Properties of Self-Compacting Concrete (SCC) Prepared with Binary and Ternary Blended Calcined Clay and Steel Slag

Abstract

1. Introduction

2. Experimental Study

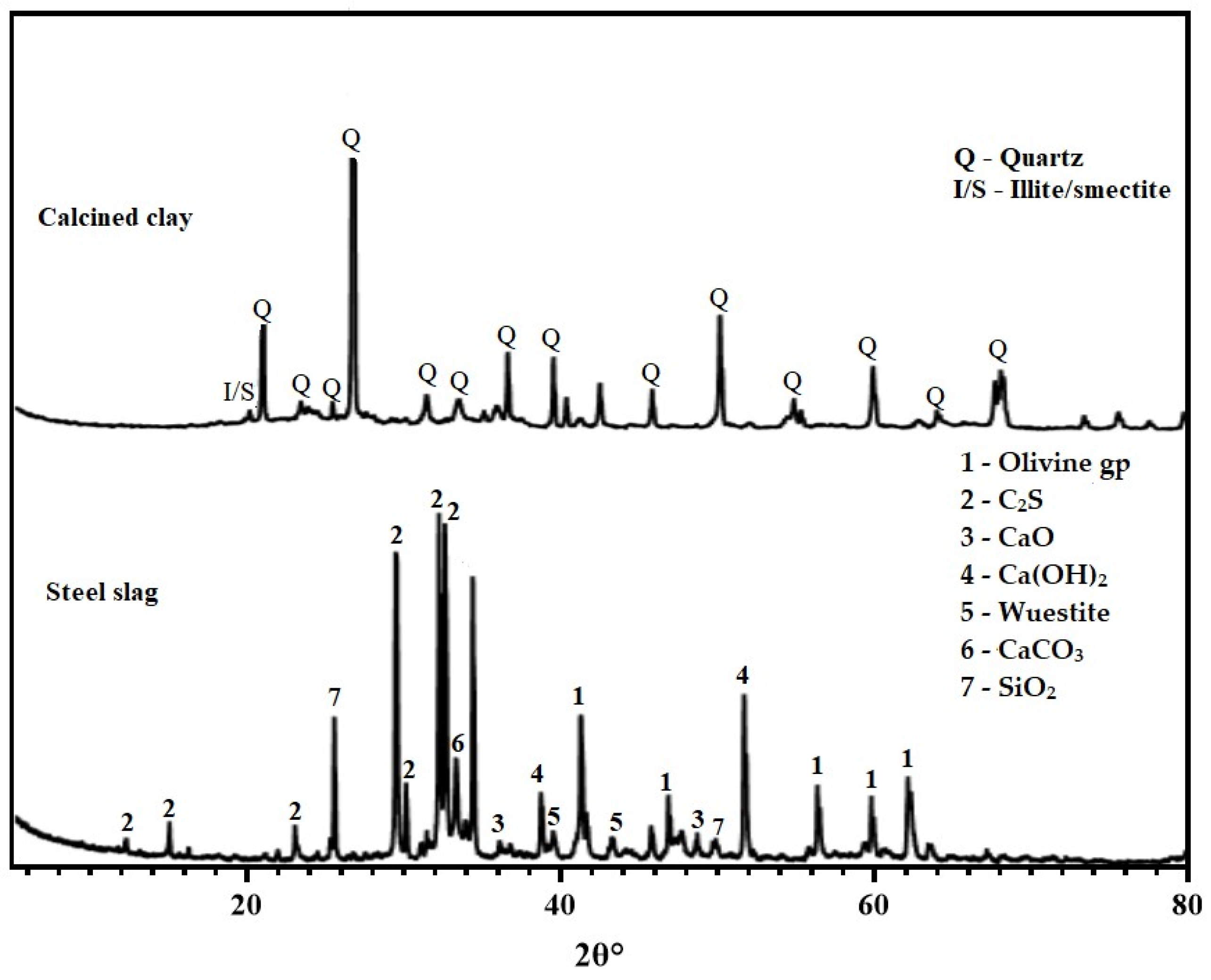

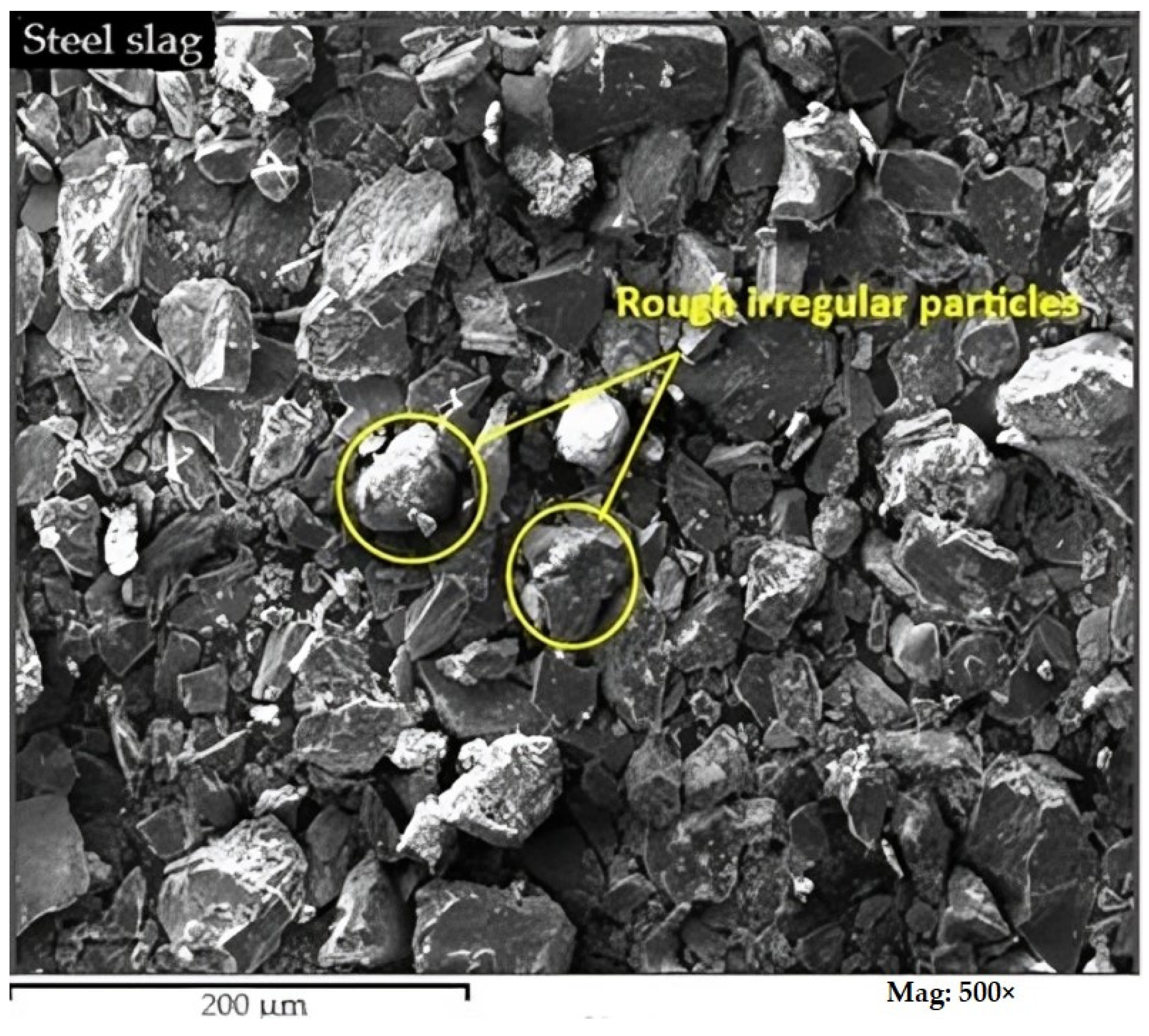

2.1. Materials

2.2. Mix Design and Casting

2.3. Testing Methods

3. Results and Discussion

3.1. Fresh SCC Properties

3.1.1. Slump Flow of SCC

3.1.2. V-Funnel and T-50 Flow Time of SCC

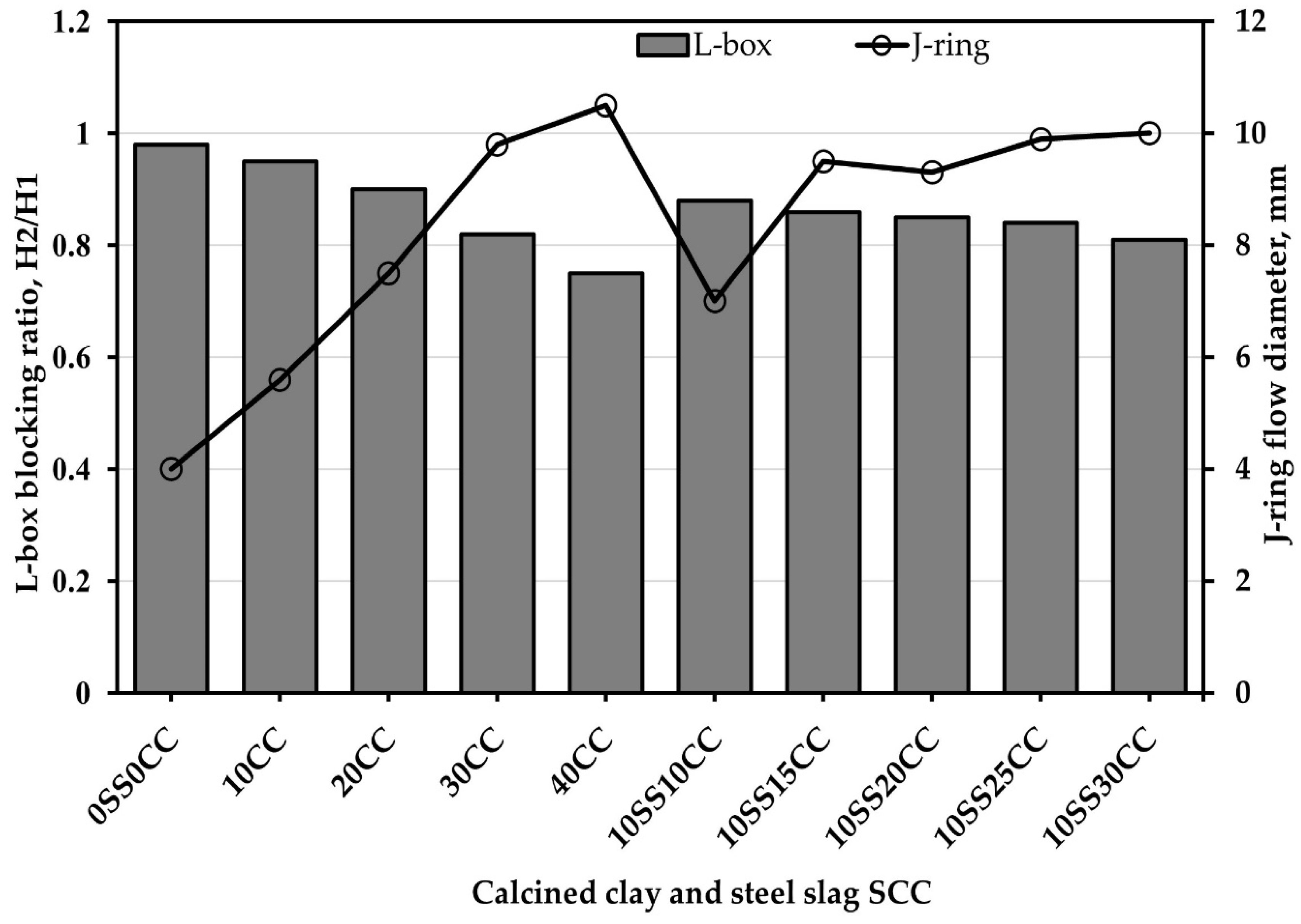

3.1.3. L-Box Blocking Ratio and J-Ring Test

3.2. Hardened SCC Properties

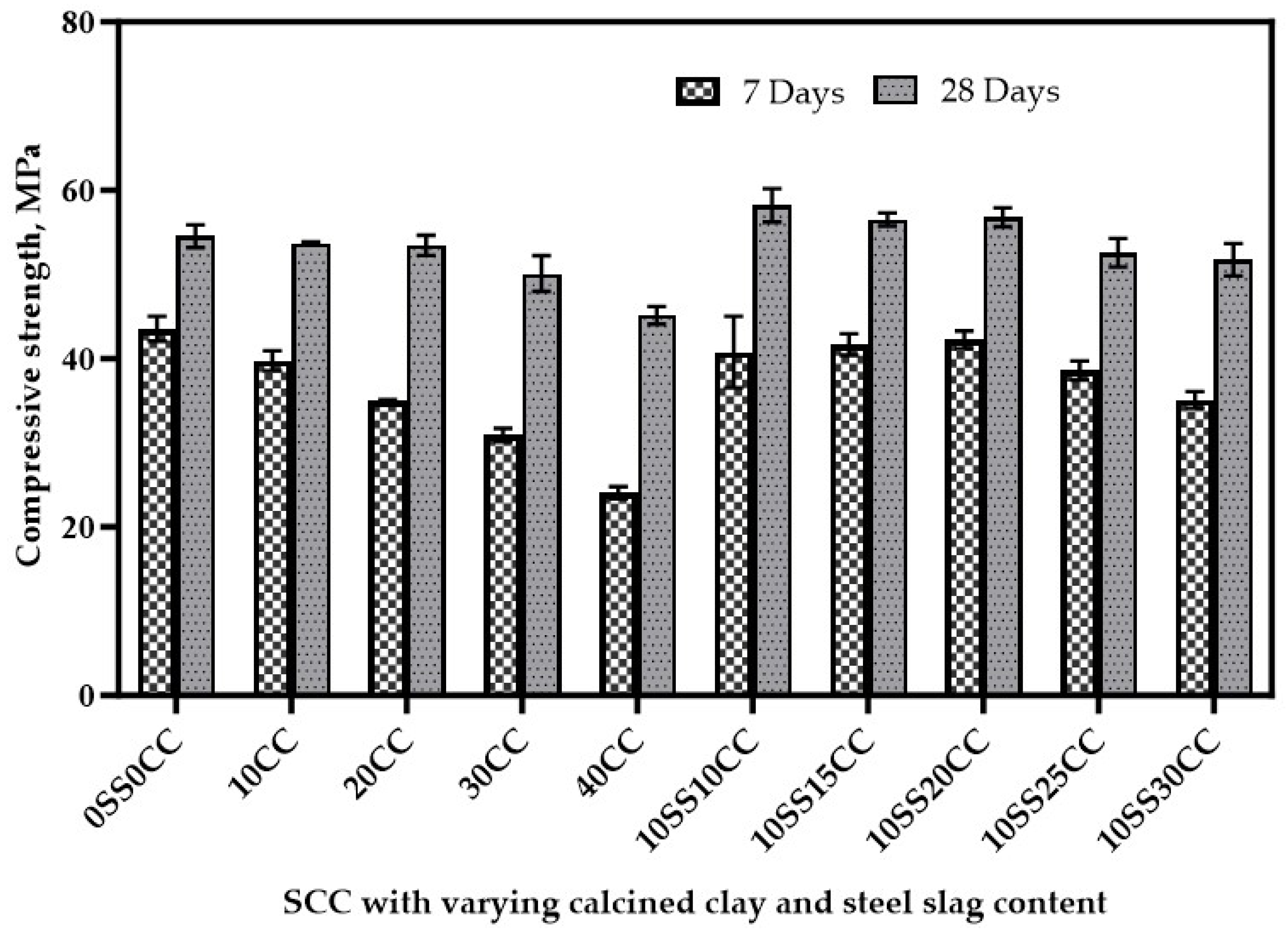

3.2.1. Compressive Strength of SCC

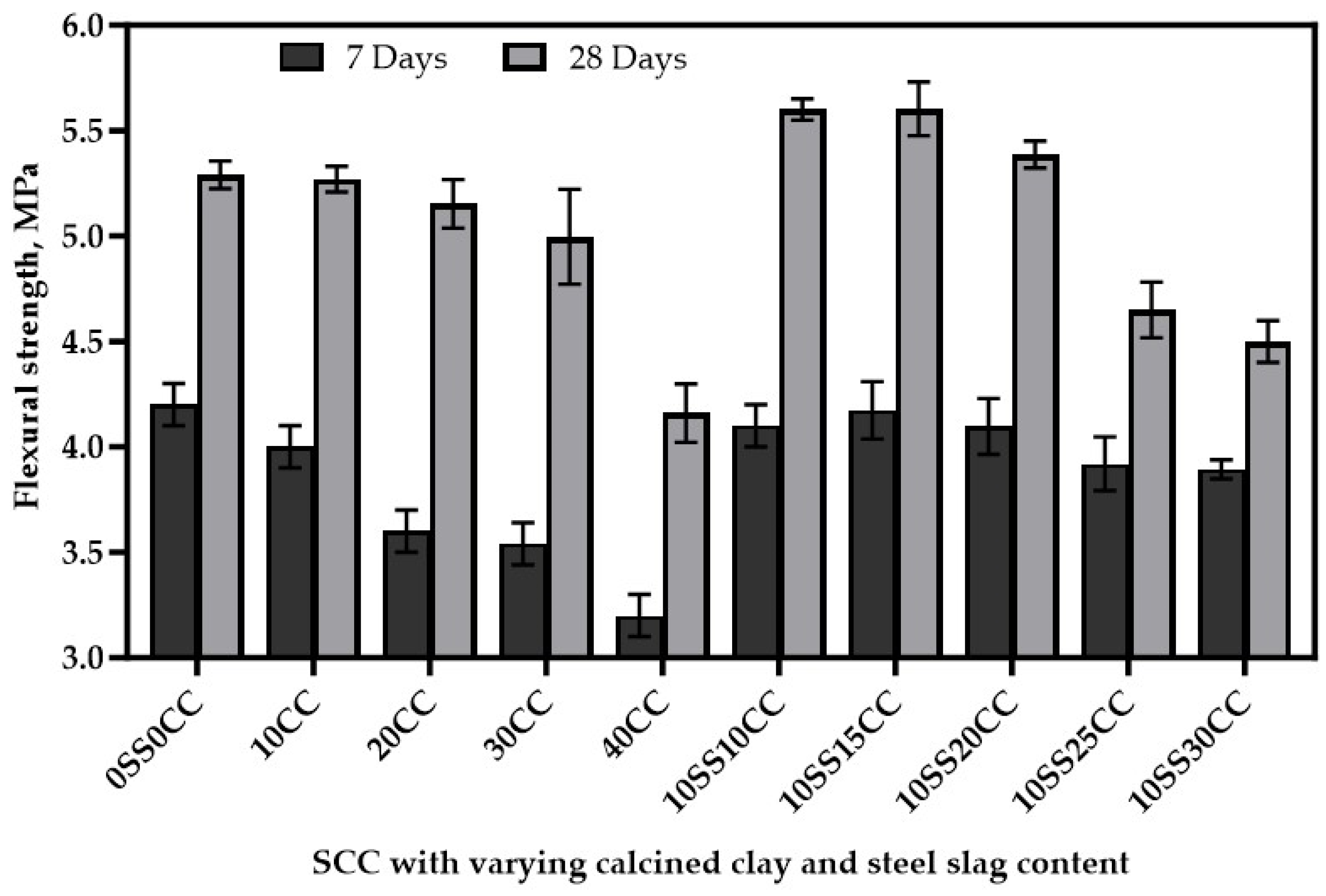

3.2.2. Flexural Strength

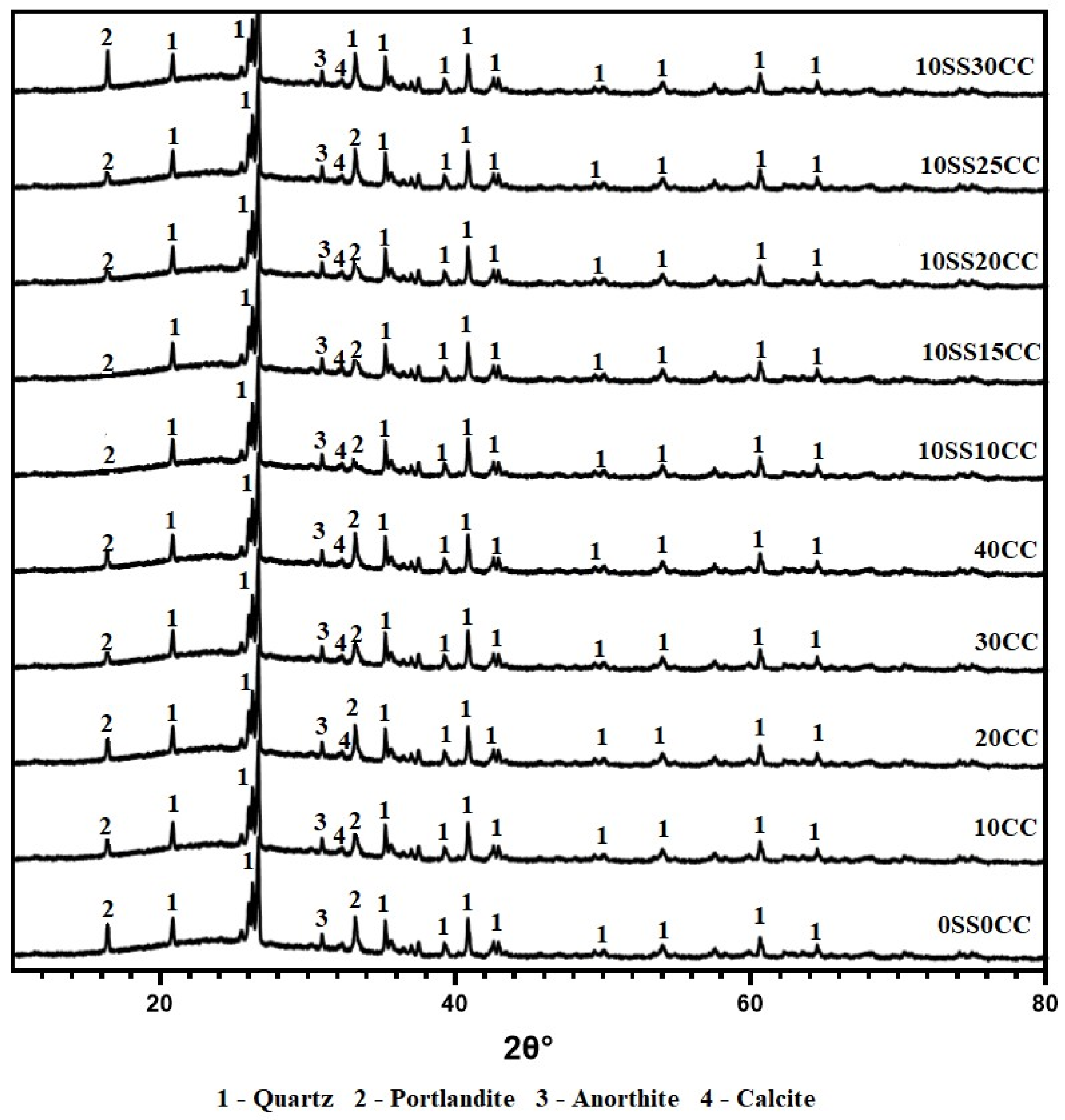

3.3. XRD Analysis of Hydrated SCC

3.4. Chloride Ingress Resistance

3.5. Sulphate Resistance

4. Conclusions

- All blends showed a good consistency and workability. Steel slag effectively compensated for the decrease in fluidity caused by the addition of calcined clay. Mixtures containing 10% and 10/15% calcined clay showed optimal performances in achieving desirable fresh SCC properties.

- After 28 days, the specimens 10SS10CC, 10SS15CC, and 10SS20CC achieved compressive strengths approximately 6.2%, 3.5%, and 3.9% higher than the reference sample. Except for sample 10SS30CC, which lagged behind the reference specimen, all mixtures containing steel slag exhibited flexural strengths higher than the reference SCC.

- Concrete containing calcined clay and steel slag obtained a minimum amount of charge passed at 7 and 28 days. This demonstrates an exceptional resistance to chloride ions at both early and later ages.

- The XRD analysis revealed a significant decrease in the peak heights of portlandite in mixtures containing steel slag and calcined clay, regardless of their replacement percentage. From the XRD analysis, there were significant reductions in the peak heights of portlandite in mixtures containing steel slag and calcined clay, irrespective of their percentage replacement. The most significant reduction was found in mixtures containing 10% steel slag and 10% calcined clay (10SS10CC) and 10% steel slag and 15% calcined clay (10SS15CC).

- Overall, the blended cement samples exhibited higher performances in resisting the sulphate attack. A direct relation was seen to exist between weight loss and strength loss due to sulphate attack. As the weight of the samples decreased, the compressive strength decreased.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Madandoust, R.; Mousavi, S.Y. Fresh and hardened properties of self-compacting concrete containing metakaolin. Constr. Build. Mater. 2012, 35, 752–760. [Google Scholar] [CrossRef]

- Sobuz, M.H.; Meraz, M.M.; Safayet, M.A.; Mim, N.J.; Mehedi, M.T.; Farsangi, E.N.; Shrestha, R.K.; Arafin, S.A.; Bibi, T.; Hussain, M.S.; et al. Performance evaluation of high-performance self-compacting concrete with waste glass aggregate and metakaolin. J. Build. Eng. 2023, 67, 105976. [Google Scholar] [CrossRef]

- Jain, A.; Gupta, R.; Chaudhary, S. Sustainable development of self-compacting concrete by using granite waste and fly ash. Constr. Build. Mater. 2020, 262, 120516. [Google Scholar] [CrossRef]

- Pravitha, J.J.; Merina, R.N.; Subash, N. Mechanical properties and microstructural characterization of ferrock as CO2–negative material in self-compacting concrete. Constr. Build. Mater. 2023, 396, 132289. [Google Scholar] [CrossRef]

- Jain, A.; Gupta, R.; Chaudhary, S. Performance of self-compacting concrete comprising granite cutting waste as fine aggregate. Constr. Build. Mater. 2019, 221, 539–552. [Google Scholar] [CrossRef]

- Choudhary, S.; Chaudhary, S.; Jain, A.; Gupta, R. Valorization of waste rubber tyre fiber in functionally graded concrete. Mater. Today Proc. 2020, 32, 645–650. [Google Scholar] [CrossRef]

- Nilimaa, J. Smart materials and technologies for sustainable concrete construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Mim, N.J.; Meraz, M.M.; Islam, M.H.; Farsangi, E.N.; Mehedi, M.T.; Arafin, S.A.; Shrestha, R.K. Eco-friendly and cost-effective self-compacting concrete using waste banana leaf ash. J. Build. Eng. 2023, 64, 105581. [Google Scholar] [CrossRef]

- Wee, J. A review on carbon dioxide capture and storage technology using coal fly ash. Appl. Energy 2013, 106, 143–151. [Google Scholar] [CrossRef]

- Boakye, K.; Khorami, M. Hydration, Reactivity and Durability Performance of Low-Grade Calcined Clay-Silica Fume Hybrid Mortar. Appl. Sci. 2023, 13, 11906. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Avet, F.; Scrivener, K. Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 124–135. [Google Scholar] [CrossRef]

- Sarfo-Ansah, J.; Atiemo, E.; Bediako, M.; Tagbor, T.A.; Boakye, K.A.; Adjei, D. The influence of calcined clay pozzolan, low-CaO steel slag and granite dust on the alkali-silica reaction in concrete. J. Eng. Res. Appl. 2015, 5, 19–27. [Google Scholar]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 2013, 37, 319–327. [Google Scholar] [CrossRef]

- Msinjili, N.S.; Vogler, N.; Sturm, P.; Neubert, M.; Schröder, H.-J.; Kühne, H.-C.; Hünger, K.-J.; Gluth, G.J. Calcined brick clays and mixed clays as supplementary cementitious materials: Effects on the performance of blended cement mortars. Constr. Build. Mater. 2021, 266, 120990. [Google Scholar] [CrossRef]

- Alujas, A.; Fernández, R.; Quintana, R.; Scrivener, K.L.; Martirena, F. Pozzolanic reactivity of low grade kaolinitic clays: Influence of calcination temperature and impact of calcination products on OPC hydration. Appl. Clay Sci. 2015, 108, 94–101. [Google Scholar] [CrossRef]

- Boakye, K.; Khorami, M. Impact of low-reactivity calcined clay on the performance of fly ash-based geopolymer mortar. Sustainability 2023, 15, 13556. [Google Scholar] [CrossRef]

- Sarfo-Ansah, J.; Atiemo, E.; Boakye, K.; Adjei, D.; Adjaottor, A. Calcined Clay Pozzolan as an Admixture to Mitigate the Alkali-Silica Reaction in Concrete. J. Mater. Sci. Chem. Eng. 2014, 2, 20–26. [Google Scholar] [CrossRef]

- Hay, R.; Celik, K. Performance enhancement and characterization of limestone calcined clay cement (LC3) produced with low-reactivity kaolinitic clay. Constr. Build. Mater. 2023, 392, 131831. [Google Scholar] [CrossRef]

- Bouchenafa, O.; Hamzaoui, R.; Bennabi, A.; Colin, J. PCA effect on structure of fly ashes and slag obtained by mechanosynthesis. Applications: Mechanical performance of substituted paste CEMI 50% slag/or fly ashes. Constr. Build. Mater. 2019, 203, 120–133. [Google Scholar] [CrossRef]

- Piemonti, A.; Conforti, A.; Cominoli, L.; Sorlini, S.; Luciano, A.; Plizzari, G. Use of iron and steel slags in concrete: State of the art and future perspectives. Sustainability 2021, 13, 556. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.; Mi, G. Effect of blended steel slag–GBFS mineral admixture on hydration and strength of cement. Constr. Build. Mater. 2012, 35, 8–14. [Google Scholar] [CrossRef]

- Diao, Z.K.; Pan, Z.H.; Ma, J.; Gao, Z.; Qiu, T. Experimental study on workability and compressive strength of self-compacting concrete with recycled aggregate of steel slag. Build. Struct. 2016, 46, 52–55. [Google Scholar]

- Atiemo, E.; Boakye, K.A.; Sarfo-Ansah, J. Hydration and mechanical properties of Portland cement blended with Low-CaO Steel Slag. J. Phys. Sci. Appl. 2014, 4, 444–449. [Google Scholar]

- Wang, M.; Xie, Y.; Long, G.; Ma, C.; Zeng, X.; Qiang, F. The impact mechanical characteristics of steam-cured concrete under different curing temperature conditions. Constr. Build. Mater. 2020, 241, 118042. [Google Scholar] [CrossRef]

- Devi, V.S.; Kumar, M.M.; Iswarya, N.; Gnanavel, B.K. Durability of steel slag concrete under various exposure conditions. Mater. Today Proc. 2020, 22, 2764–2771. [Google Scholar] [CrossRef]

- Khatib, J.M.; Hibbert, J.J. Selected engineering properties of concrete incorporating slag and metakaolin. Constr. Build. Mater. 2005, 19, 460–472. [Google Scholar] [CrossRef]

- Sullivan, M.S.; Chorzepa, M.G.; Durham, S.A. Characterizing the performance of ternary concrete mixtures involving slag and metakaolin. Infrastructures 2020, 5, 14. [Google Scholar] [CrossRef]

- Singh, S.K.; Tiwari, N.; Jyoti. Development of sustainable ternary cementitious binder with OPC integrating calcined clay and LF slag. J. Build. Eng. 2023, 75, 107025. [Google Scholar] [CrossRef]

- British Standards Institution. BS EN 197-1; 2011-Cement—Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution: Milton Keynes, UK, 2019.

- EFNARCF. Specification and Guidelines for Self-Compacting Concrete; European Federation of Specialist Construction Chemicals and Concrete System: Farnham, UK, 2002. [Google Scholar]

- ASTM C109/C109M; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or 50 mm Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM C78/C78M-18; Standard Test Method for Flexural Strength of Concrete Using Simple Beam with Third-Point Loading. ASTM International: West Conshohocken, PA, USA, 2018.

- Ramezanianpour, A.A.; Pilvar, A.; Mahdikhani, M.; Moodi, F. Practical evaluation of relationship between concrete resistivity, water penetration, rapid chloride penetration and compressive strength. Constr. Build. Mater. 2011, 25, 2472–2479. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M. Properties of self-compacting mortars with binary and ternary cementitious blends of fly ash and metakaolin. Mater. Struct. 2008, 41, 1519–1531. [Google Scholar] [CrossRef]

- Karthiga@Shenbagam, N.; Arun Siddharth, M.; Kannan, V.; Dhanusree, C. Experimental investigation of self-compacting concrete (SCC) using fly ash. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoglu, M.; Al-Goody, A.; İpek, S. Fresh and rheological behavior of nano-silica and fly ash blended self-compacting concrete. Constr. Build. Mater. 2015, 95, 29–44. [Google Scholar] [CrossRef]

- Barkat, A.; Kenai, S.; Menadi, B.; Kadri, E.; Soualhi, H. Effects of local metakaolin addition on rheological and mechanical performance of self-compacting limestone cement concrete. J. Adhes. Sci. Technol. 2019, 33, 963–985. [Google Scholar] [CrossRef]

- Al-Oran, A.A.A.; Safiee, N.A.; Nasir, N.A.M. Fresh and hardened properties of self-compacting concrete using metakaolin and GGBS as cement replacement. Eur. J. Environ. Civ. Eng. 2022, 26, 379–392. [Google Scholar] [CrossRef]

- Sfikas, I.P.; Badogiannis, E.G.; Trezos, K.G. Rheology and mechanical characteristics of self-compacting concrete mixtures containing metakaolin. Constr. Build. Mater. 2014, 64, 121–129. [Google Scholar] [CrossRef]

- Badogiannis, E.G.; Sfikas, I.P.; Voukia, D.V.; Trezos, K.G.; Tsivilis, S.G. Durability of metakaolin Self-Compacting Concrete. Constr. Build. Mater. 2015, 82, 133–141. [Google Scholar] [CrossRef]

- Boakye, K.; Khorami, M.; Saidani, M.; Ganjian, E.; Dunster, A.; Ehsani, A.; Tyrer, M. Mechanochemical characterisation of calcined impure kaolinitic clay as a composite binder in cementitious mortars. J. Compos. Sci. 2022, 6, 134. [Google Scholar] [CrossRef]

- Dixit, A.; Du, H.; Pang, S.D. Marine clay in ultra-high performance concrete for filler substitution. Constr. Build. Mater. 2020, 263, 120250. [Google Scholar] [CrossRef]

- Wild, S.; Khatib, J.M.; Jones, A. Relative strength, pozzolanic activity and cement hydration in superplasticised metakaolin concrete. Cem. Concr. Res. 1996, 26, 1537–1544. [Google Scholar] [CrossRef]

- Hasan, Z.A.; Nasr, M.S.; Abed, M.K. Properties of reactive powder concrete containing different combinations of fly ash and metakaolin. Mater. Today Proc. 2021, 42, 2436–2440. [Google Scholar] [CrossRef]

- Saboo, N.; Shivhare, S.; Kori, K.K.; Chandrappa, A.K. Effect of fly ash and metakaolin on pervious concrete properties. Constr. Build. Mater. 2019, 223, 322–328. [Google Scholar] [CrossRef]

- Vance, K.; Aguayo, M.; Oey, T.; Sant, G.; Neithalath, N. Hydration and strength development in ternary portland cement blends containing limestone and fly ash or metakaolin. Cem. Concr. Compos. 2013, 39, 93–103. [Google Scholar] [CrossRef]

- Moser, R.D.; Jayapalan, A.R.; Garas, V.Y.; Kurtis, K.E. Assessment of binary and ternary blends of metakaolin and Class C fly ash for alkali-silica reaction mitigation in concrete. Cem. Concr. Res. 2010, 40, 1664–1672. [Google Scholar] [CrossRef]

- Boakye, K.; Khorami, M. Influence of Calcined Clay Pozzolan and Aggregate Size on the Mechanical and Durability Properties of Pervious Concrete. J. Compos. Sci. 2023, 7, 182. [Google Scholar] [CrossRef]

- Sujjavanich, S.; Suwanvitaya, P.; Chaysuwan, D.; Heness, G. Synergistic effect of metakaolin and fly ash on properties of concrete. Constr. Build. Mater. 2017, 155, 830–837. [Google Scholar] [CrossRef]

- Fernandez, R.; Martirena, F.; Scrivener, K.L. The origin of the pozzolanic activity of calcined clay minerals: A comparison between kaolinite, illite and montmorillonite. Cem. Concr. Res. 2011, 41, 113–122. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, S.; Kawashima, S.; Shah, S.P. Influence of kaolinite clay on the chloride diffusion property of cement-based materials. Cem. Concr. Compos. 2014, 45, 117–124. [Google Scholar] [CrossRef]

- Garg, R.; Garg, R.; Eddy, N.O.; Khan, M.A.; Khan, A.H.; Alomayri, T.; Berwal, P. Mechanical strength and durability analysis of mortars prepared with fly ash and nano-metakaolin. Case Stud. Constr. Mater. 2023, 18, e01796. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Li, C.; Monteiro, P.J.M. Eco-friendly mortar with high-volume diatomite and fly ash: Performance and life-cycle assessment with regional variability. J. Clean. Prod. 2020, 261, 121224. [Google Scholar] [CrossRef]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- Shen, P.; Lu, L.; Chen, W.; Wang, F.; Hu, S. Efficiency of metakaolin in steam cured high strength concrete. Constr. Build. Mater. 2017, 152, 357–366. [Google Scholar] [CrossRef]

- Dhanya, B.S.; Santhanam, M. Performance evaluation of rapid chloride permeability test in concretes with supplementary cementitious materials. Mater. Struct. 2017, 50, 67. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Sakthivel, T.; Santhanam, M.; Gettu, R.; Pillai, R.G. Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 136–151. [Google Scholar] [CrossRef]

- Rossetti, A.; Ikumi, T.; Segura, I.; Irassar, E.F. Sulfate performance of blended cements (limestone and illite calcined clay) exposed to aggressive environment after casting. Cem. Concr. Res. 2021, 147, 106495. [Google Scholar] [CrossRef]

| Composition, % | SiO2 | A12O3 | Fe2O3 | MgO | CaO | Na2O | K2O | MnO | TiO2 | P2O5 | Cl | SO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Calcined clay | 63.52 | 17.89 | 12.75 | 1.54 | 0.31 | 0.02 | 1.69 | 0.46 | 0.34 | 0.01 | – | 0.13 | 1.34 |

| Steel slag | 10.51 | 2.12 | 25.8 | 6.86 | 42.89 | 0.62 | 0.12 | 4.37 | 0.63 | 0.31 | – | 0.12 | 5.65 |

| OPC | 17.56 | 3.05 | 3.84 | 2.05 | 60.24 | 4.05 | 2.31 | 0.13 | 0.15 | 0.21 | 0.02 | 4.68 | 1.71 |

| Mix ID | Cement, | SS, | Calcined Clay, | Sand, | CA | Superplasticizer, |

|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | % | |

| 0SS0CC | 600 | 0 | 0 | 1050 | 900 | 1 |

| 10CC | 540 | 0 | 60 | 1050 | 900 | 1 |

| 20CC | 480 | 0 | 120 | 1050 | 900 | 1 |

| 30CC | 420 | 0 | 180 | 1050 | 900 | 1 |

| 40CC | 360 | 0 | 240 | 1050 | 900 | 1 |

| 10SS10CC | 480 | 60 | 60 | 1050 | 900 | 1 |

| 10SS15CC | 450 | 60 | 90 | 1050 | 900 | 1 |

| 10SS20CC | 420 | 60 | 120 | 1050 | 900 | 1 |

| 10SS25CC | 390 | 60 | 150 | 1050 | 900 | 1 |

| 10SS30CC | 360 | 60 | 180 | 1050 | 900 | 1 |

| Sample | Weight Loss, % | Strength Loss, % |

|---|---|---|

| 0SS0CC | 12.3 | 7.5 |

| 10CC | 10.5 | 6.5 |

| 20CC | 9.5 | 5.7 |

| 30CC | 8.3 | 5 |

| 40CC | 4.5 | 3.6 |

| 10SS10CC | 3.6 | 2.4 |

| 10SS15CC | 3.45 | 2.1 |

| 10SS20CC | 3.7 | 2.3 |

| 10SS25CC | 3.1 | 2.3 |

| 10SS30CC | 2.3 | 2.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boakye, K.; Khorami, M. Properties of Self-Compacting Concrete (SCC) Prepared with Binary and Ternary Blended Calcined Clay and Steel Slag. Infrastructures 2024, 9, 46. https://doi.org/10.3390/infrastructures9030046

Boakye K, Khorami M. Properties of Self-Compacting Concrete (SCC) Prepared with Binary and Ternary Blended Calcined Clay and Steel Slag. Infrastructures. 2024; 9(3):46. https://doi.org/10.3390/infrastructures9030046

Chicago/Turabian StyleBoakye, Kwabena, and Morteza Khorami. 2024. "Properties of Self-Compacting Concrete (SCC) Prepared with Binary and Ternary Blended Calcined Clay and Steel Slag" Infrastructures 9, no. 3: 46. https://doi.org/10.3390/infrastructures9030046

APA StyleBoakye, K., & Khorami, M. (2024). Properties of Self-Compacting Concrete (SCC) Prepared with Binary and Ternary Blended Calcined Clay and Steel Slag. Infrastructures, 9(3), 46. https://doi.org/10.3390/infrastructures9030046