The Efficiency of the Benefits of Tire-Derived Aggregate Backfill for Buried Concrete Pipes Beneath Paved and Unpaved Roads

Abstract

1. Introduction

- (1)

- To develop a three-dimensional finite element (3D FE) model that is able to accurately calculate the pipe wall bending moment.

- (2)

- To examine the efficiency of TDA for different pipe diameters and burial depths.

- (3)

- To compare the efficiency of TDA for both paved and unpaved roads.

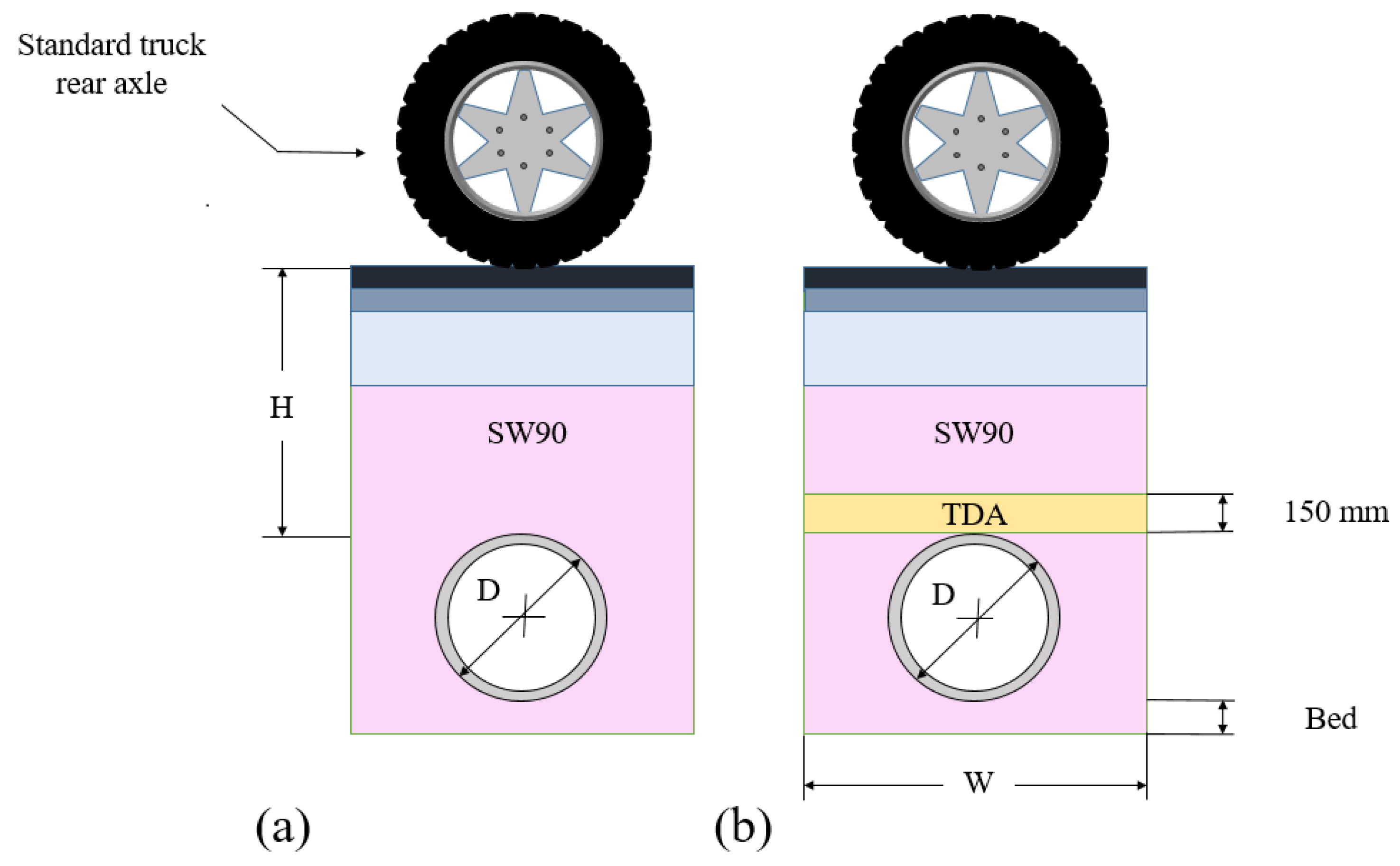

2. Statement of the Problem

3. Methodology

3.1. Constitutive Models

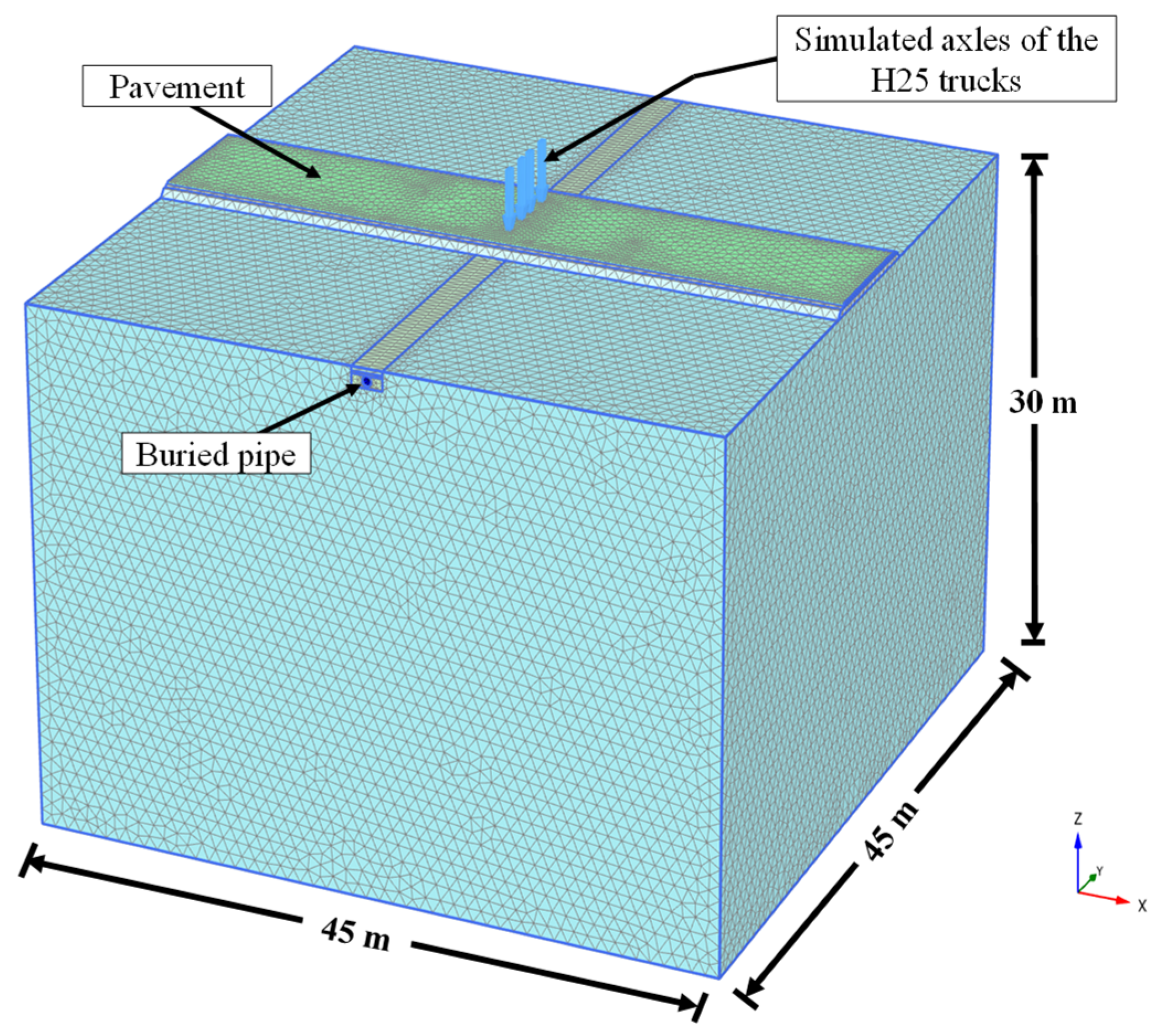

3.2. The Numerical Model

- -

- The first step involved modeling the in situ (geostatic stress) stresses of the soil. The vertical stresses in this step were calculated using the unit weight and the depth of the soil, while the horizontal stresses were calculated using the Jackey equation.

- -

- The second step simulated the excavation of the trench.

- -

- The third step simulated pipe installation.

- -

- The fourth step simulated the backfilling of the soil.

- -

- The fifth step involved the construction of the road embankment and surface layer.

- -

- The sixth step involved the application of the rear axle loads of the two H25 trucks.

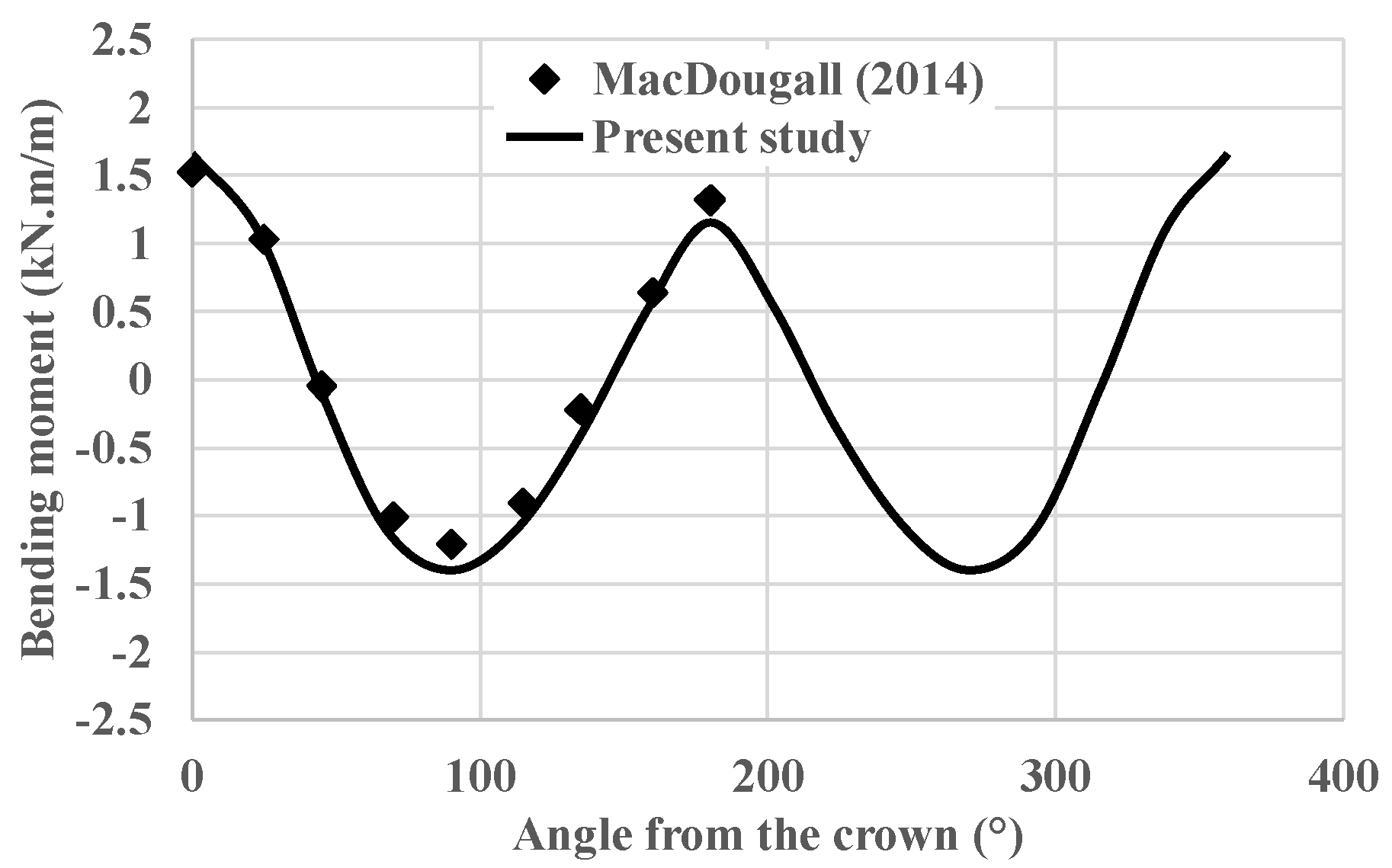

3.3. Validation of the FE Model

4. Parametric Study

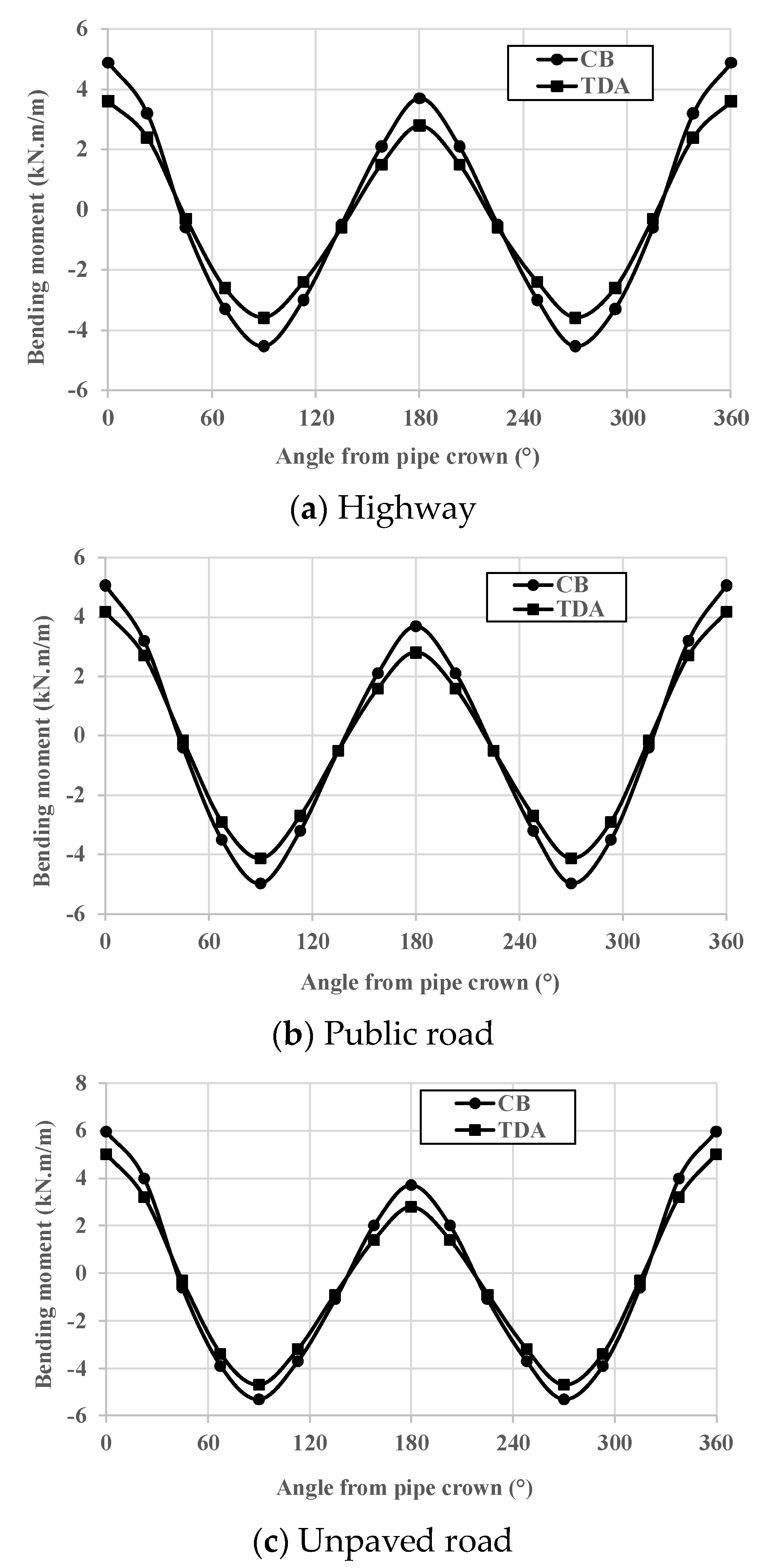

4.1. Effect of TDA on the Distribution of Bending Moment

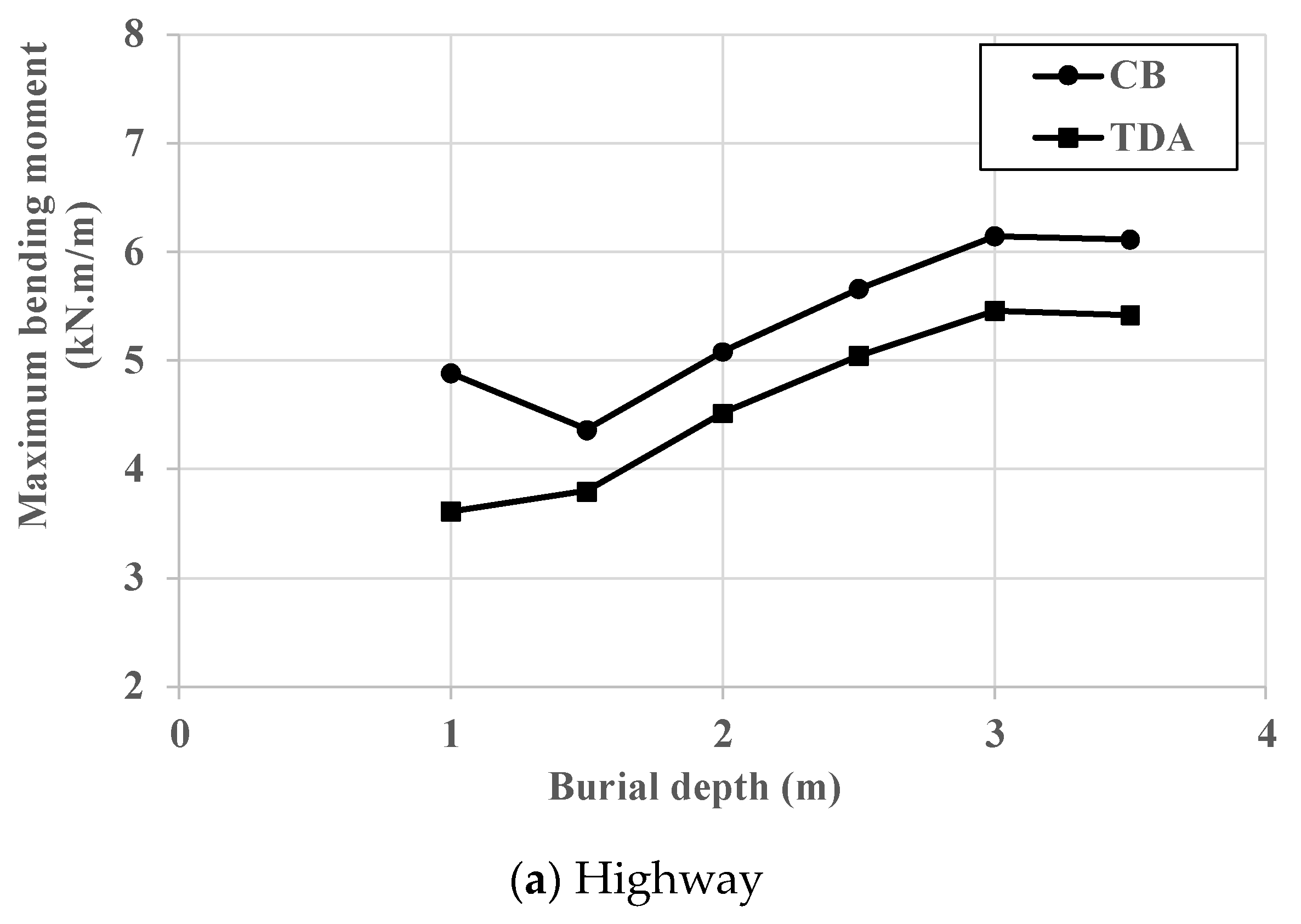

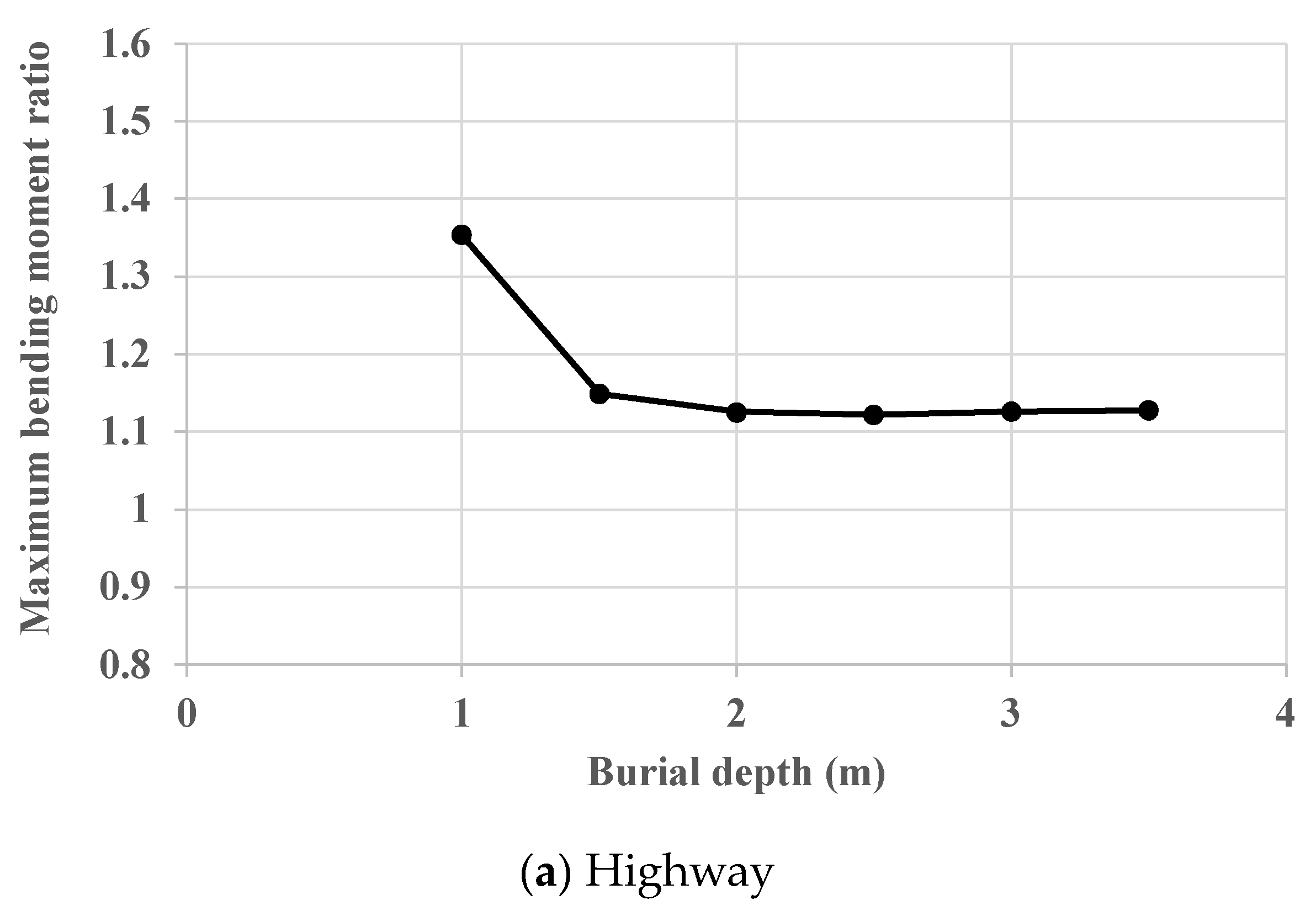

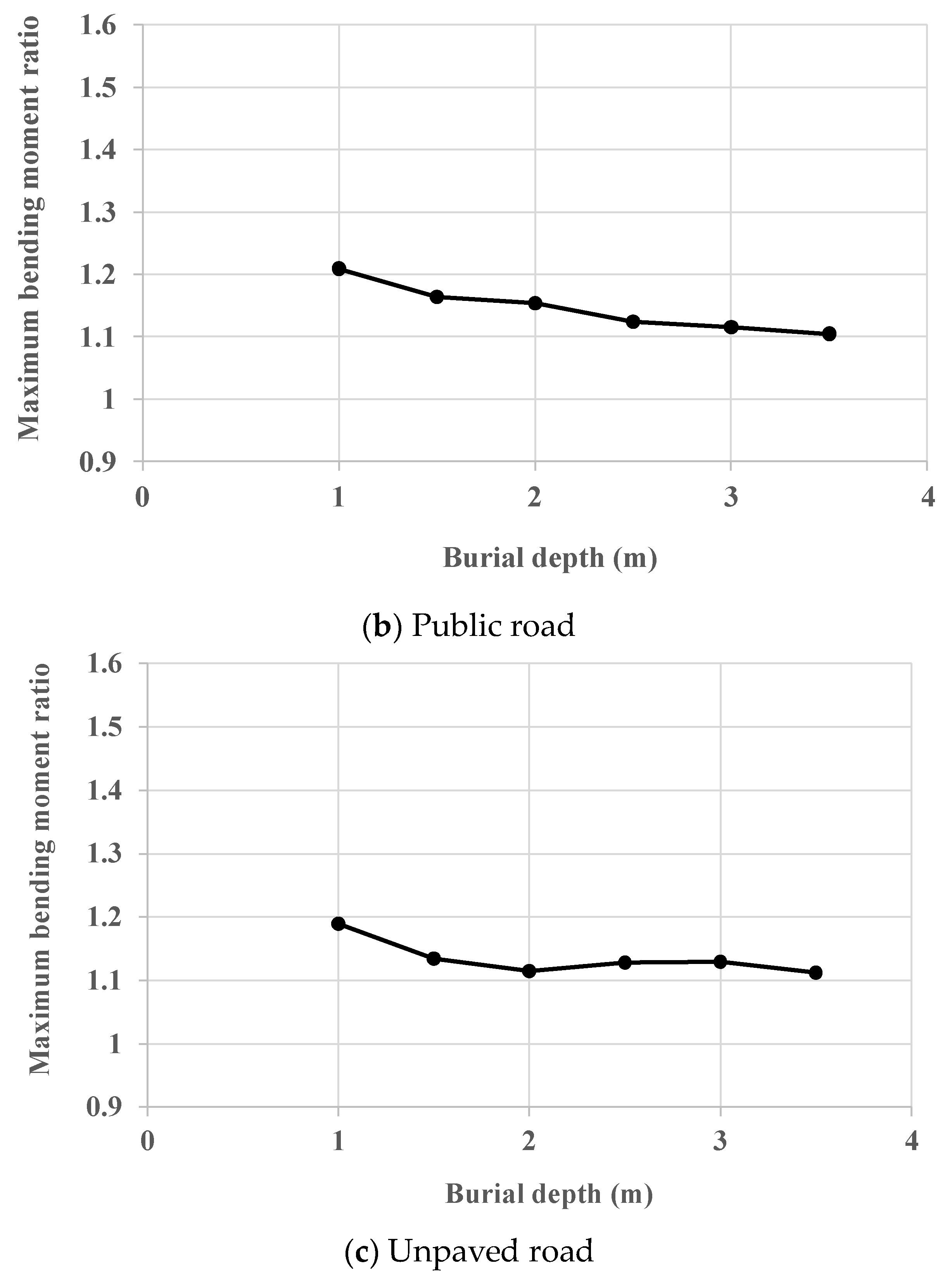

4.2. Effect of Burial Depth on the Efficiency of TDA

4.3. Effect of Pipe Diameter on the Efficiency of TDA

5. Summary and Conclusions

- 1-

- The application of TDA results in a reduction in the bending moment experienced by the wall of a concrete pipe when it is buried and subjected to both soil and traffic loads. However, TDA does not affect the trend of the bending moment distribution in the pipe wall.

- 2-

- The maximum reduction in the bending moment due to the presence of TDA happens at a burial depth of 1.0 m. In addition, the beneficial effect of TDA reduces as the burial depth rises and stabilizes. This is due to the reduction in positive arching as the depth of burial increases.

- 3-

- Generally, the efficiency of TDA is higher for pipes with inner diameters of 30 cm and 60 cm and reduces as the inner diameter of the pipe increases to 120 cm. In addition, the TDA effect becomes very minor for a pipe diameter of 240 cm, and the percentage reduction in the maximum bending moment becomes less than 10%.

- 4-

- There is no generalized conclusion that could be stated regarding the difference in TDA efficiency for different road sections. This is due to the complex behavior of soil arching and its sensitivity to the presence of the pavement layer, the thickness of the pavement layer, burial depth, and the effect of the traffic load on the plastic (failure) state of the soil, especially in the case of the unpaved road.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ASTM D6270; Standard Practice for Use of Scrap Tires in Civil Engineering Applications. ASTM International: West Conshohocken, PA, USA, 2008.

- Tafreshi, S.M.; Mehrjardi, G.T.; Dawson, A.R. Buried pipes in rubber-soil backfilled trenches under cyclic loading. J. Geotech. Geoenviron. Eng. 2012, 138, 1346–1356. [Google Scholar] [CrossRef]

- Meguid, M.A.; Youssef, T.A. Experimental investigation of the earth pressure distribution on buried pipes backfilled with tire-derived aggregate. Transp. Geotechn. 2018, 14, 117–125. [Google Scholar] [CrossRef]

- Mahgoub, A.; El Naggar, H. Using TDA as an engineered stress-reduction fill over preexisting buried pipes. J. Pipeline Syst. Eng. Pract. 2019, 10, 04018034. [Google Scholar] [CrossRef]

- Mahgoub, A.; El Naggar, H. Coupled TDA–geocell stress-bridging system for buried corrugated metal pipes. J. Geotech. Geoenviron. Eng. 2020, 1467, 04020052. [Google Scholar] [CrossRef]

- Al-Naddaf, M.; Han, J.; Xu, C.; Rahmaninezhad, S.M. Effect of geofoam on vertical stress distribution on buried structures subjected to static and cyclic footing loads. J. Pipeline Syst. Eng. Pract. 2019, 10, 04018027. [Google Scholar] [CrossRef]

- Ni, P.; Qin, X.; Yi, Y. Numerical study of earth pressures on rigid pipes with tire-derived aggregate inclusions. Geosynth. Int. 2018, 25, 494–506. [Google Scholar] [CrossRef]

- Mahgoub, A.; El Naggar, H. Innovative application of tire-derived aggregate around corrugated steel plate culverts. J. Pipeline Syst. Eng. Pract. 2020, 11, 04020025. [Google Scholar] [CrossRef]

- Alzabeebee, S.; Alshibany, S.M.; Keawsawasvong, S. Influence of Using Tire-Derived Aggregate on the Structural Performance of Buried Concrete Pipe under Embankment Load. Geotechnics 2022, 2, 989–1002. [Google Scholar] [CrossRef]

- Karaman, M.; Demirci, H.E.; Ecemis, N.; Bhattacharya, S. Usage of Tyre Derived Aggregates as backfill around buried pipelines crossing strike-slip faults; model tests. Bull. Earthq. Eng. 2022, 20, 3143–3165. [Google Scholar] [CrossRef]

- Ni, P.; Qin, X.; Yi, Y. Use of tire-derived aggregate for seismic mitigation of buried pipelines under strike-slip faults. Soil Dyn. Earthq. Eng. 2018, 115, 495–506. [Google Scholar] [CrossRef]

- Ni, P.; Moore, I.D.; Take, W.A. Distributed fibre optic sensing of strains on buried full-scale PVC pipelines crossing a normal fault. Géotechnique 2018, 68, 1–17. [Google Scholar] [CrossRef]

- Strenk, P.M.; Wartman, J.; Grubb, D.G.; Humphrey, D.N.; Natale, M.F. Variability and scale-dependency of tire-derived aggregate. J. Mater. Civ. Eng. 2007, 19, 233–241. [Google Scholar] [CrossRef]

- Chwała, M. Undrained bearing capacity of spatially random soil for rectangular footings. Soils Found. 2019, 59, 1508–1521. [Google Scholar] [CrossRef]

- Savvides, A.A.; Papadrakakis, M. A computational study on the uncertainty quantification of failure of clays with a modified Cam-Clay yield criterion. SN Appl. Sci. 2021, 3, 659. [Google Scholar] [CrossRef]

- Yaghoubi, E.; Al-Taie, A.; Disfani, M.; Fragomeni, S. Recycled aggregate mixtures for backfilling sewer trenches in nontrafficable Areas. Int. J. Geomech. 2022, 22, 04021308. [Google Scholar] [CrossRef]

- Teodosio, B.; Al-Taie, A.; Yaghoubi, E.; Wasantha, P.L.P. Satellite Imaging Techniques for Ground Movement Monitoring of a Deep Pipeline Trench Backfilled with Recycled Materials. Remote Sens. 2022, 15, 204. [Google Scholar] [CrossRef]

- Kang, J.; Stuart, S.J.; Davidson, J.S. Analytical study of minimum cover required for thermoplastic pipes used in highway construction. Struct. Infrastruct. Eng. 2014, 10, 316–327. [Google Scholar] [CrossRef]

- Alzabeebee, S.; Chapman, D.N.; Faramarzi, A. Development of a novel model to estimate bedding factors to ensure the economic and robust design of rigid pipes under soil loads. Tunn. Undergr. Sp. Technol. 2018, 71, 567–578. [Google Scholar] [CrossRef]

- Schanz, T.; Vermeer, P.A.; Bonnier, P.G. The hardening soil model: Formulation and verification. In Beyond 2000 in Computational Geotechnics; Routledge: Oxfordshire, UK, 2019. [Google Scholar] [CrossRef]

- Boscardin, M.D.; Selig, E.T.; Lin, R.S.; Yang, G.R. Hyperbolic parameters for compacted soils. J. Geotech. Eng. 1990, 116, 88–104. [Google Scholar] [CrossRef]

- CNA Consulting Engineers Simpson, Gumpertz & Heger. An Investigation of Suitable Soil Constitutive Models for 3-D Finite Element Studies of Live Load Distribution through Fills Onto Culverts. Appendix A of National Cooperative Highway Research Program Project 15–29 Report. 2009. Available online: https://onlinepubs.trb.org/onlinepubs/nchrp/nchrp_rpt_647appendixa.pdf (accessed on 16 May 2023).

- Bowers, J.T.; Webb, M.C.; Beaver, J.L. Soil Parameters for Design with the 3D PLAXIS Hardening Soil Model. J. Transp. Res. Board 2019, 2673, 708–713. [Google Scholar] [CrossRef]

- Thompson, M.R.; Elliott, R.P. ILLI-PAVE based response algorithms for design of conventional flexible pavements. J. Transp. Res. Board 1985, 1043, 50–57. [Google Scholar]

- Huang, Y.H. Pavement Analysis and Design; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2004; Volume 2, pp. 401–409. [Google Scholar]

- Forcellini, D. Assessment of Geotechnical Seismic Isolation (GSI) as a Mitigation Technique for Seismic Hazard Events. Geosciences 2020, 10, 222. [Google Scholar] [CrossRef]

- Forcellini, D. 3D Numerical simulations of elastomeric bearings for bridges. Innov. Infrastruct. Solut. 2016, 1, 45. [Google Scholar] [CrossRef]

- Jaiswal, A.; Kumar, R. Finite element analysis of granular column for various encasement conditions subjected to shear load. Geomech. Eng. 2022, 29, 645–655. [Google Scholar] [CrossRef]

- Karira, H.; Kumar, A.; Ali, T.H.; Mangnejo, D.A.; Mangi, N. A parametric study of settlement and load transfer mechanism of piled raft due to adjacent excavation using 3D finite element analysis. Geomech. Eng. 2022, 30, 169–185. [Google Scholar] [CrossRef]

- Shi, J.; Wang, J.; Ji, X.; Liu, H.; Lu, H. Three-dimensional numerical parametric study of tunneling effects on existing pipelines. Geomech. Eng. 2022, 30, 383–392. [Google Scholar] [CrossRef]

- Shukla, R.P.; Jakka, R.S. Bearing capacity and failure mechanism of skirted footings. Geomech. Eng. 2022, 30, 51–66. [Google Scholar] [CrossRef]

- Khademi-Zahedi, R. Application of the finite element method for evaluating the stress distribution in buried damaged polyethylene gas pipes. Undergr. Space 2019, 4, 59–71. [Google Scholar] [CrossRef]

- Zhang, Y.; Wong, R.C.K. Effect of corrosion on buried pipe responses under external load: Experimental and numerical study. Tunn. Undergr. Space Technol. 2023, 132, 104934. [Google Scholar] [CrossRef]

- Gaj, N.; Madramootoo, C.A. Structural response of non-perforated and perforated corrugated high-density polyethylene pipes under variable loading. Biosyst. Eng. 2021, 207, 120–140. [Google Scholar] [CrossRef]

- Alzabeebee, S.; Chapman, D.N.; Faramarzi, A. A comparative study of the response of buried pipes under static and moving loads. Transp. Geotechn. 2018, 15, 39–46. [Google Scholar] [CrossRef]

- Sheldon, T.; Sezen, H.; Moore, I.D. Joint response of existing pipe culverts under surface live loads. J. Perform. Constr. Facil. 2015, 29, 04014037. [Google Scholar] [CrossRef]

- Yeau, K.Y.; Sezen, H.; Fox, P.J. Load performance of in situ corrugated steel highway culverts. J. Perform. Constr. Facil. 2009, 23, 32–39. [Google Scholar] [CrossRef]

- MacDougall, K. Behaviour and Design of Reinforced Concrete Pipes; Queen’s University: Kingston, ON, Canada, 2014. [Google Scholar]

| Parameter | SW90 | TDA |

|---|---|---|

| Unit weight (kN/m3) | 20.99 | 7.00 |

| E50ref (KPa) | 32,446 | 2750 |

| Eoedref (KPa) | 32,446 | 2200 |

| Eurref (KPa) | 97,338 | 8250 |

| υur | 0.20 | 0.20 |

| Cohesion (kPa) | 0.01 | 24 |

| Angle of internal friction (°) | 45.5 | 26.5 |

| Dilatancy angle (°) | 15.5 | 0.0 |

| m | 0.75 | 0.50 |

| Konc | 0.31 | 0.55 |

| Rf | 0.75 | 0.95 |

| Pref (kPa) | 101 | 25 |

| Parameter | Asphalt | Base Course | Subbase | Subgrade |

|---|---|---|---|---|

| Unit weight (kN/m3) | 22.79 | 21.22 | 19.00 | 17.00 |

| Elastic Modulus (KPa) | 3104 | 214 | 93 | 31 |

| Poisson’s ratio | 0.35 | 0.38 | 0.35 | 0.30 |

| Cohesion (kPa) | - | 0 | 0 | 20 |

| Angle of internal friction (°) | - | 50.0 | 40.0 | 30.0 |

| Dilatancy angle (°) | - | 20.0 | 10.0 | 0.0 |

| Inner Diameter (cm) | Outer Diameter |

|---|---|

| 30 | 41 |

| 60 | 79 |

| 120 | 49 |

| 240 | 2.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alzabeebee, S.; Alshibany, S.M.; Keawsawasvong, S.; Forcellini, D. The Efficiency of the Benefits of Tire-Derived Aggregate Backfill for Buried Concrete Pipes Beneath Paved and Unpaved Roads. Infrastructures 2023, 8, 107. https://doi.org/10.3390/infrastructures8070107

Alzabeebee S, Alshibany SM, Keawsawasvong S, Forcellini D. The Efficiency of the Benefits of Tire-Derived Aggregate Backfill for Buried Concrete Pipes Beneath Paved and Unpaved Roads. Infrastructures. 2023; 8(7):107. https://doi.org/10.3390/infrastructures8070107

Chicago/Turabian StyleAlzabeebee, Saif, Safaa Manfi Alshibany, Suraparb Keawsawasvong, and Davide Forcellini. 2023. "The Efficiency of the Benefits of Tire-Derived Aggregate Backfill for Buried Concrete Pipes Beneath Paved and Unpaved Roads" Infrastructures 8, no. 7: 107. https://doi.org/10.3390/infrastructures8070107

APA StyleAlzabeebee, S., Alshibany, S. M., Keawsawasvong, S., & Forcellini, D. (2023). The Efficiency of the Benefits of Tire-Derived Aggregate Backfill for Buried Concrete Pipes Beneath Paved and Unpaved Roads. Infrastructures, 8(7), 107. https://doi.org/10.3390/infrastructures8070107