Evaluating the Performance of Lateritic Soil Stabilized with Cement and Biomass Bottom Ash for Use as Pavement Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

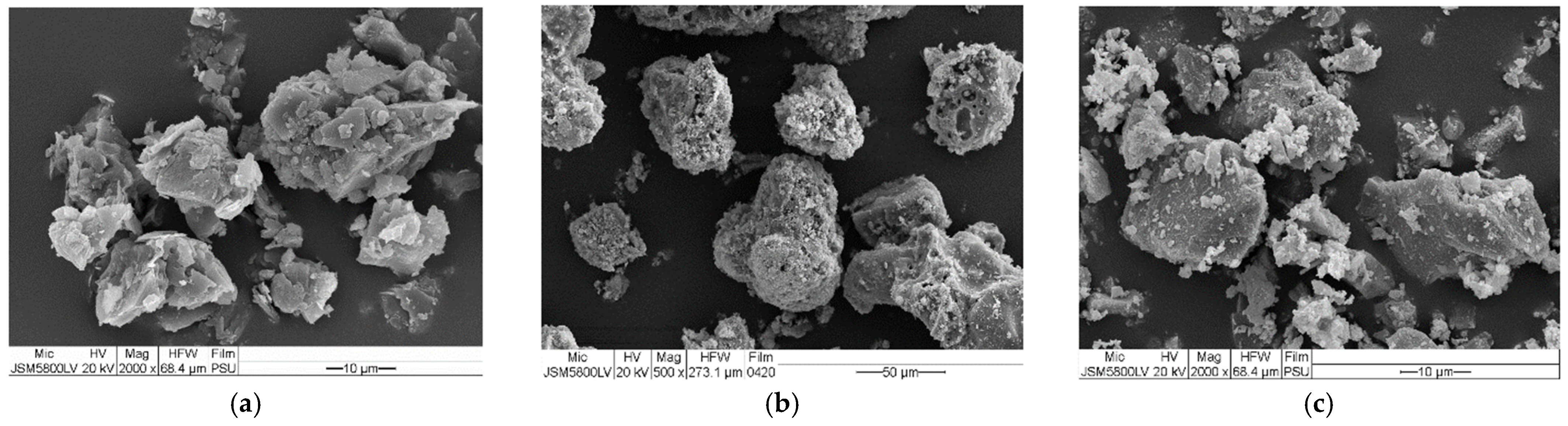

2.1.1. Lateritic Soil

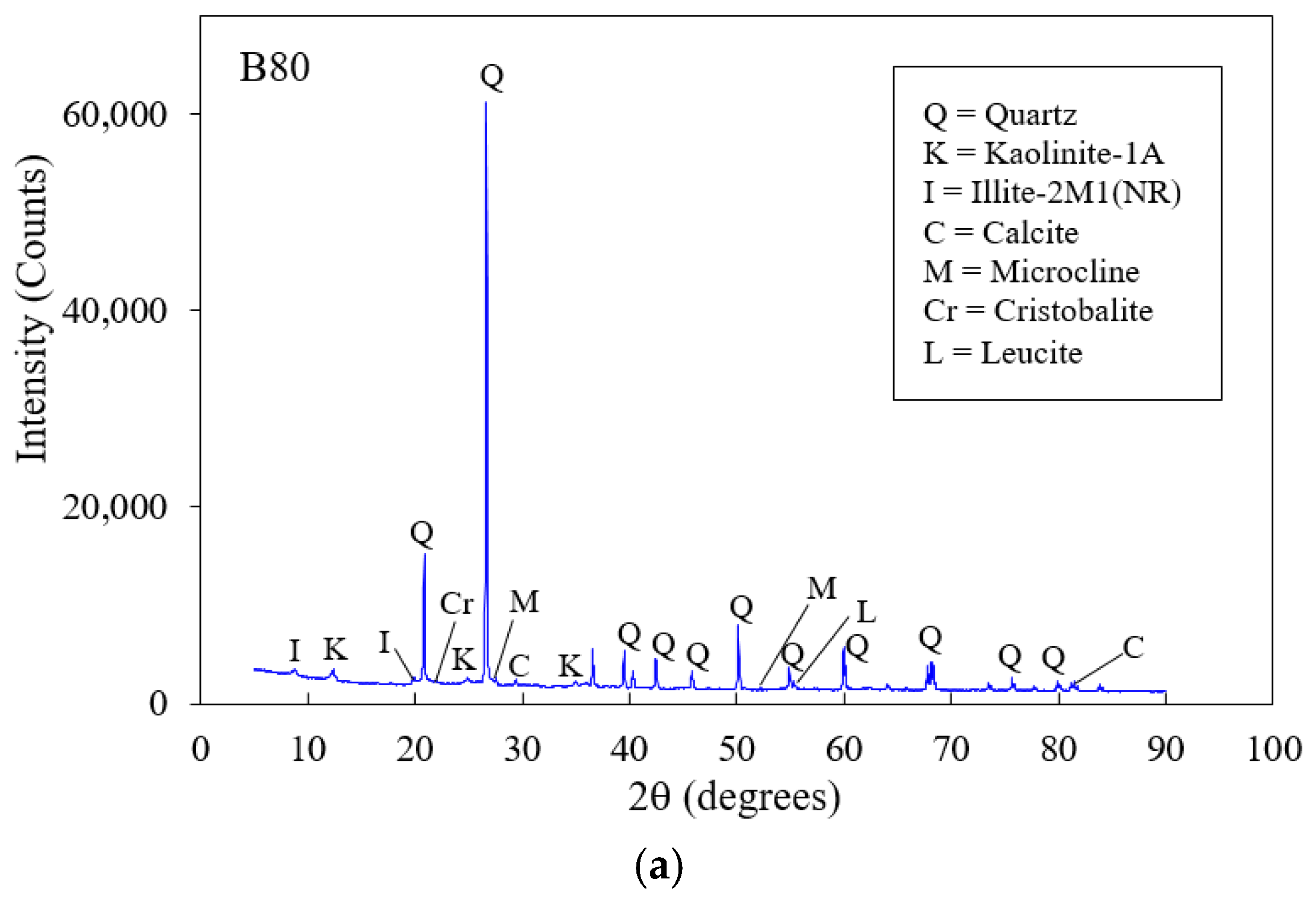

2.1.2. Biomass Bottom Ash

2.1.3. Hydraulic Cement

2.2. Sample Preparation and Testing

2.2.1. Compaction and CBR Tests

2.2.2. Unconfined Compression (UC) Test

2.2.3. Leachate Test

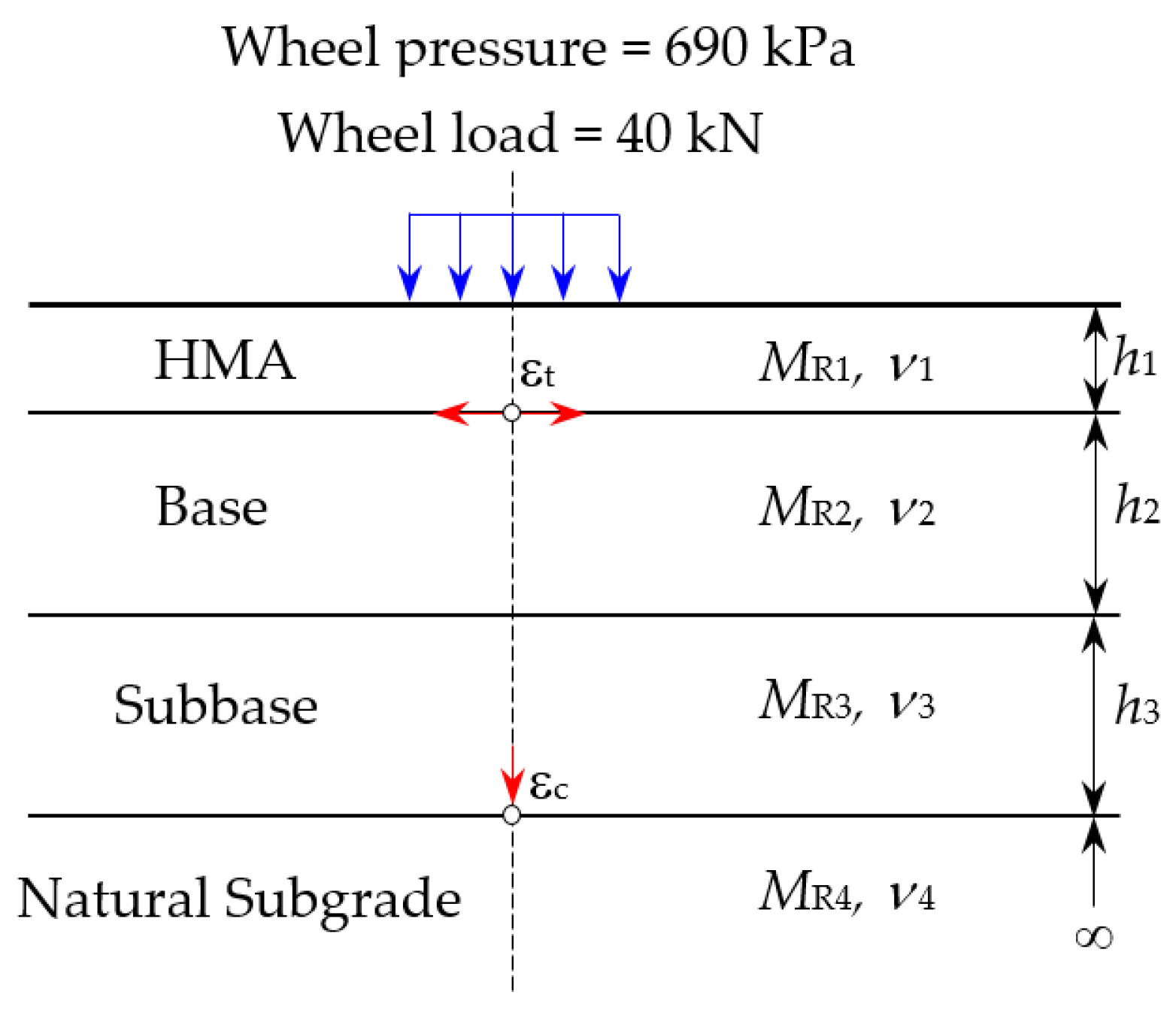

2.3. Pavement Design

- (i)

- Assigning the number of layers and the thickness of each layer based on the Thailand DOH. The four-layer systems (Figure 3) consisted of a hot mix asphalt (HMA) surface course, base course, subbase course, and natural subgrade.

- (ii)

- Assigning the traffic load condition of a single axle with a dual tire, standard axle load (80 kN), and contact pressure of 690 kPa.

- (iii)

- Pavement materials assumed linear elastic behavior for all layers. The Poisson’s ratio (ν) and resilient modulus (MR) were varied depending on specific layers. Determination of the MR values for the stabilized subbase material used the empirical correlation of the unconfined compressive strengths (qu) obtained from this experiment’s tests.

- (iv)

- The pavement response analysis to evaluate the benefits of using the CSS as road pavement materials were documented.

- (a)

- For untreated soil

- (b)

- For treated soil [44]MR = 149qu

- (c)

- For HMA, the MR value presented by Saglik and Gungor [45], which is a simplified Witczak’s dynamic modulus equation, was adopted. The experimental results from the study of Lukjan et al., 2022 [46] were used for assessing the MR values of the hot mix asphalt concrete (HMA) pavement:MR = 3.75 + 0.029P200 − 0.00177[P200]2 − 0.0028R4 − 0.058Va − 0.8[Vb/(Vb + Va)] + [A/B]A = 3.87 − 0.0021R4 + 0.004R3/8 − 1.7 × 10−5 [R3/8]2 + 0.0055R3/4where MR = resilient modulus (kPa), qu = unconfined compressive strength (kPa), Va = air void (%),Vb = effective asphalt content (%), P200 = passing No.200 sieve (%), R4 = retained No.4 sieve (%), R3/8 = retained No.3/8 sieve (%), R3/4 = retained No.3/4 sieve (%), and pen = penetration of asphalt cement.

2.4. Performance Analysis

3. Results

3.1. Compaction and CBR Characteristics

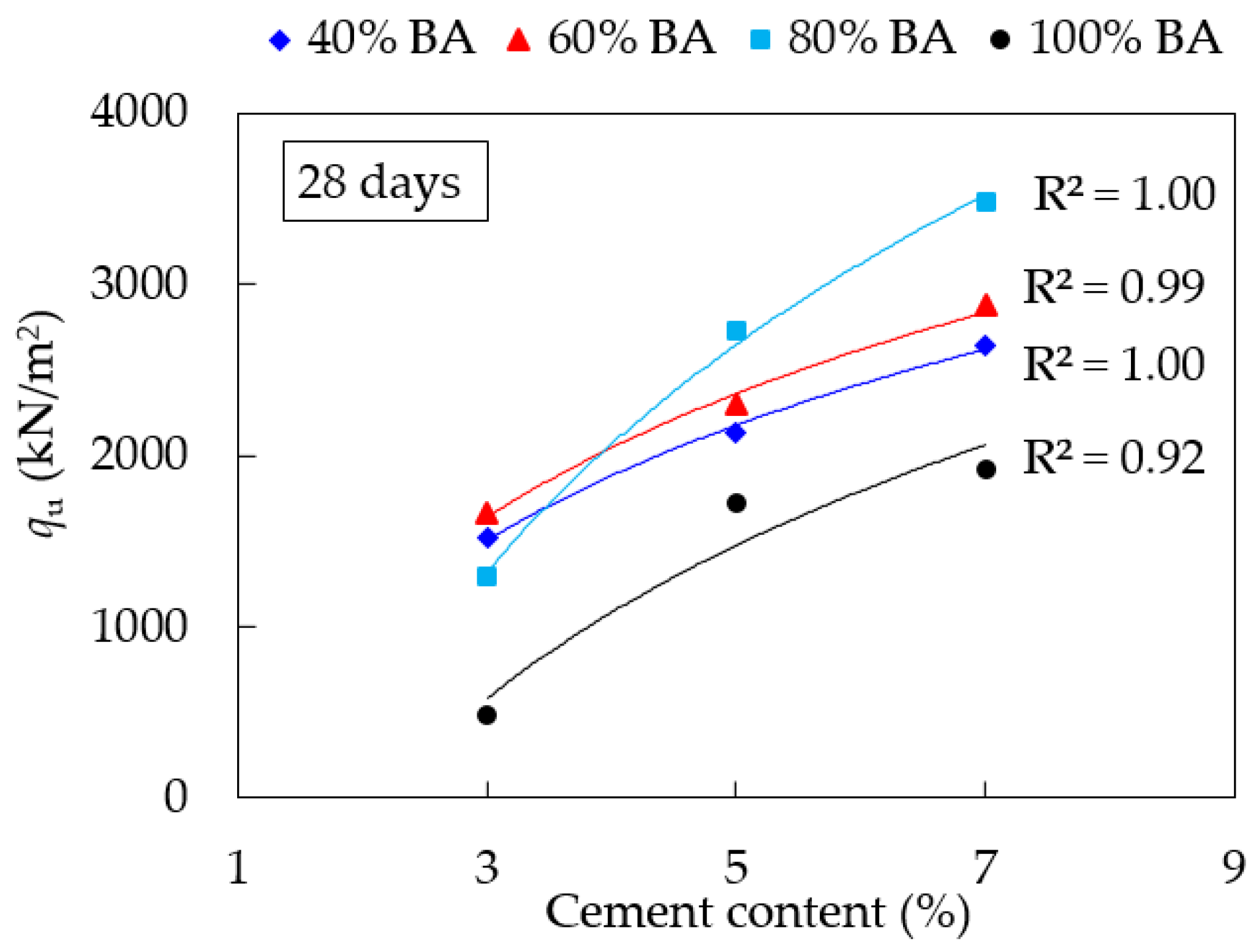

3.2. Effects of BA and HC Contents on Strength

3.3. Leaching Analysis

3.4. Pavement Design and Analysis

4. Discussions

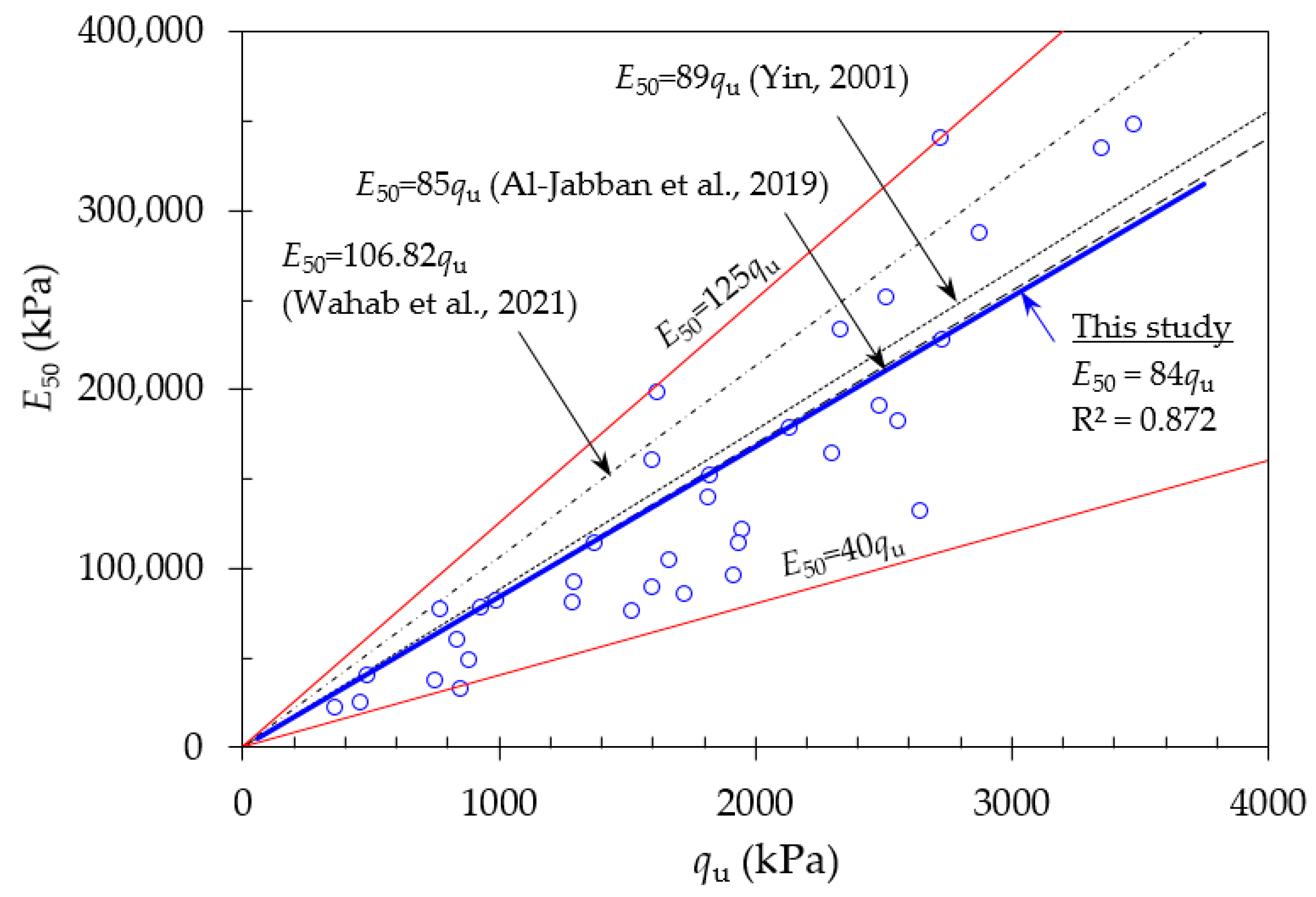

4.1. Strength Development and Stiffness

4.2. Benefit of BA for Subbase Stabilization

5. Conclusions

- The soaked CBR values of the poor-quality LS were improved as a result of blending with BA, which met the requirement for subbase material in the Thailand highway specifications. However, the LS mixed with BA was still unsuitable for use as road material, because the Cr concentration still exceeded the national allowable limits for drinking water.

- The results of the UC test on the CSS specimens indicated that it had a significant strength improvement, which satisfied the minimum requirement for soil–cement subbase course. To maximize the utilization of the BA, the blend of the LS with 80% BA and cement-stabilized with 5% is suggested for applications in the subbase layer of pavement. It had remarkable results in terms of geotechnical engineering properties and has no environmental impact.

- The results of the M–E approach pavement analysis indicated that using the CSS presented in this study as a soil–cement subbase layer would reduce the layer thickness by a maximum of 25%; extend the service life of the pavement; and extend the fatigue life and the rutting life by 1.20–1.27 times and 1.23–2.23 times respectively.

- The outcomes of this research could be helpful for the development of new mixtures for future use of recycled biomass bottom ash in pavement applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Office of the National Economic and Social Development Board. National Strategy (2018–2037). 2018. Available online: https://sto.go.th/en/about/policy/20-year-strategic-plan (accessed on 8 April 2022).

- Rashid, A.S.A.; Latifi, N.; Meehan, C.L.; Manahiloh, K.N. Sustainable improvement of tropical residual soil using an environmentally friendly additive. Geotech. Geol. Eng. 2017, 35, 2613–2623. [Google Scholar] [CrossRef]

- Fredlund, D.G.; Rahardjo, H. Soil Mechanics for Unsaturated Soils; John Wiley&Sons, Inc.: New York, NY, USA, 1993. [Google Scholar]

- Koppejan, J.; Van Loo, S. The Handbook of Biomass Combustion and Co-Firing; Routledge: London, UK, 2012. [Google Scholar]

- Lu, Y.; Tian, A.; Zhang, J.; Tang, Y.; Shi, P.; Tang, Q.; Huang, Y. Physical and chemical properties, pretreatment, and recycling of municipal solid waste incineration fly ash and bottom ash for highway engineering: A literature review. Adv. Civ. Eng. 2020, 2020, 8886134. [Google Scholar] [CrossRef]

- López, E.L.; Vega-Zamanillo, A.; Pérez, M.A.C.; Hernández-Sanz, A. Bearing capacity of bottom ash and its mixture with soils. Soil Found. 2015, 55, 529–535. [Google Scholar] [CrossRef]

- Cabrera, M.; Galvín, A.P.; Agrela, F.; Carvajal, M.D.; Ayuso, J. Characterisation and technical feasibility of using biomass bottom ash for civil infrastructures. Constr. Build. Mater. 2014, 58, 234–244. [Google Scholar] [CrossRef]

- Paine, K.A.; Dhir, R.K.; Doran, V.P.A. Incinerator bottom ash: Engineering and environmental properties as a cement bound paving material. Int. J. Pavement Eng. 2002, 3, 43–52. [Google Scholar] [CrossRef]

- Jaritngam, S.; Somchainuek, O.; Taneerananon, P. An investigation of lateritic soil cement for sustainable pavements. Indian J. Sci. Technol. 2012, 5, 2603–2606. [Google Scholar] [CrossRef]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of woody biomass fly ash in cement-based materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- Donrak, J.; Hoy, M.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M.; Rashid, A.S.A. Environmental assessment of cement stabilized marginal lateritic soil/melamine debris blends for pavement applications. Environ. Geotech. 2019, 1–7. [Google Scholar] [CrossRef]

- Wahab, N.A.; Roshan, M.J.; Rashid, A.S.A.; Hezmi, M.A.; Jusoh, S.N.; Norsyahariati, N.D.N.; Tamassoki, S. Strength and durability of cement-treated lateritic soil. Sustainability. 2021, 13, 6430. [Google Scholar] [CrossRef]

- Ghosh, A.; Subbarao, C. Hydraulic conductivity and leachate characteristics of stabilized fly ash. J Env. Eng. 1998, 124, 812–820. [Google Scholar] [CrossRef]

- Bruder-Hubscher, V.; Lagarde, F.; Leroy, M.J.F.; Coughanowr, C.; Enguehard, F. Utilisation of bottom ash in road construction: Evaluation of the environmental impact. Waste Manag. Res. 2001, 19, 545–556. [Google Scholar] [CrossRef]

- Yoon, S.; Balunaini, U.; Yildirim, I.Z.; Prezzi, M.; Siddiki, N.Z.J. Construction of an embankment with a fly and bottom ash mixture: Field performance study. Mater. Civ. Eng. 2009, 21, 271–278. [Google Scholar] [CrossRef]

- Dabo, D.; Badreddine, R.; De Windt, L.; Drouadaine, I. Ten-year chemical evolution of leachate and municipal solid waste incineration bottom ash used in a test site. J. Hazard. Mater. 2009, 172, 904–913. [Google Scholar] [CrossRef]

- del Valle-Zermeño, R.; Formosa, J.; Prieto, M.; Nadal, R.; Niubó, M.; Chimenos, J.M. Pilot-scale road subbase made with granular material formulated with MSWI bottom ash and stabilized APC fly ash: Environmental impact assessment. J. Hazard Mater. 2014, 266, 132–140. [Google Scholar] [CrossRef]

- Cabrera, M.; Galvín, A.P.; Agrela, F.; Beltran, M.G.; Ayuso, J. Reduction of leaching impacts by applying biomass bottom ash and recycled mixed aggregates in structural layers of roads. Materials 2016, 9, 228. [Google Scholar] [CrossRef]

- Selvi, P. Fatigue and rutting strain analysis on lime stabilized subgrades to develop a pavement design chart. Transp. Geotech. 2015, 2, 86–98. [Google Scholar] [CrossRef]

- Lekha, B.M.; Goutham, S.; Shankar, A.U.R. Evaluation of lateritic soil stabilized with Arecanut coir for low volume pavements. Transp. Geotech. 2015, 2, 20–29. [Google Scholar] [CrossRef]

- Sahu, V.; Srivastava, A.; Misra, A.K.; Sharma, A.K. Stabilization of fly ash and lime sludge composites: Assessment of its performance as base course material. Arch. Civ. Mech. Eng. 2017, 17, 475–485. [Google Scholar] [CrossRef]

- Anaokar, M.; Mhaiskar, S. Numerical analysis of lime stabilized capping under embankments based on expansive subgrades. Heliyon 2019, 5, e02473. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Li, Z. Embankment displacement PLAXIS simulation and microstructure behavior of treated-coal gangue. Minerals 2020, 10, 218. [Google Scholar] [CrossRef]

- Sultan, S.A.; Guo, Z. Evaluating the performance of sustainable perpetual pavement using recycled asphalt pavement in China. Int. J. Transp. Sci. Technol. 2016, 5, 200–209. [Google Scholar] [CrossRef]

- Loulizi, A.; Al-Qadi, I.L.; Elseifi, M. Difference between in situ flexible pavement measured and calculated stresses and strains. J. Transp. Eng. 2006, 132, 574–579. [Google Scholar] [CrossRef]

- Solanki, P.; Zaman, M.; Muraleetharan, K.K.; Timm, D. Evaluation of resilient moduli of pavement layers at an instrumented section on I-35 in Oklahoma. Road Mater. Pavement Des. 2009, 10, 167–188. [Google Scholar] [CrossRef]

- Solanki, P.; Zaman, M. Design of semi-rigid type of flexible pavement. Int. J. Pavement Res. Technol. 2017, 10, 99–111. [Google Scholar] [CrossRef][Green Version]

- Galvín, A.P.; López-Uceda, A.; Cabrera, M.; Rosales, J.; Ayuso, J. Stabilization of expansive soils with biomass bottom ashes for an eco-efficient construction. Environ. Sci. Pollut. Res. 2020, 28, 24441–24454. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2013, 47, 1055–1065. [Google Scholar] [CrossRef]

- Tosti, L.; Zomeren, A.V.; Pels, J.R.; Damgaard, A.; Comans, R.N.J. Life cycle assessment of the reuse of fly ash from biomass combustion as secondary cementitious material in cement products. J. Clean. Prod. 2020, 245, 118937. [Google Scholar] [CrossRef]

- Songkhla Province. Songkhla Provincial Development Plan (2018–2022). 2021. Available online: https://www.songkhla.go.th/news_develop_plan (accessed on 8 April 2022). (In Thai).

- Department of Highways (DOH). Standard of Soil-Cement Subbase; DH-S 206/2532; Department of Highways Standard: Bangkok, Thailand, 1989. (In Thai)

- Horpibulsuk, S.; Phetchuay, C.; Chinkulkijniwat, A.; Cholaphatsorn, A. Strength development in silty clay stabilized with calcium carbide residue and fly ash. Soils Found. 2013, 53, 477–486. [Google Scholar] [CrossRef]

- Fookes, P.G. Tropical Residual Soils: A Geological Society Engineering Group; Geological Society of London: London, UK, 1997. [Google Scholar]

- ASTM. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM C 618; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Thai Industrial Standards Institute (TISI). Hydraulic Cement; TIS 2594-2013; Industrial Product Standards: Bangkok, Thailand, 2013. (In Thai)

- ASTM. Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2700 kN-m/m3); ASTM D 1557; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils; ASTM D 1883; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Huang, Y.H. Pavement Analysis and Design, 2nd ed.; Prentice Hall Inc.: Hoboken, NJ, USA, 2004. [Google Scholar]

- Miller, G.A.; Cerato, A.B.; Snethen, D.R.; Holderby, E.; Boodagh, P. Empirical method for predicting time-dependent strength and resilient modulus of chemically treated soil. Transp. Geotech. 2021, 29, 100551. [Google Scholar] [CrossRef]

- AASHTO. AASHTO Guide for Design of Pavement Structures; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2003. [Google Scholar]

- Heukelom, W.; Klom, A.J.G. Dynamics Testing as a Means of Controlling Pavement During and After Construction. In Proceeding of the International Conference on the Structure Design of Asphalt Pavement, Ann Arbor, MI, USA, 20–24 August 1962. [Google Scholar]

- Powell, W.D.; Potter, J.F.; Mayhew, H.C.; Nunn, M.E. The Structural Design of Bituminous Roads; TRRL Report 1132; Transport and Road Research Laboratory (TRRL): Berkshire, UK, 1984. [Google Scholar]

- Yoobanpot, N.; Jamsawang, P.; Simarat, P.; Pornkasem, J.; Likitlersuang, S. Sustainable reuse of dredged sediments as pavement materials by cement and fly ash stabilization. J. Soils Sediments 2020, 20, 3807–3823. [Google Scholar] [CrossRef]

- Sağlik, A.; Gungor, G. Resilient modulus of unbound and bituminous bound road materials. In Proceeding of the 5th Eurasphalt & Eurobitume Congress, Istanbul, Turkey, 13–15 June 2012. [Google Scholar]

- Lukjan, A.; Iyaruk, A.; Somboon, C. Evaluation on mechanical deterioration of the asphalt mixtures containing waste materials when exposed to corrosion solutions. Int. J. Eng. Technol. Innov. 2022, 12, 130–144. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Yi-qiu, T. Mechanistic approach for polypropylene-modified flexible pavements. Mater. Des. 2009, 30, 1133–1140. [Google Scholar] [CrossRef]

- Timm, D.; Birgisson, B.; Newcomb, D. Development of mechanistic-empirical pavement design in Minnesota. Transp. Res. Rec. 1998, 1629, 181–188. [Google Scholar] [CrossRef]

- Lynn, C.J.; Ghataora, G.S.; Dhir OBE, R.K. Municipal incinerated bottom ash (MIBA) characteristics and potential for use in road pavements. Int. J. Pavement Res. Technol. 2017, 10, 185–210. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Katkan, W.; Sirilerdwattana, W.; Rachan, R. Strength development in cement stabilized low plasticity and coarse grained soils: Laboratory and field study. Soils Found. 2006, 46, 351–366. [Google Scholar] [CrossRef]

- Yoobanpot, N.; Jamsawang, P. Effect of cement replacement by rice husk ash on soft soil stabilization. Kasetsart J. (Nat. Sci.) 2014, 48, 323–332. [Google Scholar]

- Ministry of Natural Resources and Environment, Thailand. Soil Quality Standards; The notification of the national environmental committee: Bangkok, Thailand, 2021. (In Thai)

- Ministry of Natural Resources and Environment, Thailand. Groundwater Quality Standards; The notification of the national environmental committee: Bangkok, Thailand, 2004. (In Thai)

- US Environmental Protection Agency: US EPA. National Primary Drinking Water Regulations; EPA: Washington, DC, USA, 2009.

- Wartman, J.; Grubb, D.G.; Nasim, A. Select engineering characteristics of crushed glass. J. Mater. Civ. Eng. 2004, 16, 526–539. [Google Scholar] [CrossRef]

- Dermatas, D.; Meng, X. Utilization of fly ash for stabilization/solidification of heavy metal contaminated soils. Eng. Geol. 2003, 70, 377–394. [Google Scholar] [CrossRef]

- Rechard, Y. The Development and Evaluation of Protocols for the Laboratory Characterisation of Cemented Materials; Austroads Technical Report, AP-T101/08; Austroads: Sydney, Australia, 2008. [Google Scholar]

- Cabrera, M.; Agrela, F.; Ayuso, J.; Galvin, A.P.; Rosales, J. Feasible use of biomass bottom ash in the manufacture of cement treated recycled materials. Mater. Struct. 2016, 49, 3227–3238. [Google Scholar] [CrossRef]

- Al-Jabban, W.; Laue, J.; Knutsson, S.; Al-Ansari, N. A comparative evaluation of cement and by-product petrit T in soil stabilization. Appl. Sci. 2019, 9, 5238. [Google Scholar] [CrossRef]

- Yin, J.-H. Stress-strain-strength characteristics of soft Hong Kong marine deposits without or with cement treatment. Lowland Technol. Int. 2001, 3, 1–13. [Google Scholar]

- Horpibulsuk, S.; Rachan, R.; Chinkulkitnuwat, A.; Raksachon, T. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

| Materials | Specific Gravity | Consistency Limit (%) | D50 (mm) | Soil Fraction (%) | USCS Symbol | ||||

|---|---|---|---|---|---|---|---|---|---|

| LL | PL | PI | Gravel | Sand | Silt & Clay | ||||

| LS | 2.755 | 30 | 21 | 9 | 0.15 | 32 | 21 | 47 | GC |

| BA | 2.405 | Non-plastic | 1.60 | 26 | 71 | 3 | SP | ||

| Materials | Chemical Composing (%) | LOI | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | SO3 | TiO2 | Na2O | P2O5 | Other | ||

| LS | 59.79 | 20.59 | 8.07 | 0.04 | 1.48 | 3.05 | 0.07 | 0.87 | 0.03 | 0.12 | 0.33 | 5.56 |

| BA | 61.73 | 8.57 | 5.32 | 11.4 | 1.77 | 5.02 | 0.17 | 0.71 | 0.14 | 1.17 | 0.46 | 3.54 |

| HC | 15.12 | 3.49 | 2.98 | 64.99 | 1.29 | 0.46 | 2.81 | 0.27 | 0.11 | 0.06 | 0.23 | 8.19 |

| Testing | LS:BA Proportions | Cement Content (%) | Water Content (%) | Curing Time (days) | Remark |

|---|---|---|---|---|---|

| Compaction | 100:0, 60:40, 40:60, 20:80, 0:100 | 0 | - | - | Uncemented specimens |

| 60:40, 40:60, 20:80, 0:100 | 3, 5, 7 | - | - | CSS specimens | |

| Soaked CBR | 100:0, 60:40, 40:60, 20:80, 0:100 | 0 | OMC | 4 | Uncemented specimens |

| UC test | 60:40, 40:60, 20:80, 0:100 | 3, 5, 7 | OMC | 7, 14, 28 | CSS specimens |

| Specimens | BA Content (%) | Cement Content (%) | qu (kPa) | E50 (kPa) | ||||

|---|---|---|---|---|---|---|---|---|

| Curing Time (Days) | Curing Time (Days) | |||||||

| 7 | 14 | 28 | 7 | 14 | 28 | |||

| B0C0 | 0 | 0 | 482 | 482 | 482 | 482 | 482 | 482 |

| B40C3 | 40 | 3 | 774 | 1294 | 1522 | 77,400 | 92,429 | 76,100 |

| B60C3 | 60 | 3 | 848 | 1602 | 1666 | 32,615 | 89,000 | 104,125 |

| B80C3 | 80 | 3 | 753 | 839 | 1290 | 37,650 | 59,929 | 80,625 |

| B100C3 | 100 | 3 | 361 | 459 | 485 | 22,563 | 25,500 | 40,417 |

| B40C5 | 40 | 5 | 987 | 1933 | 2136 | 82,250 | 113,706 | 178,000 |

| B60C5 | 60 | 5 | 932 | 1823 | 2299 | 77,667 | 151,917 | 164,214 |

| B80C5 | 80 | 5 | 1374 | 2332 | 2726 | 114,500 | 233,200 | 340,750 |

| B100C5 | 100 | 5 | 883 | 1600 | 1722 | 48,938 | 160,000 | 86,100 |

| B40C7 | 40 | 7 | 1947 | 2556 | 2647 | 121,688 | 182,571 | 132,350 |

| B60C7 | 60 | 7 | 2284 | 2731 | 2874 | 207,000 | 227,583 | 287,400 |

| B80C7 | 80 | 7 | 2511 | 3350 | 3477 | 251,100 | 335,000 | 347,700 |

| B100C7 | 100 | 7 | 1620 | 1818 | 1916 | 198,417 | 139,846 | 95,800 |

| From Solid Sample | From Leachate Sample | ||||||

|---|---|---|---|---|---|---|---|

| B100 (mg/kg) | Allowable Limits (mg/kg) [52] | B100 (ppm) | B80C0 (ppm) | B80C5 (ppm) | Allowable Limits (ppm) [53]/[54] | Threshold Limit (ppm) [53]/[54] | |

| Arsenic (As) | 14.80 | 6 | ND | ND | ND | 0.01/0.01 | 1.00/1.00 |

| Cadmium (Cd) | ND | 67 | ND | ND | ND | 0.003/0.005 | 0.30/0.50 |

| Chromium (Cr) | 82.86 | 17.5 | 0.065 | 0.052 | 0.0225 | 0.05/0.10 | 5.00/10.00 |

| Copper (Cu) | 16.60 | 2920 | 0.102 | 0.081 | 0.0731 | 1.00/1.00 | 100.00/100.00 |

| Nickel (Ni) | 16.64 | 436.5 | 0.008 | 0.006 | 0.0032 | 0.02/- | 2.00/- |

| Lead (Pb) | ND | 400 | ND | ND | ND | 0.01/0.015 | 1.00/1.50 |

| Zinc (Zn) | 32.02 | - | 0.017 | 0.016 | 0.0105 | 5.00/5.00 | 500.00/500.00 |

| Model Layer | Pavement Layer | h(cm) | Conventional Materials | Stabilized-Subbase Materials | |||||

|---|---|---|---|---|---|---|---|---|---|

| MR (MPa) | ν | CBR (%) | MR (MPa) | ν | CBR (%) | qu (MPa) | |||

| 1 | HMA | 10 | 3000 | 0.35 | - | 3,000 | 0.35 | - | - |

| 2 | Base | 20 | 300 | 0.35 | 85 | 300 | 0.35 | 85 | - |

| 3 | Subbase | 20, 17.5, 15, 12.5 | 150 | 0.35 | 30 | 400 | 0.30 | - | 2.70 |

| 4 | Subgrade | ∞ | 50 | 0.40 | 5 | 50 | 0.40 | 5 | - |

| Subbase Course | Constant HMA and Base Course | |||||||

|---|---|---|---|---|---|---|---|---|

| Subbase Thicks, mm | Δz (mm) | εt (×10−4) | εc (×10−4) | Nf (×106) | Nr (×106) | TBRf | TBRr | |

| Unstabilized | 200 | 0.55 | 2.41 | 4.44 | 1.16 | 1.08 | 1.00 | 1.00 |

| Stabilized | 200 | 0.48 | 2.24 | 3.63 | 1.47 | 2.41 | 1.27 | 2.23 |

| 175 | 0.49 | 2.26 | 3.90 | 1.44 | 1.81 | 1.24 | 1.67 | |

| 150 | 0.51 | 2.25 | 4.20 | 1.39 | 1.34 | 1.20 | 1.23 | |

| 125 | 0.60 | 2.35 | 5.31 | 1.25 | 0.53 | 1.08 | 0.49 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iyaruk, A.; Promputthangkoon, P.; Lukjan, A. Evaluating the Performance of Lateritic Soil Stabilized with Cement and Biomass Bottom Ash for Use as Pavement Materials. Infrastructures 2022, 7, 66. https://doi.org/10.3390/infrastructures7050066

Iyaruk A, Promputthangkoon P, Lukjan A. Evaluating the Performance of Lateritic Soil Stabilized with Cement and Biomass Bottom Ash for Use as Pavement Materials. Infrastructures. 2022; 7(5):66. https://doi.org/10.3390/infrastructures7050066

Chicago/Turabian StyleIyaruk, Arsit, Panu Promputthangkoon, and Arun Lukjan. 2022. "Evaluating the Performance of Lateritic Soil Stabilized with Cement and Biomass Bottom Ash for Use as Pavement Materials" Infrastructures 7, no. 5: 66. https://doi.org/10.3390/infrastructures7050066

APA StyleIyaruk, A., Promputthangkoon, P., & Lukjan, A. (2022). Evaluating the Performance of Lateritic Soil Stabilized with Cement and Biomass Bottom Ash for Use as Pavement Materials. Infrastructures, 7(5), 66. https://doi.org/10.3390/infrastructures7050066