities and weight relationships of various criteria were obtained to serve as references for evaluating the applicability of airport pavement management system models.

- (2)

- Chang [7] utilized pavement condition indicators (including smoothness and pavement damage), pavement structure strength indicators (including pavement and subgrade structure strength), traffic volume, heavy vehicle ratio, and maintenance costs as evaluation indicators for maintenance ranking. AHP was employed for expert questionnaire surveys to establish the weights of evaluation indicators based on survey results, which were then integrated into the pavement management system for subsequent score calculations and maintenance decisions.

- (3)

- Ho [8] first used the Fuzzy Delphi Method to conduct an initial expert questionnaire survey to determine key indicators for pavement maintenance. The survey analyzed data such as road excavation, pothole repairs, IRI values, road damage, road inspections, and citizen reports as evaluation indicators for maintenance ranking. Subsequently, the Analytic Network Process (ANP) was used for a second expert questionnaire survey to determine the weights of various evaluation indicators. These weights were then incorporated into the pavement management system for maintenance ranking.

- (4)

- Henri Siswanto [9] employs the Analytical Hierarchy Process (AHP) to prioritize district road maintenance in Indonesia, considering factors such as road conditions, traffic, land use, and economics. The findings highlight variations in the criteria prioritization between different regions, demonstrating AHP’s effectiveness in optimizing road maintenance priorities under limited resources.

- (5)

- Okan Sirin [10] uses AHP to identify and rank key factors affecting pavement performance in Qatar, aimed at improving the pavement design, construction, and maintenance stages. The critical factors identified include an unconsidered heavy vehicle volume, a low asphalt content, poor mechanical and thermal properties, and a unexpected high traffic volume.

- (6)

- Anjali Ashok [11] established scoring factors and weights for benefits and costs, where benefit factors included trafficability, durability, serviceability, and safety and cost factors included input costs, traffic impact, project time, environmental impact, and resident impact. Through AHP questionnaire surveys for benefit and cost factors, weights were calculated. The weighted scores were then used to calculate benefit and cost scores, and the results were sorted using the Benefit–Cost Ratio, with higher ratios indicating a higher priority for maintenance operations.

- (7)

- D. Moazami and colleagues [12] identified a lack of objective maintenance decision models in Tehran, Iran, leading to the ineffective allocation of maintenance funds. They used road grades, pavement conditions, and traffic volume as maintenance indicators and utilized AHP to calculate the weights of each maintenance indicator factor for maintenance weight score calculations and decision-making.

- (8)

- B. G. Sreelekshmi and colleagues [13] further integrated their decision-making model into a Geographic Information System (GIS) for analysis. Their AHP-based analysis considered maintenance indicator factors such as the pavement condition, traffic volume, intersection count, accident rate, drainage, and congestion, proving that this method’s prioritization analysis effectively provided maintenance units with maintenance reference information.

2.3. Pavement Management Systems

2.3.1. Domestic Pavement Management Systems

- (1)

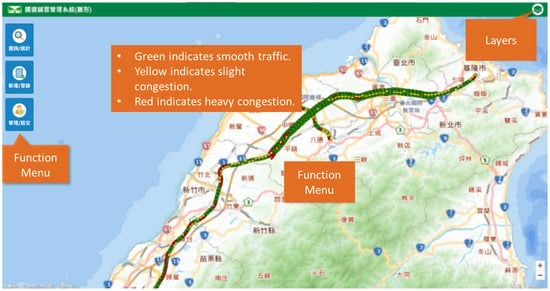

- National Highway Pavement Management System: Developed by the Highway Bureau, the system aims to enhance maintenance management efficiency and quality. Key features include integrating basic pavement data, project history, pavement inspections, and surveys, utilizing a lifecycle management approach to improve sustainability and functionality. The system supports data collection and analysis, providing performance curves and decision trees for damage management and ultimately optimizing resource allocation and improving maintenance efficiency, as shown in Figure 1.

Figure 1. National Highway Pavement Management System.

Figure 1. National Highway Pavement Management System.

- (2)

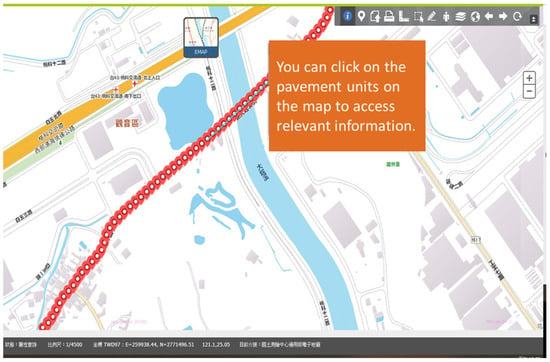

- Taoyuan City Pavement Management System: This system is developed to enhance road service standards, integrating system operations with business execution processes. It enables personnel to log in or query road excavation conditions and access road-related data at any time. The system aims to systemize and scientifically manage road maintenance by establishing long-term road data and providing rapid decision-making references for road maintenance. The current system allows for spatial analysis based on fundamental data, inspection data (IRI, PCI inspection results), patrol data, and maintenance records. This enables the automatic sequencing of road milling and paving operations, the establishment of related information, and the delineation of milling and paving areas, as shown in Figure 2.

Figure 2. Taoyuan City Pavement Management System.

Figure 2. Taoyuan City Pavement Management System.

- (3)

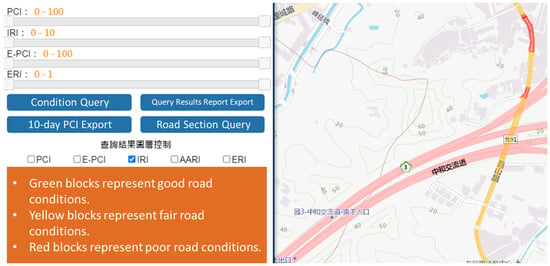

- New Taipei City iRoad Road Management System: This system is designed to enhance the efficiency of pipeline excavation, inspection, construction, and management within the road maintenance scope. It includes functions like pipeline excavation integration, dynamic construction monitoring management, disaster reporting and handling, road patrols, road inspection, and maintenance data analysis to strengthen data-driven decision-making in road maintenance, as shown in Figure 3.

Figure 3. New Taipei City iRoad Road Management System.

Figure 3. New Taipei City iRoad Road Management System.

2.3.2. International Pavement Management System Applications

- (1)

- Japan Pavement Management System: Equipped with browsing functions, road surface characteristics, and various road information, it includes a construction method selection function to assist road managers in decision-making. The system’s four main functional modules are real-time access to road conditions using actual road photo information, collecting and recording past road data on system maps for easy search and analysis, convenient access to road pavement ledger data, and the simulation of various maintenance methods to select the optimal maintenance plan.

- (2)

- Shabir Hussain Khahro [14] presents a comprehensive system tailored to address the challenges of maintaining flexible pavements in developing countries. The proposed Pavement Management System (PMS) functions include data collection and management, using both automated and manual methods to assess pavement conditions and integrate the data into a centralized database. It features condition assessment using performance metrics for functional, structural, safety, and serviceability aspects and employs predictive models for proactive maintenance planning. The system prioritizes maintenance activities using the Analytical Network Process (ANP), categorizing them into routine, periodic, and emergency plans. It emphasizes cost-effective decision-making, optimizing resource allocation for critical maintenance needs, and includes emergency response plans for severe pavement issues. The model ensures the optimization of maintenance strategies through ANP and sensitivity analysis, aiding road planners in making informed and efficient decisions.

- (3)

- Hey Kyo Lee [15] explores the development and operation of a Pavement Management System (PMS) in Gangwon-do, Korea. Key points include the necessity for efficient maintenance systems due to aging infrastructure and the challenges local governments face in manpower and budget. The PMS features include database construction using automated equipment, decision support through quantitative and qualitative analysis, and detailed report generation. The application of ICT technology enhances accuracy and efficiency, offering real-time data updates and remote monitoring. Expected benefits include improved maintenance efficiency, reduced costs, and enhanced road safety.

- (4)

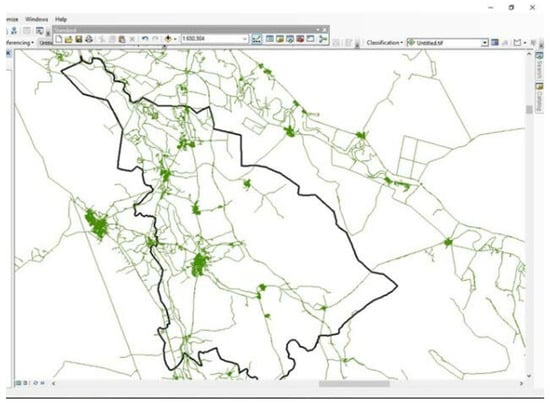

- Tariq Al-Mansoori [16] focuses on the functionalities and applications of Pavement Management Systems (PMS), with an emphasis on a GIS-enhanced PMS in Babylon, Iraq. PMS is a crucial tool for highway infrastructure aimed at optimizing maintenance and rehabilitation processes. Integrating GIS technology into PMS allows for efficient data storage, retrieval, analysis, and reporting, thereby enhancing decision-making processes related to road maintenance. The GIS-enhanced PMS includes a comprehensive database of road networks, pavement condition evaluations, and a decision-making framework based on the pavement condition index (PCI) and Markov chain models. The study demonstrates the application of this system in Babylon, showcasing its ability to determine maintenance strategies, set rehabilitation priorities, and make investment decisions. At both the network and project levels, the system supports lifecycle cost minimization and maintenance optimization, ensuring the longevity and cost-effectiveness of road infrastructure. The findings suggest that implementing GIS-enhanced PMS can lead to more accurate budget allocation, prevent widespread infrastructure deterioration, and provide a strategic approach to road maintenance. This research underscores the importance of using GIS technology to predict future road conditions and streamline maintenance planning, ultimately recommending its adoption in other cities to enhance maintenance efficiency and reduce costs, as shown in Figure 4.

Figure 4. GIS-enhanced PMS.

Figure 4. GIS-enhanced PMS.

3. Method and Planning

3.1. The Analytic Hierarchy Process (AHP) Analysis Approach

This paper will use the Analytic Hierarchy Process (AHP) to analyze the weights of pavement maintenance indicators. The concept is to systematize complex evaluation problems into a hierarchical structure of factors. Expert interviews will be conducted based on this hierarchical structure, and quantitative calculations will be used to determine the context for comprehensive assessment, analyzing the weights of each level item. The analysis method referred to in this paper is based on Saaty’s work [17,18,19,20], with the following steps:

- (1)

- Establishing a Hierarchy Structure

Decompose the maintenance decision indicators into a hierarchical structure consisting of goals, evaluation criteria, and sub-evaluation criteria. The evaluation criteria should be independent of each other. Additionally, following Miller’s recommendation [21] that humans cannot simultaneously compare more than seven items, each level of evaluation items should not exceed seven.

- (2)

- Creating Expert Questionnaires

Establish expert questionnaires based on the hierarchy analysis framework for survey purposes. The goal of the questionnaire is to compare the importance of criteria, analyzing the weights of each criterion. Saaty suggests using a scale of 1 to 9 for the questionnaire assessment, including options like equally important, slightly important, moderately important, very important, and extremely important. Corresponding numerical evaluations are 1, 3, 5, 7, and 9, while 2, 4, 6, and 8 represent intermediate values between adjacent scales, as explained in Table 5.

Table 5.

Analytic Hierarchy Process (AHP) scale definitions and explanations.

The questionnaire compares the importance of evaluation criteria and sub-criteria pairwise, considering transitivity. First, an importance comparison is conducted for the evaluation criteria and then separately for the sub-criteria. The comparison in the questionnaire is based on three criteria, A, B, and C. Taking the example of comparing three evaluation criteria, if the importance of A criterion compared to B criterion is such that A is six times more important than B, then circle 6 next to A; if the importance of A criterion is equal to that of C criterion, then circle 1; if the importance of B criterion compared to C criterion is such that C is five times more important than B, then circle 5 next to C. The filling method for the questionnaire is shown in Table 6.

Table 6.

The filling method for the questionnaire.

- (3)

- Creating a Pairwise Comparison Matrix

The first step is to transform the analysis results of each expert questionnaire into a pairwise comparison matrix. The pairwise comparison criterion is a symmetric matrix where the diagonal elements are all one. Taking the questionnaire filling in Table 6 as an example, it is transformed into a pairwise comparison matrix, as shown in Table 7.

Table 7.

Example of a pairwise comparison matrix.

- (4)

- Consistency Check

A consistency check is conducted on pairwise comparison matrices with three or more items in each expert questionnaire to examine the rationality of judgments made by experts during the questionnaire filling process. Typically, consistency is assessed using the Consistency Index (C.I.) and Consistency Ratio (C.R.), calculated as shown in example one of an equation and in example two of an equation. If C.I. = 0, it indicates complete consistency in judgments before and after the interview; Saaty recommends C.I. ≤ 0.1 as an acceptable deviation, and when C.R. ≤ 0.1, the consistency of the matrix is considered satisfactory.

where

- C.I. = Consistency Index

- R.I. = Random Index (Table 8)

Table 8. Random Index.

Table 8. Random Index.

- λmax = Maximum Eigenvalue

- n = items in the matrix

- (5)

- Integration of Pairwise Comparison Matrices

Next, integrate the pairwise comparison matrices of each expert. Saaty recommends using the geometric mean for integration. Therefore, calculate the geometric mean of the matrix values from each expert to obtain the integrated pairwise comparison matrix.

- (6)

- Calculation of Maintenance Indicator Weights

Calculate the maximum eigenvalue and its corresponding eigenvector for the integrated pairwise comparison matrix. The eigenvector obtained is the weights of the items in the pairwise comparison matrix. Subsequently, use these weights for ranking and analysis.

3.2. Expert Questionnaire Design

- (1)

- Questionnaire Structure

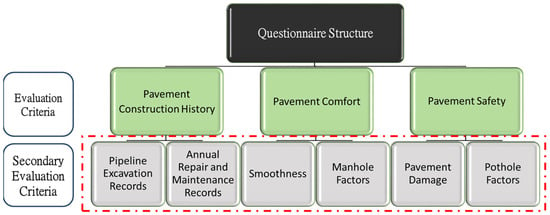

Next, establish the AHP hierarchical analysis questionnaire structure. This study adopts the maintenance indicators currently used by provincial highway maintenance units, as described in Section 2.1, including pipeline excavation history, annual maintenance history, smoothness, manhole factors, pothole factors, and pavement damage, totaling six maintenance indicators for establishing maintenance strategies that meet the needs of maintenance units.

The annual maintenance history and pipeline excavation history are incorporated into the pavement construction history assessment criteria, smoothness and manholes factor into pavement comfort assessment criteria, and pavement damage and potholes factor into pavement safety criteria, totaling three major assessment criteria. The six maintenance indicators serve as sub-criteria, and the hierarchical analysis questionnaire structure is established based on this concept, as shown in Figure 5.

Figure 5.

Questionnaire Structure.

- (2)

- Questionnaire Content

Following this, an AHP expert questionnaire will be distributed based on these three major evaluation criteria and six minor evaluation criteria. Experts will compare the importance of each criterion and sub-criterion for provincial road pavements. The questionnaire forms are shown in Table 9, Table 10, Table 11 and Table 12.

Table 9.

Comparison table of evaluation criteria importance.

Table 10.

Comparison table of secondary evaluation criteria importance under pavement construction history criteria.

Table 11.

Comparison table of secondary evaluation criteria importance under pavement comfort criteria.

Table 12.

Comparison table of secondary evaluation criteria importance under pavement safety criteria.

3.3. Expert Questionnaire Analysis Results

3.3.1. Survey Distribution Statistics

The target respondents of this survey were primarily provincial road maintenance decision-makers and scholars related to the research. A total of 25 surveys were distributed, out of which 23 were returned, resulting in an overall survey response rate of 92%. The statistical results are shown in Table 13.

Table 13.

Expert survey distribution statistics.

3.3.2. Questionnaire Analysis

- (1)

- Establish Pairwise Comparison Matrices

Convert the survey responses of each expert into pairwise comparison matrices.

- (2)

- Consistency Check

Conduct consistency checks on the pairwise comparison matrices of each expert using equations one and two to ensure consistency before proceeding with further questionnaire analysis.

- (3)

- Integration of Pairwise Comparison Matrices

Following Saaty’s recommendations from previous studies, integrate the pairwise comparison matrices of each expert using the geometric mean method. The integrated pairwise comparison matrix for the three major evaluation criteria is shown in Table 14, and the pairwise comparison matrices for the sub-criteria under each criterion are shown in Table 15, Table 16 and Table 17.

Table 14.

Pairwise comparison matrix of evaluation criteria.

Table 15.

Pairwise comparison matrix of secondary evaluation criteria—pavement construction history criteria.

Table 16.

Pairwise comparison matrix of secondary evaluation criteria- pavement comfort criteria.

Table 17.

Pairwise comparison matrix of secondary evaluation criteria—pavement safety criteria.

3.3.3. Calculation of Pavement Maintenance Indicator Weights

For the previously integrated pairwise comparison matrix, the maximum eigenvalue and corresponding eigenvector were calculated to determine the weights of each criterion. The calculated weights are presented in Table 18 From the final weight analysis results, it is evident that the top three factors influencing the pavement maintenance ranking are, in order, pothole factors, pavement damage, and smoothness. Therefore, pavement managers should focus particularly on these three indicators for regular inspections to understand pavement conditions.

Table 18.

Pavement maintenance indicator weight analysis.

Once the maintenance weights for each criterion are determined, they will be integrated into the pavement database. This integration allows for the multiplication of the values of each criterion in the database by their respective weights to calculate scores. Subsequently, maintenance ranking will be conducted based on these scores.

4. Developing Provincial Highway Pavement Maintenance Strategies and Implementing Them into Pavement Management Systems

4.1. Developing Pavement Maintenance Strategies

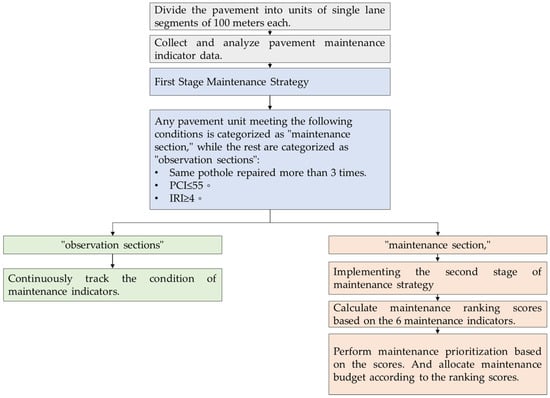

The paper plans to use every 100 m as a pavement unit and collect data on six maintenance indicators for each unit to carry out a two-stage maintenance strategy.

4.1.1. First Stage Maintenance Strategy—“Pavement Indicator Rating”

Analyzing the weights of each maintenance indicator based on expert questionnaire interviews reveals that the top three important maintenance indicators are pothole factors, pavement damage, and smoothness. These three indicators represent key decision-making factors for maintenance. Therefore, this paper uses these three indicators to conduct the first stage of maintenance decision-making, as follows:

- (1)

- Pothole Factor Indicator Rating

The provincial highway maintenance unit tracks the repair of each pothole. If the same pothole is repaired more than three times, it is considered an “abnormal repair section”. Therefore, this paper rates the pothole factor indicator, listing pavement units with “abnormal repair sections” as “maintenance sections”.

- (2)

- Pavement Damage Indicator Rating

Refer to Table 2 for the PCI rating. Pavement units with a PCI ≤ 55 are classified as “maintenance sections”.

- (3)

- Smoothness Indicator Rating

Refer to Table 3 for the IRI rating. Pavement units with an IRI ≥ 4 are classified as “maintenance sections”.

- (4)

- First-Stage Maintenance Strategy Rating Results

After rating the pothole factor, pavement damage, and smoothness indicators separately, any pavement unit rated as a “maintenance section” based on any of these indicators proceeds to the second stage of the maintenance strategy, while the rest are categorized as “observation sections”.

4.1.2. Second-Stage Maintenance Strategy—“Pavement Maintenance Prioritization”

For pavement units classified as “maintenance sections” in the first stage, a maintenance ranking is conducted using the six maintenance indicators, as follows:

- (1)

- Normalize the six maintenance indicators for each pavement unit.

- ●

- For indicators such as annual repair and maintenance history, pipeline excavation history, pothole factors, smoothness, and manhole factors, smaller values indicate better pavement conditions. Therefore, the transformation method for these five indicators is as in example three of an equation.

- ●

- For the pavement damage indicator, larger values indicate better pavement conditions. Therefore, the transformation method for this indicator is as in example three of an equation.

- x′ = Normalized score of the indicator for the pavement unit

- x = Original indicator value of the pavement unit

- Max = Maximum value of the original indicator value (based on filtering criteria)

- Min = Minimum value of the original indicator value (based on filtering criteria)

- x′ = Normalized score of the indicator for the pavement unit

- x = Original indicator value of the pavement unit

- Max = Maximum value of the original indicator value (based on filtering criteria)

- Min = Minimum value of the original indicator value (based on filtering criteria)

- (2)

- Calculate the Ranking Scores

After normalizing the six maintenance indicators for each pavement unit, multiply the normalized scores by the weights from Table 18 and then sum them up to obtain the ranking score, as shown in example four of an equation.

- (3)

- Maintenance Ranking Based on the Scores

Based on the ranking scores, lower scores indicate a higher priority for maintenance. Finally, the maintenance budget can be allocated based on this ranking result.

4.1.3. The Process of the Provincial Highway Maintenance Strategy

The two-stage maintenance strategy process established in this paper is illustrated in Figure 6.

Figure 6.

The Process of the Provincial Highway Maintenance Strategy.

4.2. Creating a Pavement Maintenance Database

The study focuses on the Provincial Highway No. 2 (Taiwan North Coast Highway) under the jurisdiction of the Taiwan Ministry of Transportation’s Highway Bureau. Each section of the road, defined as every 100 m, is considered a pavement unit for this research. Subsequently, a database will be established for each pavement unit within this scope, and the data will be imported into the pavement management system for analysis and application.

- (1)

- Basic Information

First, the location data for each pavement unit will be established, including the direction, mileage unit, number of lanes, lane width, and coordinates. The coordinate data will be used for geographic information system (GIS) management, allowing for management and analysis within the GIS maps in the system. The database construction method for basic information is outlined in Table 19.

Table 19.

Example of Pavement Basic Database Establishment.

- (2)

- Inspection Company Pothole Inspection Data

Potholes are a type of pavement damage that affects the safety and comfort of road users. Therefore, inspection companies need to conduct daily inspections of the pavement. Additionally, they must collaborate with relevant notification systems (such as public petition systems, dispatch systems, inspection app systems, etc.) to address reported cases, conduct inspections, take on-site photos, and report back. For the potholes discovered during these inspections, emergency repairs with either normal temperature asphalt concrete or high-performance all-weather normal temperature asphalt concrete are carried out. Potholes can reoccur due to road surface aging, continuous rainfall, or weakened roadbeds. Therefore, considerations for recurring pothole damage need to be incorporated into the database. The database construction includes the direction, location, notification time and source, repair materials and scope, repair date, and repair photos, as shown in Table 20.

Table 20.

Example of Inspection Company Pothole Inspection Database Establishment.

- (3)

- Inspection Data

- ●

- IRI

Provincial highways conduct IRI inspections twice a year. Therefore, the database for IRI includes the direction, mile unit, lanes, year, inspection frequency (first or second time), and IRI value, as shown in Table 21.

Table 21.

Example of IRI Database Establishment.

- ●

- Manhole Height Difference

Provincial highways conduct inspections for manhole height differences on the pavement. The database for manhole height differences includes the direction, mile unit, lanes, year, and manhole height difference, as shown in Table 22.

Table 22.

Example of Manhole Height Difference Database Establishment.

- ●

- PCI

The database for the pavement damage condition (PCI) includes the direction, mile unit, lanes, year, and PCI value, as shown in Table 23.

Table 23.

Example of PCI Database Establishment.

- (4)

- Construction History

The quality and condition of pavement deteriorate over time due to aging, emphasizing the perspective of full life-cycle maintenance. Pavement should undergo regular maintenance before permanent damage occurs. Therefore, the construction history of each annual maintenance is crucial data, serving as a reference for the next maintenance schedule. Additionally, for pavement degradation analysis, changes in the pavement condition from each maintenance session must be considered, making construction history a significant dataset.

Taking scheduled routine maintenance as an example, the main construction operations are divided into general maintenance and preventive maintenance. Accordingly, databases are established separately for general maintenance and preventive maintenance.

- ●

- Annual Repair and Maintenance Records

Annual maintenance operations primarily involve surface milling and overlay, as well as subgrade improvement. The thickness of surface milling and overlay depends on the extent of damage. Therefore, the database for general maintenance history includes the maintenance time, direction, maintenance mile segment, lane details, and maintenance method, as shown in Table 24.

Table 24.

Example of Annual Repair and Maintenance Records Database Establishment.

- ●

- Pipeline Excavation Records

Provincial highways also have pipeline units that apply for pipeline excavation permits. After pipeline excavation, pavement milling and overlay operations are conducted. Hence, this construction history is also integrated into the system, with its database outlined in Table 25.

Table 25.

Example of Pipeline Excavation Records Database Establishment.

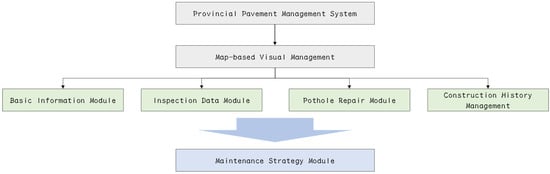

4.3. Establishing a Pavement Management System

4.3.1. Provincial Pavement Management System Architecture

Based on the establishment of pavement units, various pavement databases are created. These databases are then integrated into the provincial pavement management system planned in this paper. The system is combined with a map platform to provide visualized management. It incorporates the two-stage maintenance strategy developed in this paper to maximize construction resources and extend the project’s overall lifecycle. The architecture is illustrated in Figure 7.

Figure 7.

Provincial Pavement Management System Architecture.

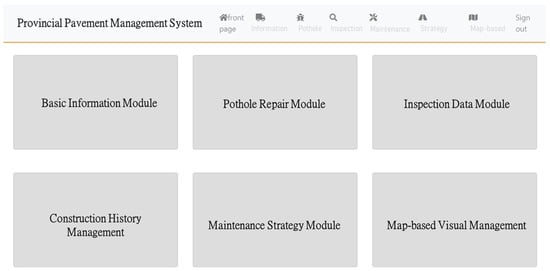

4.3.2. Module Functions

The provincial pavement management system established in this paper includes the following main modules: the Basic Information Module, Inspection Data Module, Pothole Repair Module, Construction History Module, and Maintenance Strategy Module. The system’s homepage is depicted in Figure 8.

Figure 8.

System homepage.

- (1)

- Pavement Management Unit

This paper plans to use every 100 m as a basic unit for pavement management. Subsequently, databases will be established for each pavement unit and imported into the pavement management system for analysis and application.

- (2)

- Basic Information Module

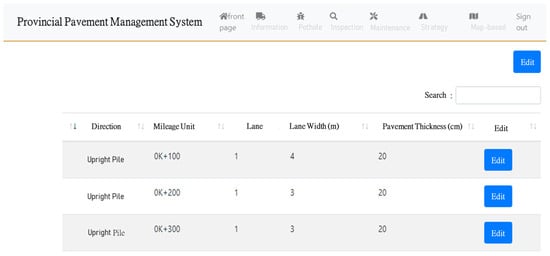

The basic information module in the pavement management system, as planned in this paper and shown in Table 19, allows administrators to perform queries and management tasks within the system. The basic data should be linked with subsequent project history data. Whenever project history is imported, pavement materials, pavement structures, and other relevant data should be automatically updated accordingly. The system interface is illustrated in Figure 9.

Figure 9.

The page for the basic information module.

- (3)

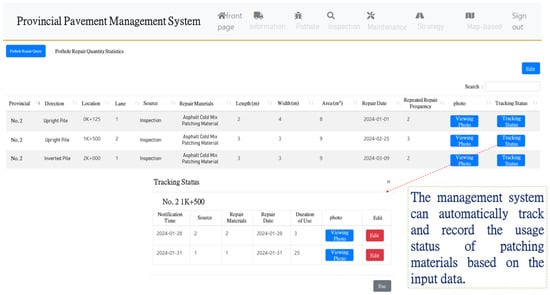

- Pothole Repair Module

The inspection data planned in this paper includes data from both the highway bureau’s autonomous inspections and contractor inspections regarding potholes. Administrators can track the pothole repair situation within the system to understand the usage duration of repair materials and repeated repair conditions. Additionally, this module can be linked with construction history. For instance, if a pothole location undergoes milling and repaving, the tracking status will show it has been milled, along with the usage duration of the repair materials. In addition, it can also calculate the repeated repair frequency, as shown in Figure 10.

Figure 10.

The page for the pothole repair module.

- (4)

- Inspection Data Module

The primary inspection data planned in this paper include manhole height differences, IRI, and PCI, as shown in Table 21, Table 22 and Table 23, respectively. Administrators can use the system for inspection data queries and statistical analysis to understand the pavement condition. The system interface is depicted in Figure 11.

Figure 11.

The page for the inspection data module.

- (5)

- Construction History Management

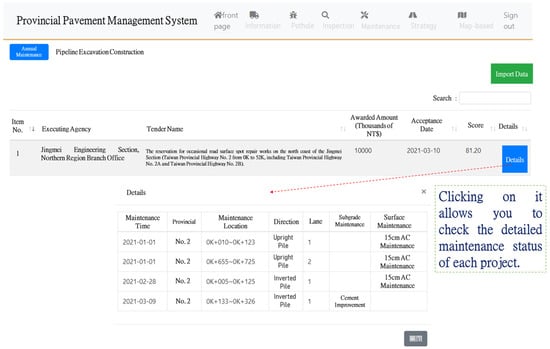

The system can document pavement maintenance and repair activities, including pavement maintenance repairs and pipeline excavation. As pavement construction affects pavement materials and structures, the documented data can be interconnected with the basic information and pothole repair modules. After the construction history documentation is completed, the system can automatically update the pavement’s basic information and pothole repair status.

For routine maintenance, the system in this paper is set up to manage the construction history and provide a maintenance status query function to automatically summarize the maintenance status of each pavement unit.

- ●

- Annual Maintenance Operation Query Function:

Different projects’ basic data can be established, and the maintenance database for each project can be imported, as shown in Table 24. Subsequently, the system can be used to query the construction status of each project, as shown in Figure 12.

Figure 12.

The page for annual maintenance.

- ●

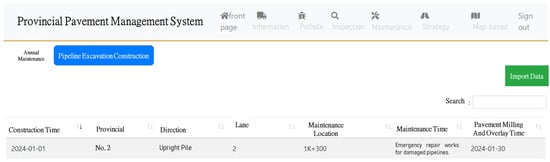

- Pipeline Excavation Construction History Query:

Import data from the database shown in Table 25 and then query pipeline excavation sections within the system and track the milling and repaving status, as shown in Figure 13.

Figure 13.

The page for pipeline excavation construction.

- (6)

- Maintenance Strategy Module

The ultimate goal of establishing the aforementioned modules is to assist pavement maintenance units in making maintenance decisions. The two-stage maintenance strategy proposed in this paper is applied in the system as detailed in Section 4.3.3.

- (7)

- Map-based Visual Management

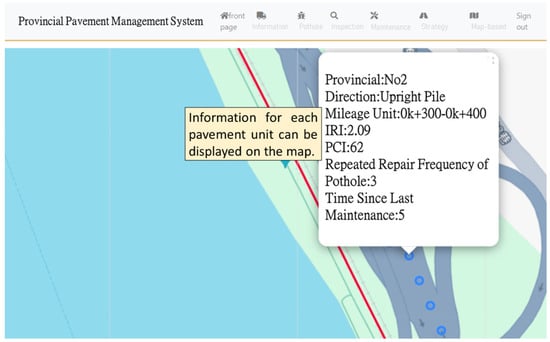

The pavement management system’s map data segments provincial roads into pavement units every 100 m. Taking Provincial Highway 2 as an example, the above databases are imported, as shown in Figure 14 Clicking on each pavement unit in the map layer displays its basic information, inspection data, construction history, and other attribute data. Additionally, the results of the maintenance strategy from Section 4.3.3 can be visually represented using different color blocks on the map layer, allowing administrators to manage visually and easily grasp the pavement condition.

Figure 14.

The page for map-based visual management.

4.3.3. Implementing Maintenance Decisions for Management

The ultimate goal of establishing the provincial road pavement management system is to assist the provincial road maintenance unit in making pavement maintenance decisions. Therefore, this paper will integrate the two-stage maintenance strategy into the provincial road pavement management system to aid in maintenance decision-making, as outlined below.

- (1)

- First-Stage Maintenance Strategy

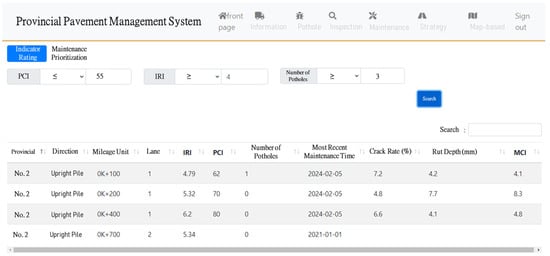

This paper incorporates the number of potholes, IRI (International Roughness Index), and PCI (Pavement Condition Index) into the decision-making indicators. The provincial road maintenance unit inputs filtering thresholds based on the process outlined in Figure 3, and the system automatically filters out the “maintenance sections” for the first stage, as shown in Figure 15 Subsequently, based on the filtering results, the second-stage maintenance strategy is executed.

Figure 15.

The page for the first-stage maintenance strategy.

- (2)

- Second-Stage Maintenance Strategy

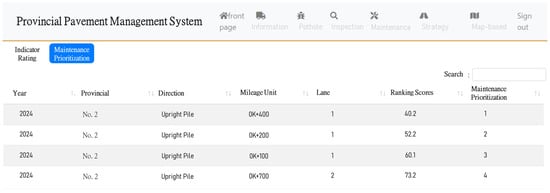

Following the first-stage filtering of “maintenance sections”, a maintenance ranking analysis is conducted. The maintenance weights analyzed in this paper are imported into the system and combined with system data to perform maintenance ranking. This provides pavement managers with a reference for maintenance decision-making. The system analysis logic is as follows:

- ●

- Reference the maintenance indicators commonly used by the provincial road maintenance unit to set ranking indicators, including “smoothness data (IRI value)”, “pavement damage data (PCI value)”, “manhole height difference”, “pothole data from inspections”, “maintenance times from construction records”, and “pipeline excavation times”. The system uses pavement units to link the above data for subsequent ranking analysis.

- ●

- The system performs normalization calculations based on equation three, ensuring data falls within the 0 to 100 range.

- ●

- The system multiplies and sums the normalized data for each pavement unit by the corresponding weights, as in equation four, yielding a score for each pavement unit.

- ●

- The system conducts maintenance ranking based on scores, as shown in Figure 16 Lower scores indicate a greater need for maintenance. The maintenance unit can then allocate maintenance budgets based on the maintenance ranking results, enabling the efficient and objective development of maintenance plans.

Figure 16. The page for the second-stage maintenance strategy.

Figure 16. The page for the second-stage maintenance strategy.

5. Conclusions

- (1)

- Given that Taiwan’s provincial highway maintenance units primarily rely on manual experience and paper-based records for maintenance decision-making, this approach results in inefficiency and a lack of objective analysis methods. Therefore, this study references past maintenance decision methods and advances beyond traditional decision-making approaches by integrating “Pavement Indicator Rating” and “Pavement Maintenance Prioritization” into a two-stage maintenance strategy. This integration offers a more objective and efficient maintenance decision-making process, ensuring the maximization of resource utilization, reducing redundant investments, and enhancing the allocation efficiency of maintenance funds.

- ●

- First-Stage Maintenance Strategy: Identify pavement units meeting any of the following criteria as “Maintenance Sections”: repaired potholes more than three times, PCI ≤ 55, or IRI ≥ 4.

- ●

- Second-Stage Maintenance Strategy: Calculate maintenance ranking scores for pavement units classified as “Maintenance Sections” in the first-stage strategy. Determine maintenance priority based on the maintenance scores and allocate maintenance budgets accordingly.

- (2)

- This study establishes a comprehensive database and management system by developing a provincial highway maintenance management system that integrates a two-stage maintenance strategy. The system offers extensive data query, statistical analysis, and decision support functions, significantly reducing labor costs and maintenance expenditures. Additionally, the system utilizes a map platform to divide the maintenance units into 100 m pavement segments, achieving the visual management of maintenance data. This visual representation allows managers to intuitively grasp pavement conditions, enhancing the convenience and efficiency of maintenance management.

- (3)

- Based on previous literature, traffic volume is also a crucial factor in maintenance decision-making. However, the provincial highway maintenance units have not yet collected comprehensive traffic volume data. It is recommended that, in the future, traffic volume data should be collected and incorporated into maintenance decision-making analyses to enhance the accuracy of the decisions.

Author Contributions

Conceptualization, L.-L.H. and C.-H.K.; methodology, J.-D.L. and W.-H.H.; validation, Y.-S.C.; formal analysis, M.-Y.H.; investigation, M.-Y.H.; resources, Y.-S.C.; data curation, Yi-Shian Chiou; writing—original draft preparation, L.-L.H. and C.-H.K.; writing—review and editing, L.-L.H. and C.-H.K.; visualization, L.-L.H. and C.-H.K.; supervision, J.-D.L. and W.-H.H.; project administration, J.-D.L. and W.-H.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Northern Region Branch Office. Highway Maintenance Manual of Northern Region Branch Office; Northern Region Branch Office: New Taipei City, Taiwan, 2019. [Google Scholar]

- ASTM D6433-20; Standard Practice for Roads and Parking Lots Pavement Condition Index Surveys. ASTM International: West Conshohocken, PA, USA, 2020.

- World Bank. Guidelines for Conducting and Calibrating Road Roughness Measurements; World Bank Technical Paper, No. 46; World Bank: Washington, DC, USA, 1986; ISSN 0253-7494. [Google Scholar]

- Bucknam Infrastructure Group, Inc. Update of Pavement Management Program (Citywide) 2017–2022; Final Report for the City of South Gate, 22 May 2017; Bucknam Infrastructure Group, Inc.: Oceanside, CA, USA, 2017. [Google Scholar]

- Simpson, A.L.; Rada, G.R.; Visintine, B.A.; Groeger, J.L. Interstate Pavement Condition Sampling; Publication No. FHWA-HIF-17-022; U.S. Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2016. [Google Scholar]

- Chang, H.-W. Finding Key Considerations in Choosing Airport Pavement Management System with the Analytic Hierarchy Process. Master’s Thesis, Department of Civil Engineering, National Central University, Taoyuan City, Taiwan, 2007. [Google Scholar]

- Chang, J.-R. The Network-Level Flexible Pavement Maintenance Management System in Taiwan—The Case Study of Chung-Li Engineering Section of Taiwan Highway Bureau. Master’s Thesis, Department of Civil Engineering, National Central University, Taoyuan City, Taiwan, 2001. [Google Scholar]

- Ho, K.-I. Establishing the Taoyuan City Urban Road Pavement Maintenance Prioritization Using DANP. Master’s Thesis, Department of Civil Engineering, National Central University, Taoyuan City, Taiwan, 2017. [Google Scholar]

- Siswanto, H.; Supriyanto, B.; Pranoto; Prihatditya, R.P.; Friansa, M.A. District Road Maintenance Priority Using Analytical Hierarchy Process. AIP Conf. Proc. 2019, 2114, 060019. [Google Scholar]

- Sirin, O.; Gunduz, M.; Shamiyeh, M.E. Application of Analytic Hierarchy Process (AHP) for Sustainable Pavement Performance Management in Qatar. Eng. Constr. Archit. Manag. 2021, 28, 3106–3122. [Google Scholar] [CrossRef]

- Ashok, A.; Thasneem, T.K.M.; Vincent, S. Pavement Rehabilitation Prioritization Using Analytical Hierarchy Process (AHP). Int. J. Innov. Res. Sci. Eng. Technol. 2016, 5, 6858–6865. [Google Scholar]

- Moazami, D.; Muniandy, R.; Hamid, H.; Md Yusoff, Z. The Use of Analytical Hierarchy Process in Priority Rating of Pavement Maintenance. Sci. Res. Essays 2011, 6, 2447–2456. [Google Scholar]

- Sreelekshmi, B.G. Maintenance Prioritization of Roads Based on Asset Score Using GIS and AHP. In Proceedings of the SECON’22: Structural Engineering and Construction Management, Angamaly, India, 1–3 June 2022. [Google Scholar]

- Khahro, S.H.; Memon, Z.A.; Gungat, L.; Yazid, M.R.M.; Rahim, A.; Mubaraki, M.; Md. Yusoff, N.I. Low-Cost Pavement Management System for Developing Countries. Sustainability 2021, 13, 5941. [Google Scholar] [CrossRef]

- Lee, H.K.; Lim, K.J. Development Strategies for Pavement Management Systems in Gangwon-do. J. Agric. Life Environ. Sci. 2023, 35, 454–473. [Google Scholar]

- Al-Mansoori, T.; Abdalkadhum, A.J.; Al-Husainy, A.S. A GIS-Enhanced Pavement Management System: A Case Study in Iraq. J. Eng. Sci. Technol. 2020, 15, 2639–2648. [Google Scholar]

- Saaty, T.L. A Scaling Method for Priorities in Hierarchical Structure. J. Math. Psychol. 1977, 15, 234–281. [Google Scholar] [CrossRef]

- Saaty, T.L. How to Make a Decision: The Analytic Hierarchy Process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Saaty, T.L. Fundamentals of Decision Making and Priority Theory with the Analytic Hierarchy Process; RWS Publication: Pittsburgh, PA, USA, 1994. [Google Scholar]

- Saaty, T.L. Decision Making with Dependence and Feedback: The Analytic Network Process; RWS Publication: Pittsburgh, PA, USA, 1996. [Google Scholar]

- Miller, G.A. The Magical Number Seven, Plus or Minus Two: Some Limits on Our Capacity for Processing Information. Psychol. Rev. 1956, 63, 81–97. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).