Abstract

This research work aims to compare the strength and fracture mechanics properties of plain concretes, obtained from different coarse aggregates. During the study, mechanical parameters including compressive strength (fcm) and splitting tensile strength (fctm), as well as fracture parameters involving critical stress intensity factor and critical crack tip opening displacement (CTODc) were evaluated. The effect of the aggregates used on the brittleness of the concretes was also analyzed. For better understanding of the crack initiation and propagation in concretes with different coarse aggregates, a macroscopic failure surfaces examination of the tested beams is also presented. Crushed aggregates covered were basalt (BA), granite (GT), and limestone (LM), and natural peeble gravel aggregate (GL) were used in the concrete mixtures. Fracture toughness tests were performed on an MTS 810 testing machine. Due to the high strength of the rock material, the rough surface of the aggregate grains, and good bonding in the ITZ area between the aggregate and the paste, the concretes with crushed aggregates exhibited high fracture toughness. Both of the analyzed fracture mechanics parameters, i.e., and CTODc, increased significantly in the case of concretes which were manufactured with crushed aggregates. They amounted, in comparison to concrete based on gravel aggregate, to levels ranging from 20% for concrete with limestone aggregate to over 30% for concrete with a granite aggregate, and to as much as over 70% for concrete with basalt aggregate. On the other hand, the concrete with gravel aggregate showed the lowest fracture toughness because of the smooth surface of the aggregate grains and poor bonding between the aggregate and the cement paste. However, the fracture process in each series of concrete was quasi-plastic in the case of gravel concrete, semi-brittle in the case of limestone concrete, and clearly brittle in the case of the concretes based on granite and basalt aggregates. The results obtained help to explain how the coarse aggregate type affects the strength parameters and fracture toughness at bending.

1. Introduction

In ordinary concrete, which is a composite due to its structure, there are two basic phases, i.e., cement matrix and aggregate grains, which are included in the structure of the paste [1,2]. The matrix in a concrete composite, which is a continuous phase, is susceptible to moisture, temperature, and corrosion. However, rigid grains of aggregate, as fillers in the concrete composite structure, are characterized by their resistance to environmental influences and the independence of their properties from working time [3,4,5].

In concrete, the volume of aggregate is on average 60% to 80% [6,7,8,9,10,11]. This means that both concrete type and grain size are two of the basic factors that have a significant impact on concrete features as follows [12,13,14,15,16,17]:

- Thickness and quality of Interfacial Transition Zone (ITZ) between aggregate and the paste;

- Strain capacity;

- Mechanical parameters;

- Fracture toughness;

- Critical stress levels;

- Fatigue properties;

- Behavior at elevated temperatures.

Moreover, aggregates are relatively cheap compared to other components of concrete. This means that, whenever possible, they are also used to reduce the total cost of the construction materials [18,19]. All the above factors mean that the characteristics of aggregates are necessary for the design and prediction of important features of cement concretes [20,21,22].

In Poland, as well as in most European Union countries and the USA, for the production of concrete, usually mineral aggregates are used as coarse aggregates [7,23]. These are fillers obtained from rock massifs, as opposed to artificial aggregates, mainly derived from industrial waste such as gravelite, shale, aluminoporite, ashburst, foamed slag, etc. [24,25]. There are two basic groups of mineral aggregates [26,27,28,29]:

- Natural aggregates;

- Crushed aggregates.

A natural aggregate is created from the crumbling of rocks caused by the forces of nature, mainly rock erosion. A group of these aggregates includes, among others, sands, sand–gravel mixes, and gravels [30,31,32]. In turn, a crushed stone aggregate is created from the fragmentation of rocks as a result of intentional human activity. Aggregates belonging to this group are mainly granites, limestones, and dolomites. The remaining crushed stone aggregates come from rocks: sandstones, diorites, basalts, and gabbro [33,34,35,36,37].

Among mineral aggregates, gravels constitute the largest share in the production of concrete, which is understandable due to their price and availability [38,39,40,41,42]. The remaining part consists of crushed stone aggregates. It is estimated that in the USA mineral aggregates used for concrete account for more than 90% of all types of aggregates used (approximately 50% are gravels and the rest are crushed stone aggregates, of which 66% are crushed aggregates from carbonate rocks). However, in Poland and the European Union, 97% of mineral aggregates are used for concrete, including 65% from gravel and 35% from crushed aggregates, from which 20% are derived from carbonate rocks [6,7,23]. Aggregates obtained from carbonate rocks are usually limestones or dolomites [43,44,45].

Because in modern concrete technology, aggregates belonging to both groups discussed above, i.e., both natural and crushed aggregates, are used to a large extent, this article presents in-depth research results on the important material characteristics of concrete composites made using various types of mineral aggregates. The article focuses on the assessment of the fracture toughness of concretes made of aggregates from various types of rocks [46,47,48]. In addition, in this study, analysis has been performed on the zones of the composites where damages occurred and on how the process of intra-material cracks propagated in the concrete structure [49,50,51,52,53].

It should be noted that such research is important both from a scientific and engineering point of view. This is due to the fact that possible changes in both the basic strength characteristics of concrete composites and their other specific parameters and properties, e.g., brittleness, tendency to develop structural damage, or fracture toughness, are strictly dependent on the characteristics of coarse aggregate grains as follows [52,53,54,55,56]:

- Surface texture;

- Shape;

- Size;

- Strength;

- Mineralogical composition;

- Hardness;

- Modulus of elasticity and elastic properties.

2. Properties of Mineral Aggregates in Terms of Susceptibility of Concrete to Brittle Fracture

The quality of aggregates is determined by the conditions of their formation, as well as the geological characteristics and mineral composition of the rocks from which they are obtained [4,57,58,59]. A detailed breakdown of mineral aggregates depending on their genetic and petrographic origin is presented, e.g., in [6]. In addition to the petrographic characteristics, their external features such as the size, shape, and texture of the grain surface are also important [6,60,61]. These properties determine their adhesion, and thus the structure of the ITZ between the coarse aggregate and the paste [62,63,64].

The shape of the grains of natural aggregates is usually spherical, oval, very rounded, rounded, or irregular, while the shape of crushed stone aggregates is elongated, thickset, flat, or angular [6]. The share of flat and elongated grains in the crumbs pile negatively affects the workability of the concrete mix, which reduces the tightness, frost resistance, and strength of the concrete. In addition, such grains have a larger surface area in relation to the volume, which has a negative impact as it causes the unnecessary increase in the amount of cement in concrete [65,66,67]. Based on [6,68,69], it was found that the most beneficial effect is achieved when the shape of the aggregate grains is similar to a sphere or cube. This reduces the friction between the paste and the aggregate, which results in better workability of the concrete mix and an increase in the tightness and strength of the composite. According to [6], the void content of the aggregate decreases from about 40.5% in the absence of rounded grains in the crumb pile to 34% with the content consisting of 100% spherical grains. The resulting reduction in intergranular voids also affects the apparent density of concrete, which consequently improves its mechanical and strength parameters, and reduces its susceptibility to possible damage [47,70,71,72].

The second important parameter that describes the structure of aggregates is their texture. It determines the adhesion of grains to the cement paste and influences the water demand for the concrete mixture. Texture also has an impact on the strength of concrete, mainly bending strength [6,22,73,74]. Grains of natural aggregates usually have a smooth texture, while crushed aggregate grains have a rough or crystalline texture. A rougher texture results in greater adhesion forces between the aggregate grains and the cement paste. The above conclusion therefore proves that crushed aggregates have a higher adhesion than natural aggregates [75,76]. This is determined by the rougher surface of these fillers. It enables the mechanical bonding of the inclusions in question at the contact surfaces with the cement matrix [6,10,77,78].

Another factor that has a significant impact on the increase or decrease in aggregate adhesion is the share of mineral dusts with a diameter below 0.063 mm in the cement paste. Such dusts, in most cases, adversely affect the properties of the concrete mix and concrete, as they increase water demand and surround the aggregate grains, hindering the direct access of the cement paste. The exceptions here are fillers obtained from carbonate rocks. Limestone or dolomite powders increase the tightness and strength of the concrete [6,79]. It has also been observed that in the case of carbonate aggregates their favorable chemical and physical composition causes the formation of chemical bonds on their surfaces, which positively affects adhesion [6,80,81]. In addition, the use of granite powder as a partial substitute for fine aggregates also has a beneficial effect on improving the strength properties of concrete [82,83].

In previous studies on the influence of the type of coarse aggregate on the strength and mechanical parameters of concrete and its fracture toughness, it was found that the dominant role here is played by the features of the aggregate discussed above, and the adhesion between the aggregate and the paste [84]. The above factors also affect the structure of the ITZ between the coarse aggregate and the paste. On the other hand, this zone in concrete has a decisive influence on the fracture behavior of the construction material.

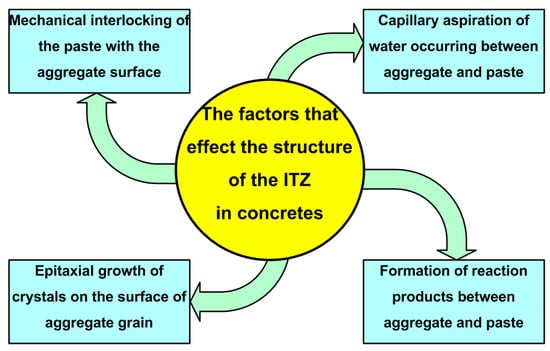

Thus, recapitulating the above considerations, it should be stated that the adhesion of hardened cement paste to the coarse aggregate and, consequently, the fracture toughness of concrete is influenced by such features of aggregates as: mechanical bonding of the paste to the aggregate surface, the formation of chemical reaction products between these materials, and capillary adhesion between the aggregate and the paste. The fourth factor that can determine the formation of strong ITZs in the structure of concrete is the so-called epitaxy phenomenon, which is a chemical process that causes the construction and growth of new crystal networks on the surface of aggregate grains. This phenomenon is usually observed in chemically reactive aggregates and can intensify the strengthening of the ITZ zone in concretes with fillers of this type [28]. Considering the above, Figure 1 shows schematically all the factors determining the ITZ in cement concretes, which have a direct and indirect effect on the susceptibility of concrete to cracking.

Figure 1.

The main factors determining the structure of the ITZ and the susceptibility of concrete to cracking.

With regards to testing the strength parameters of concrete, for example, it was observed that crushed granite and crushed basalt performed best at compression than those made with natural gravels of similar grading [85,86]. Moreover, the highest compressive strength was achieved from concrete containing crushed quartzite, followed by concrete containing river gravel [86]. Similarly, the study presented in [87,88] for different grades of concrete revealed that the highest compressive strength was achieved by all grades of concrete containing 12 mm quartzite, followed by concrete containing granite and river gravel. However, according to [89,90], the type of coarse aggregate used has a great influence on the strength and elasticity modulus of ordinary and high-performance concrete.

The results of the first studies analyzing the impact of the type of aggregates used on the parameters of concrete fracture mechanics using the first model of cracking [91,92] showed that the values of the fracture energy (GIc) and the critical stress intensity factor (KIc) are higher in the case of concretes made of high-strength aggregates, e.g., crushed stone aggregates, obtained from igneous or carbonate rocks, than weaker ones, e.g., gravels or gravelites [91,92]. A beneficial effect on the values of fracture mechanics parameters when using aggregates from igneous rocks is demonstrated in [33,34,93,94,95]. On the other hand, the high fracture toughness of concretes made of limestone aggregates in comparison to gravel concretes was confirmed, e.g., in the tests described in [34]. The favorable fracture toughness results obtained for concrete with limestone aggregate resulted from the physical and chemical reactions occurring in the ITZ area between the coarse aggregates and the paste [80]. These reactions improved bond strength between paste and limestone aggregates [96].

The influence of the type of aggregate used on the parameters of the concrete fracture mechanics, using the first model of cracking, was also discussed in the works [97,98,99,100,101,102]. In these studies, composites with dolomite and gravel fillers were analyzed. Additionally, the addition of silica fume (SF) was used to strengthen the structure of the composites. The results of the conducted research showed that the highest KIc and critical crack tip opening displacement (CTODc) values appeared for dolomite concretes containing 10% SF, while the lowest values were in the case of gravel concretes without the addition of active SF [97,98].

In turn, in work [99], the influence of six different types of coarse aggregate on the fracture energy values of ordinary concretes was studied. The following types of aggregates were taken into account: dolerite, dolomitic limestone, granite, limestone, quartzite, and river grave. The obtained results of the experiments showed that the highest fracture toughness was in the case of concretes made with a granite and limestone aggregate, while the lowest fracture toughness was for concrete with gravel aggregate, and puzzlingly, dolomite aggregate. The relatively low fracture toughness of concrete with dolomite aggregates was due to the smooth grain surface of this aggregate. This, in turn, resulted in a weakening of the ITZ between the aggregate and the paste and, consequently, lower fracture toughness values for this material [100].

At this point, it should also be noted that research has also been carried out so far on the influence of the type of coarse aggregates on the fracture toughness of cementitious concretes using the second model of cracking [93,101,102,103], and the assessment of the destruction surface of concretes made of various aggregates using the fractal technique [104,105] and digital image correlation technique [106,107]. Moreover, the influence of the type of coarse aggregate in the context of improving the fracture toughness of concretes intended for road construction was also assessed [78,108,109,110].

Analyzing the previous publications in this field, it should be stated that the results of tests on fracture toughness of concretes made using various types of aggregates presented in the literature are ambiguous. In addition, they do not contain the full range of data on the scope of fracture toughness of such materials. There is also a lack of detailed information about the processes of initiation and propagation of cracks depending on the type of aggregate used.

In addition, the results to date on the fracture toughness of concretes with different aggregates mostly refer to the analysis of only one selected fracture mechanics parameter, usually in terms of linear fracture mechanics. To date, the most commonly analyzed parameter has been the critical stress intensity factor or fracture energy. However, the literature lacks research results that comprehensively analyze the effect of the type of coarse aggregate on the parameters of both linear and nonlinear fracture mechanics of concretes. In addition, there is no clear indication in the literature as to which of the factors, listed in Figure 1, significantly affect the fracture toughness of concretes made using different types of coarse aggregates.

Therefore, it was proposed to undertake experimental research in this area. The aim was to accurately assess the impact of the type of mineral aggregate on the values of the basic parameters of the fracture mechanics of ordinary concretes, in both linear and non-linear terms. In order to obtain the most reliable comparison of the obtained test results, mineral aggregates, both natural and crushed, from the same geographic area were used in the experiments [111].

3. Experimental Section

3.1. Research Framework and Methodology

In order to meet the objectives of the study, the author implemented a detailed research strategy. Within the framework of the research program, four types of Polish aggregates were tested, as well as ordinary concretes with w/c ratios of 0.4 with these aggregates. Moreover, it should be noted that aggregates used in the study originated from different types of rock massifs.

The present study has examined the strength parameters and fracture properties of the analyzed concrete composites under mode I loading conditions. The evaluated fracture toughness, under three-point flexural loads, were critical stress intensity factor () and critical crack tip opening displacement (CTODc). The main strength parameters, such as compressive strength (fcm) and splitting tensile strength (fctm), as well as the brittleness of these concretes were also examined.

3.2. Materials

In this subsection, the crucial parameters of materials used in the study and detailed and extensive characteristics of the four different types of aggregates of the analyzed concretes are presented. The materials used in this research are as follows.

3.2.1. Cement

The ordinary Portland cement (OPC) CEM I 32.5 R from Chełm cement plant, with properties in accordance with the PN-EN 197-1 [112], was used for concretes with all aggregates. Moreover, it should be added that no mineral additives were used in the concrete mixtures.

The chemical and mineralogical compositions of OPC used are shown in Table 1, whereas the main physical properties of the OPC are presented in Table 2. It should be noted that the mineralogical composition of the binder was analyzed by the Bogue method.

Table 1.

Chemical and mineralogical composition of the OPC used (% mass).

Table 2.

Physical properties of OPC used.

3.2.2. Water

In order to prepare the concrete mixtures, water from the city’s water supply, free of all contaminants was used. The tap water used met the requirements of standard provision EN 1008:2002 [113].

3.2.3. Admixture

In this study, a calcium lignosulfonate-based plasticizer, Basf Liquol BV-18, was used. The plasticizer was used in an amount of 0.6% of the mass of the binder in order to maintain a similar consistency of all mixtures.

3.2.4. Aggregates

The tests involved four coarse aggregates of fractions 2–8 mm. There were three crushed aggregates: basalt, granite, limestone, and natural gravel. It should be added here that the crushed basalt and granite aggregates were inert, while the limestone aggregate was chemically active.

Aggregates came from the following Polish rock beds:

- Basalt (BA)—Winna Góra quarry, near Legnica;

- Granite (GT)—Graniczna quarry, near Wrocław;

- Limestone (LM)—Trzuskawica quarry, near Kielce;

- Natural gravel (GL)—gravel plant Sobolewo, near Suwałki.

In addition, natural pit sand with 2.0 mm maximum size—from Markuszów deposit—was used as fine aggregate. Images of all coarse aggregates used are shown in Figure 2. However, the appearance of the fine aggregate is shown in [78].

Figure 2.

Appearance of coarse aggregate used in the studies: (a) basalt, (b) granite, (c) limestone, (d) gravel.

The photos shown in Figure 2 clearly show the differences between the shape and texture of three crushed aggregates (Figure 2a–c) compared to the appearance of gravel aggregate (Figure 2d). All crushed aggregates had clearly irregular shapes, sharp ends, and a visible rough surface. On the other hand, the gravel grains were rounded and had quite regular shapes and smooth surfaces.

Aggregates used in the studies were tested in terms of grain composition, crushing strength, absorption by weight, content of irregular grains and mineral dust, as well as bulk and specific density.

The main properties of all aggregates used are given in Table 3, whereas the particle size gradation of fine and coarse aggregates is presented in Table 4. It should be noted that the aggregates’ compositions were chosen in such a way that they were contained in the most favorable field between the boundary curves of grading. For this purpose, the study was based on the very precise recommendations included in the German standard DIN 4226-1 [114].

Table 3.

Properties of fine and coarse aggregates.

Table 4.

Grain size distribution of the fine and coarse aggregates.

Based on the data contained in Table 4, it is clear that the different types of aggregates used had very similar distributions of grains. Therefore, it was possible to compare the impact of only the type of aggregate on the analyzed mechanical parameters, because the percentage share of grain fractions of the aggregates used was very similar (Table 4).

3.3. Mix Proportioning

In order to be able to compare reliably the strengths of the effects of aggregate types on the properties of concretes in the same w/c ratios, the principle of maintaining the same volume of cement paste in 1 m3 of mixture was adopted. It is very common in research to find a situation where concretes with the same component weights are compared—as, for example, in studies of the effect of the type of coarse aggregate on strength and fracture toughness parameters of concrete [115]. This is not correct, as the different volumetric densities of the components mean that the tightness condition is not met, and this should be the first consideration. In these tests, the sum of the volumes of all the components in each concrete is 1 m3. This is why the content of cement, water, and sand in mixtures with the same w/c ratio was constant. On the other hand, when determining the amount of individual coarse aggregates in 1 m3, their different densities were taken into account (Table 3). The composition of concrete mixtures is given in Table 5. It should be noted that the designations of the concretes in question were closely related to the type of aggregate used to make them.

Table 5.

Composition of concrete mixtures.

3.4. Casting Specimens and Curing Procedure

The specimens were made in accordance with the EN 12390-2:2019 standard [116]. The concrete mixture was prepared in a DZB-300 counter-rotating mixer with a capacity of 150 L and power of 1.1 kW.

The stages of concrete mixture preparation were as follows:

- First step—dry mixing of coarse and fine aggregate for 120 s; it should be noted that aggregates were washed with water and the surface dried before mixing it with OPC;

- Second step—adding OPC to the mixer container and dry mix for 180 s;

- Third step—mixing the pre-mixed 0.5 water and plasticizer for 30 s and then adding this mixture to the mixer container and mix for 90 s;

- Fourth step—adding the remaining amount of water and performing the final mixing of all the used concrete mix components for 120 s to obtain a homogeneous mass of the mixture.

After preparing the concrete mix, samples were made for strength tests and the assessment of concrete fracture toughness. It should be noted that for each type of concrete and each type of test, six control elements were prepared. For this reason, a total of 48 cubes with a side of 150 mm and 24 beams with dimensions of 700 × 150 × 80 mm were prepared (see Section 3.5). The specific activities included in this part of the research were as follows:

- (a)

- Preparation of plastic and wooden molds for casting of the specimens:

- Bolting of wooden molds to fabricate the beams;

- Lubrication of all molds with an anti-adhesive agent.

- (b)

- Casting of concrete specimens:

- Pouring the fresh mixture in two layers into the molds;

- Compacting each layer of the mixture on the vibrating table;

- Removing excess mix and smoothing the upper areas of the formed specimens;

- Placing steel inserts in the molded beams in order to model the initial cracks in them.

- (c)

- Curing of the specimens after fabrication:

- Covering the samples with damp cloth and storage in the casting room at 20 ± 2 °C;

- Successively spraying the specimens with water.

- (d)

- Demolding the specimens:

- Demolding of cubes using a compressor;

- Demolding the beams and removing the steel inserts.

- (e)

- Curing of the specimens after demolding:

- Placing the specimens in a water tank for 2 weeks under the following heat and humidity conditions: t = 20 ± 2 °C, RH = 95–100%;

- Curing the specimens for the next 2 weeks under laboratory conditions, i.e., with: t = 20 ± 2 °C, RH = 40%.

3.5. Testing Procedures

3.5.1. Strength Parameters Testing

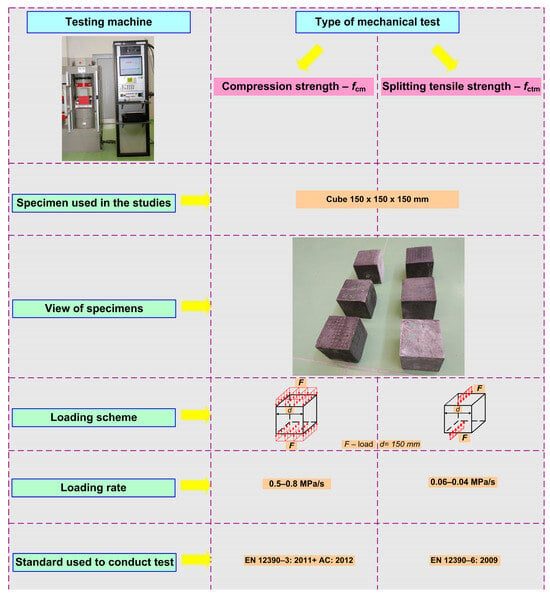

The testing of the main strength characteristics of the analyzed concretes, i.e., fcm–based on the standard EN 12390-3:2011+AC:2012 [117] and fctm–based on the standard EN 12390-6:2009 [118], was carried out on a Walter + Bai ag type NS19/PA1 testing machine with a maximum capacity of 3000 kN. The experiments were carried out under static loading. The flowchart for testing the mechanical parameters of concretes is illustrated in Figure 3.

Figure 3.

Flowchart for testing the mechanical parameters of concretes.

3.5.2. Effect of Aggregates Used on the Brittleness of Concretes

Nowadays, concrete structures should be made of materials that are both resistant and ensure durability and safety in the facilities used. Therefore, due to the fact that coarse aggregate occupies the most space in concrete, both in terms of weight and volume, it also has a decisive impact on an important parameter of the concrete composite related to its susceptibility to damage and durability, i.e., brittleness. In relation to the grains of coarse aggregate, the type of rock from which it was obtained is of decisive importance in this aspect [4,5,11,113]. In addition, the characteristics of fillers obtained from a given rock massif are also important [4,5,11,30,38,54,79,119]. The most important features of the rocks from which the aggregate is obtained and the properties of the aggregate grains that are important from the point of view of concrete brittleness are summarized comprehensively in Table 6.

Table 6.

The main properties of rock massifs and aggregates relevant to the brittleness of concrete.

The above features, collected in Table 6, directly relate to the characteristics of coarse aggregate grains and have a decisive impact on the process of destruction of the concrete composite. They have an influence on the geometries of cracking paths occurring in the material structure and their tortuosity between the grains of aggregates. They also decide to a large extent in which areas of the composite cracks will propagate [99,120,121]. Based on numerous previous studies, it has been shown that the destruction of concrete elements can occur in two ways, i.e., [99]:

- Almost exclusively by cracking paths through transition layers of aggregate and paste (ITZ)—in the case of less brittle concretes, and those containing aggregate grains with low strength parameters;

- Mainly through coarse aggregate grains and partly through ITZ—in the case of concretes with higher strength and greater brittleness, containing aggregates capable of creating durable bonds at the interface between aggregate grains and cement paste.

Therefore, this research not only thoroughly analyzes the strength parameters and fracture processes but also investigates how different types of coarse aggregates influence the brittleness of the concrete. The assessment of this parameter was made on the basis of the analysis of the percentage brittleness index (BI) for individual composites based on the results of the strength tests. This parameter for individual concretes has been determined from the Formula (1):

It should be noted here that the brittleness of concrete composites estimated in this way is an important material parameter both in relation to traditional mature concretes and concretes with a modified binder composition [122,123,124,125].

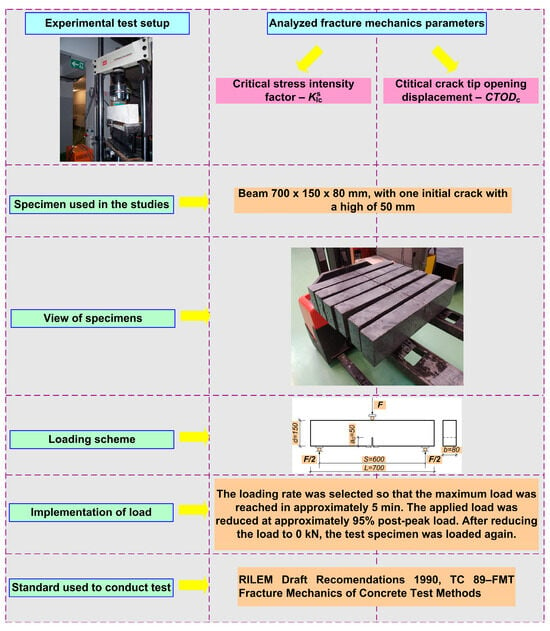

3.5.3. Fracture Toughness Examination

Experiments were carried out on the MTS 810 strength press. The research was carried out by successively loading and unloading the test beams until their destruction. Based on the conducted studies, and the provisions of the RILEM instruction [126], it was possible to calculate the analyzed fracture mechanics parameters, i.e., and CTODc [127,128]. A flowchart for assessing the fracture toughness of the concretes in question is presented in Figure 4.

Figure 4.

Flowchart for the evaluation of the fracture toughness of composites.

4. Findings and Their Analysis

4.1. Mechanical Properties

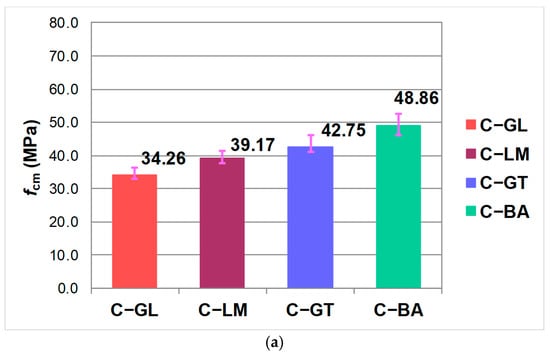

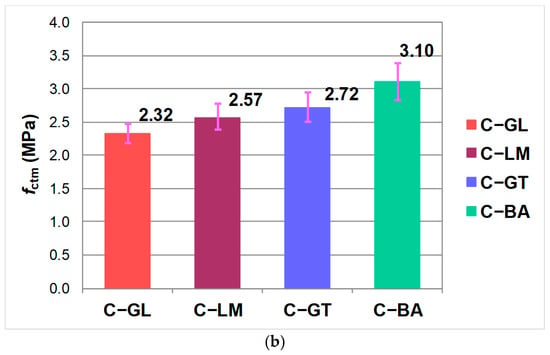

The average values of concrete strength parameters along with error bars for composites containing various types of coarse aggregates are shown in Figure 5.

Figure 5.

Strength parameters of tested concretes: (a) compressive strength, (b) splitting tensile strength.

Based on the graphs shown in Figure 5, it is clear that a change in the type of coarse aggregate used had a clear impact on the values of both strength parameters. What comes to the fore is a clear improvement in both fcm and fctm in the case of all concretes containing crushed stone aggregates, compared to concrete made of gravel aggregates. In addition, it should be stated that the upward trends for both analyzed strength parameters were closely convergent between the individual materials (Figure 5). It was also observed that the error bars in individual series of concretes were very similar in terms of deviation values. This, in turn, would suggest a fairly good convergence in the obtained experimental results (Figure 5).

Based on a detailed analysis of the results obtained, it should be concluded that particularly favorable strength parameters were obtained in the case of both concretes made of aggregates derived from igneous rocks, i.e., basalt and granite aggregates. The increases in both strength parameters in the case of C–BA and C–GT series concretes were approximately 40% and 20% higher compared to the values obtained for concrete made of the most commonly used gravel aggregate in construction, i.e., C–GL (43 and 25% in the case of fcm and 34% and 17% in the case of fctm, respectively).

It should be noted that an equally beneficial effect on the mechanical parameters of concrete composites made of aggregates derived from igneous rocks was observed in [5,6]. The results contained in those works showed clearly better results of compressive strength and elastic modulus obtained in the case of concretes with basalt and granite aggregate. Lower results in strength tests were obtained for concretes with dolomite, gravel, and quartz aggregates [4,5,28,33]. In turn, work [129] showed a clear improvement in the tensile strength of concrete when the natural gravel aggregate was replaced with crushed granite aggregate.

A slightly lower, although still quite clear increase in the value of strength parameters was recorded in the case of concrete made of limestone aggregate, i.e., C–LM. For this composite, the increases in both strength parameters oscillated at the level of only a dozen or so percent. Nevertheless, such results also seem to be very favorable compared to the values obtained in the case of C–GL series concrete (Figure 4) [55,96].

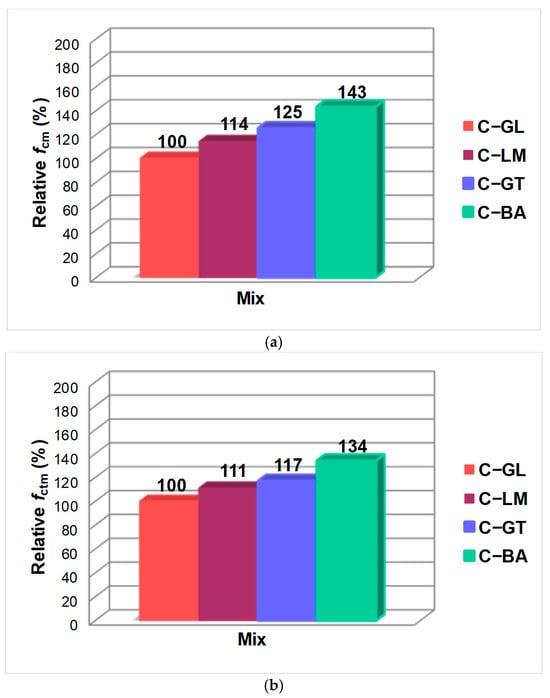

The reasons for such beneficial effects of the crushed aggregates used will be discussed in Section 5. However, in order to illustrate more clearly the progress in the obtained results of strength parameters, resulting from the replacement of the type of coarse aggregate used to make individual series of concretes, Figure 6 shows the relative percentage increments fcm and fctm for all tested composites. Changes in both strength parameters in the case of concretes made of crushed stone aggregates have been compared to the values obtained for gravel concrete commonly used in construction practices.

Figure 6.

Relative changes in analyzed mechanical parameters of concretes based on different types of aggregates: (a) compressive strength, (b) splitting tensile strength.

4.2. Brittleness of Composites

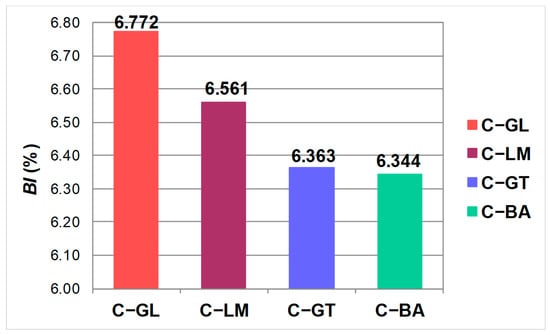

The results of brittleness indexes for individual concretes, the values of which depended on the type of coarse aggregate used, are summarized in Figure 7.

Figure 7.

Brittleness index (BI) of tested concretes.

According to predictions and previous literature reports [5,6,58,68], the lowest BI values, and thus the highest brittleness, were recorded in the case of concretes made of aggregates obtained from igneous rocks, i.e., basalt and granite. The brittleness of C–BA series concrete, amounting to 6.344, was the highest. However, the C–GT series concrete had only a slightly higher BI parameter value, equal to 6.363. Concrete made of limestone aggregate turned out to be a slightly less brittle material, with BI = 6.561 (Figure 7).

It should be noted however, that the mechanical parameters of fillers from carbonate rocks did not differ so much from the values of compressive strength or the elastic modulus obtained for igneous rock aggregates, e.g., granite aggregates (Table 1). However, the specific properties of limestone aggregates, which were described, e.g., in [123,124], meant that the concretes containing them behaved during destruction process as materials with intermediate characteristics between clearly brittle and quasi-plastic materials [80]. Concretes with these aggregates can therefore be classified as semi-brittle concrete.

The least brittle material of all four series was concrete with gravel aggregate. The grains of these fillers were characterized by the lowest strength indexes (Table 1). In addition, their rounded shape and smooth surface mean that they are usually poorly embedded in the concrete structure. They also tend to rotate in the cementitious matrix under the impact of the load. Sometimes, separation of grains that are weakly bonded to the composite matrix may also occur [130] (see Section 4.3.2).

The phenomenon of reduced brittleness in the case of concretes based on gravel aggregate has been observed, among others, in [89]. The results presented in this work showed that concrete with limestone aggregate was definitely more brittle than concrete with gravel aggregate [89].

In order to trace precisely the phenomena occurring during the destruction of the test elements, a macroscopic analysis of the beam fractures for each concrete series is presented in Section 4.3.2. The purpose of these visual inspections was to assess the fracture surface of the samples associated with the above assessment of the composites’ brittleness.

4.3. Fracture Toughness

4.3.1. Evaluation of Fracture Mechanics Parameters

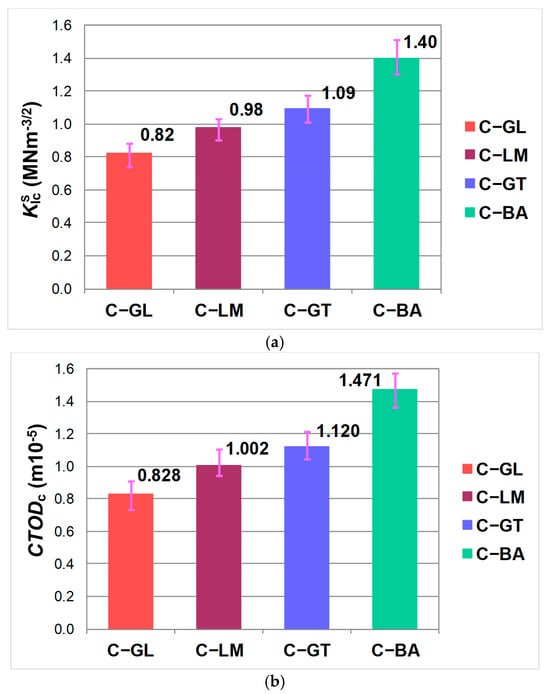

The average values with error bars of the analyzed fracture mechanics parameters in concrete composites containing different kinds of coarse aggregates are shown in Figure 8.

Figure 8.

The results of fracture mechanics parameters of the analyzed concretes with error bars: (a) , (b) CTODc.

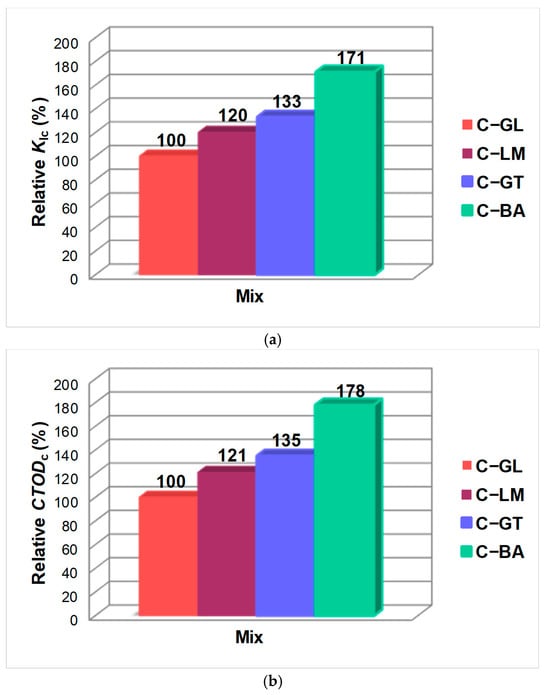

Based on the data presented in the above figures, it can be strongly concluded that, as in the case of strength parameters and with regard to the fracture toughness results, the effect of the coarse aggregate kind, as well as the type of rock massif from which it was extracted, is evident. Both of the analyzed fracture mechanics parameters, i.e., and CTODc, increased significantly in the case of concretes which were manufactured with crushed aggregates. They amounted, in comparison to concrete based on gravel aggregate, to levels ranging from 20% for concrete of the C–LM series, i.e., with limestone aggregate, to over 30% for concrete with a granite aggregate, i.e., C–GT series, and to as much as over 70% for concrete with basalt aggregate, i.e., C-BA series. What the exact relative percentage increases in and CTODc looked like for the tested composites with crushed aggregates are shown in detail in Figure 9.

Figure 9.

Relative changes in analyzed fracture mechanics parameters of concretes based on different type of aggregates: (a) , (b) CTODc.

4.3.2. Examination of Fracture Surfaces of Cracked Beams

The assessment of the basic parameters of fracture mechanics, both in linear and non-linear terms, showed a significant increase in the case of all series of concretes made of crushed stone aggregates. However, the level of increase in and CTODc indexes was significantly different for each of the three composites. This was certainly influenced by the specific properties of the types of rocks from which a given type of coarse aggregate was obtained.

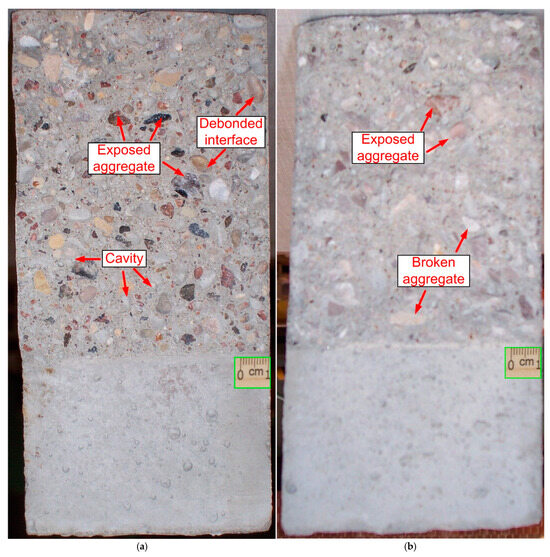

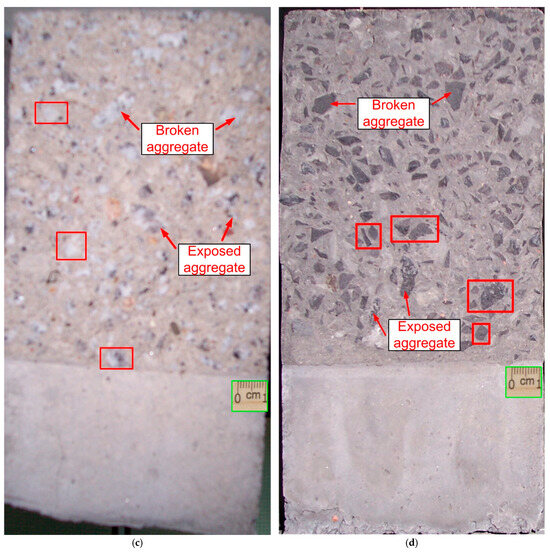

Therefore, in order to explain the existing differences, macroscopic analyses of the beam destruction surface were carried out. Figure 10 presents examples of characteristic fracture surfaces of samples after fracture toughness tests. In addition, all characteristic details observed in the coarse aggregate inclusion phase, which were directly related to the fracture processes of individual composites, have been marked and described on the cross-sections. Due to the analysis of the fracture surfaces in places where the initial cracks were modeled before the tests, it was possible to determine the exact causes of the formation and propagation of microcracks and the cracks in the structure of the materials. On this basis, an attempt was made to determine how the destruction process of individual composites looked like, and what the main factors that led to their final destruction were. In the course of the visual inspection of the fracture surface, the findings are as follows:

Figure 10.

Cross-section of analyzed concrete composites after fracture toughness test with indication of the details visible on the fracture surfaces: (a) C–GL, (b) C–LM, (c) C–GT, (d) C–BA; description in the text.

- For C–GL concrete—the fracture propagation process was typical for concrete made of smooth, non-reactive pebble aggregate. Macroscopically, cleavage fractures were observed in the matrix of this concrete. In addition, due to the low cohesion properties of gravel, implying weak bonds in the ITZ area, in the fracture process of this concrete, there was initially a partial loosening of the aggregate grains from the cement matrix. Then these grains were exposed. However, in places where the ITZ areas were the weakest, the complete separation of aggregate grains from the cement matrix was observed. Therefore, characteristic cavities were visible at points in the matrix structure. In the concrete of this series, cracks propagated mainly through the contact areas between the grains of coarse aggregate and the cement matrix, and through the matrix itself. (Figure 10a). Therefore, it should be concluded that the fracture process of this concrete corresponded to the quasi-plastic fracture pattern. This phenomenon therefore coincided with the high BI index of this material, indicating its low brittleness (Figure 7);

- For C–LM concrete—the fracture process was intermediate between brittle and quasi-plastic. Due to the fact that limestone aggregates are chemically reactive, they are able to create quite durable ITZ between the grains of aggregate and paste [81,130,131,132]. For this reason, not too many aggregates exposed or torn up from the matrix structure were observed in the concrete of this series. However, through-fractures appeared across the limestone grains, characteristic of the brittle destruction of concrete (Figure 10b). The places where cracked aggregate grains were observed are marked on the cross-section of limestone concrete, and on the cross-sections of other concretes in Figure 10 in red rectangles. Destruction of this composite was therefore the result of the propagation of fractures occurring both in the contact areas between the aggregate and paste grains, as well as propagating through the coarse aggregate grains (Figure 10b). C–LM series concrete was therefore clearly more brittle than the gravel concrete. This is also indicated by the results presented in Figure 7;

- For C–GT concrete—mainly cleavage fractures through granite aggregate grains were observed. Only in a few places were there still visible fractures at the contact areas of the aggregates with the cement matrix (Figure 10c). The high strength and rigidity of granite grains, and their rough surface allowed for the formation of good bonds in the composite structure. This resulted in practically no visible fractures in the matrix and a clearly brittle way of material destruction (Figure 7);

- For C-BA concrete—to an even greater extent than in C–GT series concrete, the destruction of samples was determined by the favorable features of aggregates obtained from igneous rocks. In the cross-sections of the beams, almost all the aggregate grains were cracked through. Due to the very high strength of basalt aggregates and their rough texture, they were well embedded in the matrix structure. Therefore, only a few exposed aggregate grains were observed in the concrete of this series (Figure 10d). A detailed visual inspection of the cross-sections of the samples after the fracture toughness tests, therefore clearly indicates the brittle mode of destruction of this composite (Figure 7).

5. Discussion of the Obtained Research Results

The type of coarse aggregate used, in addition to factors such as the aggregate’s grain size and its volumetric content, have a decisive impact on the fracture toughness of concrete and the characteristics of its fracture process. Therefore, this article attempts to determine the impact of four different types of coarse mineral aggregates as follows:

- Values of the basic parameters of fracture mechanics in linear and non-linear terms, i.e., and CTODc;

- Places of the first microcracks occurring in each material;

- The course of the development process of structural microcracks that determined the destruction of the concrete composite.

In addition, the impact of coarse aggregates used on the basic concrete strength parameters, i.e., fcm and fctm, was also examined, and the brittleness index was calculated for each material, i.e., BI. In order to characterize the impact of selected types of coarse aggregate on the analyzed processes in the most holistic approach, fillers significantly different from each other were used to make the concretes. Differences between the individual aggregates occurred in relation to the way in which they were formed, the rock massifs from which they were obtained, and the important feature from the point of view of fractures development in the concrete, i.e., the characteristics of the surface of their grains. What is important, all aggregates used had very close grain size distributions.

Aggregates with the following important features were used to make the concretes (Table 2):

- Natural gravel aggregate with a low strength of 34 MPa, and smooth and rounded grains;

- Crushed, chemically reactive limestone aggregate with a quite high strength of 100.2 MPa, and a rough grain surface;

- Crushed, not chemically reactive granite aggregate with a high strength of 115.8 MPa, and a rough grain surface;

- Crushed, not chemically reactive basalt aggregate with a very high strength of 142.5 MPa, and a rough grain surface.

Analyzing the obtained test results for mechanical parameters, one can see a clear improvement in all concretes made of crushed stone aggregates. In the case of all series of concretes, made both on limestone aggregate obtained from carbonate rocks and aggregates obtained from igneous rocks, i.e., granites and basalt, both the fracture mechanics parameters, and CTODc, as well as the strength parameters, fcm and fctm, were clearly higher than the values obtained for concrete with a gravel aggregate.

Moreover, based on the analysis of the relationships presented in Figure 9, a clear correlation of changes in the obtained results between the strength parameters and the fracture mechanics parameters can be seen. However, it is worth noting that the impact of the applied change in the structure of the material, consisting of the replacement of the gravel aggregate with crushed stone aggregates, was more clearly visible in the case of changes in the values of fracture mechanics parameters (Figure 6 and Figure 9).

The obtained results on mechanical parameters were rather expected, because as shown in previous works, both the shape of crushed stone aggregate grains, their texture, and the properties of the rocks from which they are obtained have a decidedly positive effect on improving the parameters of concretes [4,5,55,56,66,130,131]. However, the level of the beneficial effect resulting from the replacement of pebble aggregate with crushed stone aggregates varied depending on its type.

Based on the results shown in the graphs of relative changes in the analyzed parameters, it can be seen that the strength indexes have improved in the range from several percent for concrete with limestone aggregate to over 40% for concrete with basalt aggregate (Figure 5). However, in the case of fracture mechanics parameters, the benefits from the change in the type of coarse aggregate ranged from 20% for C–LM series concrete to over 70% for C–BA series concrete (Figure 9).

Such results confirm the theses and conclusions resulting from other previous studies. They showed that the applied material modification of concrete, and in particular the change in its basic component, i.e., the type of coarse aggregate, has a much more significant impact on the parameters of the fracture mechanics of the concrete. However, changes in the values of strength parameters as a result of such activities are noticeable to a lesser extent [34,81].

Differences in percentage changes between the strength parameters and the fracture mechanics parameters result from the fact that the change in the coarse aggregate used has a stronger impact on the process of damage and destruction of the concrete, and consequently, on the parameters describing this phenomenon.

Therefore, in order to correlate the values of fracture mechanics parameters with the process of development of fractures in the structure of materials, their brittleness has been assessed. Also, an inspection of the cross sections’ destruction of the concrete samples after the fracture toughness test has been performed. The analysis of the research material showed a strict dependence of the concrete brittleness index and the nature of the beam fracture on the type of coarse aggregate used to prepare the samples (Figure 10).

However, on the basis of macroscopic examination of the sample fractures, it was found that in the process of their destruction, three phenomena occurred as follows:

- Decohesion at the boundary of inclusion of aggregate grains and cement matrix—damage in the ITZ area;

- Cracking through aggregate grains;

- Cracking in the paste.

The phenomenon of decohesion in the ITZ area is dominated by the forces of cohesion between the aggregate and the paste. These forces are most often the result of the mechanical interlocking of paste particles with the rough surface of the aggregates. In addition, in the case of chemically reactive aggregates they can be strengthened with chemical reaction products, causing the formation of additional bonds in the ITZ rea (Figure 1).

In the cross-sections of concrete samples, the largest signs of decohesion were observed in C–GL series concrete. The contact areas of smooth gravel grains were clearly exposed, with clear damage in the ITZ areas. In addition, in the concrete of this series, damages in the cement matrix were also visible (Figure 10a).

Concrete of the C–LM series had much better cohesion at the boundary of paste and coarse aggregate. Damages in the ITZ area of this material were visible to a lesser extent than in the case of gravel concrete. In the structure of this material, through-fractures across the grains appeared in a small number (Figure 10b). The compactness of the material in the ITZ area of these concretes was the result of both the rough surface of the limestone aggregates and the presence of chemical reaction products of the aggregate with the paste, as well as the presence of epitaxial crystals on the grain surface of these fillers.

However, in the case of both series of concretes made of aggregates derived from igneous rocks characterized by high strength parameters, i.e., C–GT and C–BA, the process of samples destruction was mainly the result of damage occurring through the grains of the coarse aggregate. This way of destruction proves the high brittleness of both concretes (Figure 6) and the high level of cohesion in the ITZ area of these materials. However, the cohesion between the grains of granite and basalt aggregates with the paste was mainly the result of the favorable properties of these aggregates, and their rough texture. The rough lamellar surface of basalt and granite aggregates clearly improved the properties of the ITZ area and increased the fracture toughness of concretes with these aggregates. It should be noted that due to the very beneficial properties of aggregates derived from igneous rocks, they are often used as a filler in high-performance and ultra-high-performance concretes [79,122], and road concretes [100,101,102,103,132].

In order to determine the exact reasons for the fracture toughness results obtained, an additional in-depth structural evaluation of all concretes was carried out after the experiments. Based on the comprehensive analyses of the failure surfaces of each of the analyzed materials (Figure 10) in conjunction with their fracture mechanics parameters (Figure 8), an attempt was made to determine which characteristic features of each aggregate had a decisive influence on the obtained test results.

On this basis, it was found that the high values of both and CTODc were determined in the case of basalt concretes by the strength of the aggregate itself and the “lamellar” shape of the basalt grains, which behaved like wedges in the process of material failure (Figure 10d). These aggregates worked similarly to dowels in concrete structures in the process of force transmission in the concrete structure. Therefore, they could further reduce the spreading forces present in the material structure. This is evidenced by the observation of basalt grains very well bonded to the structure of the cement matrix (Figure 10d). Thanks to these characteristics, basalt aggregates clearly delayed the fracture processes of C–BA series concrete, resulting in its best fracture toughness (Figure 8).

The characteristics of the granite aggregates, such as their high strength and varied surface, had a similar effect on the fairly high fracture toughness of the C–GT series concrete. This implied the formation of compact interfaces in the ITZ area between granite grains and the paste, as observed in Figure 10c. Consequently, this resulted in a clear improvement in the fracture toughness of this concrete (Figure 8).

On the other hand, decidedly different characteristics of the aggregates determined the fracture toughness of the C–LM series concrete. In addition to the well-developed and varied grain surface of these aggregates (Figure 10b), the chemical reactivity of the limestones and their unique and specific epitaxial features (Figure 8) influenced the rather high values of the fracture mechanics parameters of this material.

In contrast, the low fracture toughness of the C–GL series of concrete was the result of the poorly developed and unshaped surface of the spherical gravel grains. Aggregates of this type, additionally characterized by low mechanic parameters (Table 3), were not able to form sufficiently strong interfaces in the ITZ area between gravel grains and the paste. This resulted in the formation of decohesion cracks in this area of the concrete, as shown in Figure 10a. The consequence was a marked decrease in the fracture toughness of this material in both linear and non-linear terms (Figure 8).

A summary of the data including the results of the tests of fracture mechanics parameters and the assessment of fracture processes of concretes made of aggregates from various types of rocks is presented in Table 7.

Table 7.

Characterization of concretes based on aggregates extracted from various rocks in regard to the study of their fracture toughness and fracture processes.

6. Conclusions

In the present study, an attempt has been made to analyze the effect of the type of coarse aggregate extracted from various rocks on fracture mechanics parameters of ordinary concrete, its brittleness, and the nature of crack propagation in the material structure, and the following conclusions are drawn:

- (1)

- Basalt concrete has exhibited the highest strength and fracture toughness among all types. It is followed by granite, limestone, and gravel concrete;

- (2)

- Due to the high strength of the rock material, the rough surface of the aggregate grains and good bonding in the ITZ area between the aggregate and the paste, the concretes with crushed aggregates exhibited high fracture toughness. On the other hand, the concrete with the gravel aggregate showed the lowest fracture toughness because of the smooth surface of the aggregate grains and poor bonding between the aggregate and the cement paste;

- (3)

- The high fracture toughness of concretes with limestone aggregates was due to the presence of a compact ITZ formed by the rough surface of the aggregates, the presence of chemical reaction products of the aggregate with the paste, and the presence of epitaxial crystals on the grain surface of these fillers;

- (4)

- The very high fracture toughness of concretes with aggregates from igneous rocks was related to the high strength and stiffness of the rock material of these fillers and the rough lamellar surface of granite and basalt grains;

- (5)

- A clear correlation in the changes in the obtained results between the main strength parameters and fracture mechanics parameters was observed;

- (6)

- The most brittle concretes were those made of aggregates derived from magmatic rocks, i.e., granite and basalt, while the least brittle were gravel concretes;

- (7)

- The fracture process in each series of concrete was as follows:

- Quasi-plastic in the case of the C–GL series of concrete;

- Semi-brittle in the case of the C–LM series of concrete;

- Clearly brittle in the case of the C–GT and C–BA series of concrete.

- (8)

- The predominant deteriorations leading to material failure in each series of concrete were as follows:

- Decohesion in the ITZ area and matrix cracking in the case of the C–GL series of concrete;

- Decohesion in the ITZ area and cracking across the aggregate in the case of the C–LM series of concrete;

- Cracking across the aggregate in the case of the C–GT and C–BA series of concrete.

Funding

This work was financially supported by the Ministry of Education and Science of the Republic of Poland within the statutory research numbers: FD-20/IL-4/017.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The author declares no conflict of interest.

References

- Phuyal, K.; Sharma, U.; Mahar, J.; Mondal, K.; Mashal, M. A Sustainable and Environmentally Friendly Concrete for Structural Applications. Sustainability 2023, 15, 14694. [Google Scholar] [CrossRef]

- Udeze, O.J.; Mohammed, B.S.; Adebanjo, A.U.; Abdulkadir, I. Optimizing an Eco-friendly High-density Concrete for Offshore Applications: A study on Fly Ash Partial Replacement and Graphene Oxide Nano Reinforcement. C Stud. Chem. Environ. Eng. 2024, 9, 100592. [Google Scholar] [CrossRef]

- Ogah, O. Comparison of Some Strength Properties of Concrete Made from Reclaimed Aggregates and Crushed Granite Aggregate. Int. J. Eng. Sci. 2014, 3, 1–6. [Google Scholar]

- Piasta, W.; Budzyński, W.; Góra, J. Properties of Coarse Mineral Aggregates Against Properties of Concrete. Arch. Civ. Eng. Environ. 2018, 3, 97–105. [Google Scholar] [CrossRef]

- Góra, J.; Piasta, W. Test Results of the Modulus of Elasticity of Concretes with Various Coarse Aggregates and Standard Recommendations. Adv. Sci. Technol. Res. J. 2022, 16, 232–243. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Pearson Education Limited: Essex, UK, 2011. [Google Scholar]

- Van Mier, J.G.M. Fracture Processes of Concrete: Assessment of Material Parameters for Fracture Models; CRC Press: Boca Raton, FL, USA; New York, NY, USA; Londyn, UK; Tokyo, Japan, 2000. [Google Scholar]

- Bostanci, S.C.; Ajogi, E.I.; Kew, H. Waste Coal Cement Concrete for Sustainable Production. Eur. J. Environ. Civ. Eng. 2024, 28, 197–221. [Google Scholar] [CrossRef]

- Golewski, G.L. The Specificity of Shaping and Execution of Monolithic Pocket Foundations (PF) in Hall Buildings. Buildings 2022, 12, 192. [Google Scholar] [CrossRef]

- Karasin, A.; Hadzima-Nyarko, M.; Işık, E.; Doğruyol, M.; Karasin, I.B.; Czarnecki, S. The Effect of Basalt Aggregates and Mineral Admixtures on the Mechanical Properties of Concrete Exposed to Sulphate Attacks. Materials 2022, 15, 1581. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Y.; Xu, B. Effect of Coarse Aggregate Size Distribution on Fracture Toughness of Concrete Based on Boundary Effect Model. Theor. Appl. Fract. Mech. 2021, 113, 102970. [Google Scholar] [CrossRef]

- Xie, T.; Yang, G.; Zhao, X.; Xu, J.; Fang, C. A Unified Model for Predicting the Compressive Strength of Recycled Aggregate Concrete Containing Supplementary Cementitious Materials. J. Clean. Prod. 2020, 251, 119752. [Google Scholar] [CrossRef]

- Perfilov, V.A. Effects of Various Factors on Concrete Strength and Crack Resistance. J. Phys. Conf. Ser. 2021, 1967, 012056. [Google Scholar] [CrossRef]

- Seitl, S.; Miarka, P.; Bilek, V. Fatigue and Fracture Mechanical Properties of Selected Concrete for Subtle Precast Structural Elements. MATEC WoC 2020, 310, 00033. [Google Scholar] [CrossRef][Green Version]

- Golewski, G.; Sadowski, T. Fracture Toughness at Shear (Mode II) of Concretes Made of Natural and Broken Aggregates. Brittle Matrix Compos. 2006, 8, 537–546. [Google Scholar]

- Quayson, J.H.; Mustapha, Z. Impact of Coarse Aggregate on Compressive Strength of Concreter. Built Environ. J. 2019, 16, 49–58. [Google Scholar] [CrossRef]

- Zhang, P.; Han, S.; Golewski, G.L.; Wang, X. Nanoparticle-reinforced building materials with applications in civil engineering. Adv. Mech. Eng. 2020, 12, 1–4. [Google Scholar] [CrossRef]

- Malathy, R.; Rajagopal Sentilkumar, S.R.; Prakash, A.R.; Das, B.B.; Chung, I.-M.; Kim, S.-H.; Prabakaran, M. Use of Industrial Silica Sand as a Fine Aggregate in Concrete—An Explorative Study. Buildings 2022, 12, 1273. [Google Scholar] [CrossRef]

- Golewski, G.L. Studies of Natural Radioactivity of Concrete with Siliceous Fly Ash Addition. Cem. Wapno Beton 2015, 2, 106–114. [Google Scholar]

- Canul, J.A.; Moreno, E.I.; Mendoza-Rangel, J.M. Fly Ash Effect on Mechanical Properties of Concretes Made with High Absorbent Crushed Limestone Aggregates. ALCONPAT J. 2016, 6, 235–247. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Effect of Nano Admixture of CSH on Selected Strength Parameters of Concrete Including Fly Ash. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012105. [Google Scholar] [CrossRef]

- Lomboy, G.R.; Bektas, F.; Wang, K. Extended Use of Limestone Fines in Various Concretes. J. Civ. Eng. Arch. 2016, 10, 995–1005. [Google Scholar]

- Lewicka, E.; Szlugaj, J.; Burkowicz, A.; Galos, K. Sources and Markets of Limestone Flour in Poland. Resources 2020, 9, 118. [Google Scholar] [CrossRef]

- Xin, C.; Yang, Y.; Yang, M.; Di, J.; Sun, Y.; Liang, P.; Wang, Y. Multi-Scale Analysis of the Damage Evolution of Coal Gangue Coarse Aggregate Concrete after Freeze–Thaw Cycle Based on CT Technology. Materials 2024, 17, 975. [Google Scholar] [CrossRef] [PubMed]

- Gil, D.M.; Golewski, G.L. Effect of silica fume and siliceous fly ash addition on the fracture toughness of plain concrete in mode I. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012065. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, D.; Yu, X.; Liu, R.; Liao, Y. Properties of Cementitious Materials Utilizing Seashells as Aggregate or Cement: Prospects and Challenges. Materials 2024, 17, 1222. [Google Scholar] [CrossRef]

- Gupta, M.; Raj, R.; Kumar Sahu, A. Mechanical properties of high strength concrete incorporating chopped basalt fibers: Experimental and analytical study. Mater. Res. Express 2022, 9, 125305. [Google Scholar] [CrossRef]

- Prokopski, G.; Halbiniak, J.; Langier, B. The Examination of the Fracture Toughness of Concretes with Diverse Structure. J. Mater. Sci. 1998, 33, 1819–1825. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. A Study on Mode III Fracture Toughness in Young and Mature Concrete with Fly Ash Additive. Sol. State. Phenom. 2016, 254, 120–125. [Google Scholar] [CrossRef]

- Guo, L.; Wu, Z.; Zhong, L.; Luo, Y. Effect of Aggregate Characteristics on Properties of Cemented Sand and Gravel. Sci. Eng. Compos. Mater. 2023, 30, 202220220. [Google Scholar] [CrossRef]

- Li, J.; Wang, B.; Zhang, P.; Wang, Z.; Wang, M. Parametric Study on Mechanical Properties of Basalt Fiber-Reinforced Pea Gravel Concrete. Buildings 2024, 14, 380. [Google Scholar] [CrossRef]

- Golewski, G.L. Examination of water absorption of low volume fly ash concrete (LVFAC) under water immersion condition. Mater. Res. Express 2023, 10, 085505. [Google Scholar] [CrossRef]

- Prokopski, G. Effect of Coarse Aggrregate Quantity on Fracture Toughness of Concretes. J. Mater. Sci. 1993, 28, 5717–5721. [Google Scholar] [CrossRef]

- Hordijk, D.A.; Wolsink, G.M.; de Vries, J. Fracture and Fatigue Behaviour of a High Strength Limestone Concrete as a Compared to Gravel Concrete. Heron 1995, 40, 125–146. [Google Scholar]

- Marques, A.S.; Amaral, P.M.; Rosa, L.G.; Fernandes, J.C. Study of Aggregate Size Effect on Fracture Toughness of Petreous Macrocomposites (Concrete). Mater. Sci. Forum 2010, 636–637, 1342–1348. [Google Scholar] [CrossRef]

- Amran, M.; Onaizi, A.M.; Qader, D.N.; Murali, G. Innovative use of fly ash-finely powdered glass cullet as a nano additives for a sustainable concrete: Strength and microstructure and cost analysis. C. Stud. Constr. Mater. 2022, 17, e01688. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Hu, K.; Qian, G.; Gong, X.; Yu, H. Preparation Method and Applicability Evaluation of 3D Printing Alumina Ceramic Artificial Coarse Aggregate. Mater. Res. Express 2024, 11, 055506. [Google Scholar] [CrossRef]

- Konkol, J.; Prokopski, G. The Effect of Concrete Mix Composition on the Character of Fractures of Set Concrete. J. Geogr. Geol. 2014, 6, 29–41. [Google Scholar] [CrossRef]

- Craciun, E.M. Energy Criteria for Crack Propagation in Prestresses Elastic Composites. Sol. Mech. Appl. 2008, 154, 193–237. [Google Scholar]

- Wardach, M.; Krentowski, J.R.; Mackiewicz, M. Evaluation of Precast Beam Deflections Resulting in Cracks in Curtain Walls. Eng. Fail. Anal. 2022, 140, 106568. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Gao, Z.; Wang, F. A Review on Fracture Properties of Steel Fiber Reinforced Concrete. J. Build. Eng. 2023, 67, 105975. [Google Scholar] [CrossRef]

- Akram, A. The Overview of Fracture Mechanics Models for Concrete. Arch. Civ. Eng. Environ. 2021, 1, 376–385. [Google Scholar] [CrossRef]

- Golewski, G.L. An analysis of Fracture Toughness in Concrete with Fly Ash Addition, Considering All Models of Cracking. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012029. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Al-Lami, K.; Vatin, N.I.; Dixit, S.; Fediuk, R. Pure and mixed-mode (I/III) fracture toughness of preplaced aggregate fibrous concrete and slurry infiltrated fibre concrete and hybrid combination comprising nano carbon tubes. Constr. Build. Mater. 2023, 362, 129696. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, P.; Golewski, G.L.; Guan, J. Editorial: Fabrication and properties of concrete containing industrial waste. Front. Mater. 2023, 10, 1169715. [Google Scholar] [CrossRef]

- Zhang, N.; Hedayat, A.; Han, S.; Ma, S.; Bolanos Sosa, H.G.; Huamani Bernal, R.P.; Tupa, N.; Morales, I.Y.; Canahua Loza, R.S. Fracture properties of tailings-based geopolymer incorporated with class F fly ash under mode I loading conditions. Eng. Fract. Mech. 2022, 271, 108646. [Google Scholar] [CrossRef]

- Xiao, M.; Xi, J.; Qiu, P.; Deng, C.; Li, F.; Wei, J.; Gao, P.; Yu, Q. Evaluation of tensile properties and cracking potential evolution of fly ash-cement mortar at early age based on digital image correlation method. Constr. Build. Mater. 2024, 412, 134855. [Google Scholar] [CrossRef]

- Zhang, P.; Yuan, P.; Guan, J.; Guo, J. Fracture Behavior of Multi-Scale Nano-SiO2 and Polyvinyl Alcohol Fiber Reinforced Cementitious Composites under the Complex Environments. Theor. Appl. Fract. Mech. 2022, 122, 103584. [Google Scholar] [CrossRef]

- Golewski, G.L. Investigating the effect of using three pozzolans (including the nanoadditive) in combination on the formation and development of cracks in concretes using non-contact measurement method. Adv. Nano Res. 2024, 16, 217–229. [Google Scholar]

- Mehri Khansari, N.; Fakoor, M.; Berto, F. Probabilistic micromechanical damage model for mixed mode I/II fracture investigation of composite materials. Theor. Appl. Fract. Mech. 2019, 99, 177–193. [Google Scholar] [CrossRef]

- Gil, D.M.; Golewski, G.L. Potential of siliceous fly ash and silica fume as a substitute of binder in cementitious concrete. E3S Web Conf. 2018, 49, 00030. [Google Scholar] [CrossRef]

- Oluwasola, E.A.; Afolayan, A.; Ipindola, O.O.; Popoola, M.O.; Oginni, A.O. Effect of aggregate Shapes on the Properties of Concrete. LAUTECH J. Civ. Environ. Stud. 2020, 5, 1–10. [Google Scholar] [CrossRef]

- Golewski, G.L. Assessing of water absorption on concrete composites containing fly ash up to 30% in regards to structures completely immersed in water. C. Stud. Constr. Mater. 2023, 19, e02337. [Google Scholar] [CrossRef]

- Siregar, P.N.; Pasaribu, E.L.; Suarnita, W. The Effect of Coarse Aggregate Hardness on the fracture Toughness. MATEC WoC 2019, 258, 04011. [Google Scholar]

- Carlos, A.; Masumi, I.; Hiroaki, M.; Maki, M.; Takahisa, O. The Effects of Limestone Aggregate on Concrete Properties. Constr. Build. Mater. 2010, 24, 2363–2368. [Google Scholar]

- Bochenek, A.; Prokopski, G. The Investigation of Aggregate Grain Size Effect on Fracture Toughness of Ordinary Concrete Structures. Int. J. Fract. 1989, 41, 197–205. [Google Scholar] [CrossRef]

- Teye Buertey, J.I.; Offei, S.W.; Kumi, T.A.; Atsrim, F. Effect of Aggregates Minerology on the Strength of Concrete: Case Study of Three Selected Quarry Products in Ghana. J. Civ. Eng. Constr. Technol. 2018, 9, 1–10. [Google Scholar]

- Saini, S.; Bharadwaj, A.; Agnihotri, A.; Pastariya, S. Effect of Geological Characteristics of Coarse Aggregate on Properties of Concrete. Int. J. Res. Publ. Rev. 2023, 4, 2390–2395. [Google Scholar]

- Golewski, G.L. Study of strength and microstructure of a new sustainable concrete incorporating pozzolanic materials. Struct. Eng. Mech. 2023, 86, 431–441. [Google Scholar]

- Babangida, B.; Abdullahi, S.Y.; Gizaki, B.Y.; Sulaiman, M. Effects of aggregate size on concrete strength. Int. J. Environ. Des. Constr. Manag. 2021, 24, 306–319. [Google Scholar]

- Choi, H.-B.; Park, J.-O. Study on Mechanical Properties of Concrete Using Basalt-Based Recycled Aggregate and Varying Curing Conditions. Materials 2022, 15, 4563. [Google Scholar] [CrossRef]

- Fan, C.; Zheng, Y.; Zhuo, J.; Du, C.; Hu, S. Study on mechanical and bonding properties of nano-SiO2 reinforced recycled concrete: Macro test and micro analysis. J. Build. Eng. 2024, 94, 109877. [Google Scholar] [CrossRef]

- Thukkaram, S.; Kumar, A.A. Behaviour of sewage sludge based lightweight aggregate in geopolymer concrete. Mater. Res. Express 2024, 11, 055501. [Google Scholar] [CrossRef]

- Golewski, G.L. The role of pozzolanic activity of siliceous fly ash in the formation of the structure of sustainable cementitious composites. Sustain. Chem. 2022, 3, 520–534. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Turkiewicz, T.; Góra, J.; Piasta, W. The effect of igneous rock aggregates on flexural and compressive strength of concrete. Struct. Environ. 2013, 5, 12–18. [Google Scholar]

- Golewski, G.L. A new principles for implementation and operation of foundations for machines: A review of recent advances. Struct. Eng. Mech. 2019, 71, 317–327. [Google Scholar]

- Soroushian, P.; Elzafraney, M. Damage effects on concrete performance and microstructure. Cem. Concr. Compos. 2004, 26, 853–859. [Google Scholar] [CrossRef]

- Soroushian, P.; Elzafraney, M. Morphological operations, planar mathematical formulations, and stereogical interpretations for automatem imane analysis of concrete microstructure. Cem. Concr. Compos. 2005, 27, 823–833. [Google Scholar] [CrossRef]

- Reddy, S.M.; Krishna, G.R.; Ramakrishna, B. Rupture Probability of Type of Coarse Aggregate on Fracture Surface of Concrete. Int. Res. J. Eng. Technol. (IRJET) 2017, 274, 1985–1990. [Google Scholar]

- Díaz-Rodríguez, J.G.; Pertúz-Comas, A.D.; Bohórquez-Becerra, O.R.; Braga, A.M.B.; Prada-Parra, D. Plastic Zone Radius Criteria for Crack Propagation Angle Evaluated with Experimentally Obtained Displacement Fields. Buildings 2024, 14, 495. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. Experimental Investigation and Numerical Modelling Fracture Processes in Fly Ash Concrete at Early Age. Sol. State Phenom. 2012, 188, 158–163. [Google Scholar] [CrossRef]

- Ren, Q.; Pacheco, J.; de Brito, J.; Hu, J. Analysis of the influence of the attached mortar’s geometry on the mechanical behaviour of recycled aggregate concrete through mesoscale modeling. Eng. Fract. Mech. 2024, 297, 109876. [Google Scholar] [CrossRef]

- Echeta, C.B.; Ikponmwosa, E.E.; Fadipe, A.O. Effect of Partial Replacement of Granite with Washed Gravel on the Characteristic Strength and Workability of Concrete. ARPN J. Eng. Appl. Sci. 2013, 8, 954–959. [Google Scholar]

- Sun, Z.; Xiong, J.; Cao, S.; Zhu, J.; Jia, X.; Hu, Z.; Liu, K. Effect of Different Fine Aggregate Characteristics on Fracture Toughness and Microstructure of Sand Concrete. Materials 2023, 16, 2080. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Chen, X.; Guo, S. Evaluation of Fracture Process Zone in the Flexural Response of Different Concrete Materials Using DIC Method. KSCE J. Civ. Eng. 2020, 24, 2435–2448. [Google Scholar] [CrossRef]

- Odeyemi, S.O. Mechanical Properties of Granite-Gravel Porous Concrete. Int. J. Eng. Res. Affrica 2020, 57, 115–123. [Google Scholar] [CrossRef]

- Szcześniak, A.; Siwiński, J.; Stolarski, A. Effect of Aggregate Type on Properties of Ultra-High-Strength Concrete. Materials 2022, 15, 5072. [Google Scholar] [CrossRef]

- Ioannou, I.; Petrou, M.F.; Fournari, R.; Andreou, A.; Hadjigeorgiou, C.; Tsikouras, B.; Hatzipanagiotou, K.J.G.S. Crushed Limestone as an Aggregate in Concrete Production: The Cyprus Case. Int. J. Eng. Res. Affrica Geol. Soc. London Spec. Publ. 2010, 331, 127–135. [Google Scholar] [CrossRef]

- Alanazi, H. Effect of Aggregate Types on the Mechanical Properties of Traditional Concrete and Geopolymer Concrete. Crystals 2021, 11, 1110. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of coarse aggregate graiding on mechanical parameters and fracture toughness of limestone concrete. Infrastructures 2023, 8, 117. [Google Scholar] [CrossRef]

- Chajec, A. Granite powder vs. fly ash for the sustainable production of air-cured cementitious mortars. Materials 2021, 14, 1208. [Google Scholar]

- Raghavendra, R.; Sharada, S.A.; Narayana, G. Flexural Strength of High Performance Concrete Using Granite Powder as Fine Aggregate. Int. Res. J. Eng. Technol. (IRJET) 2015, 4, 43–46. [Google Scholar]

- Qi, J.; Jiang, L.; Zhu, M.; Mu, C.; Li, R. Experimental Study on the Effect of Limestone Powder Content on the Dynamic and Static Mechanical Properties of Seawater Coral Aggregate Concrete (SCAC). Materials 2023, 16, 3381. [Google Scholar] [CrossRef] [PubMed]

- Aginam, C.H.; Chidolue, C.A.; Nwakire, C. Investigating the Effects of Coarse Aggregate Types on the Compressive Strength of Concrete. Int. J. Eng. Res. Appl. 2013, 3, 1140–1144. [Google Scholar]

- Casimir, G. Effects of Dimensions of Basalt Aggregates on Concrete Properties. Case of Crushed Stone and Sand from the Menchum River in North-West Cameroon. Eur. J. Appl. Sci. 2022, 10, 629–642. [Google Scholar]

- Abdullahi, M. Effect of Aggregate Type on Compressive Strength of Concrete. Int. J. Civ. Struct. Eng. 2012, 2, 791–800. [Google Scholar] [CrossRef]

- Bhavya, K.; Sanjeev, N. Effect of Different Types of Coarse Aggregates on Physical Properties of Mostly used Grades M20, M25, M30 of Concrete. IOSR J. Mech. Civ. Eng. 2017, 14, 46–51. [Google Scholar] [CrossRef]

- Kalra, M.; Mehmood, G. A Review Paper on the Effect of Different Types of Coarse Aggregate on Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 431, 082001. [Google Scholar] [CrossRef]

- Kabir, N.; Aliyu, S.; Nasara, M.A.; Chinade, A.U.; Shehu, A. Characteristics of Different Type of Coarse Aggregate on Properties of High Performance Concrete. Sust. Struct. Mater. 2019, 2, 88–96. [Google Scholar]

- Petersoon, P.E. Fracture Energy of Concrete: Method of Determination. Cem. Concr. Res. 1980, 10, 78–89. [Google Scholar] [CrossRef]

- Nallathambi, P.; Karihaloo, B.L.; Heaton, B.S. Various Size Effects in Fracture of Concrete. Cem. Concr. Res. 1985, 15, 117–126. [Google Scholar] [CrossRef]

- Siva Murthy Reddy, S.; Ramakrishna, B. Fracture and Strength Studies on Concrete with Different Types of Coarse Aggregates. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 2120–2136. [Google Scholar]

- Sengul, O.; Sengul, C.; Keskin, G.; Akkaya, Y.; Tasdemir, C.; Tasdemir, M.A. Fracture and Microstructural Studies of Normal and High Strength Concretes with Different Types of Coarse Aggregates. In Proceedings of the VIII International Conference on Fracture Mechanics of Concrete and Concrete Structures, FraMCoS-8, Toledo, Spain, 11–14 March 2013. [Google Scholar]

- Fernandes, J.C.; Pires, V.; Amaral, P.M.; Rosa, L.G. Analysis of Strength Scaling Effect in Portuguese Limestone:Comparison between Three- and Four-point Bending Tests. Mater. Sci. For. 2010, 636–637, 1336–1341. [Google Scholar]

- Ismail, A.I.M.; Elmaghraby, M.S. Effect of Limestone Composition and Microstructure on the Strength of Aggregates and Concretes. Interceram.—Int. Ceram. Rev. 2015, 64, 28–32. [Google Scholar] [CrossRef]

- Prokopski, G.; Halbiniak, J. Interfacial Transition Zone in Cementitious Materials. Cem. Concr. Res. 2000, 30, 579–583. [Google Scholar] [CrossRef]

- Prokopski, G.; Langier, B. Effect of Water/Cement Ratio and Silica Fume Addition on the Fracture Toughness and Morphology of Fractured Surfaces of Gravel Concretes. Cem. Concr. Res. 2000, 30, 1427–1433. [Google Scholar] [CrossRef]

- Tasdemir, C.; Tasdemir, M.A.; Lydon, F.D.; Barr, B.I.G. Effects of silica fume and Aggregate Size on the Brittleness of Concrete. Cem. Concr. Res. 1996, 26, 63–68. [Google Scholar] [CrossRef]

- Gangnant, A.; Saliba, J.; Christian La Borderie, C.; Morel, S. Modeling of the Quasibrittle Fracture of Concrete at Meso-scale: Effect of Classes of Aggregates on Global and Local Behavior. Cem. Concr. Res. 2016, 89, 35–44. [Google Scholar] [CrossRef]

- Golewski, G.L. Determination of Fracture Mechanic Parameters of Concretes Based on Cement Matrix Enhanced by Fly Ash and Nano-Silica. Materials 2024, 17, 4230. [Google Scholar] [CrossRef]

- Rao, K.B.; Desai, V.B.; Mohan, D.J. Probabilistic Analysis of Mode II fracture of Concrete with Crushed Granite Stone Fine Aggregate Replacing Sand. Constr. Build. Mater. 2012, 27, 319–330. [Google Scholar]

- Kanchi Balaji Raoa, k.b.; Desaib, v.b.; Mohan, D.J. Experimental Investigations on Mode II Fracture of Concrete with Crushed Granite Stone Fine Aggregate Replacing Sand. Mater. Res. 2012, 15, 41–50. [Google Scholar]

- Li, G.; Ren, Z.; Yu, J. Mixed-Mode I-II Fracture Process Zone Characteristic of the Four-Point Shearing Concrete Beam. Materials 2020, 13, 3203. [Google Scholar] [CrossRef]