Risk Management of Bored Piling Construction on Sandy Soils with Real-Time Cost Control

Abstract

1. Introduction

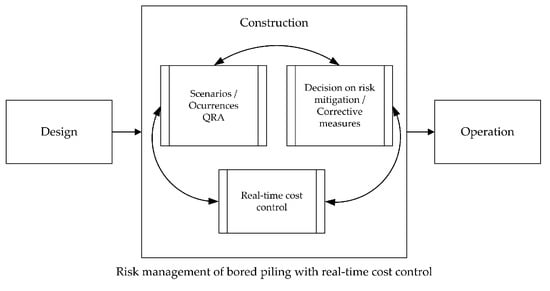

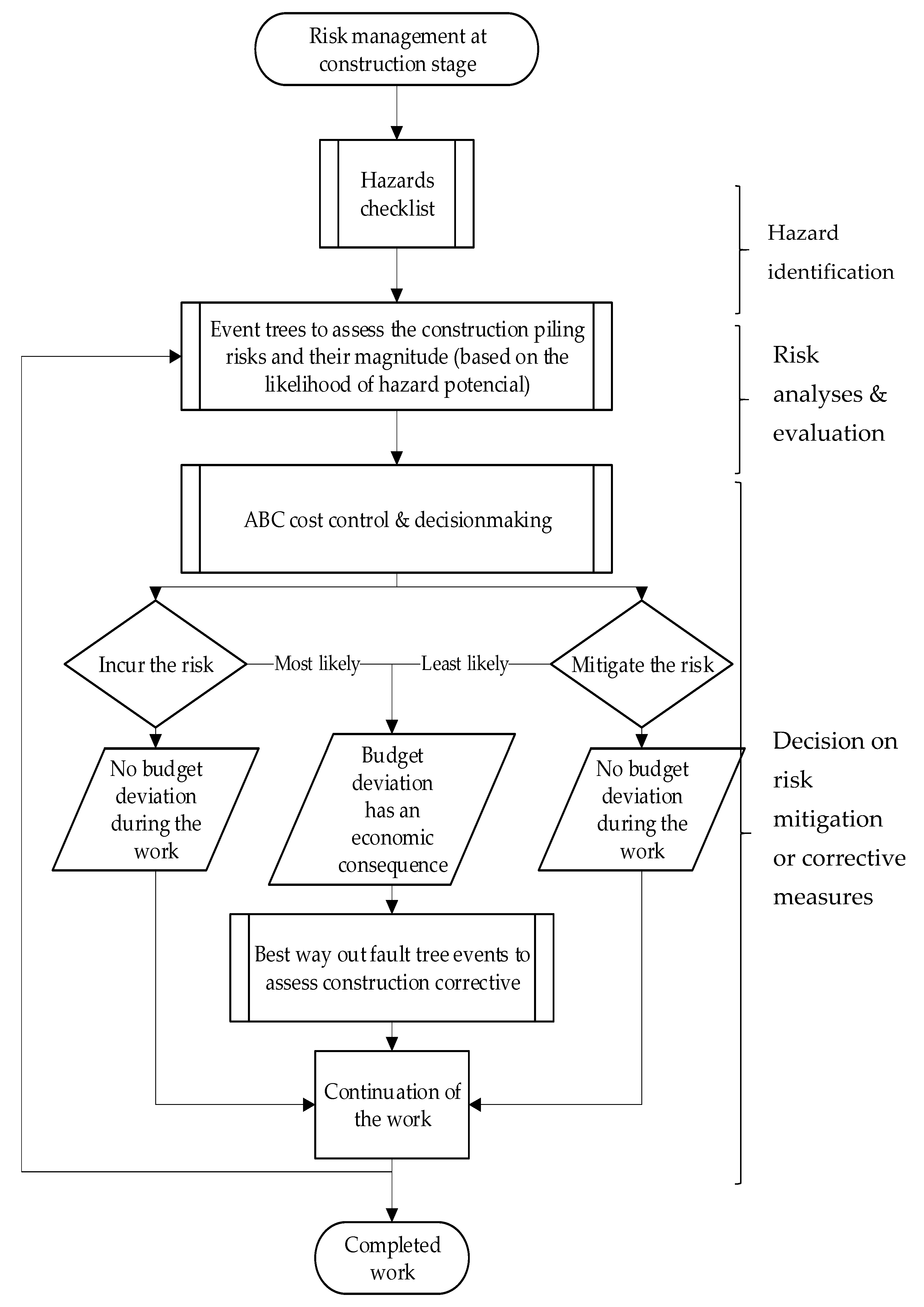

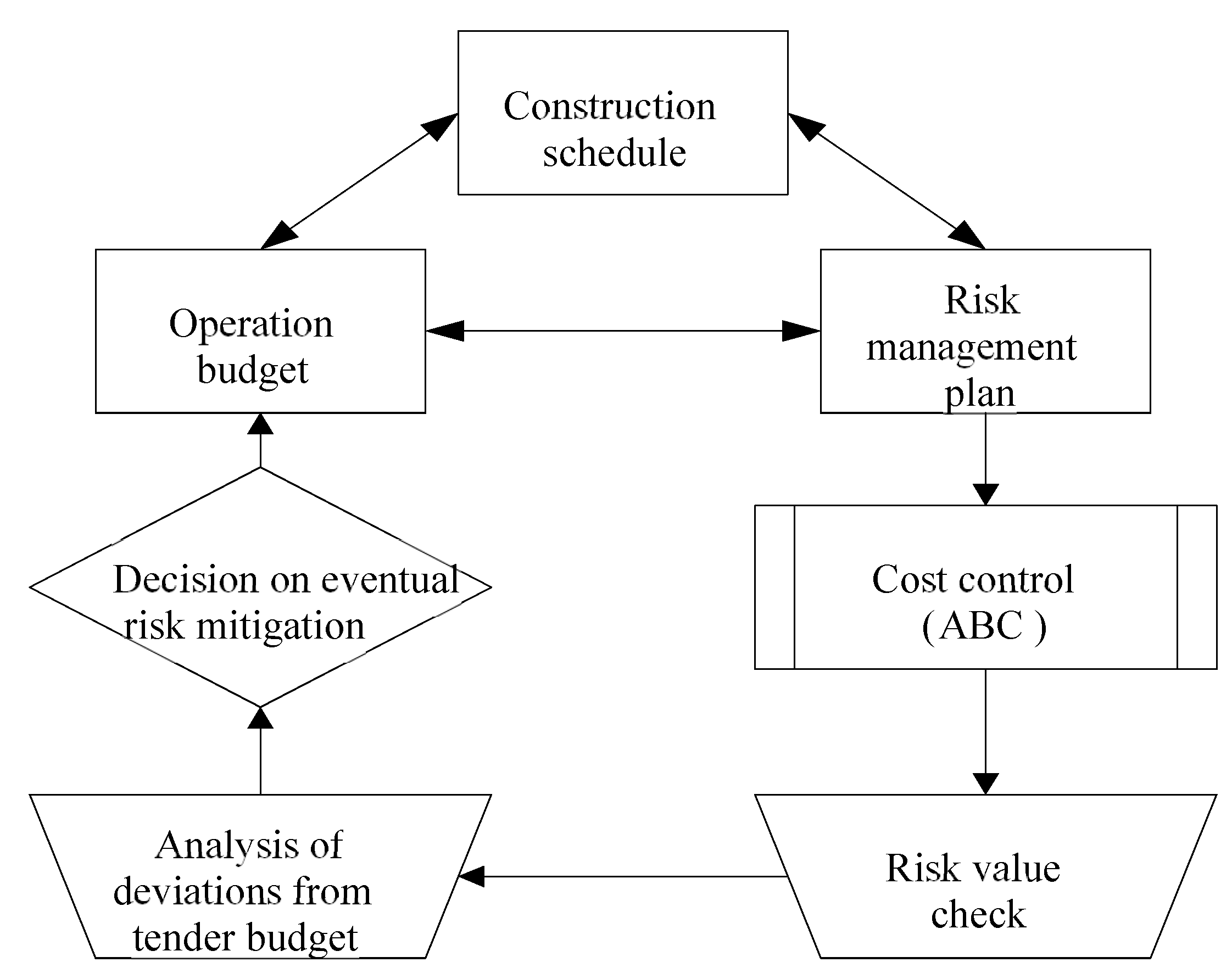

2. Risk Associated with Bored Piles Construction

3. Proposed Methodology and Its Justification

- -

- Geological hazards: as a potential source of consequences, the uncertainties of the geological environment have significant implications for construction. If there are enough small variations in lithology or groundwater level not considered in the project, it can lead to the rethink of the entire construction process and the need to review the project. Adequate site investigation is the best way to avoid them; however, it is important to define the acceptable cost for the information obtained. Nevertheless, imponderable situations, intrinsic to geology, may still happen because it is not affordable to have a survey at each pile to be built [17];

- -

- Human hazards: events that have as a potential source of damage to the works the site operatives. Their training and skills are relevant for the construction of foundations—for example, continuous education and training for operatives directly or indirectly involved at works is key to the successful use of bentonite suspensions. Local culture directly influences productivity and the acceptability of risks [34,35], so it is necessary to know local customs to maximize productivity. Human error was not considered, as in the case studies consulted it was not identified so their associated likelihood is too low or null;

- -

- Technical hazards: events that have as a potential source of consequence the inadequacy or incapacity of the equipment. The availability of equipment is conditioned by the resources of the contracting company, but also by geographical location because it is possible that a company may have the necessary means, but they are not available locally.

- The presence of gravel, pebbles or blocks is a geological hazard in the execution of piles with bentonite suspensions due to two reasons that may occur simultaneously, or independently: the loss of bentonite and/or the incapacity of bentonite to behave as a thixotropic fluid and form a cake, ensuring the stability of the bored walls when crossing these coarse soils.

- Clay interception is a geological hazard in bored piles with bentonite support fluids whenever these soils contaminate the mud (by addiction), causing its density to increase and making impossible to pump the mud to desanding and/or decreasing the mud thixotropy.

- The presence of brackish or saltwater is a geological hazard in piling with bentonite slurry since these salts will react with bentonite suspension inducing flocculation and affecting the mud thixotropy negatively.

- The existence of cemented layers (rocks) or blocks is a geological hazard in the execution of bored piles with casing when their strength prevents the casing progression.

- Artesian groundwater levels in sands are a geological hazard in the execution of bored piles with casing when it causes the coarse soils to ascend inside the casing, preventing their cleaning.

- The site operatives often lack skills in construction of bored piles with casing or bentonite support fluids giving rise to quality problems of the pile executed.

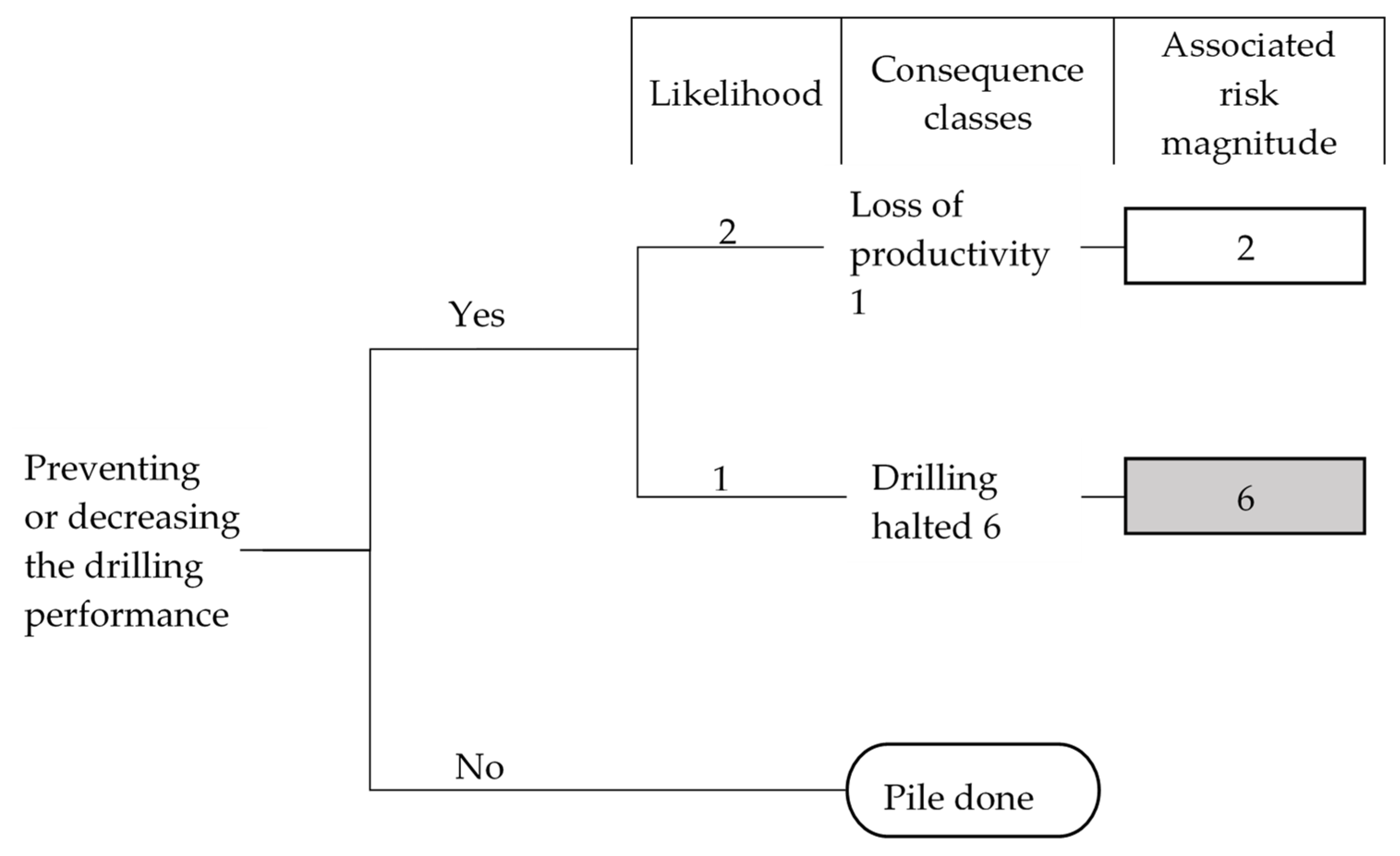

- For both types of aforementioned bored pile technics, the inadequacy of the method or equipment used is a technical hazard that manifests itself whenever the equipment or method available for the work is not suitable for the site or when the equipment is sub/oversized for the work to be carried out, negatively influencing the budget.

- (i)

- “Drilling halted”: when changing the construction method or adjusting or replacing the equipment, the work must be stopped.

- (ii)

- “Sand inclusions” can occur while concreting when the sand lodged inside the casing is not completely dragged out in front of the concrete, thus forming sand inclusions in the pile. This situation can only be verified after the end of the pile construction through quality control by pile dynamic integrity tests (PIT), sonic tests or core drilling.

- (iii)

- “Impediment to construction”: the construction process must be stopped until new solutions are approved.

- (iv)

- “Rebar uplift”: while concreting operation, at the removal of casing sections, the reinforcement rises with the upward movement of the casing.

- (v)

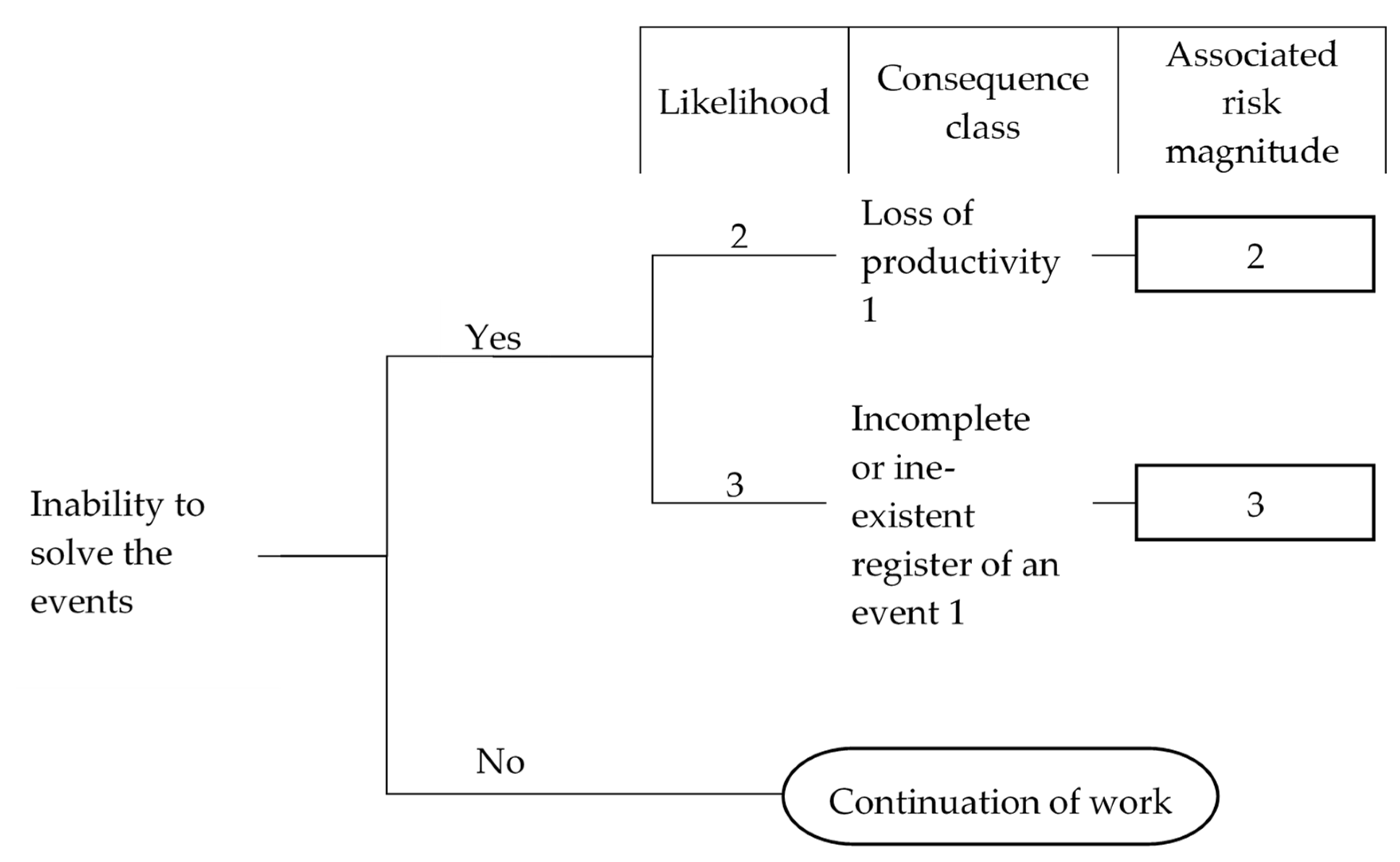

- “Loss of productivity”: production yield is lower than estimated.

- (vi)

- “Incomplete or non-existent registration of the event occurred”: no document is drawn up for the events that gave rise to the consequence.

- (vii)

- “Lost of a pile”: when element collapses after completion of excavation.

- (viii)

- “Collapse of the pile” when the pile collapses while excavating.

- (ix)

- “Impediment or difficulty in mud pumping”: bentonite support fluid becomes more viscous making it difficult or preventing its pumping for recycling.

- (x)

- “Concrete overconsumption” the volume of concrete used in concreting of the pile is higher than that considered in the tendering budget.

4. Application of the Methodology at Two Site Works in Luanda (Angola)

4.1. Case Study 1—Talatona Church

4.1.1. Potential Hazards Identification and Associated Risk Analyses

4.1.2. Risk Analyses and Evaluation

4.1.3. Contingency Measures and Discussion

- With the application of the proposed methodology, the work took 17 days, if risk management had not been applied it would have taken 25.5 days, e.g., 1.5 more time.

- The additional 7.5 days would correspond to a direct increase in cost, except for included material costs for works where there is a 20% increase (value obtained from the accounting).

- Such increase would have raised the cost (c) in the contract of the first 17 days (c17). The cost of the work for the 25.5 days (c25.5) would be (c25.5) = 1.4 × (c17).

- Using the absolute values of the invoicing (I) and the costs (c) of the accounting, it would have the final margin for 25.5 days (mf25.5) = f − 1.4 × (c17), which corresponds to (I − 1.4 × (c17))/I = 0.83%.

4.2. Case 2—Viaduct Nelito Soares

4.2.1. Potential Hazards Identification and Associated Risk Analyses

4.2.2. Risk Analyses and Evaluation

4.2.3. Contingency Measures and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Latapie, B.; Alzaylaie, M.; Albelda, R.A.; Sumputh, J.; Samra, M.A. A review of piling industry practices in Dubai, UAE: Proposed UCS-based correlations. Geotech. Res. 2019, 6, 103–129. [Google Scholar] [CrossRef]

- Chapman, T.; Marcetteau, A. Achieving economy and reliability in piled foundation design for a building project. Struct. Eng. 2004, 2, 32–37. [Google Scholar]

- Hoek, E.; Palmieri, A. Geotechnical risks on large civil engineering projects. In Proceedings of the Keynote address for Theme I—International Association of Engineering Geologists Congress, Vancouver, BC, Canada, 21–25 September 1998; p. 12. [Google Scholar]

- Chapman, T.J.P. The relevance of developer costs in geotechnical risk management. In Proceedings of the Second BGA International Conference on Foundations, ICOF2008; Brown, M.J., Bransby, M.F., Brennan, A.J., Knappett, J.A., Eds.; IHS BRE Press: London, UK, 2008; pp. 1–26. [Google Scholar]

- Hosny, H.E.; Ibrahim, A.H.; Fraig, R.F. Risk management framework for Continuous Flight Auger piles construction in Egypt. Alex. Eng. J. 2018, 57, 2667–2677. [Google Scholar] [CrossRef]

- Larisch, M. Risk Management for Piles & Deep Foundations; New Zealand Geotechnical Society: Wellington, New Zealand, 2018. [Google Scholar]

- Bles, T.; Al-Jibouri, S.; Van den Abel, J. A risk model for pile foundations. In Proceedings of the 20th International Symposium on Automation and Robotics in Construction ISARC2003 the Future Site, Eindhoven, The Netherlands, 21–24 September 2003; pp. 421–426. [Google Scholar]

- Stuedlein, A.W.; Reddy, S.C. Factors Affecting the Reliability of Augered Cast-In-Place Piles in Granular Soils at the Serviceability Limit State (DFI 2013 Young Professor Paper Competition Winner). J. Deep Found. Inst. 2013, 7, 46–57. [Google Scholar] [CrossRef]

- Spross, J.; Stille, H.; Johansson, F.; Palmstrøm, A. On the Need for a Risk-Based Framework in Eurocode 7 to Facilitate Design of Underground Openings in Rock. Rock Mech. Rock Eng. 2018, 51, 2427–2431. [Google Scholar] [CrossRef]

- Briaud, J. Failure Has Consequences. Geostrata 2020, 24, 18–20. [Google Scholar]

- Lacasse, S. Hazard, Reliability and Risk Assessment -Research and Practice for Increased Safety. In Proceedings of the NGM 2016 Reykjavik 17th Nordic Geotechnical Meeting Challenges in Nordic Geotechnic, Reykjavik, Iceland, 25–28 May 2016; pp. 18–42. [Google Scholar]

- Reed, J.; Eisenbraun, R.; Wade, D.; Johnson, D.; Martin, J.; Allen, J. Risk Management for Dam Construction; U.S. Society on Dams: Denver, CO, USA, 2017. [Google Scholar]

- Schubert, P. Geotechnical Risks in Rock Tunnels; Taylor & Francis: Aveiro, Portugal, 2004; pp. 53–62. [Google Scholar]

- Palmieri, A. Managing financial risk for uncertainty. In Proceedings of the International symposium Practices and Trends for Financing and Contracting Tunnels and Underground Works, Athens, Greece, 22–23 March 2012; pp. 1–15. [Google Scholar]

- Nawaz, A.; Waqar, A.; Shah, S.A.R.; Sajid, M.; Khalid, M.I. An Innovative Framework for Risk Management in Construction Projects in Developing Countries: Evidence from Pakistan. Risks 2019, 7, 24. [Google Scholar] [CrossRef]

- Ahmed, S.M.; Fayed, A.L. Mitigation of Risks Associated with Deep Excavations: State of the Art Review. Ind. Acad. Collab. 2015, 18, 6–8. [Google Scholar]

- Mata, P.; Silva, A.P.; Pinho, F. Risk management procedure in the construction of deep foundations. In Proceedings of the Geotechincs for Sustainable Infrastructure Development; Long, P.D., Ed.; Geotechincs for Sustainable Infrastructure Development: Hanoi, Vietnam, 2016; pp. 261–269. [Google Scholar]

- Gransberg, D.D.; Loulakis, M.; Touran, A.; Gad, G.; McLain, K.; Sweitzer, S.; Pittenger, D.; Nova, I.C.; Pereira, R.T.; Pinto-Nunez, M. Guidelines for Managing Geotechnical Risks in Design-Build Projects; Transportation Research Board: Washington, DC, USA, 2018; ISBN 978-0-309-39060-6. [Google Scholar]

- Zhang, G.; Wang, C.; Jiao, Y.; Wang, H.; Qin, W.; Chen, W.; Zhong, G. Collapse Risk Analysis of Deep Foundation Pits in Metro Stations Using a Fuzzy Bayesian Network and a Fuzzy AHP. Math. Probl. Eng. 2020, 2020, 4214379. [Google Scholar] [CrossRef]

- You, W.; Wang, J.; Zhang, W.; Liu, F.; Yang, D. Construction risk assessment of deep foundation pit in metro station based on G-COWA method. IOP Conf. Ser. Earth Environ. Sci. 2018, 153. [Google Scholar] [CrossRef]

- Spross, J.; Olsson, L.; Stille, H. The Swedish Geotechnical Society’s methodology for risk management: A tool for engineers in their everyday work. Georisk 2017, 12. [Google Scholar] [CrossRef]

- Kalsnes, B.; Vanglelsten, B.V.; Eidsvig, U. Risk analyses in excavation and foundation work. In Proceedings of the 17th Nordic Geotechnical Meeting Challenges in Nordic Geotechnic, Reykjavik, Iceland, 25–28 May 2016; pp. 487–494. [Google Scholar]

- Larisch, M.D. Fundamental Mechanisms of Concrete Bleeding in Bored Piles. In Proceedings of the Concrete 2019 Conference, Sydney, Australia, 8–11 September 2019; p. 9. [Google Scholar]

- Larisch, M.D. Construction and stability risks for fluid supported deep excavations and their effects on design parameters. In Proceedings of the DFI-PFSF Piling & Ground Improvement Conference, Sydney, Australia, 23–25 February 2022; p. 20. [Google Scholar]

- Cooper, R.; Kaplan, R.S. Profit Priorities from Activity-Based Costing. Harv. Bus. Rev. 1991, 69, 130–135. [Google Scholar]

- Räikkönen, M.; Molarius, R.; Mäki, K.; Forssén, K.; Petiet, P.; Nieuwenhuijs, A. Creating stakeholder value through risk mitigation measures in the context of disaster management. Infrastructures 2017, 2, 14. [Google Scholar] [CrossRef]

- Anjum, R.L.; Rocca, E. From Ideal to Real Risk: Philosophy of Causation Meets Risk Analysis. Risk Anal. 2019, 39, 729–740. [Google Scholar] [CrossRef] [PubMed]

- Aven, T.; Renn, O. Improving government policy on risk: Eight key principles. Reliab. Eng. Syst. Saf. 2018, 176, 230–241. [Google Scholar] [CrossRef]

- (ISO 31000: 2018). Risk Management Guidelines; IPQ: Caparica, Portugal, 2018. [Google Scholar]

- Chapman, T.J.P.; van Staveren, M.T.; Stacey, T.R.; Hellings, J.E. Ground risk mitigation by better geotechnical design and construction management. In Proceedings of the ISGSR2007 First International Symposium on Geotechnical Safety & Risk, Shangai, China, 18–19 October 2007; pp. 645–656. [Google Scholar]

- Mata, P.; Fortuna, C.; Tropa, C.; Gama, C.; Pontes, F.; Silveira, G.; Marques, H.; Quintero, J.; Poças, J.; Guimarães, J.; et al. Portugal First. Entrepreneurs are Needed! “Portugal Primeiro. Empreendedores Precisam-se!”; First.; Edições Sílabo: Lisbon, Portugal, 2011; ISBN 978-972-618-654-0. [Google Scholar]

- Powderham, A.; Anthony, O. The Observational Method in Civil Engineering—Minimising Risck, Maximising Economy; Primeira; Taylor & Francis: Boca Raton, FL, USA, 2021; ISBN 9780429344244. [Google Scholar]

- Kaplan, R.S.; Anderson, S.R. Time-Driven Activity-Based Costing. Available online: https://ssrn.com/abstract=485443 (accessed on 13 April 2021).

- Aven, T. Foundations of Risk Analysis: A Knowledge and Decision-Oriented Perspective; Wiley: Stavanger, Norway, 2003; ISBN 0471495484. [Google Scholar]

- Rozell, D.J. Values in risk assessment. In Dangerous Science: Science Policy and Risk Analysis for Scientists and Engineers; Ubiquity Press: London, UK, 2020; pp. 29–56. ISBN 9781911529880. [Google Scholar]

- Cox, L.A. What’s wrong with risk matrices? Risk Anal. 2008, 28, 497–512. [Google Scholar] [CrossRef] [PubMed]

- Project Management Institute. A Guide to the Project Management Body of Knowledge (PMBOK Guide), 6th ed.; Project Managment Intitute: Newtown Square, PA, USA, 2017; ISBN 9781628251845. [Google Scholar]

- BS EN 1997-1:2004 Geotechnical Design; General Rules; British Standard Institute: London, UK, 2004; p. 168.

- Spross, J.; Johansson, F. When is the observational method in geotechnical engineering favourable. Struct. Saf. 2017, 66, 17–26. [Google Scholar] [CrossRef]

- Bauer Maschinen GmbH. BG 15 H Rotary Drilling Rig; Bauer GmbH: Schrobenhausen, Germany, 2015; p. 12. [Google Scholar]

- Bauer Maschinen GmbH. BG 28 Rotary Drilling Rig; Bauer GmbH: Schrobenhausen, Germany, 2012; p. 12. [Google Scholar]

| Hazards | Yes/No | N/A | |

|---|---|---|---|

| Geological & Geotechnical (G&G) | Are there, visibly, constraints to the execution of the work? | ||

| Does the geotechnical report exist, and is it accessible? | |||

| Does the project replicate the characteristics of the ground identified in the geotechnical report and confirmed on site? | |||

| Does the drilled ground correspond to those listed in the geotechnical report? | |||

| Are there any gravels, cobbles, cimmented layers or blocks at the ground? | |||

| Do the contacts with the foundation layer present any known irregularity? | |||

| Does the drilling reached the projected depth for the foundation layer? | |||

| Does the project mention a groundwater table? | |||

| If so, is the groundwater level in accordance with the geotechnical report? | |||

| Is there a variation in the groundwater table while pile construction? | |||

| Is it possible to comply with regulatory or design tolerances, in the case of more restrictive ones? | |||

| Humans | Do the site operatives have the basic needs of life met? | ||

| Is there a Health and Safety Plan implemented on site applied to the foundations construction? | |||

| Do the site operatives have a specific Health and Safety plan at work (HSW) training for the work to be carried out? | |||

| Does the site operatives team have the right size? | |||

| Are equipment operators duly qualified to use it? | |||

| Is there a permanent technician on site who can interpret the project and the geotechnical report? | |||

| Is there a technician on site with knowledge of cost control techniques? | |||

| Is shift work planned? | |||

| Is the team able to extend working hours in case it is necessary to finish a pile? | |||

| Technical | Is the intersection of anthropic structures planned in the project? | ||

| If there are anthropic structures, are they identified and located in the project? | |||

| Are all the non permanent works dully contemplated at the project? | |||

| Is there an Integrated Construction Management Plan? | |||

| Is there an Equipment Maintenance Plan? | |||

| Are the equipment on site dimensioned to work with possible adverse weather conditions? | |||

| Does the contractor/sub-contractor have experience in the type of construction technique adopted at the project? | |||

| Does the contractor/sub-contractor have the means to replace equipment in case of failure? | |||

| Does the executing entity have its own means of repairing equipment locally? | |||

| Are there cutting tools suitable for the ground listed in the geotechnical report? | |||

| Are there cutting tools suitable for all the types of strata to be intersected? | |||

| In the event of a punctual extension of the work or the existence of shifts, are the suitable means of lighting ensured? | |||

| Is there a document describing work procedures? | |||

| Is there an Inspection and Testing Plan for the works? | |||

| Is there an Inspection and Testing Plan for the equipment? | |||

| Is there an Inspection and Testing Sheet for the equipment? | |||

| Economic and Financial | Is there a tender budget with ABC? | ||

| Is there an operations budget with ABC? | |||

| If there are tender and operations budget, are they directly comparable? | |||

| If there is an operations budget, is it directly comparable with accounting? | |||

| Is there a signed contract reflecting the assumptions of the geotechnical report and the project? | |||

| Is the performance obtained considered in the production budget? | |||

| Is there a clause in the contract to assign the responsibility of financial losses? Which/To whom? | |||

| Hazards | Yes/No | N/A | |

|---|---|---|---|

| G&G | Are there clays lenses/layers that may contaminate bentonite suspension by increasing its density? | ||

| Is there brackish or salt water? | |||

| Hum. | Do the site operatives master the skills and knowledge of construction piles with bentonite suspensions? | ||

| Technical | Is the bentonite method the most suitable? | ||

| If not, where the designers approached to study/aprove an alternative? | |||

| Is the equipment availabe on-site the most suitable to use with bentonites suspensions? |

| Hazards | Yes/No | N/A | |

|---|---|---|---|

| G&G | Are there any sands with an artesian groundwater level? | ||

| Humans | Do the site operatives master the skills and knowledge of construction piles using casing technique? | ||

| Technical | Is the casing method the most suitable? | ||

| If not, where the designers approached to study/aprove an alternative? | |||

| Is the equipment availabe on-site the most suitable to use casing technique? |

| Execution Technique | Construction Hazards | ||

|---|---|---|---|

| Geological | Human | Technical | |

| With bentonite support fluids | (i) Gravel or blocks (ii) Contaminant clay layers (iii) Brackish or saltwater | (vi) Poor knowledge of the technique | (vii) Inadequacy of the method or equipment |

| Using casing | (iv) Rock layers or blocks (v) Sands with artesian groundwater | ||

| Likelihood | Class | Occurrences in 24,903 m of Piles |

|---|---|---|

| Very common | 5 | >40 |

| Frequent | 4 | 20 a 40 |

| Occasional | 3 | 10 a 20 |

| Rare | 2 | 4 a 10 |

| Very rare or null | 1 | <4 |

| Construction Cost (%) | Consequence Classes |

|---|---|

| >100 | 6 |

| 80 to 100 | 5 |

| 60 to 79 | 4 |

| 40 to 59 | 3 |

| 20 to 39 | 2 |

| 1 to 19 | 1 |

| Damage | Construction Cost (%) | Consequence Classes |

|---|---|---|

| (i) Drilling halted | 65 to >100 | 6 |

| (ii) Sand inclusions | 20 to 100 | 5 |

| (iii) Impediment to construction | 50 to 85 | |

| (iv) Rebar uplift | 25 to 65 | 4 |

| (v) Loss of productivity | 1 to 10 | 1 |

| (vi) Incomplete or inexistent register of an event occurred |

| Damage | Construction Cost (%) | Consequence Classes |

|---|---|---|

| (i) Drilling halted | 75 to >100 | 6 |

| (vii) Lost of a pile | 100 | 5 |

| (iii) Impediment to construction | 20 to 75 | 4 |

| (viii) Collapse of the pile | 40 to 55 | 3 |

| (ix) Impediment or difficulty in mud pumping | 15 to 35 | 2 |

| (x) Concrete overconsumption | 10 to 25 | |

| (v) Loss of productivity | 1 to 15 | 1 |

| (vi) Incomplete or inexistent register of an event occurred | 1 to 10 |

| Consequence Classes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Likelihood | 1 | 2 | 3 | 4 | 5 | 6 | |||

| 1 | 1 | 2 | 3 | 4 | 5 | 6 | |||

| 2 | 2 | 4 | 6 | 8 | 10 | 12 | |||

| 3 | 3 | 6 | 9 | 12 | 15 | 18 | |||

| 4 | 4 | 8 | 12 | 16 | 20 | 24 | |||

| 5 | 5 | 10 | 15 | 20 | 25 | 30 | |||

| Risks | |||||||||

| Acceptable | Significant | High | Intolerable | ||||||

| Equipment Mobilization | Mobilization/Demobilization(un) | 1 |

|---|---|---|

| Piles executed | Total of piles (un) | 54 |

| Total length of piles (m) | 817.00 | |

| Total drilling with bentonite mud (m) | 481.00 | |

| Daily drilling with bentonite mud average (m) | 43.73 | |

| Total drilling using casing (m) | 336.00 | |

| Daily drilling using casing average (m/day) | 35.37 | |

| Cost control | Total margin (%) | 29.17 |

| Tendering margin (%) | 34.97 |

| Hazard | Event | Likelihood | Consequence | Risk Magnitude |

|---|---|---|---|---|

| Technical: Inadequacy of equipment | Decreased drilling performance | 2 (Rare) | 1 (Loss of productivity) | 2 (Acceptable) |

| Equipment Mobilization | Mobilization/Demobilization(un) | 2 |

|---|---|---|

| Piles executed | Total of piles (un) | 144 |

| Total length of piles (m) | 3839.85 | |

| Total drilling with bentonite mud (m) | 2549.70 | |

| Daily drilling with bentonite mud average (m) | 35.03 | |

| Total drilling using casing (m) | 1243.45 | |

| Daily drilling using casing average (m/day) | 35.03 | |

| Cost control | Total margin (%) | 39.48 |

| Tendering margin (%) | 30.12 |

| Hazard | Event | Likelihood | Consequence | Risk Magnitude |

|---|---|---|---|---|

| Poor knowledge of the technique | Unable to solve the events | 3 (occasional) or 2 (rare) | 1 (Loss of productivity and/or Incomplete or inexistent register of the event) | 3 (Acceptable) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mata, P.; Silva, P.F.; Pinho, F.F.S. Risk Management of Bored Piling Construction on Sandy Soils with Real-Time Cost Control. Infrastructures 2021, 6, 77. https://doi.org/10.3390/infrastructures6050077

Mata P, Silva PF, Pinho FFS. Risk Management of Bored Piling Construction on Sandy Soils with Real-Time Cost Control. Infrastructures. 2021; 6(5):77. https://doi.org/10.3390/infrastructures6050077

Chicago/Turabian StyleMata, Pedro, Paula F. Silva, and Fernando F. S. Pinho. 2021. "Risk Management of Bored Piling Construction on Sandy Soils with Real-Time Cost Control" Infrastructures 6, no. 5: 77. https://doi.org/10.3390/infrastructures6050077

APA StyleMata, P., Silva, P. F., & Pinho, F. F. S. (2021). Risk Management of Bored Piling Construction on Sandy Soils with Real-Time Cost Control. Infrastructures, 6(5), 77. https://doi.org/10.3390/infrastructures6050077