Performance Comparison of 45° and 90° Herringboned Permeable Interlocking Concrete Pavement

Abstract

1. Introduction

2. Experiment Program

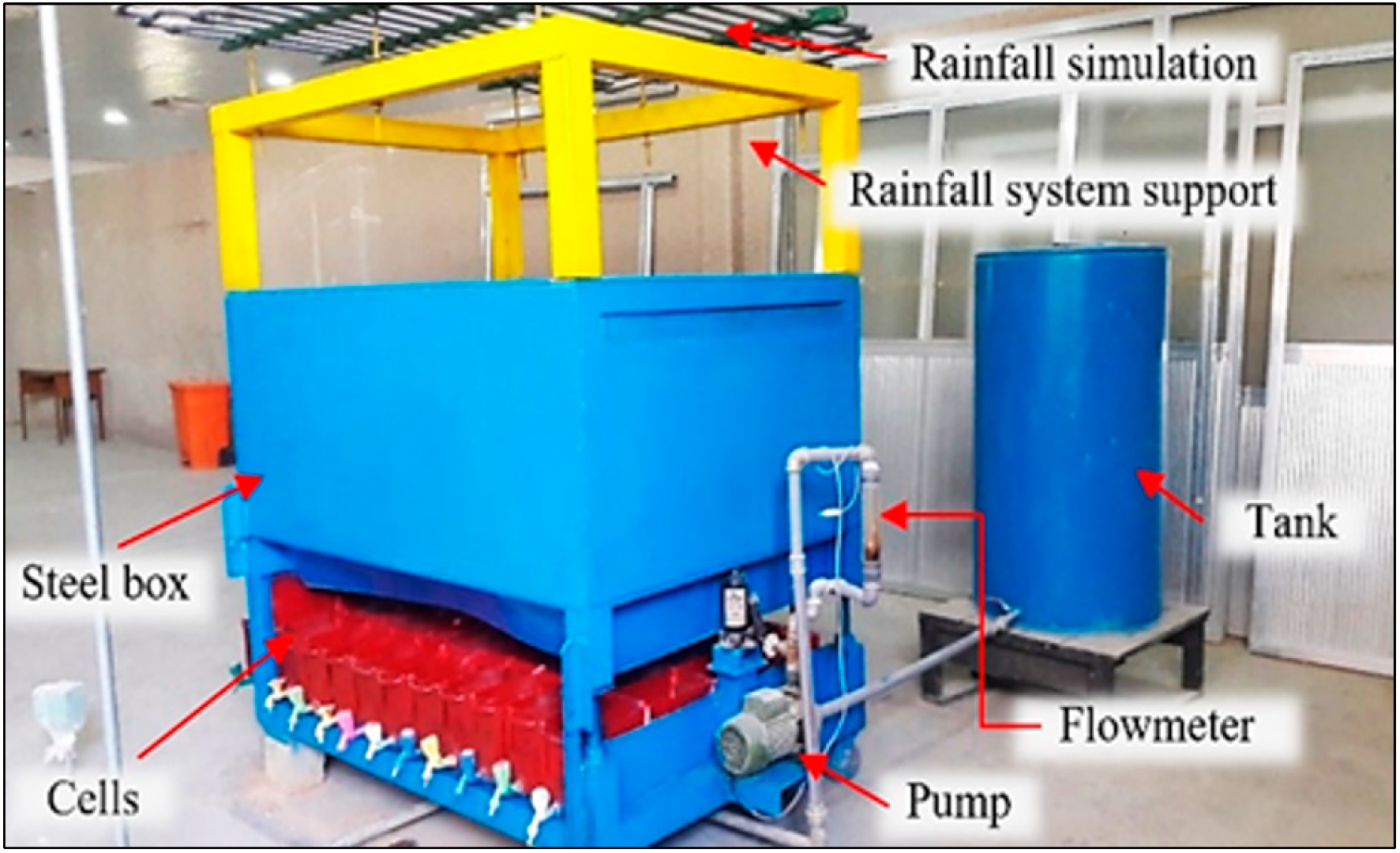

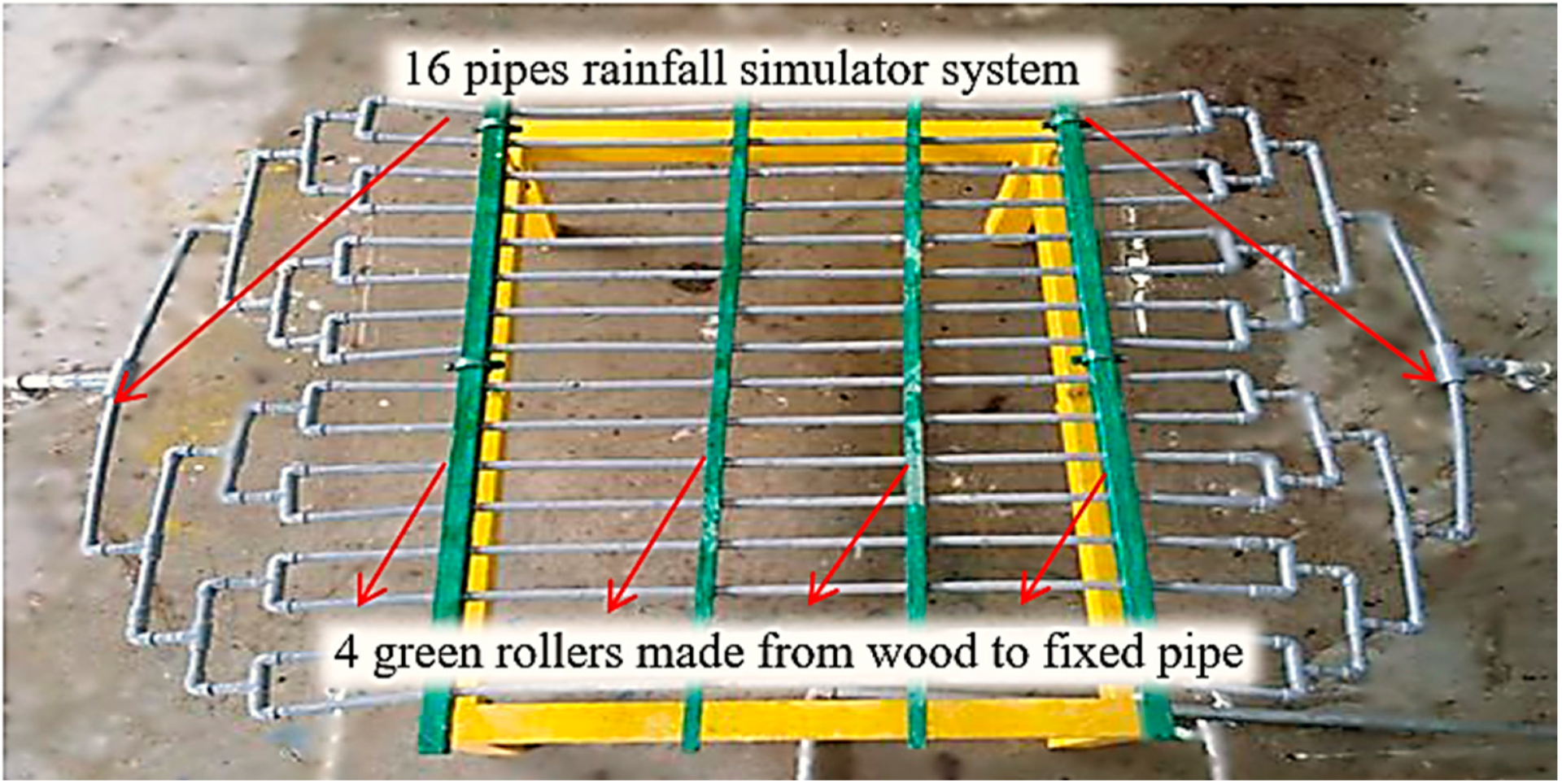

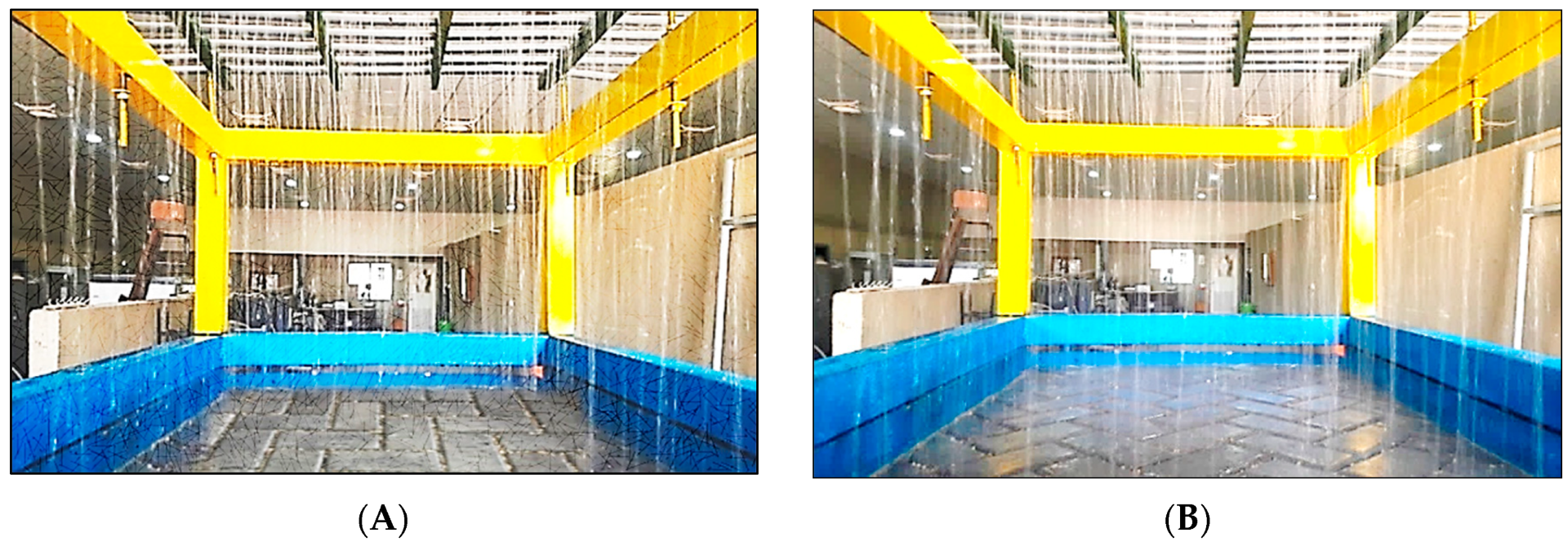

2.1. Details of the Rainfall Simulator

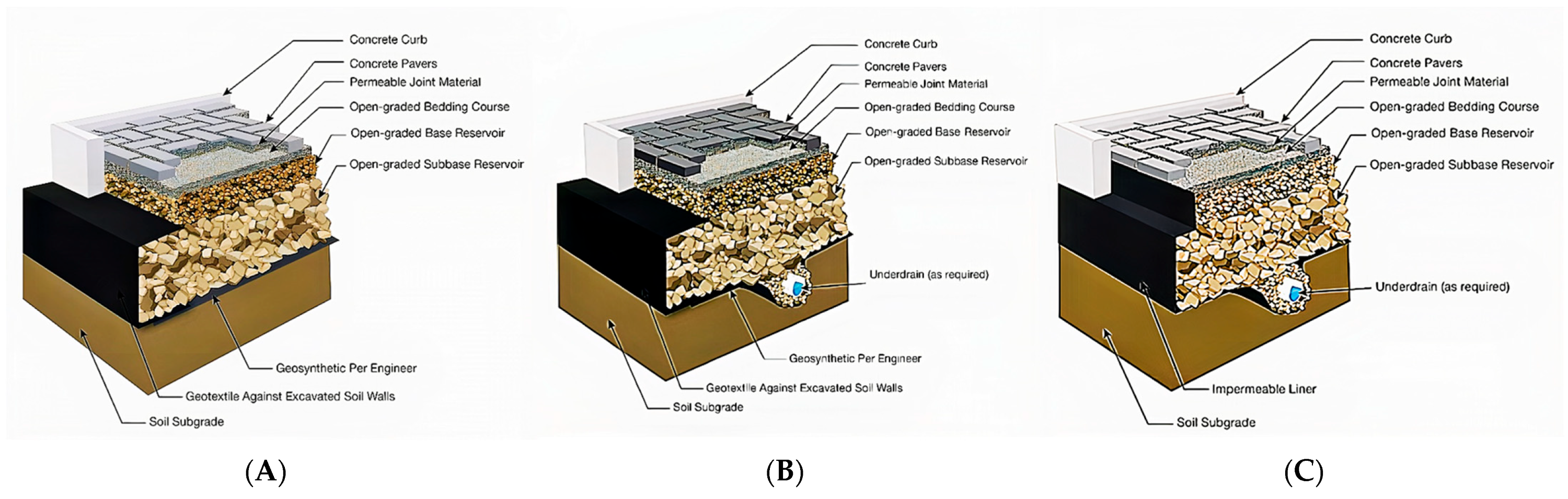

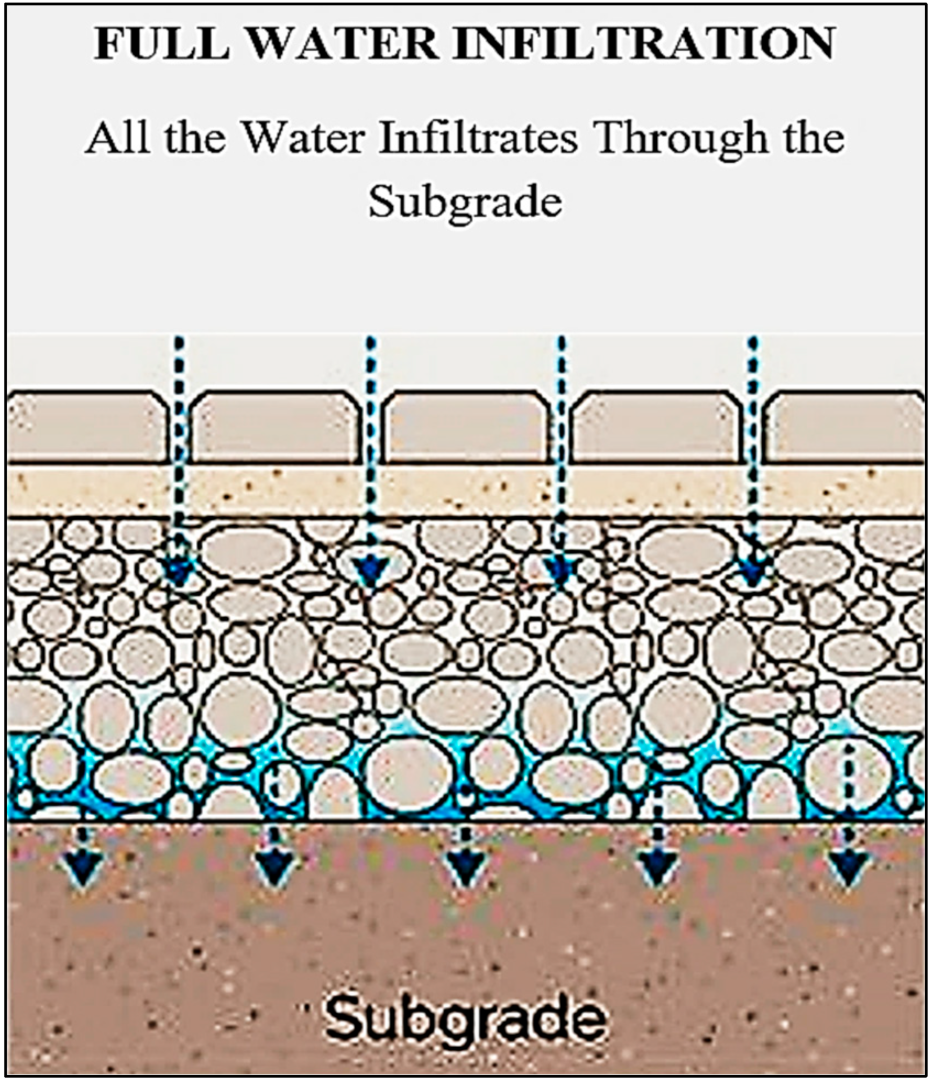

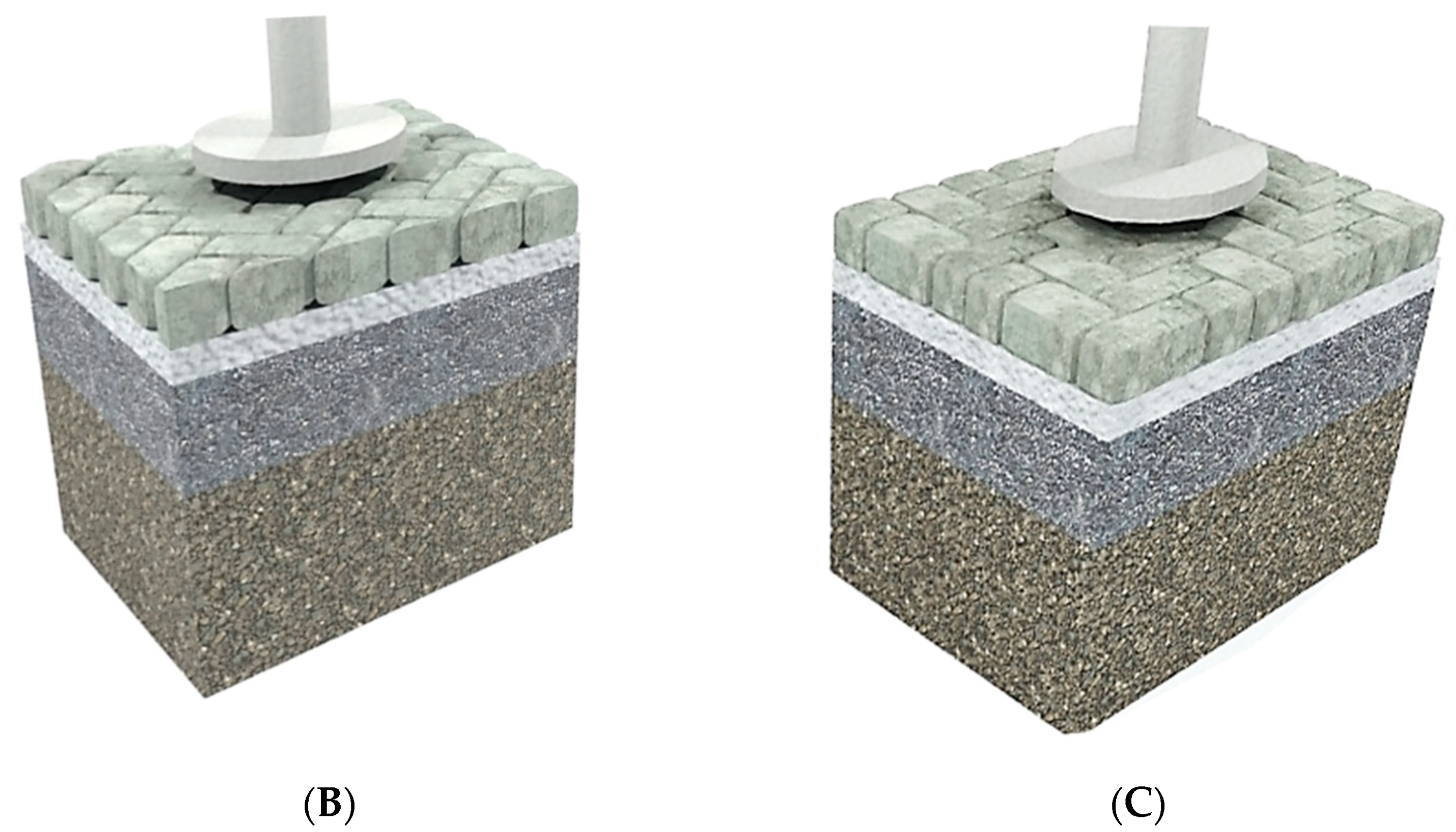

2.2. The Adopted Hydraulic Design of PICP

2.3. In-Detail Designing of the Layers of PICP

2.3.1. Surface Concrete Paver

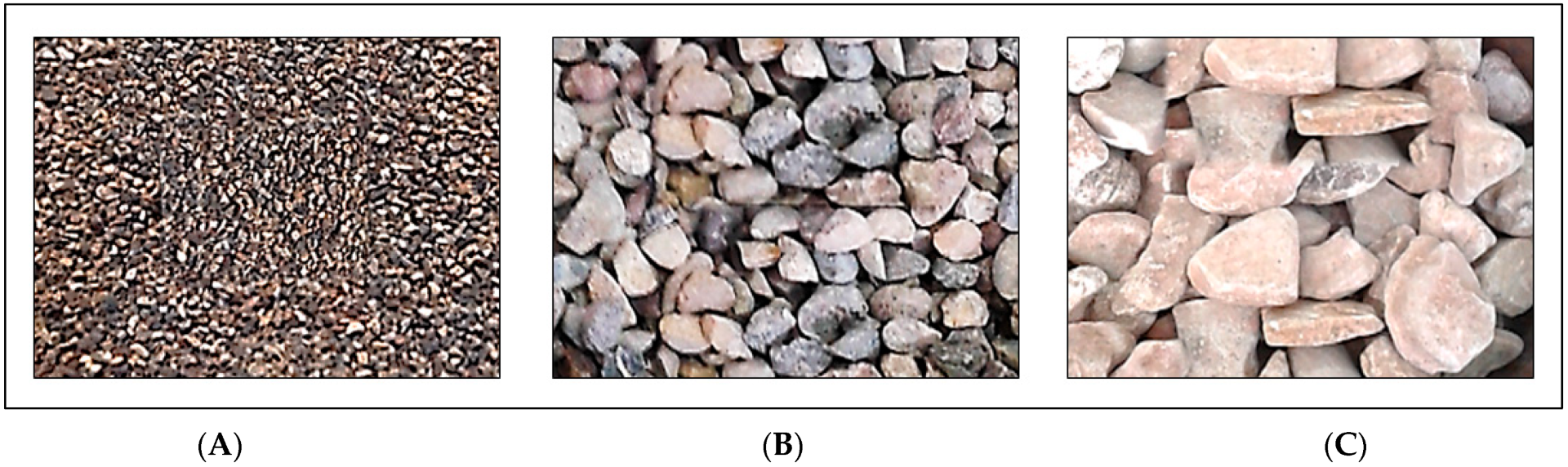

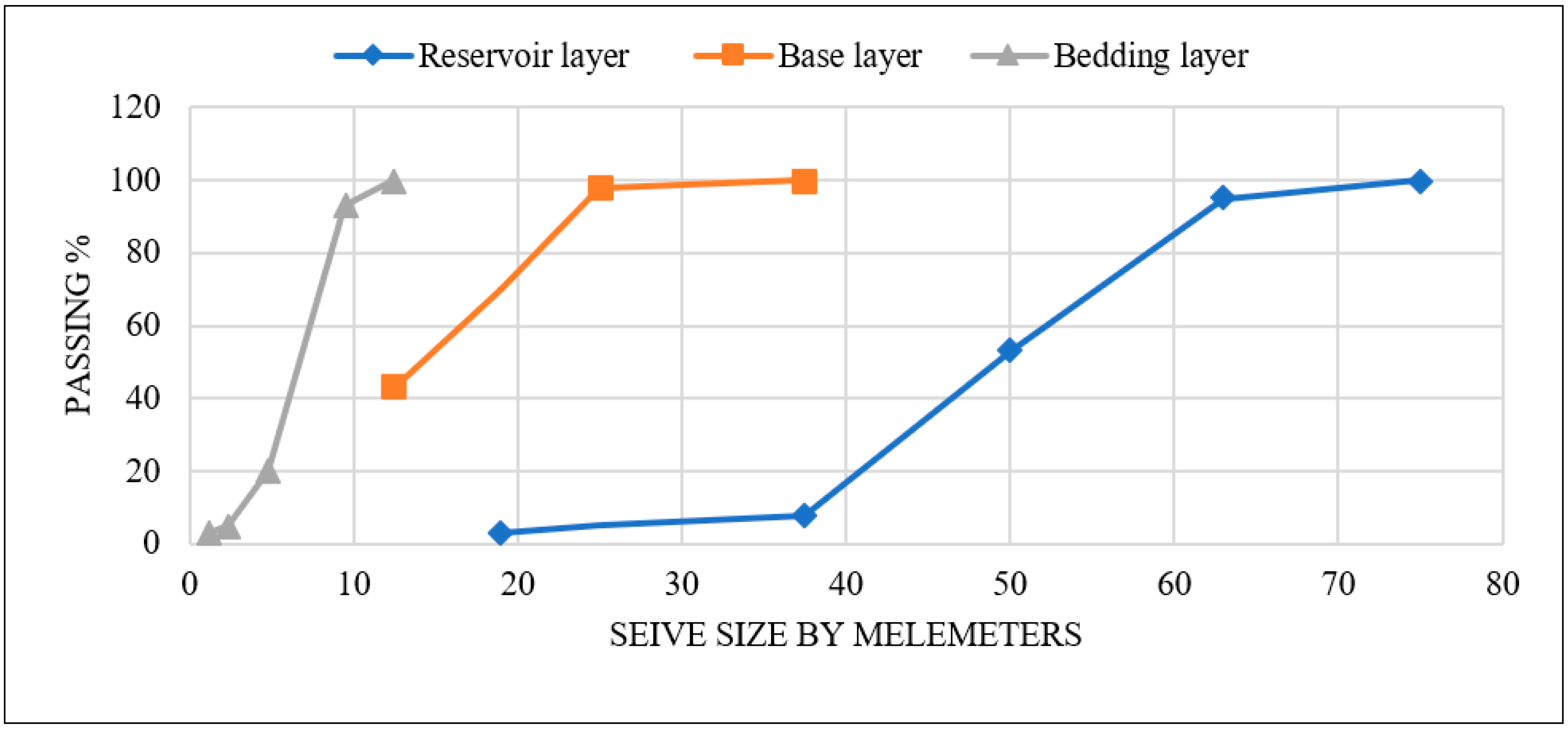

2.3.2. The Aggregate That Fills the Joints—ASTM No. 8 or 9

2.3.3. Bedding Layer—ASTM No. 8

2.3.4. Base Layer—ASTM No. 57

2.3.5. Reservoir or Subbase Layer—ASTM No. 2

2.4. Determining the Thickness of the Reservoir Layer

2.4.1. Designing by Structural Method

2.4.2. Designing by the Hydraulic Method

2.5. Laying the Layers of PICP within the Steel Box

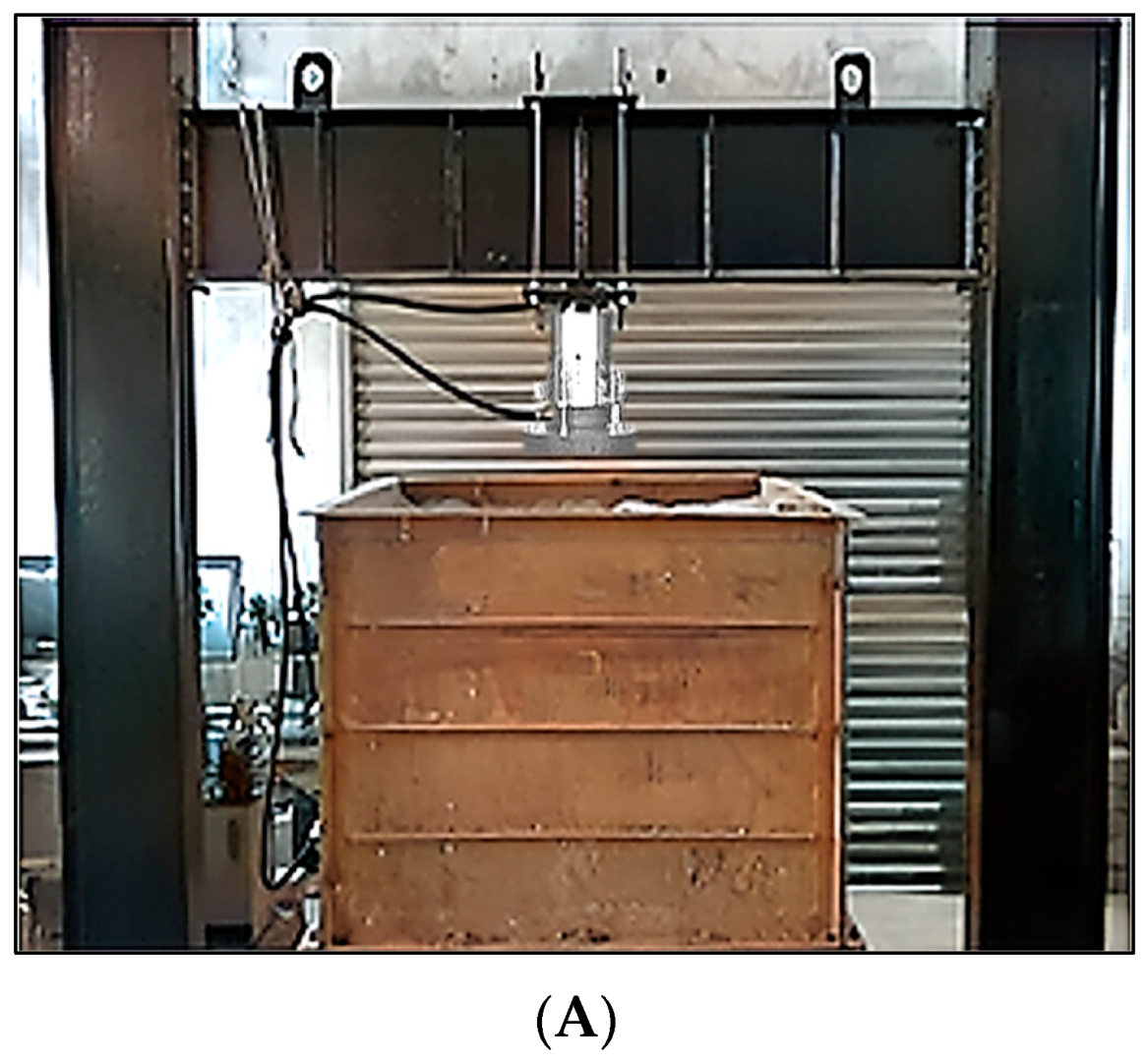

2.6. PICP Static Load Test

3. Results and Discussion

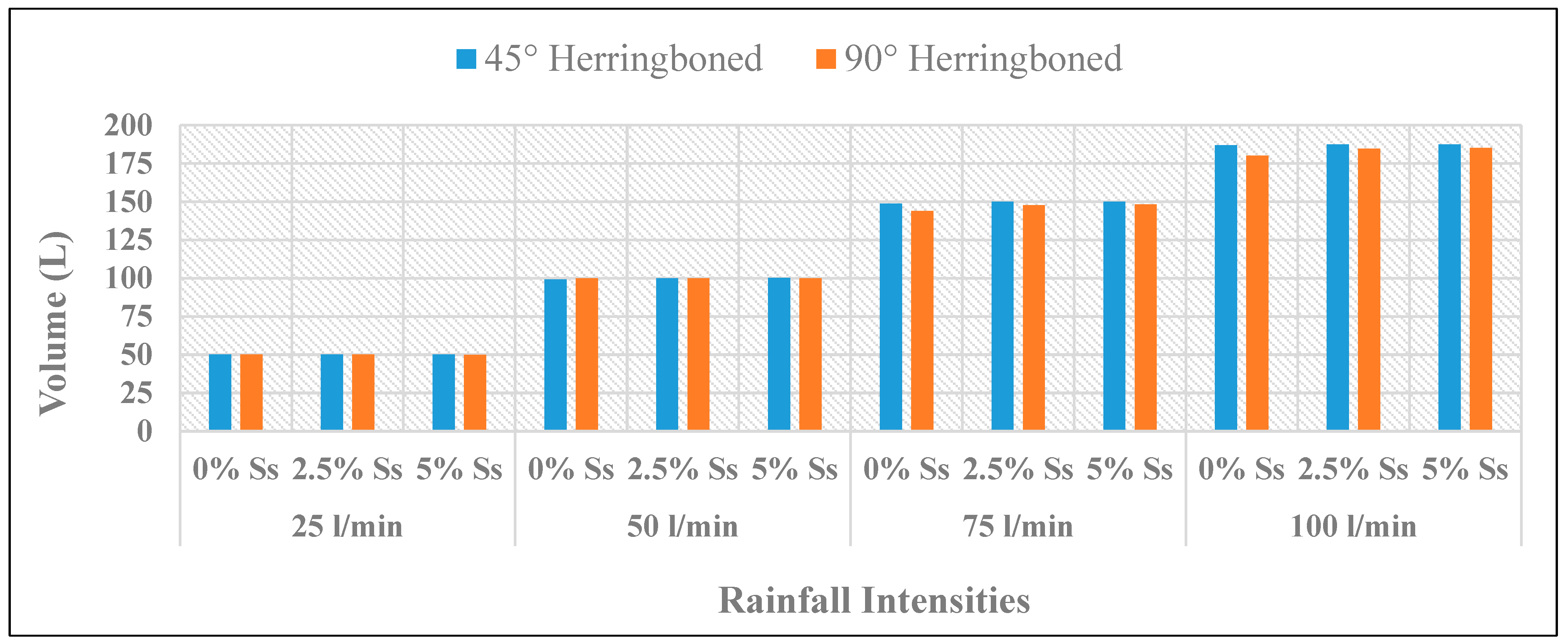

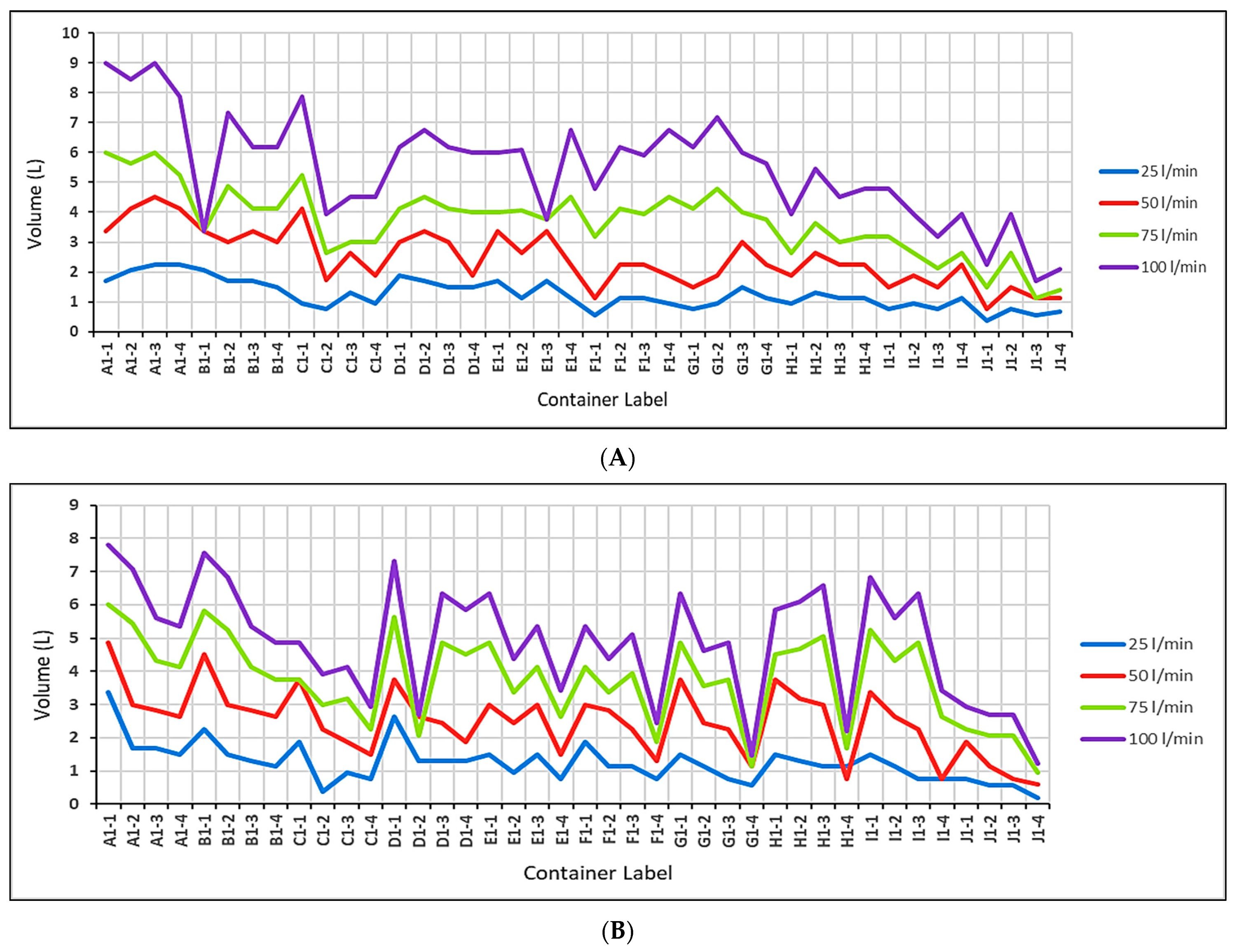

3.1. Water Infiltration through Both 45° and 90° Herringboned Surface Patterns

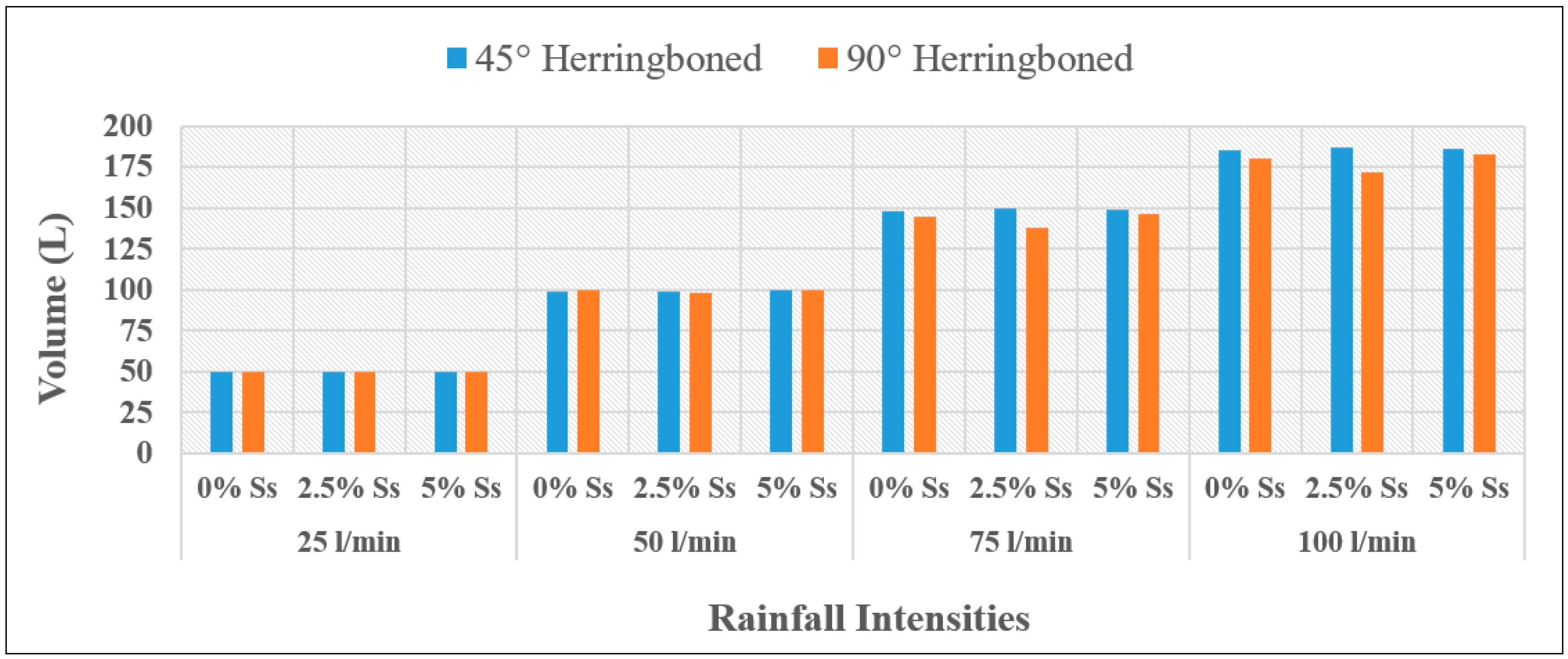

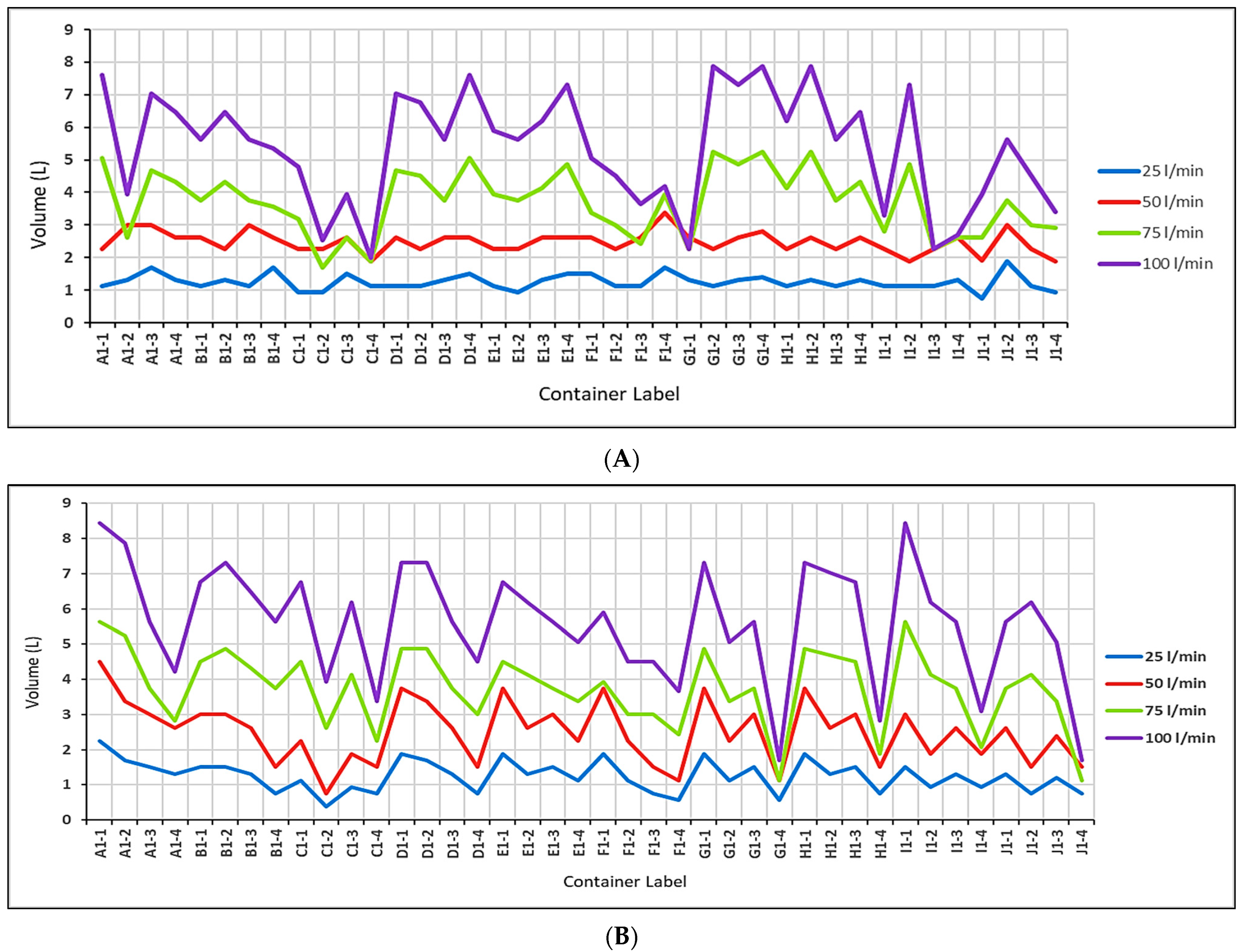

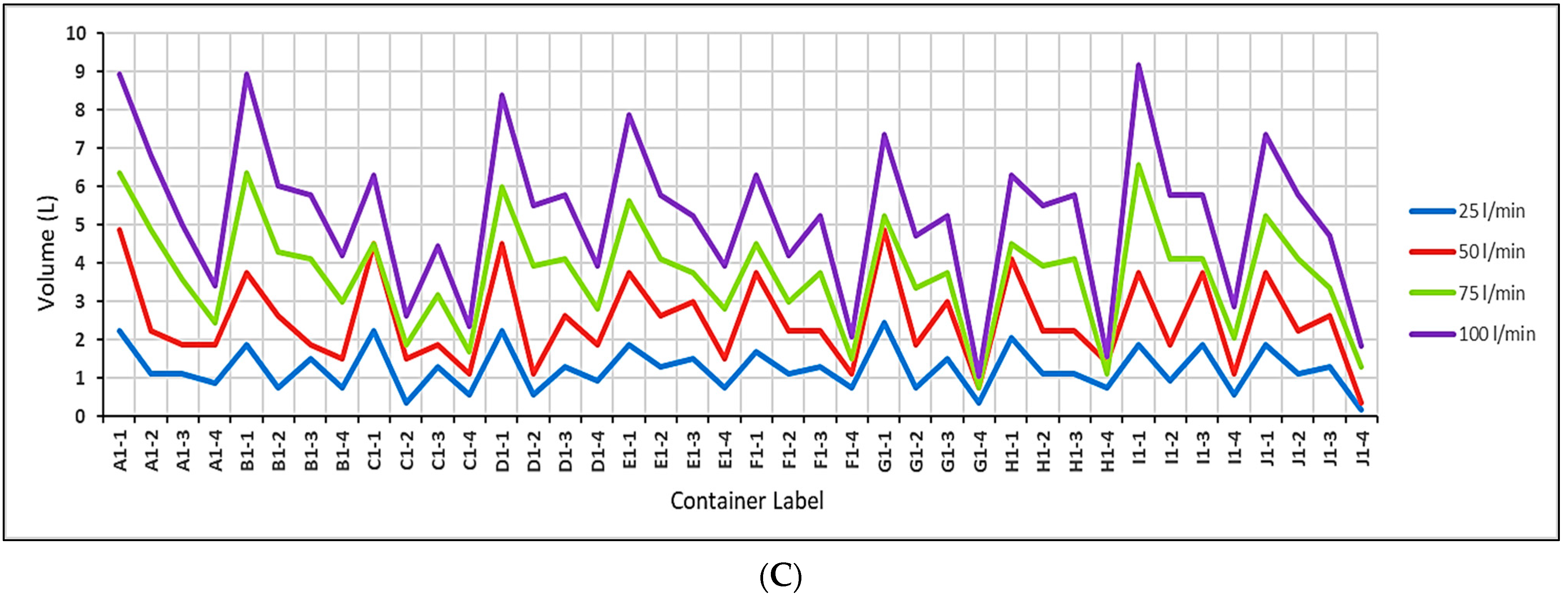

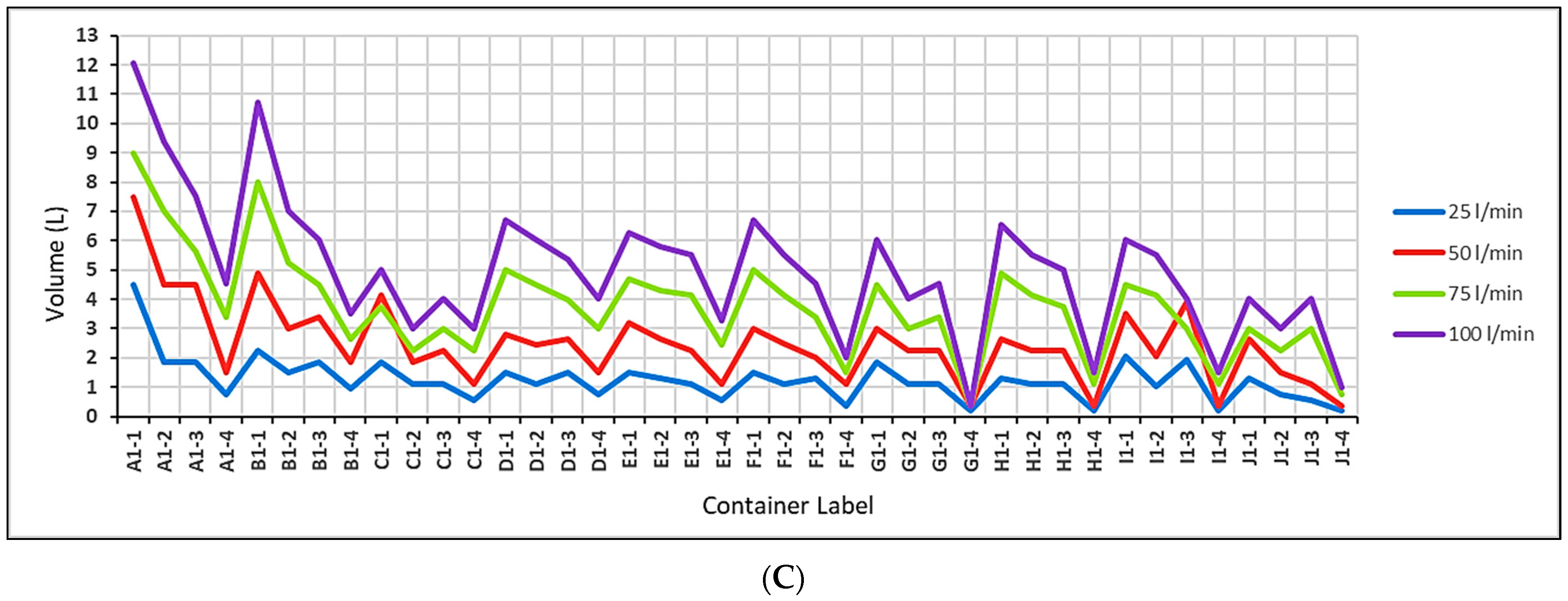

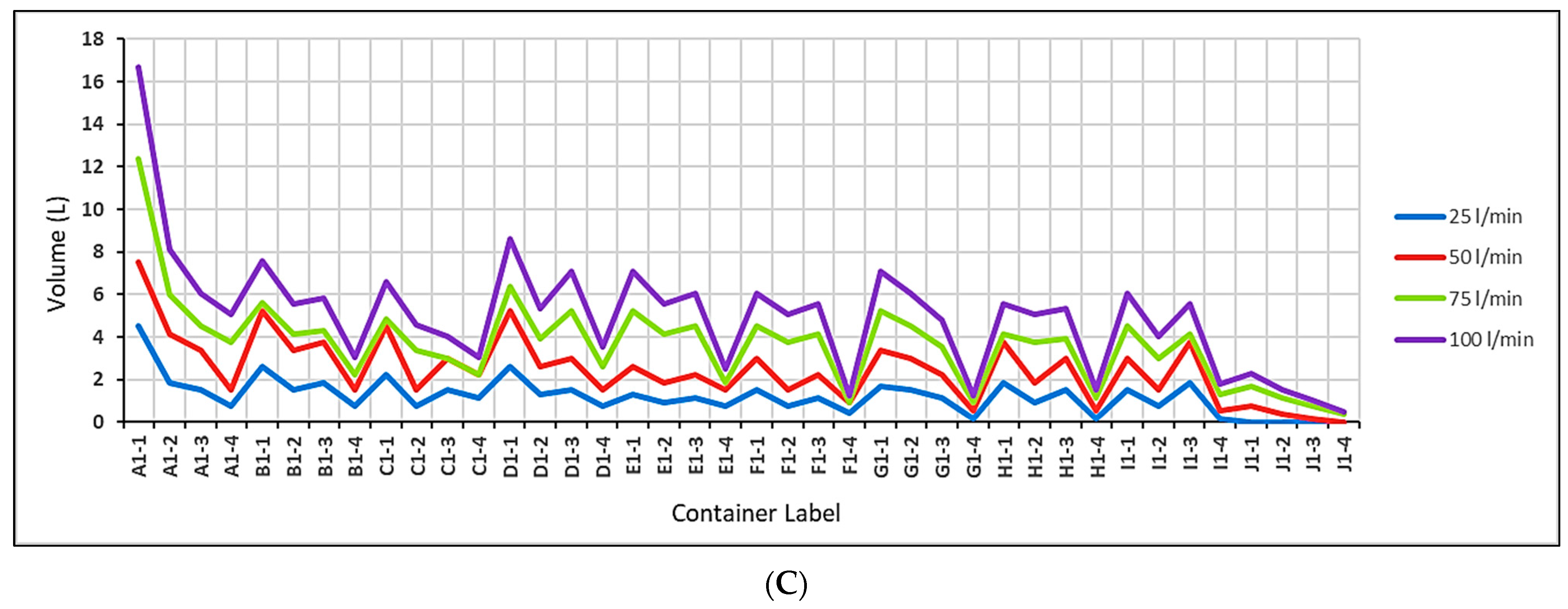

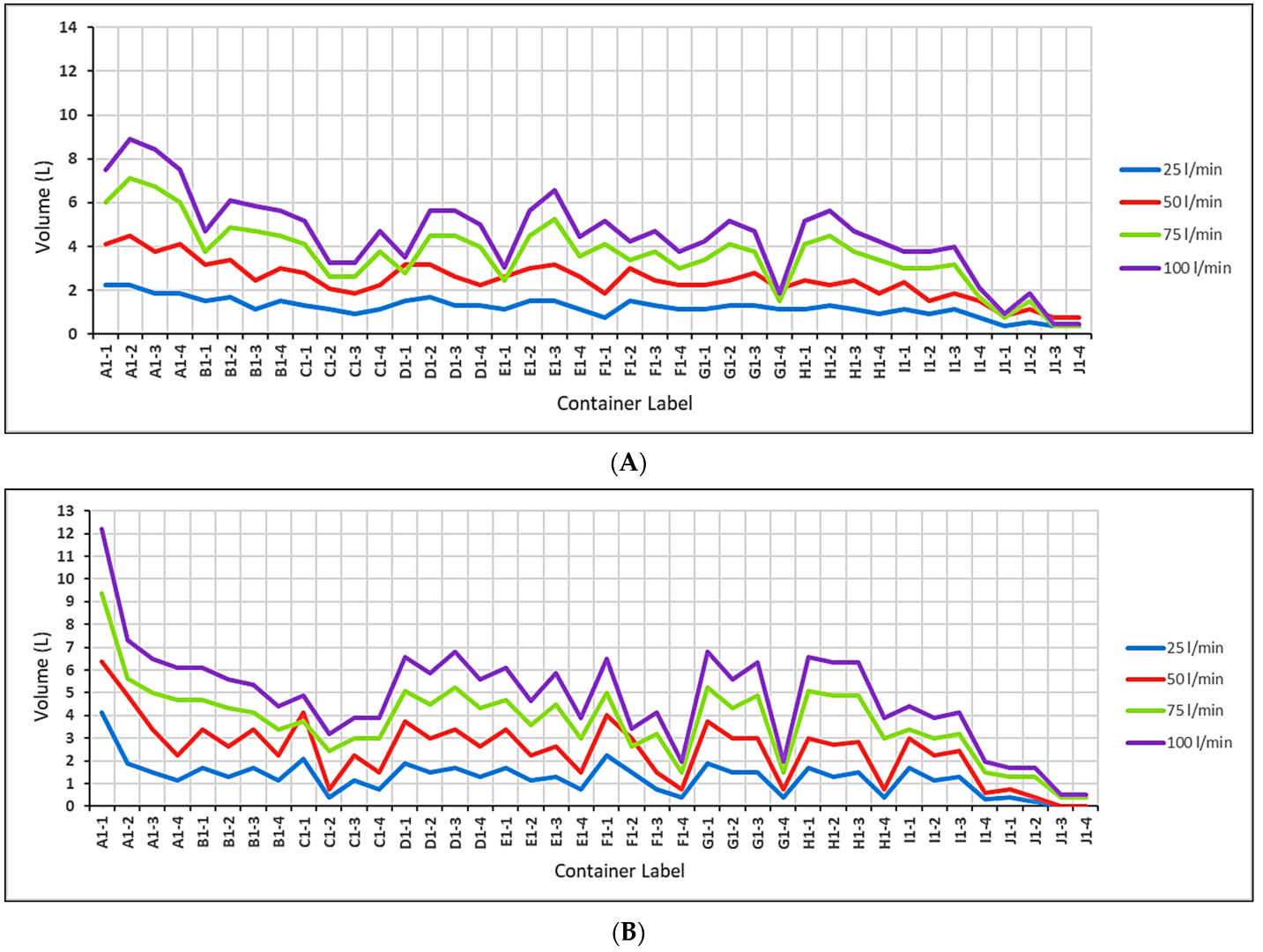

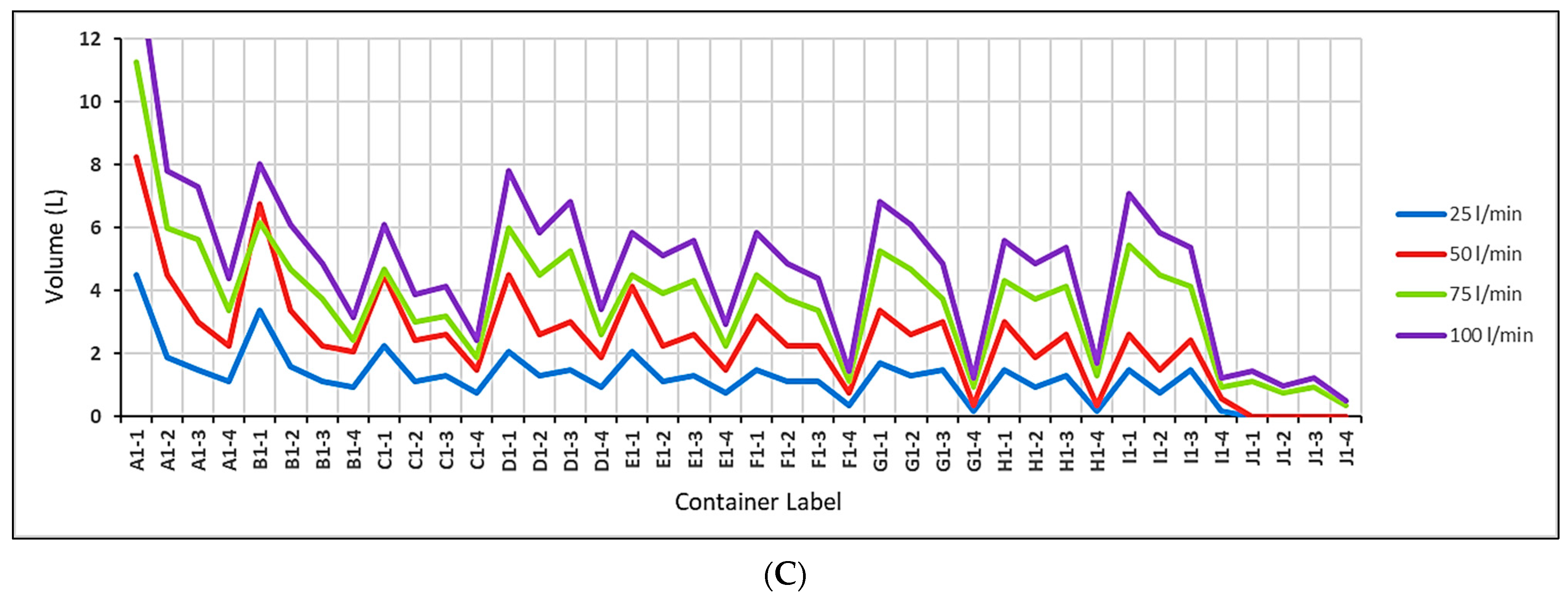

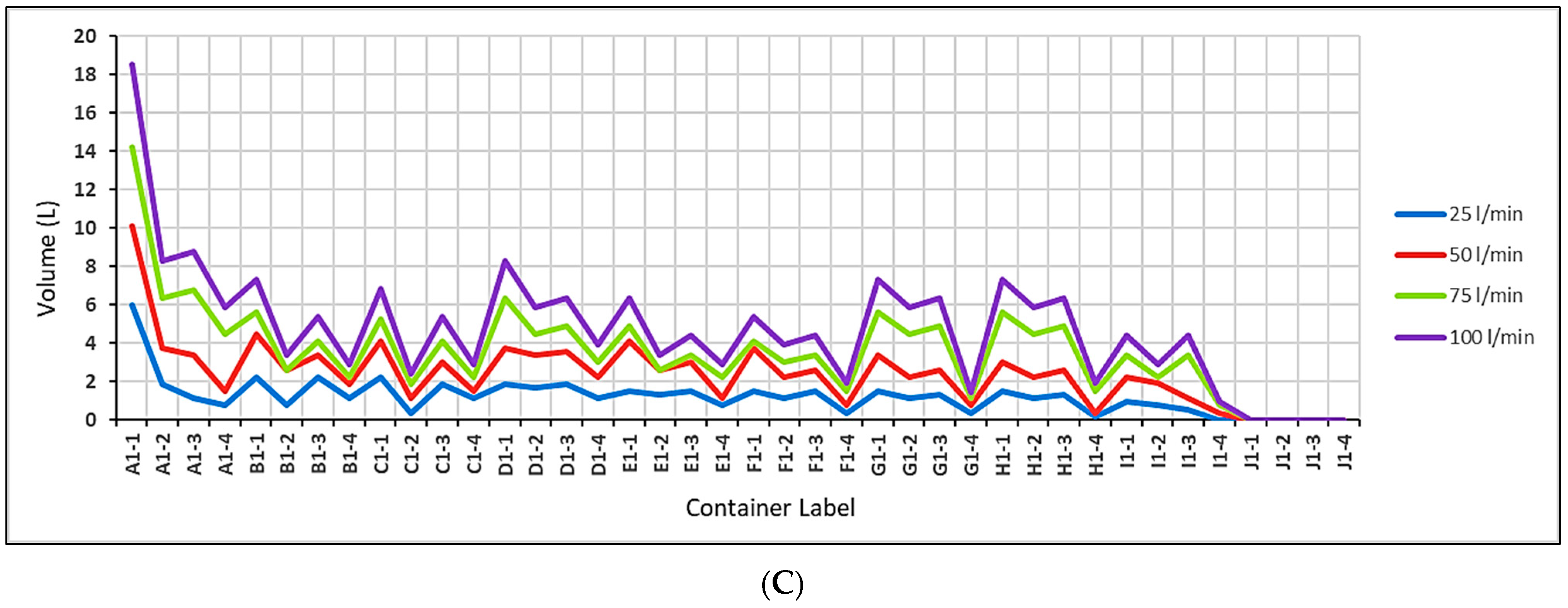

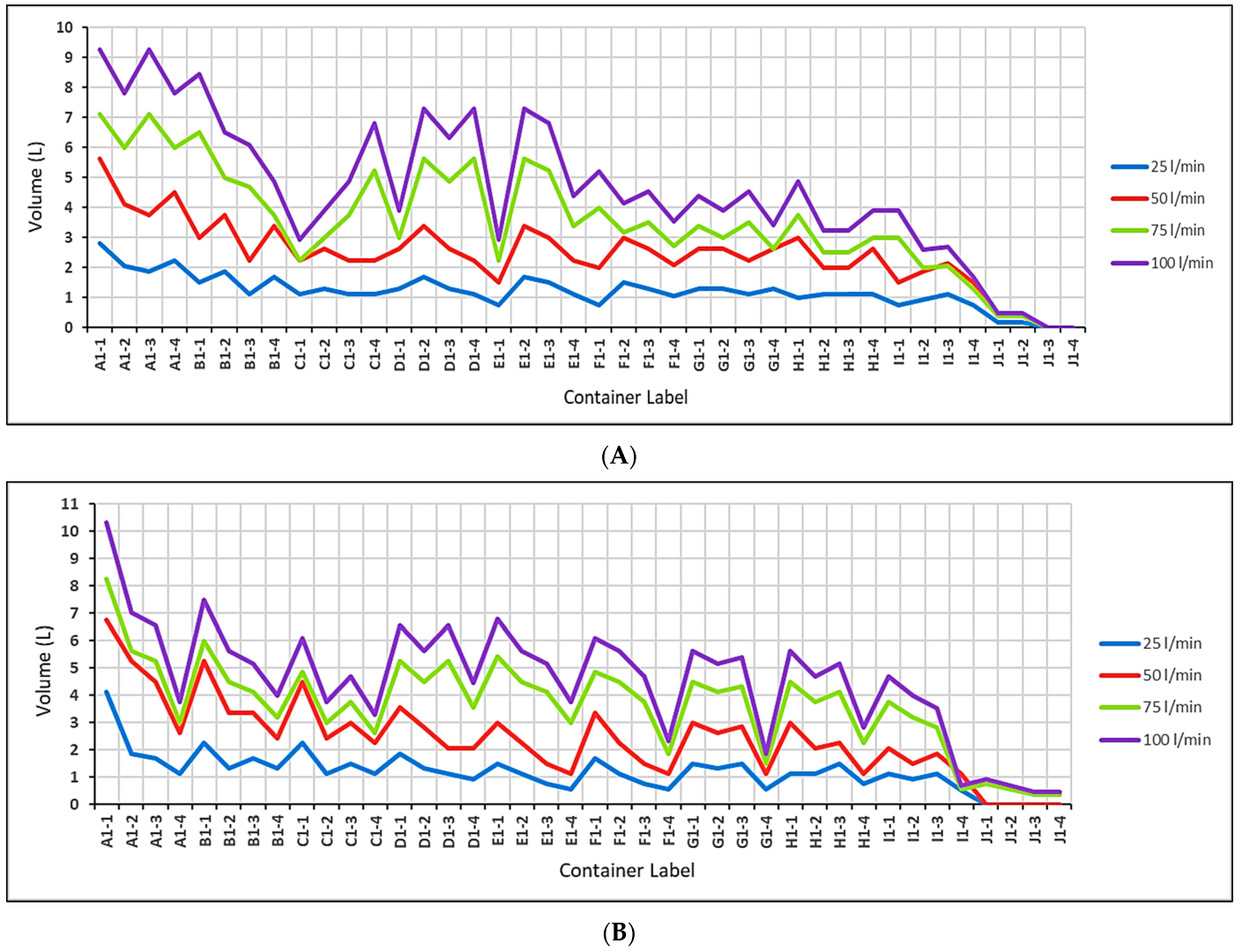

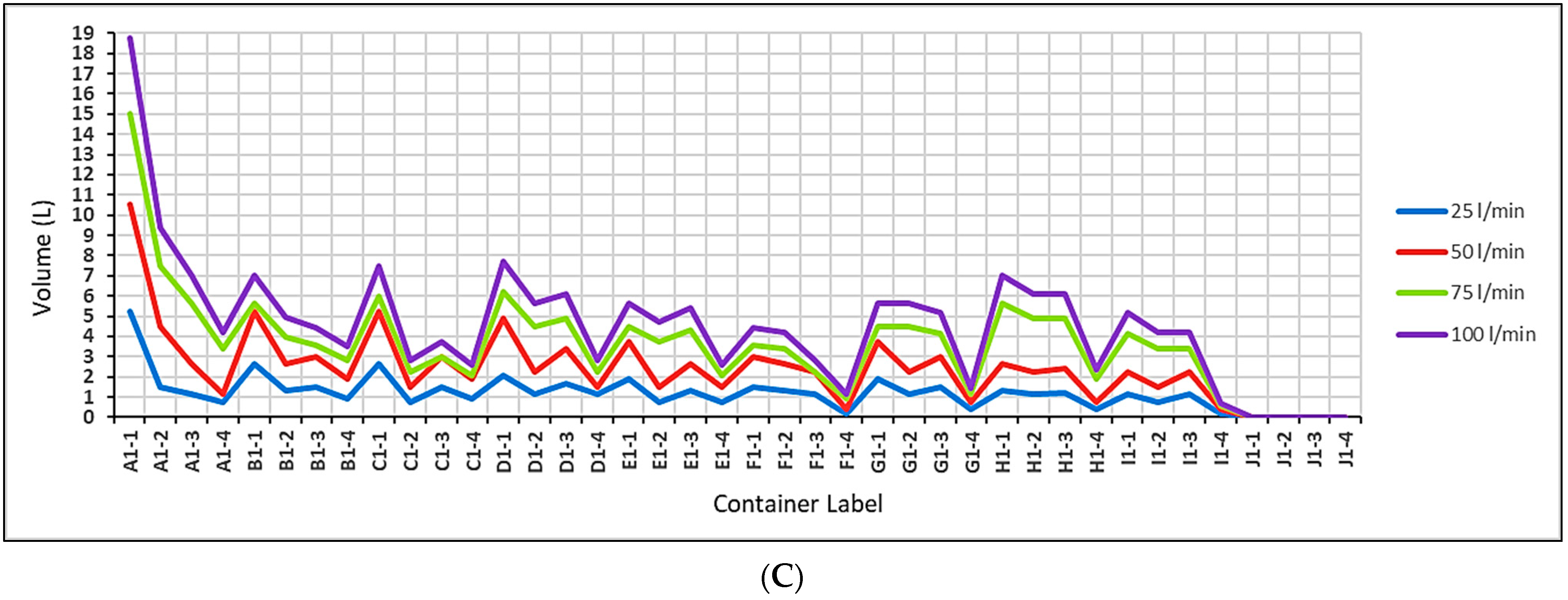

3.2. The Distribution of Infiltrated Water Beneath the Layers of PICP

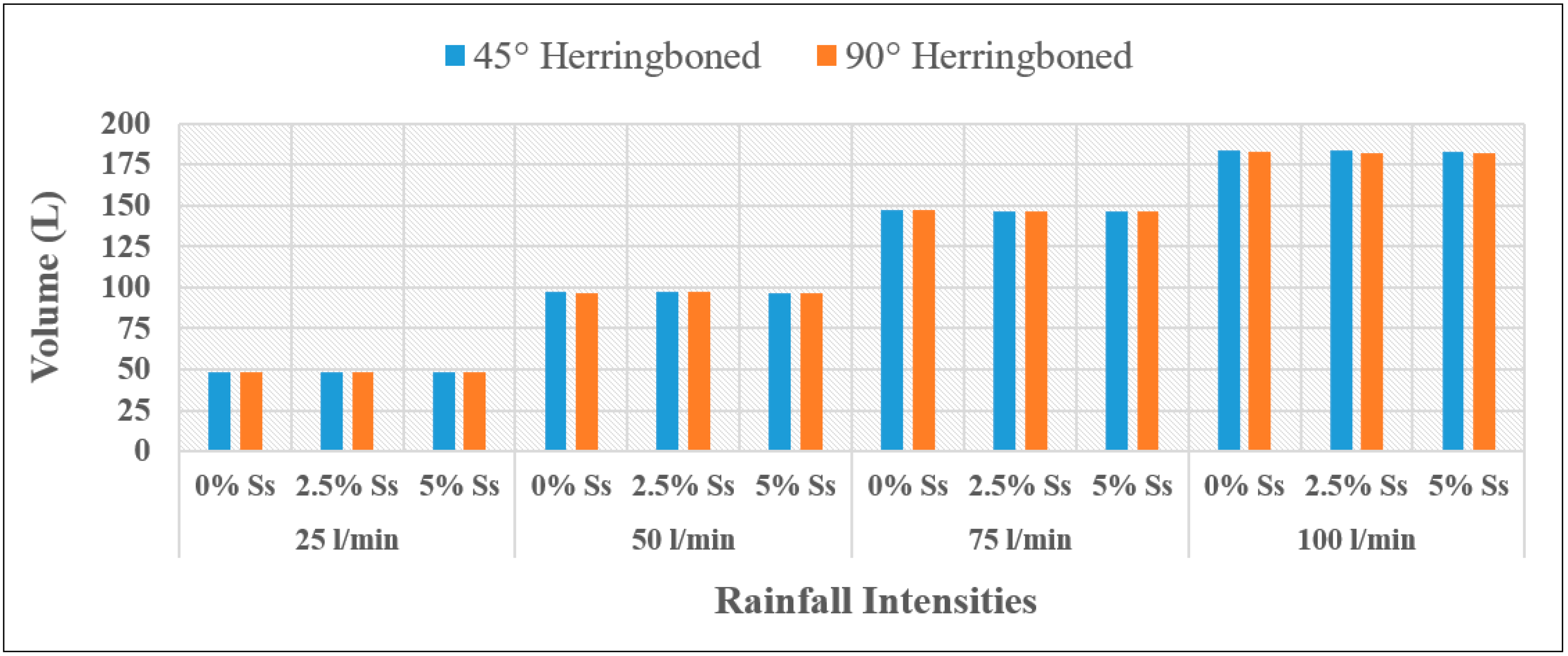

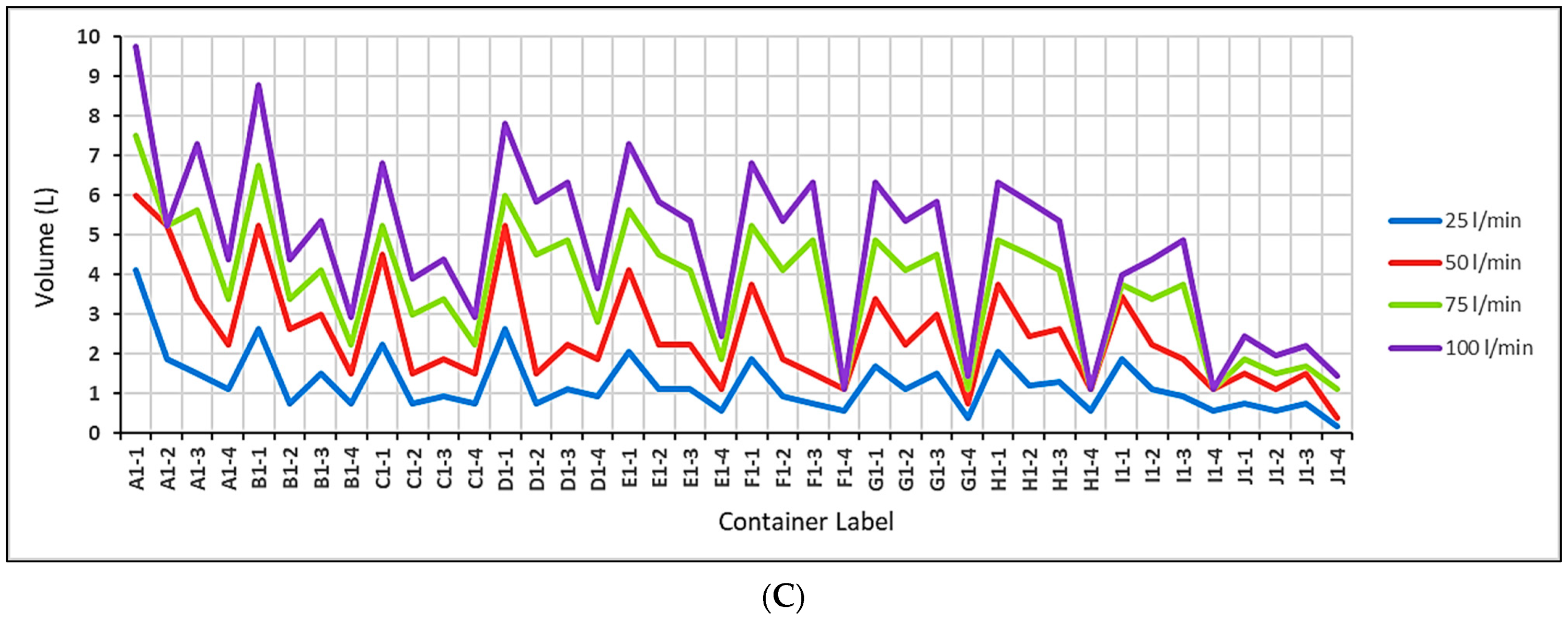

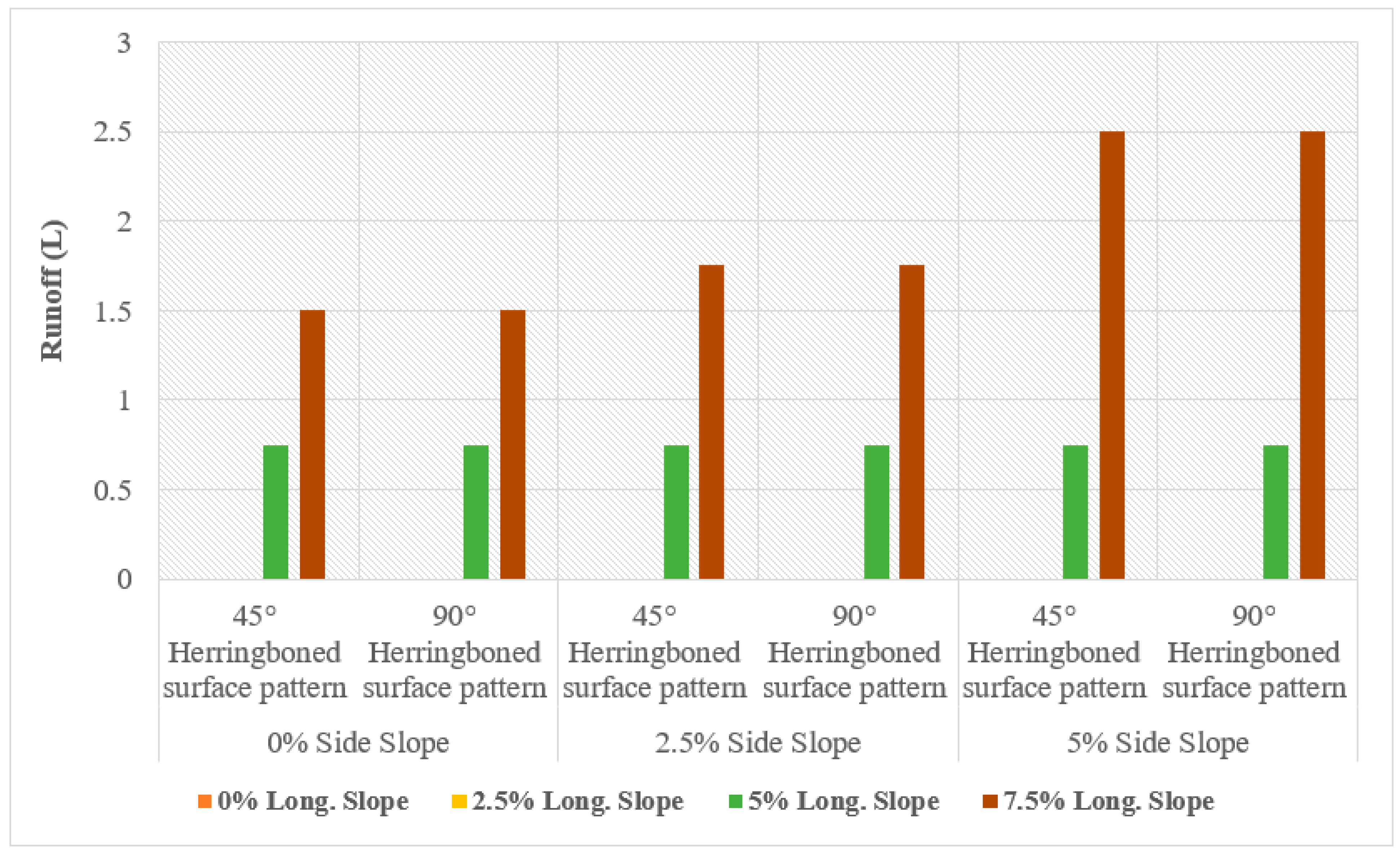

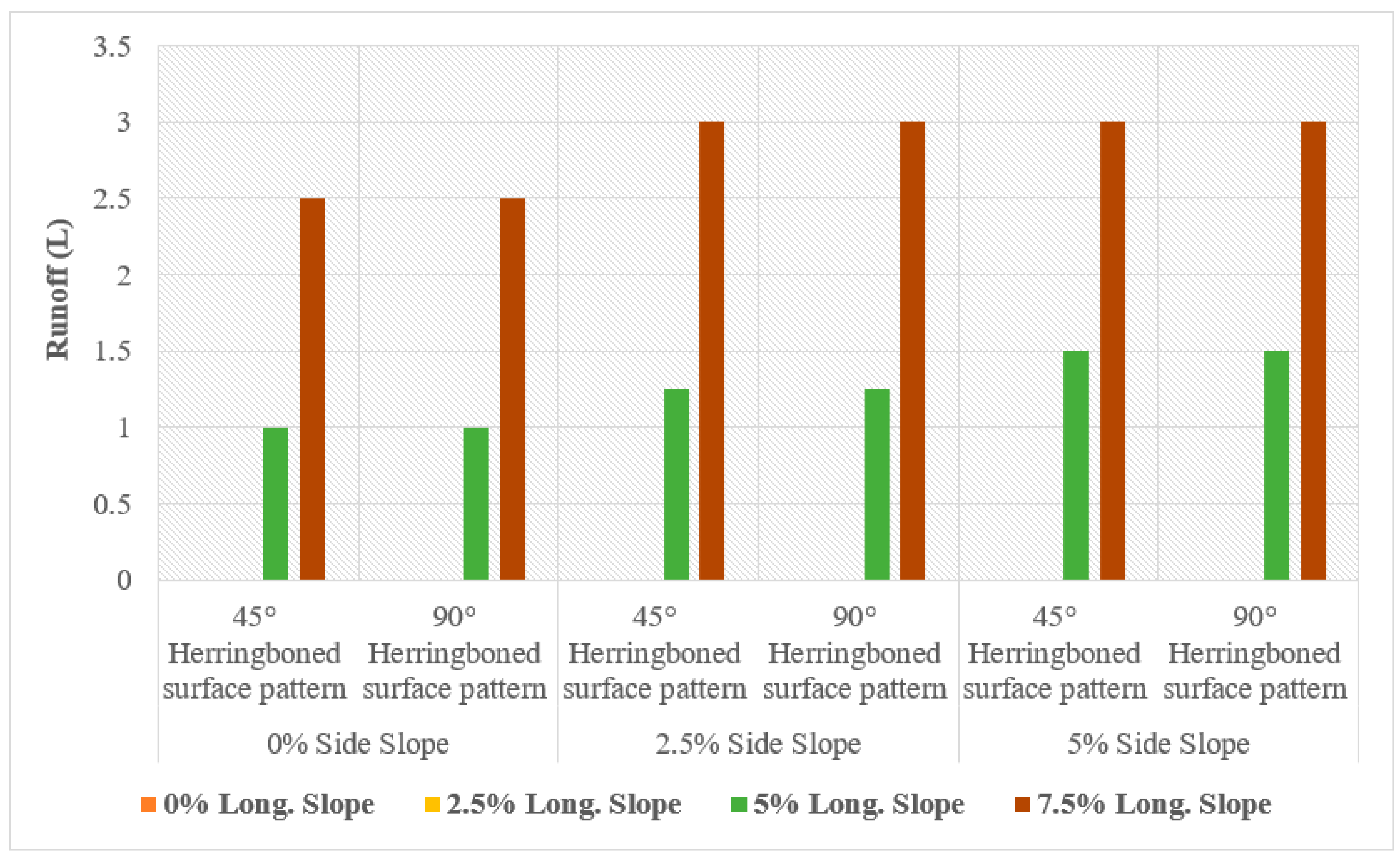

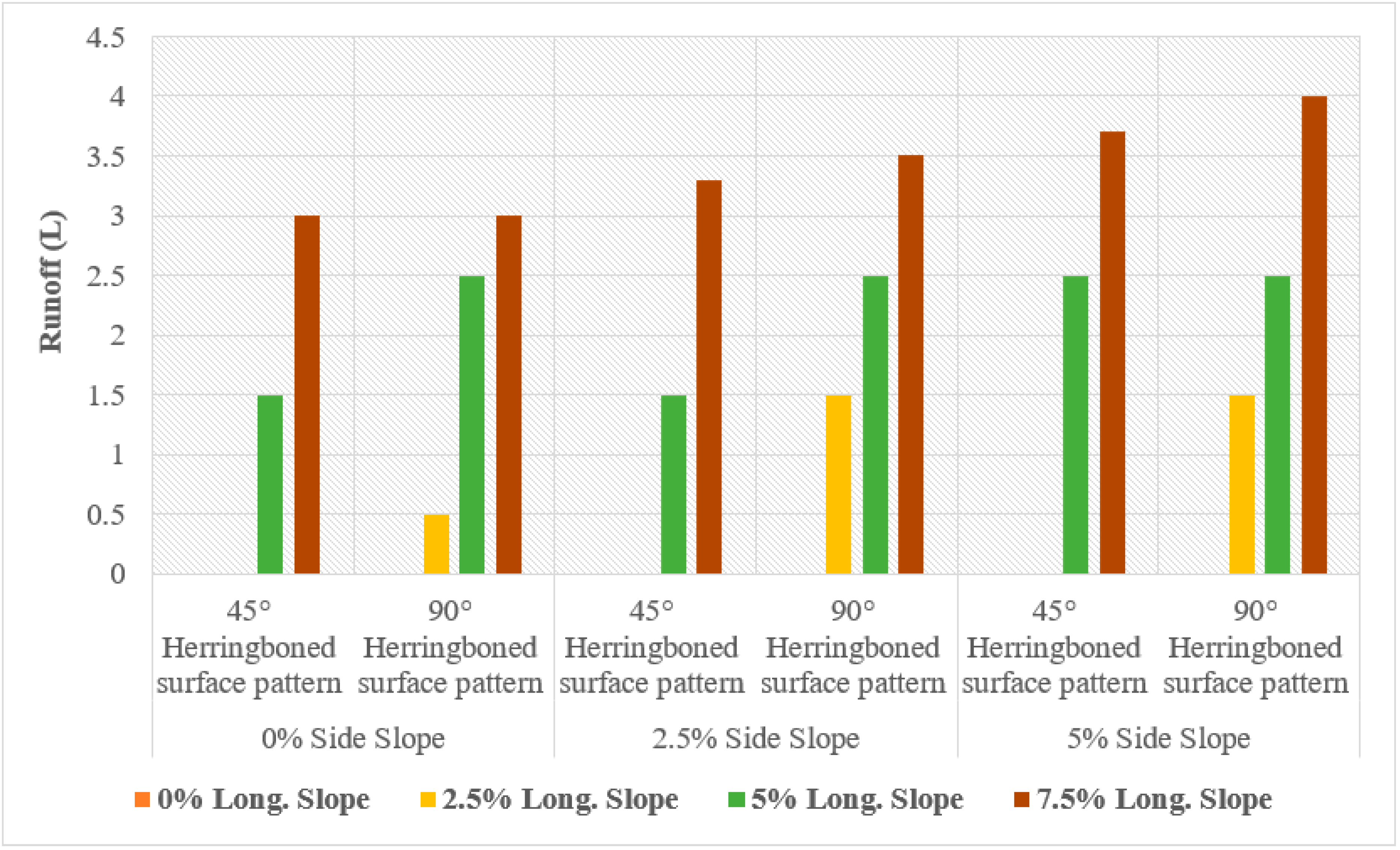

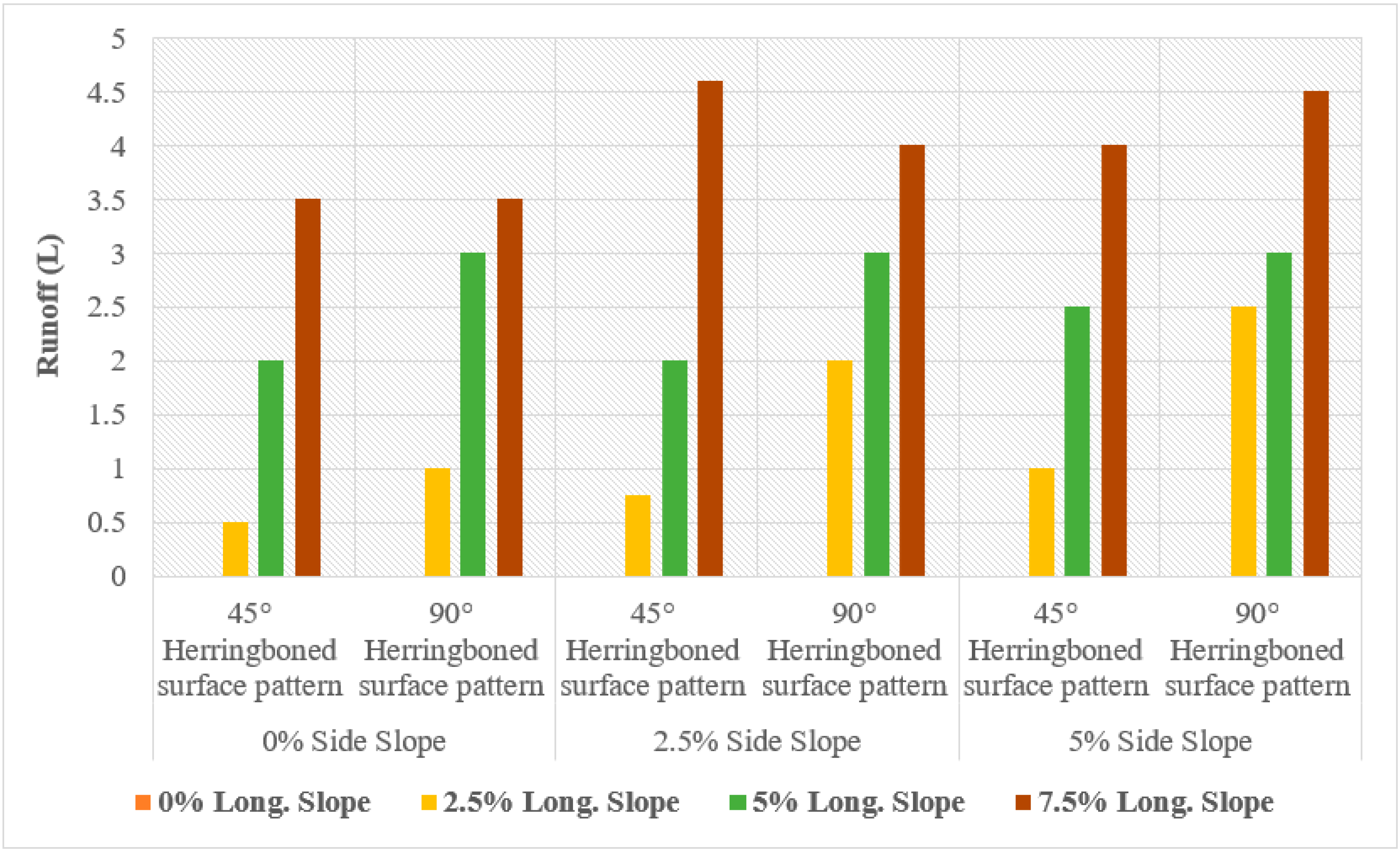

3.3. Runoff Water Volume for Both Surface Types of PICP

3.4. Load-Resistance forBboth Types of PICP

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hussein, S.A.; Al-Khafaji, Z.; Alfatlawi, T.J.M.; Abbood, A.-K.N. Improvement of Permeable Asphalt Pavement by adding Crumb Rubber. Open Eng. 2022, 12, 1030–1037. [Google Scholar] [CrossRef]

- Hashim, T.M.; Nasr, M.S.; Jebur, Y.M.; Kadhim, A.; Alkhafaji, Z.; Baig, M.G.; Adekunle, S.K.; Al-Osta, M.A.; Ahmad, S.; Yaseen, Z.M. Evaluating Rutting Resistance of Rejuvenated Recycled Hot-Mix Asphalt Mixtures Using Different Types of Recycling Agents. Materials 2022, 15, 8769. [Google Scholar] [CrossRef] [PubMed]

- Al-Khafaji, Z.S.; Jafer, H.; Dulaimi, A.F.; Atherton, W.; Al Masoodi, Z. The Soft Soil Stabilisation Using Binary Blending of Ordinary Portland Cement And High Alumina Silica Waste Material. In Proceedings of the The 3rd BUiD Doctoral Research Conference, Dubai, United Arab Emirates, 13 May 2017. [Google Scholar]

- Al-Masoodi, Z.O.; Al-Khafaji, Z.; Jafer, H.M.; Dulaimi, A.; Atherton, W. The effect of a high alumina silica waste material on the engineering properties of a cement-stabilised soft soil. In Proceedings of the 3rd BUiD Doctoral Research Conference, Dubai, United Arab Emirates, 13 May 2017. [Google Scholar]

- Al-Masoodi, Z.; Dulaimi, A.; Jafer, H.; Al-Khafaji, Z.; Atherton, W.; Safa, H. Soft Soil Treated with Waste Fluid Catalytic Cracking as a Sustainable Stabilizer Material. Iraqi Geol. J. 2022, 54, 84–98. [Google Scholar] [CrossRef]

- Hussain, A.J.; Al-Khafaji, Z.S. Reduction of environmental pollution and improving the (Mechanical, physical and chemical characteristics) of contaminated clay soil by using of recycled oil. J. Adv. Res. Dyn. Control Syst. 2020, 12, 1276–1286. [Google Scholar] [CrossRef]

- Hein, D.K.; Eng, P. Development of an ASCE standard for permeable interlocking concrete pavement. In Proceedings of the 2014 Conference of the Transportation Association of Canada Montréal, Montreal, QC, Canada, 28 September–1 October 2014; Volume 416, pp. 1–15. [Google Scholar]

- Yaseen, Z.M.; Jaafar, O.; Deo, R.C.; Kisi, O.; Adamowski, J.; Quilty, J.; El-Shafie, A. Stream-flow forecasting using extreme learning machines: A case study in a semi-arid region in Iraq. J. Hydrol. 2016, 542, 603–614. [Google Scholar] [CrossRef]

- Okasha, A.M.; Deraz, N.; Elmetwalli, A.H.; Elsayed, S.; Falah, M.W.; Farooque, A.A.; Yaseen, Z.M. Effects of Irrigation Method and Water Flow Rate on Irrigation Performance, Soil Salinity, Yield, and Water Productivity of Cauliflower. Agriculture 2022, 12, 1164. [Google Scholar] [CrossRef]

- Leipard, A.R.; Kevern, J.T.; Richardson, J.R. Hydraulic characterization and design of permeable interlocking concrete pavement. In Proceedings of the World Environmental and Water Resources Congress 2015, Austin, TX, USA, 17–21 May 2015. [Google Scholar]

- Hussein, S.A.; Al-Khafaji, Z.; Alfatlawi, T.; Abbood, A.-K.N. Assessment of Surface and Subsurface Drainage from Permeable Friction Course (As a Sustainable Pavement) under Different Geometric and Hydrologic Conditions. Iraqi Geol. J. 2022, 55, 196–207. [Google Scholar] [CrossRef]

- Smith, D.R. Permeable Interlocking Concrete Pavement [Techbrief]; Federal Highway Administration: Washington, DC, USA, 2019.

- Kayhanian, M.; Li, H.; Harvey, J.T.; Liang, X. Application of permeable pavements in highways for stormwater runoff management and pollution prevention: California research experiences. Int. J. Transp. Sci. Technol. 2019, 8, 358–372. [Google Scholar] [CrossRef]

- Drake, J.; Bradford, A.; Van Seters, T. Stormwater quality of spring–summer-fall effluent from three partial-infiltration permeable pavement systems and conventional asphalt pavement. J. Environ. Manag. 2014, 139, 69–79. [Google Scholar] [CrossRef]

- Drake, J.; Sarabian, T.; Jody, S. Maintenance Equipment Testing on Accelerated Clogged Permeable Interlocking Concrete Pavements; Interlocking Concrete Pavement Institute Foundation for Education and Research: Chantilly, VA, USA, 2020. [Google Scholar]

- Milad, A.; Adwan, I.; Majeed, S.A.; Yusoff, N.I.M.; Al-Ansari, N.; Yaseen, Z.M. Emerging Technologies of Deep Learning Models Development for Pavement Temperature Prediction. IEEE Access 2021, 9, 23840–23849. [Google Scholar] [CrossRef]

- Milad, A.; Yusoff, N.I.M.; Majeed, S.A.; Ali, Z.H.; Solla, M.; Al-Ansari, N.; Rahmat, R.A.; Yaseen, Z.M. An Educational Web-Based Expert System for Novice Highway Technology in Flexible Pavement Maintenance. Complexity 2021, 2021, 6669010. [Google Scholar] [CrossRef]

- Al Qurishee, M. Application of geosynthetics in pavement design. Int. Res. J. Eng. Technol. 2017, 4, 1–7. [Google Scholar]

- Zhang, K.; Kevern, J. Review of porous asphalt pavements in cold regions: The state of practice and case study repository in design, construction, and maintenance. J. Infrastruct. Preserv. Resil. 2021, 2, 4. [Google Scholar] [CrossRef]

- Hein, D.K.; Strecker, E.; Poresky, A.; Roseen, R. Permeable Shoulders with Stone Reservoirs; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA; Standing Committee on the Environment: Washington, DC, USA, 2013.

- Revitt, D.M.; Lundy, L.; Coulon, F.; Fairley, M. The sources, impact and management of car park runoff pollution: A review. J. Environ. Manag. 2014, 146, 552–567. [Google Scholar] [CrossRef] [PubMed]

- Weiss, P.T.; Kayhanian, M.; Khazanovich, L.; Gulliver, J.S. Permeable Pavements in Cold Climates: State of the Art and Cold Climate Case Studies; Center for Transportation Studies, University of Minnesota: Minneapolis, MN, USA, 2015. [Google Scholar]

- Admute, A.M.; Gandhi, A.V.; Adsul, S.S.; Agarkar, A.A.; Bhor, G.S.; Kolte, G.P. Permeable pavements: New technique for construction of road pavements in India. Int. Res. J. Eng. Technol. 2017, 4, 1810–1814. [Google Scholar]

- Zoccali, P.; Loprencipe, G.; Galoni, A. Sampietrini stone pavements: Distress analysis using pavement condition index method. Appl. Sci. 2017, 7, 669. [Google Scholar] [CrossRef]

- Hashim, T.M.; Al-mulali, M.Z.; Al-Khafaji, F.F.; Alwash, A.A.A.; Ali, Y.A. An Experimental Comparison between Different Types of Surface Patterns of Permeable Interlocking Concrete Pavement for Roadway Subsurface Drainage. Case Stud. Constr. Mater. 2022, 17, e01227. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Gubler, R.; Partl, M.N.; Pittet, M.; Arnaud, L.; Junod, A.; Dumont, A.-G.; Simond, E. Mechanical Properties of Porous Asphalt, Recommendations for Standardization; EMPA: Dübendorf, Switzerland, 2006. [Google Scholar]

- Huang, B.; Wu, H.; Shu, X.; Burdette, E.G. Laboratory evaluation of permeability and strength of polymer-modified pervious concrete. Constr. Build. Mater. 2010, 24, 818–823. [Google Scholar] [CrossRef]

- Lichten, K.; Schaus, L.K. How Should You Be Designing Your Permeable Pavements? New ASCE Standard. In Proceedings of the World Environmental and Water Resources Congress 2017, Sacramento, CA, USA, 21–25 May 2017; pp. 266–281. [Google Scholar]

- Liu, B.K.; Armitage, N.P. The link between Permeable Interlocking Concrete Pavement (PICP) design and nutrient removal. Water 2020, 12, 1714. [Google Scholar] [CrossRef]

- Simpson, I.M.; Winston, R.J.; Tirpak, R.A. Assessing maintenance techniques and in-situ pavement conditions to restore hydraulic function of permeable interlocking concrete pavements. J. Environ. Manag. 2021, 294, 112990. [Google Scholar] [CrossRef] [PubMed]

- Nichols, P.W.B.; Lucke, T.; Dierkes, C. Comparing two methods of determining infiltration rates of permeable interlocking concrete pavers. Water 2014, 6, 2353–2366. [Google Scholar] [CrossRef]

- Tirpak, A.; Winston, R.J.; Feliciano, M.; Dorsey, J.D. Stormwater quality performance of permeable interlocking concrete pavement receiving run-on from an asphalt traffic lane in a cold climate. Environ. Sci. Pollut. Res. 2020, 27, 21716–21732. [Google Scholar] [CrossRef]

- Smith, D.R.; Hein, D.K. Development of a National ASCE standard for permeable interlocking concrete pavement. In Proceedings of the Second Conference on Green Streets, Highways, and Development, Austin, TX, USA, 3–6 November 2013; pp. 89–105. [Google Scholar]

- Imran, H.M.; Akib, S.; Karim, M.R. Permeable pavement and stormwater management systems: A review. Environ. Technol. 2013, 34, 2649–2656. [Google Scholar] [CrossRef]

- Van Vuuren, J.H.; Dippenaar, M.A.; Van Biljon, R.; Van Rooy, L. Seepage through permeable interlocking concrete pavements and their subgrades using a large infiltration table apparatus. Int. J. Pavement Res. Technol. 2022, 15, 44–62. [Google Scholar] [CrossRef]

- Alzamly, S.A.; Aldefae, A.H.; Humaish, W.H.; Sinichenko, E.K.; Zubaidi, S.L. Design and manufacturing of rainfall simulator machine for the soil erosion investigation. In Geotechnical Engineering and Sustainable Construction: Sustainable Geotechnical Engineering; Springer: Berlin/Heidelberg, Germany, 2022; pp. 177–190. [Google Scholar]

- Mhaske, S.N.; Pathak, K.; Basak, A. A comprehensive design of rainfall simulator for the assessment of soil erosion in the laboratory. Catena 2019, 172, 408–420. [Google Scholar] [CrossRef]

- Yusuf, K.O.; Olaoke, S.O.; Iwayemi, A.K.; Adewoye, W.A.; Oyebode, O.O.; Omokore, S. Design and construction of a simple rainfall simulator from locally available materials. LAUTECH J. Eng. Technol. 2015, 9, 13–19. [Google Scholar]

- Mendes, T.A.; Pereira, S.A.D.S.; Rebolledo, J.F.R.; Gitirana, G.D.F.N., Jr.; Melo, M.T.D.S.; Luz, M.P.D. Development of a rainfall and runoff simulator for performing hydrological and geotechnical tests. Sustainability 2021, 13, 3060. [Google Scholar] [CrossRef]

- Kayhanian, M.; Weiss, P.T.; Gulliver, J.S.; Khazanovich, L. The Application of Permeable Pavement with Emphasis on Successful Design, Water Quality Benefits, and Identification of Knowledge and Data Gaps; National Center for Sustainable Transportation: Davis, CA, USA, 2015. [Google Scholar]

- Holmes, N.; O’Malley, H.; Cribbin, P.; Mullen, H.; Keane, G. Performance of masonry blocks containing different proportions of incinator bottom ash. Sustain. Mater. Technol. 2016, 8, 14–19. [Google Scholar] [CrossRef]

- ASTM, C. 563 standard: Standard test method for optimum SO3 in hydraulic cement using 24-h compressive strength. Annu. Book ASTM Stand. Sect. 2017, 4, 279–281. [Google Scholar]

- Kumar, G.R.; Sharma, U.K. Standard test methods for determination of abrasion resistance of concrete. Int. J. Civ. Eng. Res. 2014, 5, 155–162. [Google Scholar]

- Abdollahi, S.F.; Lanotte, M.; Kutay, M.E.; Bahia, H. AASHTO 1993 Plus: An alternative procedure for the calculation of structural asphalt layer coefficients. Int. J. Pavement Eng. 2022, 1–10. [Google Scholar] [CrossRef]

- Knothe, G.J. The Influence of Urbanization on Streams: The Use of GIS Spatial Analysis to Study Land Use Influence on Fish Communities, Water Quality and Physical Habitats in Southeast Texas; University of Houston-Clear Lake: Houston, TX, USA, 2012; ISBN 1267390638. [Google Scholar]

- Smith, D.R.; Sinagra, E.; Duvall, J. Surface Characteristics of Segmental Concrete Pavements Acceptable to Wheelchair Users. In Proceedings of the 12th International Conference on Concrete Block Pavement, Seoul, Republic of Korea, 16–19 October 2018; Volume 16. [Google Scholar]

- Pal, A.C.; Das, S.S. Interlocking aperture concrete block: An answer to permeable pavement. J. Inst. Eng. Ser. A 2019, 100, 427–438. [Google Scholar] [CrossRef]

| Layer Type | Role | Size of Aggregate | Designed Thickness |

|---|---|---|---|

| Concrete pavers | Permeable surface interlocking blocks to withstand the applied loads directly | Normal concrete block with 1:3:5 mixing proportion by volume | 8–10 cm of PICP [25]. |

| Bedding layer | Accommodation of the surface layer and distribution of the applied load to underlying layers | Small-sized, open-graded aggregate (AASHTO No. 8) [25]. | 4–5 cm of PICP [25]. |

| Reservoir layer | Temporary storage for infiltrated water | Base and subbase layers constructed using open-graded aggregate (AASHTO No. 57 over No. 2, 3, or 4) [25]. |

| Property | Compressive Strength | Absorption | SO3 | Thickness Reduction due to Abrasion |

|---|---|---|---|---|

| Result | 38.32 N/m2 | 2.63% | 2.75% | 1.84 mm |

| Limits | Minimum 35 N/m2 | Maximum 7% | Maximum 6% by weight of cement | Maximum 3.0 mm |

| Standards | ASTM C140 [41]. | ASTM C140 [41]. | ASTM C563-96 [42]. | ASTM C418 [43]. |

| Paving Layers | Surface Paver and Bedding | Base | Reservoir (Subbase) |

|---|---|---|---|

| Layer coefficient a | 0.3 | 0.09 | 0.06 |

| Design Method | Structural Method | Hydraulic Method |

|---|---|---|

| Reservoir depth | 35 cm | 30 cm |

| Design criteria | Minimum 20 cm | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shubbar, A.; Nasr, M.S.; Kadhim, A.; Hashim, T.M.; Sadique, M. Performance Comparison of 45° and 90° Herringboned Permeable Interlocking Concrete Pavement. Infrastructures 2023, 8, 97. https://doi.org/10.3390/infrastructures8050097

Shubbar A, Nasr MS, Kadhim A, Hashim TM, Sadique M. Performance Comparison of 45° and 90° Herringboned Permeable Interlocking Concrete Pavement. Infrastructures. 2023; 8(5):97. https://doi.org/10.3390/infrastructures8050097

Chicago/Turabian StyleShubbar, Ali, Mohammed Salah Nasr, Abdullah Kadhim, Tameem Mohammed Hashim, and Monower Sadique. 2023. "Performance Comparison of 45° and 90° Herringboned Permeable Interlocking Concrete Pavement" Infrastructures 8, no. 5: 97. https://doi.org/10.3390/infrastructures8050097

APA StyleShubbar, A., Nasr, M. S., Kadhim, A., Hashim, T. M., & Sadique, M. (2023). Performance Comparison of 45° and 90° Herringboned Permeable Interlocking Concrete Pavement. Infrastructures, 8(5), 97. https://doi.org/10.3390/infrastructures8050097